Patents

Literature

86results about How to "No need to stir" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

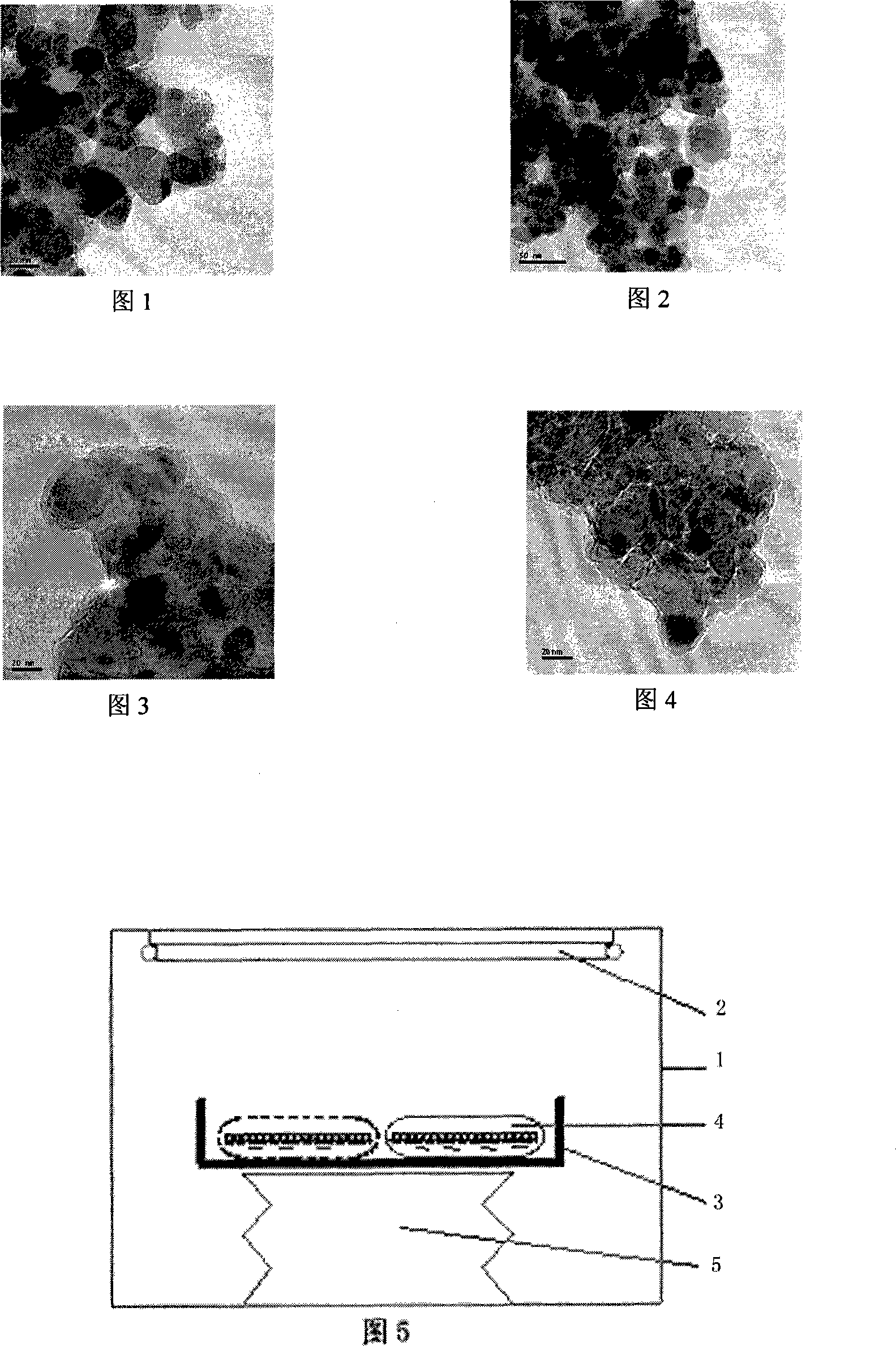

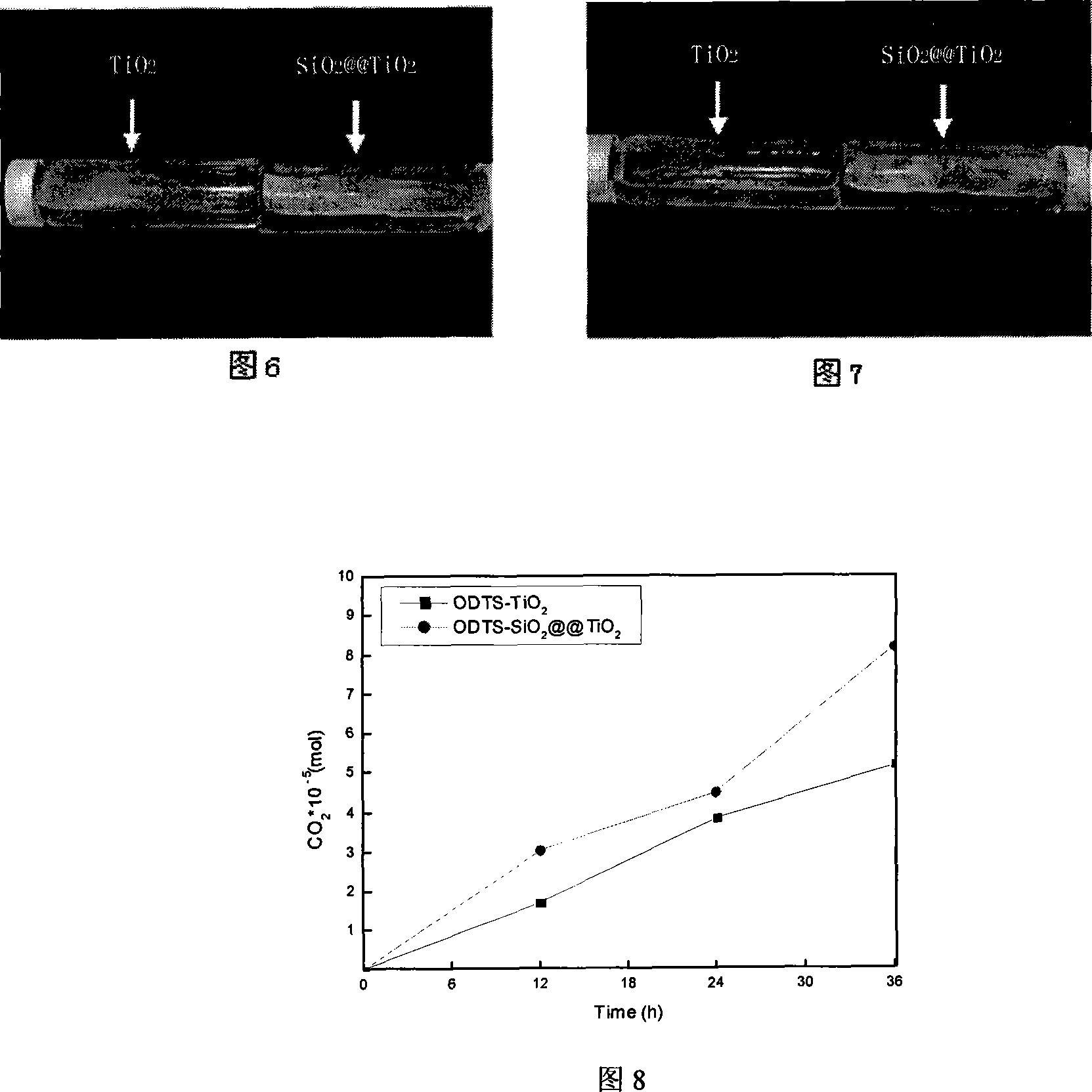

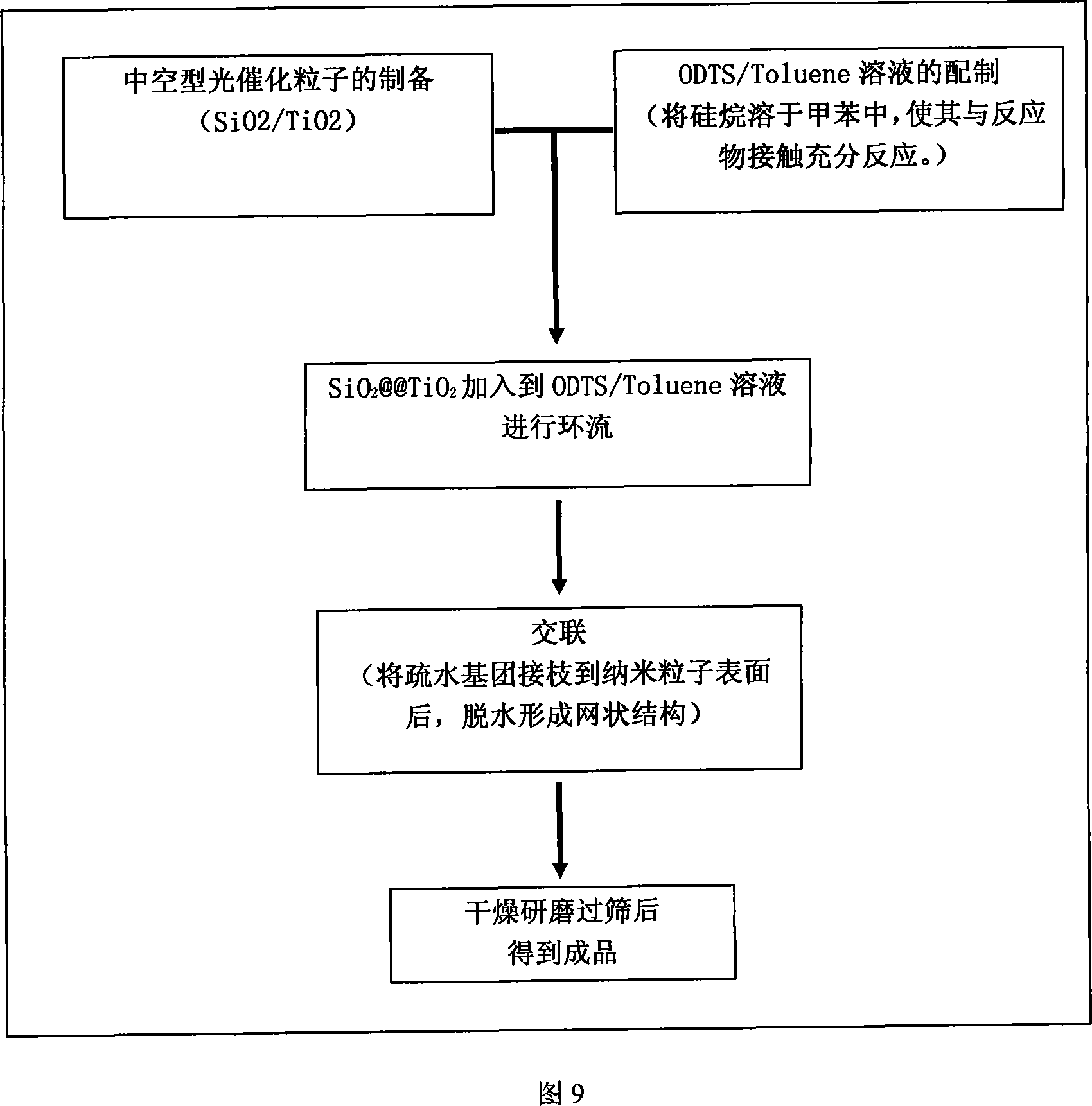

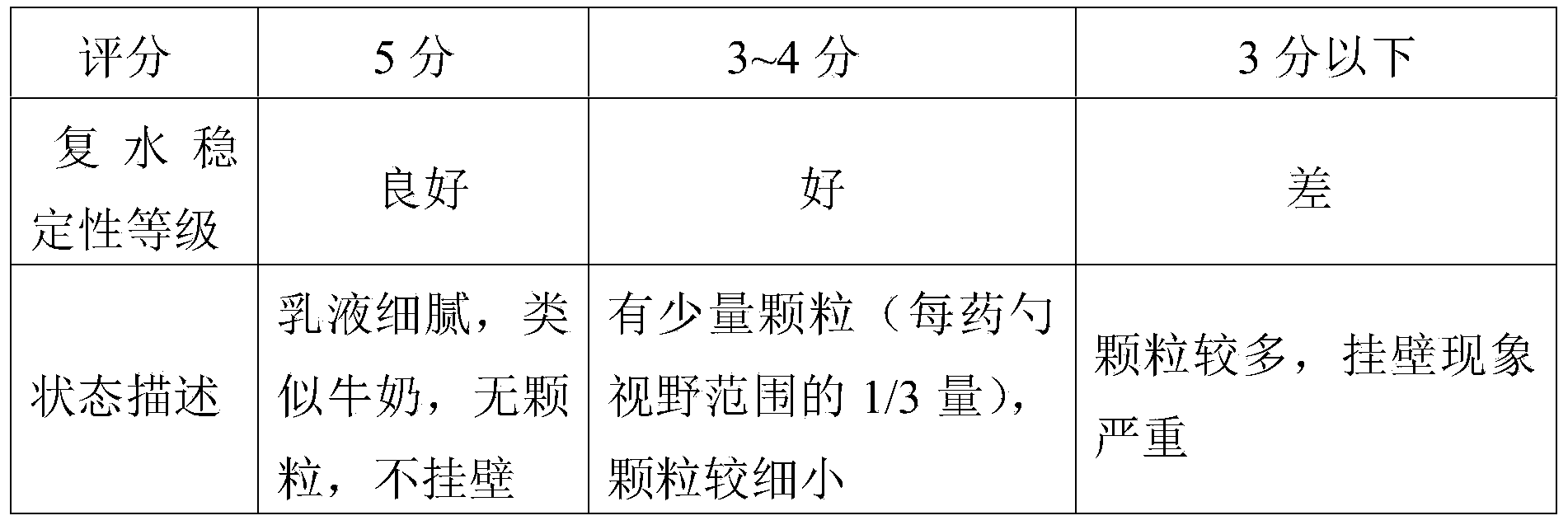

Method for preparing interface optical catalyst

ActiveCN101099929AAvoid direct contactSpread as soon as possibleCatalyst activation/preparationCross-linkPhotocatalytic reaction

The present invention relates to one kind of interface photocatalyst, and solves the technological problem of preparing one interface photocatalyst capable of floating on water surface for photocatalytic reaction and with lasting photocatalytic activity. The interface photocatalyst floating on water surface can utilize sunlight well for photocatalysis to decompose pollutant and may be recovered easily, with the decomposition produced CO2 being dispersed to the air directly. It is prepared through the following steps: 1. preparing photocatalyst particle in SiO2-hollow layer-TiO2 structure and with nanometer core; 2. preparing hydrophobic solution; 3. preparing hydrophobic hollow nanometer photocatalyst particle; and 4. cross-linking hydrophobic groups of hollow nanometer photocatalyst particle. The present invention is applied in degrading toxic pollutant to protect environment.

Owner:ZHEJIANG SCI-TECH UNIV

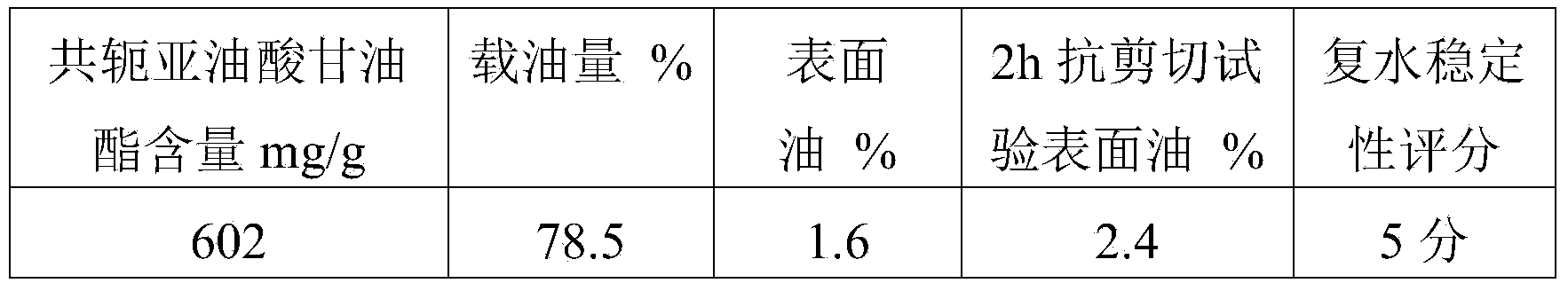

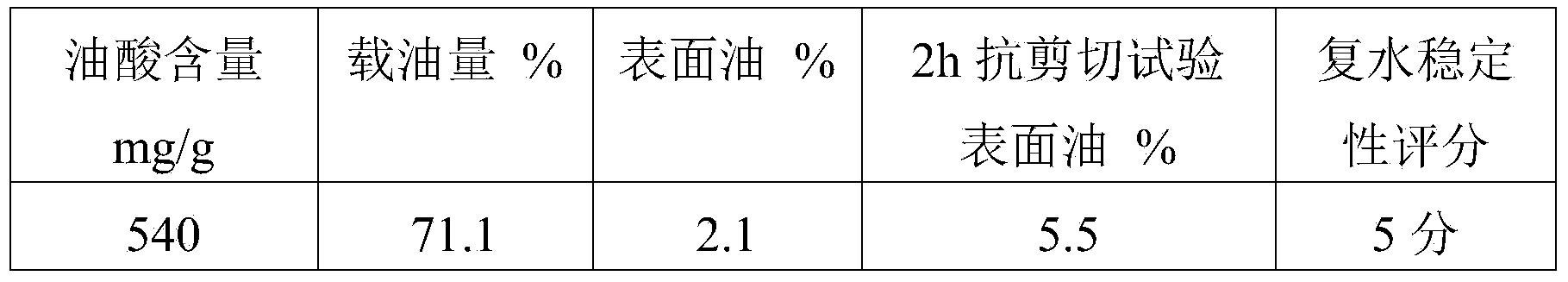

Preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring

InactiveCN104304838ASolve the fragile problemReduce dosageSugar food ingredientsVitamin food ingredientsBiotechnologyDairy foods

The invention provides a preparation method of high oil loaded nutrition lipid micro-capsule powder with tolerance to mechanical stirring. The preparation method comprises the following steps: adding protein type wall materials into water, stirring for dissolving the materials at 40-70 DEG C, adjusting the pH of an obtained solution to 7.0-12.0, reacting under the condition of 40-70 DEG C for 0.5-4 hours, adding sugar type wall materials and a stabilizing agent into an obtained reaction solution, and stirring for dissolving, thereby obtaining a water phase solution; adding an antioxidant and an emulsifier into nutrition lipid type core materials, and stirring for dissolving at 40-70 DEG C, thereby obtaining an oil phase solution; and mixing the water phase solution with the oil phase solution, emulsifying and homogenizing, and spray-drying, thereby obtaining the micro-capsule powder. The content of total fat in the micro-capsule powder reaches up to 60%-85%, and the content of surface oil in the micro-capsule powder is lower than 5%. The micro-capsule powder has tolerance to mechanical force, is good in self-emulsifying capability, can be dissolved to form uniform and stable fine emulsion without floating particles and sediments, can be applied to the field of food, and can be added to food such as bread, cookies, nutrition bars and milk products and also be taken as solid granules.

Owner:INNOBIO CORP LTD

Infrared radiation coating and preparation method thereof

The invention discloses an infrared radiation coating. The infrared radiation coating is formed by mixing a solid material with a liquid material based on a weight ratio of 1:1, wherein grain sizes of the components of the coating are from 100 nanometers to 2 microns; the liquid material is an adhesion agent; and the solid material comprises the following components in percentage by weight: 45-75percent of blackening agent, 20-45 percent of zircon sand and 0-15 percent of aluminum oxide. The grains sizes of the principal components of the coating are from 100 nanometers to 2 microns, so thatthe radiation property of the coating is improved and the service life of the coating is prolonged. The radiance (Epsilon) of the coating is higher at a high temperature of 1,000-1,400 DEG C and can reach more than 0.9; and even at the temperature of 1500 DEG C, the stable radiation still can be maintained and the normal total emissivity of the coating still can reach 0.87; meanwhile, the infrared radiation coating can be applied to different heating types of kilns.

Owner:唐山晟科陶瓷制品有限公司

Mould release agent and preparation method thereof and application of mould release agent in preparation of polyurethane mould product

InactiveCN102189627ATo achieve the demoulding effectDecreased non-release performancePolymer scienceOrganic solvent

The invention relates to a mould release agent and a preparation method thereof and the application of the mould release agent in the preparation of a polyurethane mould product. According to the formula, the mould release agent comprises the following components: a) polysiloxane with a hydroxyl functional group, b) polysiloxane with a hydrogen silane functional group, c) an organic solvent, and d) a catalyst. The preparation method comprises the following steps of: adding the substance a), the substance b) and the substance d) into the substance c); and reacting by heating or at normal temperature for a certain period of time to obtain a finished mould release agent, wherein one or more kinds of catalysts d) can be added into the reaction simultaneously or step by step, and the finished mould release agent is used for preparing the polyurethane mould product. After the mould release agent is sprayed every time, effective mould release is performed for more than 20 times and even can be performed for 100 times without the cleaning of a mould, so that the mould release agent can be used repeatedly; mould release performance is not reduced along with the increase of the mould release frequency; and the surface skin structure of the polyurethane mould product can be controlled, so that the product has high surface quality.

Owner:毕建光

Method for synthesizing organic bentonite by ultrasonic wave combined with microwave

InactiveCN101182002ASimple processEliminate filter washSilicon compoundsCation-exchange capacityIon exchange

The invention discloses a method used for synthesizing organic bentonite by ultrasonic wave associating with microwave. Granular or powder bentonite is mixed to be pasty with surfactant solution, wherein, the quantity of the surfactant is 0.2 to 2.5 times cation exchange capacity of the bentonite; then the surfactant and the bentonite go through ion exchanging by the microwave conditioning after ultrasonic oscillation treatment of the ultrasonic wave and the organic bentonite is obtained. The invention has simple processing and saves original processes such as filtering, rinsing, etc., and does not produce waste water as well as reduces energy consumption; the invention has small amount of water attending reaction, little energy waste caused by water absorption and low total energy consumption and does not need stirring in process; the ultrasonic wave speeds up the reaction and the synthesizing time is short; the ultrasonic wave simultaneously exerts grinding effect and the requirement for original soil particles of the bentonite is low; the microwave conditioning effect improves product quality and absorption performance and has good effect of removing organic pollutants.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Algaecide for flocculating and settling alga bodies and preparation method of algaecide

InactiveCN104891619AThorough algae removalHigh speedWater/sewage treatment by flocculation/precipitationGallic acid esterUltrasonic assisted

The invention relates to an algaecide and a preparation method thereof. The algaecide for flocculating and settling alga bodies contains the following components in parts by weight: 1000 parts of sodium alginate and 100-900 parts of multi-walled carbon nanotubes, wherein sodium alginate is added into deionized water at first, then the mixture is subjected to magnetic stirring until the sodium alginate is completely dissolved, and then 0.8-2.4 parts of the multi-walled carbon nanotubes or / and gallic acid are added. According to the preparation method of the algaecide, the sodium alginate, the multi-walled carbon nanotubes and an allelopathic substance namely the gallic acid are used as main ingredients to prepare a composite hydrogel ball algaecide, and the preparation method comprises the following steps: (1) adding a certain amount of sodium alginate / gallic acid into the deionized water, and performing magnetic stirring until the sodium alginate / gallic acid is completely dissolved; (2) adding the multi-walled carbon nanotubes, and mixing uniformly by using an ultrasonic assisted oscillation method to prepare a dispersion; (3) dropwise adding the dispersion into a 5-10% CaCl2 solution by using a dropper to cure into calcium gel balls, fixing for about 1-2h, then taking out, then flushing repeatedly with deionized water, and standing to remove surface residues; and (4) performing vacuum drying to prepare the algaecide.

Owner:HENAN UNIV OF URBAN CONSTR

Method for preparing functionally gradient composite coating in osmosis plating

InactiveCN102383115AImprove bindingImprove mechanical propertiesElectrolytic coatingsLiquid/solution decomposition chemical coatingChemical platingSalt spray test

The invention discloses a method for preparing a functionally gradient composite coating by using an osmosis membrane in electroplating or chemical plating. The method is applicable to the surface strengthening, decorating and repairing of various electroplating or chemical plating parts and comprises the following steps: (1) sand blasting or polishing, oil removing, etching and weak etching treatment for the surface of a base material; (2) increasing the distribution density of the strengthening phase particles by 0-90% on the surface of the osmosis membrane by adopting a flame plating or roller coating method and then placing the osmosis membrane on the surface of the base material; (3) osmosis plating in a coating bath with prepared coating solution; and (4) repeating the steps (2) and(3) until the coating reaches the required thickness, otherwise, the work stops. The method has the advantages that: (1) the bond strength of the composite coating and the base material is high, the composite coating is not easy to strip off, the strengthening phase particles are in gradient distribution along the thickness direction of the coating, and the content of the outermost layer can reach 90vol.%; (2) the surface hardness of the composite coating can reach 55-80HRC, the salt spray resistance test can reach 30-12000 hours, and the composite coating can work continuously for 4000 hoursat the high temperature of 1100 DEG C; (3) the surface is smooth and bright, and reprocessing and polishing treatment is not required; and (4) the size and shape of the workpiece are not limited, thedeformation is avoided in the osmosis plating process, the worn workpiece with processing error can be repaired, and a deep blind hole and an inner cavity with a complicated shape can be processed ifthe osmosis chemical plating is adopted.

Owner:NANCHANG HANGKONG UNIVERSITY

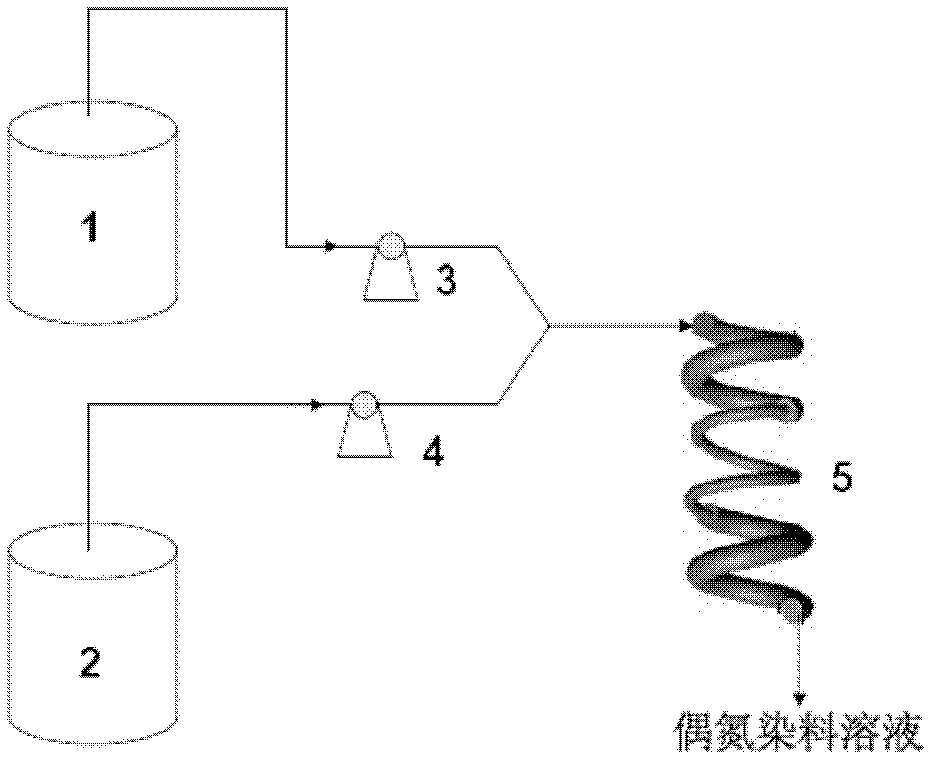

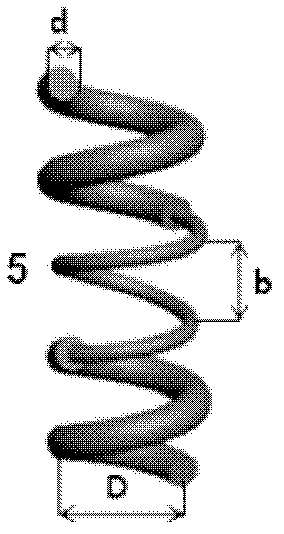

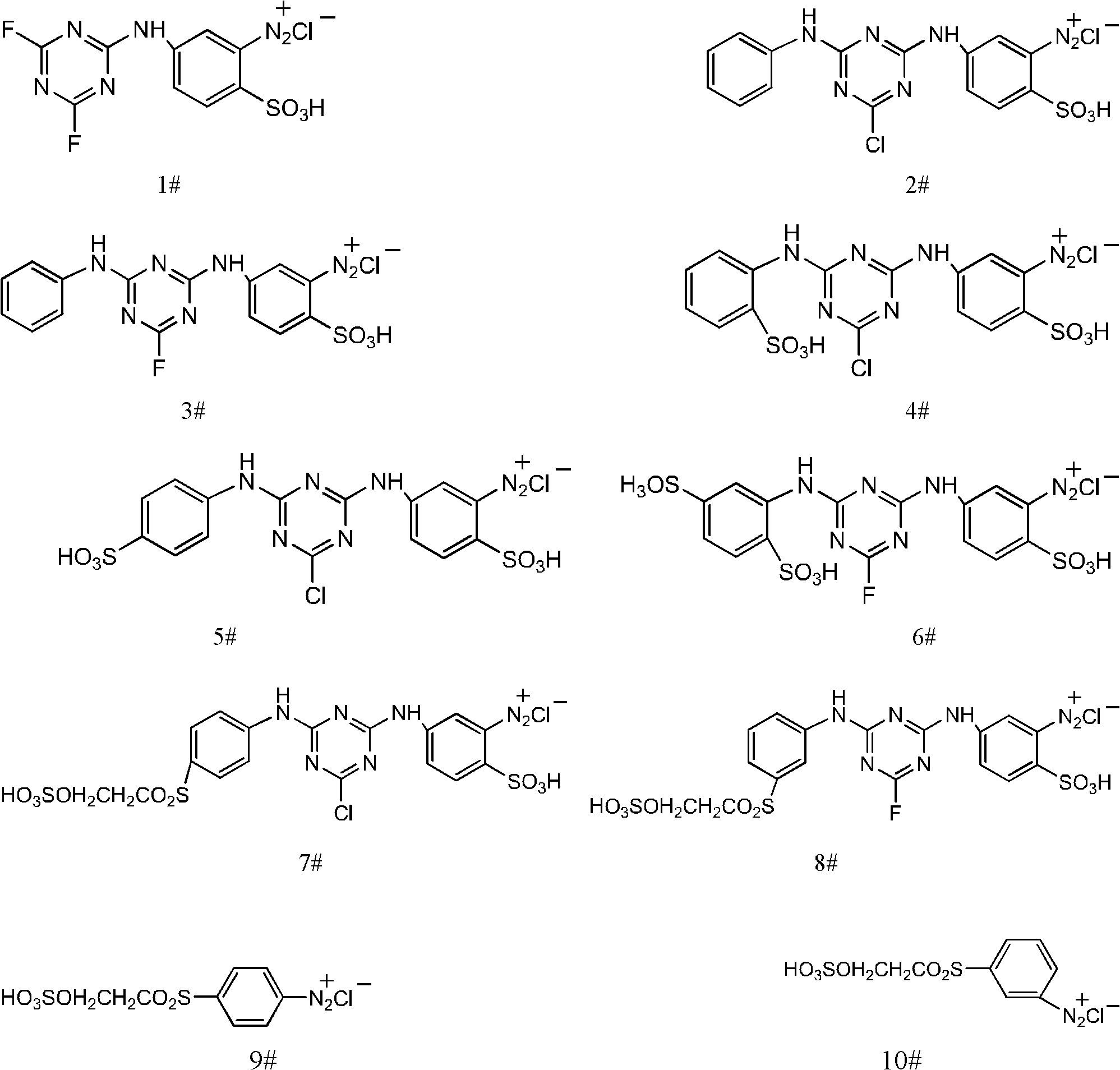

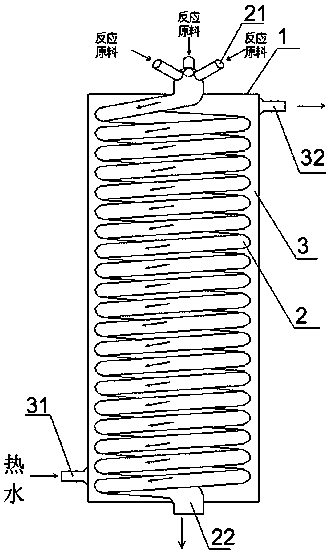

Method for preparing water-soluble azo dye continuously by chaos mixing of spiral tube

ActiveCN102618063BRapid serial productionFully contactedMonoazo dyesDisazo dyesMicroreactorStraight tube

The invention provides a method for preparing a water-soluble azo dye continuously by the chaos mixing of a spiral tube. The core is that a spiral tube sudden-expansion and sudden-contraction structure is adopted; compared with pure straight tube sudden-expansion and sudden-contraction mixed reaction, the method has the advantages that a mixed effect of a transverse secondary flow generated by fluid in a curved pipeline is far stronger than that of pure diffusion of a straight tube part; compared with the conventional spiral tube, the sudden-expansion and sudden-contraction part has the advantages that the motion trail of the fluid can be changed, the superficial area of a mixed interface can be increased and a chaos mixing effect can be enhanced; and the mixer has the advantages of quick and uniform mixing, stirring prevention, short retention time, high quality stability of the product, high speed of removing reaction heat by a tube wall and the like of a microreactor, and also overcomes the defects of small internal diameter and high possibility of blockage of the microreactor, so that the dye can be produced quickly and continuously, and the method is wide in industrial prospect.

Owner:DALIAN UNIV OF TECH

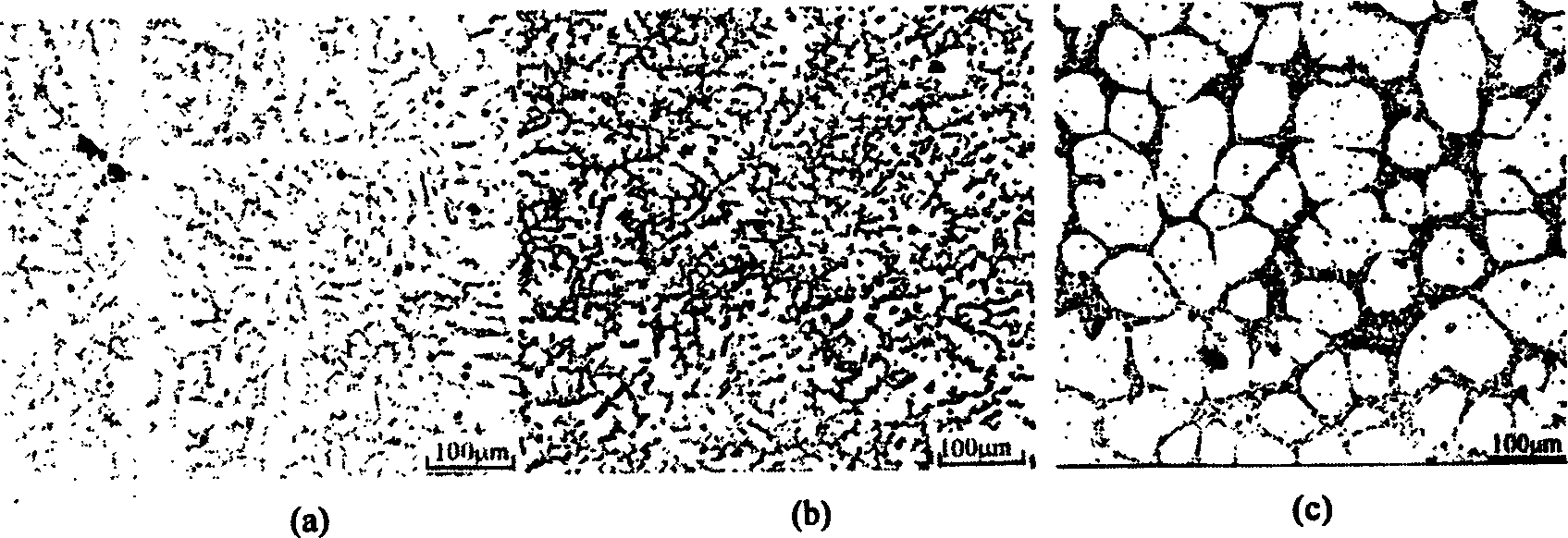

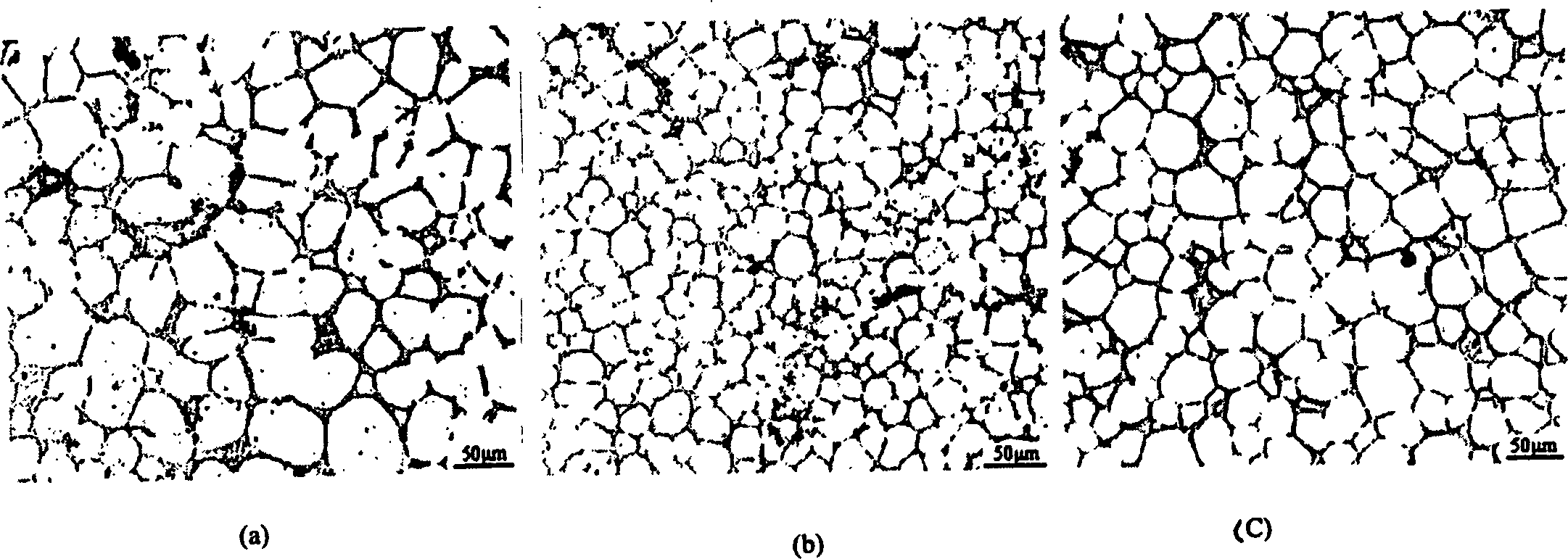

Method for preparing semisolid slurry for ultralow temperature casting magnesium alloy

The method for preparing semisolid slurry for magnesium alloy ultralow temp. casting includes the processes and steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating and standing still and semicontinuous casing. Said invention utilizes the addition of compound fire-resisting elements to implement magnesium alloy smelting free from covering agent, and utilizes the pouring process which is made under the condition of the temperature of liquid phase line or the temperature below liquid phase link at a certain cooling rate after properly standing still to implement that its interior has no dirt inclusion or porosity.

Owner:NORTHEASTERN UNIV

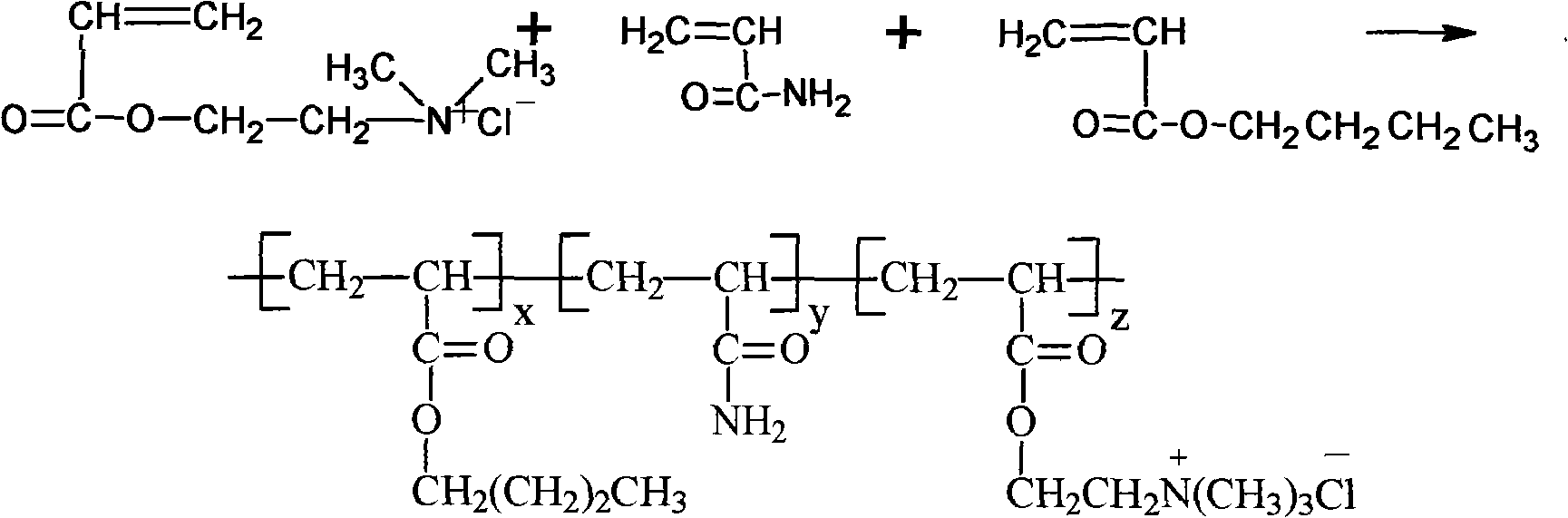

Method for preparing dewatered modified cation flocculating agent

InactiveCN101269866AImprove solubilityReduce contentWater/sewage treatment by flocculation/precipitationN-butyl acrylateSurface-active agents

The invention relates to a preparation method of a lyophobic modification cation flocculating agent, which includes the procedures that: a, acrylamide, acryloyl oxygen ethyl trimethyl lammonium chloride and cation surface active agent are dissolved by a little water, and nitrogen is led and oxygen is removed; b, butyl acrylate and quantitative water are added to prepare the solution with the total mass concentration being 20-40 percent, and the nitrogen is led and the oxygen is removed; c, evocating agent is added, and the solution is sealed; d, the solution is cooled under the condition of minus 18 to minus 12 DEG C till being completely frozen; e, under the condition of 30-35 DEG C, the frozen solution is fully dissolved, and then is set for 2-4 h for obtaining the flocculating agent, wherein, the mol ratio of the three monomers of the acrylamide, the acryloyl oxygen ethyl trimethyl lammonium chloride and the cation surface active agent is 4:1 to 3:0.2 to 0.2:0.3, the procedures a, b, and c are performed under the condition of mixing and the temperature being controlled between 0-3 DEG C. The lyophobic modification cation flocculating agent has the advantages of small unit volume consumption and good treatment effect.

Owner:MAOMING POLYTECHNIC

Method of surface grafting modification for nylon fabric

InactiveCN103074769AImprove anti-dripping performanceFacilitate the grafting reactionFibre treatmentNylon materialMicrowave method

The invention relates to a method of surface grafting modification for nylon fabric with a microwave irradiation method. The grafting reaction conducted with the microwave method has the advantages of short response time, uniform reaction and small influence on a property of the fabric. As hydroxyethyl methacrylate serves as a grafting monomer, the hygroscopicity of the grafted nylon fabric is improved obviously, and the dripping resistance is good; in addition, the reaction is combined with chemical bonds; an effect is stable and lasting; and the washing resistance is high.

Owner:BEIJING UNIV OF CHEM TECH

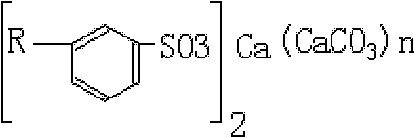

Modified water-quality stabilizing agent

InactiveCN104045171AFormulation ScienceReasonable formulaTreatment using complexing/solubilising chemicalsEnvironmental resistanceWater quality

A disclosed modified water-quality stabilizing agent is prepared from the following raw materials in parts by weight: 90-110 parts of water, 30-50 parts of polyaspartic acid, 5-10 parts of zinc sulfate, 20-35 parts of sodium polyacrylate, 4-12 parts of lignin, 25-35 parts of calcium gluconate, 6-10 parts of polyphosphate, 8-16 parts of sodium molybdate, 11-18 parts of benzotriazol, 15-25 parts of sodium silicate, 3-9 parts of ferrocyanide, 15-20 parts of isopropanol, 8-14 parts of calcium carbonate and 15-25 parts of glycol. The provided modified water-quality stabilizing agent is environment-friendly, less in usage amount, excellent in scale-inhibiting rust-inhibiting performances, and suitable for large-scale popularization.

Owner:QINGDAO BOHONG MARINE BIOTECH

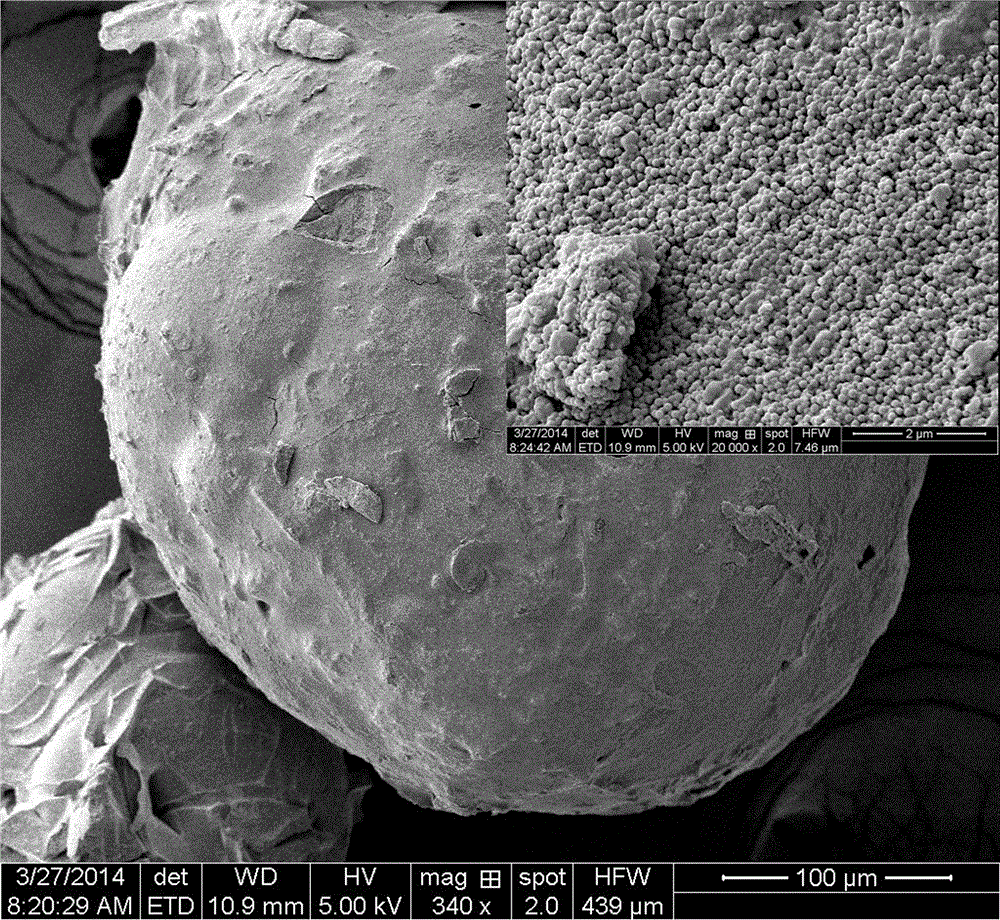

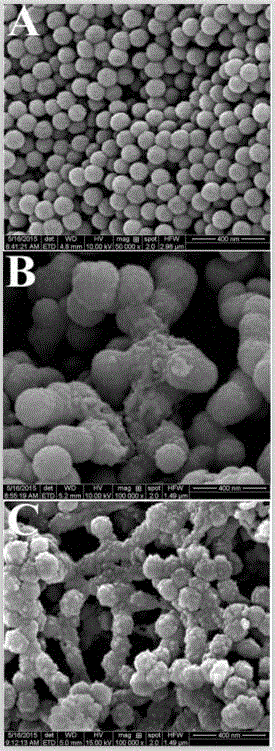

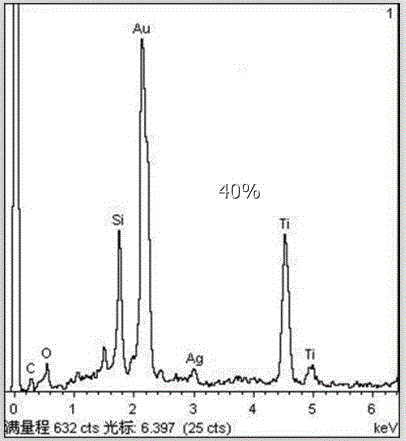

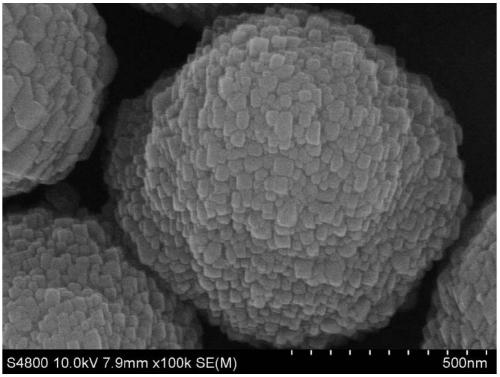

Preparation method of silver-loaded floating hollow titanium dioxide taking cationic polymer as intermediate

InactiveCN105749906AImprove stabilityImprove attachment stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPolymeric surfaceCationic polymerization

The invention discloses a preparation method of silver-loaded floating hollow titanium dioxide taking a cationic polymer as an intermediate. The preparation method comprises the following steps: selecting cationic polystyrene as an intermediate substance; adsorbing the polymer on the surface of a lightweight inorganic carrier under the action of electrical attraction to obtain inorganic carrier / cationic polymer composite particles; furthermore, depositing nano titanium dioxide and noble metal on the surface of the polymer to obtain polymer / titanium dioxide / noble metal composite particles loaded on the surface of the carrier; and finally, roasting to remove the organic polymer to realize loading and gathering of the titanium dioxide loaded with the noble metal on the surface of the lightweight inorganic carrier. The titanium dioxide prepared by the method is in a hollow structure and can be arrayed on the surface of the carrier for a plurality of layers, so that the specific surface area is relatively large and the catalytic activity is good. When the catalyst is used, the catalyst floats on the water surface and does not need to be stirred, and is not influenced by water turbidity; and the catalyst is suitable for being used in a natural environment and can be recycled and repeatedly used.

Owner:UNIV OF JINAN

Method for preparing flocculant from water treatment plant sludge and application of flocculant to algae removal

InactiveCN105906011AReduce dosageThorough algae removalWater/sewage treatment by flocculation/precipitationResource utilizationWater source

The invention relates to a method for preparing flocculant from water treatment plant sludge and application of the prepared flocculant to algae removal in water. The water treatment plant sludge with coalbed water or surface water as a water source serves as the raw material in the method for preparing the flocculant. Three parts of sludge which is dried and smashed are weighed and mixed with concentrated hydrochloric acid according to the volume ratio of 1:(0.67-2), the mixture is placed in a sealed container for modification reaction, and modified sludge is obtained; 60 parts of ultra-pure water or distilled water or cooled boiled tap water are added into the sealed container by volume to be evenly mixed with the modified sludge, then sludge residues are filtered out, and filter liquid is collected for use; the collected filter liquid is determined to 100 parts by weight by means of ultra-pure water or distilled water or cooled boiled tap water, and the flocculant finished product is prepared. The flocculant obtained through the method is used for algae removal in water, is small in consumption, quick in speed, thorough in algae removal and convenient to operate and provides a new means for resource utilization of water treatment plant sludge.

Owner:HENAN UNIV OF URBAN CONSTR

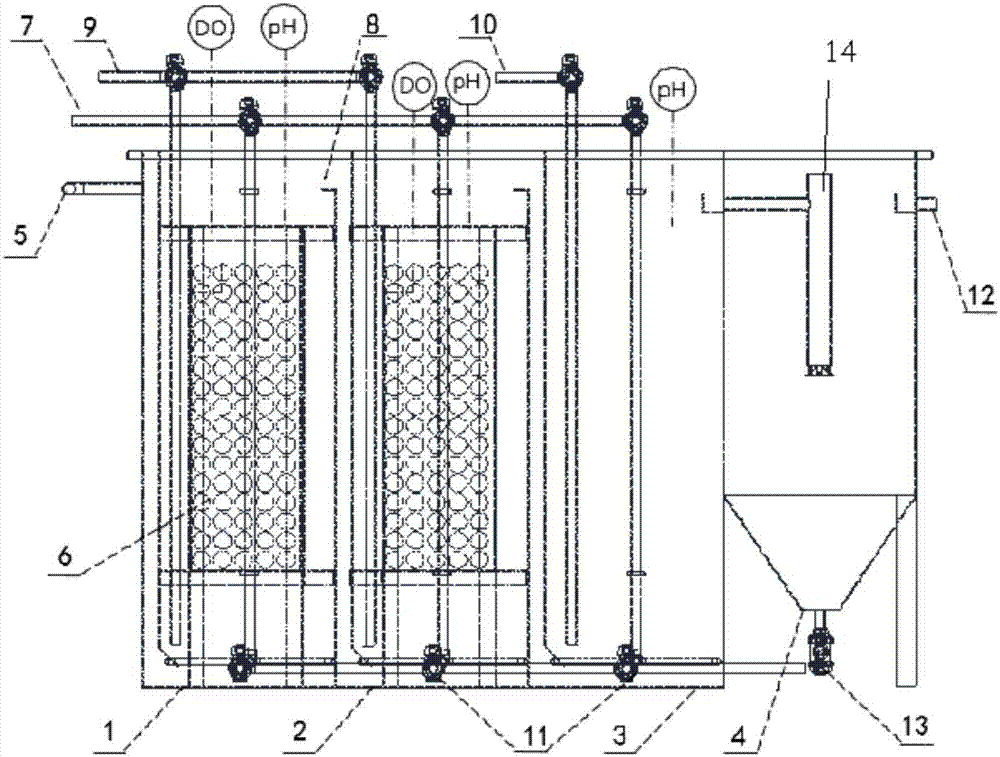

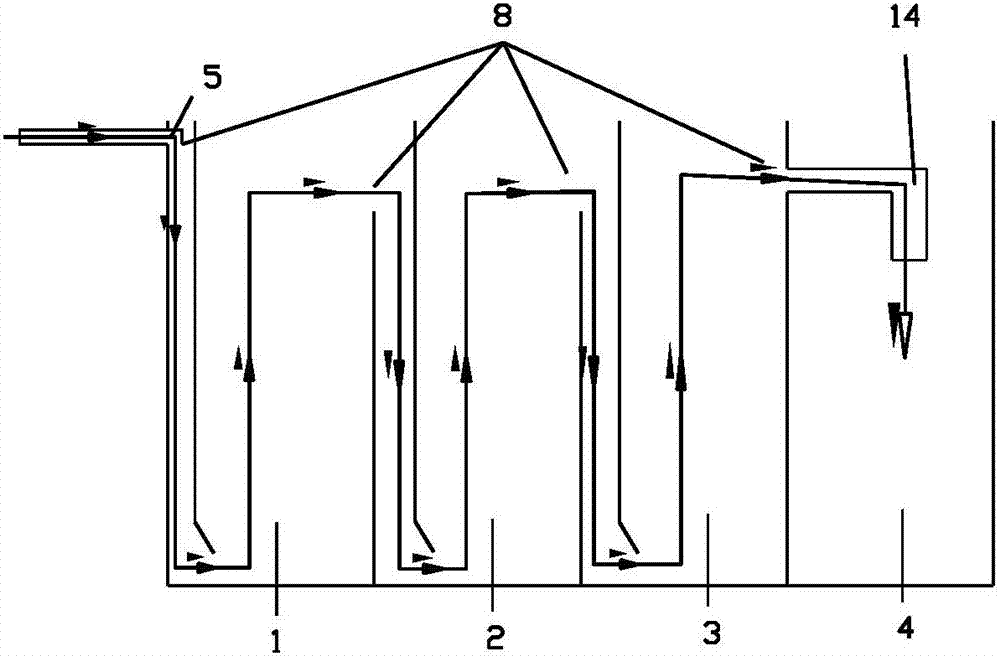

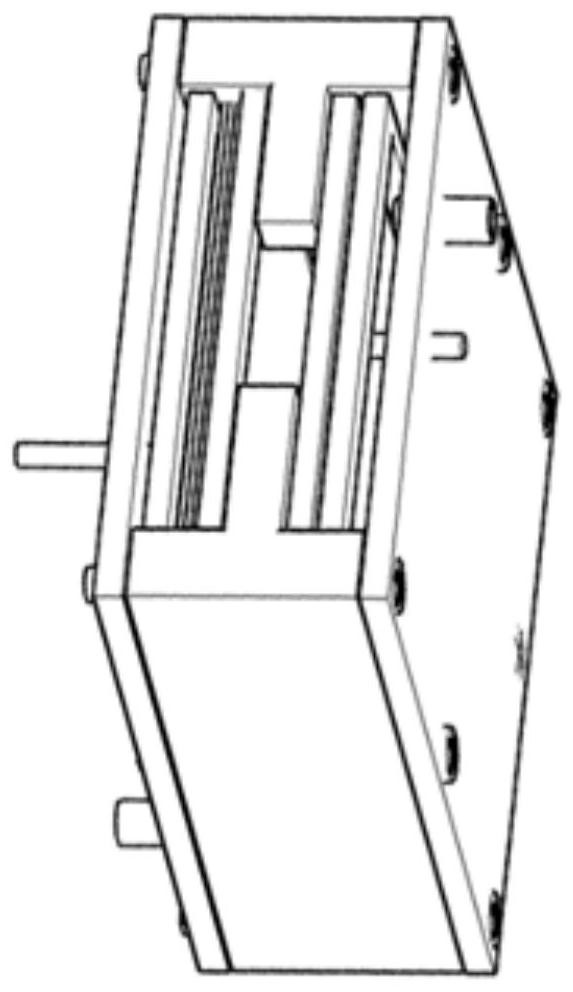

Micro-electrolysis pretreatment device of printing and dyeing wastewater, and device thereof

PendingCN107010699AFast removal rateFast electrochemical reactionWater treatment parameter controlWater contaminantsElectrolysisWater flow

A micro-electrolysis pretreatment device of printing and dyeing wastewater comprises a primary baffled micro-electrolysis cell, a secondary baffled micro-electrolysis cell, a neutralization tank and a sedimentation tank which are serially arranged, and wastewater enters a reaction tank from the bottom end through flow guiding channels arranged in the primary baffled micro-electrolysis cell, the secondary baffled micro-electrolysis cell, the neutralization tank and the sedimentation tank. The serially arranged primary and secondary baffled micro-electrolysis cells prolong the reaction time, increase the reaction space, and avoid the press hardening and channeling phenomena of a packing layer, caused by the gravity effect, under the action of the water flow and aeration; and the device can effectively remove the chroma and improve the biodegradability of printing and dyeing wastewater with high CODs, difficult degradation and poor biodegradability, greatly improves the treatment effect of the micro-electrolysis reaction, and provides good conditions for subsequent biochemical treatment.

Owner:江苏艾特克环境工程设计研究院有限公司

Black-tea-flavored modified milk powder and preparation method thereof

The invention discloses black-tea-flavored modified milk powder and a preparation method thereof. The milk powder comprises the following raw materials in parts by weight of 700-900 of a black tea leaching solution, 6000-7000 of fresh milk or 600-700 of milk powder, 180-220 of white granulated sugar, 90-110 of nonfat milk powder, 40-60 of whey powder and 0.1-0.3 of table salt. A preparation methodof the black tea leaching solution comprises the following steps of adding the black tea to the water, performing soaking, and then performing filtering treatment to obtain filtrate namely the blacktea leaching solution. A traditional concept is changed, products are made into powder, so that storage and transportation are convenient, and the quality guarantee period is long. During making of the milk tea, the black-tea-flavored modified milk powder is directly brewed with hot water, stirring is not needed, and the instant properties are good. The complex and time-consuming process is simplified, and the method is convenient and swift. The obtained black-tea-flavored modified milk powder is good in mouth feel, and has favorable sensory evaluation.

Owner:安徽达诺乳业股份有限公司

Vermiculizer for thin-wall cast iron and melting method thereof

InactiveCN101812626AStable productionEasy to manageProcess efficiency improvementSolubilityTransmitted power

The invention discloses a vermiculizer for thin-wall cast iron and a melting method thereof, and relates to a cast iron vermiculizer. The melting of the vermiculizer comprises the following steps: 1, examining before smelting; 2, charging before opening a furnace and transmitting power; 3, smelting and charging; 4, discharging from the furnace and casting; 5, crushing; and 6, checking, identifying and storing, wherein the obtained vermiculizer comprises 15 to 25 percent of rare earth (RE), 35 to 45 percent of silicon (Si), 2.5 to 4.5 percent of magnesium (Mg), 2 to 4 percent of calcium (Ca), 1.5 to 3.5 percent of zinc (Zn), 0.6 to 1.4 percent of magnesium oxide (MgO) and 20 to 40 percent of balance of ferrum (Fe) or inevitable impurity. The vermiculizer has the advantages of relatively simple and stable vermiculizing treatment process, good dissolubility, relatively wide vermiculizing range, no stirring, no desulphurization treatment for raw melted iron, and suitability for producing the thin-wall cast iron in low-sulfur and high-sulfur states.

Owner:CHINA YITUO GROUP

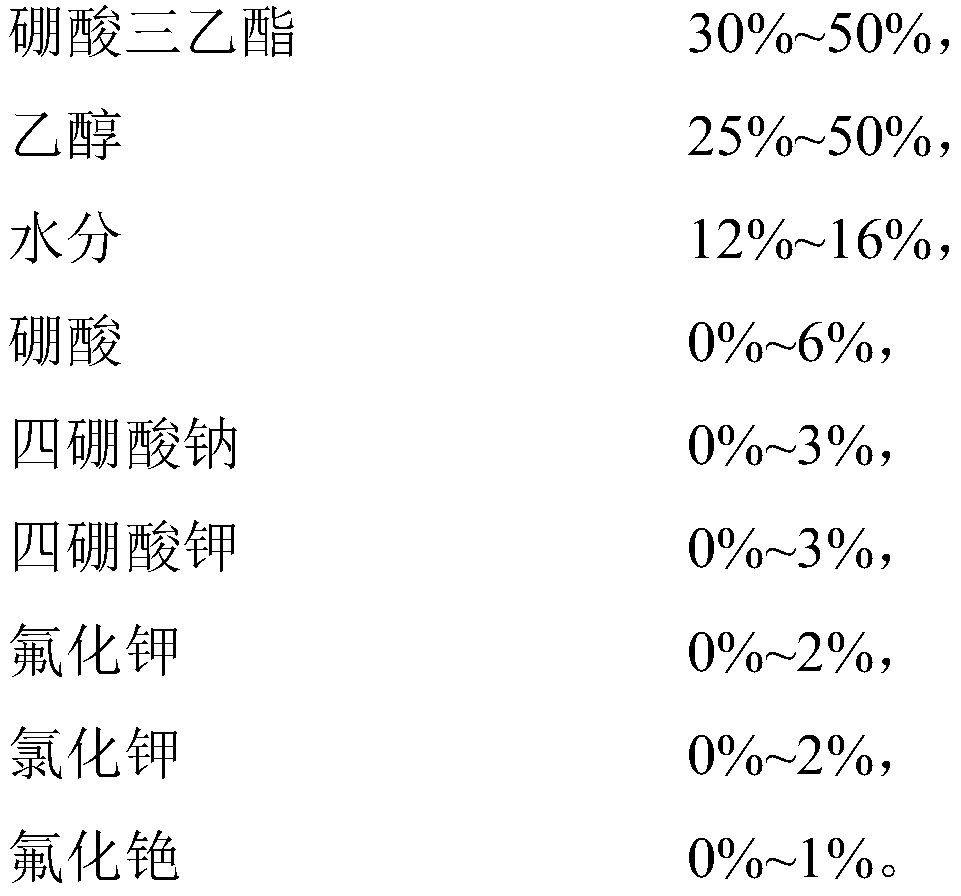

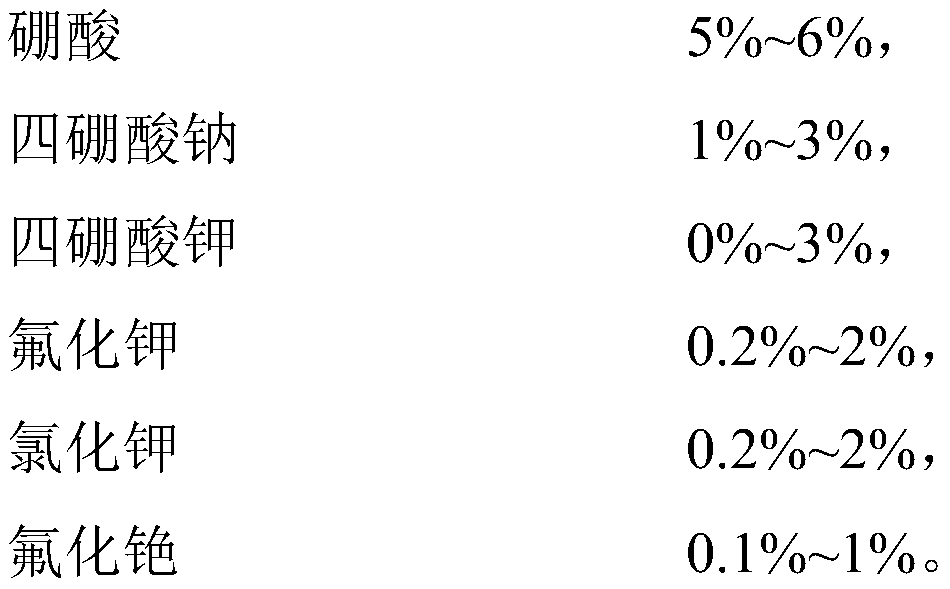

Low-volatility environment-friendly pickling-free soldering flux solution and preparation method and application thereof

ActiveCN111151924ALow saturated vapor pressureLow toxicityWelding/cutting media/materialsSoldering mediaChloride potassiumEthyl ester

The invention discloses a low-volatility environment-friendly pickling-free soldering flux solution and application of the low-volatility environment-friendly pickling-free soldering flux solution inflame soldering, high-frequency soldering or furnace soldering. The low-volatility environment-friendly pickling-free soldering flux solution comprises, by weight: 30%-50% of triethyl borate, 25%-50%of ethanol, 12%-16% of water, 0%-6% of boric acid, 0%-3% of sodium tetraborate, 0%-3% of potassium tetraborate, 0%-2% of potassium fluoride, 0%-2% of potassium chloride and 0%-1% of cesium fluoride. The invention also discloses a preparation method of the low-volatility environment-friendly pickling-free soldering flux solution. The preparation method comprises the steps of preparing a triethyl borate ethanol solution from the triethyl borate and the ethanol, adding the water into the triethyl borate ethanol solution, and then selectively adding the boric acid, the sodium tetraborate, the potassium tetraborate, the potassium fluoride, the potassium chloride and the cesium fluoride as active elements to dissolve to obtain the low-volatility environment-friendly pickling-free soldering fluxsolution.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

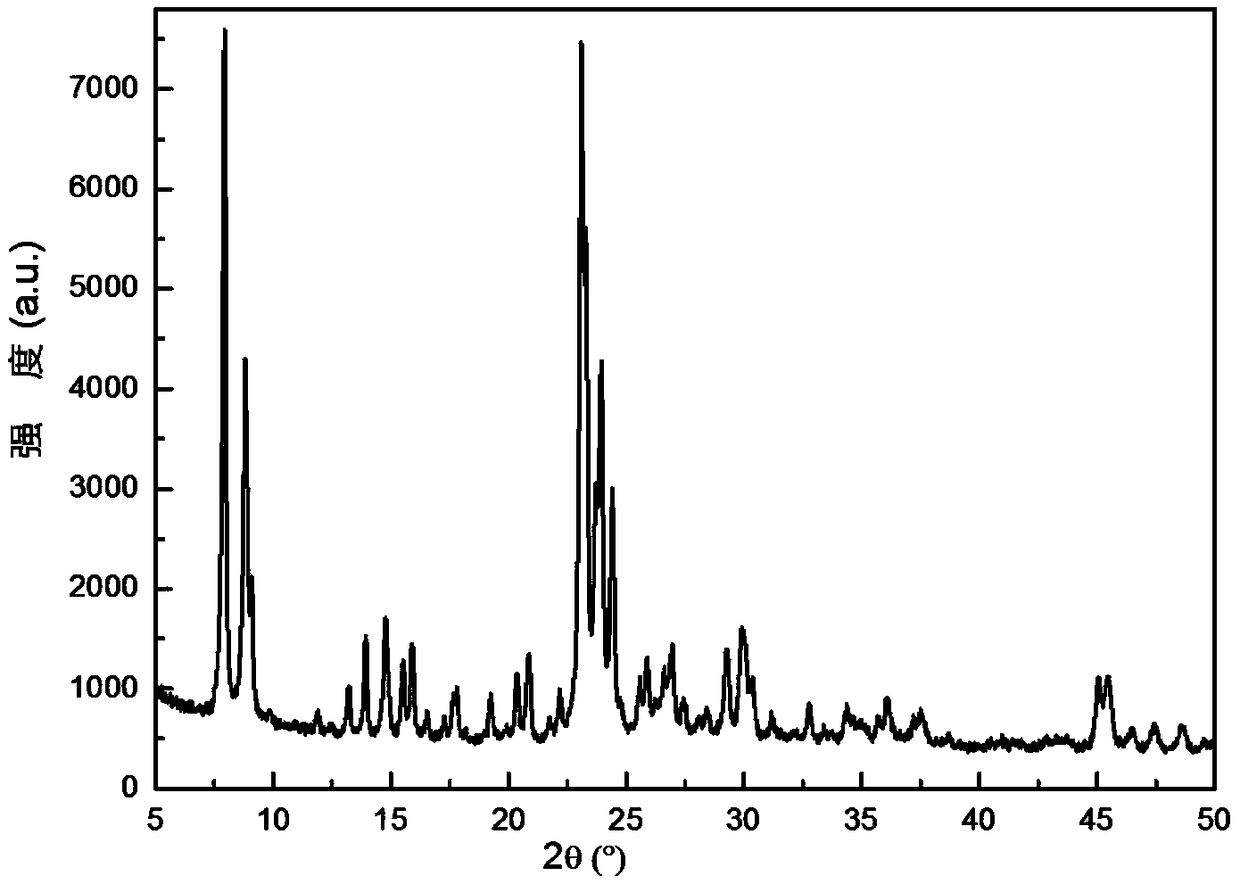

Method for preparing nano-FeZSM-5 molecular sieve, catalyst prepared from nano-FeZSM-5 molecular sieve and application thereof

InactiveCN108946759AEasy to makeReduce generationMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveGasoline

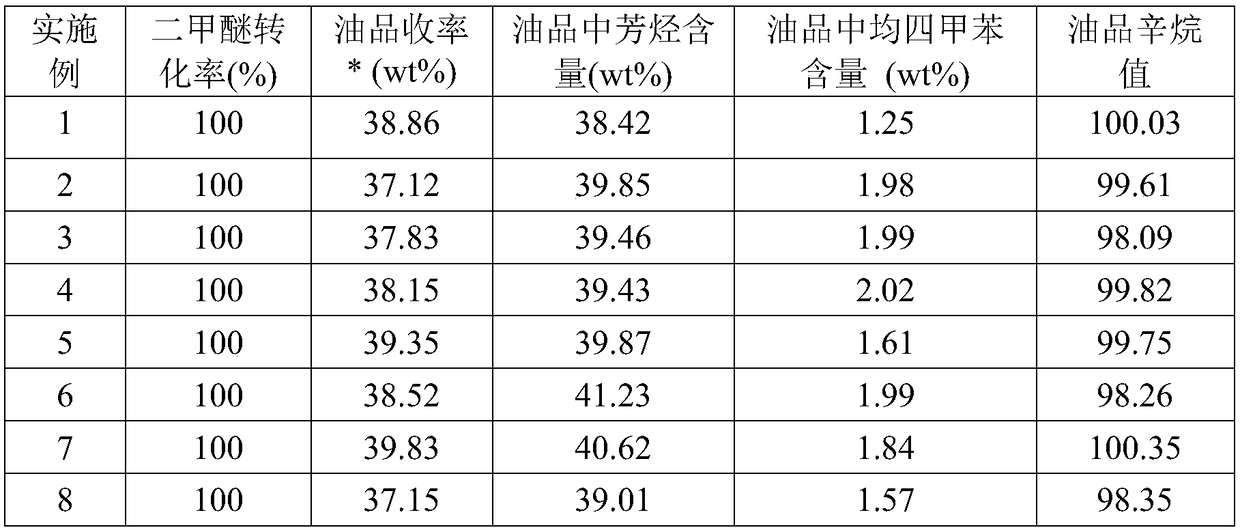

The invention discloses a method for preparing a nano-FeZSM-5 molecular sieve and application of the nano-FeZSM-5 molecular sieve in a dimethyl ether-to-gasoline (DTG) reacting process. According to the preparation method, the molecular sieve preparation process is simple, the structure directing agent in filtrate can be recycled, less waste liquid is generated, stirring is not required, and the equipment is simple; and the synthesized molecular sieve has high yield, and the prepared molecular sieve has small grain, uniform size, easy regulation and high crystallization degree; and the catalyst prepared from the nano-FeZSM-5 molecular sieve has excellent catalytic activity for DTG reaction, the dimethyl ether conversion rate is 100 percent, the single-pass oil product has high yield (morethan 35 percent), aromatic hydrocarbon in a gasoline product has low content (less than 40 percent), the content of the durene is lower than 2 percent, and the problems of low single-pass yield of oilproducts and high content of aromatic hydrocarbon, especially durene in an oil product in DTG technology can be solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

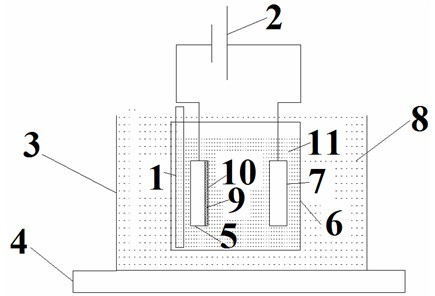

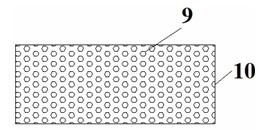

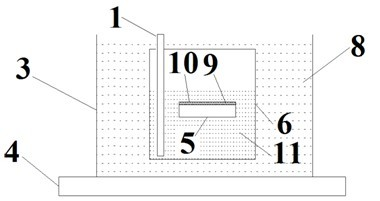

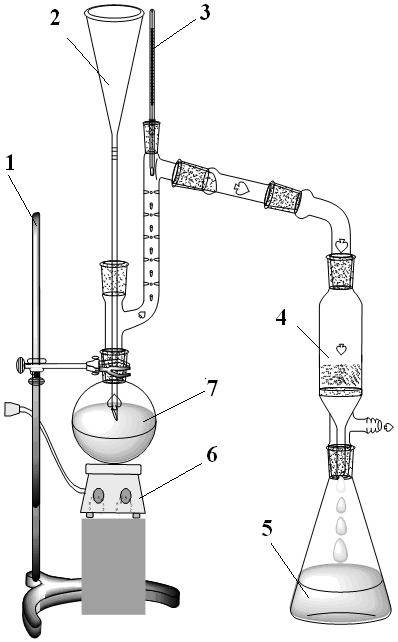

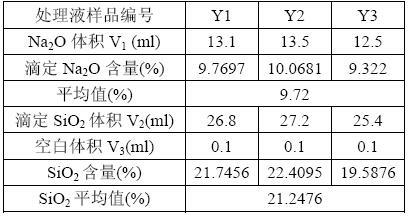

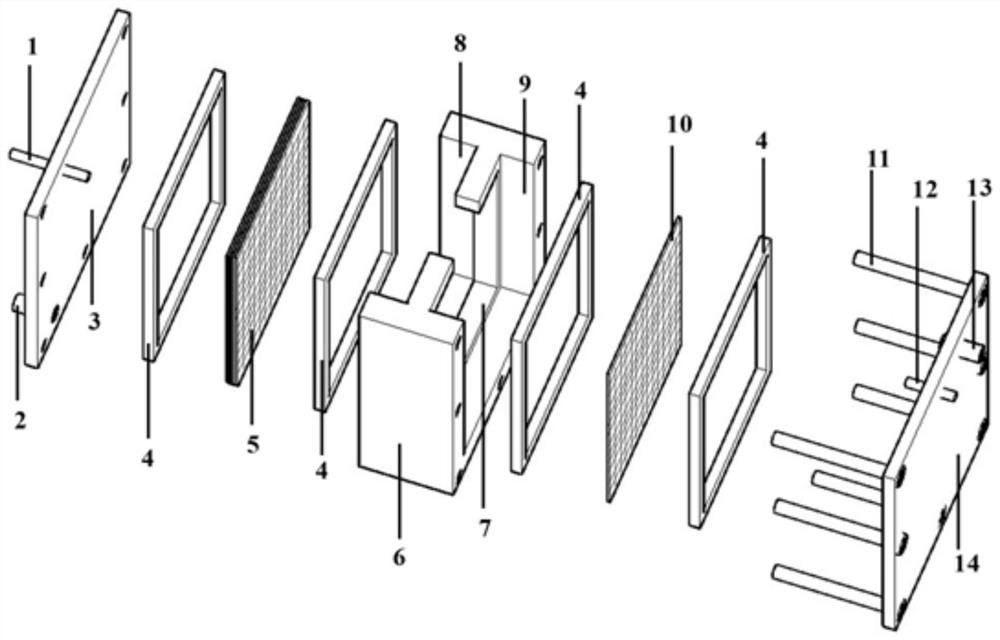

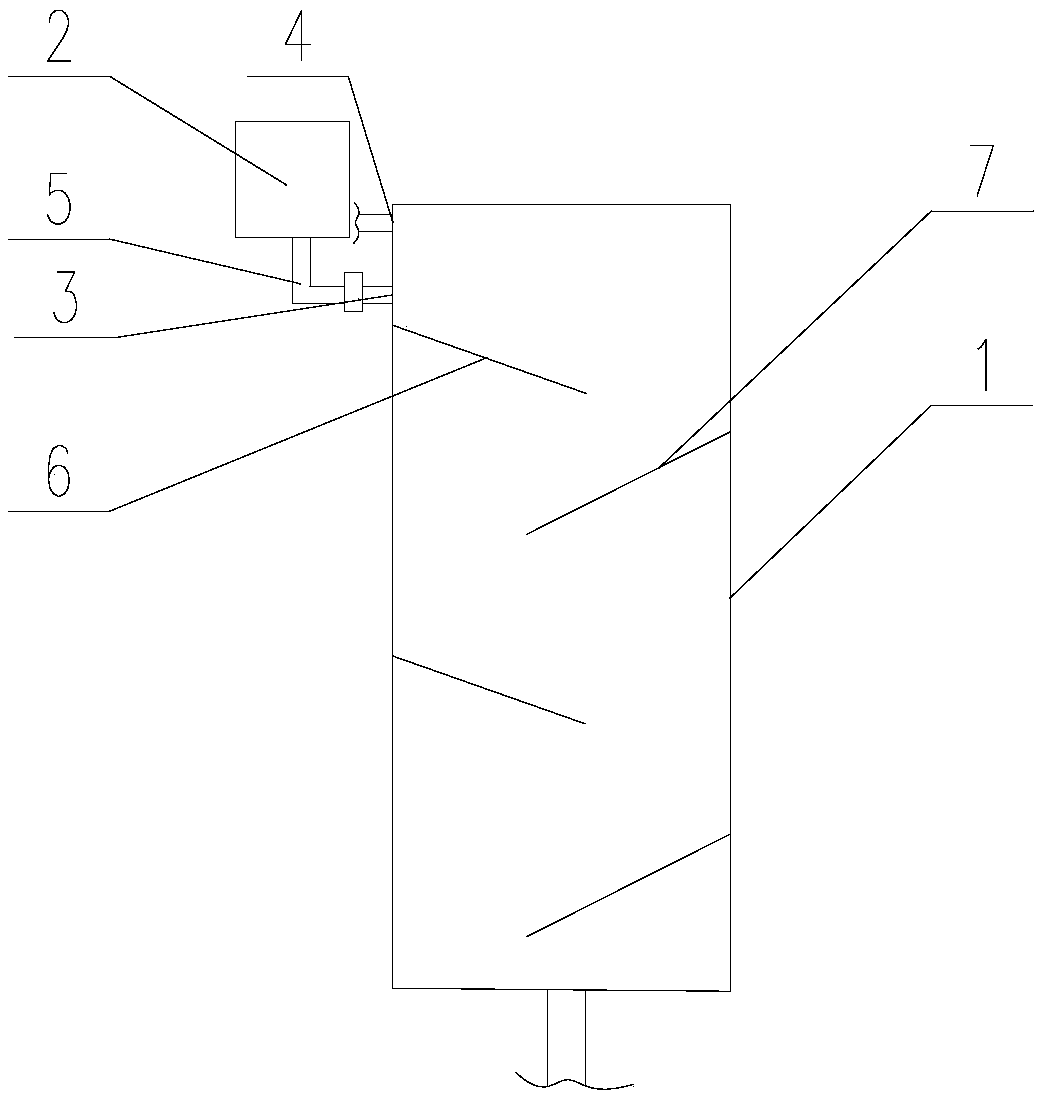

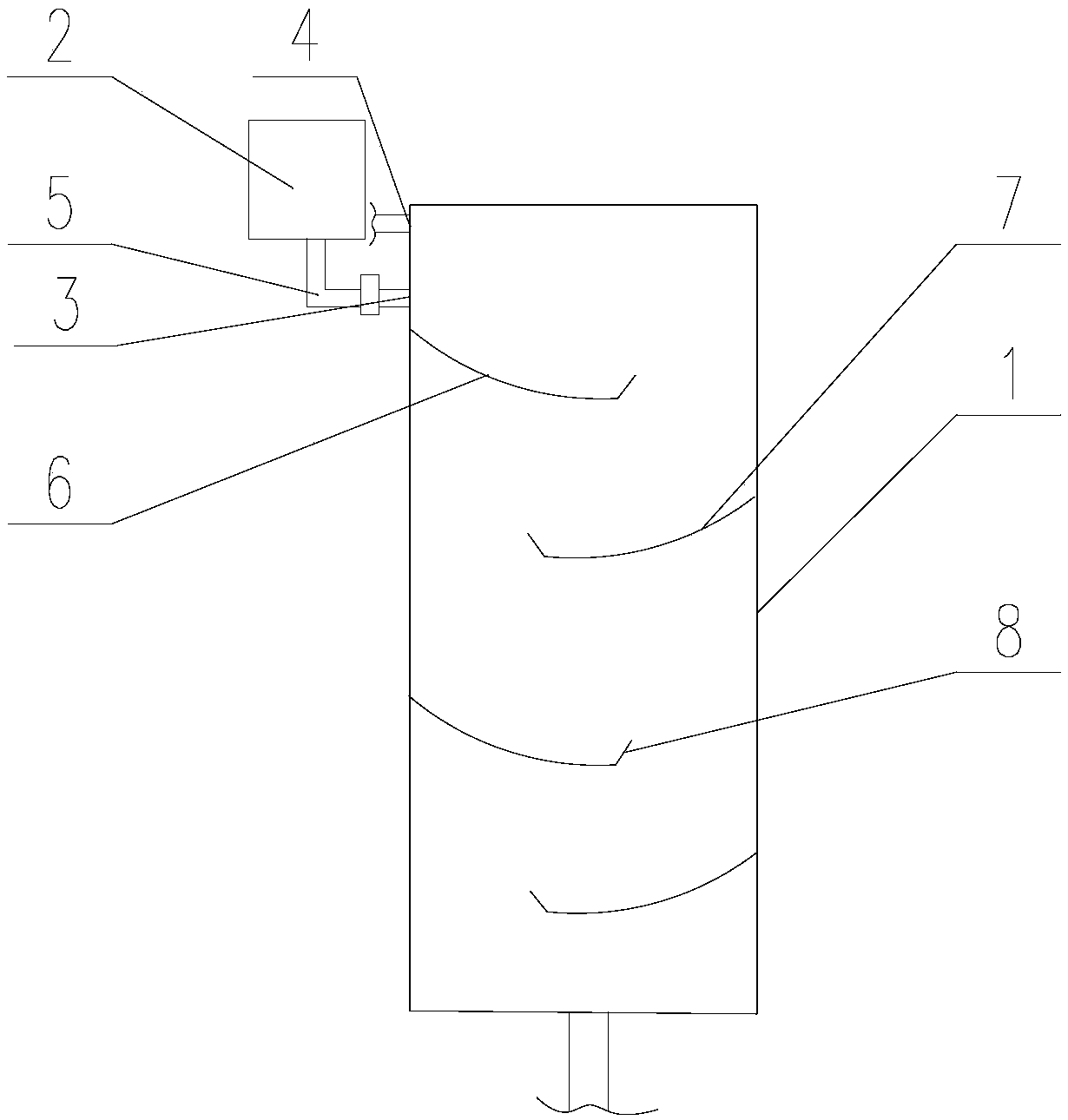

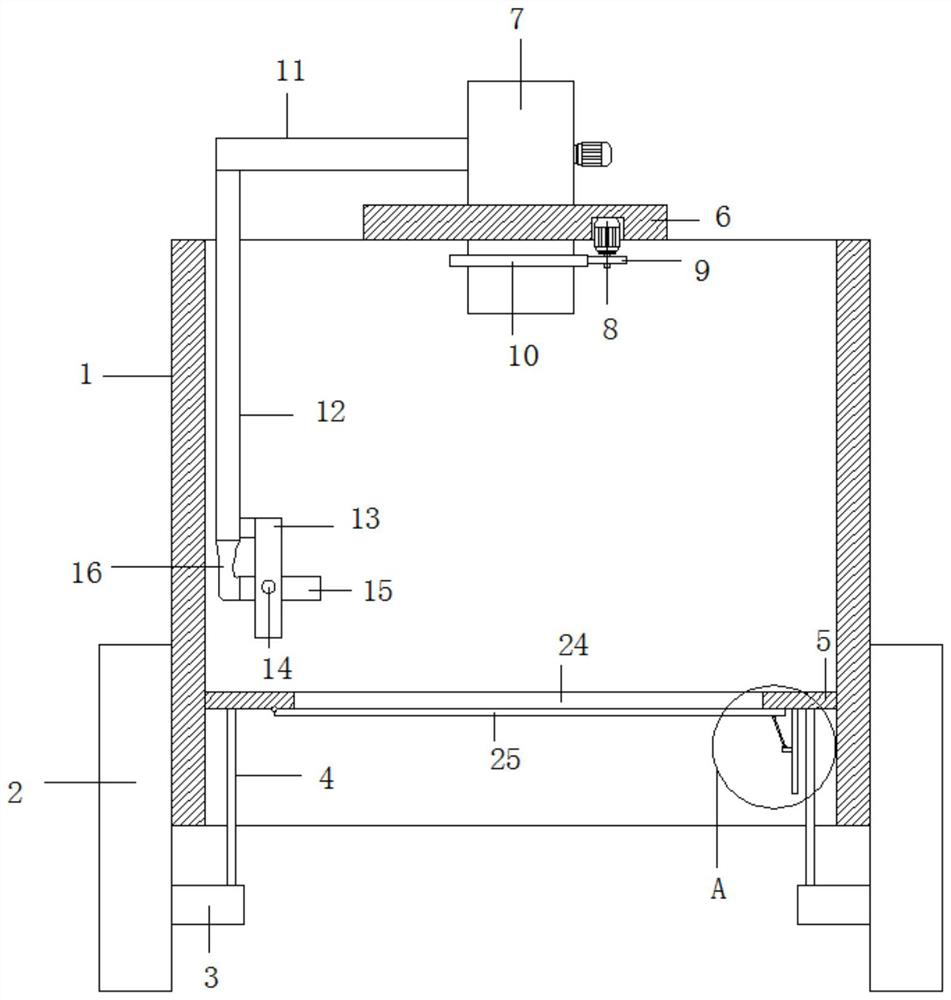

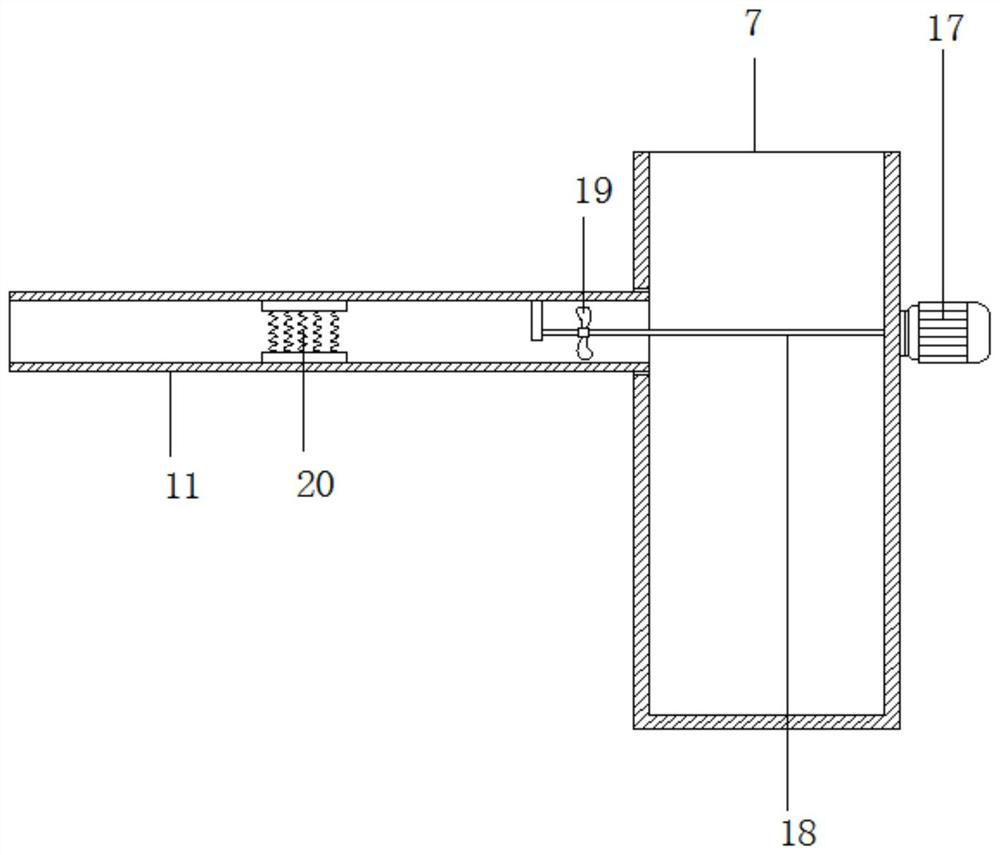

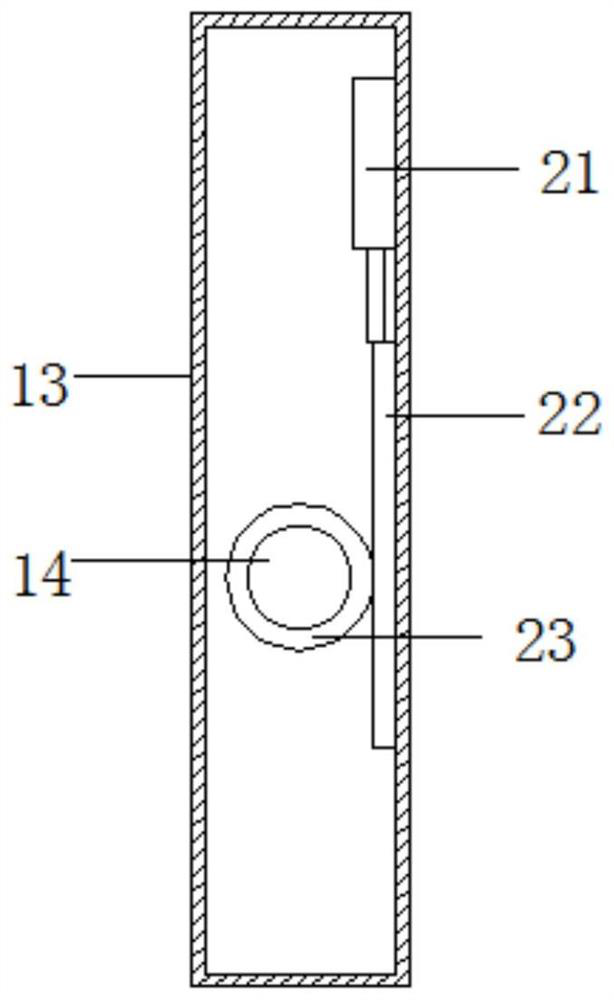

Device and method for determining total alkalinity and residual silica content of used sodium silicate-bonded sand or reclaimed sodium silicate-bonded sand

InactiveCN102628849APromote dissolutionDissolve completelyChemical analysis using titrationPreparing sample for investigationPotassium fluorideStrong acids

The invention relates to a device and a method for determining total alkalinity and residual silica content of used sodium silicate-bonded sand or reclaimed sodium silicate-bonded sand binder membranes. The method comprises the following steps of building an experimental device according to the figure 1, weighing a sample, putting the sample into a sample preparation bottle (4) shown in the figure 1, adding distilled water into a flask by a water replenishing device (2), switching on a power supply, boiling the distilled water, feeding steam into the sample preparation bottle (4) by a connection pipe, wherein the steam passing through the sample is condensed into extract, filtering the extract, wherein the filtered extract flows into a lower collector (5) to form a liquid sample for analysis, cooling the liquid sample to the room temperature, adding an indicator into the liquid sample, carrying out titration by a standard strong acid solution until a titration end point, recording the consumption amount of the standard strong acid solution, calculating total alkalinity of the sample, adding sodium fluoride or potassium fluoride solids into the solution subjected to the total alkalinity determination, shaking up, carrying out dissolution so that the solution has an alkaline color, carrying out titration of produced sodium hydroxide by a strong acid, and calculating the content of silica.

Owner:WUHAN TEXTILE UNIV

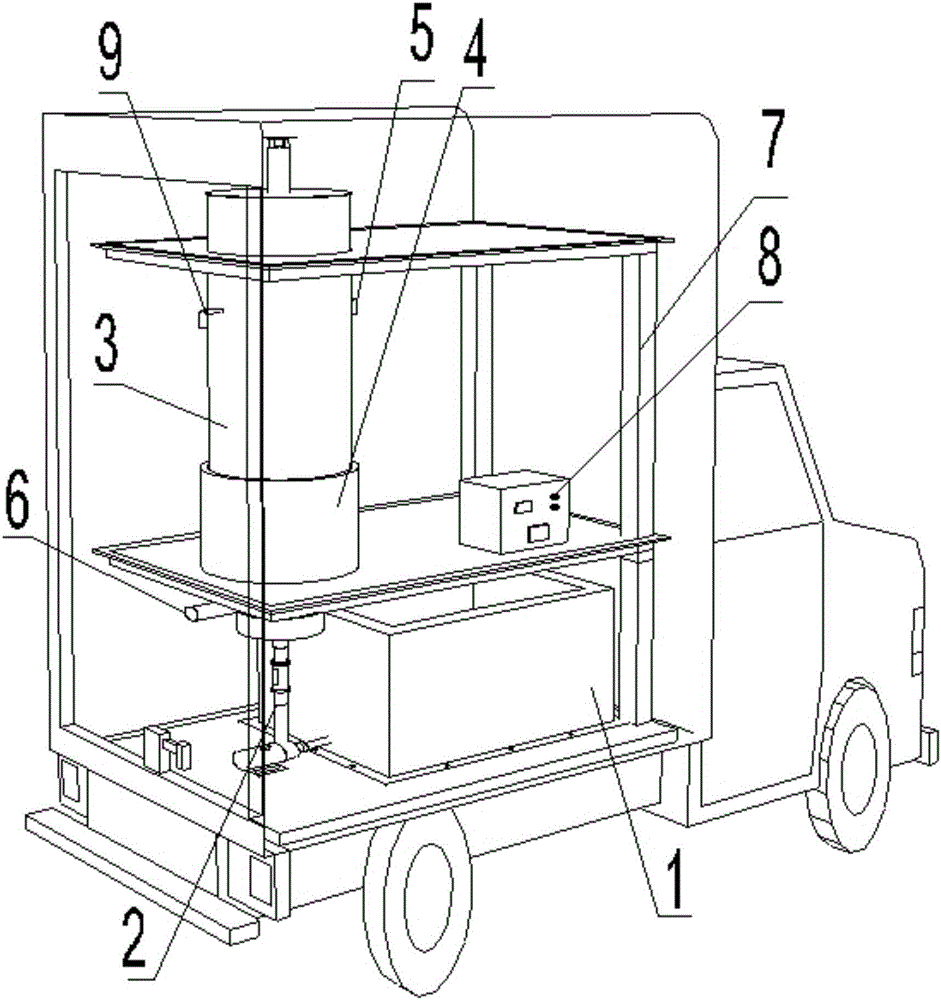

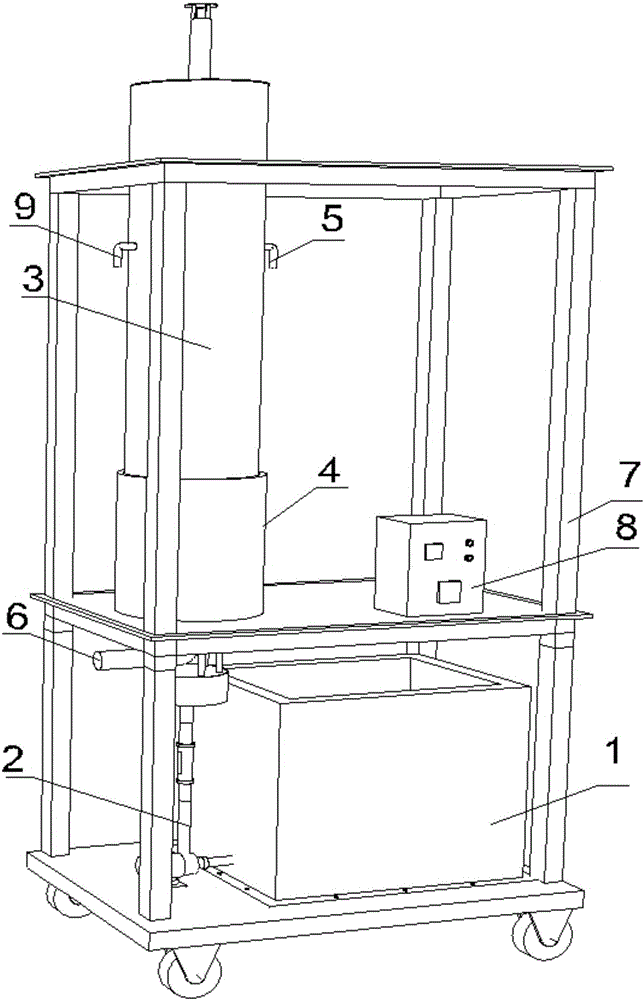

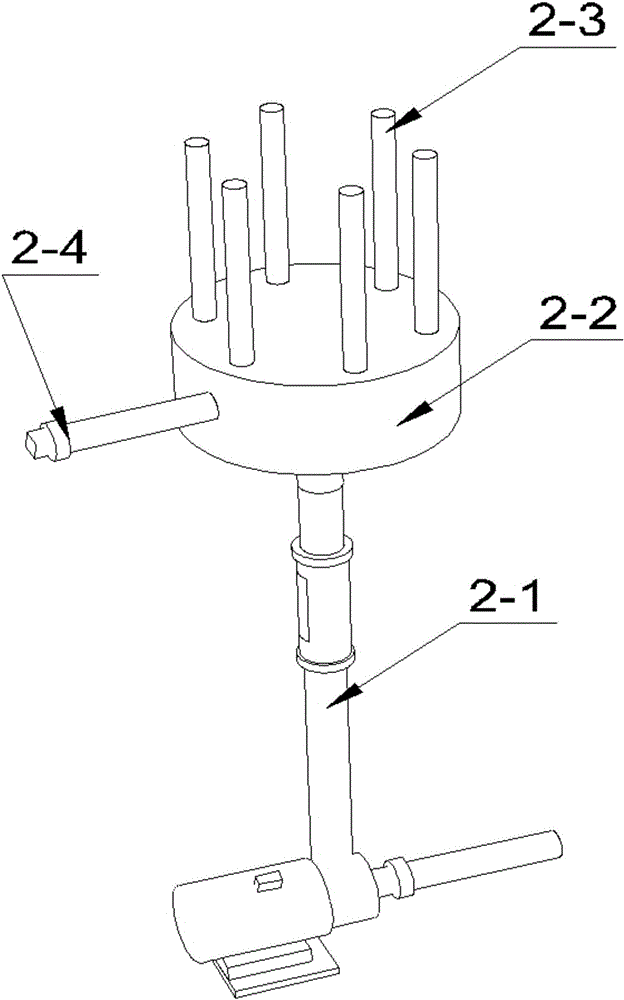

Vehicular underground water carbon tetrachloride treatment equipment and water purifying method thereof

InactiveCN106006908AReduce energy consumptionEasy to handleWater contaminantsWater/sewage treatment apparatusDraining tubeSludge

The invention discloses vehicular underground water carbon tetrachloride treatment equipment which consists of a buffer pool, a water distribution device, a reaction column, a heating device, a drainage pipe, a silt discharge pipe, a movable frame and a control system, wherein the water distribution device conveys the to-be-treated underground water to the center of the bottom of the reaction column from the bottom of the buffer pool; the heating device heats the lower end of the reaction column; the to-be-treated underground water reacts with fresh air at the bottom of the reaction column; the to-be-treated underground water slowly flows from bottom to top and is completely reacted after reaching the top of the reaction column; the generated clear water is discharged from the upper part of the reaction column along the drainage pipe; the carbon tetrachloride gas is discharged from the top of the reaction column; and the settled sludge is discharged from the bottom of the reaction column. The vehicular underground water carbon tetrachloride treatment equipment disclosed by the invention has the advantages of good treatment effect on carbon tetrachloride, low energy consumption and small floor area and is suitable for treating the underground water rich in carbon tetrachloride.

Owner:XUZHOU TENGRUI INTELLIGENT EQUIP CO LTD

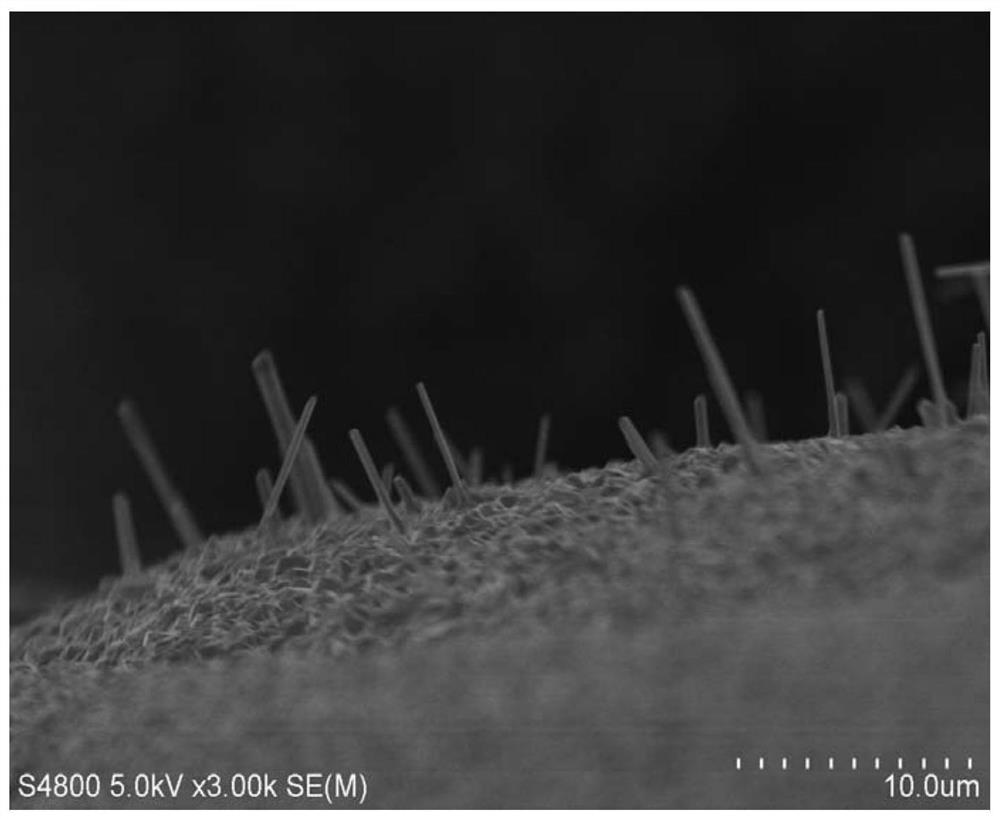

Electrochemical filter for removing total nitrogen in water

ActiveCN113772787AIncrease the effective reaction areaAdd reactive sitesWater contaminantsWater/sewage treatmentElectrochemical responseTotal nitrogen

The invention belongs to the technical field of water treatment, and discloses an electrochemical filter for removing total nitrogen in water. A water body to be treated is continuously pumped into a cathode reaction chamber through a water inlet, sequentially flows through a three-dimensional nano tip porous cathode and an anode under certain current and voltage, and reacts for a certain period of time, and finally, nitrate nitrogen, ammonia nitrogen and nitrite nitrogen in the water body are converted into nitrogen. The mass transfer distance from a substance to the surface of an electrode can be shortened by utilizing a micron-sized aperture electrode, the collision opportunity of pollutants and the electrode in the liquid flowing process is increased by the nano-tip structure in the pore channel, and meanwhile, reaction ions are limited in the internal channel of the three-dimensional nano-tip porous electrode; and the repulsive interaction of like ions under the action of electric field force is weakened, and the problems that a traditional electrochemical reactor electrode is small in effective reaction area, too large in distance between two electrodes, low in mass transfer efficiency and low in reaction efficiency, reactants are rejected by the electrode, reactant gas is accumulated, and the reactor is difficult to amplify are solved.

Owner:DALIAN UNIV OF TECH

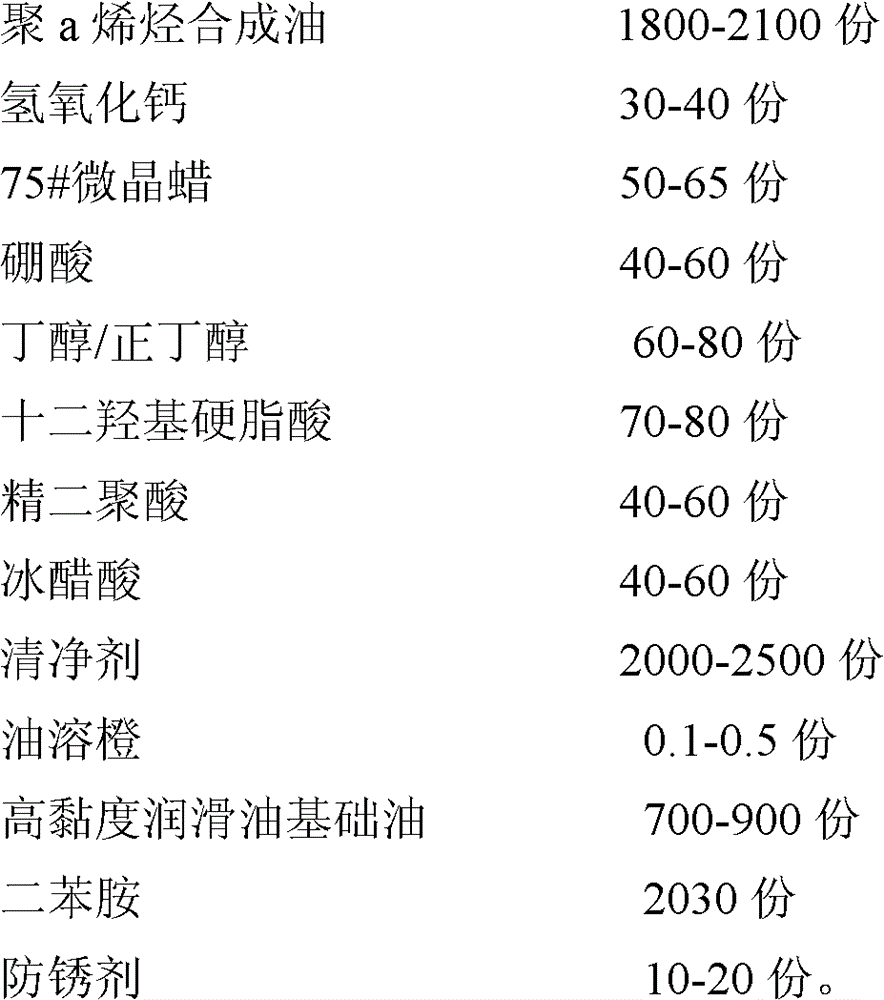

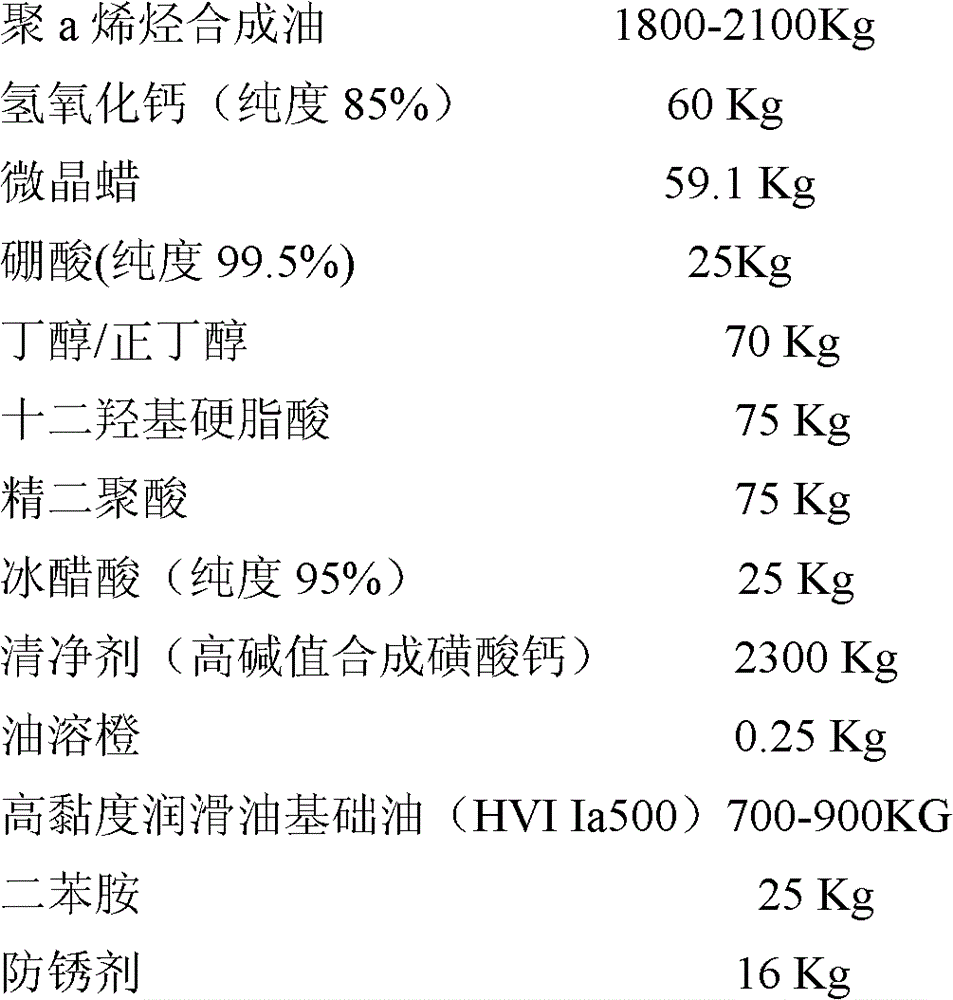

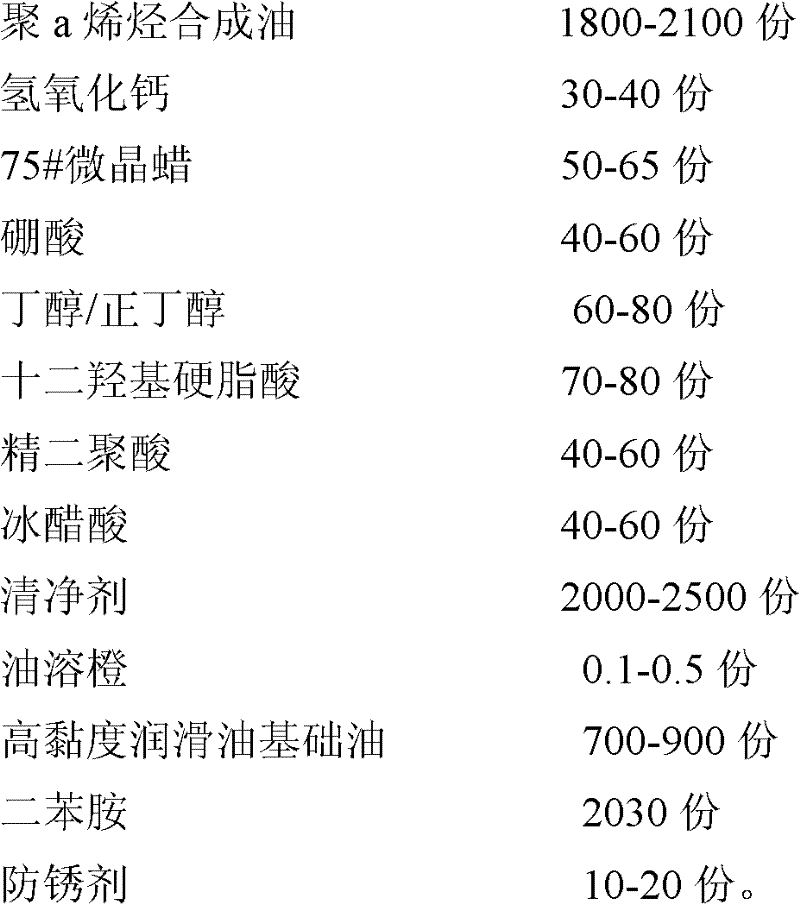

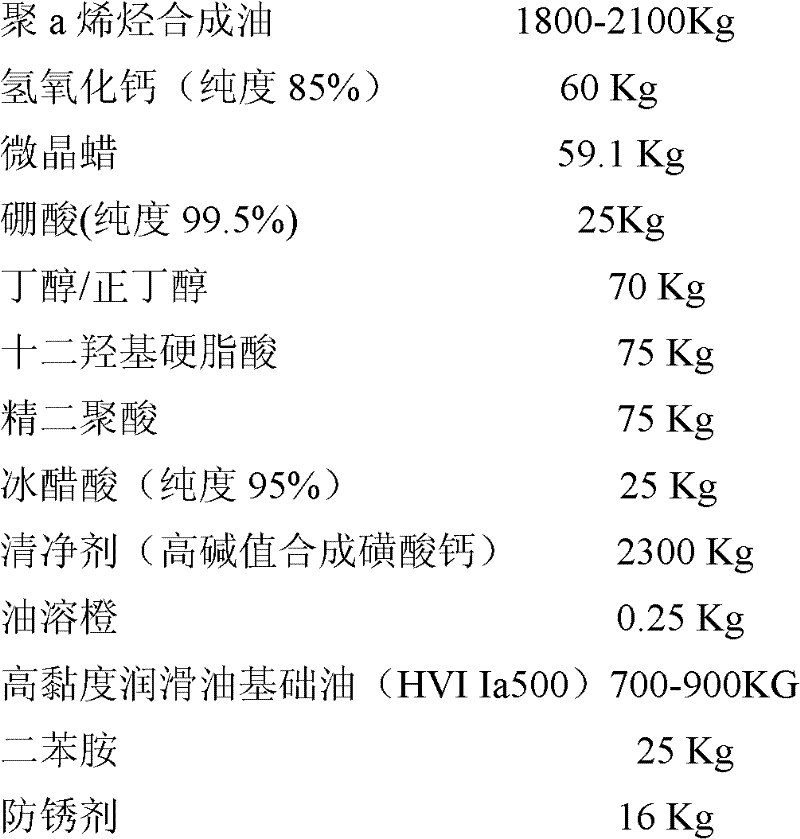

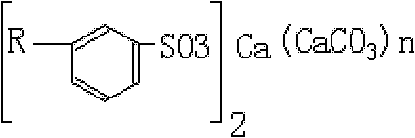

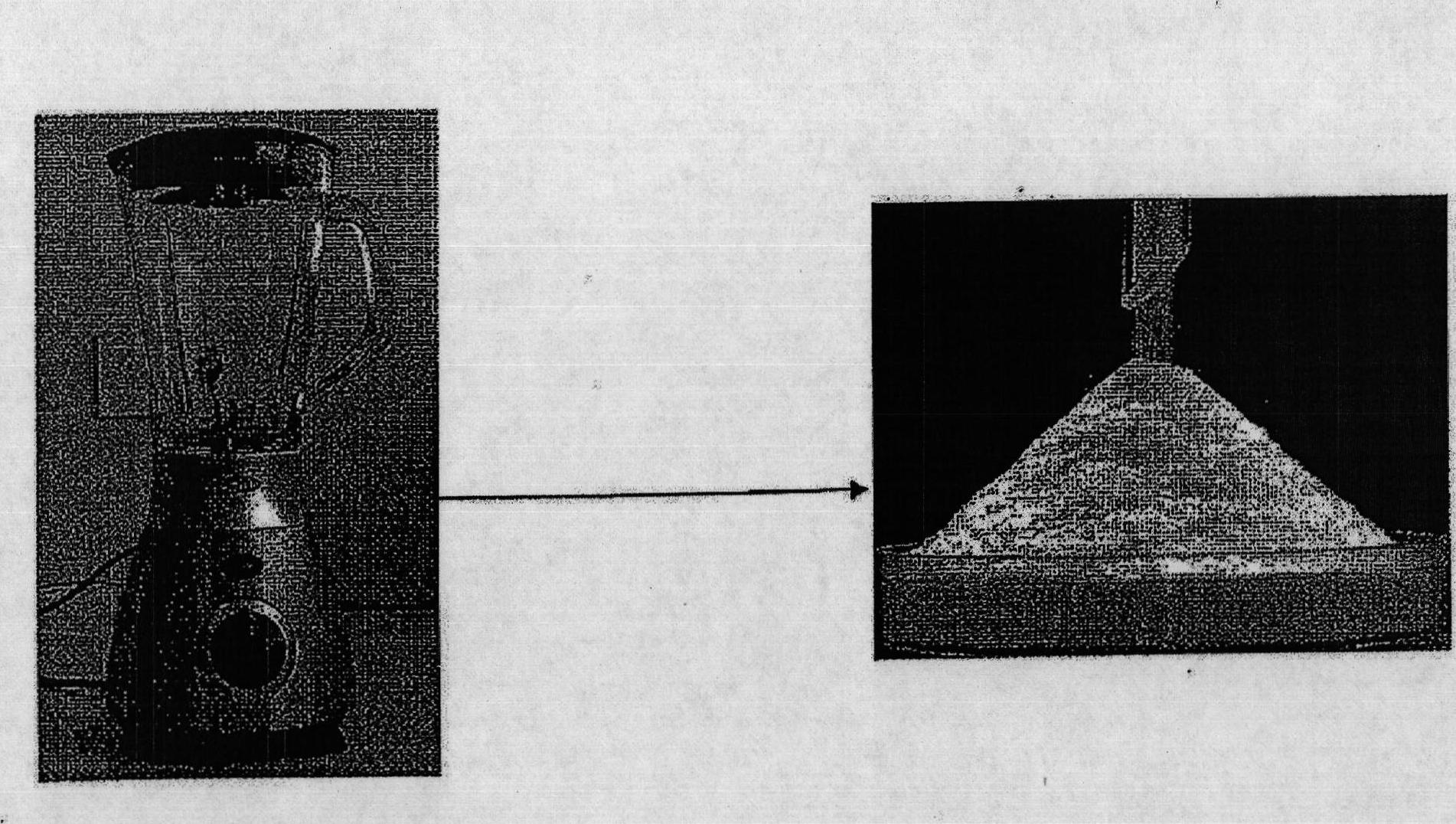

Storage lubricating grease and method for preparing same

The invention relates to storage lubricating grease and a method for preparing the same. The storage lubricating grease consist of the following ingredients in part by weight: 1,800 to 2,100 parts of polyalphaolefin, 30 to 40 parts of calcium hydroxide, 50 to 65 parts of 75# ceresine wax, 40 to 60 parts of boric acid, 60 to 80 parts of butyl alcohol / n-butyl alcohol, 70 to 80 parts of 12-hydroxy stearic acid, 40 to 60 parts of purified dimer acid, 40 to 60 parts of glacial acetic acid, 2,000 to 2,500 parts of cleaning agent, 700 to 900 parts of 0.25 percent oil orange and high-viscosity lube base oil, 2,030 parts of diphenylamine and 10 to 20 parts of anti-rusting agent. The preparation method comprises the following steps of: 1, charging; 2, saponifying; 3, performing supplement saponificatio; 4, cooling to reduce temperature; and 5, dewaxing to obtain the finished product of the storage lubricating grease. The storage lubricating grease of the invention can effectively resist corrosion of chemicals, oil, water and gas and avoid affecting rubber and plastics and is applicable to the environment polluted by chemicals, oil or water at extremely high temperature. The deformed steel bars are not rusted under the protection of the storage lubricating grease.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

Energy saving apparatus for flocculation of industrial waste liquid

InactiveCN108609705AWell mixedFlow slows and increasesWater/sewage treatment by flocculation/precipitationFlocculationLiquid waste

The invention discloses an energy saving apparatus for flocculation of industrial waste liquid and solves the problems that flocculation in the prior art needs stirring and is high in energy consumption. The apparatus includes a flocculant header tank, a central transporting pipe, a flocculant adding inlet, and a waste liquid adding inlet. A flocculant adding pipe is connected to the lower end ofthe flocculant header tank. The flocculant adding inlet and the waste liquid adding inlet are disposed on the upper end of the central transporting pipe, wherein the waste liquid adding inlet is located above the flocculant adding inlet. A plurality of first baffles and a plurality of second baffles, which are inclined down and are in the shape of major arc, are arranged on the inner wall of the central transporting pipe, wherein the arc-shaped ends of the first baffles and second baffles are completely contacted with and fixed to the inner wall of the central transporting pipe. The first baffles are distributed in one side of the central transporting pipe vertically while the second baffles are distributed in the opposite side of the central transporting pipe vertically and are staggeredwith the first baffles. The apparatus can prolong mixing time of the flocculant and to-be-treated industrial waste liquid, so that the liquids are mixed more completely. The apparatus has high mixingefficiency and can save energy.

Owner:四川省宏茂环保技术服务有限公司

Preparing method for superfine silver powder

The invention discloses a preparing method for superfine silver powder, and the preparing method is used in the technical field of silver powder wet process preparing equipment. A plurality of reaction raw materials are continuously added into a reactor with the curve flow path through a plurality of feeding ports at the same time. The reaction raw materials flow in the reactor along the curve flow path under the action of gravity, mixing and reacting are finished in the flow process, and products obtained through the reaction flow out of the reactor through a discharging port of the reactor.According to the disclosed preparing method for the superfine silver powder, the multiple reaction raw materials are added in the reactor with the multiple feeding ports and the curve flow path at thesame time, reaction raw material mixing and reacting are finished in the process that the reaction raw materials flow towards the discharging port from the feeding ports, stirring is not needed, mixing of the reaction raw materials is uniform, and the grain diameter of obtained silver powder is uniform.

Owner:成都市天甫金属粉体有限责任公司

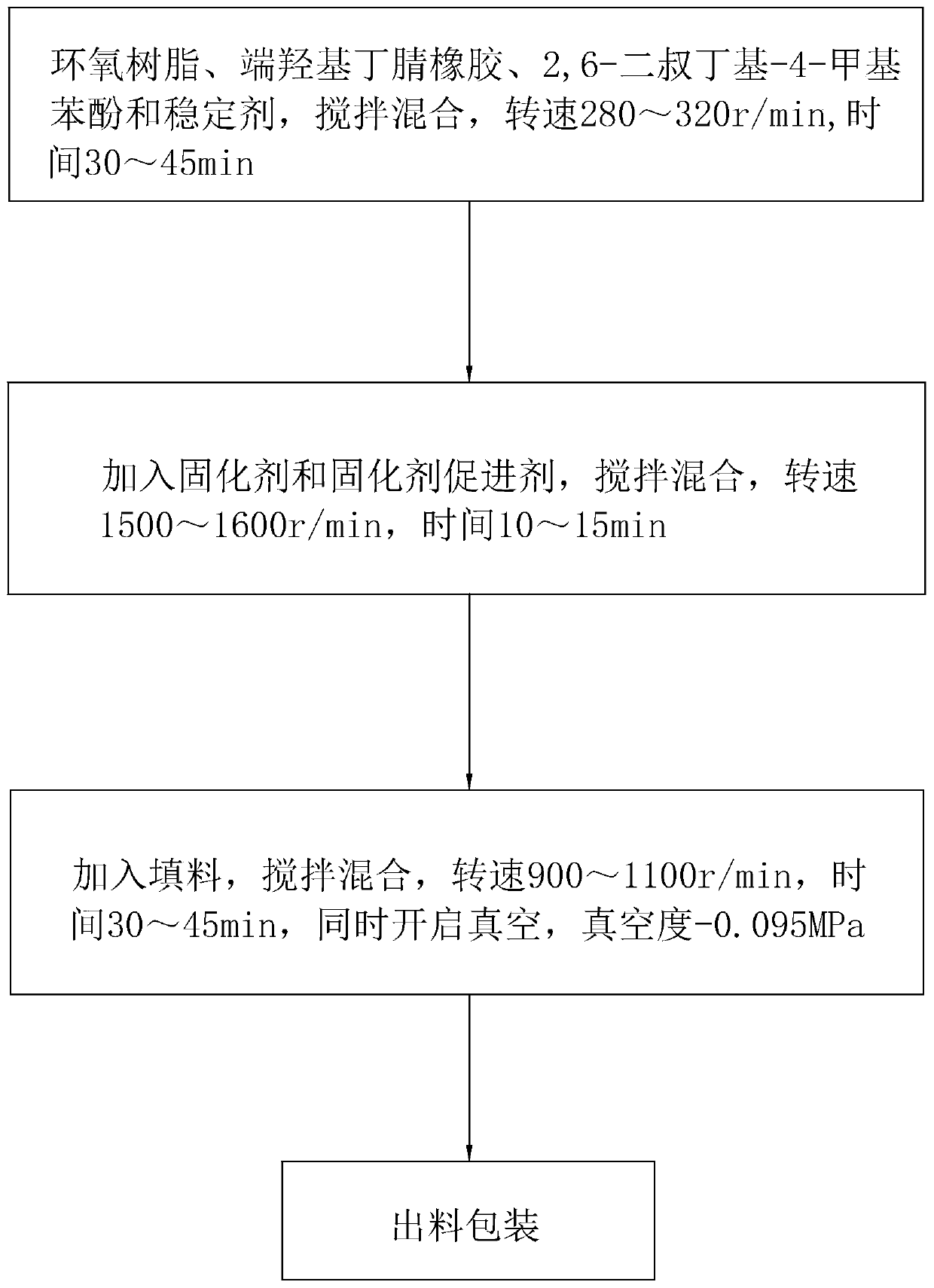

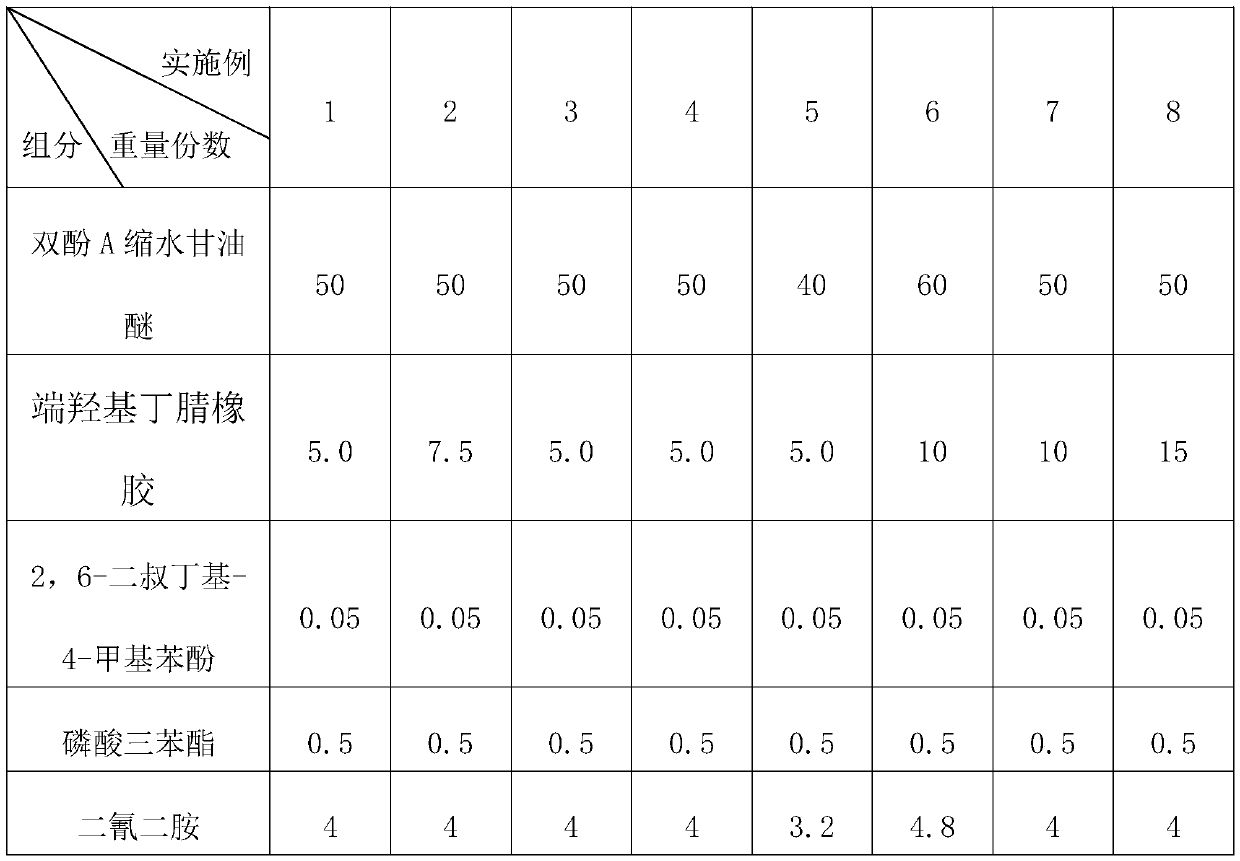

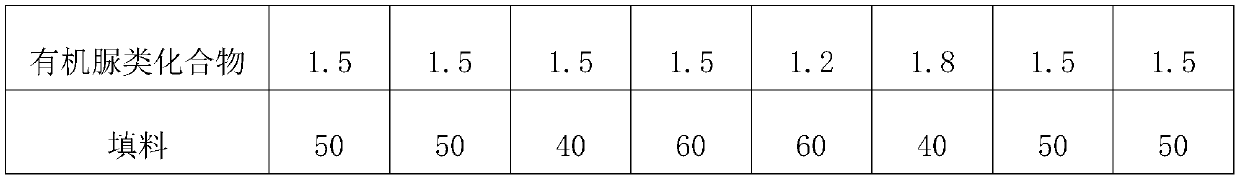

Single-component shunt-stabilized high-strength epoxy encapsulated resin adhesive and preparation method thereof

InactiveCN111378410ALong-lasting and stable rheologyNot easy to flowNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberPolymer science

The invention discloses a high-strength epoxy encapsulated resin adhesive with single-component diverting and stabilizing functions and a preparation method of the high-strength epoxy encapsulated resin adhesive. According to the technical scheme, the high-strength epoxy encapsulated resin adhesive with the single-component diverting and stabilizing function is prepared from, by weight, 40 to 60 parts of epoxy resin, 0.05 to 0.5 part of 2,6-di-tert-butyl-4-methylphenol, 5 to 15 parts of a toughening agent, 40 to 60 parts of a filling material, 3 to 15 parts of a curing agent, 0.5 to 5 parts ofa curing accelerator, and 0.5 to 1 part of a stabilizing agent; wherein the filler is a composition of fiber powders in different length-to-diameter ratios according to the following ratio: 10-30% oflength-to-diameter ratio being (1-10):1, 40-60% of length-to-diameter ratio being (10-20):1, and 10-30% of length-to-diameter ratio being (20-30):1. According to the present invention, the combination of the fiber powders with different contents and different length-diameter ratios is used, and the rheological property of the encapsulation adhesive is controlled by using the different mutual winding degrees of the fiber powders with different length-diameter ratios in the epoxy resin, such that the prepared product has advantages of rheology stability and high strength.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

Storage lubricating grease and method for preparing same

The invention relates to storage lubricating grease and a method for preparing the same. The storage lubricating grease consist of the following ingredients in part by weight: 1,800 to 2,100 parts of polyalphaolefin, 30 to 40 parts of calcium hydroxide, 50 to 65 parts of 75# ceresine wax, 40 to 60 parts of boric acid, 60 to 80 parts of butyl alcohol / n-butyl alcohol, 70 to 80 parts of 12-hydroxy stearic acid, 40 to 60 parts of purified dimer acid, 40 to 60 parts of glacial acetic acid, 2,000 to 2,500 parts of cleaning agent, 700 to 900 parts of 0.25 percent oil orange and high-viscosity lube base oil, 2,030 parts of diphenylamine and 10 to 20 parts of anti-rusting agent. The preparation method comprises the following steps of: 1, charging; 2, saponifying; 3, performing supplement saponificatio; 4, cooling to reduce temperature; and 5, dewaxing to obtain the finished product of the storage lubricating grease. The storage lubricating grease of the invention can effectively resist corrosion of chemicals, oil, water and gas and avoid affecting rubber and plastics and is applicable to the environment polluted by chemicals, oil or water at extremely high temperature. The deformed steel bars are not rusted under the protection of the storage lubricating grease.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

Clathrates for gas storage

InactiveCN102119207AFavorable mechanicsFavorable recyclabilitySolidificationLiquefactionHydrogenEmulsion

This invention relates to a gas hydrate (often referred to as a clathrate) comprising a water- in-gas emulsion (egdrywater (DW)) and an enclathrated exogenous gas such as for example methane, natural gas, hydrogen orcarbon dioxide.

Owner:UNIV OF LIVERPOOL

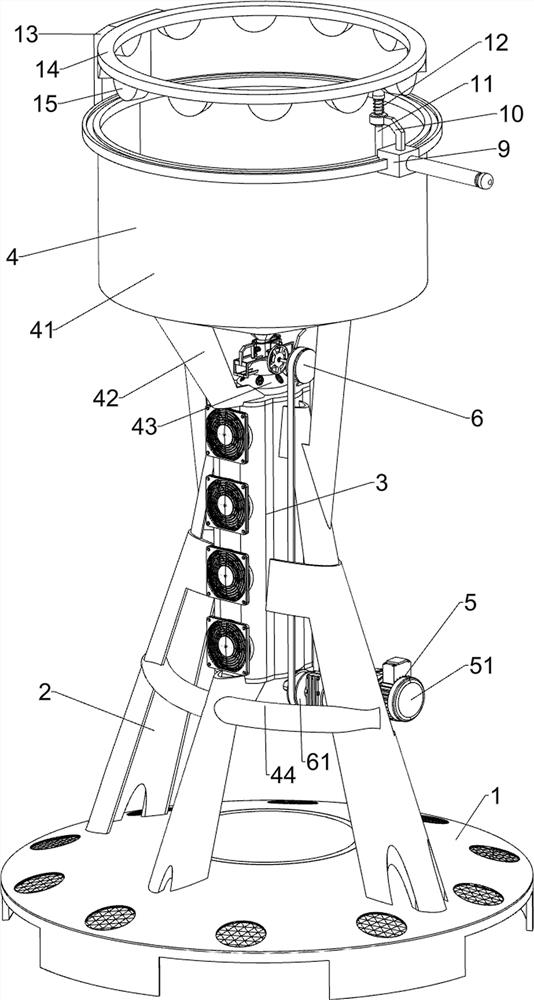

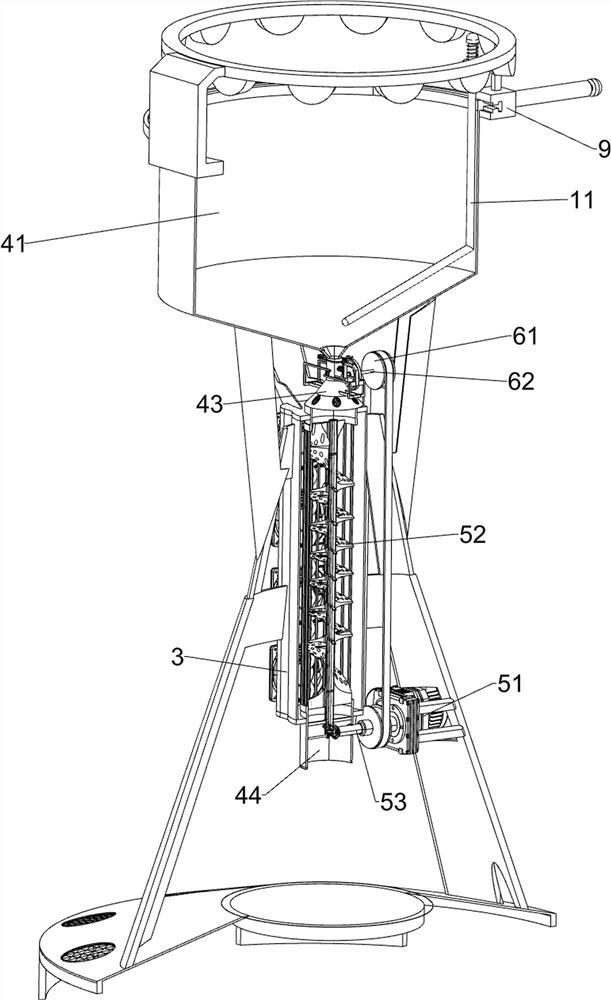

Efficient drying equipment for chicken feed processing

PendingCN114234576AAchieve dryingIntegrity guaranteedGranular material dryingFeeding-stuffPipe fittingStructural engineering

The invention discloses efficient drying equipment for chicken feed processing, and belongs to the technical field of feed processing.The efficient drying equipment comprises a pipe fitting, supporting plates are fixedly installed on the two sides of the pipe fitting, lifting blocks are slidably installed on the opposite sides of the two supporting plates, a shaking plate is slidably installed in the pipe fitting, and a connecting rod is fixed between the shaking plate and the lifting blocks; an outlet is formed in the shaking plate, a sealing cover is hinged to the bottom of the outlet, an opening and closing assembly used for opening and closing the sealing cover is arranged on the shaking plate, a transverse plate is installed at the top of the pipe fitting, a vertical pipe is rotationally installed on the transverse plate, a heating pipe is fixed to one side of the vertical pipe, and an electric heating wire is installed in the heating pipe. Fan blades are rotationally mounted in the heating pipe; according to the feed drying device, large-area air blowing is achieved to dry feed, the feed is thrown upwards, the feed is conveniently and evenly heated, air blowing drying is conducted on the thrown feed at different height positions, the drying uniformity is improved, stirring is not needed, and the completeness of feed particles is guaranteed.

Owner:瑞昌市久兴农业科技有限公司

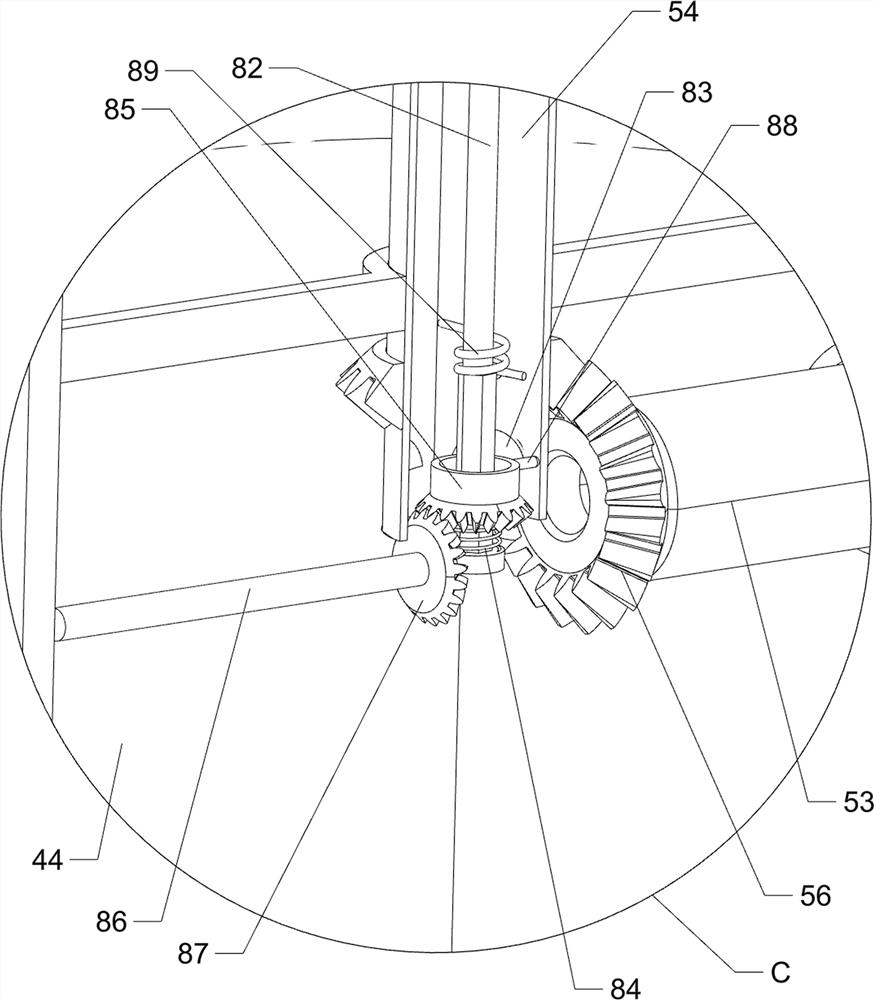

Apricot kernel drying machine for traditional Chinese medicine processing

PendingCN113834285ANo need to stirAvoid the influence of conveying and drying on the conveying plateGrain treatmentsPreliminary solid treatment for dryingEngineeringProcess engineering

The invention relates to an apricot kernel drying machine for traditional Chinese medicine processing. The apricot kernel drying machine comprises a base, supporting legs, a drying shell, a material guiding mechanism and a conveying mechanism, wherein the supporting legs are fixedly connected to one side of the base in the circumferential direction, the drying shell is fixedly connected among the three ends, away from the base, of the supporting legs, the material guiding mechanism is installed between the supporting legs and the drying shell, and the conveying mechanism is installed between the supporting legs and the material guiding mechanism. According to the apricot kernel drying machine, the drying shell is started to emit heat, then the conveying mechanism is started to operate, a proper quantity of apricot kernels are poured into the material guiding mechanism, the apricot kernels in the material guiding mechanism fall onto the conveying mechanism, the conveying mechanism drives the apricot kernels to move downwards, and the drying shell dries the apricot kernels comprehensively. Thus, the apricot kernels can be comprehensively dried; and the apricot kernels do not need to be manually stirred, so that the drying process is convenient.

Owner:杨晓玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com