Method for preparing nano-FeZSM-5 molecular sieve, catalyst prepared from nano-FeZSM-5 molecular sieve and application thereof

A molecular sieve and catalyst technology, which is applied in the field of preparing nano-FeZSM-5 molecular sieves, can solve the problems of reduced effective space utilization of reactors, difficulties in production and reactor design, difficulties in reactor design, etc., and achieve excellent catalytic activity, uniform size, effect of small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

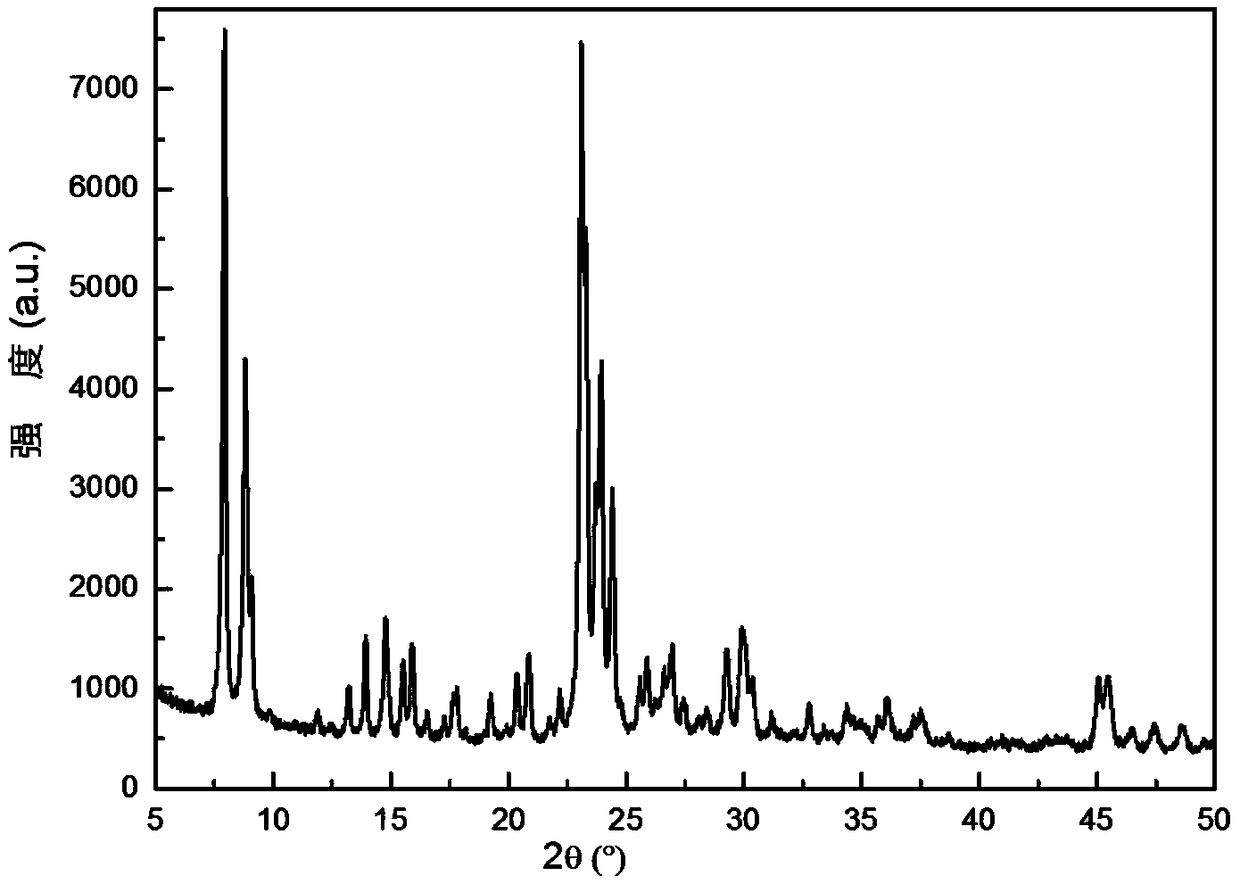

[0033] According to the mol ratio of each material that forms dry glue precursor solution in the step a) of preparation method of the present invention: silicon source (using SiO 2 In terms of): aluminum source (as Al 2 o 3 In terms of): iron salt (as Fe 2 o 3 Meter): deionized water=25-100:1:0.2-1:50-500, the preferred molar ratio is: silicon source (using SiO 2 In terms of): aluminum source (as Al 2 o 3 In terms of): iron salt (as Fe 2 o 3 meter): deionized water=50-80:1:0.5-1:80-400. When the ratio of various components is not within this range, the crystallinity of the molecular sieve will decrease, and even miscellaneous crystals will be produced.

[0034] Preferably, the ratio of the aqueous solution of the structure directing agent in step b) is: the volume ratio of water to the structure directing agent is 1:0.5 to 1:5, and the mass ratio of the dry rubber particles to the structure directing agent is 1:1 to 1:6 . However, molecular sieves cannot be synthesiz...

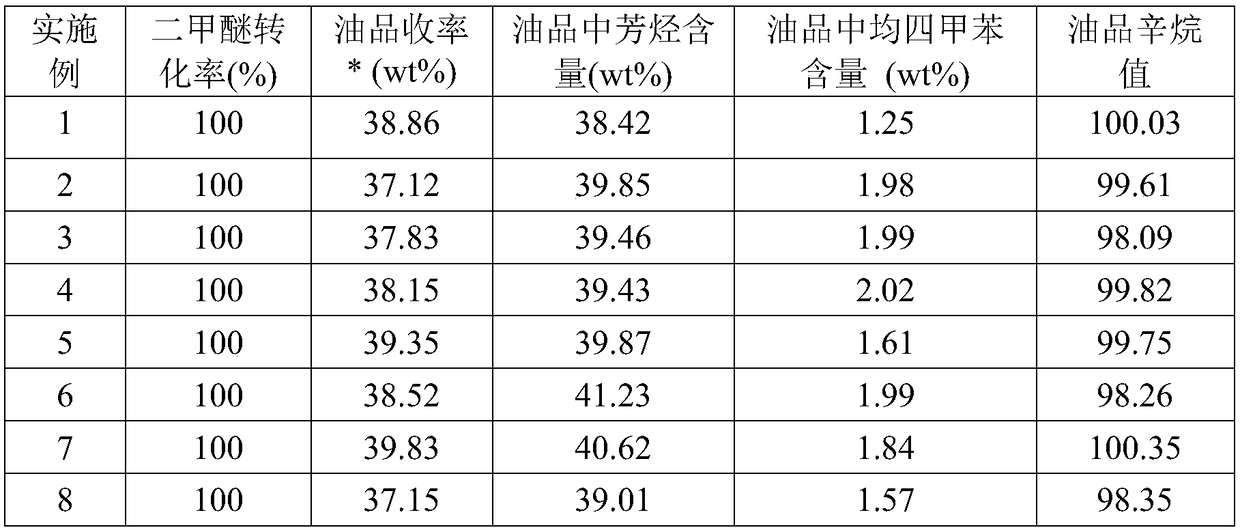

Embodiment 1

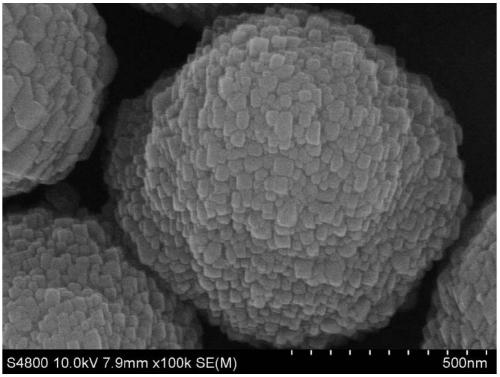

[0038] (1) Preparation of nanoscale FeZSM-5 molecular sieve:

[0039] a) First prepare the dry glue in the following molar ratio: silicon source (with SiO 2 In terms of): aluminum source (as Al 2 O3): iron salt (as Fe 2 o 3 Count): H 2 O=60:1:0.5:200.

[0040] Dissolve 1.1g of sodium metaaluminate in 24g of deionized water, stir at a constant temperature of 35°C until clarification, and add 83.34g of tetraethyl orthosilicate (TEOS) and 2.7g of Fe(NO 3 ) 3 .9H 2 0, continue stirring for 4 hours to form a dry glue precursor solution, and dry the dry glue precursor solution at 80° C. to obtain a dry glue;

[0041] b) Grinding and sieving the obtained dry glue, 20g, a mixed solution of 20-40 mesh dry glue and 40g tetrapropylammonium hydroxide and an equal volume of water (the volume ratio of tetrapropylammonium hydroxide and water is 1:1 ) were fully mixed under stirring conditions, and sodium hydroxide was added to adjust the pH value of the mixed solution to 11, the mixe...

Embodiment 2

[0048] (1) Preparation of nanoscale FeZSM-5 molecular sieve:

[0049] a) First prepare the dry glue in the following molar ratio: silicon source (with SiO 2 In terms of): aluminum source (as Al 2 o 3 In terms of): iron salt (as Fe 2 o 3 Count): H 2 O=45:1:0.5:200.

[0050] Dissolve 1.1g of sodium metaaluminate in 24g of deionized water, stir at a constant temperature of 35°C until clarification, and add 62.51g of tetraethyl orthosilicate (TEOS) and 2.7g of Fe(NO 3 ) 3 9H 2 0, continue stirring for 4 hours to form a dry glue precursor solution, and dry the dry glue precursor solution at 80° C. to obtain a dry glue;

[0051] b) the gained dry glue is ground and sieved, get 20g, the mixed solution of 20-40 purpose dry glue and 40g tetrapropyl ammonium hydroxide and equal volume water (the volume ratio of tetrapropyl ammonium hydroxide and water is 1: 1) Fully mix under stirring conditions, and add sodium hydroxide to adjust the pH value of the mixed solution to 11, put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com