Preparation method of silver-loaded floating hollow titanium dioxide taking cationic polymer as intermediate

A cationic, titanium dioxide technology, used in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. The effect of improving the activity and utilization efficiency of visible light, improving the adhesion stability, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

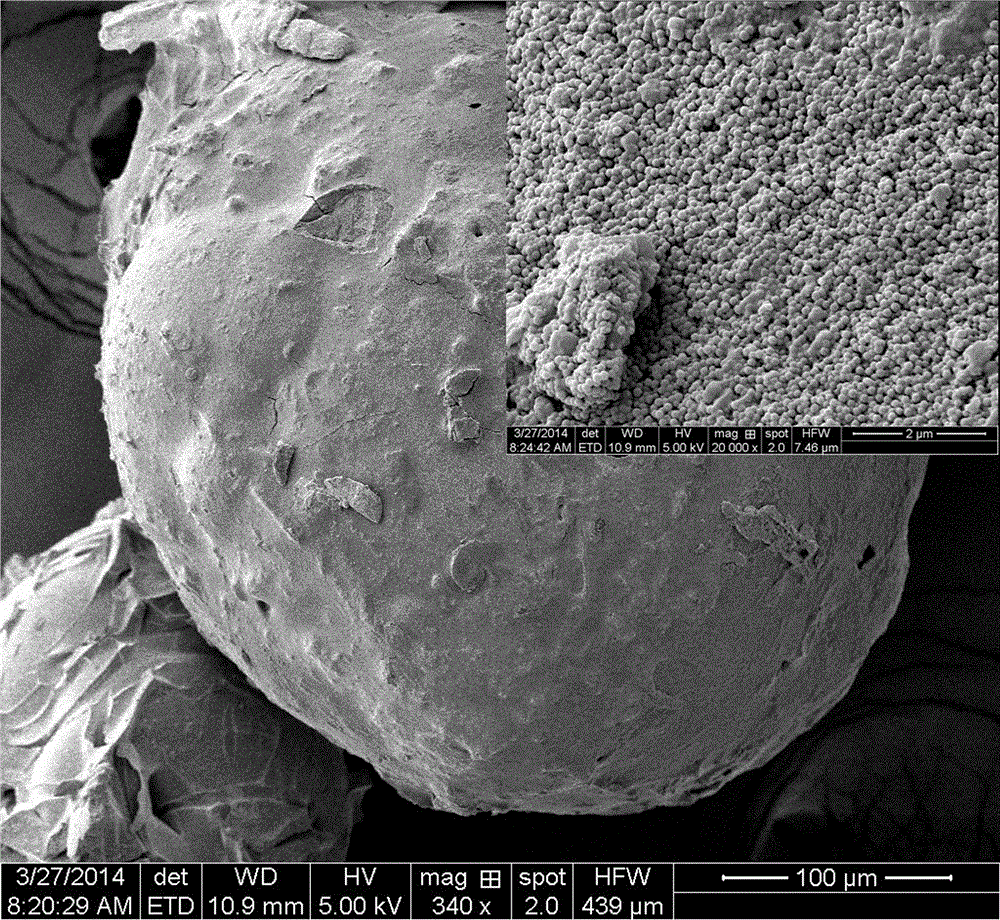

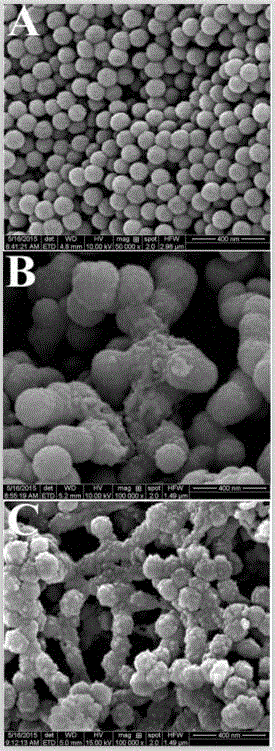

[0028] A silver-loaded floating hollow titanium dioxide with a cationic polymer as an intermediate, the preparation method of which is as follows:

[0029] (1) Dilute 250mL of cationic polystyrene C-PSt emulsion with a solid content of 20% with water to a solid content of 5%; add 50g of fly ash to the above emulsion and stir for 10 minutes, let it stand, and remove the floating powder Coal ash particles are separated and dried to obtain fly ash particles Fly-ash / C-PSt loaded with C-PSt;

[0030] (2) Add the Fly-ash / C-PSt particles separated in step (1) into 500mL alcohol aqueous solution, wherein the alcohol aqueous solution is prepared by ethanol and water at a volume ratio of 49:1. Dilute 20mL of tetrabutyl titanate with ethanol to 50mL, and slowly add it into the above-mentioned alcohol aqueous solution under stirring conditions, stir well until a large amount of white precipitate is formed, let it stand still, separate the upper layer of fly ash particles, and dry at 80°C ...

Embodiment 2

[0034] A floating hollow titanium dioxide with a cationic polymer as an intermediate, the preparation method of which is as follows:

[0035] (1) Dilute 250mL of cationic polystyrene C-PSt emulsion with a solid content of 20% with water to a solid content of 5%; add 50g of fly ash to the above emulsion and stir for 10 minutes, let it stand, and remove the floating powder Coal ash particles are separated and dried to obtain fly ash particles Fly-ash / C-PSt loaded with C-PSt;

[0036] (2) Add the Fly-ash / C-PSt particles separated in step (1) into 500mL alcohol aqueous solution, wherein the alcohol aqueous solution is prepared by ethanol and water at a volume ratio of 49:1. Dilute 20mL of tetrabutyl titanate with ethanol to 50mL, and slowly add it to the above alcohol aqueous solution under stirring conditions, stir well until a large amount of white precipitate is formed, let it stand, separate the upper layer of fly ash particles, and dry at 80°C Obtain composite particles Fly-...

Embodiment 3

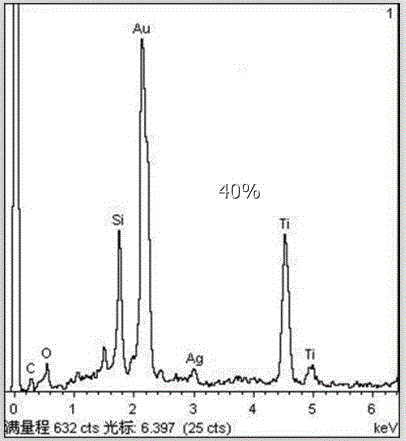

[0039] A kind of fly ash directly loads the catalyst of titanium dioxide, and its preparation method is as follows:

[0040]Add 50g of fly ash particles to 500mL of alcohol aqueous solution prepared by ethanol and water at a volume ratio of 49:1, then dilute 20mL of tetrabutyl titanate with ethanol to 50mL and then add 0.6mL of 0.1mol / L AgNO 3 The solution is prepared as a mixed solution, and then the mixed solution is slowly added to the alcohol aqueous solution containing fly ash particles under stirring conditions, fully stirred until a large amount of white precipitates are formed, let it stand, and the upper layer of fly ash particles are separated, 80 ℃ After drying, and then roasting at 600°C for 4 hours, the silver-doped composite catalyst Fly-ash / TiO directly loaded on the fly ash particles was obtained. 2 / Ag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com