Patents

Literature

61results about How to "Improve attachment stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

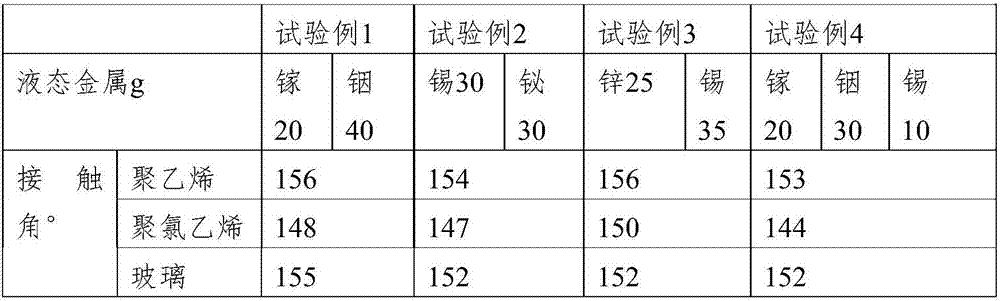

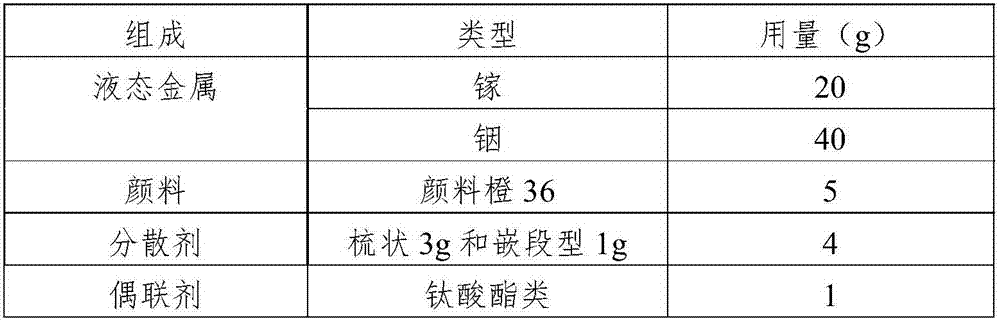

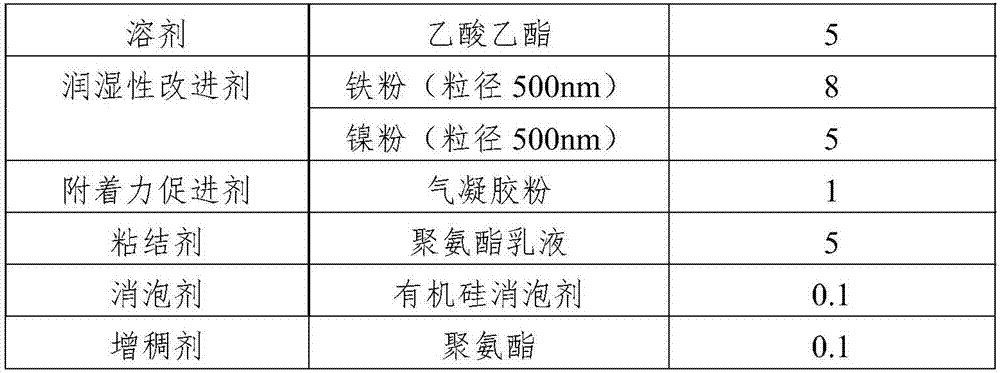

Colored liquid metal printing ink and preparation method thereof

The invention provides colored liquid metal printing ink. The printing ink is prepared from, in percentage by weight, 40%-70% of liquid metal, 2%-10% of pigment, 10%-30% of a wettability improver, 1%-5% of a dispersant, 0.5%-3% of a coupling agent, 1%-10% of a binder, 0.5%-3% of an adhesion promoter, 1%-5% of a solvent and the balance of other aids, wherein the liquid metal is a conductive nanofluid formed by low-melting-point metal or alloy or metal nanoparticles with the melting point being 300 DEG C or below and a fluid dispersant. The concept and the preparation method of the colored liquid metal printing ink are proposed for the first time, the existing application method that pigment powder is directly adopted in liquid metal is changed, color paste rather than pigment is adopted to provide colors for the liquid metal, and the color saturation and stability of a colored liquid metal composite are further improved, so that the composite has both good conductivity of liquid metal and rich colors of pigment.

Owner:BEIJING DREAM INK TECH CO LTD

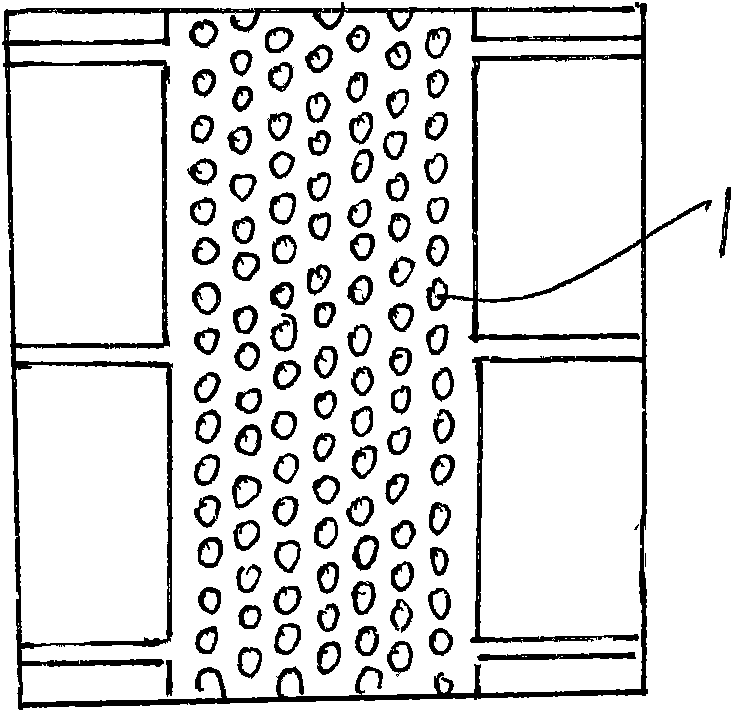

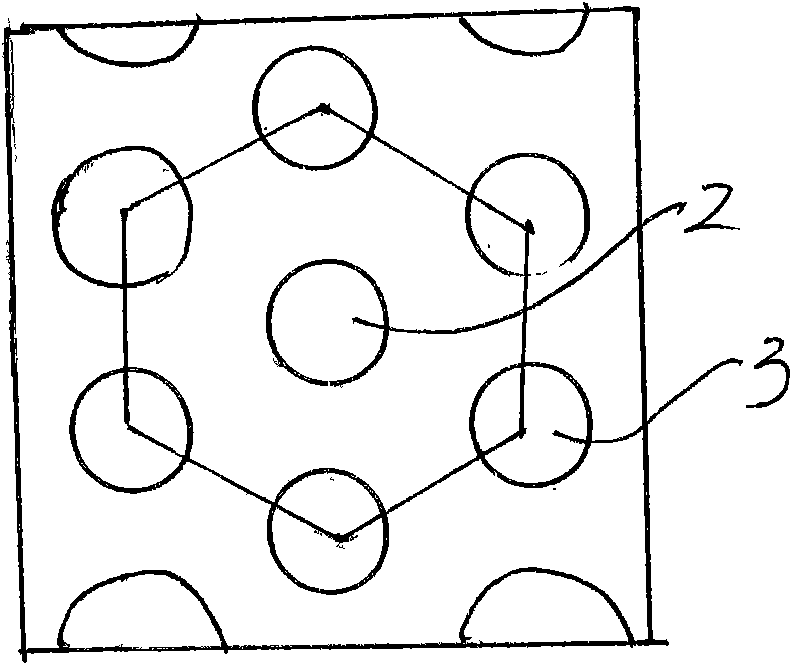

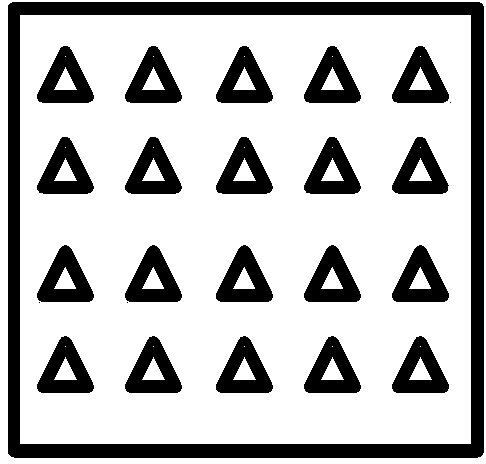

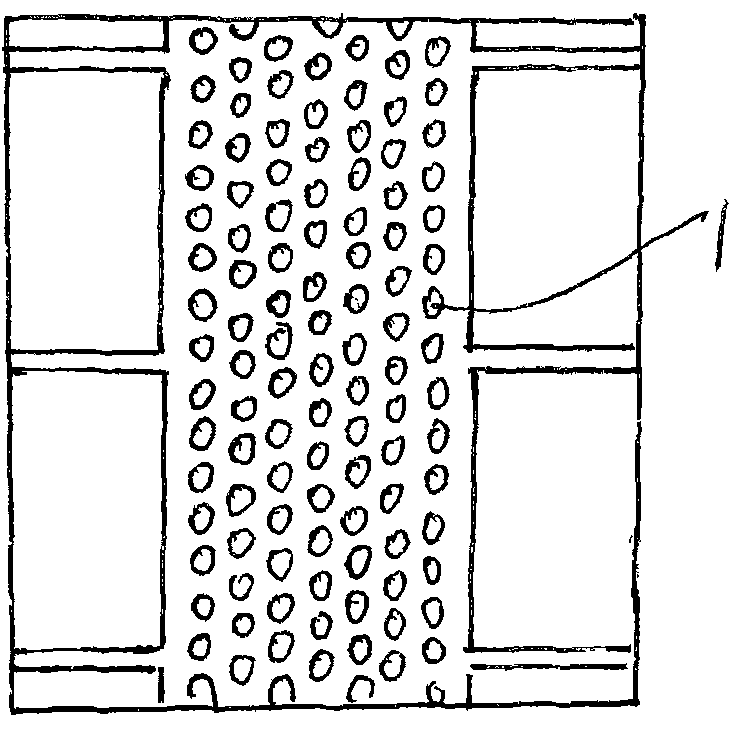

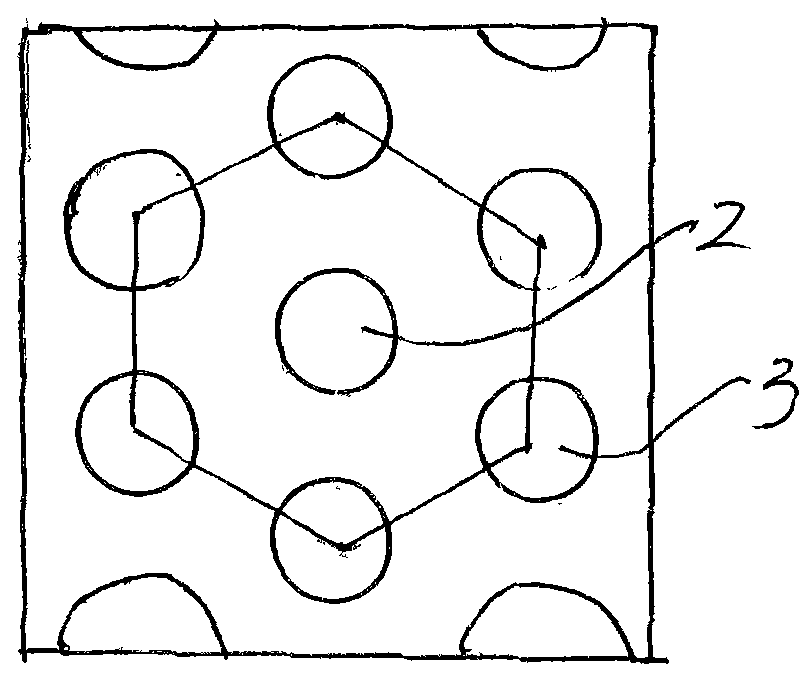

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848AStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of the conductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

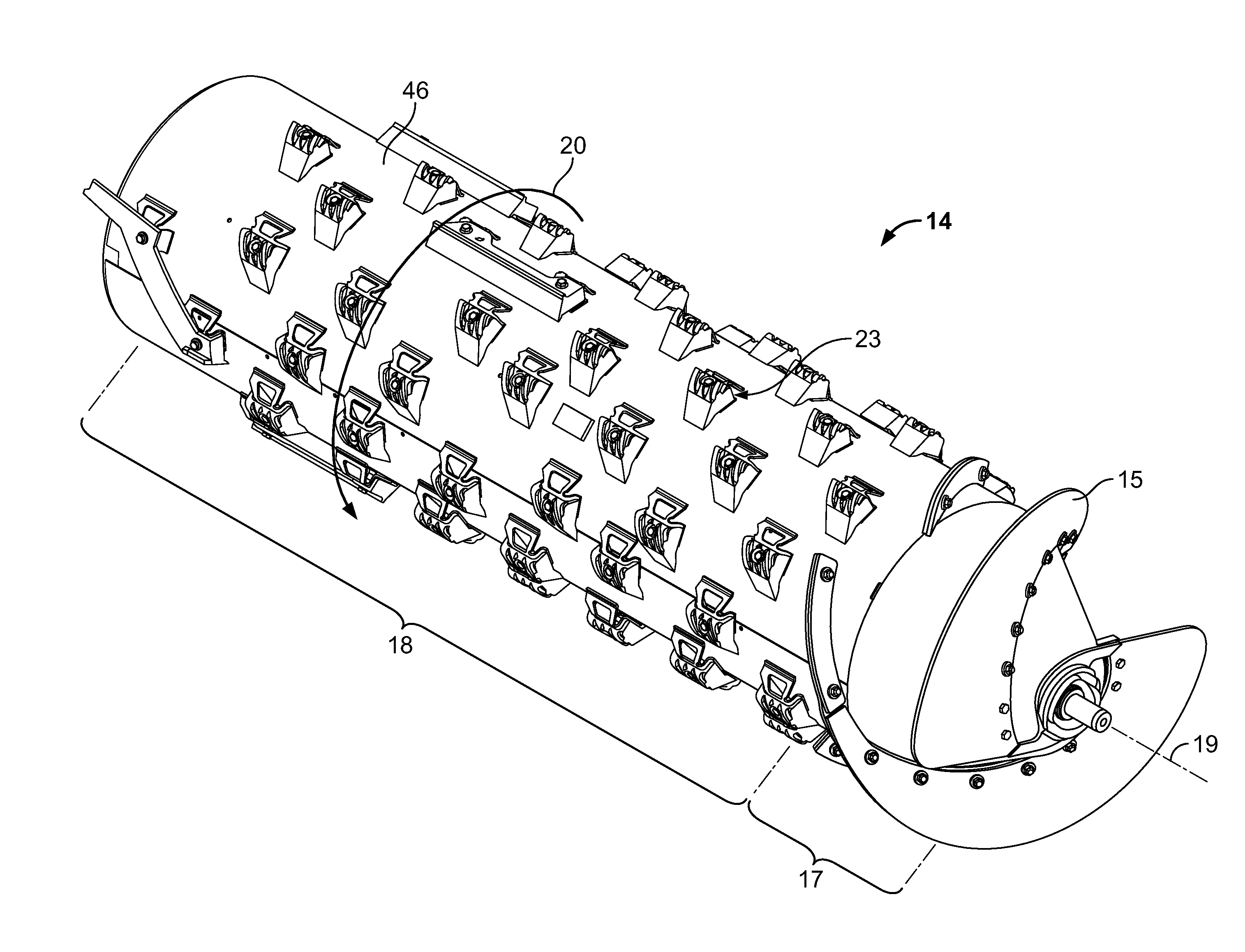

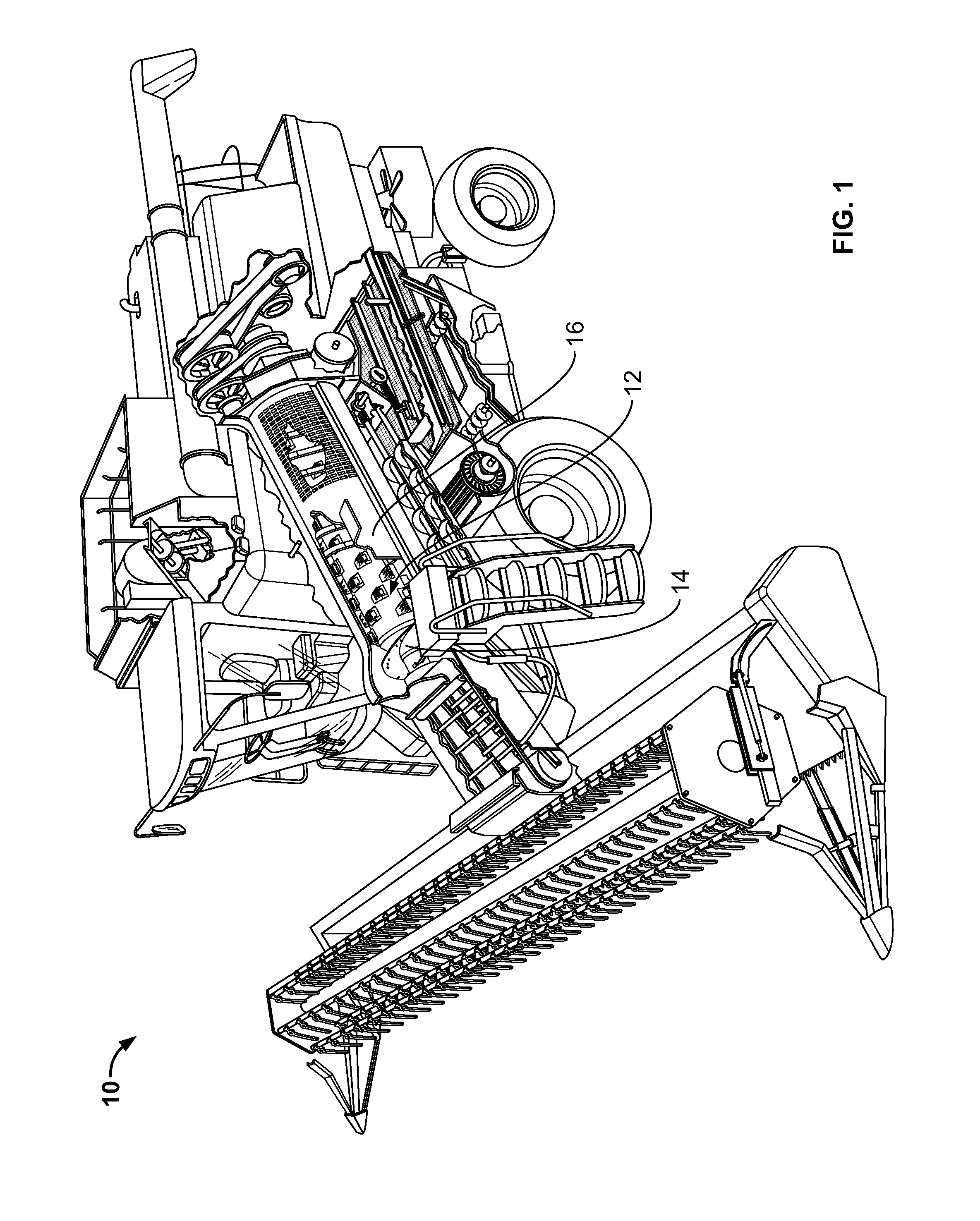

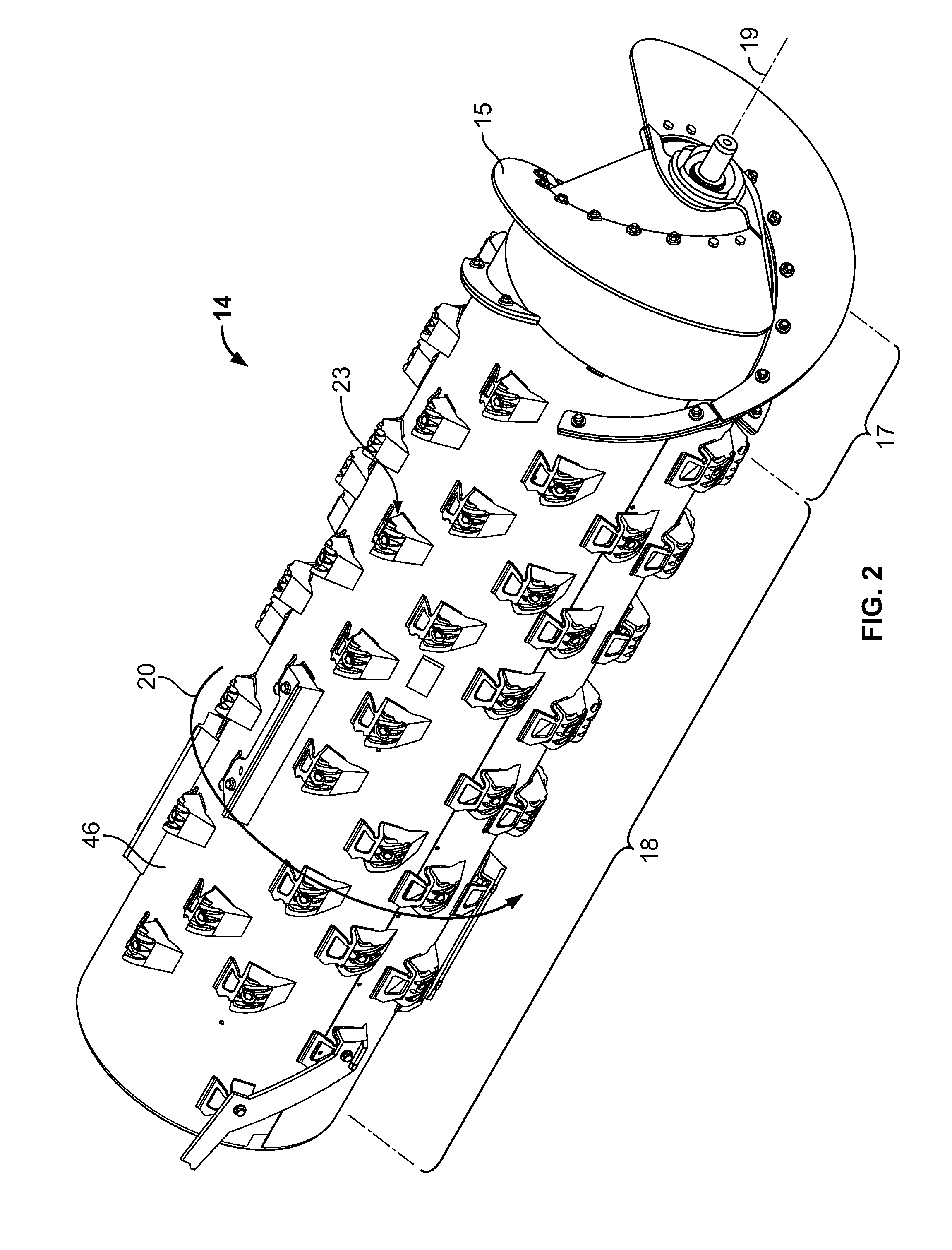

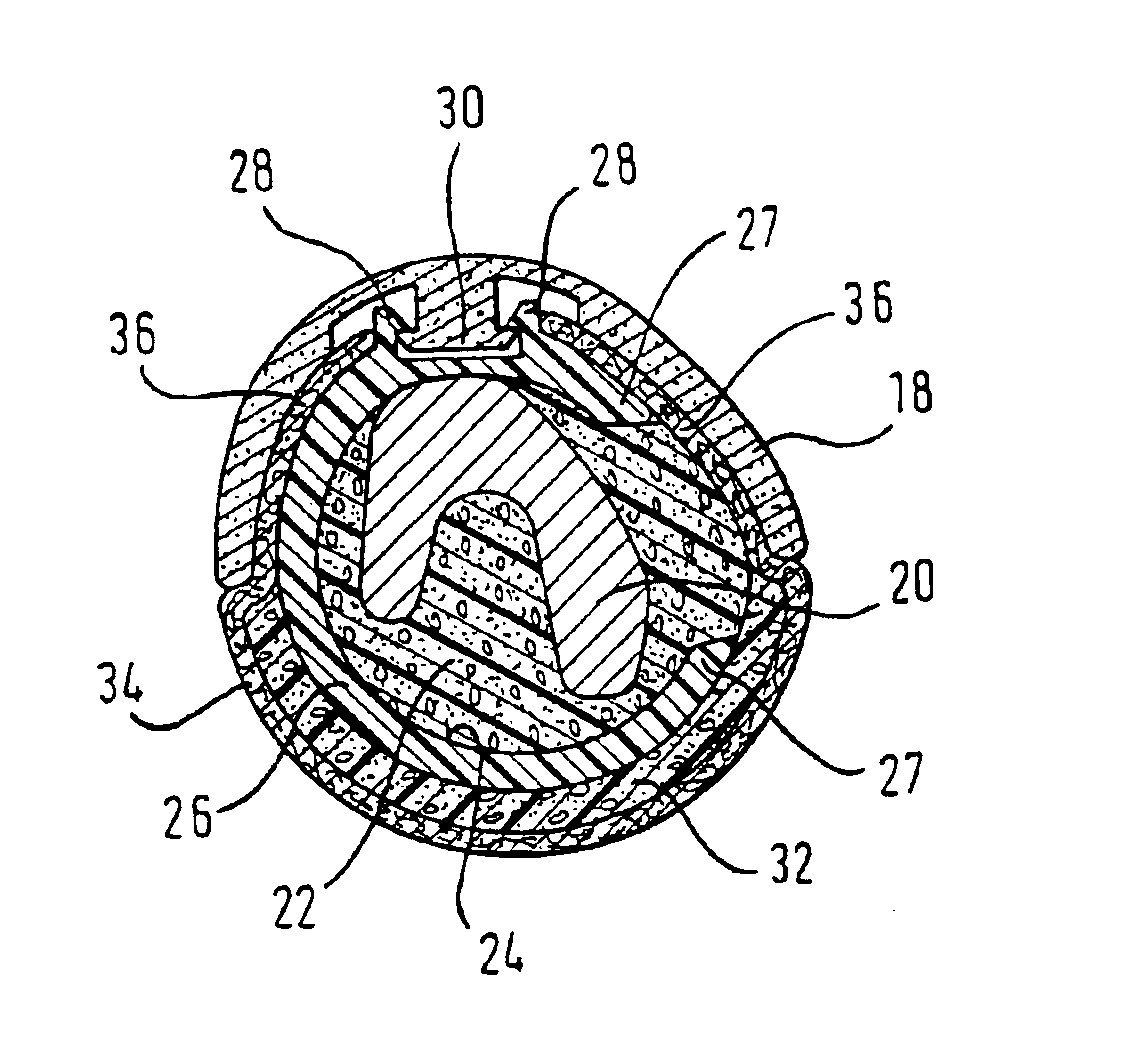

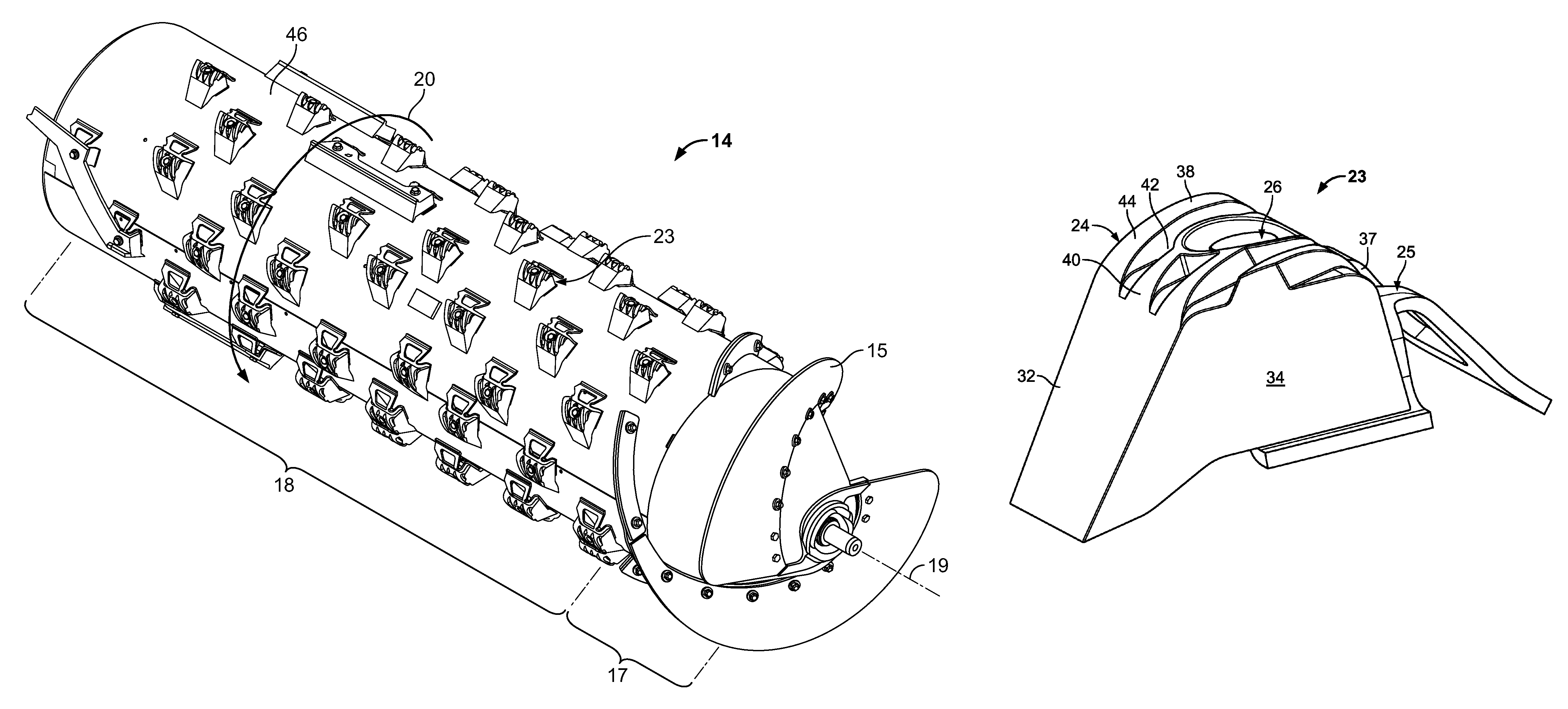

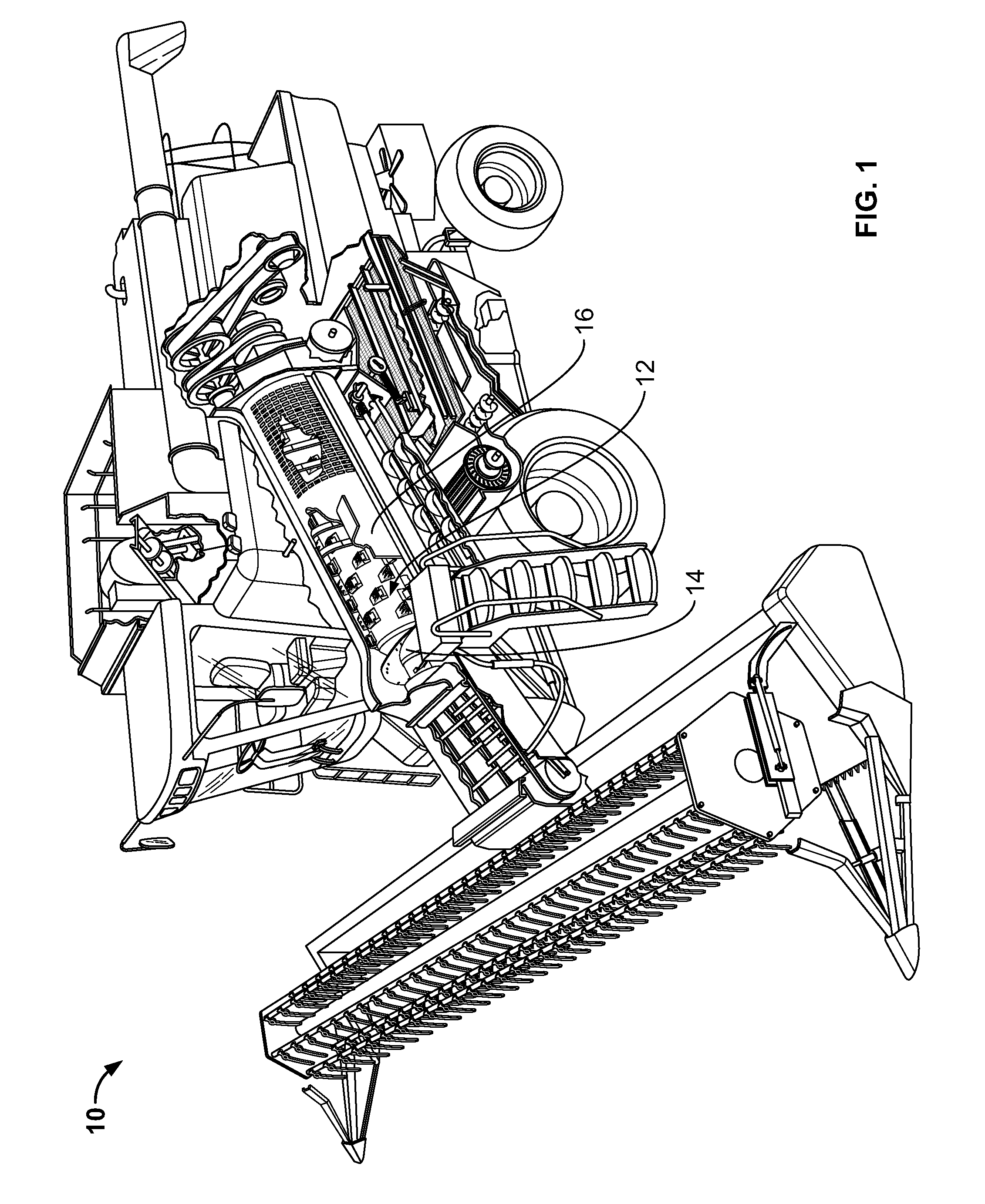

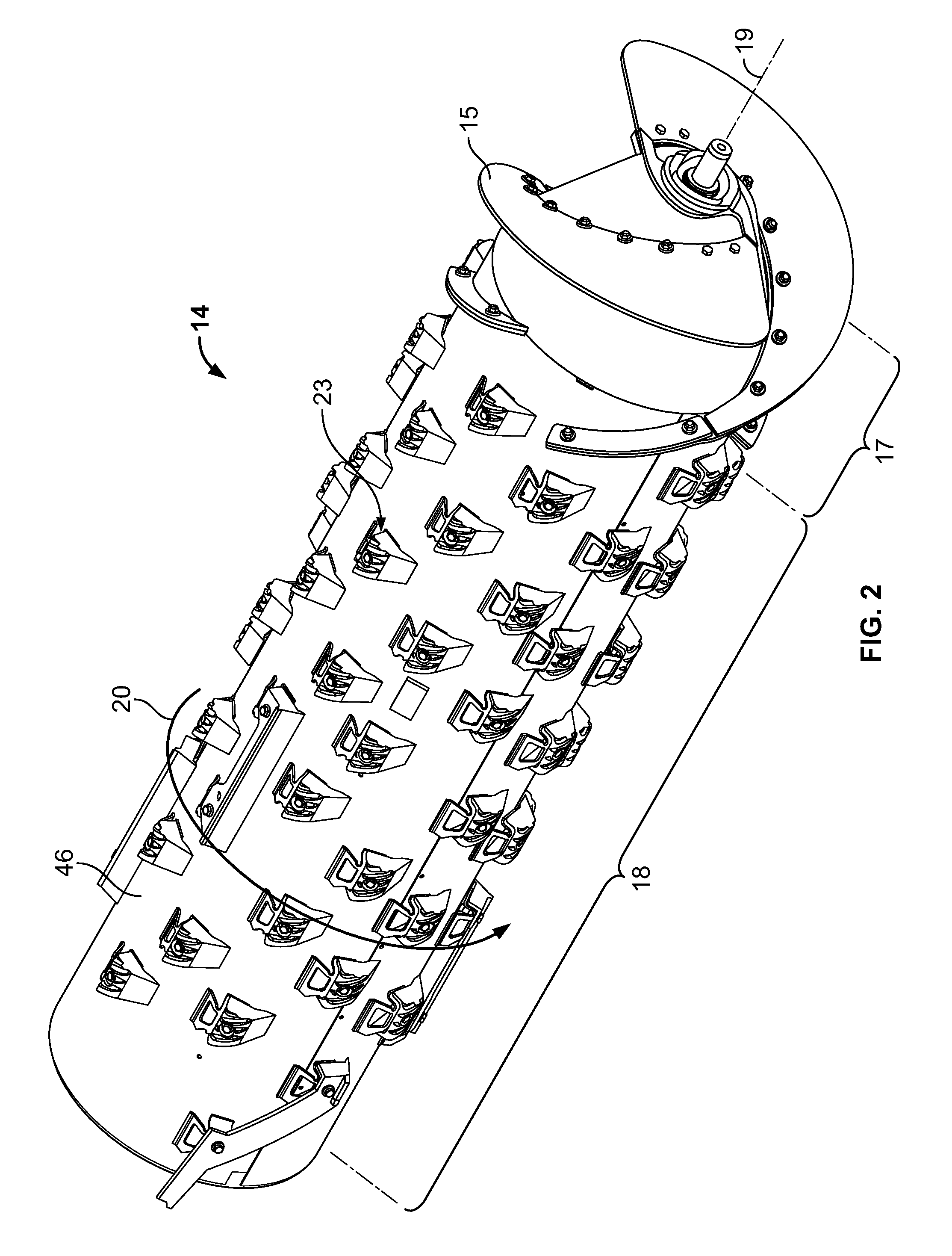

Rasp bar and support

ActiveUS20120214560A1Improve attachment stabilityProtection from damageThreshersMechanical engineering

Owner:BLUE LEAF I P INC

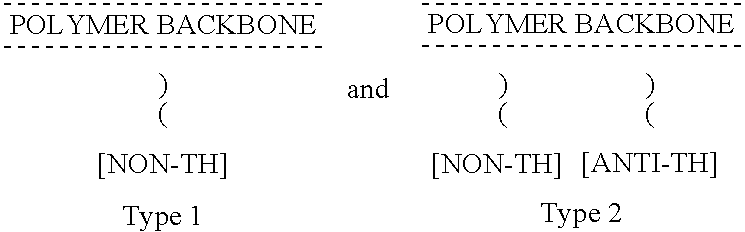

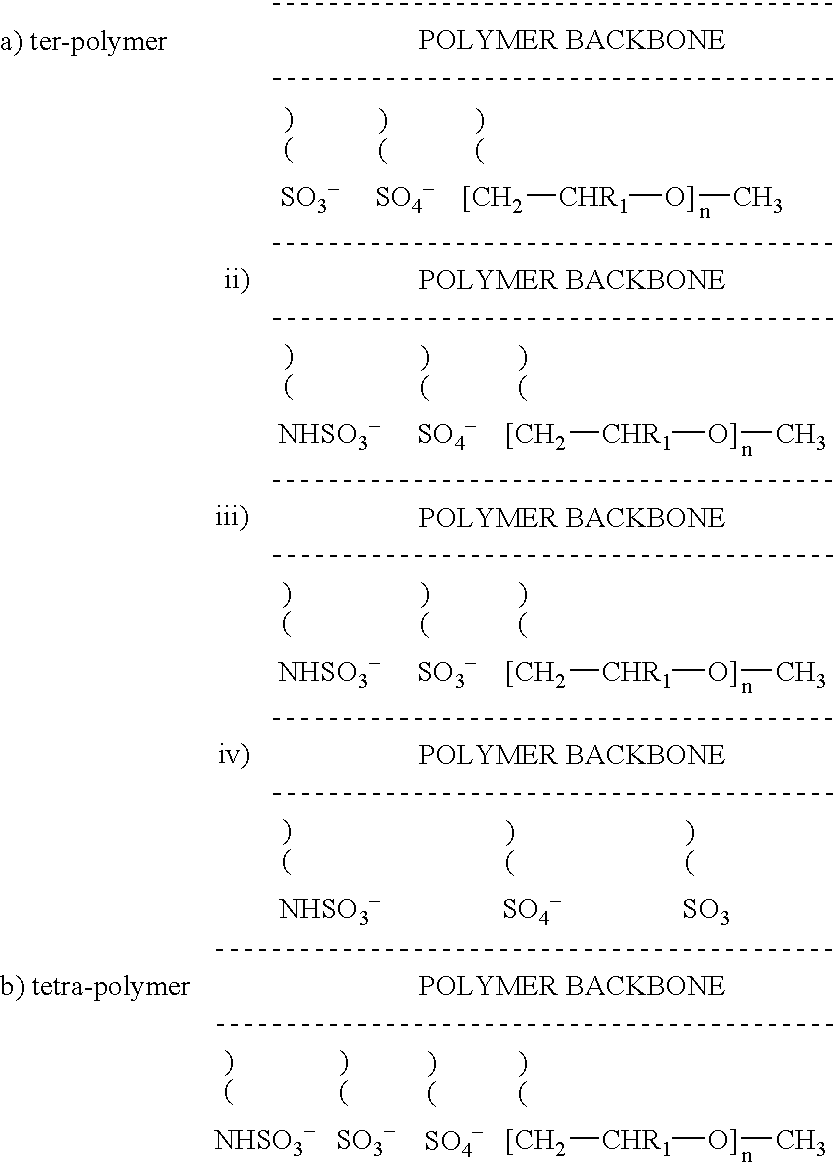

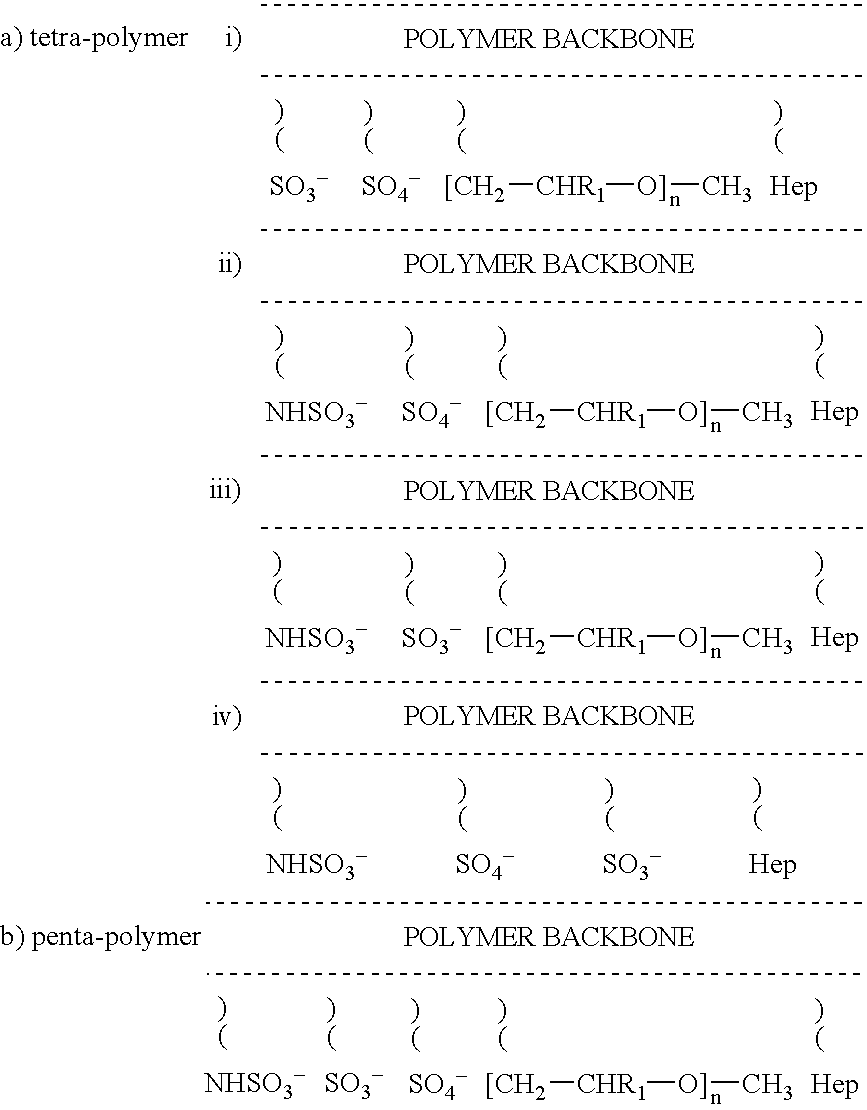

Non-thrombogenic and anti-thrombogenic polymers

InactiveUS7034061B1Improve attachment stabilityPreferential ionic bondingPeptide/protein ingredientsPharmaceutical non-active ingredientsWarfarinPolymer science

Polymers having non-thrombogenic properties can be prepared by copolymerizing monomers of at least three classes selected from (a) monomers having sulphate groups, (b) monomers having sulphonate groups, (c) monomers having sulphamate groups, (d) monomers having polyoxyalkylene ether groups, and (e) monomers having zwitterionic groups. The polymers can additionally be provided with anti-thrombogenic properties by including an additional comonomer having a pendant heparin (or hirudin, warfarin or hyaluronic acid) group. The polymers can be used as coating materials for medical devices, such as tubing or connectors, in order to provide them with non-thrombogenic, and optionally anti-thrombogenic, properties.

Owner:BIOINTERACTIONS

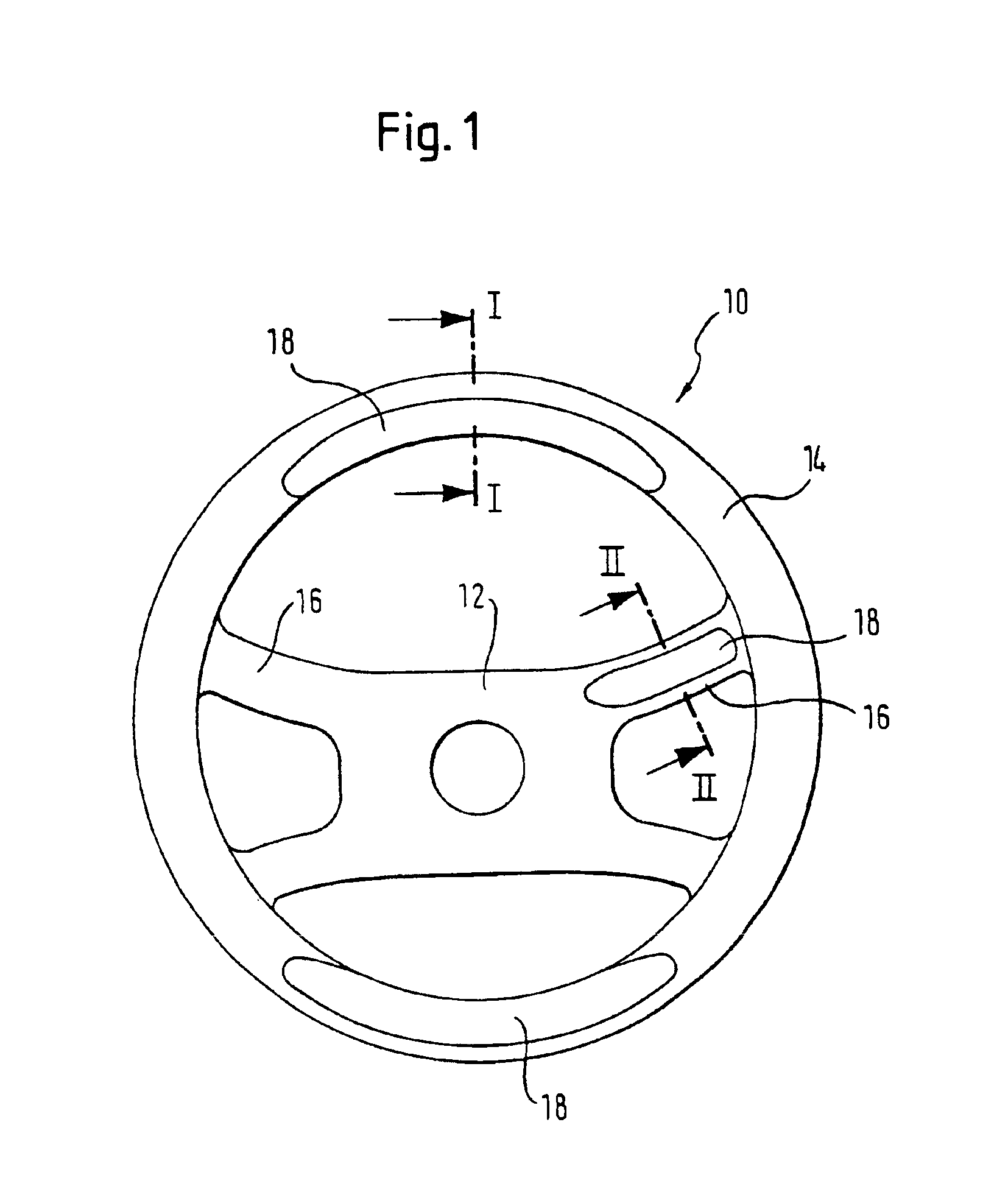

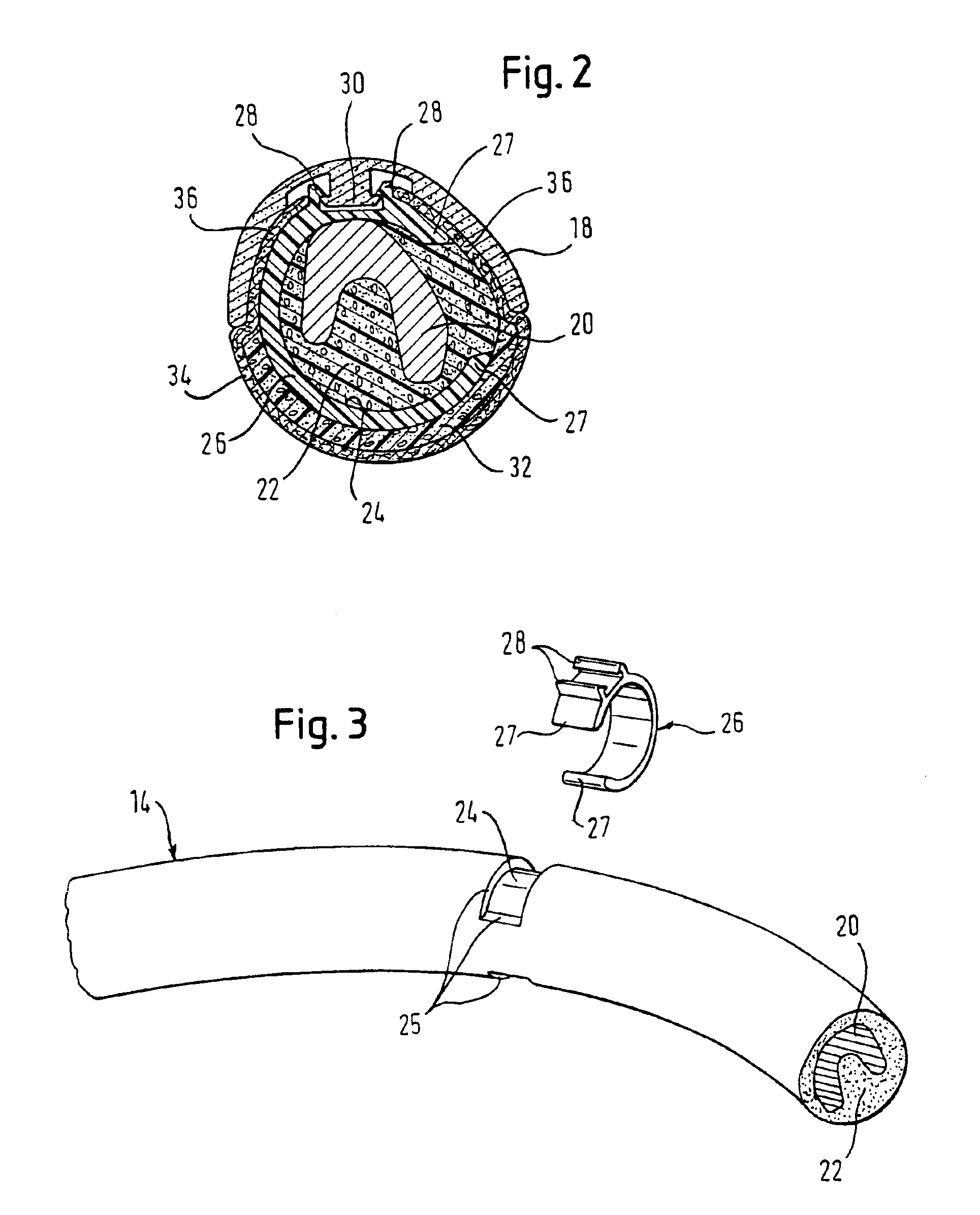

Steering wheel with decorative element

InactiveUS6877397B2Simple and safe attachmentImprove attachment stabilityControlling membersMechanical apparatusSteering wheelEngineering

A steering wheel includes a hub, a steering wheel rim and at least one spoke connecting the hub and the steering wheel rim. At least one of the steering wheel rim and the spoke has a skeleton and a sheathing surrounding the skeleton. The steering wheel further includes at least one decorative element and at least one clamp element at which the decorative element is latched. The clamp element at least partly encompasses the sheathing.

Owner:TRW AUTOMOTIVE SAFETY SYST

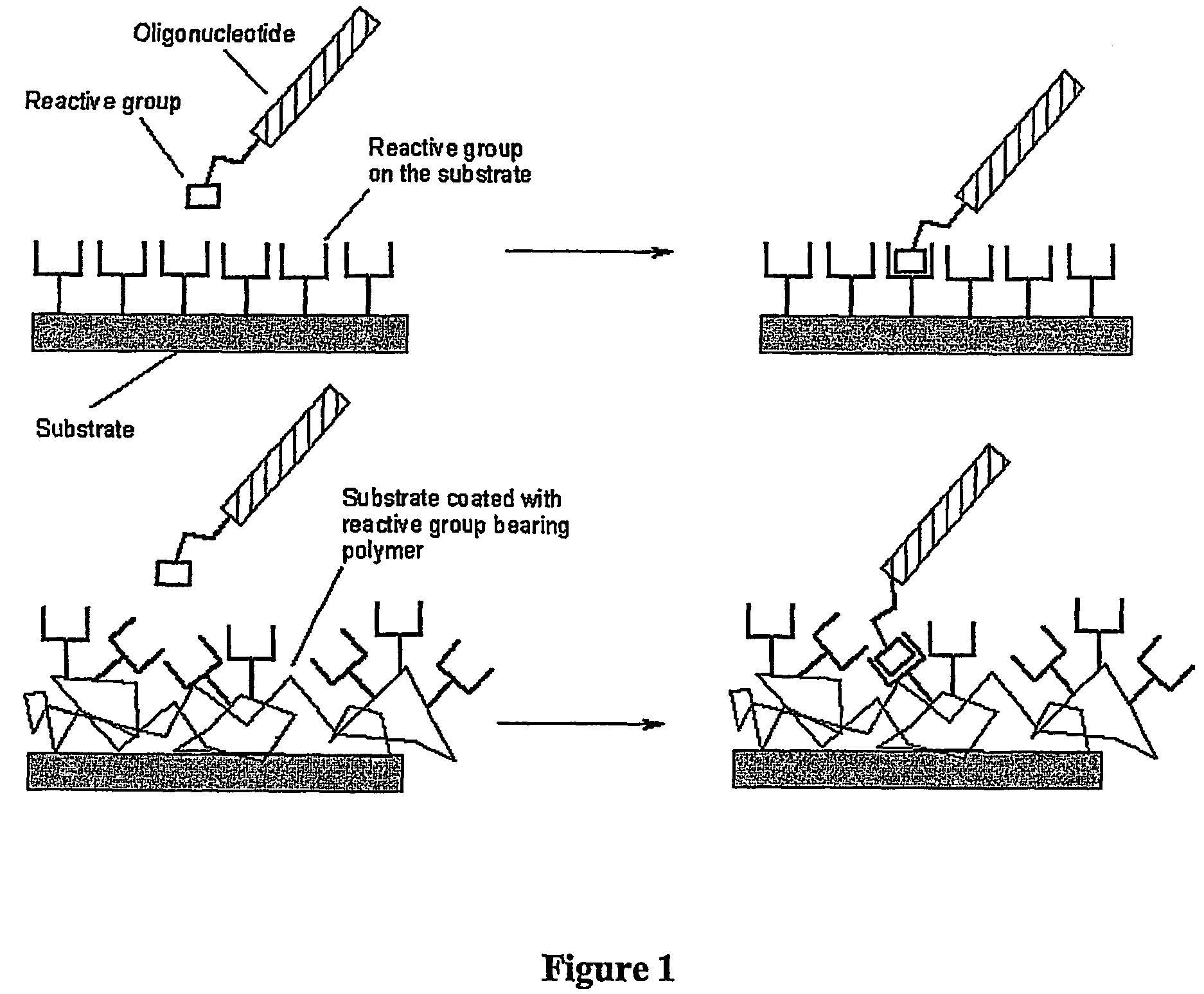

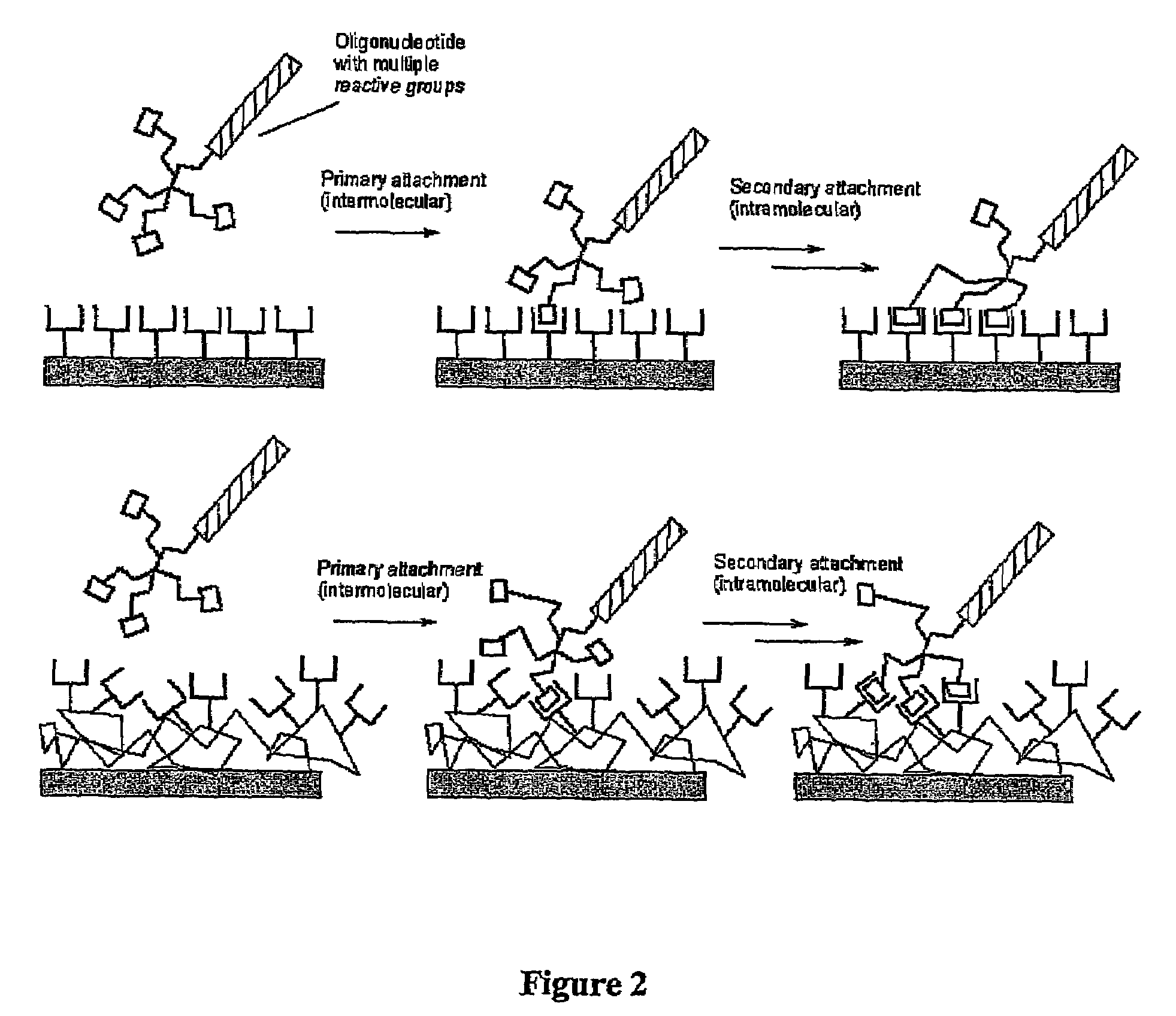

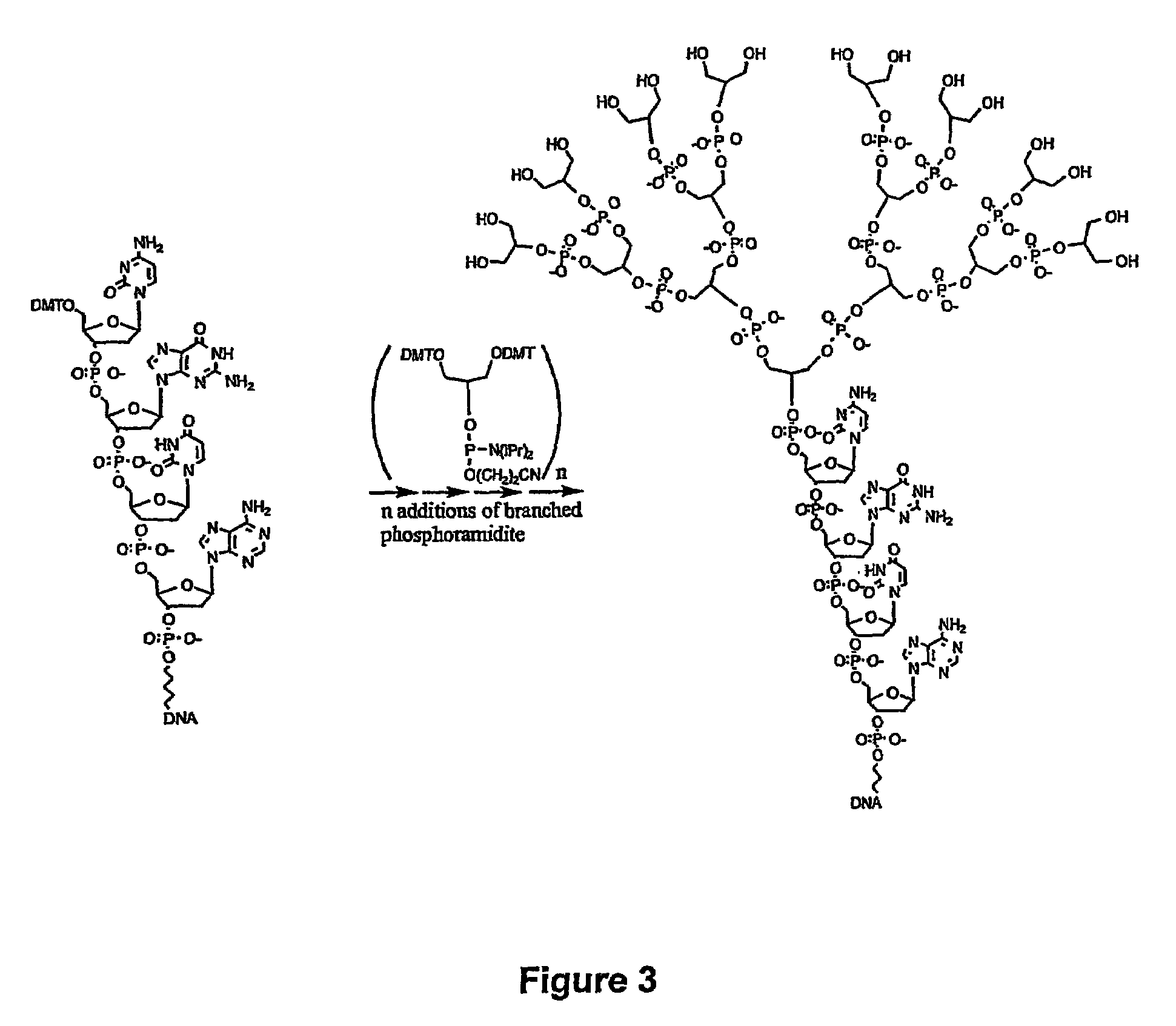

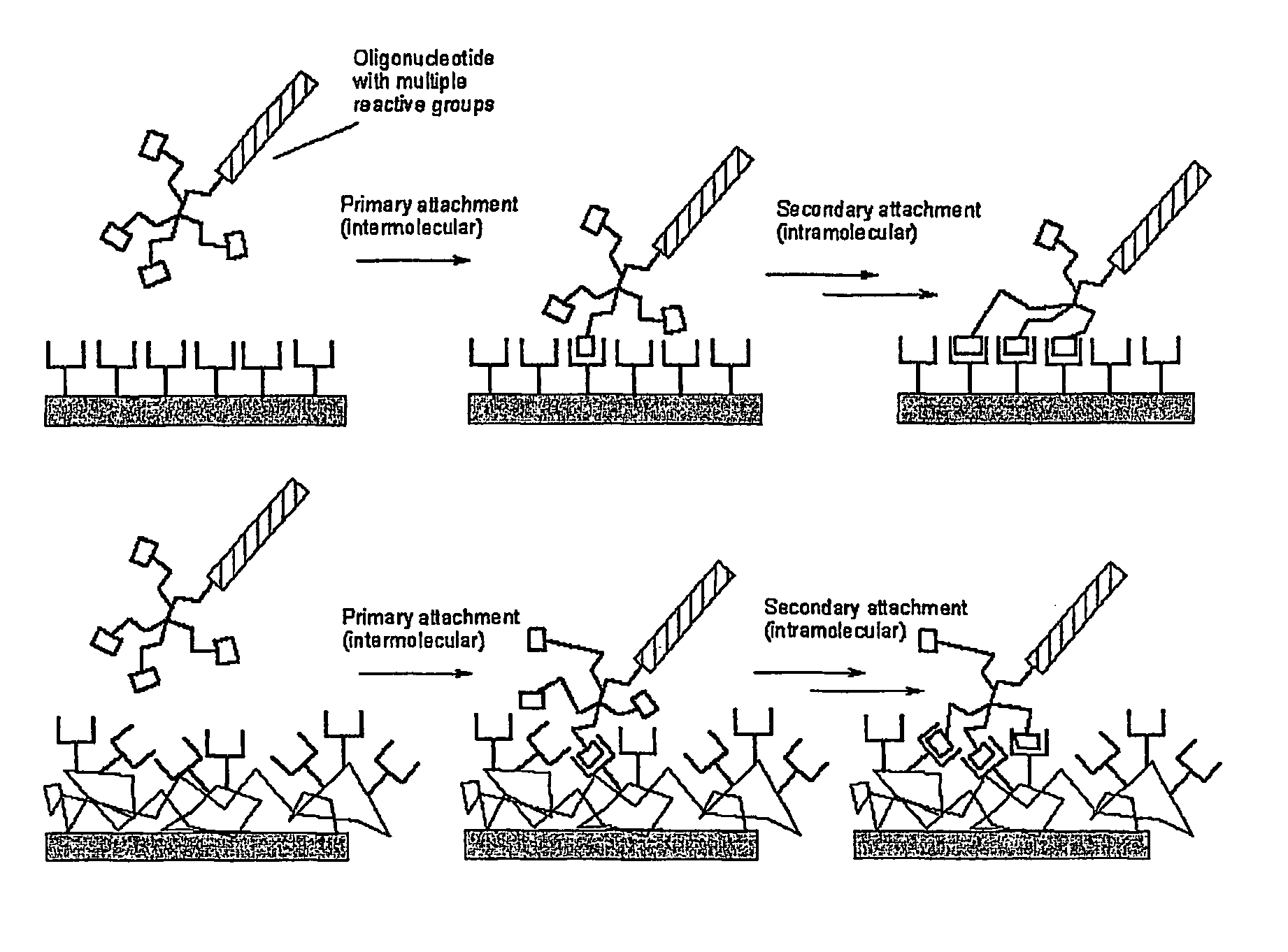

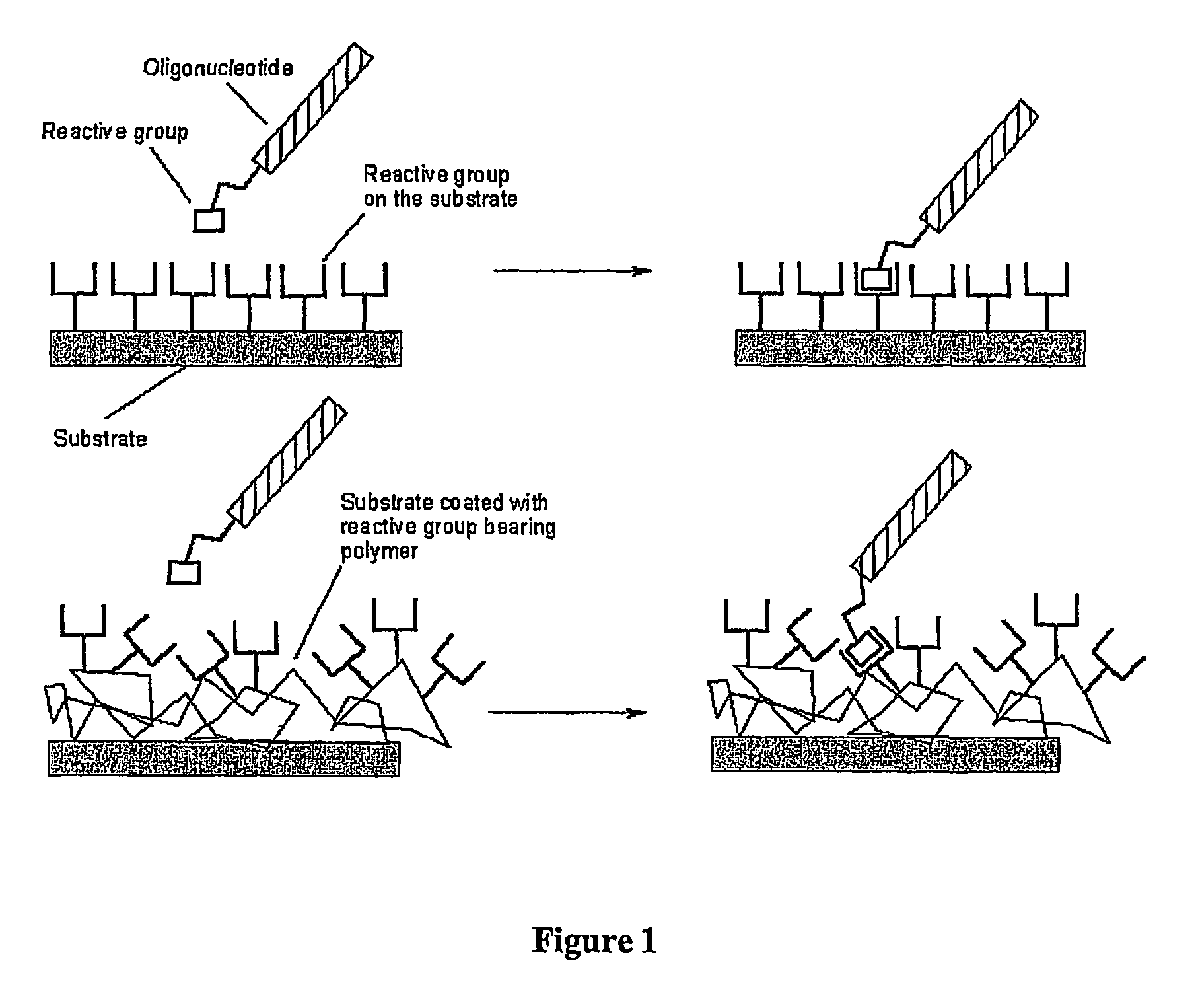

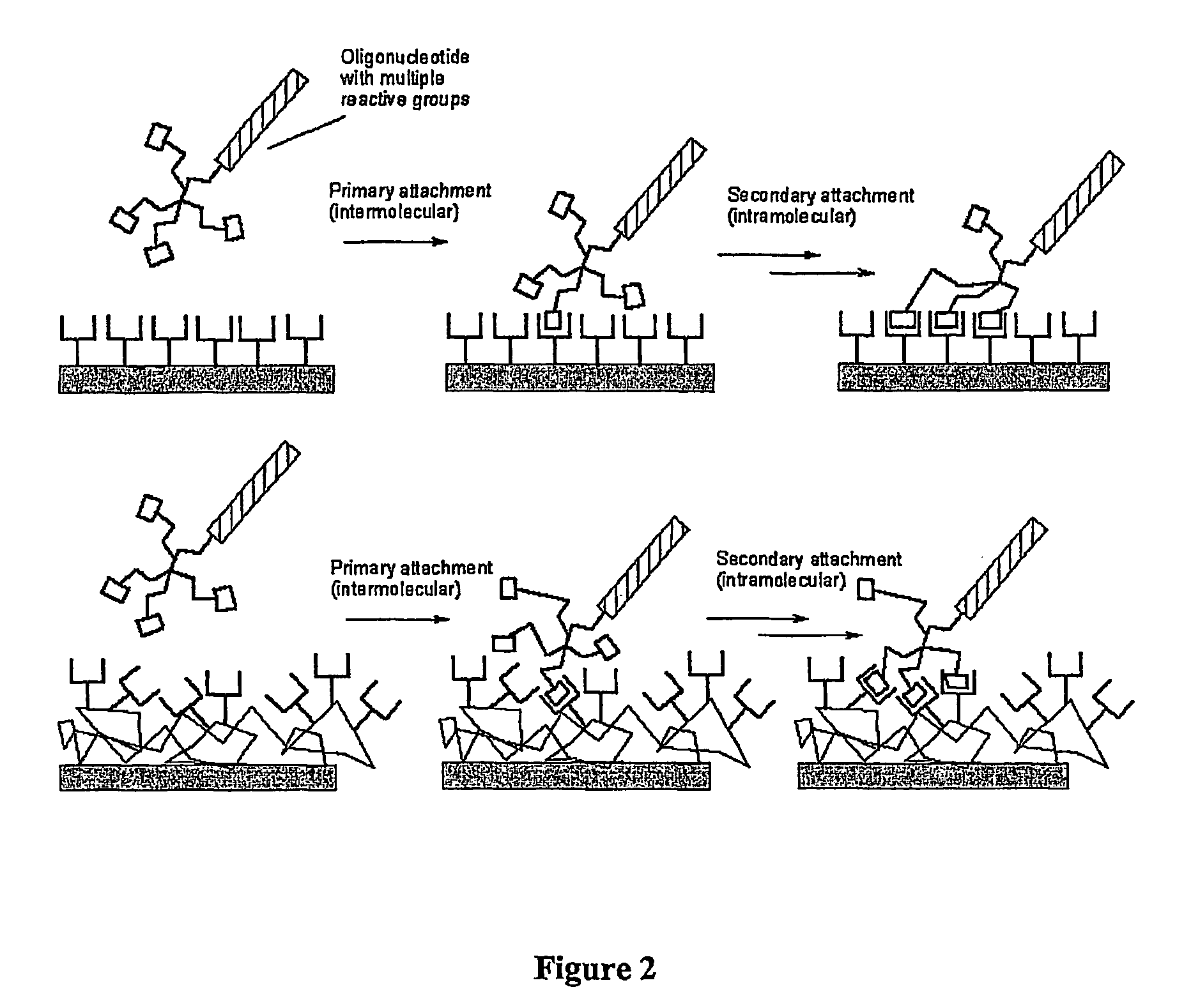

Biomolecules having multiple attachment moieties for binding to a substrate surface

InactiveUS7186813B1High oligonucleotide loadingEasy to attachBioreactor/fermenter combinationsBiological substance pretreatmentsBinding siteCombinatorial chemistry

Biomolecules are provided having multiple binding sites for attachment to a substrate surface. The multiple attachment sites may be produced directly on the biomolecule or through use of branched phosphoramidite moieties that can be added in multiple to form dendritic structures which can in turn provide attachment sites for substrate binding moieties. Substrate binding moieties may include noncovalent binding moieties. For covalent binding moieties oligonucleotides containing hydrazides are provided. These hydrazides can be introduced via protected building blocks such as phosphoramidites or via building blocks containing precursor forms of such hydrazides.

Owner:SANOFI AVENTIS SA

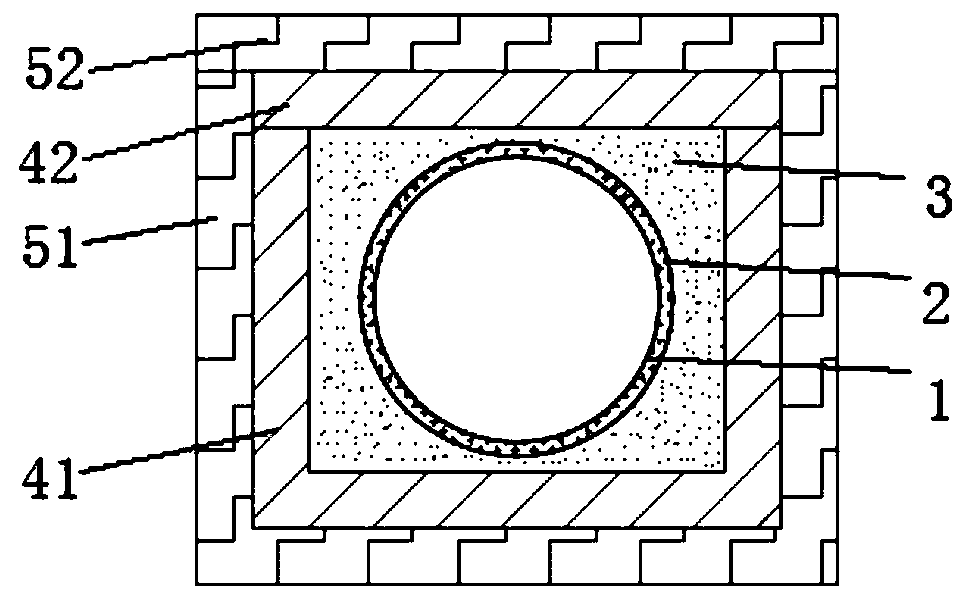

Platinum channel and manufacturing method and coating zirconium oxide dry powder mixture thereof

ActiveCN107739141ASpeed up meltingImprove melting effectLiquid surface applicatorsGlass furnace apparatusThermal insulationPt element

The invention discloses a platinum channel and a manufacturing method and a coating zirconium oxide dry powder mixture thereof. After the zirconium oxide dry powder mixture is sprayed on the surface of a platinum channel body, oxidization and volatilization of platinum in the platinum channel in a sintering process under high temperature can be effectively prevented. The zirconium oxide dry powdermixture is prepared from the following ingredients of 9.3% to 16% of SiO2, 2.7% to 4.3% of Al2O3, 80% to 87% of ZrO2 and 0.01% to 0.03% of Na2O. According to the platinum channel, the outer surface of the platinum channel is coated by a coating layer of the zirconium oxide dry powder mixture; a zirconium oxide dry powder filling material, a zirconium oxide groove profile brick and a zirconium oxide thermal insulation brick which are in tight contact are sequentially arranged outside the coating layer from inside to outside; the thickness of the coating layer is 0.8 to 1mm.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Biomolecules having multiple attachment moieties for binding to a substrate surface

InactiveUS7833715B1Increase speedHigh immobilization rateSugar derivativesMicrobiological testing/measurementElectrophileSubstrate surface

Methods of binding biomolecules to a substrate are provided that include contacting the biomolecule with a branched linking moiety to form a branched linking structure. The branched linking structure is then contacted with a binding moiety on the substrate to form a coupled substrate binding structure, thereby binding the biomolecule to the substrate. The biomolecule may contain a Lewis base or a nucleophile to react with a Lewis acid or electrophile in the branched linking moiety. Alternatively, the biomolecule may contain a Lewis acid or electrophile that can react with a Lewis base or nucleophile in the branched linking moiety. Additionally, the biomolecule can be bound to the substrate through a covalent or non-covalent bond.

Owner:SANOFI AVENTIS SA

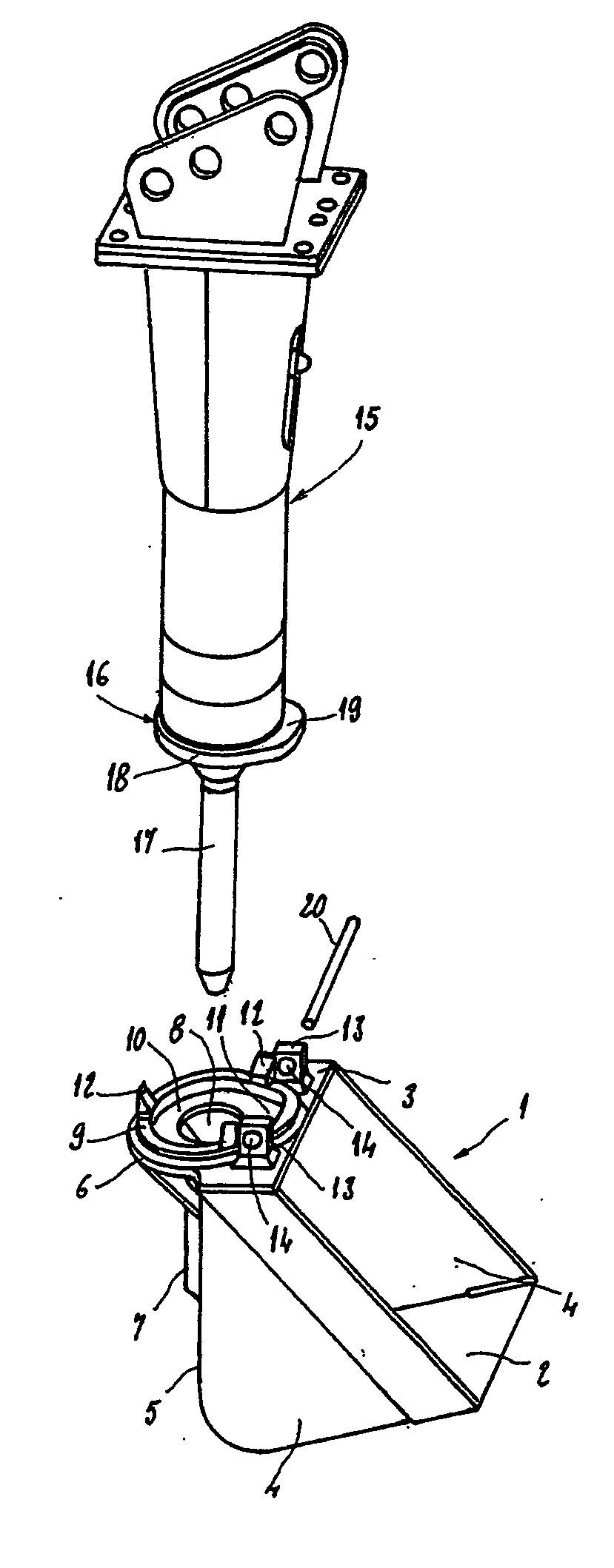

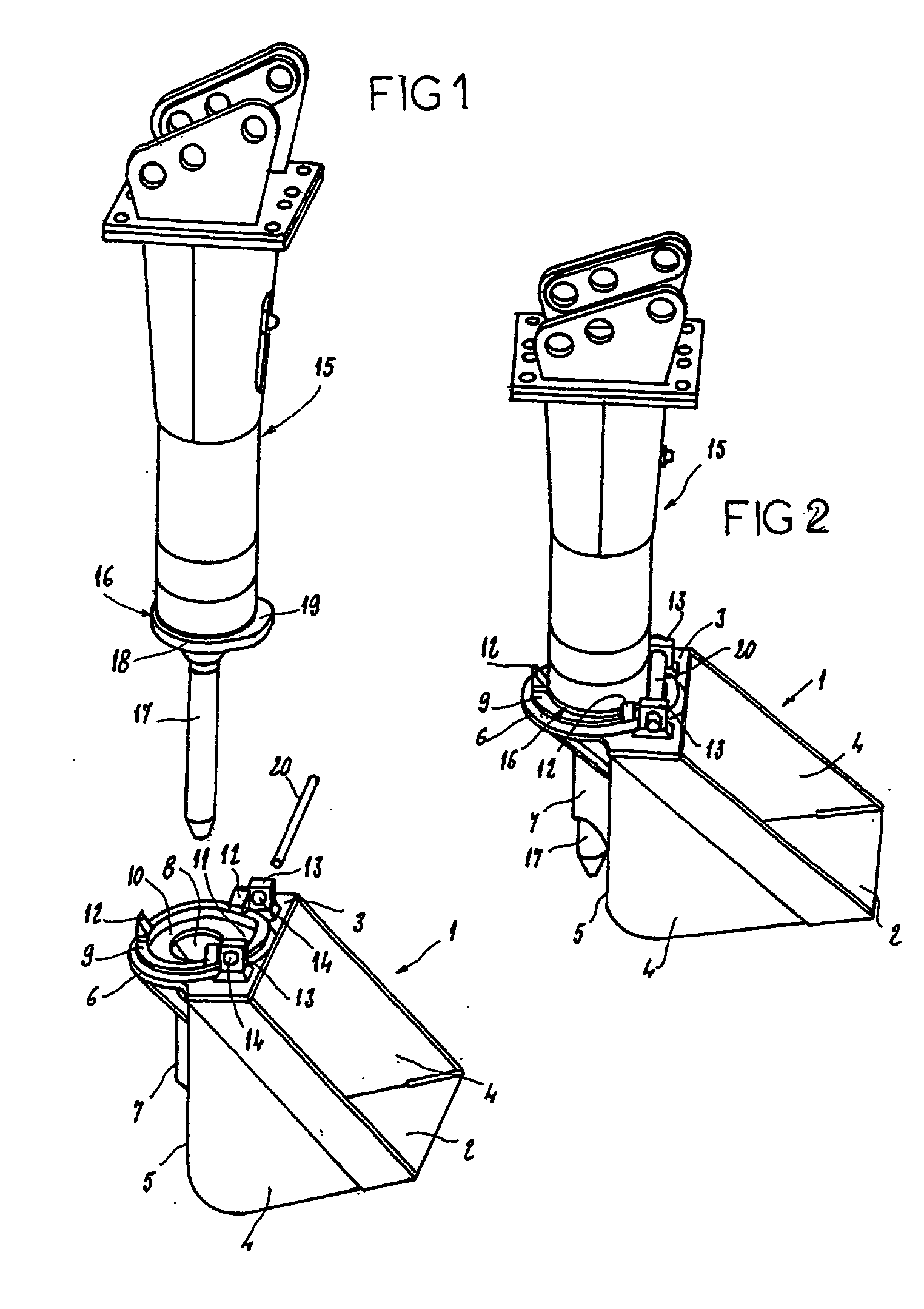

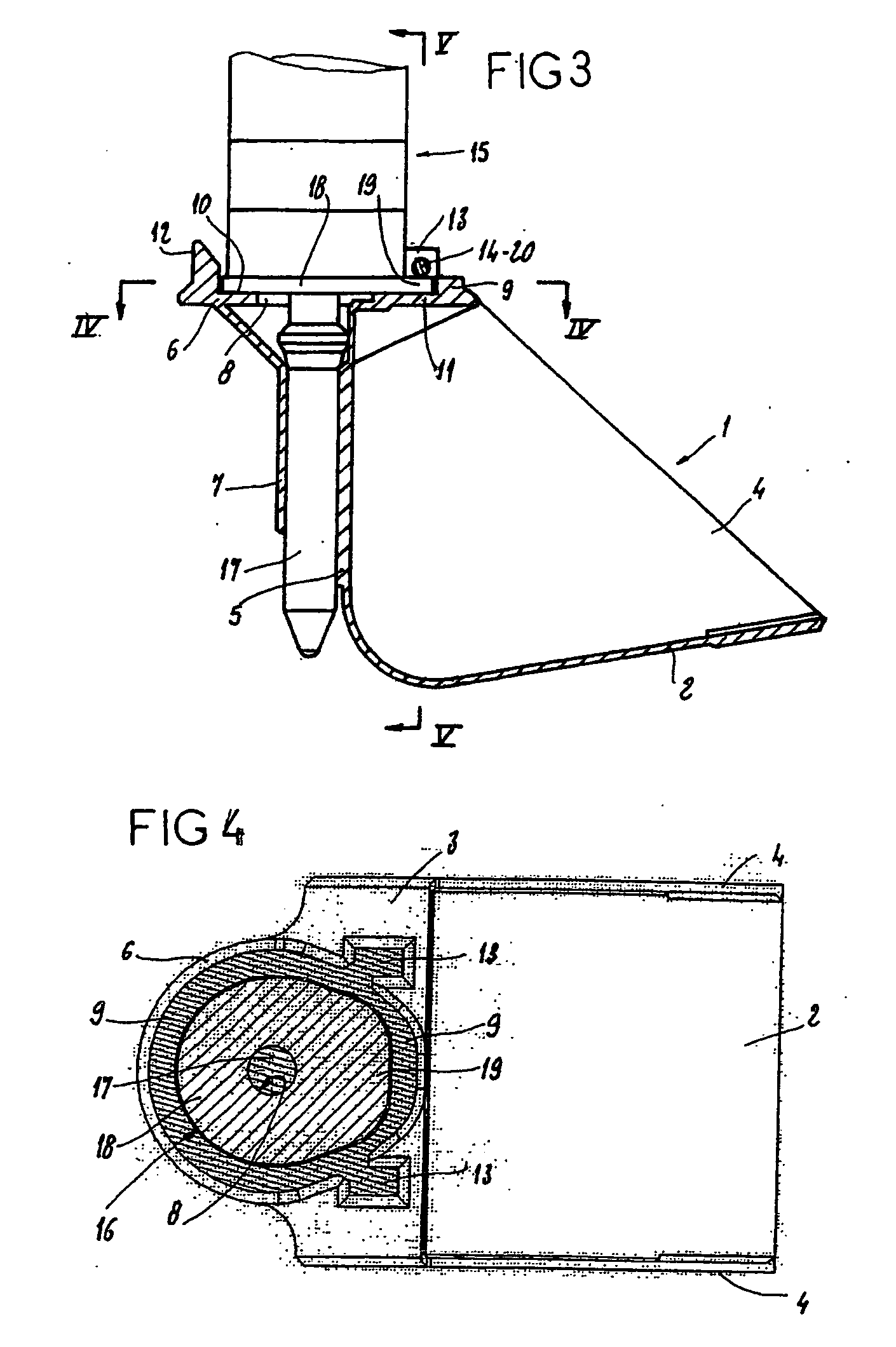

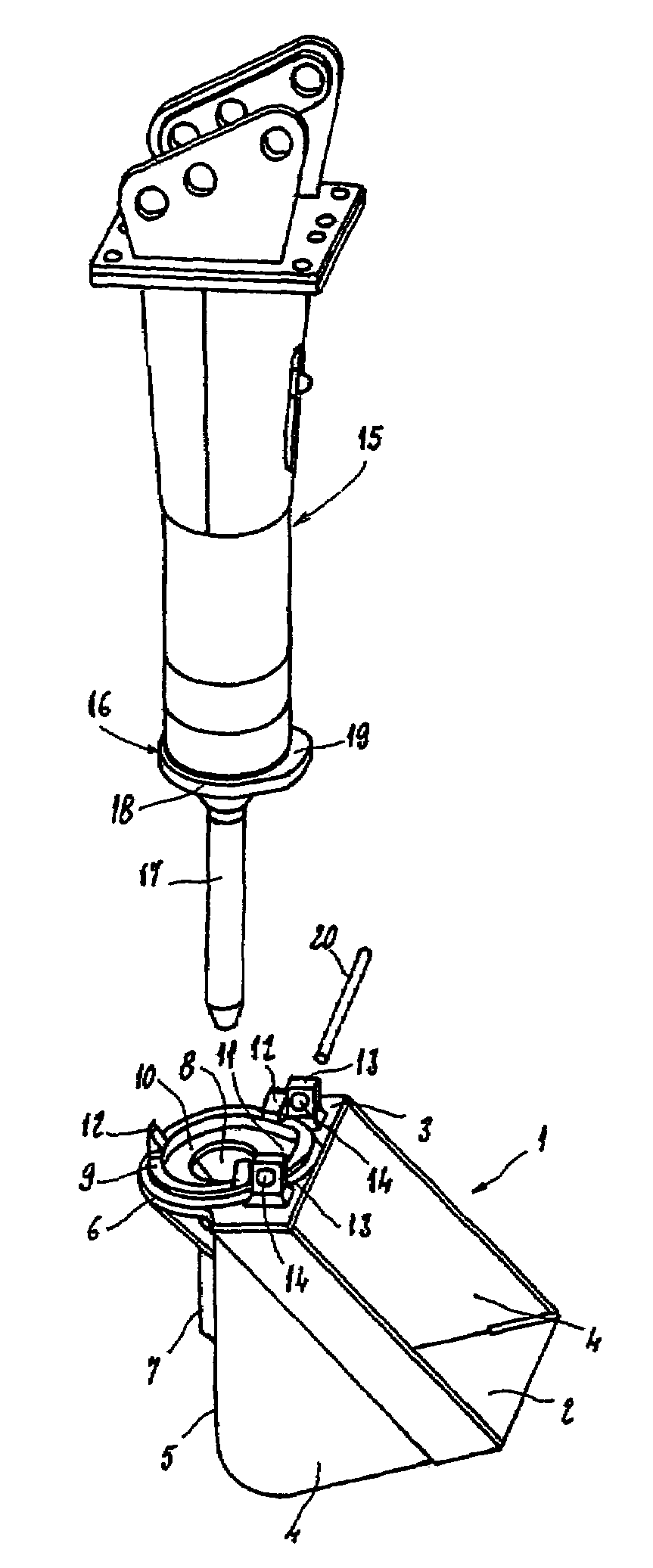

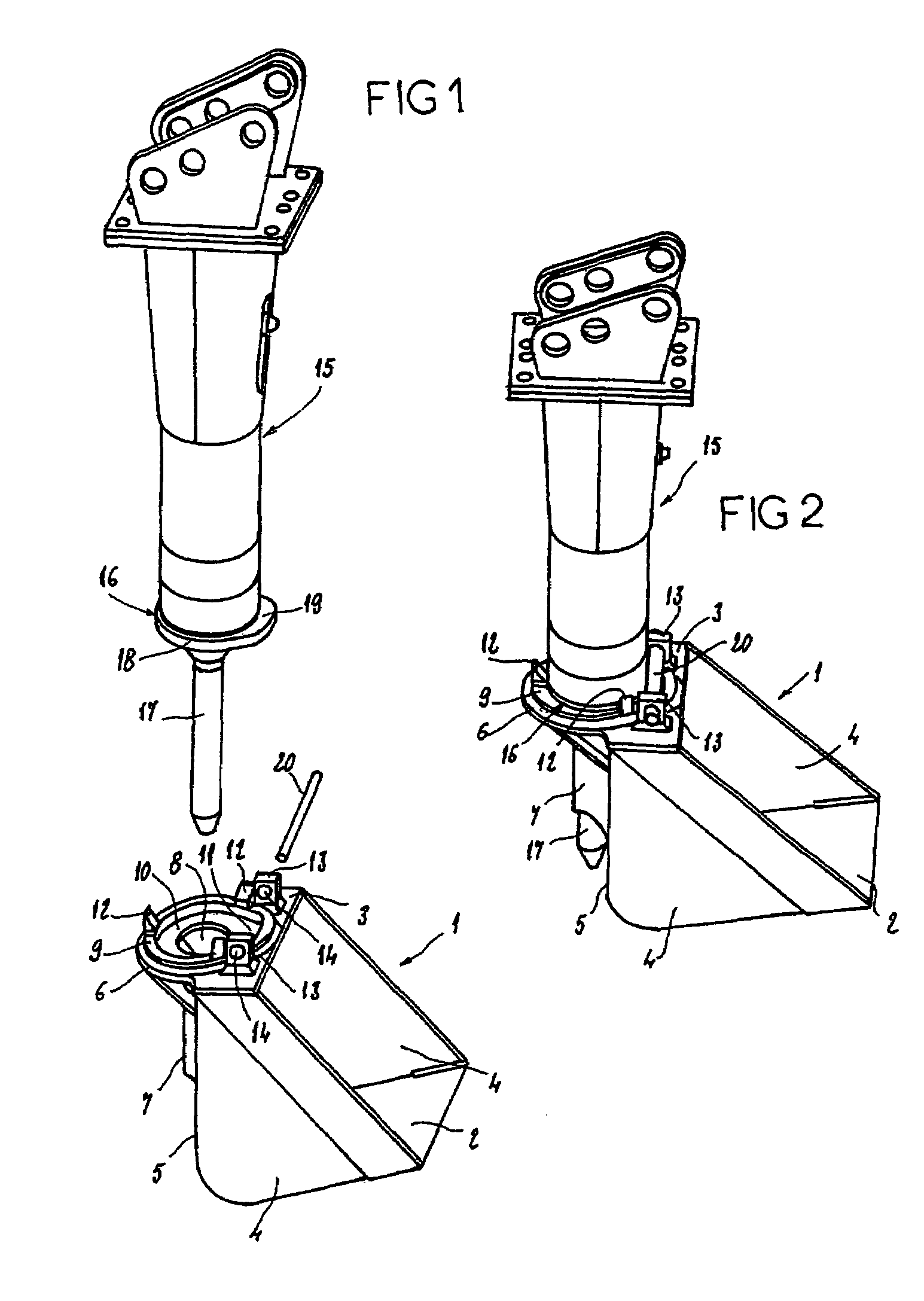

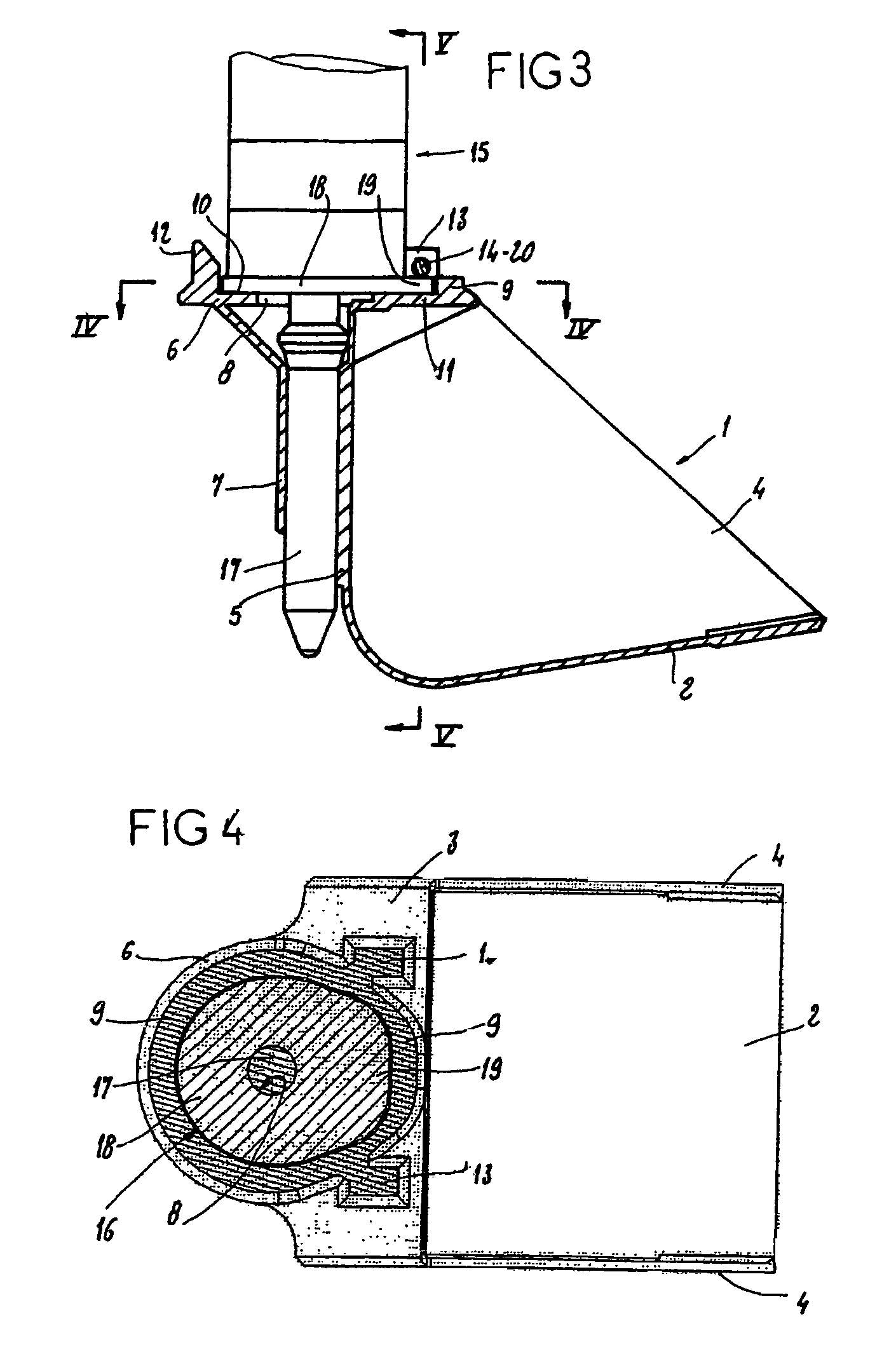

Removable attachment for a rock breaker

InactiveUS20080047171A1Improve attachment stabilityEasy to insertMechanical machines/dredgersLifting devicesStructural engineeringCrusher

Owner:MONTABERT SA

Removable attachment for a rock breaker

InactiveUS7523997B2Improve attachment stabilityEasy to insertMechanical machines/dredgersStructural engineeringCrusher

Owner:MONTABERT SA

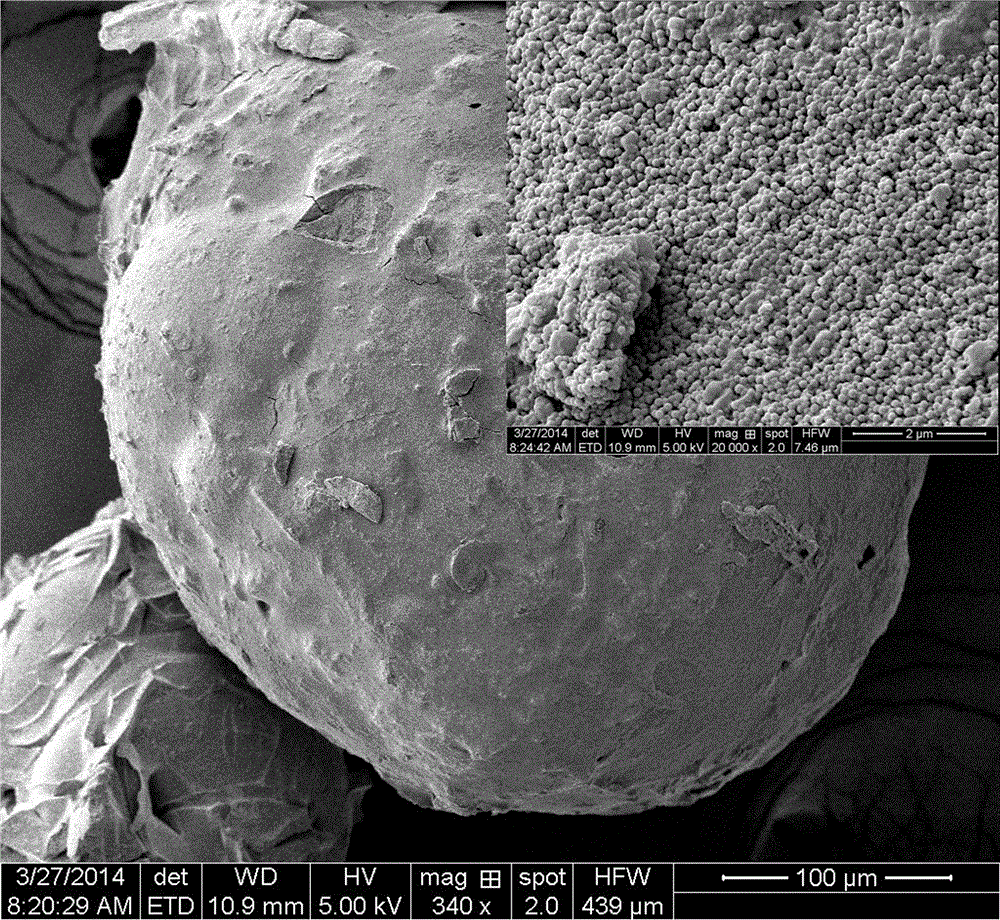

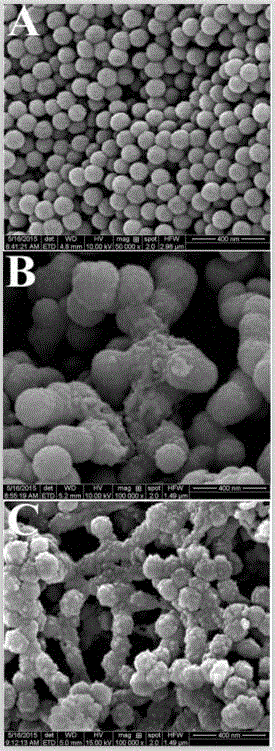

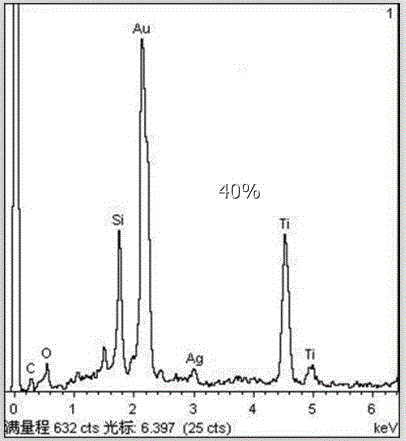

Preparation method of silver-loaded floating hollow titanium dioxide taking cationic polymer as intermediate

InactiveCN105749906AImprove stabilityImprove attachment stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPolymeric surfaceCationic polymerization

The invention discloses a preparation method of silver-loaded floating hollow titanium dioxide taking a cationic polymer as an intermediate. The preparation method comprises the following steps: selecting cationic polystyrene as an intermediate substance; adsorbing the polymer on the surface of a lightweight inorganic carrier under the action of electrical attraction to obtain inorganic carrier / cationic polymer composite particles; furthermore, depositing nano titanium dioxide and noble metal on the surface of the polymer to obtain polymer / titanium dioxide / noble metal composite particles loaded on the surface of the carrier; and finally, roasting to remove the organic polymer to realize loading and gathering of the titanium dioxide loaded with the noble metal on the surface of the lightweight inorganic carrier. The titanium dioxide prepared by the method is in a hollow structure and can be arrayed on the surface of the carrier for a plurality of layers, so that the specific surface area is relatively large and the catalytic activity is good. When the catalyst is used, the catalyst floats on the water surface and does not need to be stirred, and is not influenced by water turbidity; and the catalyst is suitable for being used in a natural environment and can be recycled and repeatedly used.

Owner:UNIV OF JINAN

Preparation method of screen cloth for automotive trim

ActiveCN104831462AHigh specific surface areaImprove adsorption capacityWarp knittingMelt spinning methodsPolyesterRefractive index

The invention relates to a preparation method of screen cloth for an automotive trim. The preparation method is characterized by comprising the following steps: I, preparing high-refractive-index functional powder; II, preparing environment-friendly functional powder: (1) preparing a carrier of nano copper oxide; (2) preparing the environment-friendly functional powder; III, preparing modified polyester master batch; IV, preparing special oiling agent for polyester monofilament; V, preparing high-performance polyester monofilament; VI, preparing screen mesh of the automotive trim. The screen cloth is produced by adopting a double-needle bed warping machine and prepared in a warping step, a weaving step and an after-arranging step. The preparation method is simple in process, wide in application range and good in performance.

Owner:FUJIAN JINJIANG HUAYU WEAVING

Antimicrobial fabric and antimicrobial processing technology thereof

InactiveCN106968107AImprove attachment stabilityIncreased persistence of antibacterialBiochemical fibre treatmentLiquid/gas/vapor removalWoolSilver particles

The invention discloses an antimicrobial fabric which is formed by knitting 50-60 D of warp silk and 50-60 D of weft silk. The warp silk is cotton yarns containing nano-silver particles, and the mass of the nano-silver particles in the warp silk is 0.003-0.008%. The weft silk is yarns obtained by blending cashmere wool, Tencel and polyamide fiber and performing and antimicrobial finishing, the cashmere wool accounts for 15%-25% of the mass of the weft fiber, the Tencel accounts for 20%-30% of the mass of the weft fiber, and the balance is the polyamide fiber. The invention further discloses an antimicrobial processing technology. The antimicrobial fabric and the antimicrobial processing technology have the following advantages that the attaching stability of antibacterial factors of the fabric is improved, the antibacterial durability is increased, an antibacterial effect is good, the safety is improved, the possibility of skin allergy is reduced, toxic substance discharge is decreased in the production process, the technology is conducive to environmental protection, the soft hand feeling of the fabric is improved, meanwhile the tensile strength and fracture strength of the fabric meet the standards, and the antimicrobial fabric also has a certain warm-keeping effect.

Owner:CHINA TEXTILE INFORMATION CENT +2

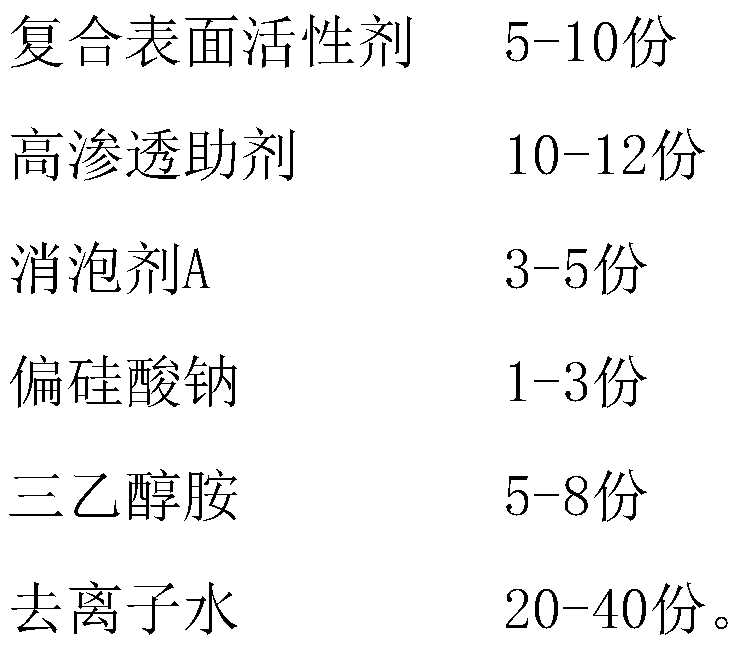

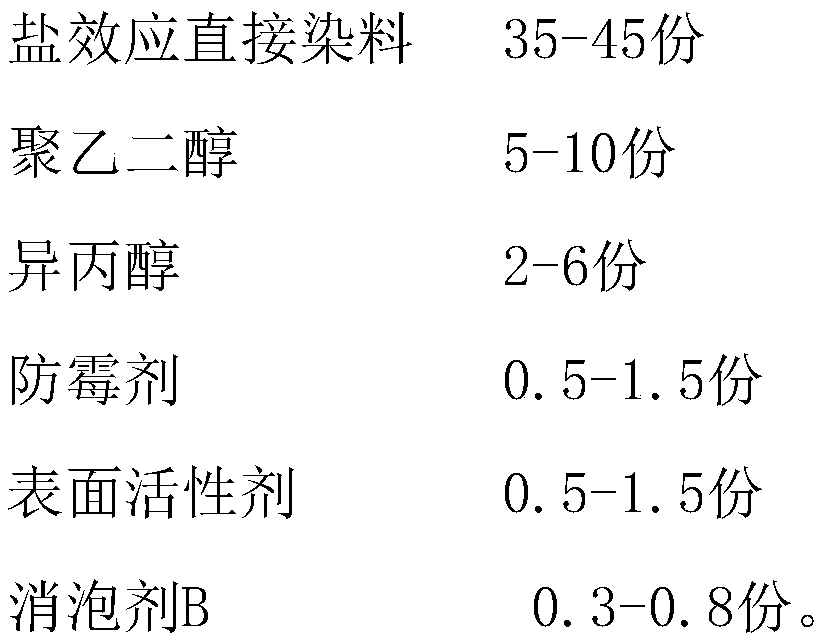

Dyeing technology of composite board

InactiveCN109853255AEasy to operateEasy to controlInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsColor effectEngineering

The invention relates to the technical field of material dyeing, in particular to a dyeing technology of a composite board. The dyeing technology comprises the following steps of board cleaning, boardrinsing, spraying and washing with water, soaking and dyeing, after-dyeing washing with water and drying. The dyeing technology is easy to implement and convenient to control, the composite board issoaked and dyed, so that the surface of the composite board adsorbs dye in a mode of combining a chemical bond with a molecular bond, the surface of the composite board and the dye are integrally combined, no externally-added dye coating is not needed, and a multi-color effect or a gradual change effect of the surface of the composite board is achieved; an injection molding mode does not need to be adopted, the production efficiency of the composite board is improved, the production cost is lowered, the product quality is high, and the dyeing technology can be applied to large-scale production.

Owner:东莞金稞电子科技有限公司

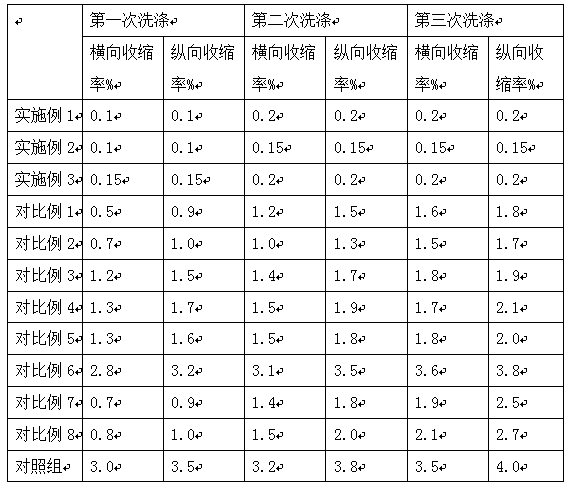

Production method for low-shrinkage-rate wool fabric

InactiveCN110042656ASmall shrinkageImprove shrinkage resistanceGrip property fibresShrinking resistant fibresCombined methodNitrogen gas

The invention discloses a production method for a low-shrinkage-rate wool fabric. The production method comprises the specific steps that 1, a wool fabric is humidified and pre-heated, and then an octadecyl trimethyl ammonium chloride water solution is atomized to be mixed with air to conduct secondary humidifying and pre-heating on the wool fabric; 2, the wool fabric obtained after humidifying and pre-heating is subjected to ozone treatment, after pressure increasing and maintaining treatment, freezing is conducted, a graphene-grafted polymer water solution is atomized and then mixed with nitrogen, the mixture of the graphene-grafted polymer and the nitrogen is pre-heated, injected into a container and subjected to ultrasonic oscillation; 3, the wool fabric is taken out and subjected to fixation by using a high-temperature and low-temperature combined method; 4, the wool fabric is pre-dried, baked and then subjected to water washing and drying, and if the wool fabric is qualified through quality testing, the wool fabric is packaged to obtain the low-shrinkage-rate wool fabric. According to the method, the wool fabric is treated, the shrinkage rate of the wool fabric can be remarkably reduced, the shrinkage resistance of the wool fabric can be improved, the dimensional stability of the wool fabric is improved, and therefore, the application requirements of the wear field are met.

Owner:合肥巧织纺织科技有限公司

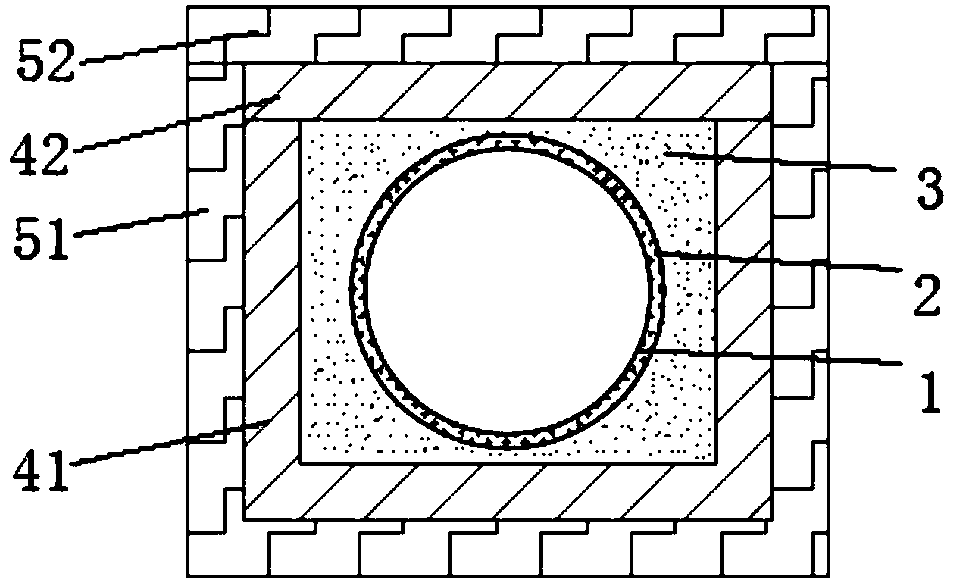

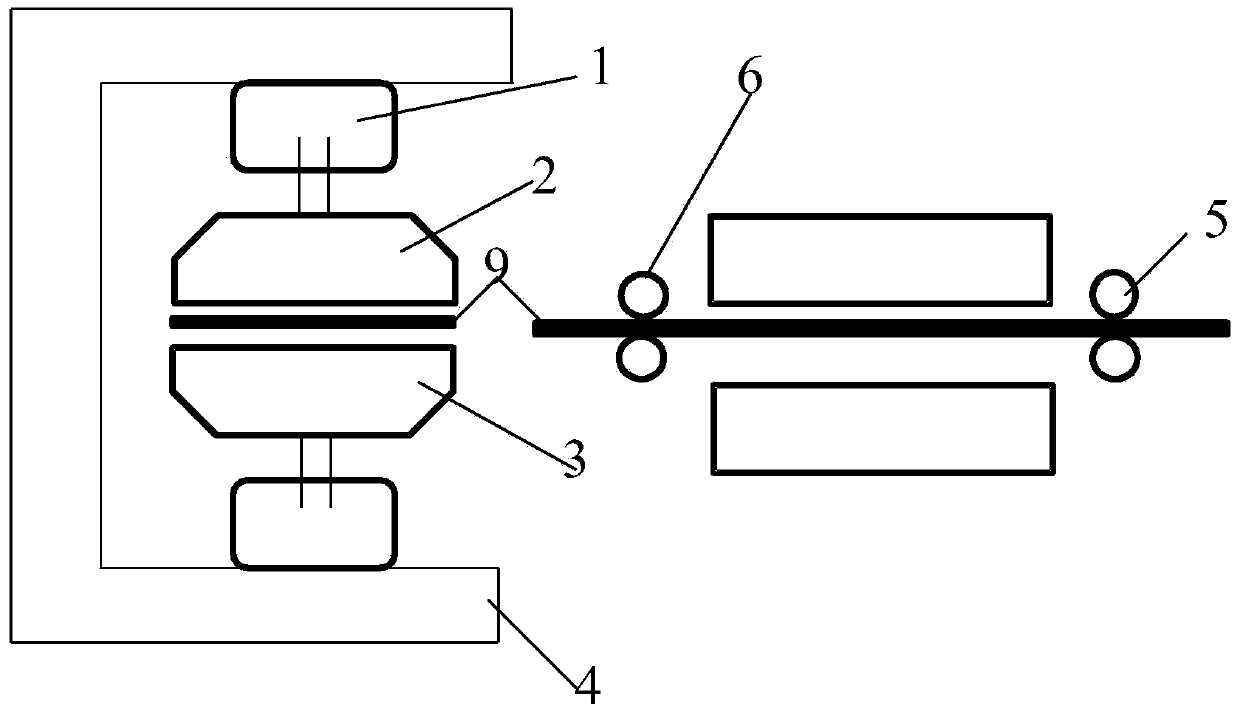

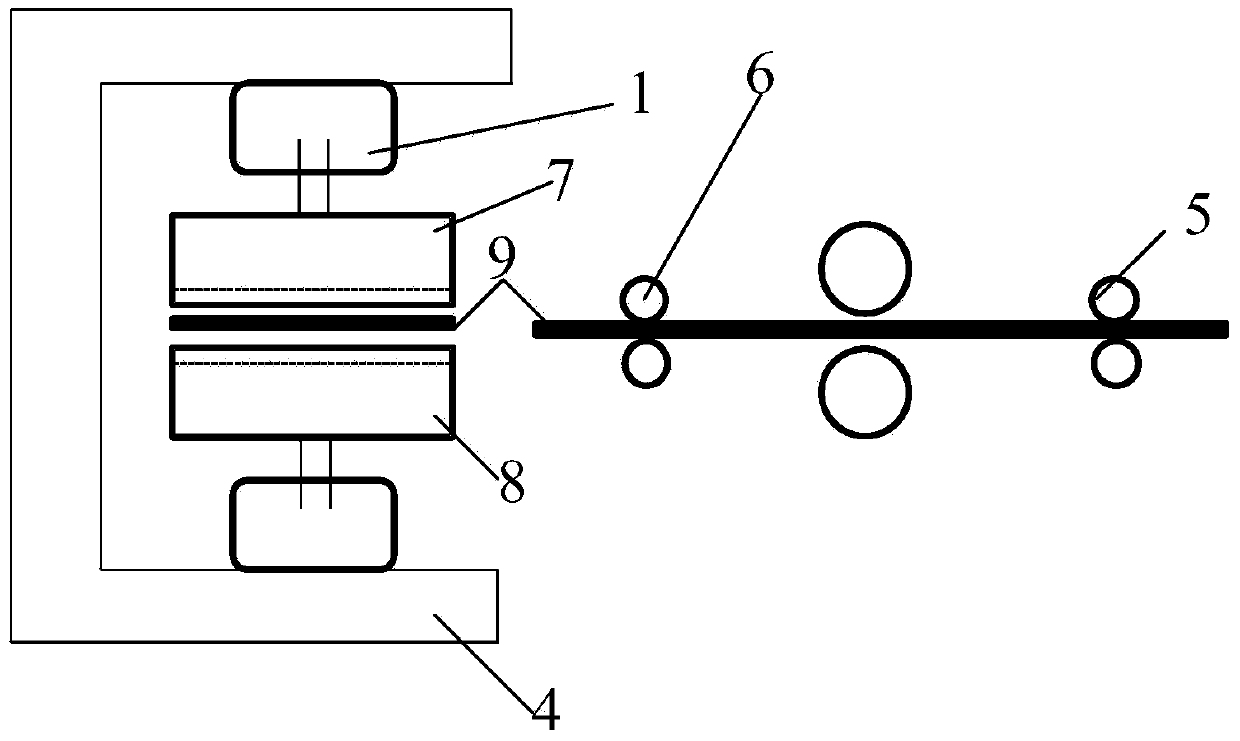

Manufacturing device and manufacturing method of battery pole plate

InactiveCN103811715AIncrease frictionIncrease the effective attachment areaManufacture by sprayingEngineeringMechanical engineering

The invention discloses a manufacturing device and a manufacturing method of a battery pole plate. The manufacturing device of the battery pole plate comprises a mould clamp, an upper mould, a lower mould, an oil press, a pole plate dragging device and a pole plate feeding device, wherein a battery pole plate blank is dragged by the pole plate dragging device and is conveyed between the upper mould and the lower mould by the pole plate feeding device; the upper mould and the lower mould are assembled in the mould clamp; the mould clamp is fixedly arranged on the oil press; mutually-matched concave-convex shapes are formed on the surface of the upper mould and the surface of the lower mould. The manufacturing device of the battery pole plate is simple in structure; the coating is uniform and the production efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

Positioning mark apparatus of a surgery navigation system and implementation instrument thereof

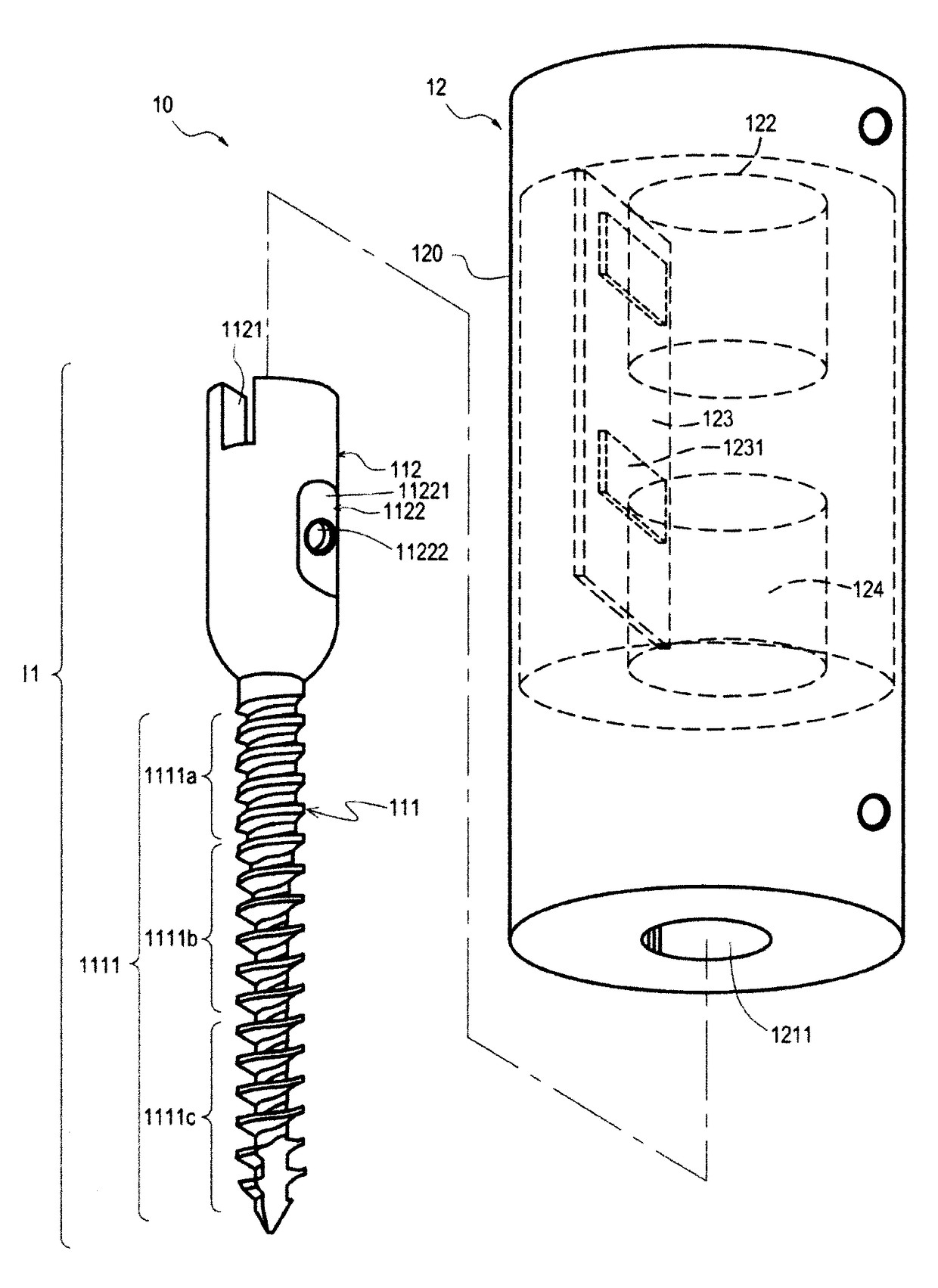

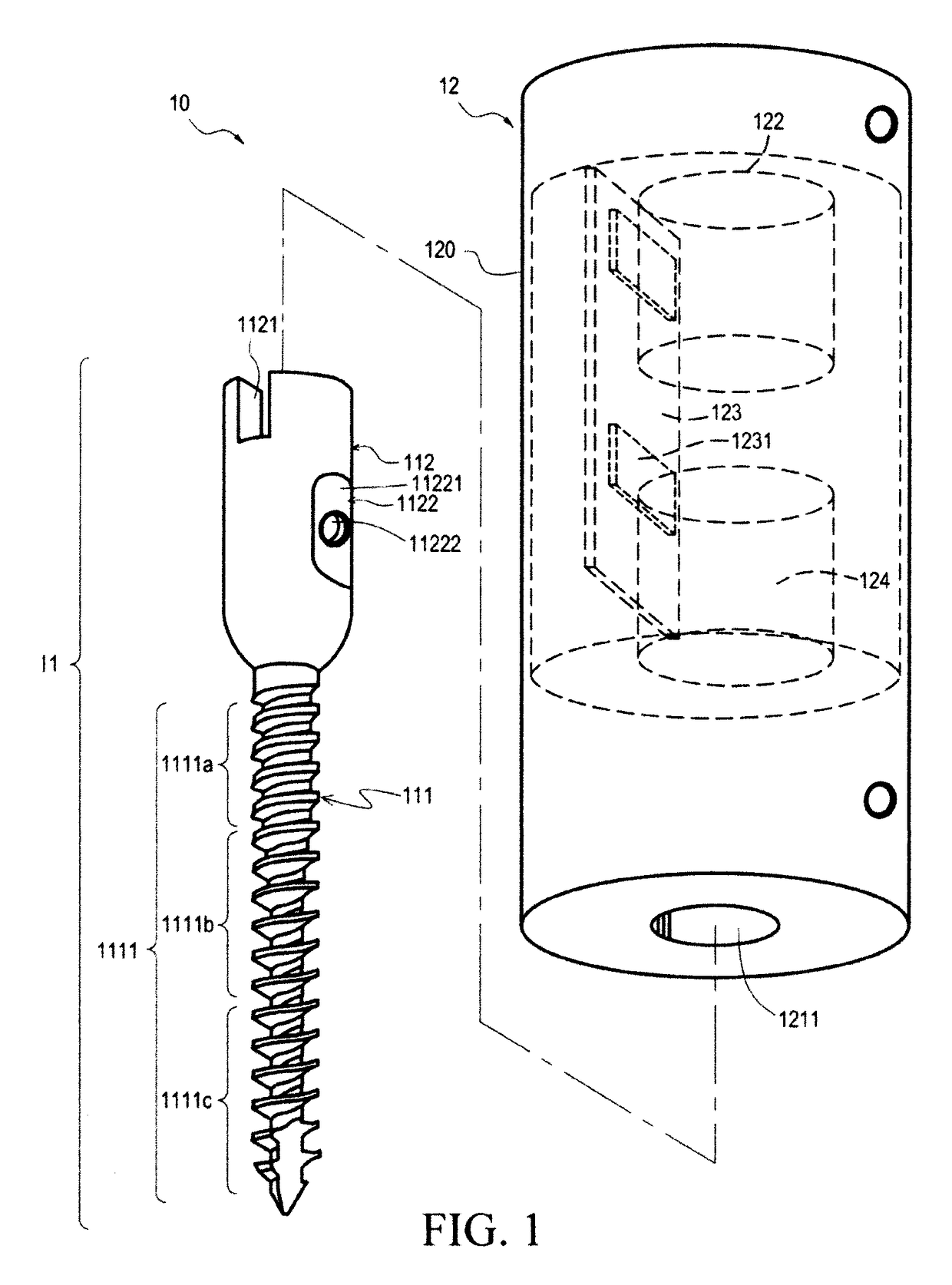

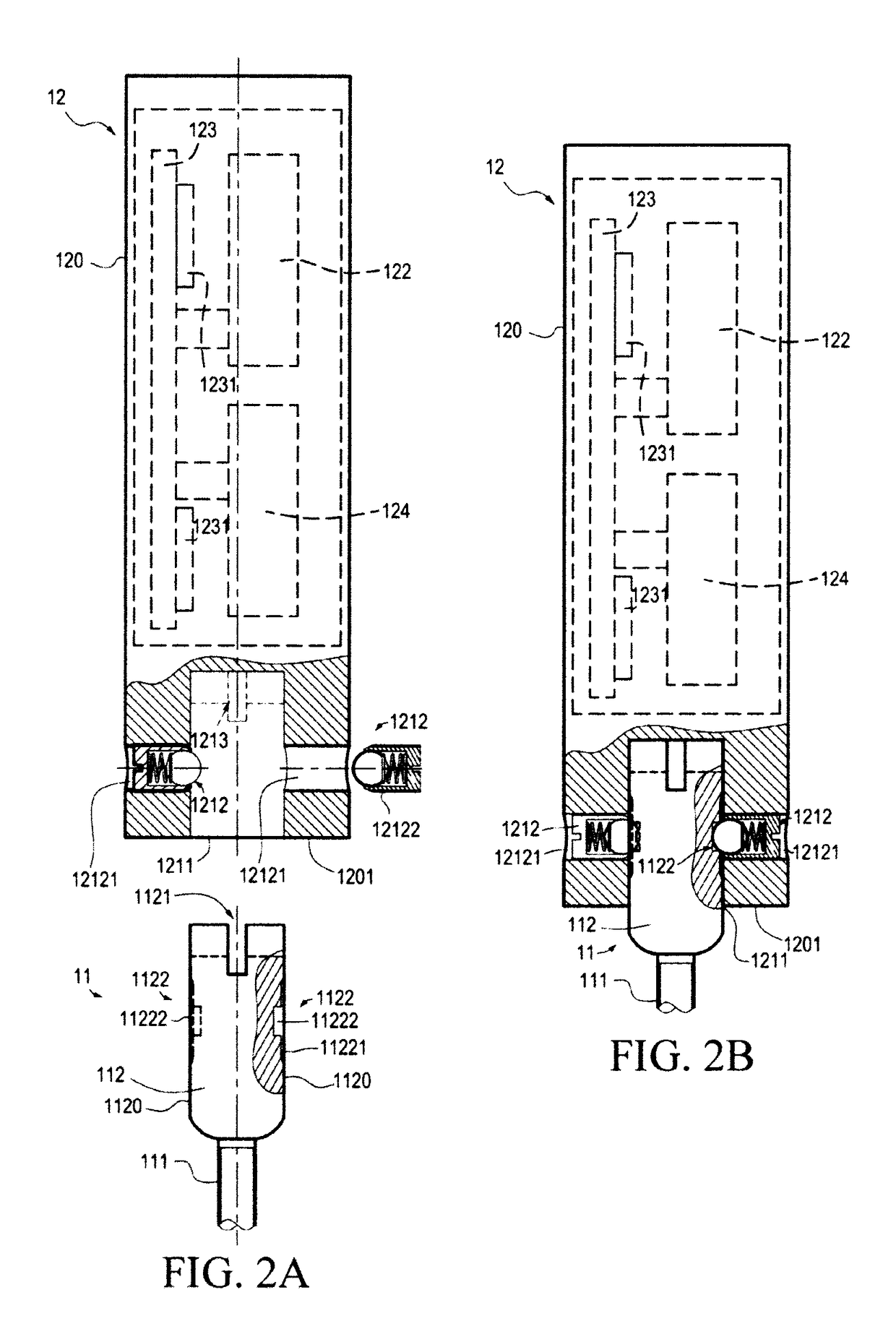

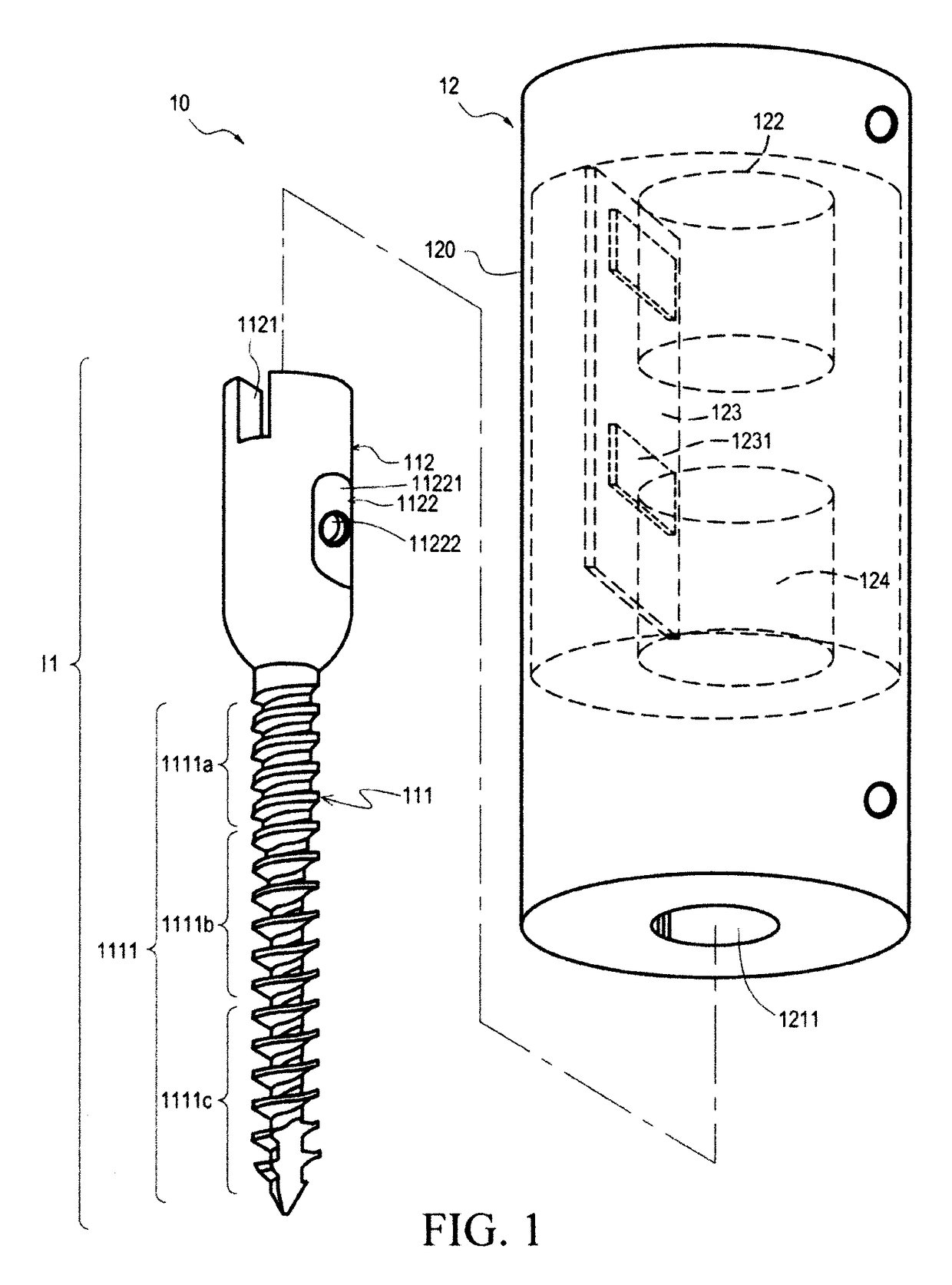

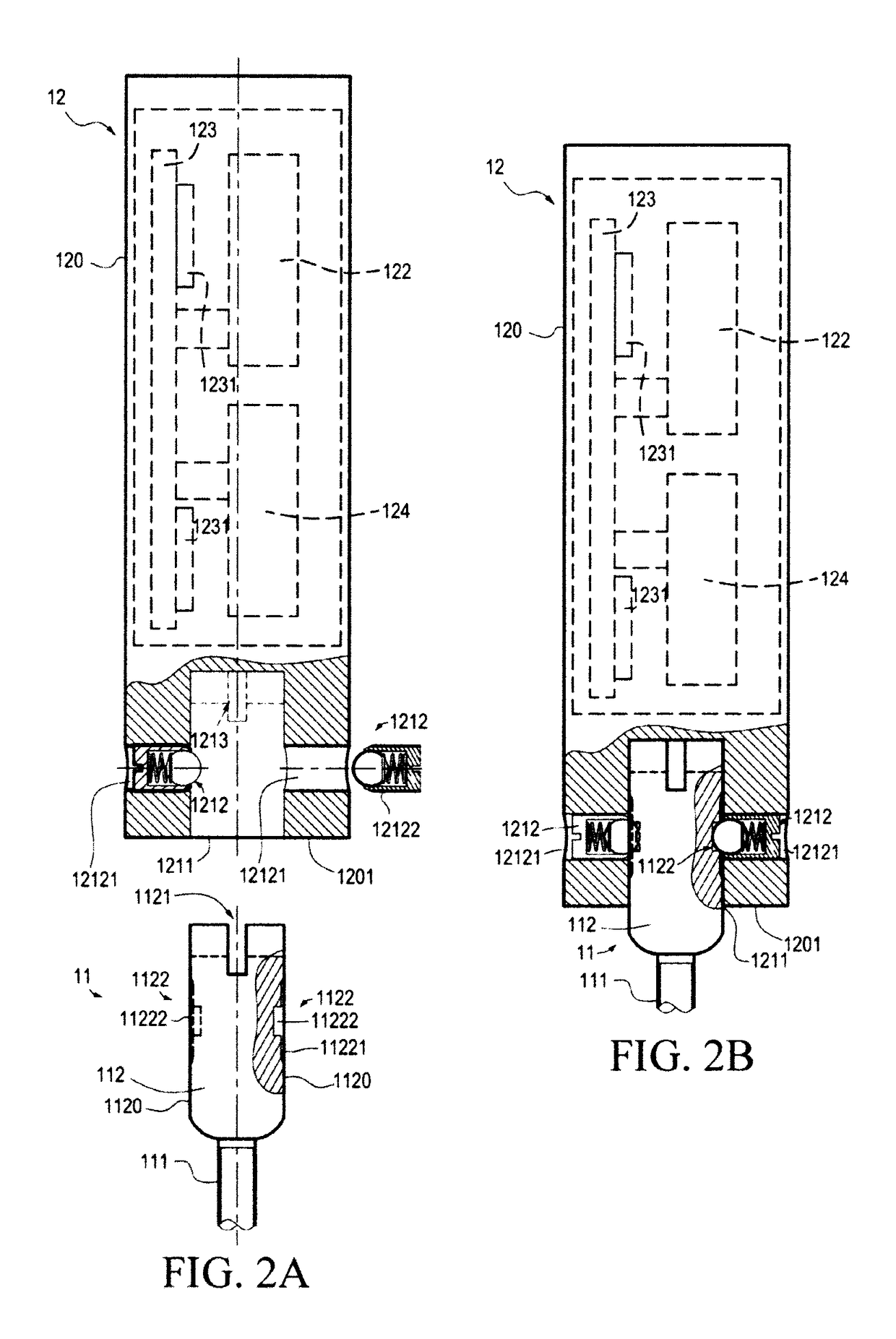

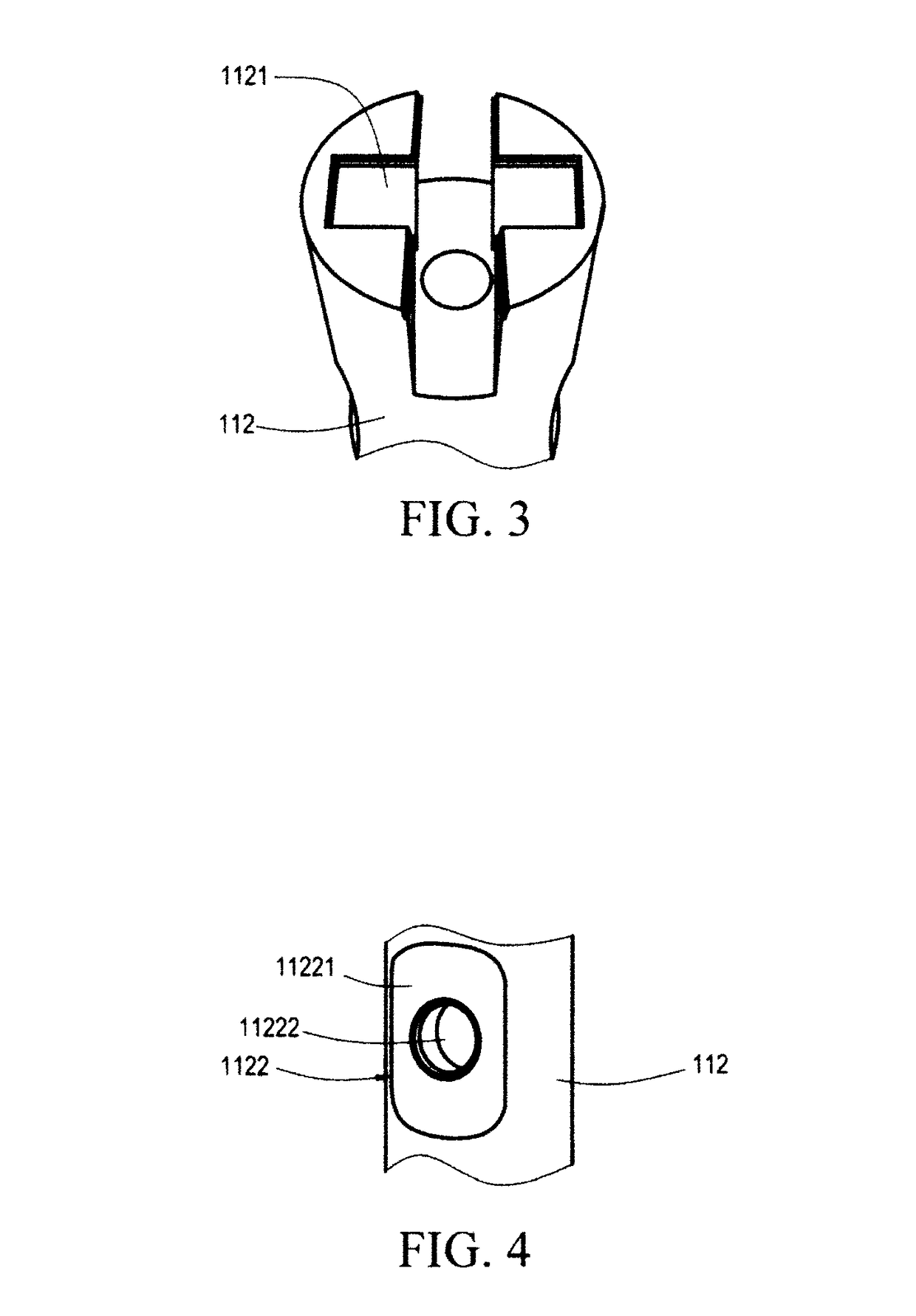

ActiveUS20170319280A1Optimize volumeHigh positioning accuracySurgical navigation systemsDiagnostic markersElectricityRadio frequency signal

A positioning mark apparatus of a surgery navigation system and an implementation instrument thereof are disclosed. The positioning mark apparatus includes a positioning base and a frequency modulated radio frequency positioning module. One end of the positioning base is a lock portion having a screw structure, another end is a head having a joint structure, and a free end of the head has a fitting structure. The frequency modulated radio frequency positioning module has a sleeving structure that cooperates with the head structure and buckles with the joint structure. The frequency modulated radio frequency positioning module includes an antenna unit, a printed circuit board unit electrically connected to the antenna unit, and an electronic component battery unit supplying power to the printed circuit board unit. The frequency modulated radio frequency positioning module may transmit, according to a received frequency modulated signal, a feedback signal including a radio frequency signal to the external.

Owner:METAL INDS RES & DEV CENT

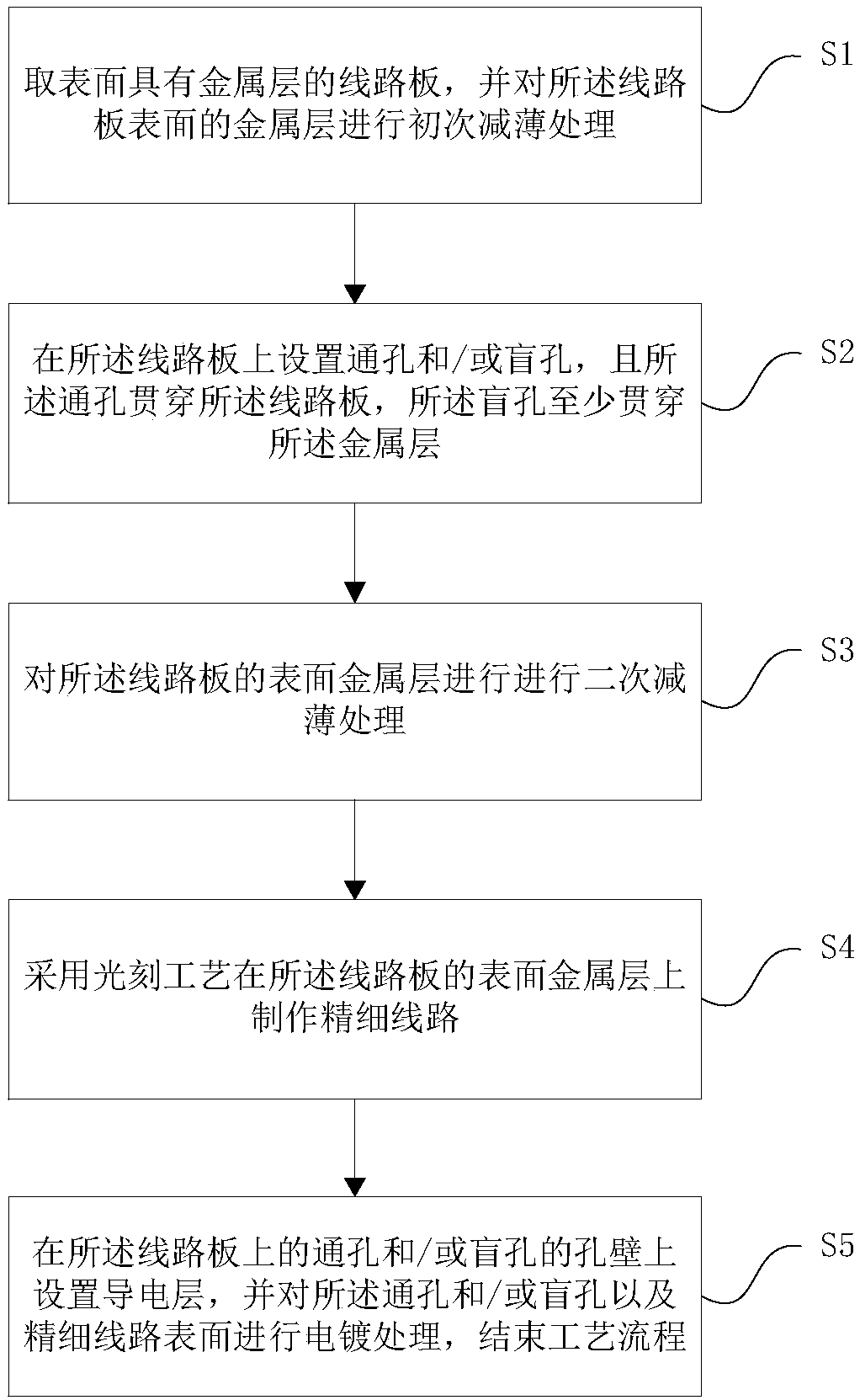

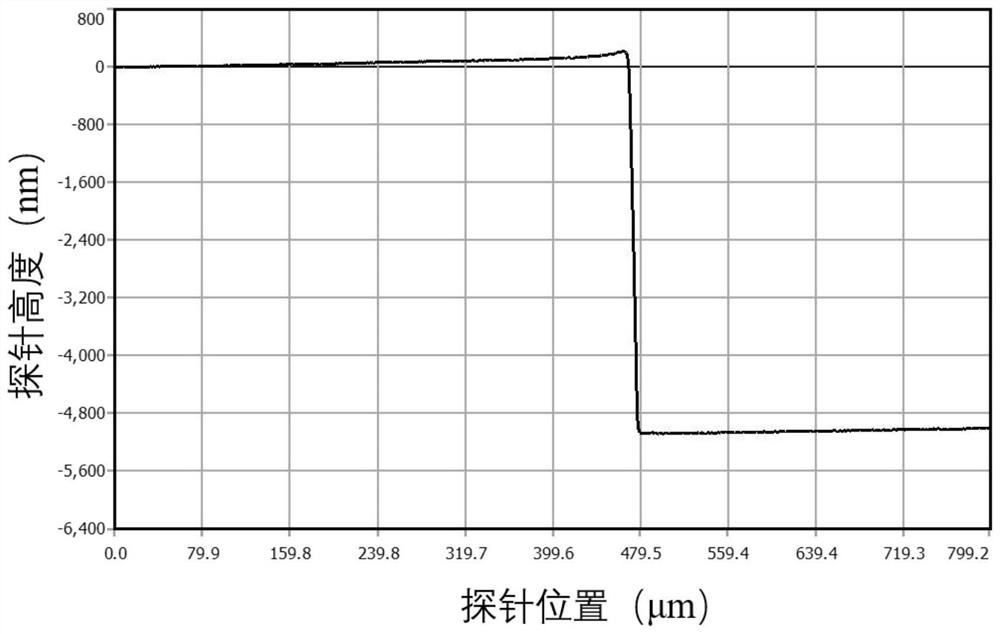

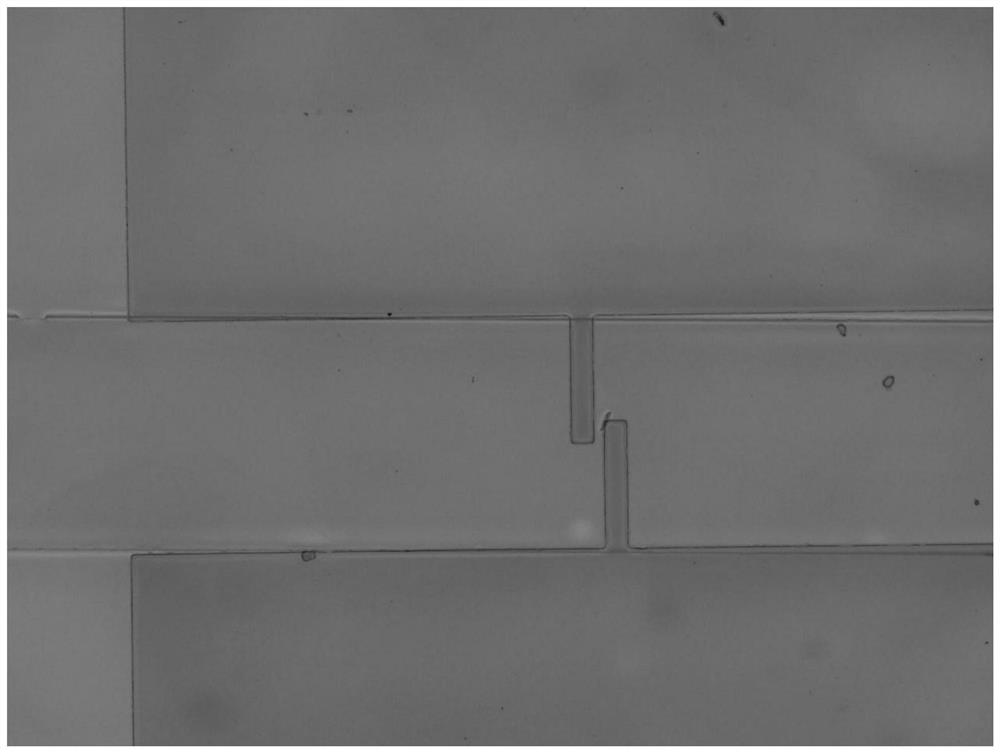

Fine line manufacturing method

ActiveCN109302808ATo achieve widening and thickeningReduced Aperture Thickness RatioPrinted circuit secondary treatmentConductive material chemical/electrolytical removalFine lineEngineering

The invention relates to a fine line manufacturing method. A metal layer in the surface of a circuit board is thinned preliminarily; the circuit board is provided with a through hole and / or a blind hole, the through hole penetrates the circuit board, and the blind hole penetrates the metal layer at least; the metal layer in the surface of the circuit board is thinned secondarily; a fine line is made on the surface metal layer of the circuit board via a photoetching process; and the hole wall(s) of the through hole and / or the blind hole in the circuit board is / are provided with a conducting layer, and the surfaces of the through hole and / or the blind hole and the fine line are electro-plated. The relatively thick circuit board material is thinned preliminarily to reduce the aperture thickness ratio, so that the micro hole can be bored in the circuit board; the bored circuit board is thinned secondarily, so that the thickness of the conductive metal layer in the surface is further reduced, and photoetching of the fine line is made possible; and prejudice in the industry is overcome, the cost is reduced greatly, deformation of the circuit board is relatively low due to support intensity of the metal layer, and the hole precision is higher.

Owner:武汉铱科赛科技有限公司

Antibacterial filter paper and preparation method thereof

ActiveCN111501414ALong-lasting excellent antibacterial effectStrong loadPaper/cardboardFiltration separationPolymer sciencePapermaking

The invention relates to the field of antibacterial filter paper. The antibacterial filter paper is composed of 50 to 70 parts of paper pulp fibers, 15 to 25 parts of an antibacterial filler, 1 to 3 parts of water-soluble resin, 1 to 3 parts of a wetting agent and 5 to 10 parts of a thickening agent. The antibacterial filler comprises a filler core, an antibacterial agent and hydroxypropyl starch,wherein the surface of the filler core is coated with the antibacterial agent and the hydroxypropyl starch. A preparation method comprises the steps: repulping and pulping the paper pulp fibers to prepare paper pulp slurry, then adding an antibacterial filler, water-soluble resin, the wetting agent and the thickening agent into the paper pulp slurry, and uniformly stirring; and carrying out papermaking, screening, squeezing, drying and curling to obtain the product. The antibacterial agent is stably loaded on the surface of the antibacterial filler in advance, and then the antibacterial filler is added into papermaking pulp to prepare the antibacterial filter paper, so that a lasting and excellent antibacterial effect can be obtained.

Owner:ASIA SYMBOL GUANGDONG PAPER

Positioning mark apparatus of a surgery navigation system and implementation instrument thereof

ActiveUS10182872B2Improve efficiencyImprove accuracySurgical navigation systemsDiagnostic markersElectricityRadio frequency signal

A positioning mark apparatus of a surgery navigation system and an implementation instrument thereof are disclosed. The positioning mark apparatus includes a positioning base and a frequency modulated radio frequency positioning module. One end of the positioning base is a lock portion having a screw structure, another end is a head having a joint structure, and a free end of the head has a fitting structure. The frequency modulated radio frequency positioning module has a sleeving structure that cooperates with the head structure and buckles with the joint structure. The frequency modulated radio frequency positioning module includes an antenna unit, a printed circuit board unit electrically connected to the antenna unit, and an electronic component battery unit supplying power to the printed circuit board unit. The frequency modulated radio frequency positioning module may transmit, according to a received frequency modulated signal, a feedback signal including a radio frequency signal to the external.

Owner:METAL INDS RES & DEV CENT

A kind of platinum channel and its manufacturing method and zirconia dry powder mixture for coating

ActiveCN107739141BSpeed up meltingImprove melting effectLiquid surface applicatorsGlass furnace apparatusPlatinumMetallurgy

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

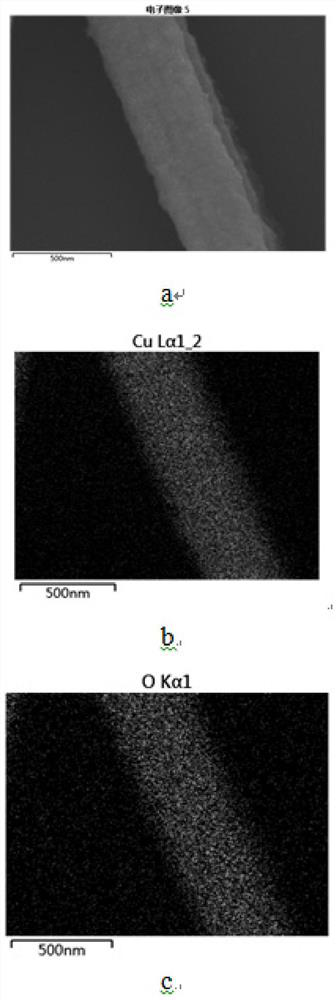

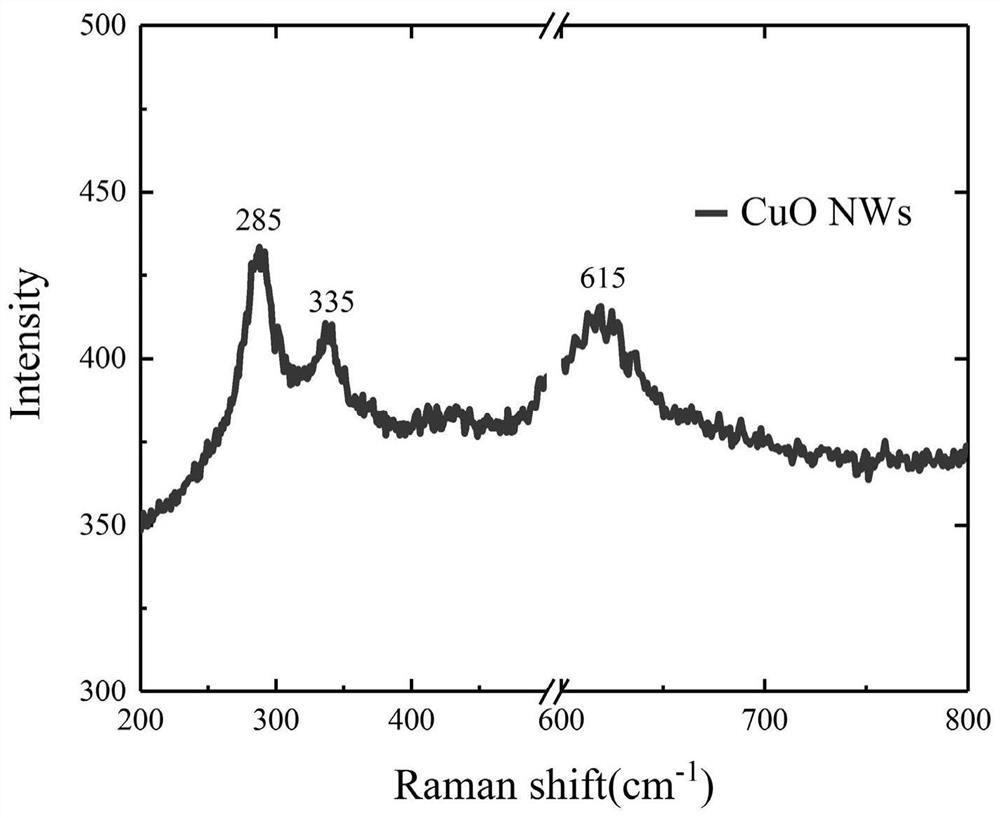

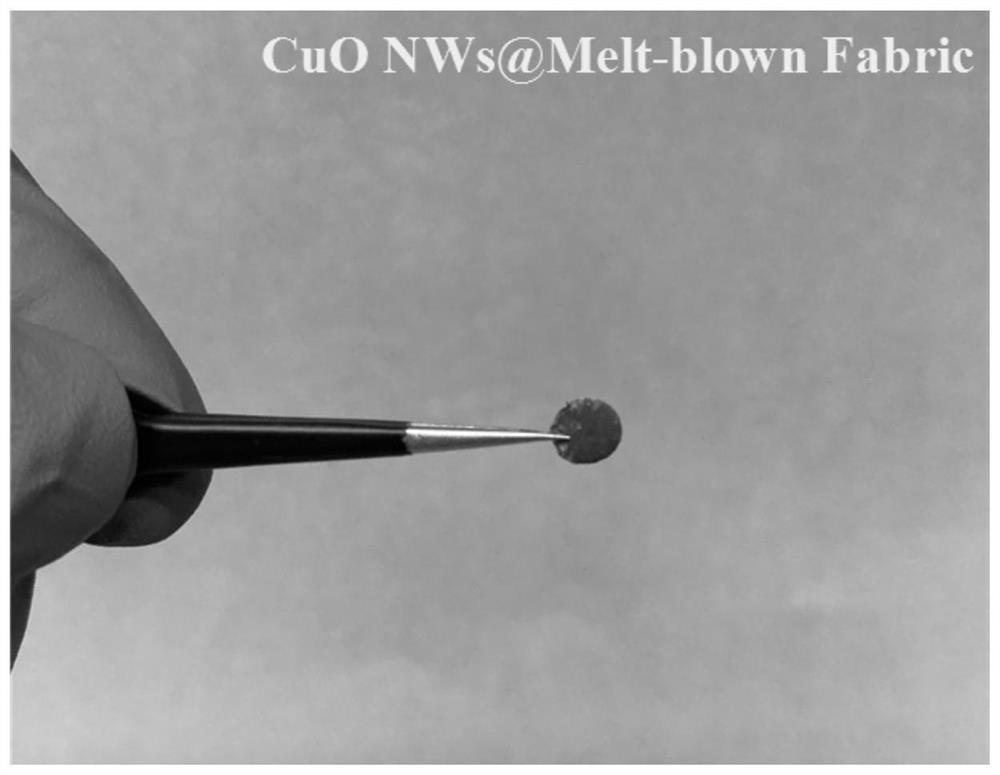

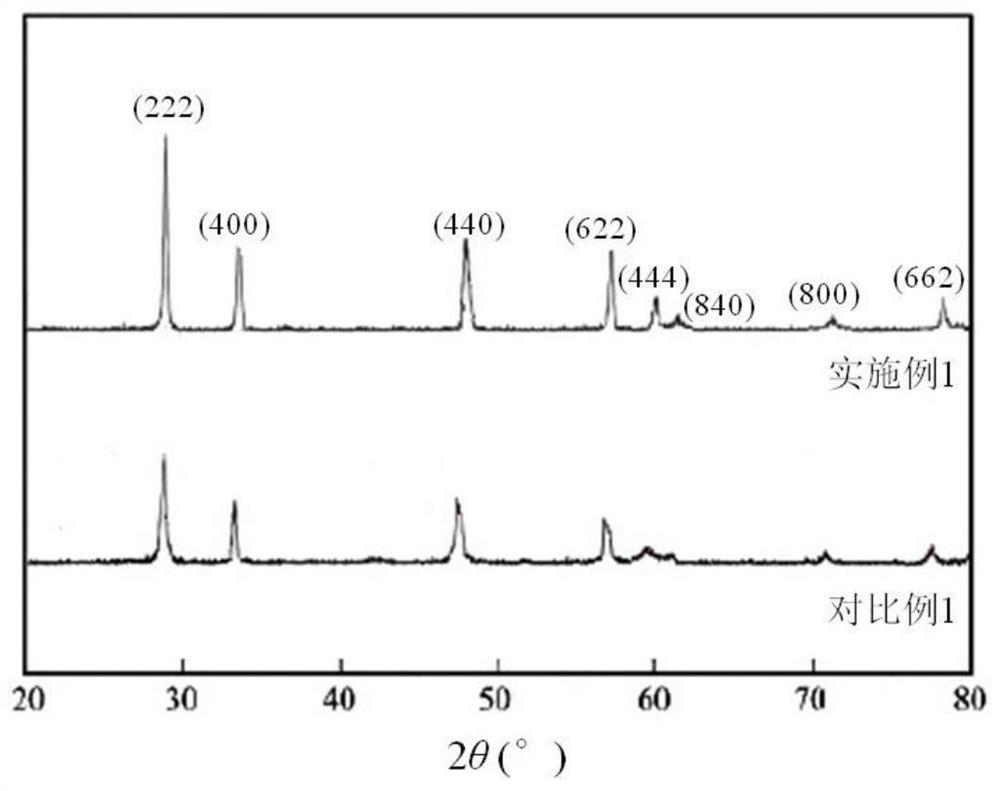

Preparation method and application of copper-based nanowire antibacterial material and preparation method of antibacterial melt-blown cloth

ActiveCN113502603ANot easy to fall offImprove attachment stabilityBiochemical fibre treatmentNon-woven fabricsInorganic saltsMetallurgy

The invention relates to the field of antibacterial material preparation, in particular to a preparation method and application of a copper-based nanowire antibacterial material and a preparation method of antibacterial melt-blown cloth. The preparation method of the copper-based nanowire antibacterial material comprises the following steps that S100, a reducing agent and copper metal inorganic salt serve as raw materials, and a pure copper nanowire is prepared in a long-chain alkylamine solvent system through a solvothermal method; S200, the pure copper nanowire is placed in a hydrophilic dispersion solvent, and a weak acid solution is added for acid pickling; and S300, the pure copper nanowire subjected to acid pickling is subjected to oxidation through a liquid-phase oxidation method or a high-temperature air oxidation method or a CVD oxidation method to prepare a copper oxide nanowire, namely the copper-based nanowire antibacterial material. The copper-based nanowire antibacterial material is high, sufficient and uniform in oxidation, the oxidized nanowire still keeps a slender structure, and the sterilization effect is good; and the adhesion stability of the material on the melt-blown cloth is high, so that the sterilizing effect is remarkable, stable and lasting when the material is applied to the melt-blown cloth.

Owner:XIAMEN UNIV

Antibacterial filler for filter paper and preparation method thereof

ActiveCN111501413AEliminates the step of applying antimicrobialsSimple preparation processPaper/cardboardFiltration separationFilter paperAnti bacterial

The invention relates to the field of filter paper, and in particular, relates to an antibacterial filler for filter paper, wherein the antibacterial filler comprises a filler, and an antibacterial agent and hydroxypropyl starch which are loaded on the surface of the filler. A preparation method comprises the steps: (1) coarsely and finely grinding the filler, and sieving with an 800-mesh sieve for later use; (2) preparing an antibacterial agent aqueous solution with the mass percentage concentration of 0.01-0.5%; (3) dispersing 20-50 g of the filler prepared in the step (1) into 1 L of the antibacterial agent aqueous solution; (4) heating the antibacterial agent aqueous solution in the step (3) to 40-60 DEG C, and then dispersing 10-30 g of hydroxypropyl starch into the antibacterial agent aqueous solution; and (5) performing sufficient stirring for 5-10 min, standing, filtering, and drying so as to obtain the product.

Owner:山东龙德复合材料科技股份有限公司

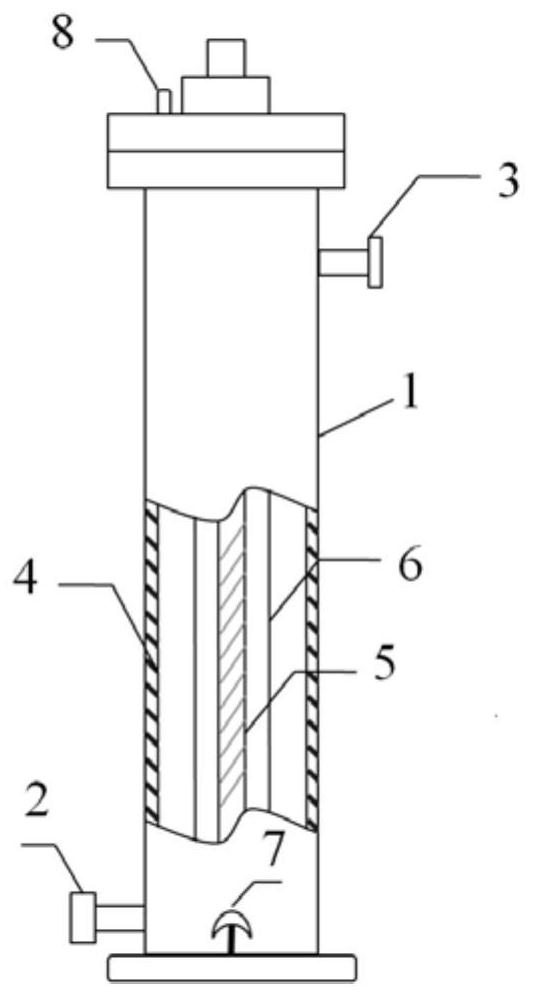

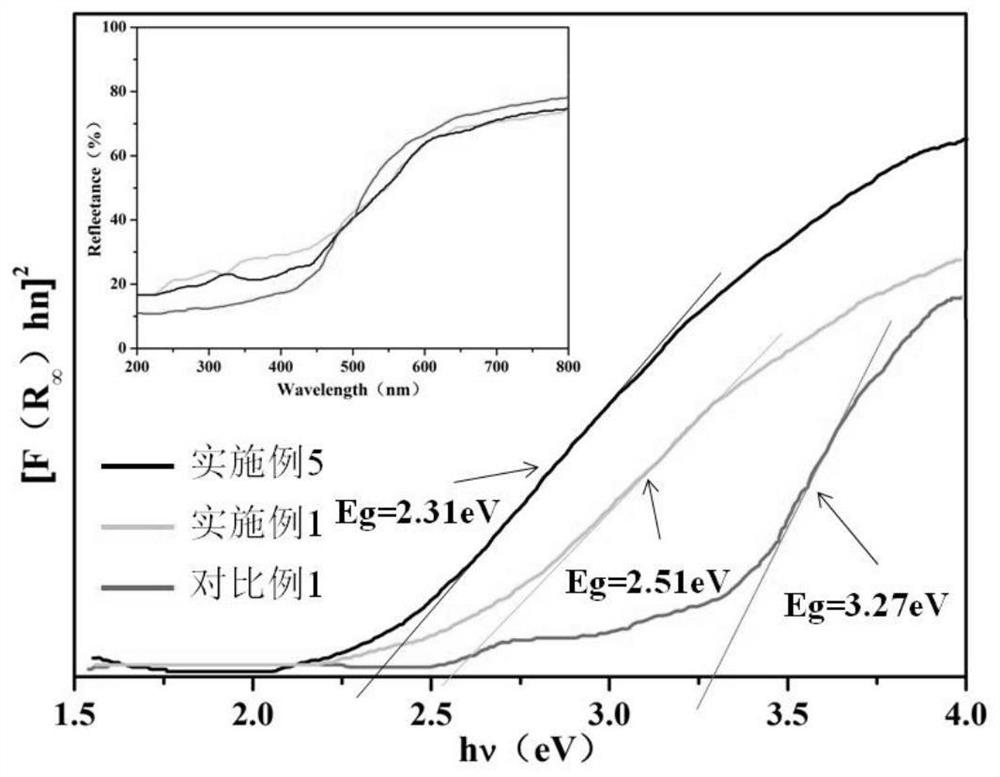

Sewage disinfection device and disinfection method

InactiveCN112354538AHigh catalytic activityNarrow band gapWater/sewage treatment by irradiationWater treatment compoundsBacterial virusUltraviolet lights

The invention discloses a sewage disinfection device and a disinfection method, and relates to the technical field of photo-catalysis and sewage treatment. The sewage disinfection device comprises a reactor which is provided with a liquid inlet and a liquid outlet, wherein the inner wall of the reactor is coated with a photocatalyst coating; and an ultraviolet lamp, which is inserted into the reactor and extends along the axis direction of the reactor. According to the prepared sewage disinfection device, the synergistic effect of the photocatalyst and the ultraviolet light is utilized, and the excellent sterilization efficiency is achieved; toxic compounds in bacteria and viruses can be directly decomposed into carbon dioxide and water, bacteria and viruses are thoroughly killed, and thephoto-reactivation phenomenon of the bacteria and the viruses can be effectively inhibited.

Owner:杭州鹿扬科技有限公司

Epoxy primer coating

InactiveCN113122110AGood heat insulationImprove insulation performanceEpoxy resin coatingsReflecting/signal paintsEpoxyPolymer science

The invention discloses an epoxy primer coating, and belongs to the technical field of coatings. The invention relates to an epoxy primer coating which comprises the following components in parts by weight: 35-40 parts of epoxy resin, 45-50 parts of filler, 5-10 parts of first modified glass beads, 5-10 parts of second modified glass beads, 4-6 parts of an anti-settling agent, 5-8 parts of a diluent and 1-2 parts of a dispersing agent, wherein the first modified glass beads are prepared by ball-milling first glass beads, graphene and a first silane coupling agent; the second modified glass beads are prepared by stirring second glass beads, titanium dioxide and a second silane coupling agent, the first glass beads are hollow glass beads, and the second glass beads are solid glass beads. The coating has excellent water resistance and heat insulation performance and can effectively prevent the coating from collapsing.

Owner:武汉双虎涂料股份有限公司

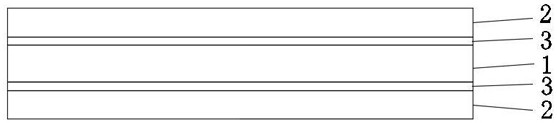

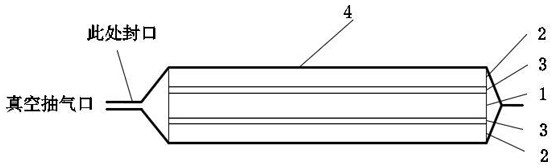

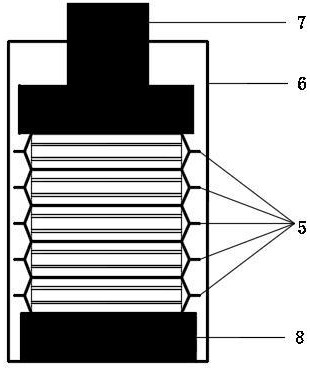

A kind of preparation method of active metal brazing copper-clad ceramic substrate

ActiveCN113953612BImprove attachment stabilityReduce void rateSemiconductor/solid-state device manufacturingSoldering auxillary devicesConductive materialsSolder paste

The invention belongs to the technical field of ceramic metallization, and in particular relates to a method for preparing a copper-clad ceramic substrate by active metal brazing; comprising: printing silver-copper-titanium active solder paste on one side of the copper plate; heating and degreasing the copper plate and the upper and lower surfaces of the ceramic plate Laminated to form a sandwich structure, the copper plate in the sandwich structure is attached with silver-copper-titanium active solder (after degreasing, the organic components of the silver-copper-titanium active solder paste are removed and transformed into powder or block silver-copper-titanium active solder) and ceramics The upper and lower sides of the board are in contact; heat-conducting materials are vacuum-packed and brazed at high temperature; the present invention adds nano-silver powder with great surface activity to the silver-copper-titanium active solder paste, thereby enhancing the solder paste on the copper plate after degreasing. Adhesion firmness: heat-conducting materials are used for vacuum packaging to adjust the vacuum degree, brazing can be completed with conventional equipment, and at the same time, the void rate of the interface can be effectively reduced, and the combination of ceramics and copper plates is more stable.

Owner:GUANGZHOU XIANYI ELECTRONICS TECH

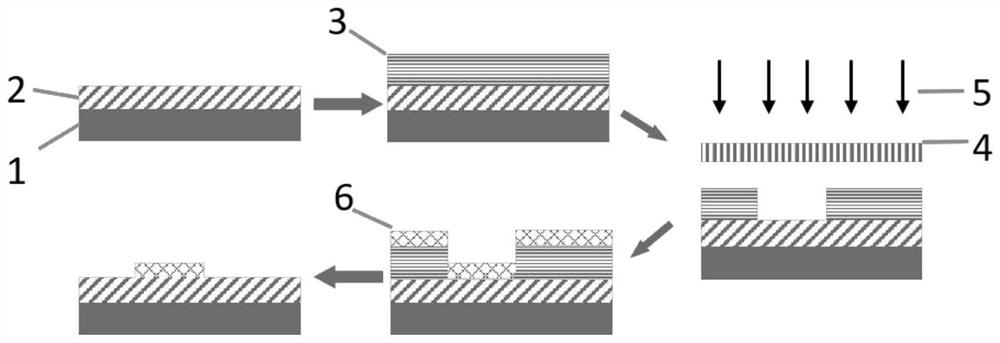

Ultraviolet lithography method for patterning and etching PEDOT:PSS transparent electrode on flexible hydrophobic group substrate

ActiveCN113054058AGood adhesionImprove stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusOrganic filmEtching

The invention relates to an ultraviolet lithography method for patterning and etching a PEDOT:PSS transparent electrode on a flexible hydrophobic group substrate. The invention aims to solve the problem that in the prior art, when a water-based solution is spin-coated on a flexible hydrophobic group substrate, good patterning and etching is difficult to achieve. The ultraviolet lithography method comprises the steps of: spin-coating polyimide on the cleaned substrate, spin-coating photoresist after curing, and drying to obtain a photoresist layer; patterning the photoresist layer by exposure of an ultraviolet lithography machine, and drying to obtain a substrate with a photoresist layer with a preset pattern; and depositing a PEDOT:PSS film on the substrate with the preset patterned photoresist layer by a spin-coating method, soaking the PEDOT:PSS film in an organic solvent, carrying out ultrasonic cleaning, and carrying out nitrogen blow-drying. The ultraviolet lithography method is applied to the field of organic film electrode processing etching and application research.

Owner:HARBIN INST OF TECH

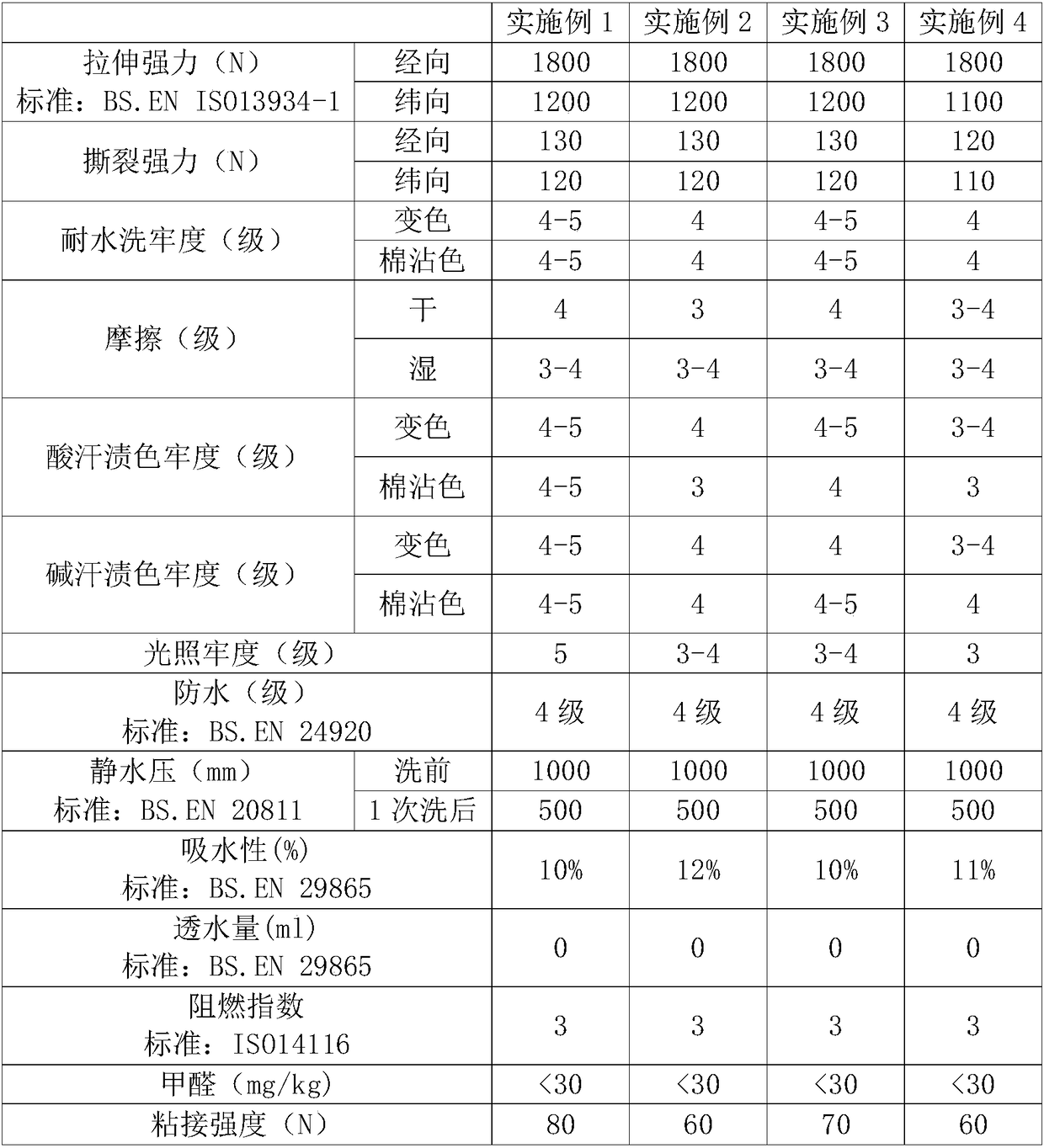

Preparation process of waterproof flame-retardant polyamide fiber fabric

InactiveCN108103768AEfficient preprocessingImprove attachment stabilityFibre typesLiquid/gas/vapor textile treatmentState of artPolyamide fibers

The invention discloses a preparation process of a waterproof flame-retardant polyamide fiber fabric, which solves the problem in the prior art that a pretreatment way capable of well ensuring the dyeing effect of synthetic fiber fabric cannot be found. The preparation process comprises a pretreatment process and a printing and waterproof flame-retardant layer coating process, wherein the pretreatment process comprises the following steps: cold rolling a gray fabric, boiling the fabric, and stereotyping the fabric, wherein when in cold rolling, caustic soda with the concentration of 35 to 45 g / L and hydrogen peroxide with the concentration of 6 to 10 g / L are used for padding the gray fabric; when in boiling, the immersion is performed in a five-time immersing and five-time rolling manner,and then the fabric is steamed; immersion additives comprise a desizing refining agent, a chelating agent, caustic soda, hydrogen peroxide and water galss, wherein the concentration of the desizing refining agent is 3 to 5 g / L, the concentration of the chelating agent is 1 to 3 g / L, the concentration of the caustic soda is 8 to 12 g / L, the concentration of the hydrogen peroxide is 4 to 6 g / L, andthe concentration of the water glass is 4 to 6 g / L; and when in the stereotyping, the speed is 85 to 95 m / min, and the temperature is 180 to 200 DEG C. The preparation process has the advantages of good dyeing effect, more stability in adhesion of a waterproof flame-retardant layer and the like.

Owner:MIANYANG GANLION PRINTING & DYEING +1

Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

ActiveCN101609848BStress reliefLess bendingFinal product manufactureSemiconductor devicesScreen printingConductive paste

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of theconductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Owner:HANWHA SOLARONE QIDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com