A kind of preparation method of active metal brazing copper-clad ceramic substrate

A copper-clad ceramic substrate and active metal technology, which is applied in the field of ceramic metallization, can solve the problems of high vacuum degree and high interface void rate, and achieve the effects of stable bonding, reduced void rate, and enhanced adhesion firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 AMB copper clad ceramic substrate

[0050] The preparation method of described AMB copper clad ceramic substrate comprises the following steps:

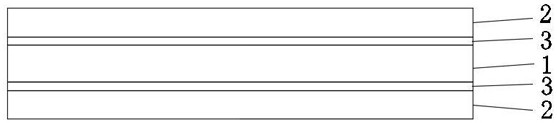

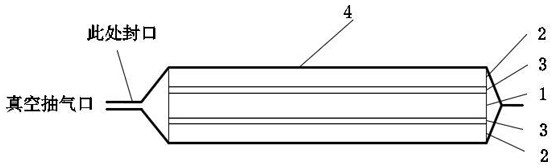

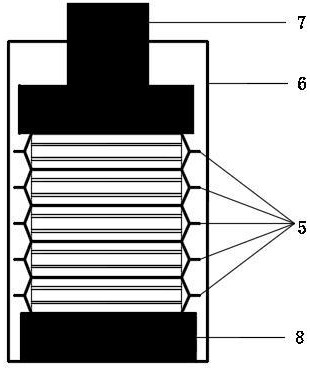

[0051] S1. Printing solder paste: dissolve 40wt% binder (halogen-free low-temperature modified rosin) and 3wt% thixotropic agent (hydrogenated castor oil) in 57 wt% diethylene glycol monobutyl ether: terpineol=7 Prepare paste raw material in the mixed solvent of 3, with 15 wt% paste raw material and 85 wt% metal powder (5wt% particle diameter is the nanometer silver powder+65wt% micron silver powder+28wt% copper powder of 50~100 nm) 2wt% titanium hydride powder) mixed and stirred to prepare silver-copper-titanium active solder paste, and then print silver-copper-titanium active solder paste with a thickness of 0.1mm on the surface of the copper plate;

[0052] S2. Degreasing treatment: Put the copper plate printed with silver-copper-titanium active solder paste obtained in step S1 into an atmosph...

Embodiment 2

[0056] Embodiment 2 Preparation of AMB copper-clad ceramic substrate

[0057] S1. Printing solder paste: dissolve 40wt% binder (halogen-free low-temperature modified rosin) and 4wt% thixotropic agent (polyurea) in 56wt% diethylene glycol monobutyl ether: terpineol = 7:3 Prepare the paste raw material in the mixed solvent of 15 wt% paste raw material and 85wt% metal powder (10 wt% particle size is the nano-silver powder+61 wt% micro-silver powder+26 wt% copper powder+ 3wt% titanium hydride powder) mixed and stirred to prepare silver-copper-titanium active solder paste, and then print silver-copper-titanium active solder paste with a thickness of 0.2mm on the surface of the copper plate;

[0058] S2. Degreasing treatment: Put the copper plate printed with silver-copper-titanium active solder paste obtained in step S1 into an atmosphere tube furnace, raise the temperature to 130°C at a rate of 3-5°C per minute under a nitrogen atmosphere, and keep it for 20 minutes to volatilize ...

Embodiment 3

[0062] Embodiment 3 Preparation of AMB copper-clad ceramic substrate

[0063] S1. Printing solder paste: Dissolve 40wt% binder (acrylic resin) and 2wt% thixotropic agent (polyurea) in 58 wt% diethylene glycol monobutyl ether: terpineol = 7:3 mixed solvent Prepare the paste raw material in , with 15 wt% paste raw material and 85 wt% metal powder (30 wt% particle diameter is the silver-copper of the nanometer silver powder+35 wt% micron silver powder+32 wt% silver copper of 200~500nm (Ag:Cu =1:1) alloy powder + 3 wt% titanium hydride powder) mixed and stirred to prepare silver-copper-titanium active solder paste, and then print silver-copper-titanium active solder paste with a thickness of 0.3mm on the surface of the copper plate;

[0064] S2. Degreasing treatment: Put the copper plate printed with silver-copper-titanium active solder paste obtained in step S1 into an atmosphere tube furnace, raise the temperature to 130°C at a rate of 3-5°C per minute under a nitrogen atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com