Ultraviolet lithography method for patterning and etching PEDOT:PSS transparent electrode on flexible hydrophobic group substrate

A transparent electrode and hydrophobic base technology, which is applied in the field of ultraviolet lithography, can solve problems such as difficult pattern etching, and achieve the effects of increasing adhesion, increasing adhesion stability, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

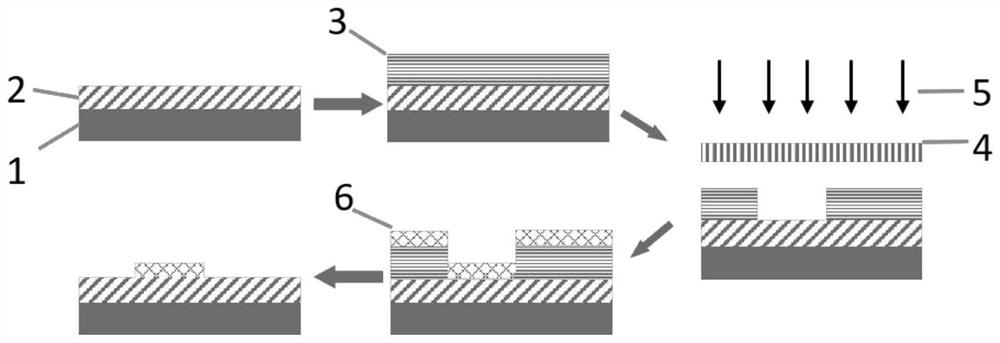

[0023] DETAILED DESCRIPTION OF THE INVENTION First: The present embodiment is patterned on a flexible hydrophobic substrate: an ultraviolet photolithography method of PSS transparent electrodes, and is completed in the following steps: 1. Coating polyaltritis on the cleaned substrate Impromine, after drying, animalized substrate;

[0024] Second, in the imidized substrate, the photoresist, dry, repeat the rubber, drying step, to obtain a photoresist layer; the rotation speed of the hierarchy machine is 1000 rpm-3000 rpm, the spin coating time is 30s -60S;

[0025] Third, using an ultraviolet exciithography, a mask is exposed to the photoresist, and then develops a substrate with a preset pattern photoresist layer after drying;

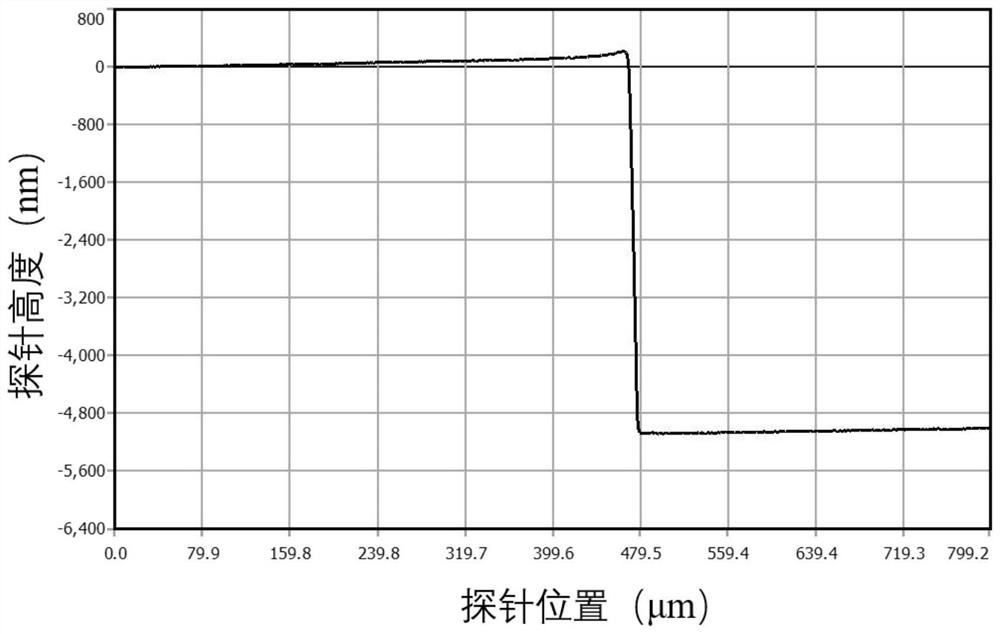

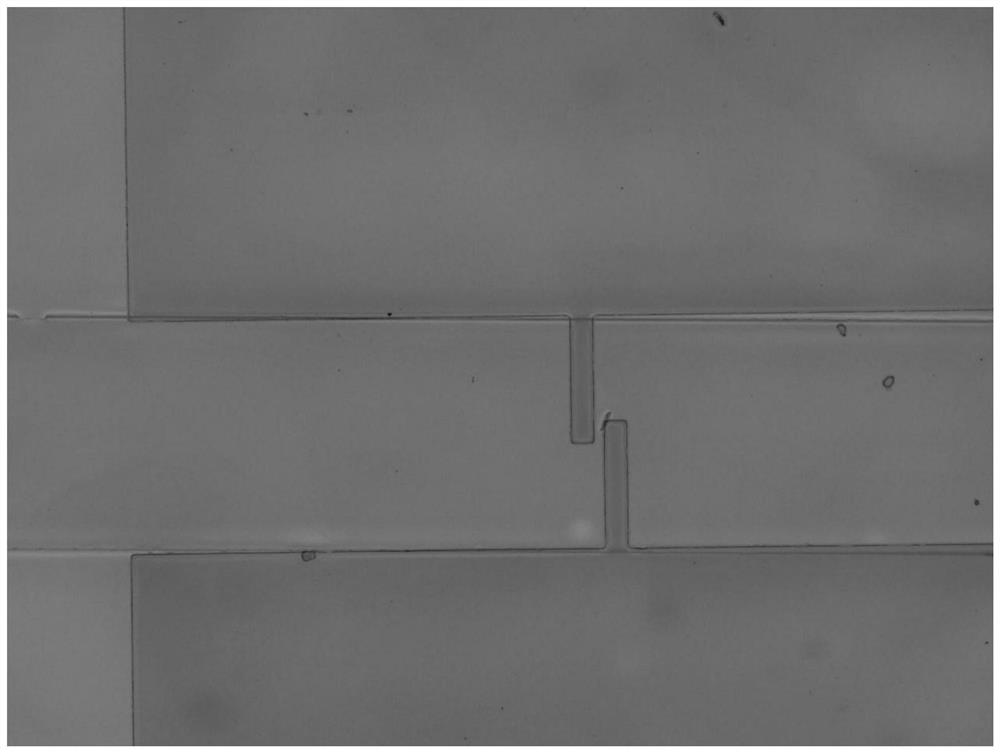

[0026] Fourth, use a homogenate in the photoresist layer with a preset pattern, a solution of PSS, heating, drying, drying temperature is 50 ° C to 70 ° C, time is 60s-180s; then placed in organic Soak and oscillated in the solvent, ultrasonic cleaning, an...

specific Embodiment approach 2

[0027] DETAILED DESCRIPTION OF THE INVENTION Different: The present embodiment differs from the specific embodiment that the hierarchical rotation speed is 1000 rpm to 5000 rpm, and the spin coating time is 30 s-60s. Others are the same as those of the specific embodiments.

specific Embodiment approach 3

[0028] BEST MODE FOR CARRYING OUT THE INVENTION The present embodiment is different from that of the particular embodiment: the solid content of the polyimide solution is 20% and the viscosity is 5000-6000 cp. Others are the same as those of the specific embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com