Front and back surface electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof

A solar cell, screen printing technology, applied in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as the high cost of crystalline silicon solar power generation, increased battery manufacturing costs, and battery bending deformation, etc. The effect of reducing the welding chip rate of components, enhancing the adhesion and reducing the degree of bending

Active Publication Date: 2010-12-01

HANWHA SOLARONE QIDONG

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of conductive paste increases the production cost of the battery, and leads to the bending deformation of the battery after the battery is sintered. The bending of the battery in the welding interconnection leads to an increase in the fragmentation rate and other factors, which make the cost of crystalline silicon solar power generation high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

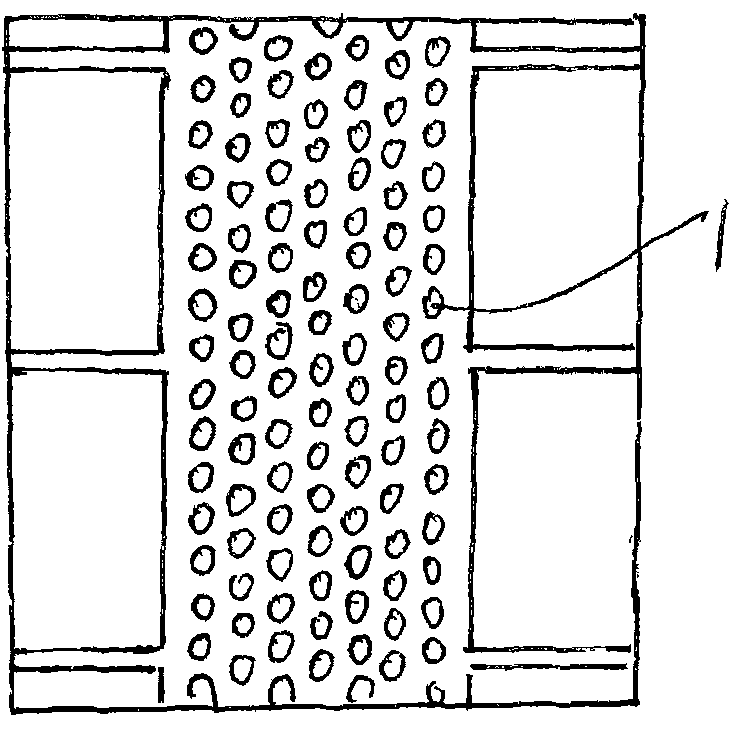

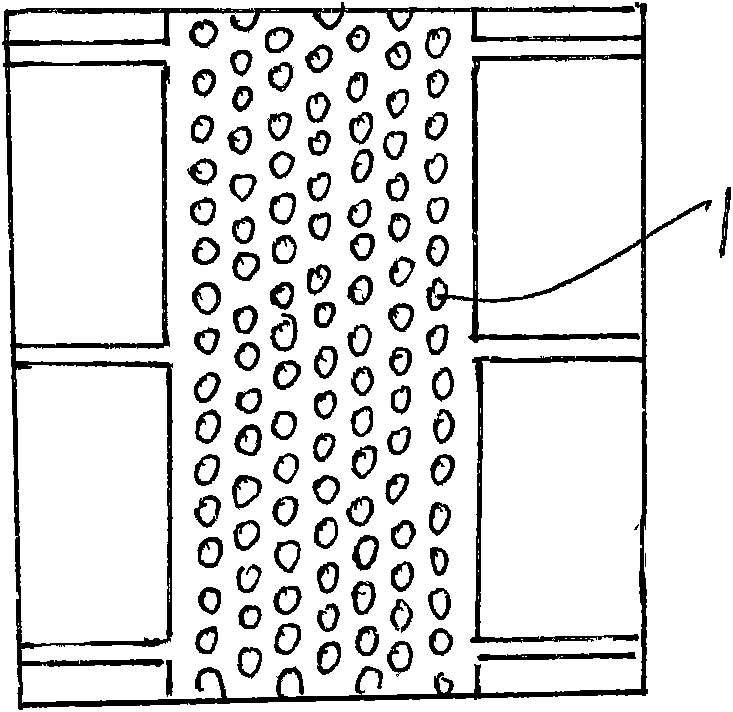

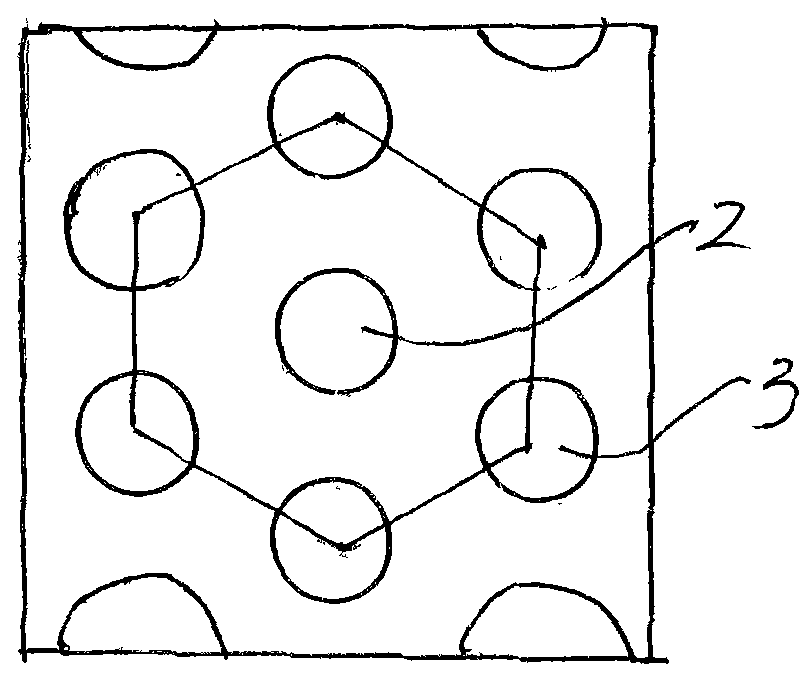

The invention discloses front and back surface electrodes of a screen printing crystalline silicon solar cell and a manufacturing method thereof; array points which are not printed into conductive paste are manufactured in an electrode main gate line; and the graphics of each array point is in a closed type. The manufacturing method comprises the step of arranging latex film array points on the screen printing plate electrode main gate line for blocking the conductive paste. The positive and back surface electrodes of the screen printing crystalline silicon solar cell and the manufacturing method thereof can effectively save the conductive paste on the positive and back surfaces of the crystalline silicon solar cell, and effectively eliminate the stress caused by different expansion coefficients of silver silicon alloy and silicon, thereby reducing the bending rate of a cell film and the welding debris rate of a component; the invention can enhance the adhesion firmness of the main gate line conductive paste on the silicon surface after being sintered and effectively solve the falling-off problem of a silver main gate line; and the invention reduces the surface contact area of theconductive paste and the silicon, and increases the open-circuit voltage and the short-circuit current.

Description

Front and back electrodes of screen printing crystalline silicon solar cell and manufacturing method thereof Technical field: The invention relates to a front and back electrode of a screen printing crystalline silicon solar cell and a manufacturing method thereof. Background technique: Crystalline silicon solar cells are semiconductor devices that directly convert light energy into electrical energy. The current generated inside the semiconductor needs to be collected by positive and negative electrodes and drawn out to connect to external circuits. In addition to the function of collecting and drawing current, the main grid lines of the positive and negative electrodes also have the functions of testing and sorting solar cells, welding and interconnecting individual solar cells, thereby increasing the output power; in order to reduce the shading loss of the electrode and the electrode The series resistance loss caused by the resistance, the production of the electrode requir...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L31/0224H01L31/18

CPCY02P70/50

Inventor 顾生刚王景霄陈文浚祁阳夏正月马跃

Owner HANWHA SOLARONE QIDONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com