Manufacturing device and manufacturing method of battery pole plate

A battery electrode plate and manufacturing device technology, applied in electrode manufacturing, battery electrode, spray manufacturing, etc., can solve the problems of complex process method, complex process, poor environmental friendliness, etc., and achieve simple process, uniform coating, and stable adhesion. Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

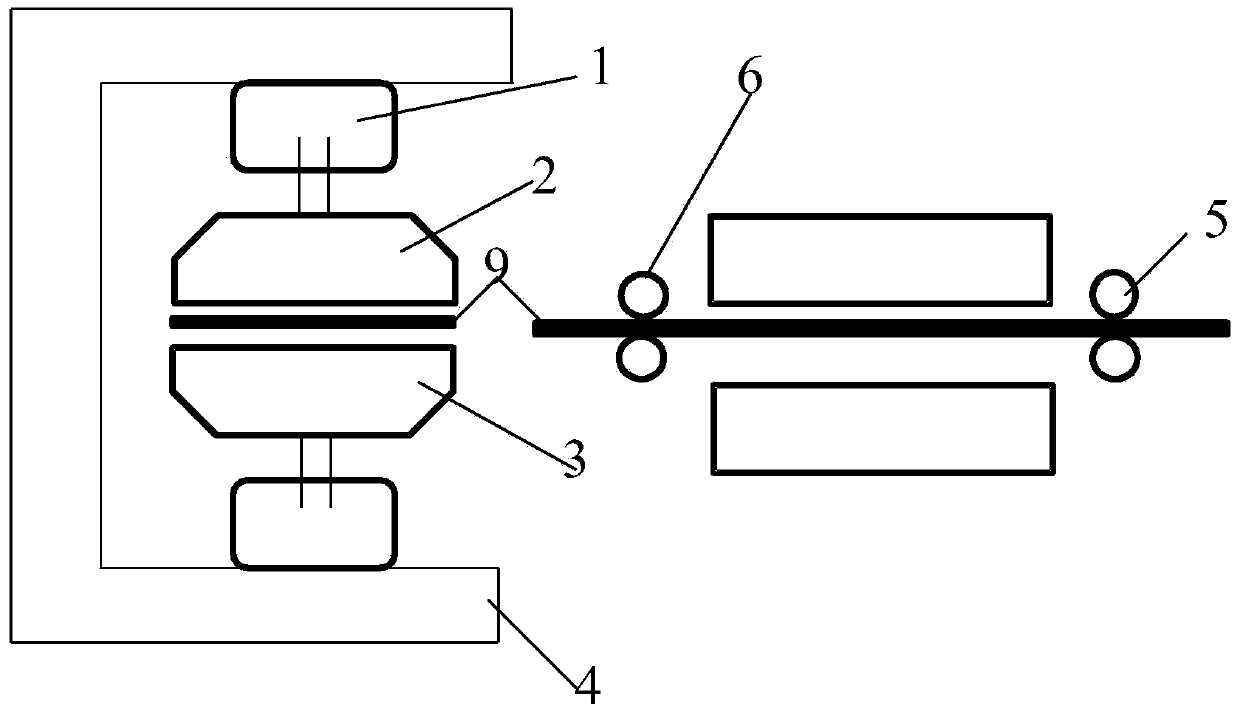

[0026] Such as figure 1 As shown, the battery pole plate manufacturing device (Example 1) of the present invention includes a mold fixture 1, a first upper mold 2, a first lower mold 3, a hydraulic press 4, a pole plate pulling device 5, a pole plate feeding device 6, and a battery The plate blank 9 is pulled by the plate pulling device, and the plate feeding device is sent between the first upper mold 2 and the first lower mold 3, and the first upper mold 2 and the first lower mold 3 are assembled in the mold fixture In 1, the mold clamp 1 is fixed on the hydraulic press 4, the first upper mold 2 and the first lower mold 3 are fixed molds, and the surface of the first upper mold 2 and the surface of the first lower mold 3 have concavo-convex shapes that cooperate with each other. For example, the mold can adopt a flat plate device with concave lines, and the above-mentioned lower mold needs to use a flat plate device with convex lines. According to the characteristics of the ...

Embodiment 2

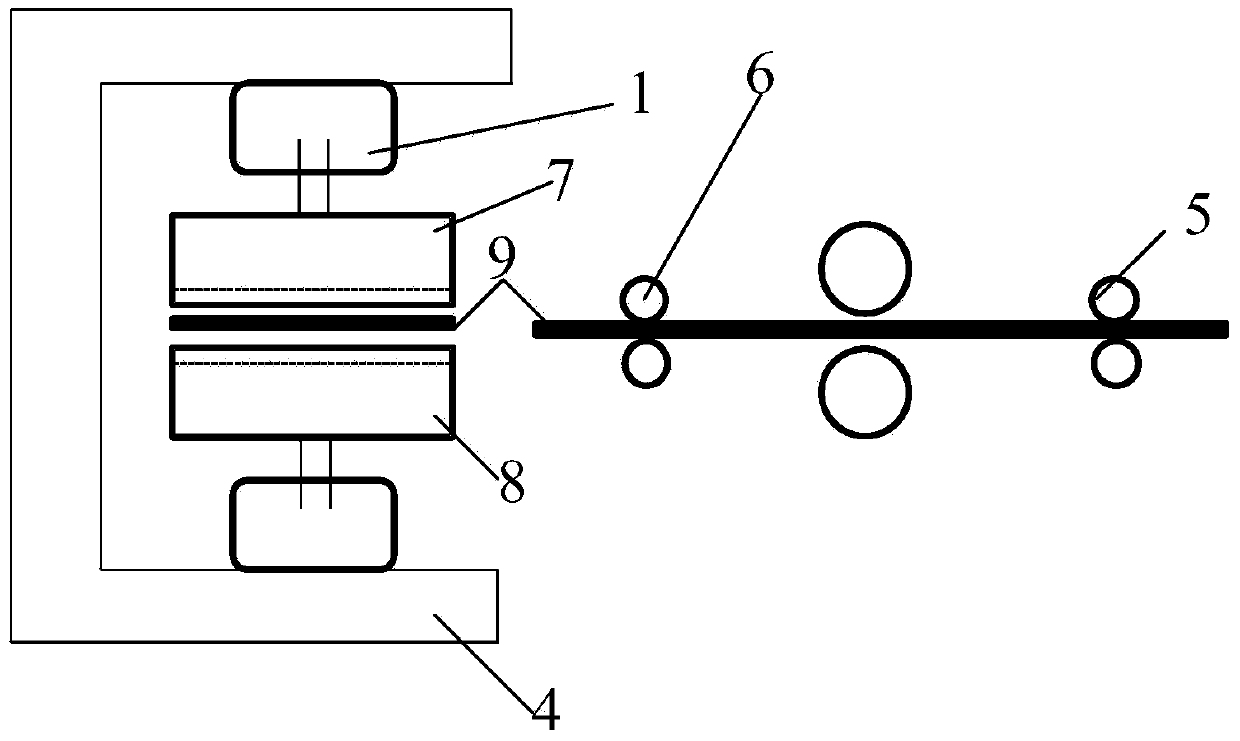

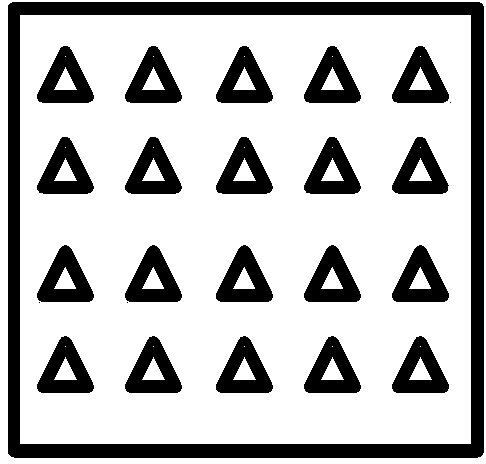

[0032] Such as figure 2 As shown, the second embodiment is basically the same as the first embodiment, the difference is that the second upper mold 7 and the second lower mold 8 are both rotating molds, and the second upper mold 7 can adopt a rotating mold with concave lines device, the second lower mold 8 needs to adopt a rotating mold device with convex lines, and according to the use characteristics of the rotating mold type mold, the concave lines of the second upper mold can be wave-shaped (Figure 3 (g)). The depth of the concave lines is 0.001 mm to 1 mm, and the distance between the central axes of the concave wavy shape is 1 mm to 10 mm. The rotary mold adopts continuous feeding method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com