Colored liquid metal printing ink and preparation method thereof

A liquid metal, printing ink technology, applied in ink, household appliances, applications, etc., can solve the problems of poor compatibility, unsatisfactory uniformity and stability of color liquid metal materials, etc., to improve the wetting ability and adhesion stability. Sexual, rich color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

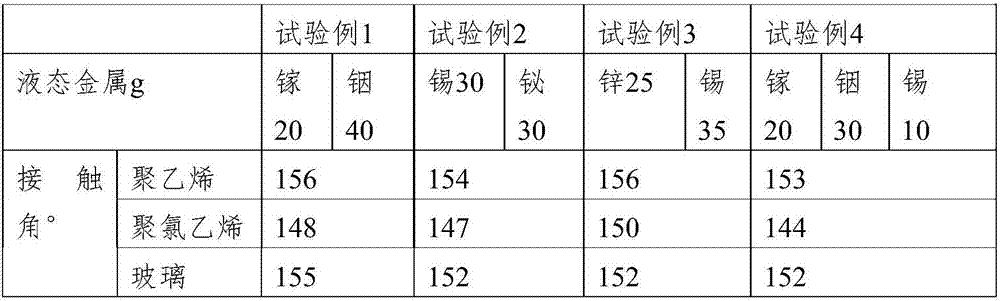

[0049] Experimental example wettability test

[0050] The liquid metal formed by gallium and indium at a mass ratio of 1:2, the contact angle measurement data on different substrates are as follows: 156 degrees on polyethylene plastic, 148 degrees on polyvinyl chloride plastic, 149 degrees on polyethylene terephthalate, 148 degrees on nitrile rubber, and 155 degrees on glass substrates, which cannot be printed on the above substrates by screen printing. The contact angle data of other alloys on different substrates are shown in Table 1.

[0051] Directly adding pigment (pigment orange 36, 5g) to gallium indium alloy 60g has no significant change in contact angle, and it cannot be printed by screen printing.

[0052] Add color paste (prepared with the step 1 method of embodiment 1) in gallium indium alloy 60g, the contact angle measurement result is: 145 degrees on polyethylene plastics, 140 degrees on polyvinyl chloride plastics, polyethylene terephthalate 140 degrees on est...

Embodiment 1

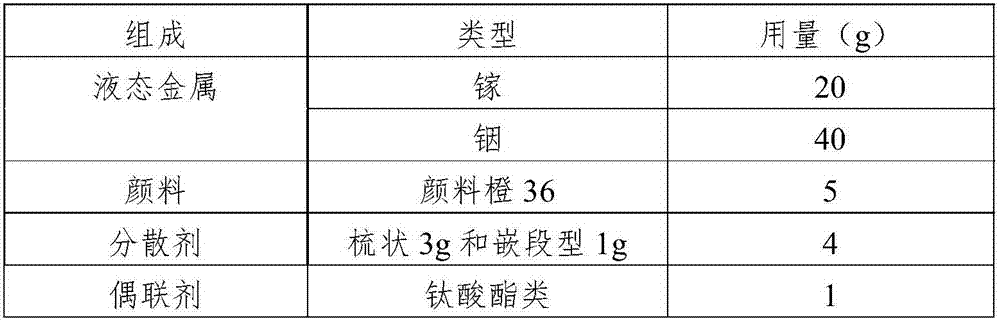

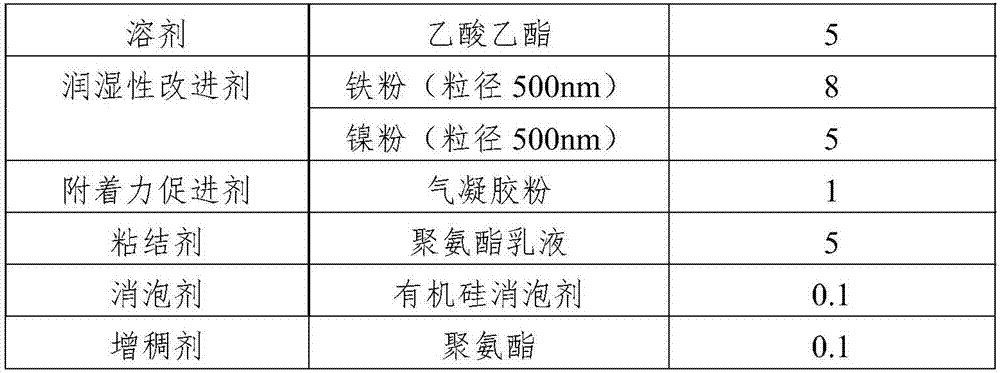

[0058] The formula composition of high wettability color liquid metal printing ink is shown in the following table:

[0059]

[0060]

[0061] Comb and block type in the formulation represent comb-like polymer dispersant and block polymer dispersant respectively.

[0062] The preparation method of the high wettability color liquid metal printing ink of this embodiment comprises the following steps:

[0063] Step 1: Preparation of color paste, add dispersant and coupling agent to the solvent according to the above formula, stir with disperser until uniformly dissolved, add defoamer and thickener (in two batches, add half first) to remove foam, add the pigment powder into the above dispersion liquid, fully disperse at 1000r / min for 60min, after the pigment is wetted and dispersed evenly, transfer the mixed slurry to a horizontal sand mill, use zirconia particles as the grinding medium in the Grind for 2 hours under the condition of 5000r / min, add the remaining thickener, ...

Embodiment 2

[0068] The formula composition of high wettability color liquid metal printing ink is shown in the following table:

[0069]

[0070]

[0071] The preparation method of the high wettability color liquid metal printing ink of this embodiment comprises the following steps:

[0072] Step 1: Preparation of color paste, add dispersant and coupling agent to the solvent according to the above formula, stir with a disperser until uniformly dissolved, add half of the defoamer and thickener to remove foam, and add the pigment powder to the above In the dispersion liquid, fully disperse at 800r / min for 40min. After the pigment is wetted and dispersed evenly, transfer the mixed slurry to a horizontal sand mill, and use zirconia particles as the grinding medium to grind at 3000r / min for 2h. , add the remaining thickener, make the viscosity of the color paste obtained by filtration be 3900cp, and obtain the color paste by filtration.

[0073] Step 2: Prepare the liquid metal alloy, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com