Patents

Literature

298results about "Shrinking resistant fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

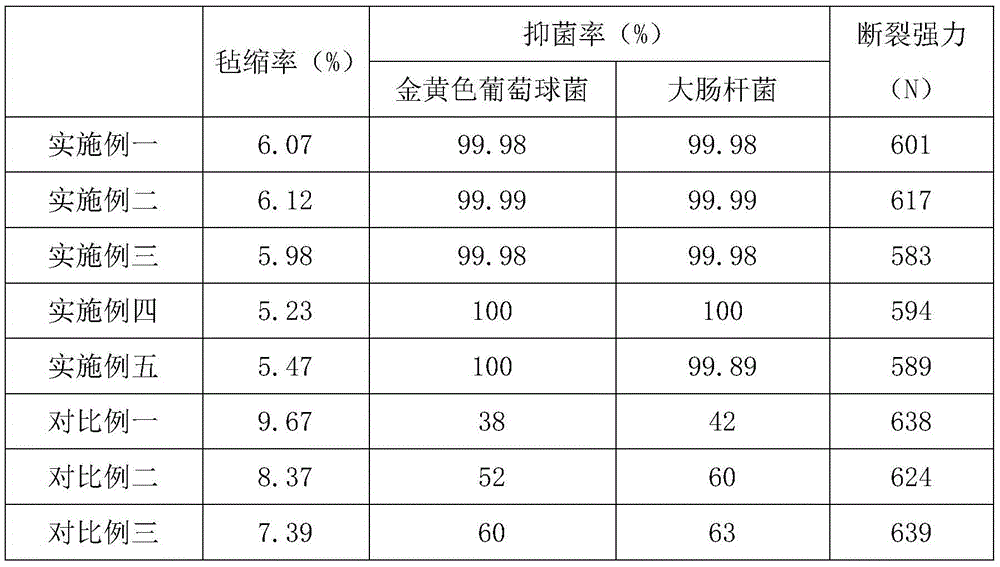

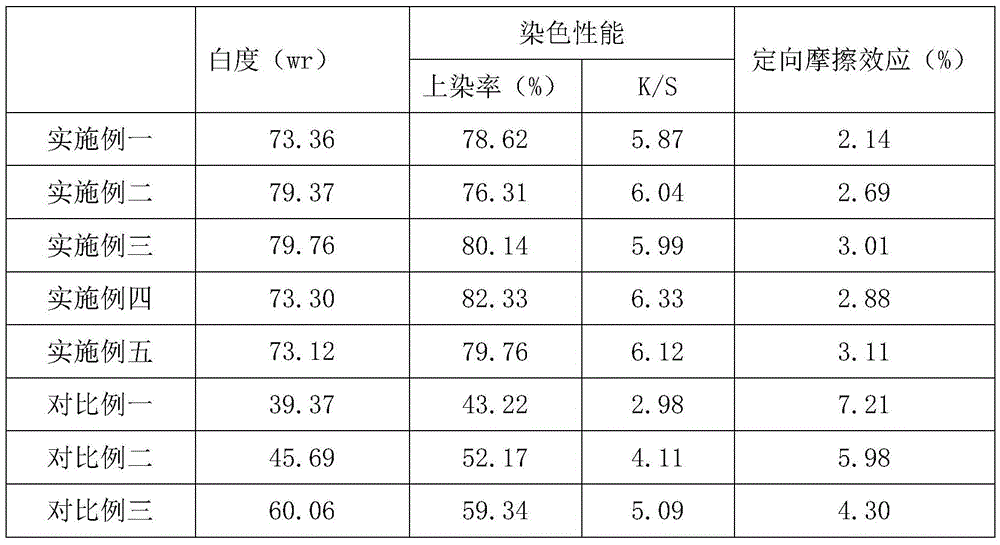

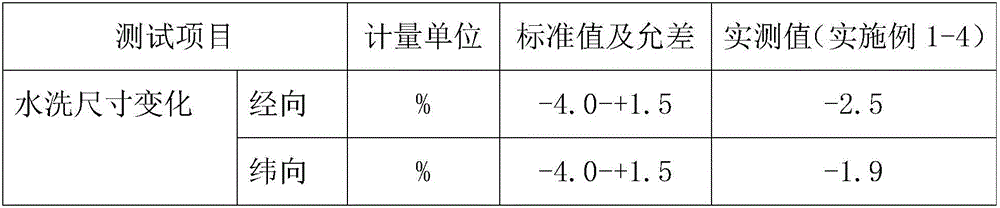

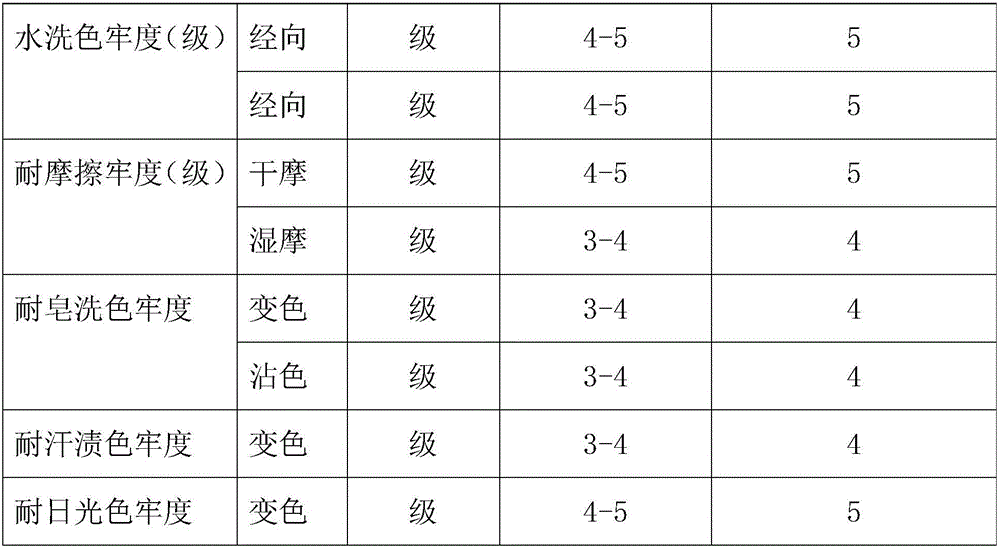

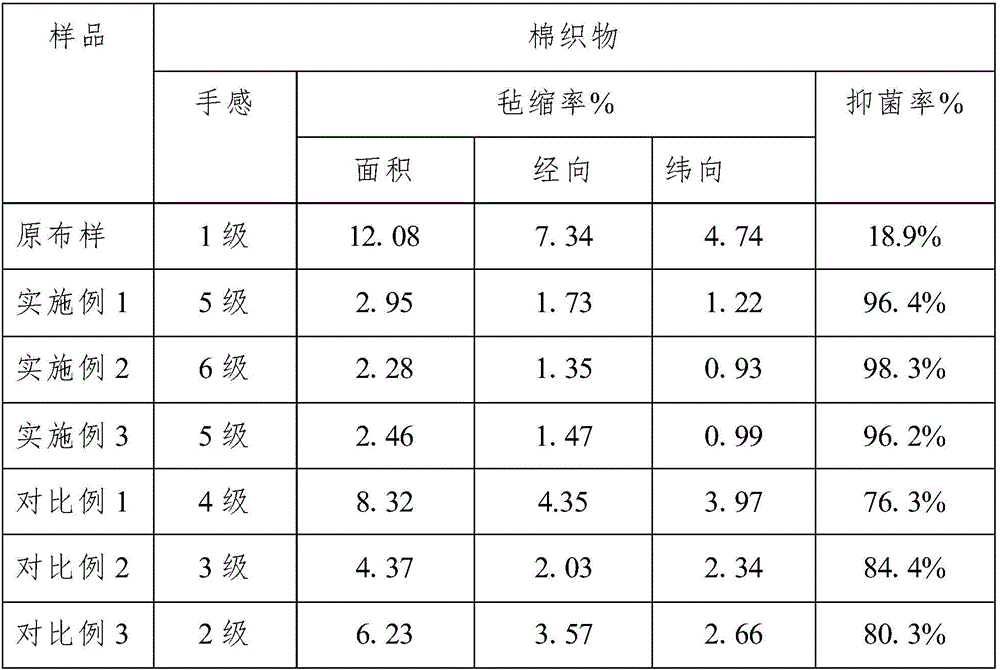

Antibacterial and anti-felting wool fabric finishing method

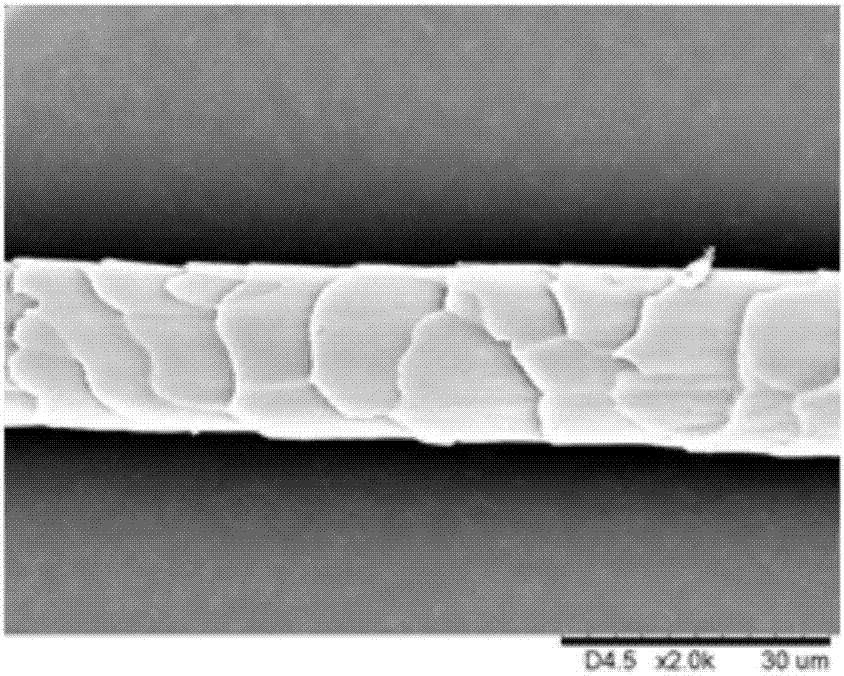

InactiveCN105544198AImprove antibacterial propertiesPrevent intrusionBiochemical treatment with enzymes/microorganismsShrinking resistant fibresTextile technologyFriction effect

Owner:海阳英伦纺织有限公司

High-count pure-cotton formaldehyde-free bright adhesive interlining and production method thereof

ActiveCN104544647AImprove the quality levelReduce qualityGarmentsDyeing processColour fastnessInterlining

The invention discloses a high-count pure-cotton formaldehyde-free bright adhesive interlining and a production method thereof. The high-count pure-cotton formaldehyde-free bright adhesive interlining is characterized in that the surface of a coating is bright; the free formaldehyde and hydrolysis formaldehyde are less than 20mg / kg; the peeling strength of hot melt adhesive points is not less than 10N; the warp and weft water washing dimension change rate is -1.0 to 0.5%; the colorfastness to washing is not less than 4-5 levels. The adhesive interlining is free of formaldehyde, so that the processed clothes can be healthy and safe; the surface is bright, thus the quality and level are increased, and the defects such as missing point and missing coating can be easily found during appearance inspection, and as a result, the loss on degradation caused by that the defect of the adhesive interlining is not influenced before being manufactured into clothes products can be avoided for a clothes enterprise; adhesive interlining is high in peeling strength, small in wrap and weft shrinkage, and high in color fastness, so that the quality of high-level clothes cannot be decreased due to poor color fastness of the adhesive interlining; the production method is easily operated, and environmentally friendly.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

Antibacterial wash-and-wear fire-retardant finishing liquid and finishing method thereof

InactiveCN105586768AImprove adsorption capacityGood compatibilityBiochemical fibre treatmentHeat resistant fibresPhosphateGlyoxal

The invention discloses an antibacterial wash-and-wear fire-retardant finishing liquid which is prepared from the following raw materials in parts by weight: 10-15 parts of glyoxal, 10-15 parts of citric acid, 5-8 parts of cyclic phosphate, 5-8 parts of a licorice extract, 3-5 parts of chitosan, 2-3 parts of magnesium chloride, 2-3 parts of sodium hypophosphite, 1-2 parts of a penetrant, 1-2 parts of a coupling agent, 1-2 parts of a softener, 1-2 parts of ethylene glycol, 1-2 parts of a fiber protecting agent, 1-2 parts of a pH adjusting agent and 1-2 parts of a dispersant. The prepared multifunctional antibacterial finishing liquid is environment-friendly and free of pollution, has good efficacies of being wash-and-wear, shrink-proof, antibacterial and flame-retardant, and can meet the requirements of people on various functional aspects of textiles.

Owner:SUNTEX

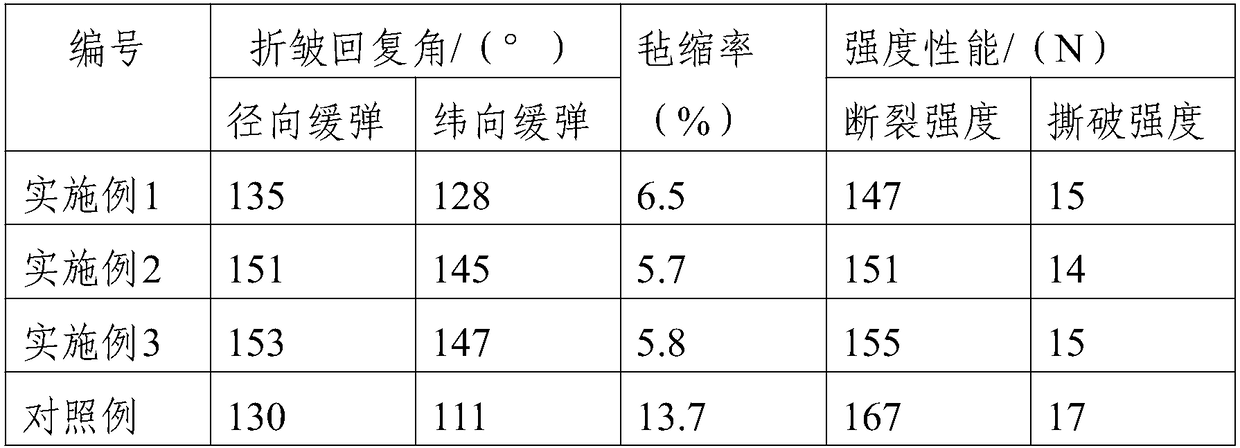

High-quality wide bamboo fiber woven fabric and production method thereof

ActiveCN105177819ASimple production processEasy to operateSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention discloses high-quality wide bamboo fiber woven fabric and a production method thereof. The production method includes the steps of singeing, preprocessing, dyeing, shrink-resistant finishing, anti-pilling finishing, mechanical pre-shrinking, inspection and package. The dyeing technology is carried out on a large-capacity jig dyeing machine. The production technology is simple, operation is convenient, product performance is excellent, the warp and weft direction washing dimension change of the fabric ranges from -3% to 1.0%, the anti-pilling level is larger than or equal to the third to fourth level, and color fastness is larger than or equal to the fourth level.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Dyeing and finishing method for cotton-Dacron blended fabric

The invention discloses a dyeing and finishing method for a cotton-Dacron blended fabric. The method is characterized by comprising the following steps: (S1) carrying out pretreatment, (S2) carrying out dyeing, (S3) carrying out softening and non-shrink, and (S4) sizing, wherein the pretreatment step comprises the steps of sequentially carrying out cold composting, oxygen bleaching and mercerization, and the dyeing step adopts a disperse dye and reactive dye dispersed bath-method for dyeing. In addition, according to the dyeing and finishing method for the cotton-Dacron blended fabric, disclosed by the invention, the method is simple, energy-saving and low-consumption, the dyeing is uniform, the color fastness is high, the color and luster are plump, and the hand feeling is soft.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Pure cotton bright black adhesive interlining and production method thereof

ActiveCN105696375APrevent penetrationNo skippingWrinkle resistant fibresDyeing processCoated surfaceInterlining

The invention discloses a pure cotton bright black adhesive interlining and a production method thereof. The production method comprises the steps of edge turning, refining, dyeing, chemical shrink resistance finishing, black HDPE powder bright coating, mechanical preshrinking and the like. The adhesive interlining is bright black in coating surface; after the adhesive interlining and a colorful thin type garment material are fitted, the problem of bright white hot melt adhesive speckles will not be generated, and the garment quality is improved. The defects of leakage points, leakage coating and the like can be easily detected during appearance inspection, and it is ensured that a clothing enterprise will not generate degradation losses of products by using a defected adhesive interlining. The free and hydrolysis methyl aldehyde of the adhesive interlining is smaller than or equal to 35 mg / kg, and the warp and weft washing dimensional change rate ranges from -0.8% to +0.5%.The production method is easy to operate, environmentally friendly and excellent in product performance.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD

Production process of colorful soft denim

InactiveCN105803761AShrinkage stableStable weightInspecting textilesLiquid/gas/vapor removalGramShrinkage rate

The invention discloses a production process of colorful soft denim. The production process comprises the specific steps as follows: pre-treating; feeding cloth-immersing in water and penetrating-straightening weft; and overfeeding-drying-dyeing-dehydrating-washing with ferment-washing and whitening-feeding a softening agent-sizing. By virtue of the process, the air permeability can be effectively improved, the light shading property is reduced, the perspective property of a fabric is avoided and an ultra-soft denim fabric with soft and light texture is prepared; a condition that the denim is faded can be effectively reduced, the stability of the shrinkage rate and the gram weight of the denim are guaranteed and the sizing property is good; and an optimal fabric condition is created for clothes manufacturing. Meanwhile, the problems of traditional denim that the color is single, a fabric surface style is dull and visual impact is lacked are solved, and the trend of times is adapted.

Owner:TAICANG QIDE GARMENT

Continuous processing technology for non-shrink treatment of chlorine-free wool top and wool product

ActiveCN105986484AQuick contactAct quicklySucessive textile treatmentsSolvent-treatmentWater chlorinationPulp and paper industry

Owner:天津市诺奥科技发展股份有限公司

Production process of wool terylene blended smooth double-faced woolen goods

ActiveCN108456965AEasy to organizeHair to smoothLiquid/gas/vapor treatment of propelled fabricsDyeing processYarnPulp and paper industry

The invention provides a production process of wool terylene blended smooth double-faced woolen goods. The production process of the smooth double-faced woolen goods includes the steps: sufficiently mixing wool fibers and terylene fibers; spinning the mixed wool fibers and terylene fibers into yarns of 13 / 1 metric number by an open-end spinning frame; weaving the spun yarns on a rapier loom; performing edge sewing, fulling, scouring, dewatering, drying, decating, teasel raising, drying, anti-shrinking finishing, dyeing, softening finishing, scalding, cutting, decating and the like on a woven gray fabric to prepare a finished product. The total number of warp yarns is 6100-6300, the acting reed width is 195-200cm, porter / permeating number is 35 / 9, weft density is 285-290 yarns / 10cm, and theweight of a fabric billet is 930-950g / m<2>. The fabric is fine, smooth and soft in hand feeling, compact in texture, bright in color and high in color fastness and does not easily felt after being washed with water.

Owner:江阴市长泾花园毛纺织有限公司

Shrink-proof moisture-absorbing quick-dry type easy-care finishing liquid for shirts and finishing method of shirts

InactiveCN106758202AGood film formingImprove anti-shrinkage and anti-wrinkle effectHeating/cooling textile fabricsLiquid/gas/vapor removalPotassium hydroxideGlycerol

The invention discloses shrink-proof moisture-absorbing quick-dry type easy-care finishing liquid for shirts and a finishing method of the shirts. The shrink-proof moisture-absorbing quick-dry type easy-care finishing liquid is prepared from octamethyl cyclotetrasiloxane, 2,4,6,8-tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane, potassium hydroxide, hexadecyl trimethyl ammonium bromide, butyl acrylate, acrylic acid, 2-methoxyethyl acrylate, potassium peroxodisulfate, an appropriate amount of octaphenyl polyoxyethyiene, propylene glycol, glycerol, butanetetracarboxylic acid, ammonium citrate, triethanolamine, butenoic acid, sodium hypophosphite, boric acid, diphenylethylene disulfonate derivatives, etherified modified amino polysiloxane, amino silicon oil, iso-tridecanol polyoxyethylene ether and an appropriate amount of deionized water. The shrink-proof moisture-absorbing quick-dry type easy-care finishing liquid for the shirts has the advantages that the finishing liquid has the shrink-proof, quick-dry and easy-care effects and is capable of keeping good fabric hand feel and making fabrics comfortable to wear; the finishing liquid is safe and environment friendly without releasing formaldehyde and harming human health and makes the finished shirts machine washable, normally aired without ironing and highly resistant to creases without deformation, thereby being worthy of popularization.

Owner:阜阳市豹子头服饰科技有限公司

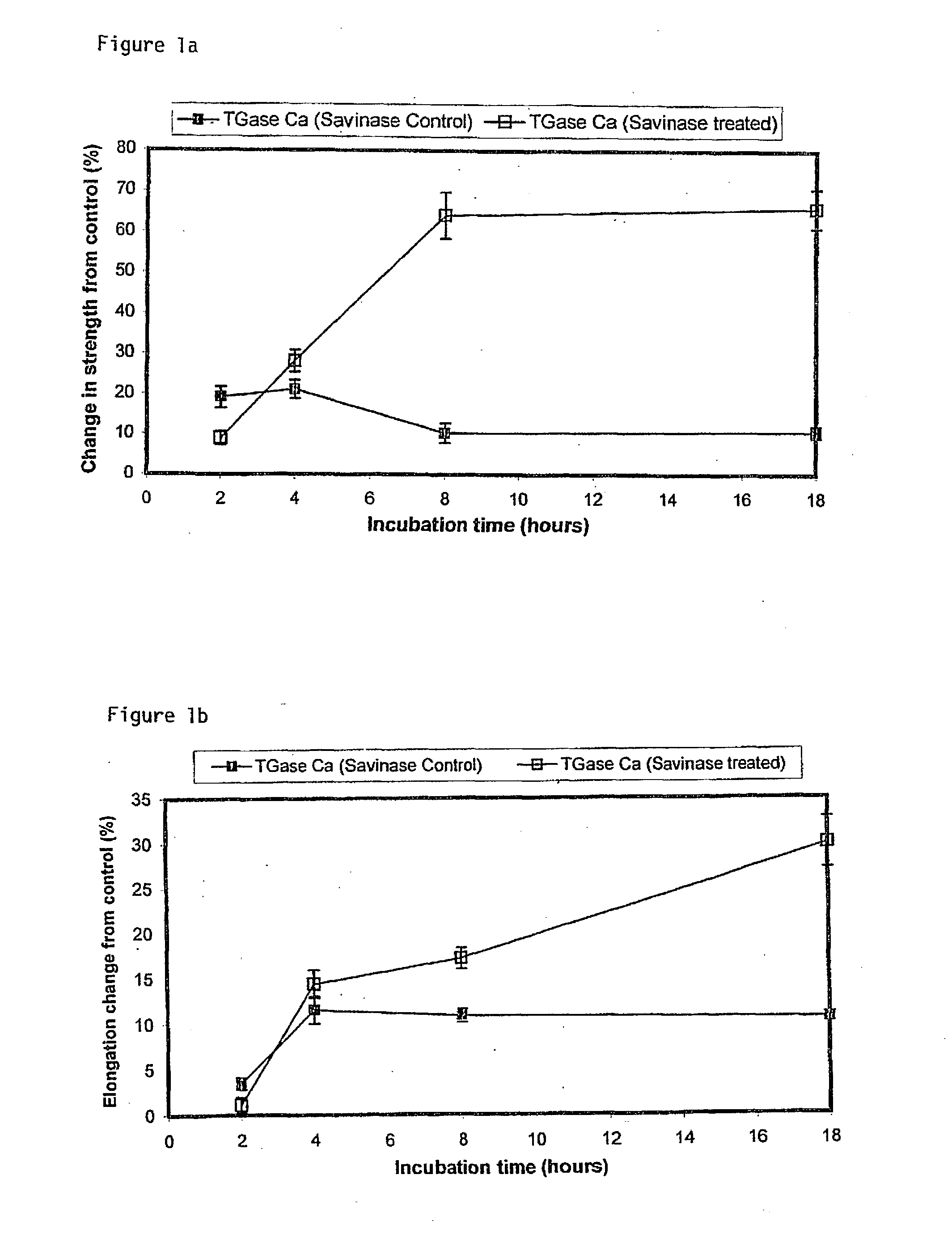

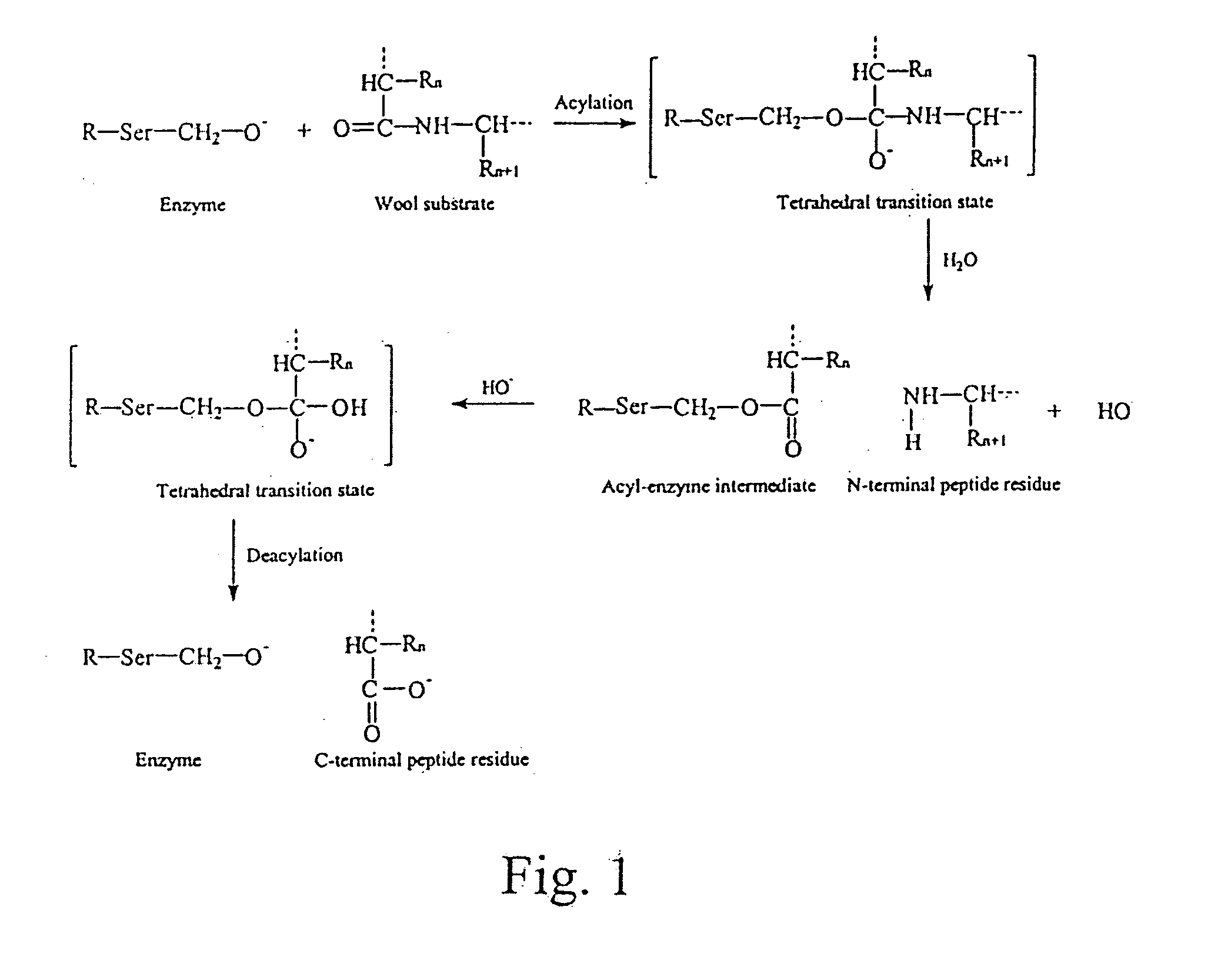

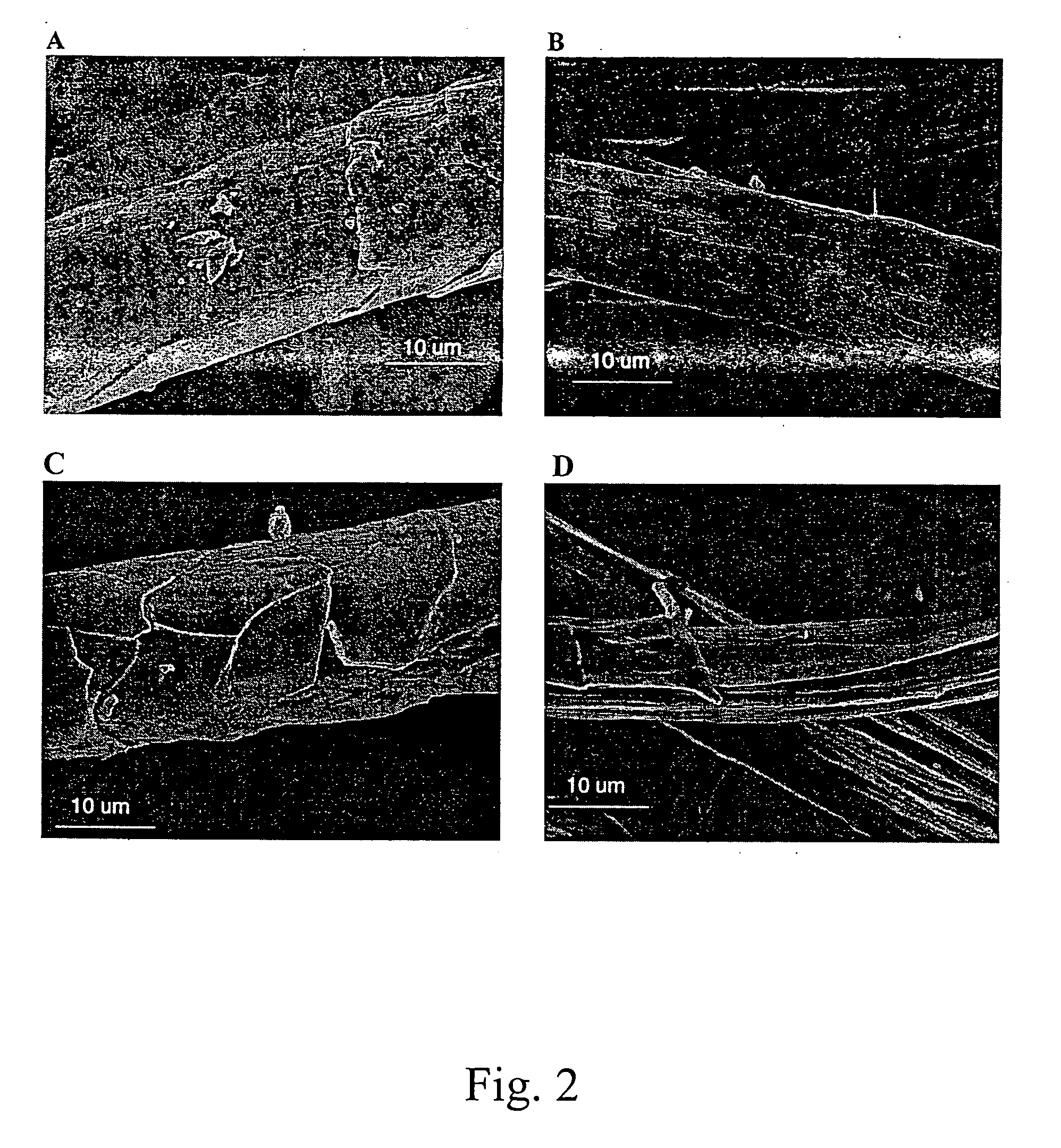

Method for enzymatic treatment of textiles such as wool

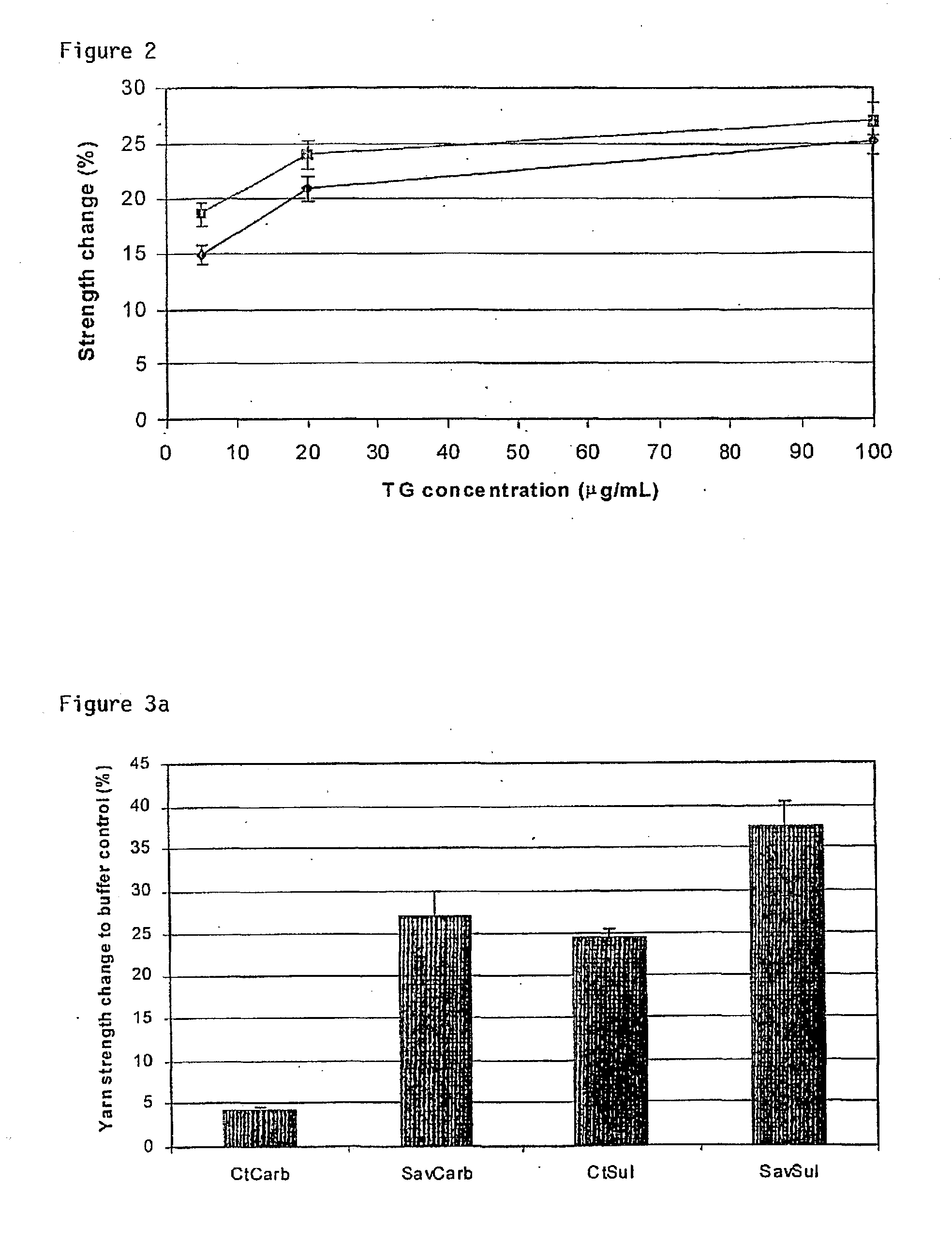

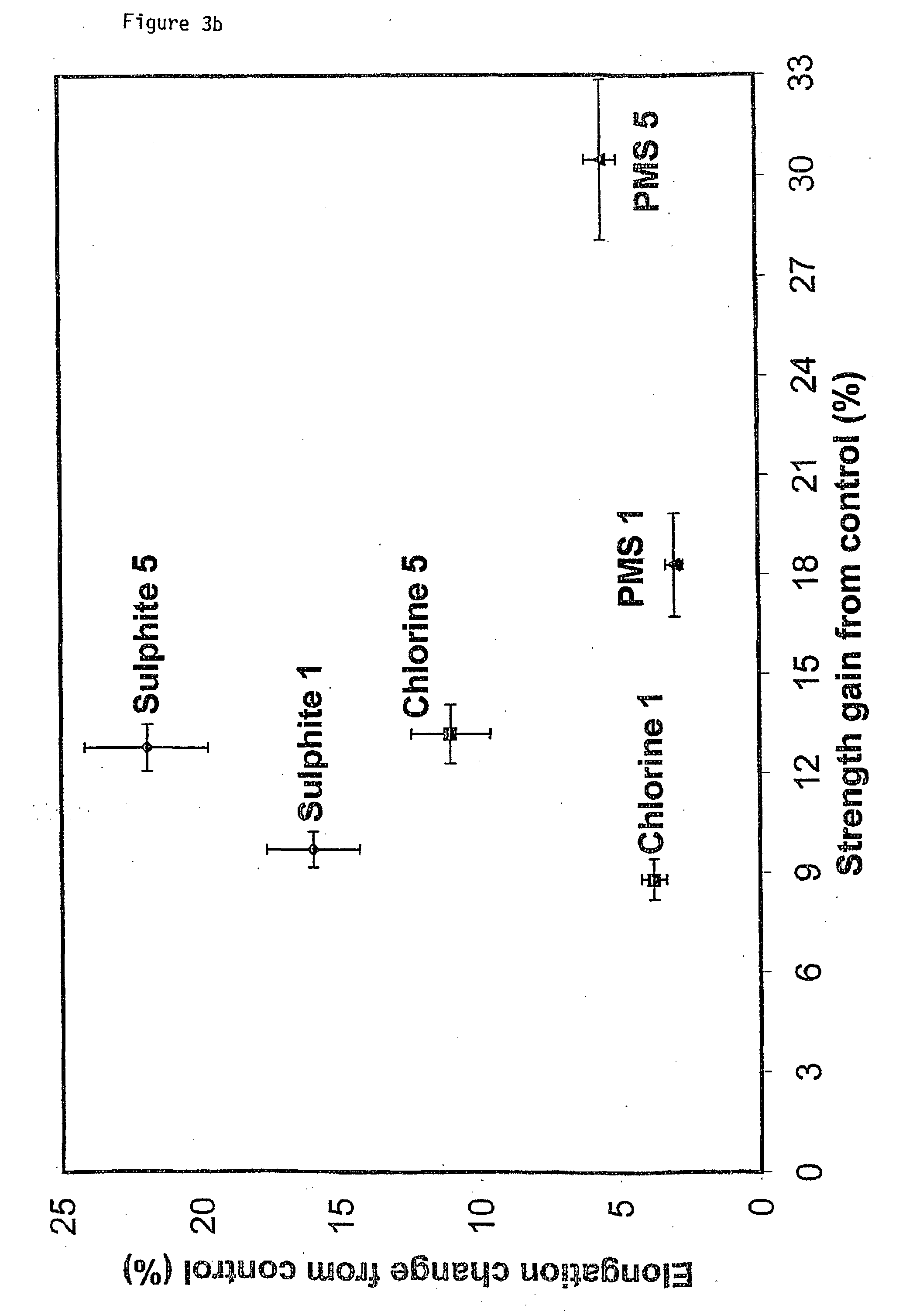

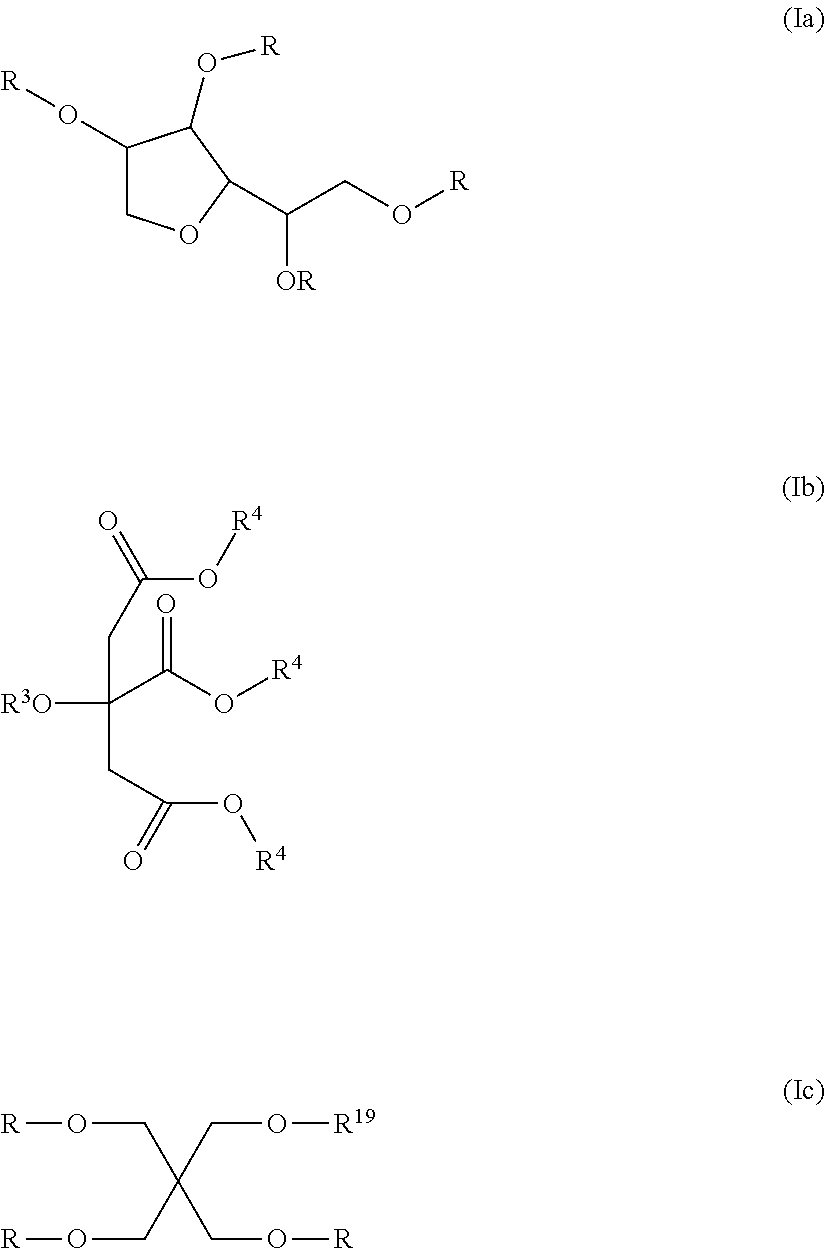

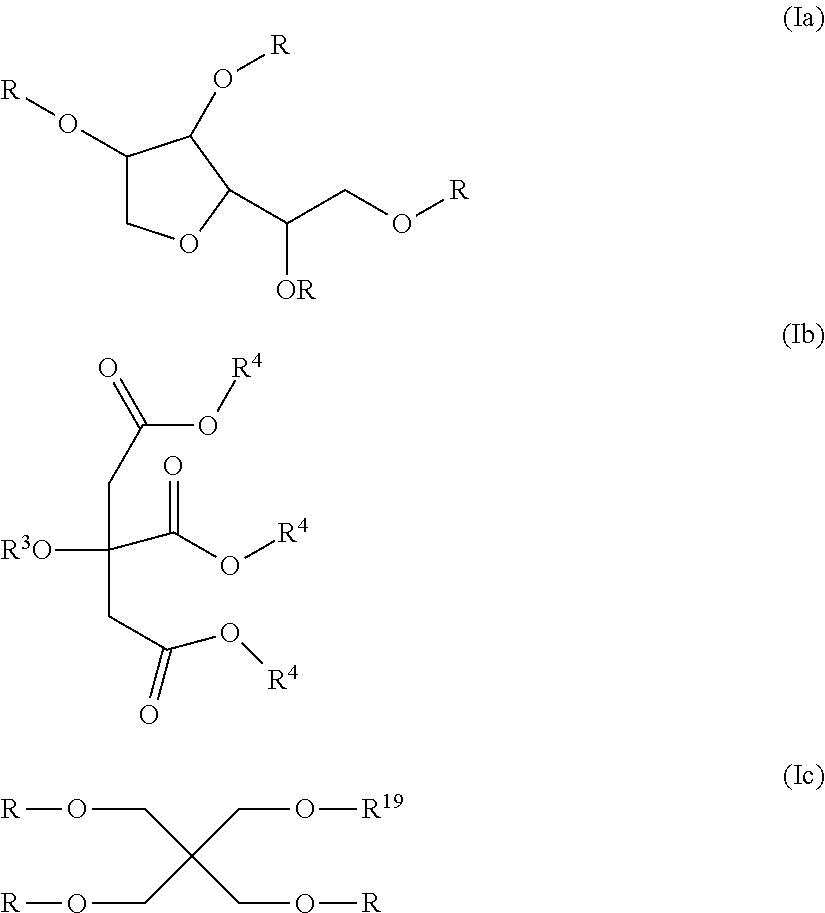

InactiveUS20030154555A1Good dimensional stabilityImprove yarn strengthPhysical treatmentWrinkle resistant fibresFiberActive agent

The application provides a method of treating fibrous textile goods comprising treating the fibrous textile goods with an enzyme. This enzyme can be used to covalently link one or more active functional compounds to the fibres and / or to trap one or more acitve functional compound within an inter-fibre matrix and / or within an intra-fibre matrix formed by the action of the enzyme. Preferably, the enzyme is a traglutaminase, especially a calcium-dependent transglutaminase. The enzyme may be used to add primary-amine containing active agents to the textile goods and also for the addition of proteins or peptides that have functional groups linked to them.

Owner:NOTTINGHAM TRENT UNIVERSITY

Production method of pure-cotton bright-red extra-wide breadth woven fabric with high wet rubbing fastness

InactiveCN107326595AReasonable production process designEasy to operateMercerising of indefinite length fabricsSingeingBreaking strengthOperability

The invention discloses a production method of a pure-cotton bright-red extra-wide breadth woven fabric with high wet rubbing fastness. A main production process flow comprises: turnover sewing, primary singeing, alkali-rolling cold-batch desizing, scouring and bleaching, secondary singeing, pre-stentering for wrinkle removal, mercerizing, cold-rolled batch dyeing or dye jigger dyeing, formaldehyde-free shrink resistant finishing, stentering finishing, mechanical pre-shrinking, calendering, checking and packing. The pure-cotton bright-red extra-wide breadth woven fabric is high in surface gloss, the wet rubbing fastness of the product reaches a level 3, the warp and weft washing dimension change rate is in a range of -3.0 percent to +1.0 percent, the pilling resistance is more than or equal to a level 4, the breaking strength is more than or equal to 250N, and a cotton fabric printing and dyeing standard for a superior product is completely reached. The production process is reasonable in design, high in operability, and environmentally-friendly.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

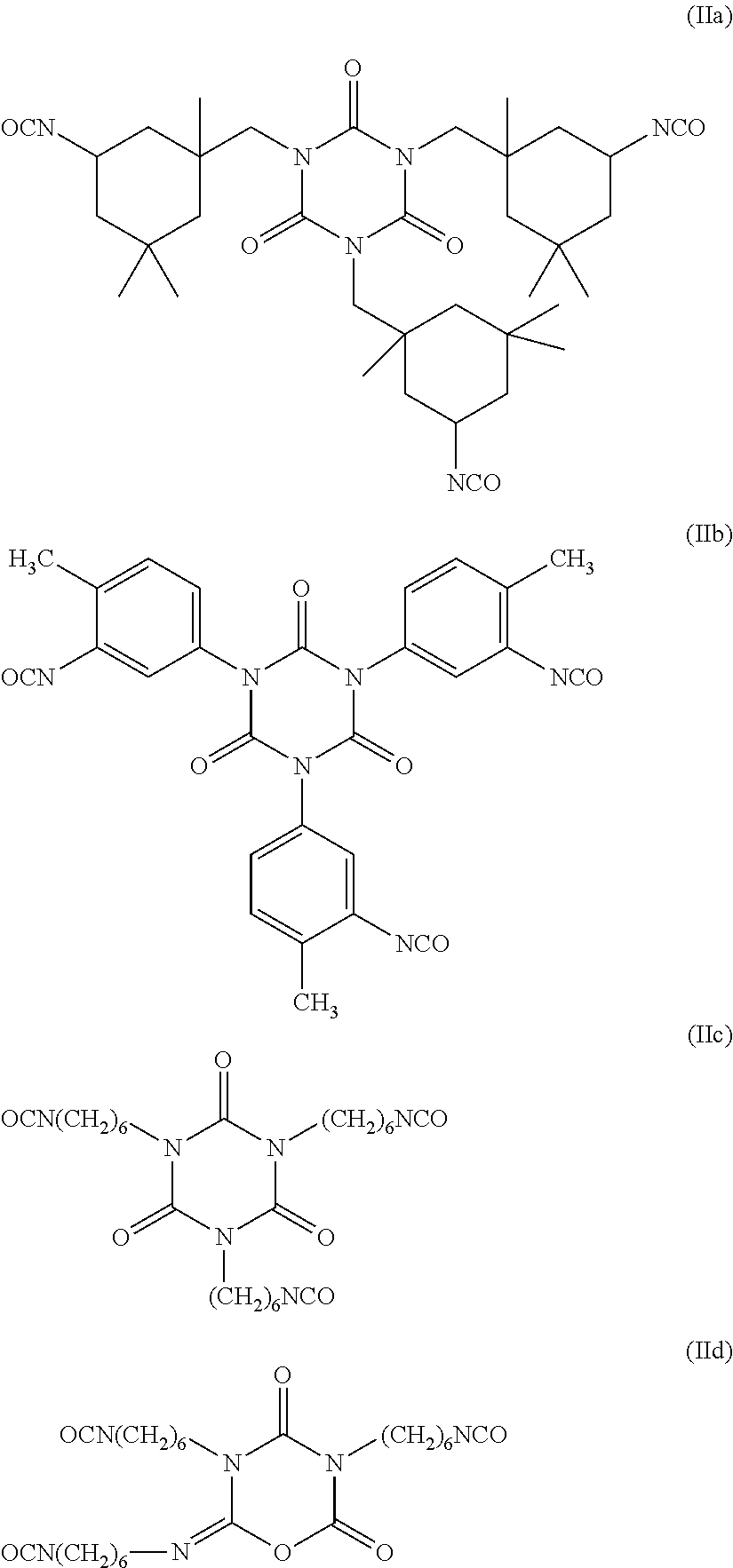

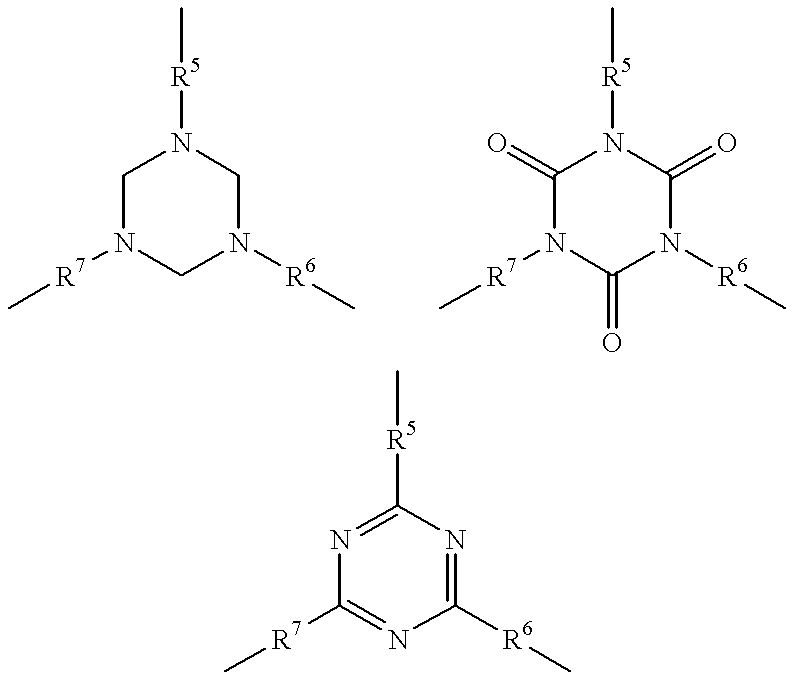

Urethane based extenders for surface effect compositions

ActiveUS20140296123A1Improve performanceIncreased durabilityStain/soil resistant fibresOrganic detergent compounding agentsPolymer scienceCarbamate

Owner:THE CHEMOURS CO FC LLC

Process for fluorinating cellulosic materials and fluorinated cellulosic materials

InactiveUS6293972B1Pulp properties modificationNon-macromolecular adhesive additivesCelluloseOrganic solvent

In the fluorinated cellulosic material obtained by a method for fluorinating a cellulosic material by reacting a cellulosic material selected from the group consisting of cellulose material and lignocellulose material with at least one fluorine-containing compound selected from the group consisting of fluorine-containing olefin compound, fluorine-containing acrylate compound and fluorine-containing methacrylate compound in an organic solvent in the presence of a catalyst, not only the surface but also the inside of the cellulose and / or lignocellulose materials are modified and high performance of the cellulose and / or lignocellulose materials is realized.

Owner:DAIKIN IND LTD

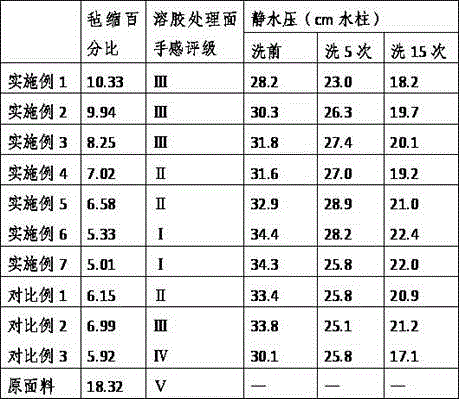

Production method of dirt repelling and felting resisting wool fabric

ActiveCN105568665AFeel goodIncreased cross-linking sitesUltrasonic/sonic fibre treatmentGrip property fibresCross-linkFiber

The invention discloses a production method of a dirt repelling and felting resisting wool fabric. The method comprises the following steps: preprocessing a wool fabric, preparing a chitosan silica sol finishing liquid, finishing the obtained wool, and drying the finished wool. Hydrogen peroxide pretreatment and chitosan solution are adopted to protect the wool fabric, so damages to the surfaces of fibers obtained after plasma treatment in low temperature atmosphere are small; the chitosan silica sol finishing liquid is finished to the surface of one side of the wool fabric, and components in the finishing liquid undergo a condensation reaction, and are cross-linked on the surface of the wool fabric to form a film with certain rigidity, so the wool fabric has single side dirt repelling and felting resisting performances; the film formed on the surface of the wool fabric also has flexibility adapting to the fabric, the bonding area between the film and the fabric is large, the bonding strength is good, and the service life of the film bonded wool fabric is long; and chitosan has bacterium prevention and moisture absorption characteristics, so the finished wool fabric has the advantages of good handle, bacterium prevention, moisture absorption and breathability.

Owner:常熟市易美纺织品有限公司

Anti-pilling finishing process of wool fabric

InactiveCN107513857AImprove hydrophilicityGood removal effectBiochemical treatment with enzymes/microorganismsGrip property fibresEngineeringWool fiber

The invention discloses an anti-pilling finishing process for wool fabrics, comprising the steps of: pretreatment; enzyme finishing; shrinking; scaling and anti-pilling one-bath method; cleaning; drying; padding; The fabric is dried, calendered and shaped. In the present invention, by adding an enzyme finishing process before the milling process, the disulfide bond of the oxidizing agent is converted into a sulfonic acid group, which destroys the continuous distribution of the lipid layer on the surface of the wool fiber, increases the hydrophilicity of the wool fiber surface, and then treats it with protease. It can further increase the removal effect of wool surface scales, and ensure the effect of the subsequent one-bath scaling and anti-wrinkle process.

Owner:太仓市芸芸化纤有限公司

Negative-ion finishing process of Australian wool tops

InactiveCN106811959AImproves felting resistanceHas the function of releasing negative ionsShrinking resistant fibresAnimal fibresSiliconMaterials science

The invention discloses a negative-ion finishing process of Australian wool tops. The negative-ion finishing process includes the steps of firstly, soaking the washed Australian wool tops into negative-ion finishing liquid, wherein the negative-ion finishing liquid comprises, by weight percentage, 8-12% of tourmaline powder, 5-8% of organic silicon resin, 2-4% of binder, 1-3% of dispersing agent, 1-2% of pH regulator, 2-4% of penetrating agent and the balance deionized water; secondly, pre-baking; thirdly, baking; fourthly, washing and drying. By the arrangement, the negative-ion finishing process has the advantages that the process is simple and easy to control, safe and environmentally friendly, the negative-ion finishing liquid reasonable in component and proportion is used to finish the Australian wool tops, the shrinkage resistance of the Australian wool tops is increased effectively, and the processed Australian wool tops can release negative ions having a healthcare effect on human bodies.

Owner:CHANGSHU XINGUANG WOOL TOP SPECIALIST PROCESSOR

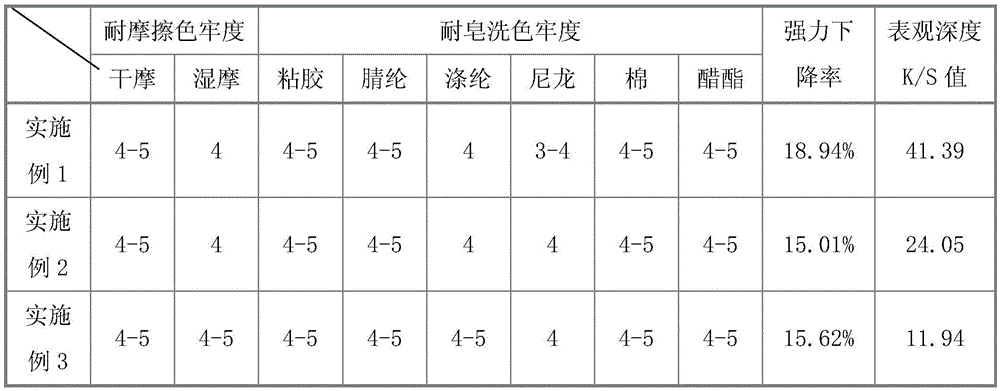

Dyeing and finishing processing method of acetate fiber/polyester fiber blended fabric

ActiveCN105421097AStrong penetrating powerDimensionally stableGrip property fibresDyeing processDisperse dyeStrength loss

The invention discloses a dyeing and finishing processing method of acetate fiber / polyester fiber blended fabric. The dyeing and finishing processing method comprises the following steps of 1) preparing scouring liquid, and pretreating the blended fabric; 2) padding with modified liquid resin, presetting for 30 to 60 seconds at 130 to 140 DEG C; 3) preparing disperse dye dye liquor of which the pH is 3.5 to 6.0, and dyeing the blended fabric for 30min to 120min under the condition of 100 to 140 DEG C; 4) performing reduction cleaning on the dyed blended fabric, washing, and stoving at 80 to 90 DEG C. The fabric dyed by the dyeing and finishing processing method is uniform in dyeing, good in dye permeability, stable in size, less in strength loss and good in fastness.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Breathable and warm air layer fabric

ActiveCN105544205AImprove breathabilityImprove dehumidification effectLayered productsGrip property fibresPunchingThermal insulation

The invention discloses a breathable and warm air layer fabric which is formed by bonding or sewing a hollowed-out fabric and air layer auxiliary materials. The preparation method of the hollowed-out fabric comprises a wool fabric pretreatment step, a chitosan zinc sol finishing liquid preparation step, a finishing step, a baking and drying step and the like. The breathable and warm air layer fabric is formed by bonding or sewing the hollowed-out fabric and the air layer auxiliary materials; the fabric is good in moisture permeability and thermal insulation property; and in the preparation process of the fabric, wool is pretreated by an ionic liquid, and the wool fabric is finished by a chitosan zinc sol finishing liquid. Condensation reaction is carried out between the components in the finishing liquid, and a film with certain rigidity is formed on the surface of the wool fabric in a crosslinking manner, so that the wool fabric has anti-felting performance and prevents the tendency that wool fibers restore the normal position; the wool fabric tends to be compact in microstructure; the wool fabric at orifices is not easy to fluff after laser punching treatment; and the punched hole pattern is stable.

Owner:福建新龙科技有限公司

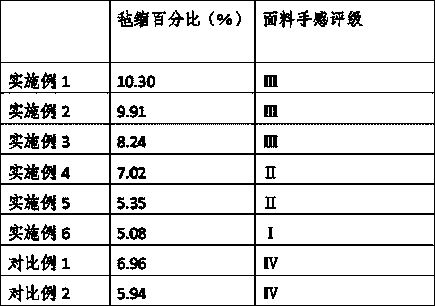

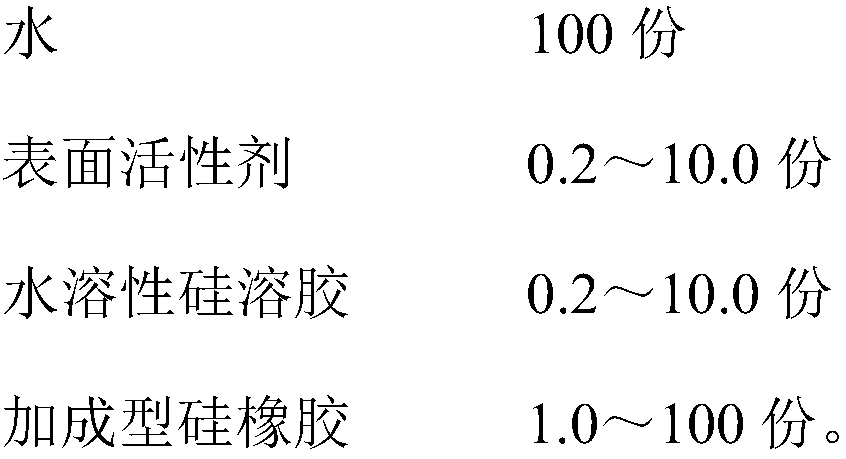

Addition-type silicone rubber latex and preparation method thereof and application product thereof

Owner:GUANGDONG POLYSIL TECH CO LTD

Manufacturing method of regenerated collagen fiber

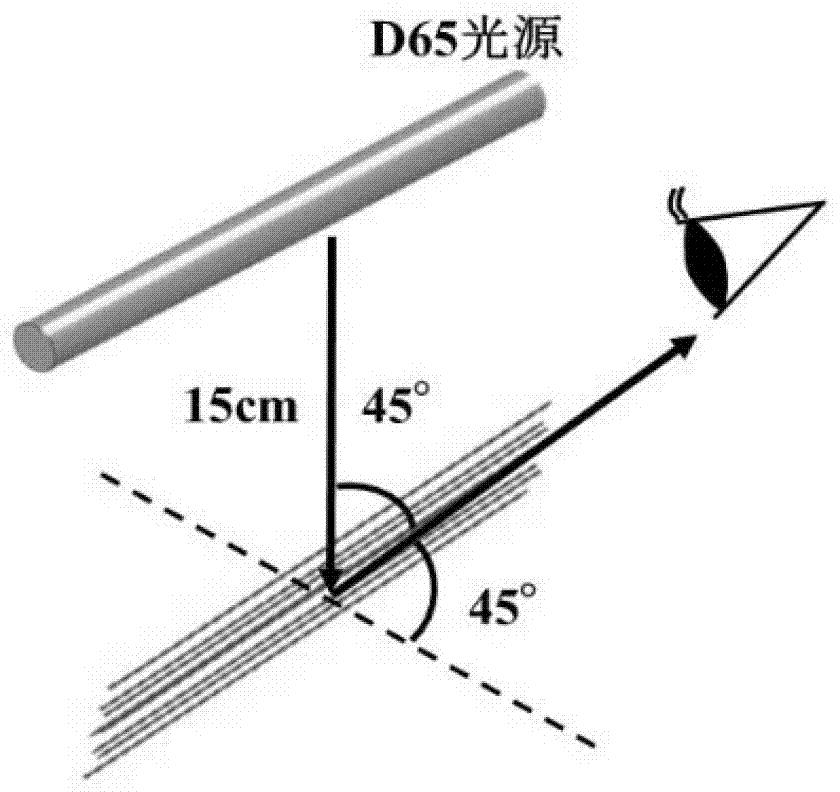

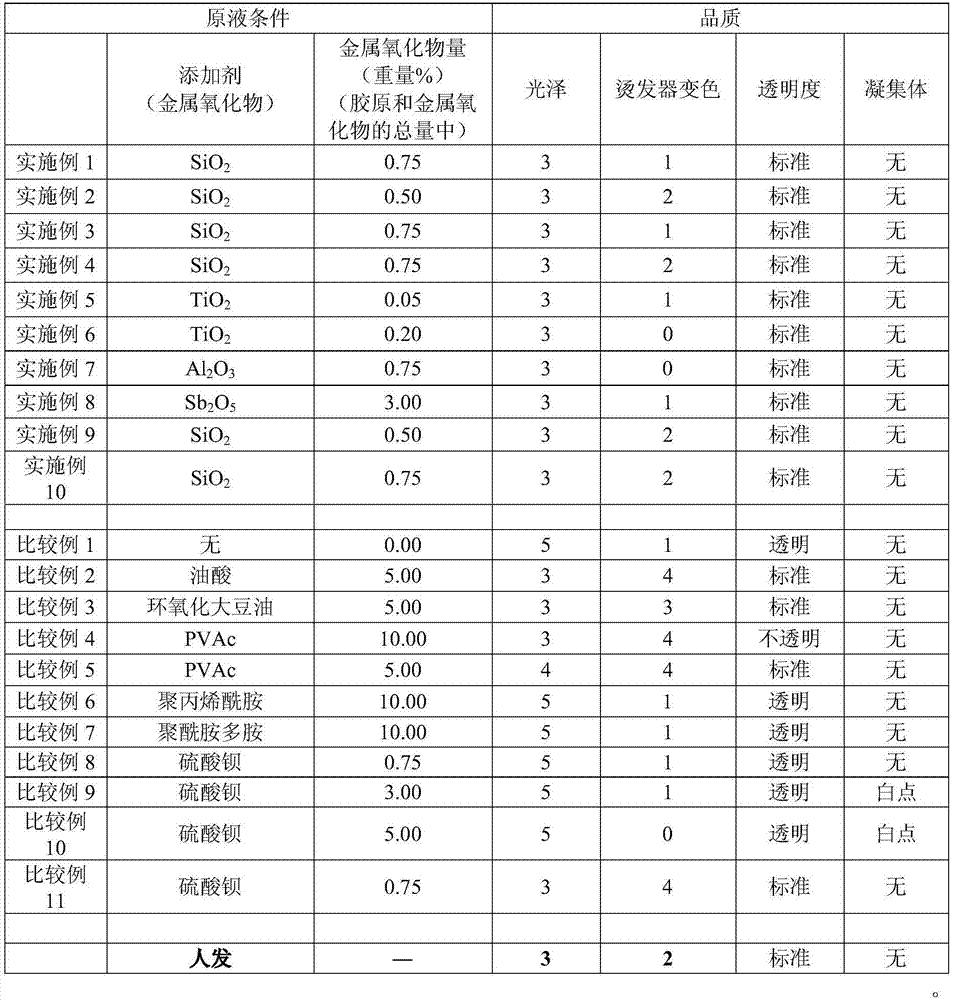

ActiveCN107190341AMaintain glossMaintain transparencyMonocomponent protein artificial filamentShrinking resistant fibresFiberAqueous solution

The invention relates to a manufacturing method of regenerated collagen fiber of which gloss and heat discolouration are inhibited. The manufacturing method comprises the steps of raw collagen liquid preparation process, spinning process, water-resisting process and drying process. In the raw collagen liquid preparation process, liquefiable collagen is used as raw collagen liquid, and an aqueous solution which contains the liquefiable collagen and metal oxides is prepared. According to the manufacturing method, the glossy regenerated collagen fiber of which heat discolouration cannot happen when a high-temperature hair iron is used for styling can be obtained.

Owner:KANEKA CORP

Production process of pure wool ripple double-faced woolen goods

InactiveCN108456971AUniform density and lengthImproves shrink resistanceFabric breaking/softeningLiquid/gas/vapor removalYarnEngineering

The invention provides a production process of pure wool ripple double-faced woolen goods. The production process of the pure wool ripple double-faced woolen goods includes the steps: opening Australian wool tops and wool and spinning the Australian wool tops and wool into yarns of 13.5 / metric number by a mule spinning process; weaving the spun yarns on a rapier loom; performing edge sewing, fulling, scouring, dewatering, drying, decating, teasel raising, drying, scalding, cutting and decating to prepare a finished product. The total number of warp yarns is 5900-6100, the acting reed width is200-205cm, porter / permeating number is 33 / 9, weft density is 270-280 yarns / 10cm, and the weight of a fabric billet is 890-910g / m<2>.

Owner:江阴市长泾花园毛纺织有限公司

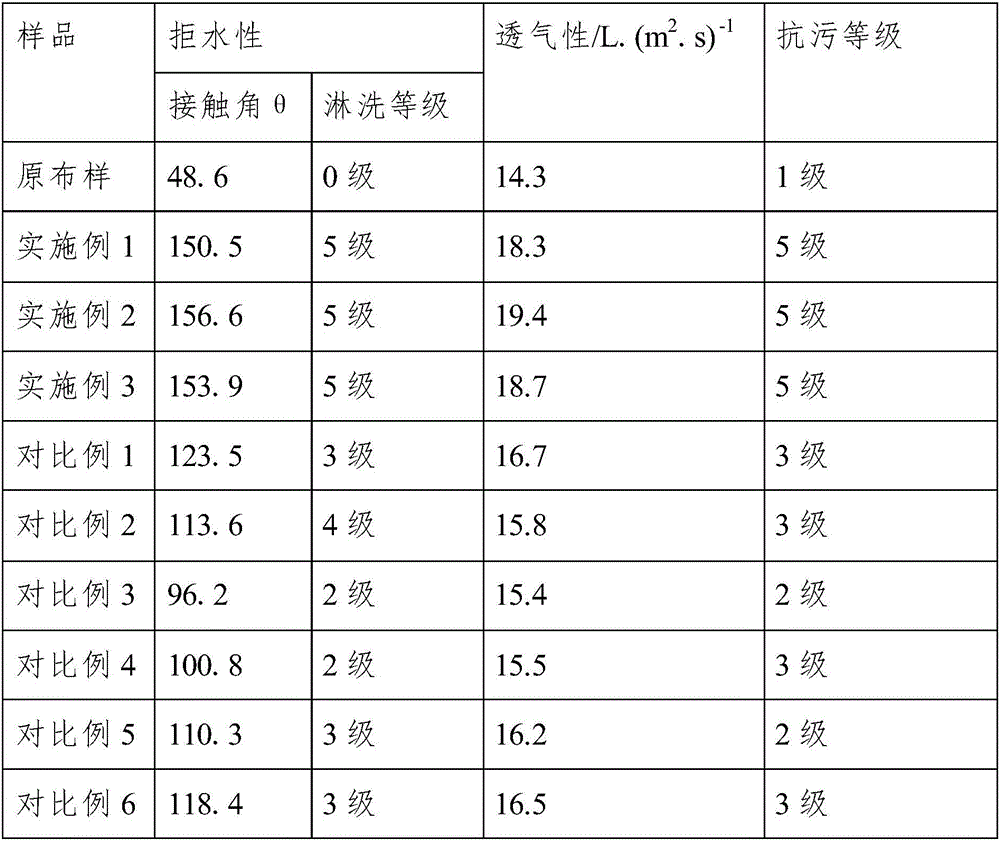

Fluoride-free water-repellent antifouling finishing agent and preparation method and application thereof

ActiveCN106012543AEasy to makeLow costStain/soil resistant fibresBiochemical fibre treatmentFluorideCHITOSAN OLIGOSACCHARIDE

The invention belongs to the field of textile finishing agents, and particularly relates to a fluoride-free water-repellent antifouling finishing agent and a preparation method and application thereof. The finishing agent comprises a system A and a system B, the weight ratio of the system A to the system B is 1:(0.6-0.8), the system A is prepared from 0.3%-3% of chitosan oligosaccharide, 1%-10% of waterborne polyurethane and the balance water, and the system B is modified nanosilicon dioxide sol. According to the fluoride-free water-repellent antifouling finishing agent, a textile finished through the finishing agent has the super-water-repellent and antifouling effects, meanwhile, the good hand feeling and breathability of the textile can be kept, the excellent antibacterial property and shrink-proofing property are achieved, and a preparation process of the finishing agent is easy to operate and suitable for application and popularization.

Owner:JIANGSU NEW REBA TECH CO LTD

Chlorine-free and shrink-proof finishing technology of wool tops

InactiveCN106758259ANo pollution in the processShort processBiochemical treatment with enzymes/microorganismsAbrasion resistant fibresAcrylic resinPollution

The invention discloses a chlorine-free and shrink-proof finishing technology of wool tops. The chlorine-free and shrink-proof finishing technology comprises the following steps: 1) washing with water: carrying out water-washing pre-treatment on the wool tops to remove impurities in the wool tops; 2) carrying out biological enzyme shrink-proof treatment: immersing the wool tops subjected to the water-washing treatment into a biological enzyme shrink-proof treatment solution; carrying out padding treatment, wherein the biological enzyme shrink-proof treatment solution is prepared from the following components in percentage by mass: 1 percent to 3 percent of hydrogen peroxide, 2 percent to 5 percent of sodium hydrogen sulfite, 15 percent to 20 percent of compound proteinase B, 35 percent to 40 percent of organic silicone resin, 7 percent to 10 percent of a penetrating agent and 29 percent to 33 percent of acrylic resin; 3) drying: drying the wool tops subjected to the biological enzyme shrink-proof treatment to obtain a wool top finished product with shrink-proof and anti-pilling performance. By adopting the manner, a technological flow is shortened so that the treated wool tops reach machine-washable shrink-proof effect of traditional chlorination and the anti-pilling performance is improved; in a finishing process, AOX (Absorbable Organic Halogen) pollution is not generated, and energy saving and environmental friendliness are realized.

Owner:CHANGSHU XINGUANG WOOL TOP SPECIALIST PROCESSOR

Methods of improving shrink-resistance of natural fibers, synthetic fibers, or mixtures thereof, or fabric or yarn composed of natural fibers, synthetic fibers, or mixtures thereof

ActiveUS7090701B2Improves shrink resistanceBleaching apparatusBiochemical treatment with enzymes/microorganismsPolyesterYarn

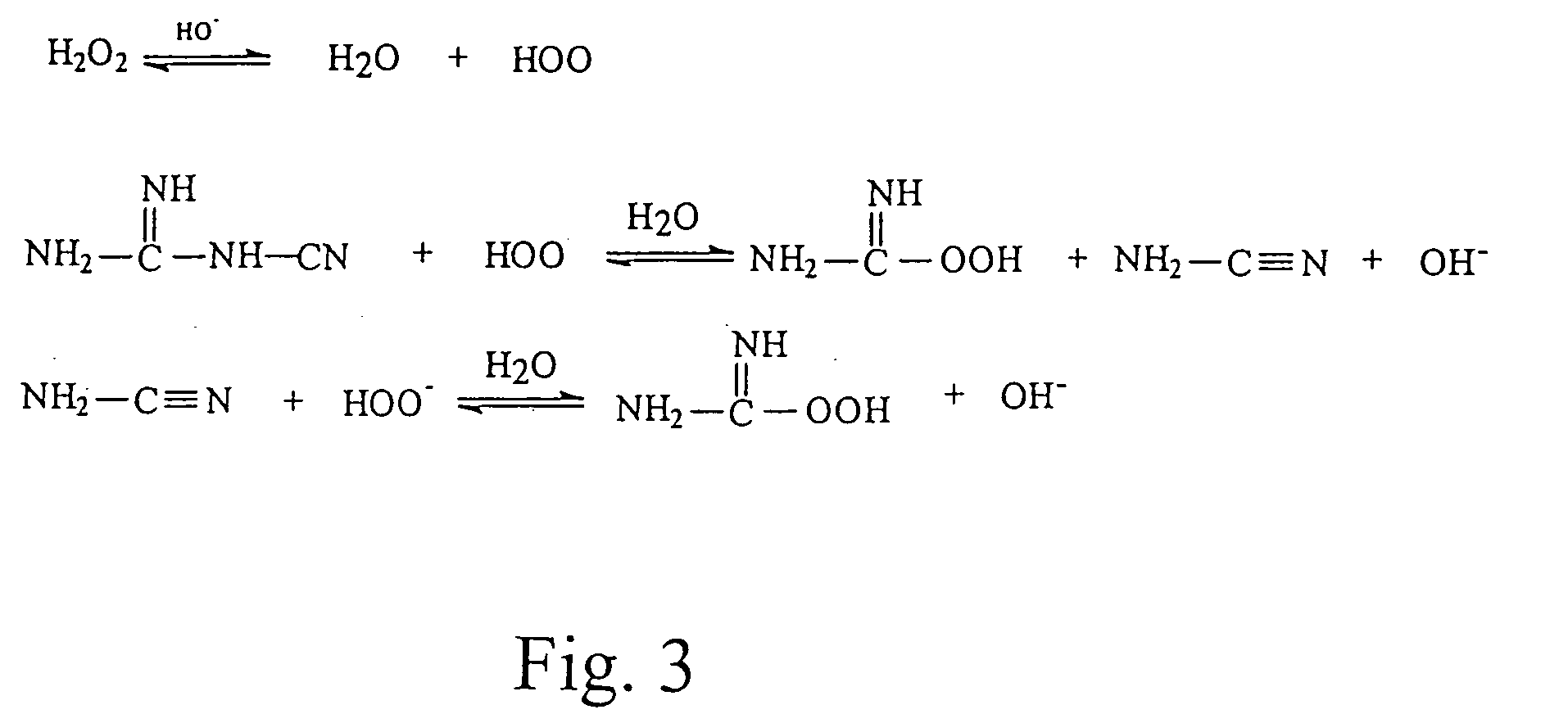

Methods of improving shrink-resistance of natural fibers (e.g., wool, wool fibers, animal hair, cotton), synthetic fibers (e.g., acetate, nylon, polyester, viscose rayon), or blends thereof (e.g., wool / cotton blends), or fabrics or yarns composed of natural fibers, synthetic fibers, or blends thereof, involving contacting the fibers (or fabric or yarn) with NaOH, H2O2, gluconic acid, dicyandiamide, and non-ionic surfactant (e.g., Triton X surfactant such as Triton X-100 and preferably Triton X-114), and optionally subsequently contacting the fibers (or fabric or yarn) with protease and non-ionic surfactant and optionally sodium sulfite and optionally triethanolamine and optionally polyacrylamide polymer. The methods do not utilize dichloroisocyanuric acid, chloroamines, peroxymonosulfuric acid, monoperoxyphthalic acid, permanganate, chlorine gas, sodium hypochlorite, or aminoplast resins.

Owner:US SEC AGRI

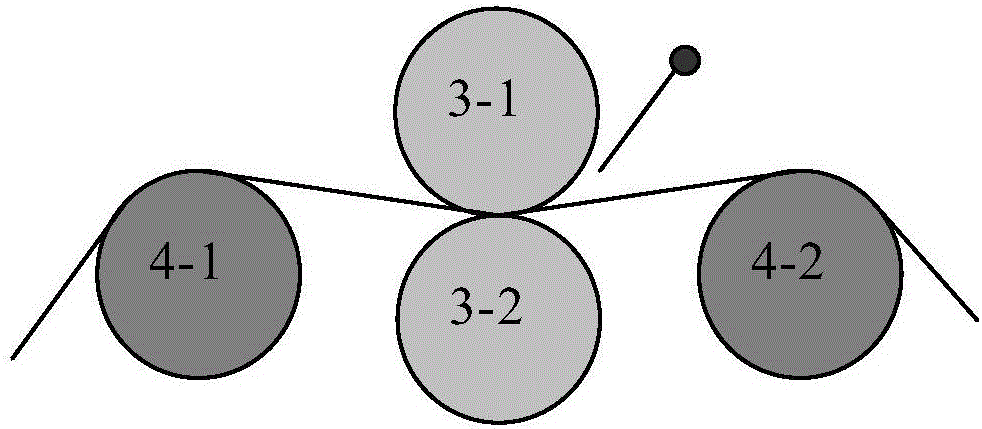

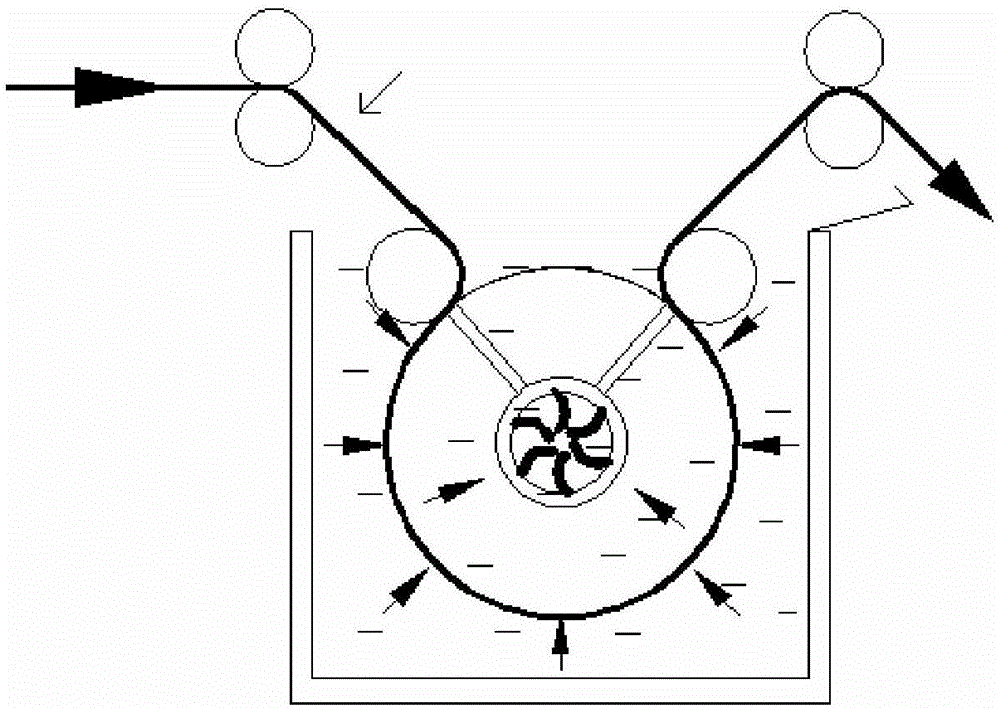

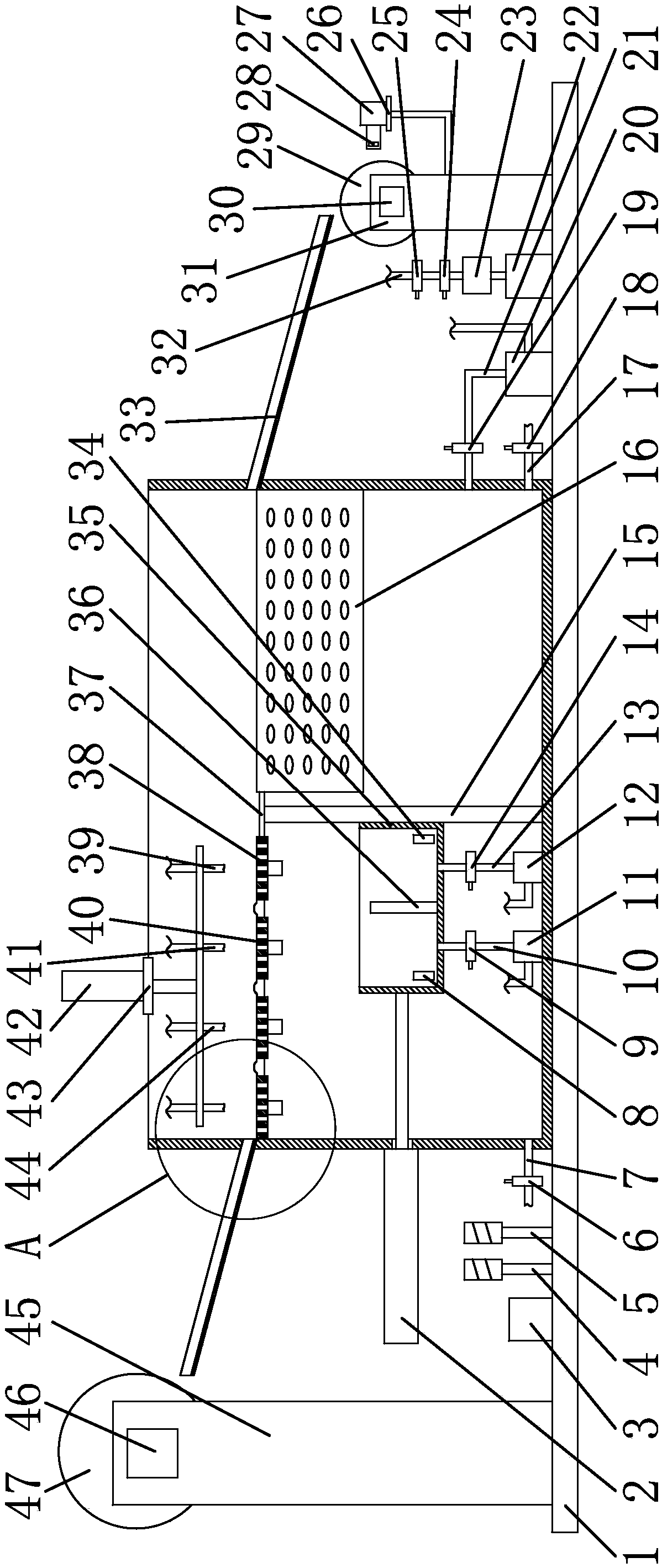

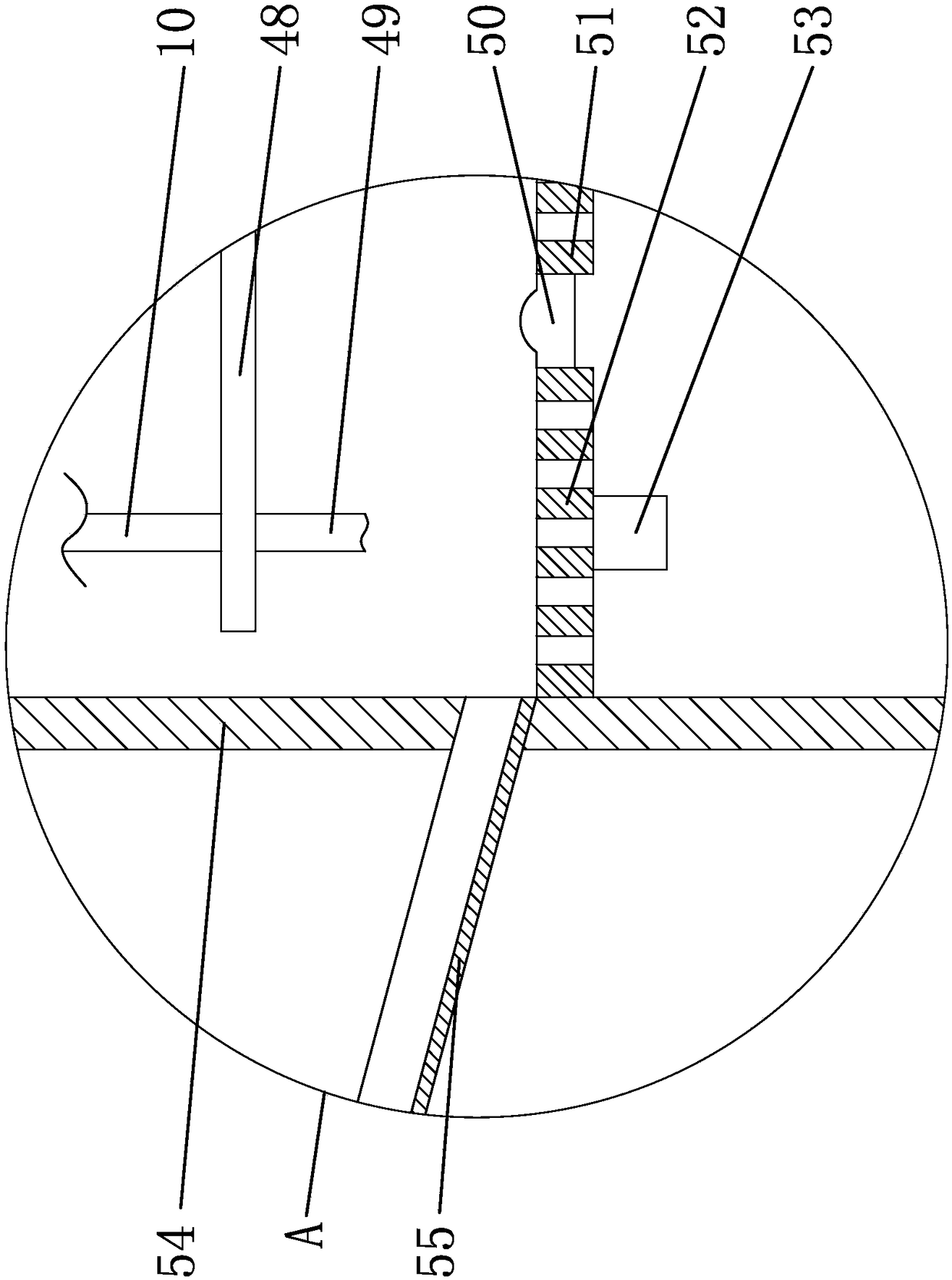

Equipment for non-shrink treatment of wool raw materials and products

InactiveCN106192266AAvoid pollutionPollution will not causeLiquid/gas/vapor removalTextile treatment machine arrangementsContinuous operationEnzyme

The invention relates to equipment for non-shrink treatment of wool raw materials and products. Specifically, the equipment comprises a multiple padding device, a washing device, an enzyme inactivation device, an optional softness treatment device and an optional dryer, wherein the multiple padding device comprises n independent padding devices arranged continuously, each padding device comprises a soaking tank and a roller, and n is a positive integer ranging from 2 to 20; the washing device is used for washing padded wool tops or wool products, and washed wool tops or wool products are formed. The equipment further comprises transmission devices located between the padding devices and non-shrink treatment liquid supplementing devices located obliquely above the downstream parts of the transmission devices. The equipment can meet the requirement for non-shrink processing treatment of wool tops and wool products, is environmentally friendly, can achieve continuous operation, has the advantages of uniform treatment and high efficiency and is quite suitable for large-scale industrial production.

Owner:TIANJIN LVYUAN TIANMEI TECH LTD +3

Yak wool dyeing method for anti-felting pretreatment of yak wool

InactiveCN107151915AAchieve low temperature dyeingImprove diffusion abilityBiochemical treatment with enzymes/microorganismsDyeing processStainingElater

The invention relates to a yak wool dyeing method for anti-felting pretreatment of yak wool; the method comprises: (1) performing anti-felting pretreatment, to be specific, oxidizing fiber, reducing the fiber, treating the fiber with proteinase, inactivating the proteinase, and washing; (2) dyeing, to be specific, dyeing with active dye at low temperature. The method has the advantages that the original single dyeing technique is replaced with the anti-felting pretreatment dyeing technique, and dyeing is benefited; in addition, the anti-felting treatment based on original staining enables the flake layer of the yak wool to be further opened, the ability of dye molecules to diffuse in the region is enhanced, dyeing activity of yak wool fiber is improved, and low-temperature dyeing of the yak wool is achieved.

Owner:JIANGSU LIANHONG TEXTILE

Method for felt proofing on wool fabric through proteinase K

ActiveCN109972390AHelps to swellGood for oxidationBiochemical treatment with enzymes/microorganismsShrinking resistant fibresCarbamide peroxideProteinase K

The invention discloses a method for felt proofing on a wool fabric through proteinase K and belongs to the technical field of application of dyeing and finishing and processing of the wool fabric inthe wool spinning industry. The problems are solved that during common proteinase felt proofing, the damage to wool strength is large, and the function of degrading keratin in a scale layer is small.The aim of optimizing proteinase felt proofing on the wool fabric is achieved. The optimization technology comprises the steps that the pure wool fabric is pretreated through urea peroxide, CMC is closed through chitosan oligosaccharide, and then the wool fabric is treated through the proteinase K. According to the wool fabric treated through the method, the felt proofing performance is obviouslyimproved, and the damage to the fabric strength is lowered. According to the method, the proteinase K is introduced into wool felt proofing for the first time, the wool scale cytokeratin is effectively degraded through the proteinase K, the good felt proofing effect on wool is achieved, and traditional chlorination felt proofing can be replaced.

Owner:JIANGNAN UNIV

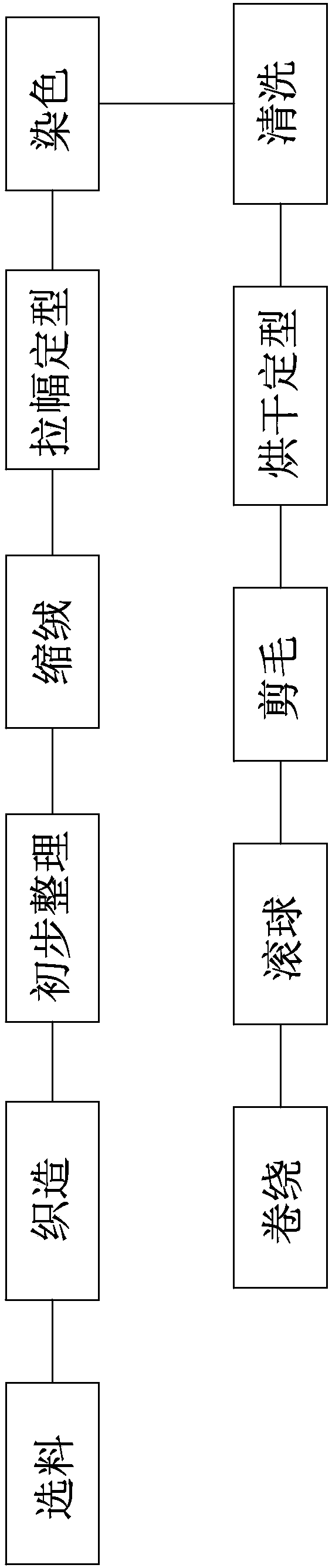

Production process of antibacterial, anti-pilling, anti-wrinkle and wear-resistant wool fabric

InactiveCN108221125AEasy to shapeAvoid deformationTextile treatment machine arrangementsStretchingPolyesterYarn

The invention provides a production process of antibacterial, anti-pilling, anti-wrinkle and wear-resistant wool fabric with an aim to solve technical problems that an existing production process is simple in process and rough in workmanship, fabric is poor in shaping, prone to deformation, free of effects of being skin-friendly, warm-keeping and non-stimulating, incapable of preventing moths, easy to pill and wrinkle, non wear-resistant, poor in function and the like. The production process includes the steps of S1, material selection, namely putting, by weight, wool fiber, cashmere fiber andpolyester fiber into a fiber mixer to obtain blended fiber, and then combing the blended fiber and making the combed blended fiber into wool tops; S2, weaving, namely making the wool tops combed in the S1 into yarn via pre-spinning, spinning, spooling, plying, double-twisting and yarn steaming and respectively taking the yarn used as warp and weft into a rapier loom for weaving to obtain the woolgray fabric. The production process has the advantage of strong functions.

Owner:孙艳

Non-chlorine shrink-proof method of wool fabric

InactiveCN105421028AWith anti-shrink effectImprove environmental protection requirementsShrinking resistant fibresAnimal fibresEnvironmental resistanceEngineering

The invention relates to a non-chlorine shrink-proof method of wool fabric. The non-chlorine shrink-proof method comprises an oxidation process and a reduction process, wherein the oxidation process is proceeded in a solution which contains a non-chlorine oxidizing agent; the reduction process is proceeded in a solution which contains a reducing agent. According to the non-chlorine shrink-proof method of the wool fabric, disclosed by the invention, the fabric obtained through the non-chlorine shrink-proof method is environmental-friendly and is easy to care, and the wool shrinkage of the processed wool fabric can be controlled within 8 percent.

Owner:SHANGHAI CHALLENGE TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com