Patents

Literature

42 results about "Elater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An elater is a cell (or structure attached to a cell) that is hygroscopic, and therefore will change shape in response to changes in moisture in the environment. Elaters come in a variety of forms, but are always associated with plant spores. In many plants that do not have seeds, they function in dispersing the spores to a new location. Mosses do not have elaters, but peristome which also change shape with changes in humidity or moisture to allow for a gradual release of spores.

Superfine flat terylene low elater and technique for producing the same

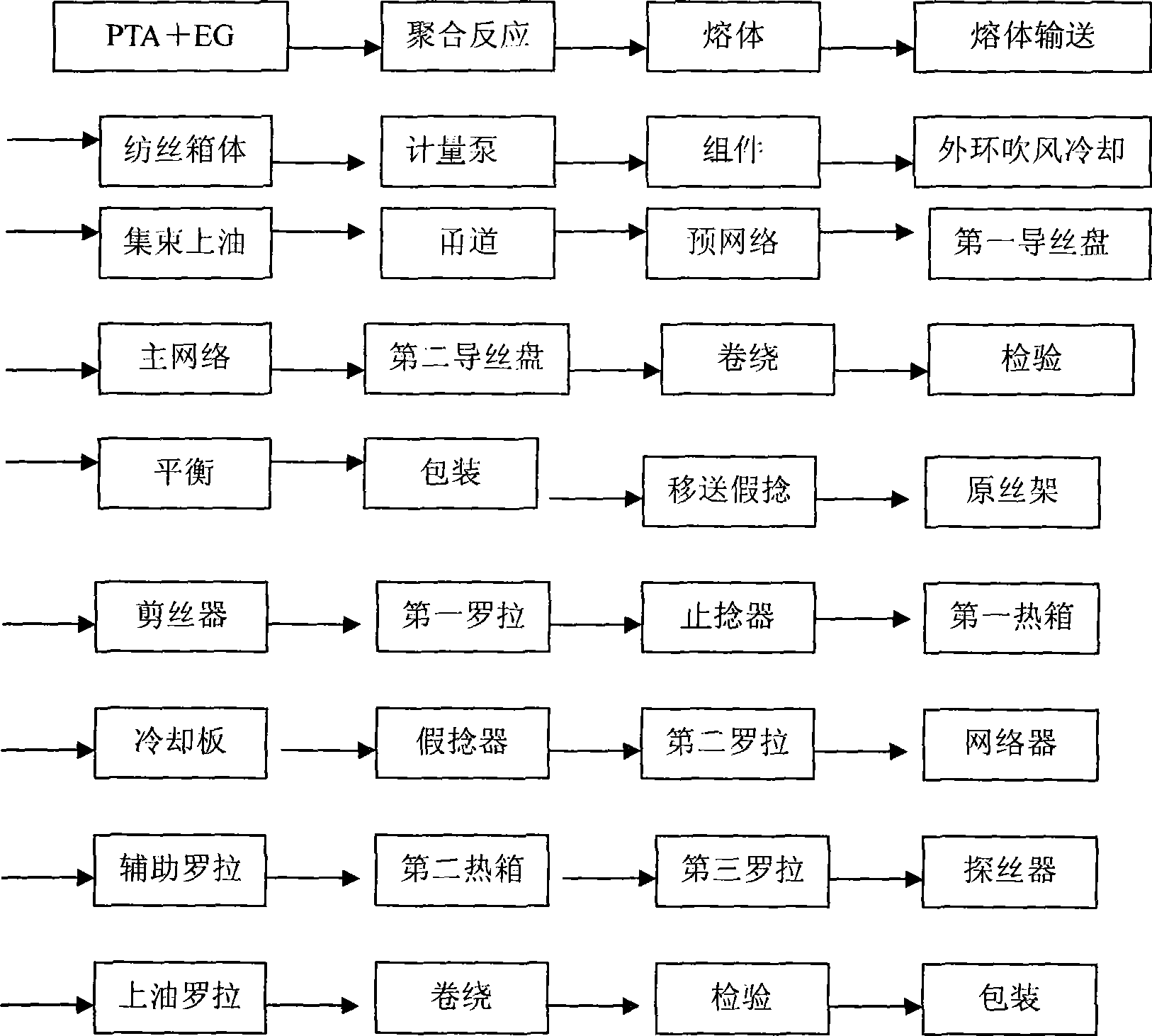

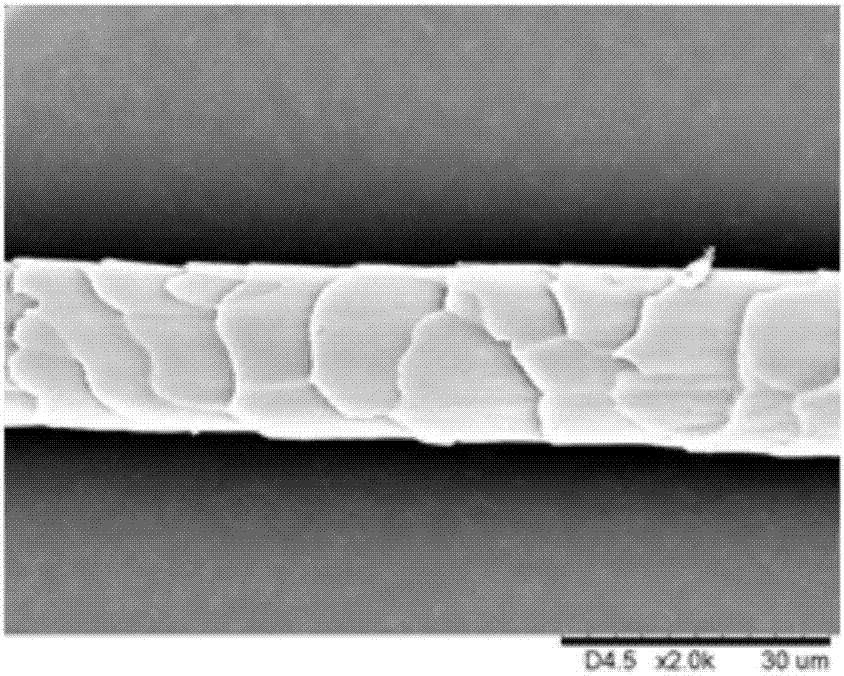

InactiveCN101498058ASoft touchGood moisture absorption and air permeabilityFilament/thread formingMonocomponent polyesters artificial filamentYarnProduction line

The invention relates to a superfine, flat, terylene and low-stretch yarn and a production technology thereof. The invention is characterized in that the superfine, flat, terylene and low-stretch yarn has the specification of (55-444)dtex / (144-576)f, the single yarn density is smaller than or equal to 0.58dtex, and the cross section shape of the yarn is a rectangle with a length-width ratio which is larger than or equal to 2. The invention adopts a fused mass direct spinning production mode and a two-step POY-DTY method production line for production; an outer ring blowing cooling mode is adopted, and a spinneret plate with a straight spinneret orifice is used in a spinning working procedure, and the spinneret plate has a high length-width ratio which is larger than or equal to 2; a pentaerythritol additive capable of changing the rheological property and the spinnability of fused mass is added in a polyester working procedure; and integrative production measures, such as a special extending deformation technology, and the like, are adopted in a false twisting working procedure. Fabrics woven by the superfine, flat, terylene and low-stretch yarn have the advantages of soft feeling, good moisture absorption and ventilation, elegant luster, good hair uprightness, easy dying, and the like as well as higher product added value.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Sorona/combed cotton fiber blended knitting fabric

The invention relates to Sorona / combed cotton fiber blended knitting fabric. The fabric is characterized in that the fabric weave is adopted as single jersey, the course is 59.5 wale / 10 cm, the wale is 40 course / 10 cm, according to a yarn, two 32S Sorona spinning yarns composed of 50 percent of Sorona fibers and 50 percent of combed cotton fibers are stranded to form the yarn, the doubling twist is 320 twist / meter, and the gram weight is 290 g / square meter. According to the Sorona / combed cotton fiber blended knitting fabric, the enough elasticity is obtained so as to ensure the comfortable wearing, and the unique molecular structure and the physical form of comfortable elastic filaments can ensure the persistent and stable elasticity of the fabric.

Owner:JIANGYIN XIANGFEI APPAREL

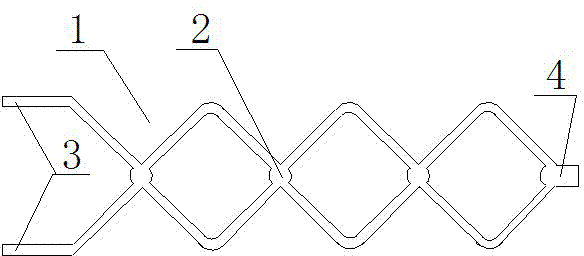

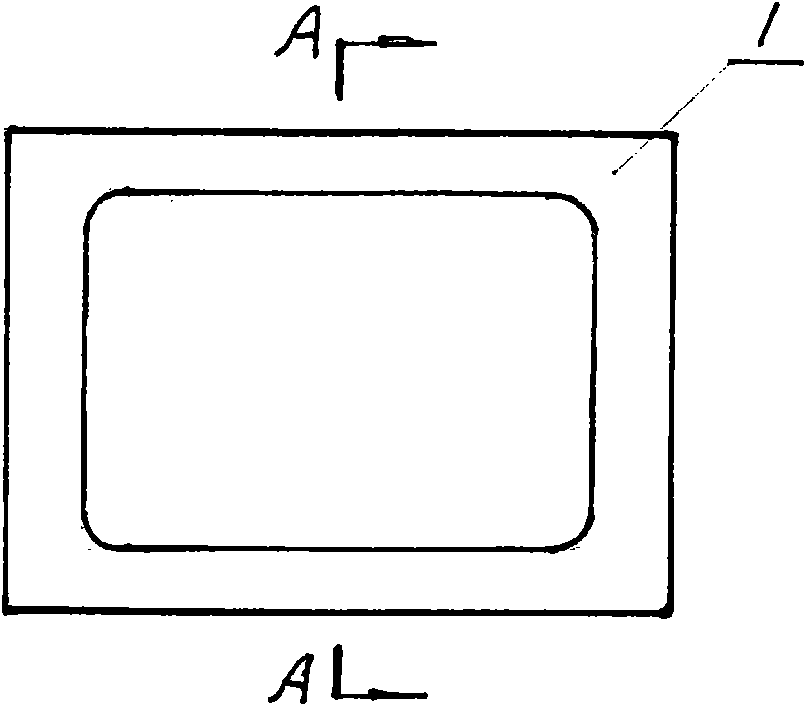

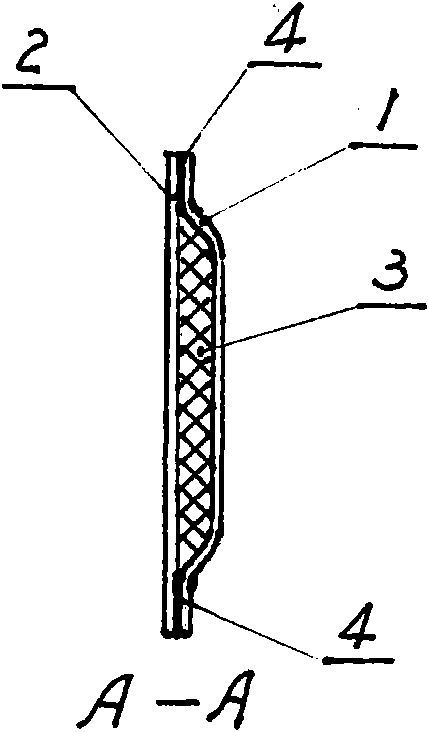

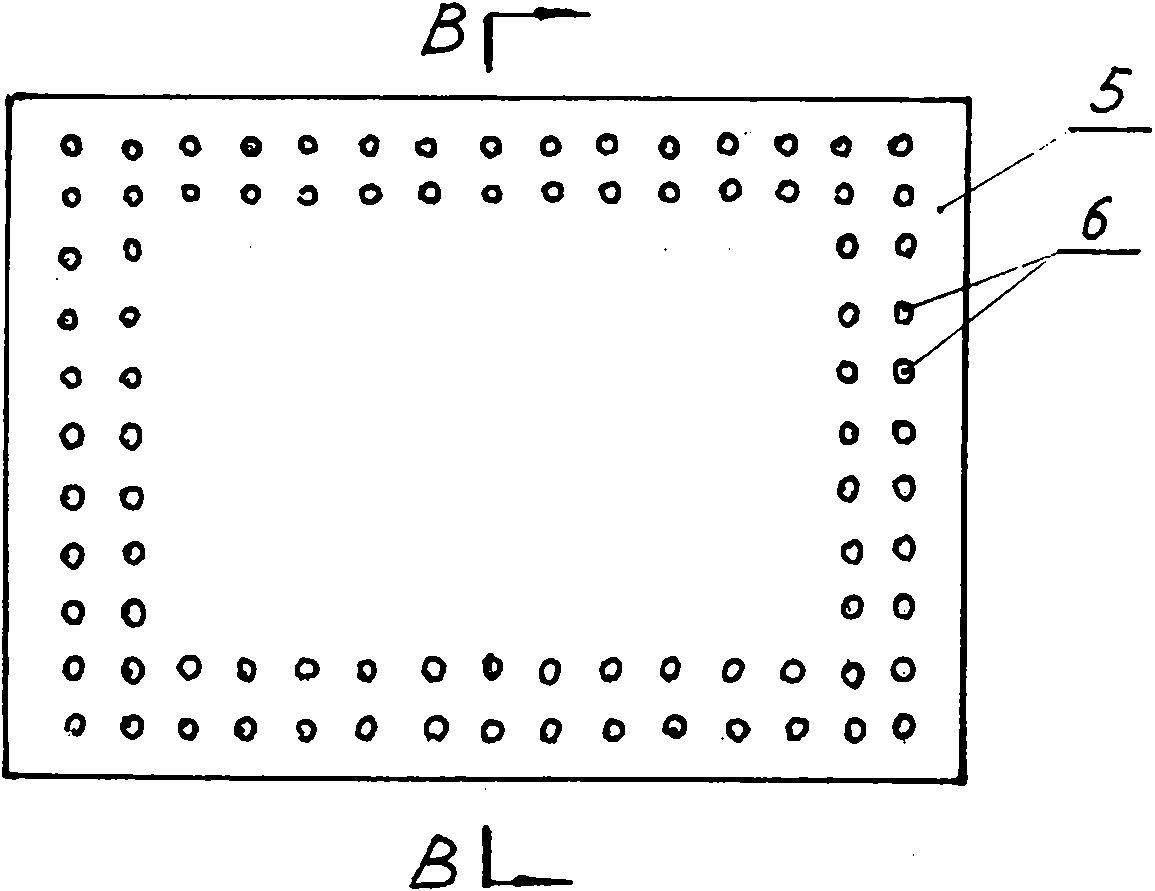

Elastic yarn with comfortable elater

The invention belongs to the field of textiles, and provides elastic yarn with comfortable elater. The elastic yarn is mainly characterized in that for the first time, traditional fiber is adopted to be mixed with the comfortable elater to spin the elastic yarn, wherein the comfortable elater is biomass elastic short fiber. Due to successful application of the comfortable elater, the historical situation that the elastic short fiber cannot be used for spinning is broken, and spandex elater can be replaced, so that the dependence of the elater over petrochemical resources and energy consumption are reduced. Compared with the prior spandex core-spun elastic yarn, the elastic yarn with the comfortable elater has the advantages of little hairiness detail, high elasticity, yarn evenness, no yarn deviation phenomenon, and the like, thereby laying a very good material basis for high-grade elastic fabric.

Owner:HENAN XINYE TEXTILE

High shrinkage polyester fibre low-elater with PTT service performance and preparing technique thereof

The invention provides a high shrinkage polyester drawn textured yarn with PTT operation performance and a manufacturing method of the high shrinkage polyester drawn textured yarn. The invention is realized by the following procedures: a group of or a plurality group of technique parameters and related product data is or are obtained by adopting an orthogonal experiment statistic method; the most reasonable technique parameter and product performance index among above data are obtained; optimization is carried out continuously on the basis, thus obtaining the technique parameter of the invention and producing related products at the same time. The curling ratio of the polyester high elastic DTY can reach up to 54 percent which is close to 60 percent of curling ratio of the PTT fiber, and the production cost of a textile enterprise can be effectively reduced by substituting the PTT fiber with the polyester high elastic DTY.

Owner:SHENGHONG GRP CO LTD

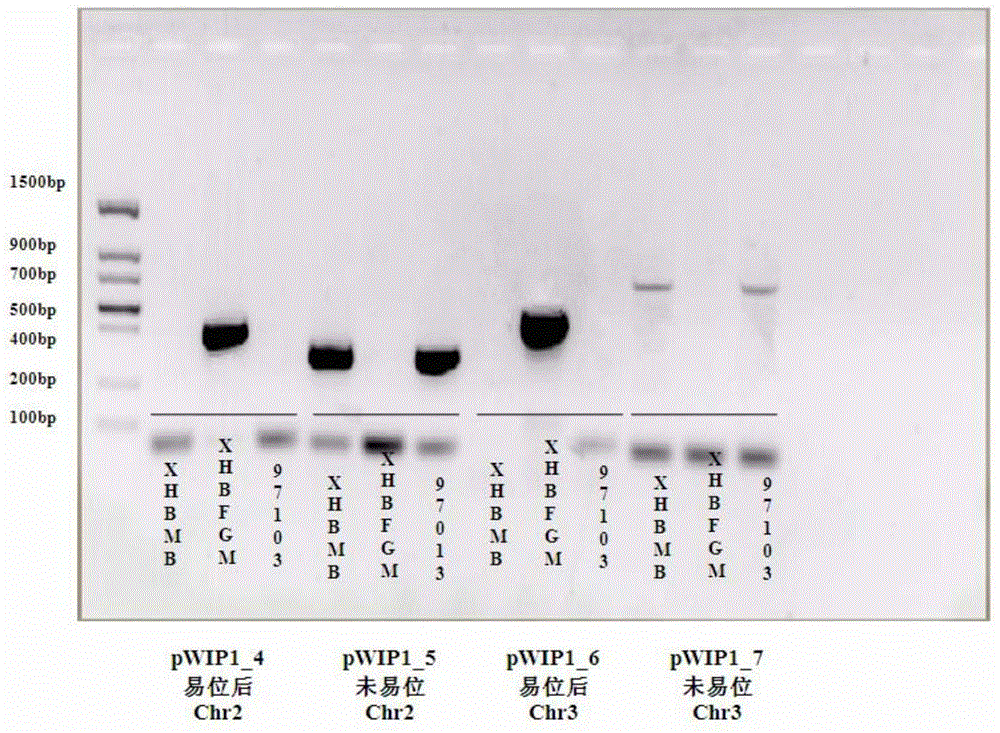

Watermelon female lines gene C1WIP1 and chromosome translocation and linkage marker

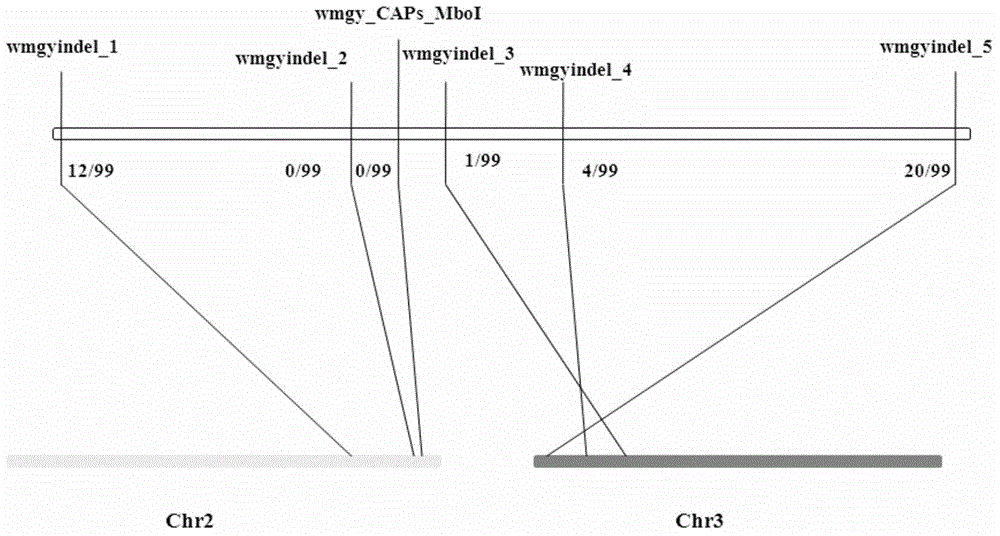

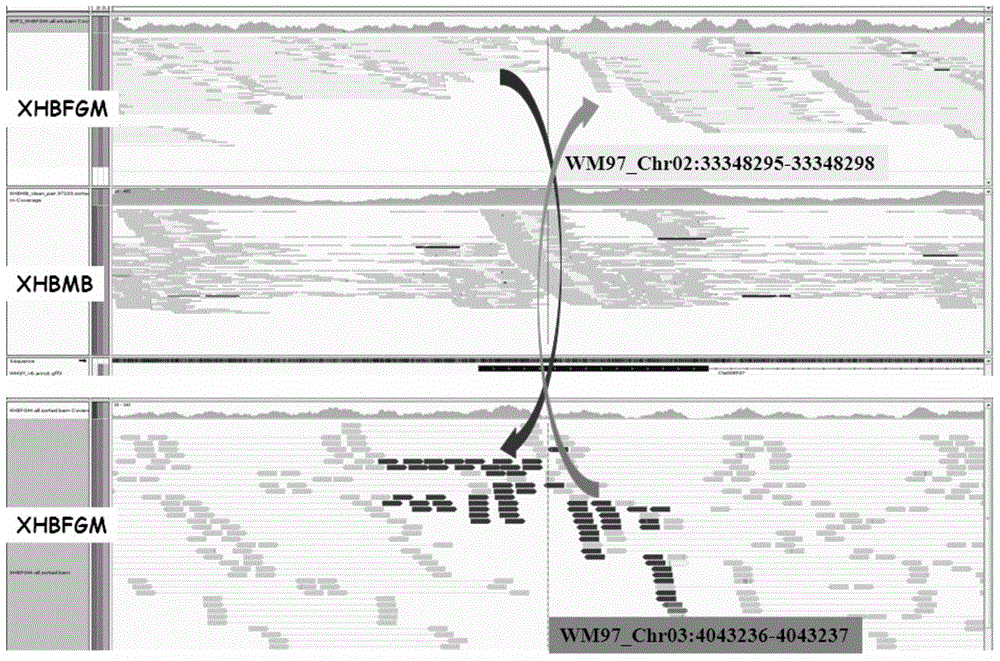

ActiveCN103937785AFast and accurate cloningReduce the cost of seed productionMicrobiological testing/measurementFermentationGenome resequencingA-DNA

The invention belongs to the molecular biology field, and more specifically relates to watermelon female lines gene(i) C1WIP1( / i) and chromosome translocation and linkage marker, which comprises a DNA sequence of watermelon female lines gene(i) gy( / i) gene(i) C1WIP1( / i), its acquisition method, a molecular marker linked with the DNA sequence, a chromosome translocation section due to appearance of the watermelon female lines and its acquisition method. According to the invention, a classic gene positioning method and a whole genome re-sequencing technology are organically combined, and watermelon female lines gene(i) C1WIP1( / i) is rapidly and accurately cloned; a PCR technology is used for confirming that a watermelon spontaneous mutant material XHBFGM is appeared by female lines phenotype due to chromosome translocation, and a preliminary research is carried out on the effect mechanism of (i) C1WIP1( / i); By aiming at the existence of the chromosome translocation, the molecular marker linked with watermelon female lines gene(i) C1WIP1( / i) is designed, the watermelon female lines phenotype which takes XHBFGB as a transfer material can be rapidly detected, the molecular marker is used for assistant breeding, seed production cost of watermelon is greatly reduced, and the seed purity is increased.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

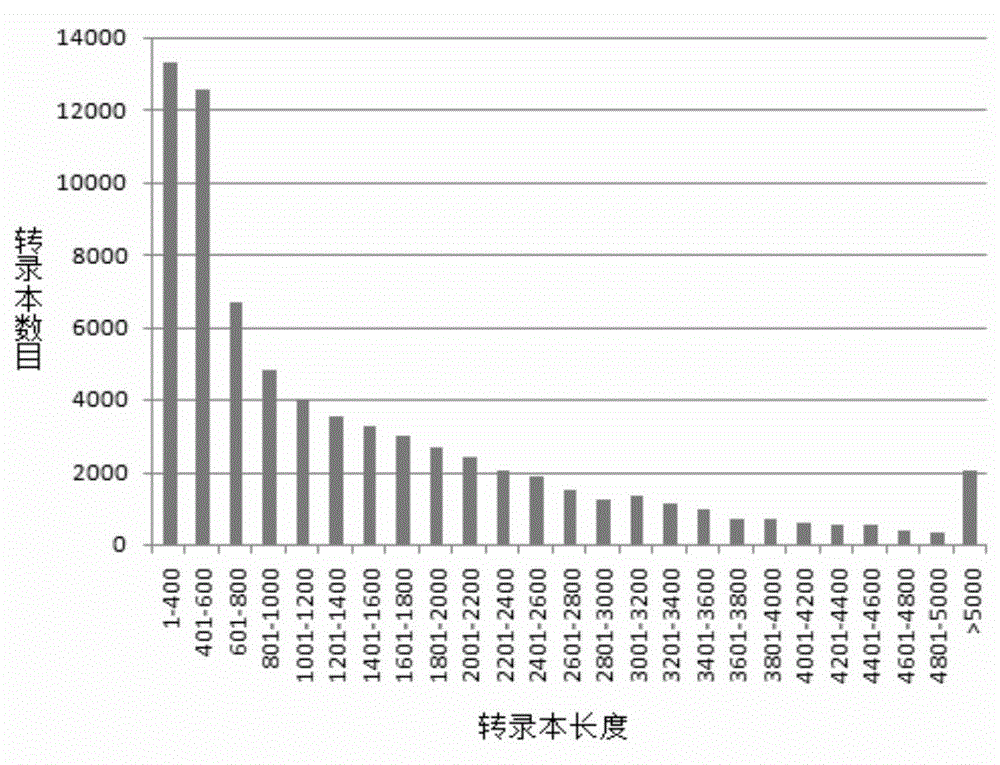

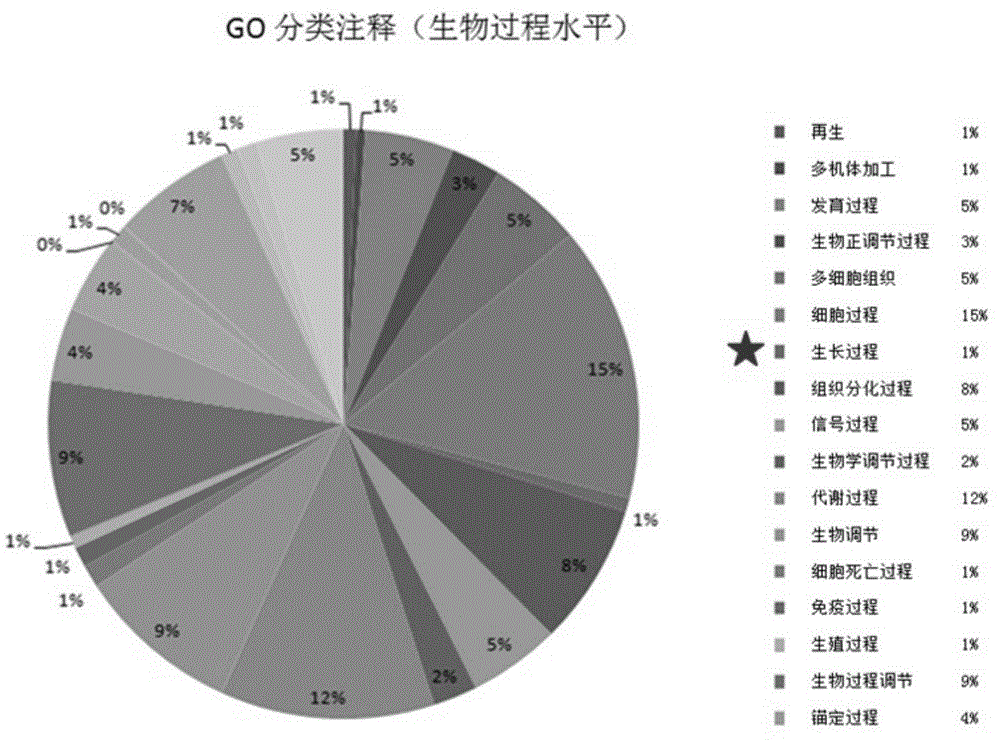

Paramisgurnus dabryanus selective breeding method

ActiveCN104351096APracticalLow costMicrobiological testing/measurementClimate change adaptationMicrosatelliteElater

The invention discloses a paramisgurnus dabryanus selective breeding method. Concretely, the method comprises the following steps that (1) 12 microsatellite molecular markers relevant to the growth properties are provided; (2) a parent group 1 is selected for electronic marking and DNA (deoxyribonucleic acid) extraction; (3) the molecular markers are adopted for carrying out genotype screening on the parent group 1, and in addition, a parent group 2 is selected; (4) the molecular markers are adopted for carrying out genotype screening on the parent group 2, and parent groups 3 and 4 with different homozygous genotypes are respectively built; (5) the parent groups 3 and 4 are used as breeding groups to be respectively subjected to artificial reproduction to obtain parent groups 5 and 6; (6) hybridization is carried out between the parent groups 5 and 6, and in addition, scaled reproduction is carried out. Compared with a conventional breeding method, the method has the characteristics of high speed, stability and reliability, the practicability is high, the cost is low, the accuracy is high, the influence due to factors such as environment is avoided, the relying on the phenotypic character authentication can be avoided, the breeding years are shortened, the breeding efficiency is improved, and great application values are realized.

Owner:SUZHOU UNIV

Anti-pilling woolen fabric

The invention discloses an anti-pilling woolen fabric, which is woven by warp yarn and weft yarn, wherein the warp yarn is mixed yarn formed by wool fiber and viscose fiber and is 45%-50% of the weight of the woolen fabric; and the weft yarn is mixed yarn formed by wool fiber and biomass elastic short fiber and is 50%-55% of the weight of the woolen fabric. According to the invention, the anti-pilling woolen fabric adopts comfort elater and wool to be mixed at a certain proportion, and the mixed yarn is interwoven with the mixed yarn formed by wool and viscose, so that the elasticity and the elastic restoring force of the woolen fabric are improved, and the effects of comfort and easiness for care are achieved; and through the rational combination of blending proportion, the elastic effect of the woolen fabric is enhanced, and as a result, the woolen fabric has favorable anti-pilling performance.

Owner:WUJIANG HONGKAI TEXTILE

Yak wool dyeing method for anti-felting pretreatment of yak wool

InactiveCN107151915AAchieve low temperature dyeingImprove diffusion abilityBiochemical treatment with enzymes/microorganismsDyeing processStainingElater

The invention relates to a yak wool dyeing method for anti-felting pretreatment of yak wool; the method comprises: (1) performing anti-felting pretreatment, to be specific, oxidizing fiber, reducing the fiber, treating the fiber with proteinase, inactivating the proteinase, and washing; (2) dyeing, to be specific, dyeing with active dye at low temperature. The method has the advantages that the original single dyeing technique is replaced with the anti-felting pretreatment dyeing technique, and dyeing is benefited; in addition, the anti-felting treatment based on original staining enables the flake layer of the yak wool to be further opened, the ability of dye molecules to diffuse in the region is enhanced, dyeing activity of yak wool fiber is improved, and low-temperature dyeing of the yak wool is achieved.

Owner:JIANGSU LIANHONG TEXTILE

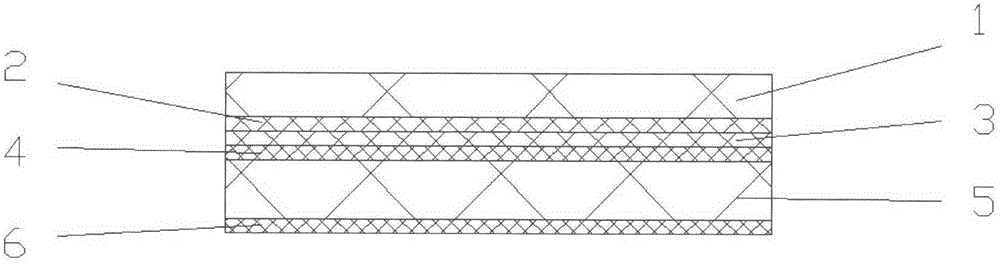

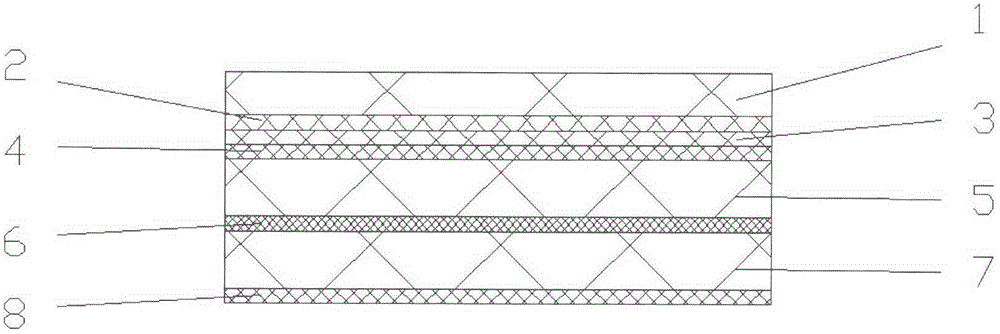

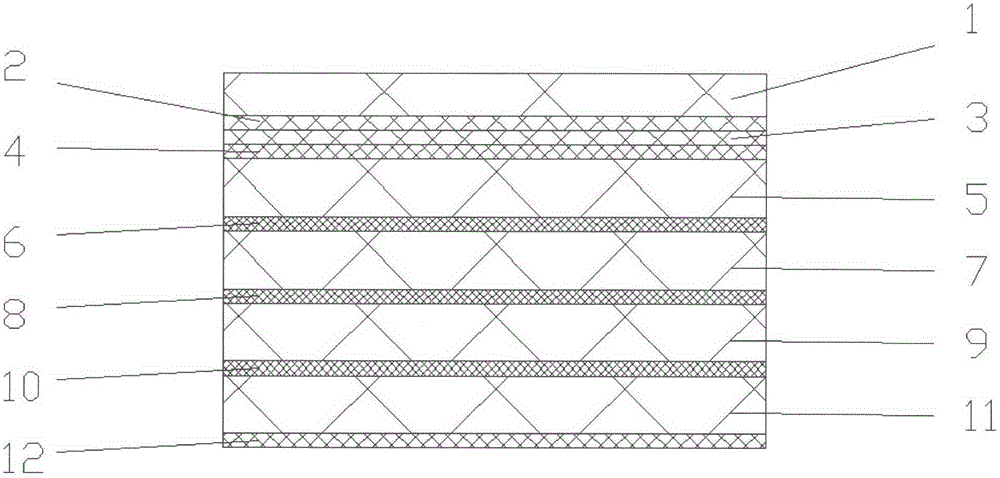

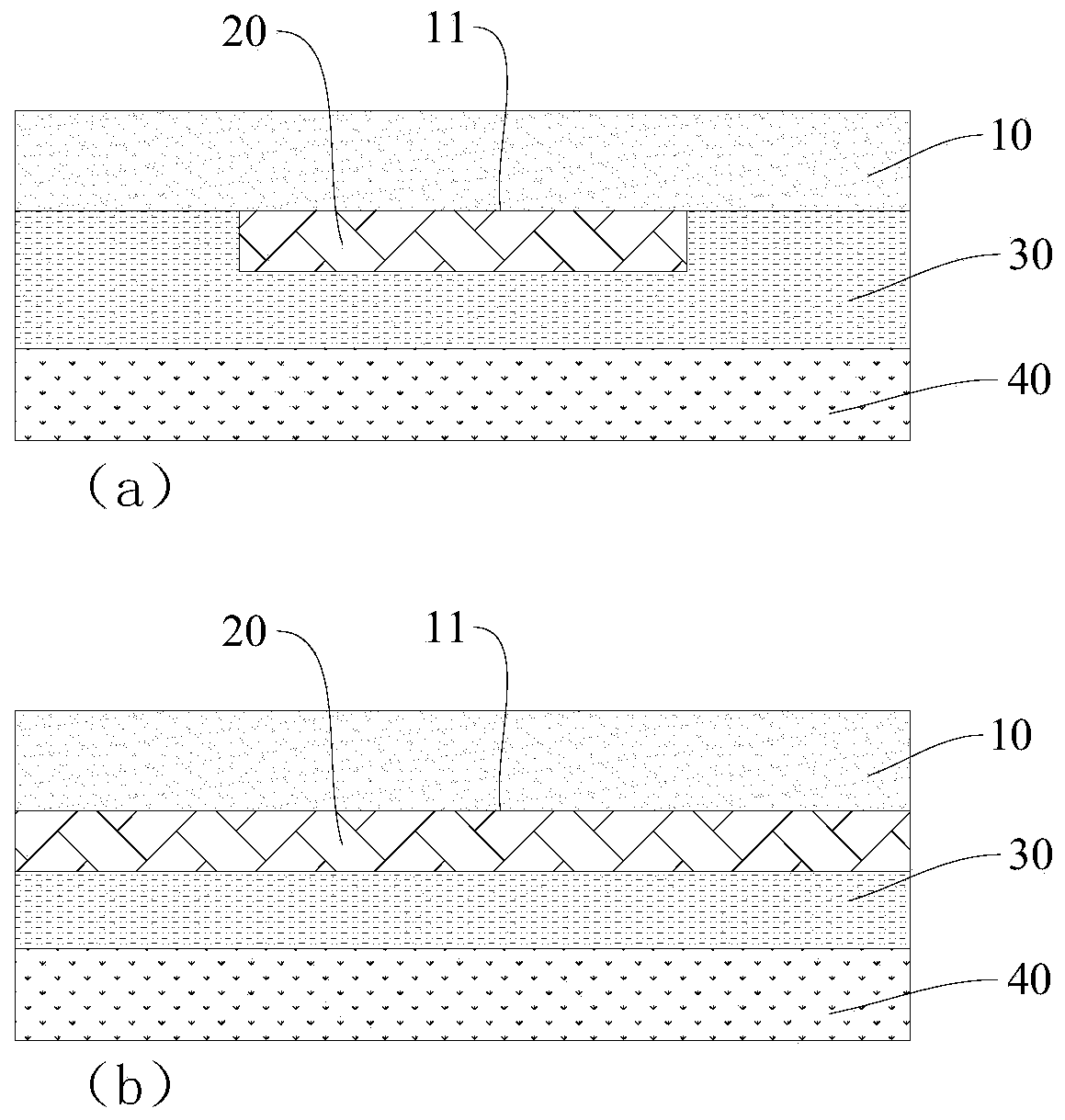

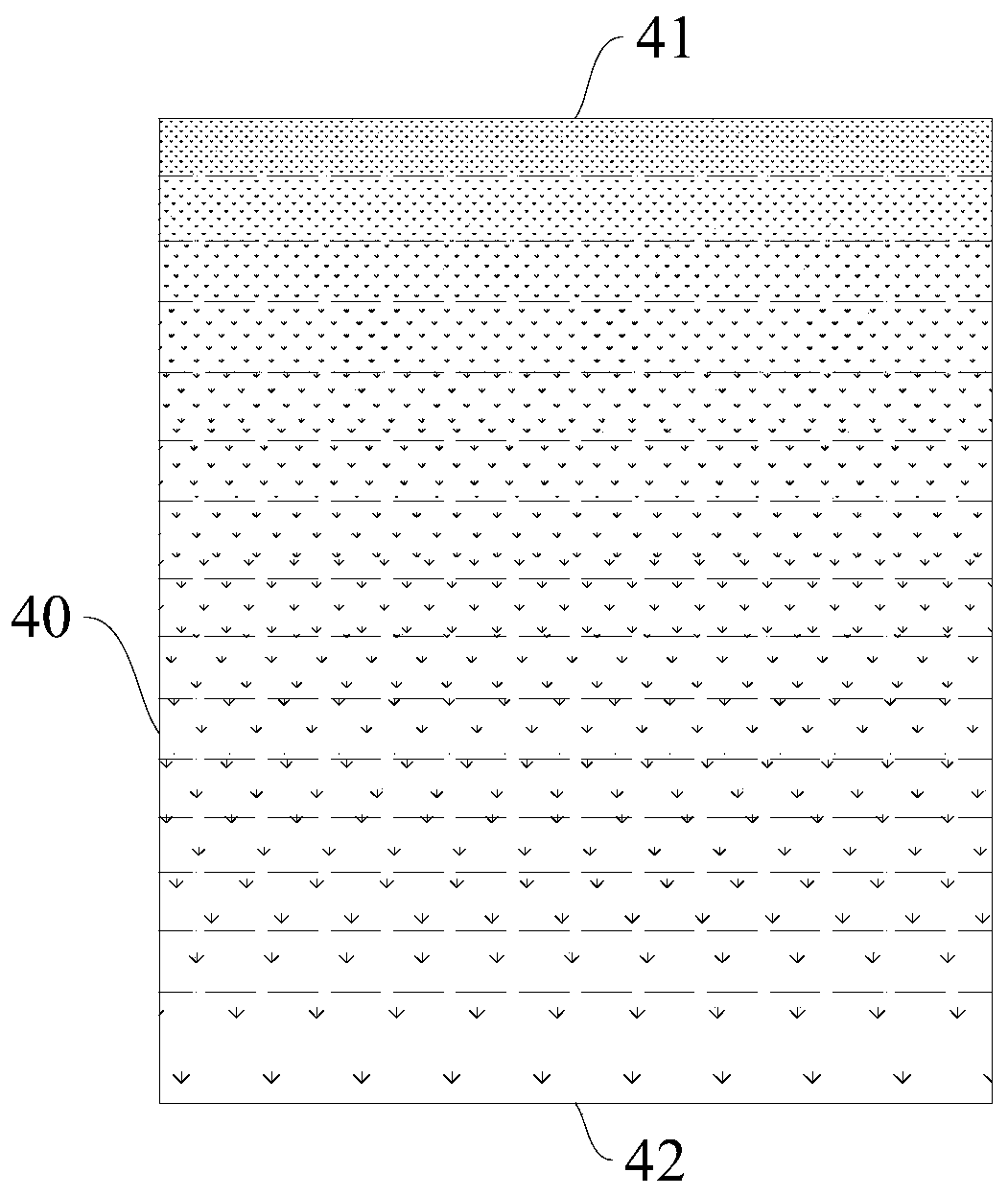

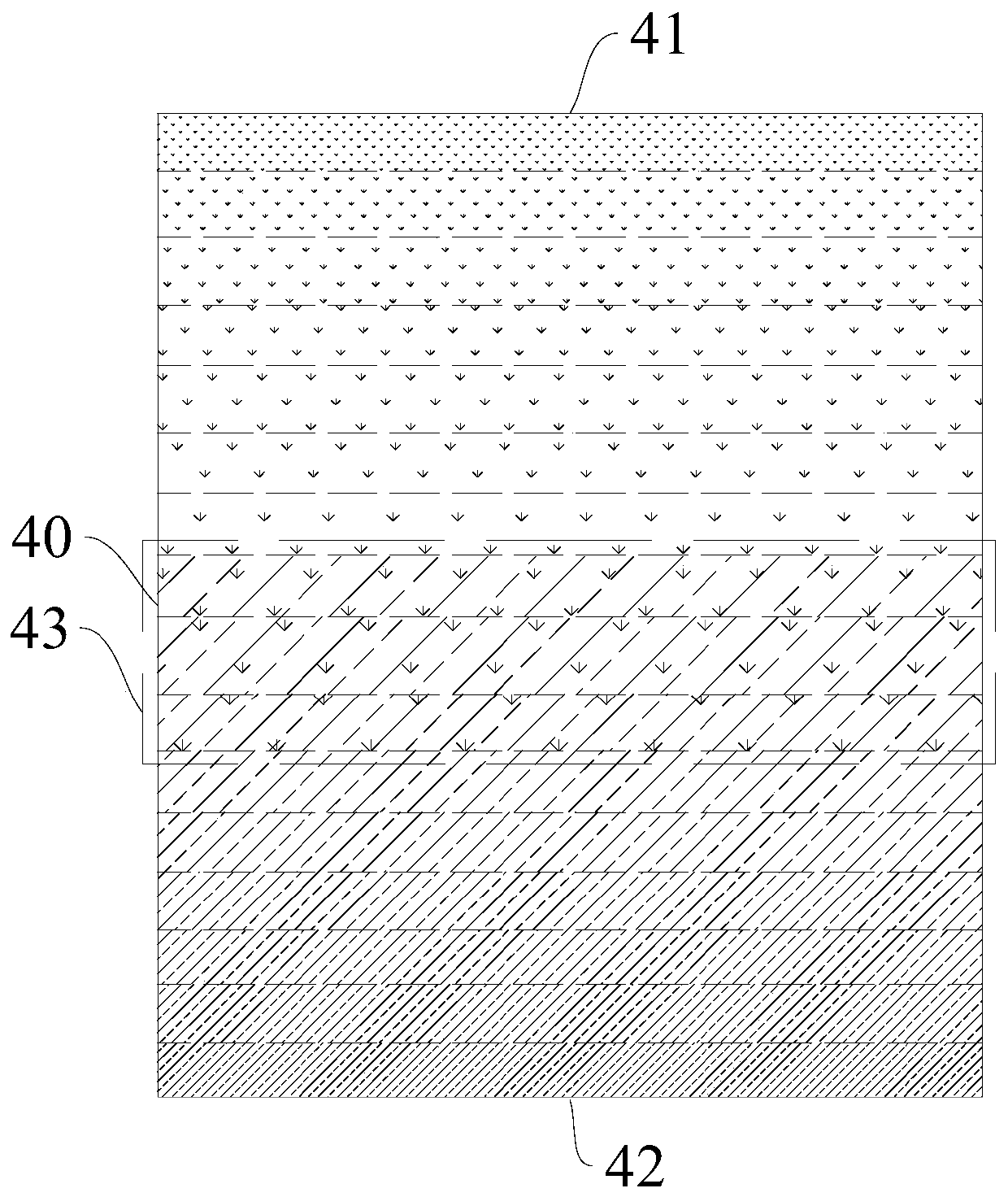

Composite board and production method thereof

ActiveCN105479866APrevent penetrationAvoid crackingLamination ancillary operationsLaminationGlass fiberSurface layer

The invention discloses a composite board and a production method thereof, and relates to the field of building materials. The composite board comprises a bamboo veneer surface layer, and glue-dipped paper layers and kraft paper which are sequentially and repeatedly arranged, or glass fiber net layers, glue-dipped paper layers and bamboo veneer layers which are sequentially and repeatedly arranged, wherein all the layers are pressed and connected together through high temperature and high pressure, large-molecular-weight glue is adopted for the first glue-dipped paper layer under the bamboo veneer surface layer, and small-molecular-weight glue is adopted for the rest of the glue-dipped paper layers. The production method of the composite board includes the following steps of firstly, conducting high-temperature desugaring and degreasing on the bamboo veneer layers except the bamboo veneer surface layer; secondly, attaching non-woven fabric or a glass fiber net to the back face of the bamboo veneer surface layer; thirdly, drying and balancing all the bamboo veneer layers processed in the first step and the second step; fourthly, absorbing fire retardant from the dried and balanced bamboo veneer layers through the negative pressure mode; fifthly, sequentially, repeatedly and flat laying the bamboo veneer surface layer, the glue-dipped paper layers and the kraft paper or laying the glass fiber net layers, the glue-dipped paper layers and the bamboo veneer layers on a pressing machine layer by layer, and closely pressing all the bamboo veneer layers and the kraft layers or pressing the glass fiber net layers and the glue-dipped paper together through pressure of the pressing machine. By means of the technical scheme, the composite board has effects of water prevention, fire retardance and high strength.

Owner:陈竹

Preparation technology of nutritious stretched noodles

InactiveCN104855812AImprove toughnessGreat tasteMulti-step food processesFood ingredient functionsNutritive valuesProtein molecules

The invention discloses a preparation technology of nutritious stretched noodles. The preparation technology of the nutritious stretched noodles is characterized by comprising the following steps: (1) preparing raw materials; (2) mixing the prepared ingredients; (3) performing pressing; (4) performing rolling; (5) forming round by rubbing; (6) performing stretching; (7) performing drying; (8) performing cutting so as to obtain sections; (9) performing polishing. The preparation technology has the advantages that (1) auxiliary juice is added in the ingredients, the nutritive value is high, and the health of humans is benefited; (2) during the preparation of stretched noodles, repeated dough fermentation is performed, and protein molecules sufficiently absorb moisture and stretch during dough fermentation, so that the prepared stretched noodles are tough, chewy and smooth, and do not contaminate soup; (3) repeated stretching is performed during the preparation of the stretched noodles, the volume is reduced, and the surface area is enlarged, so that the inside protein molecules are combined with water, the toughness of the stretched noodles is uniform, and the problem that the stretched noodles are likely to fracture is effectively solved; (4) the dried stretched noodles are polished, the particles and flour, which are attached to the surface of the stretched noodles are cleared away, so that the noodles are smooth, the soup for cooking the noodles is clear, the cooked stretched noodles do not stick to each other, and the noodles are convenient to eat.

Owner:巴彦淖尔市冠生园食品有限责任公司

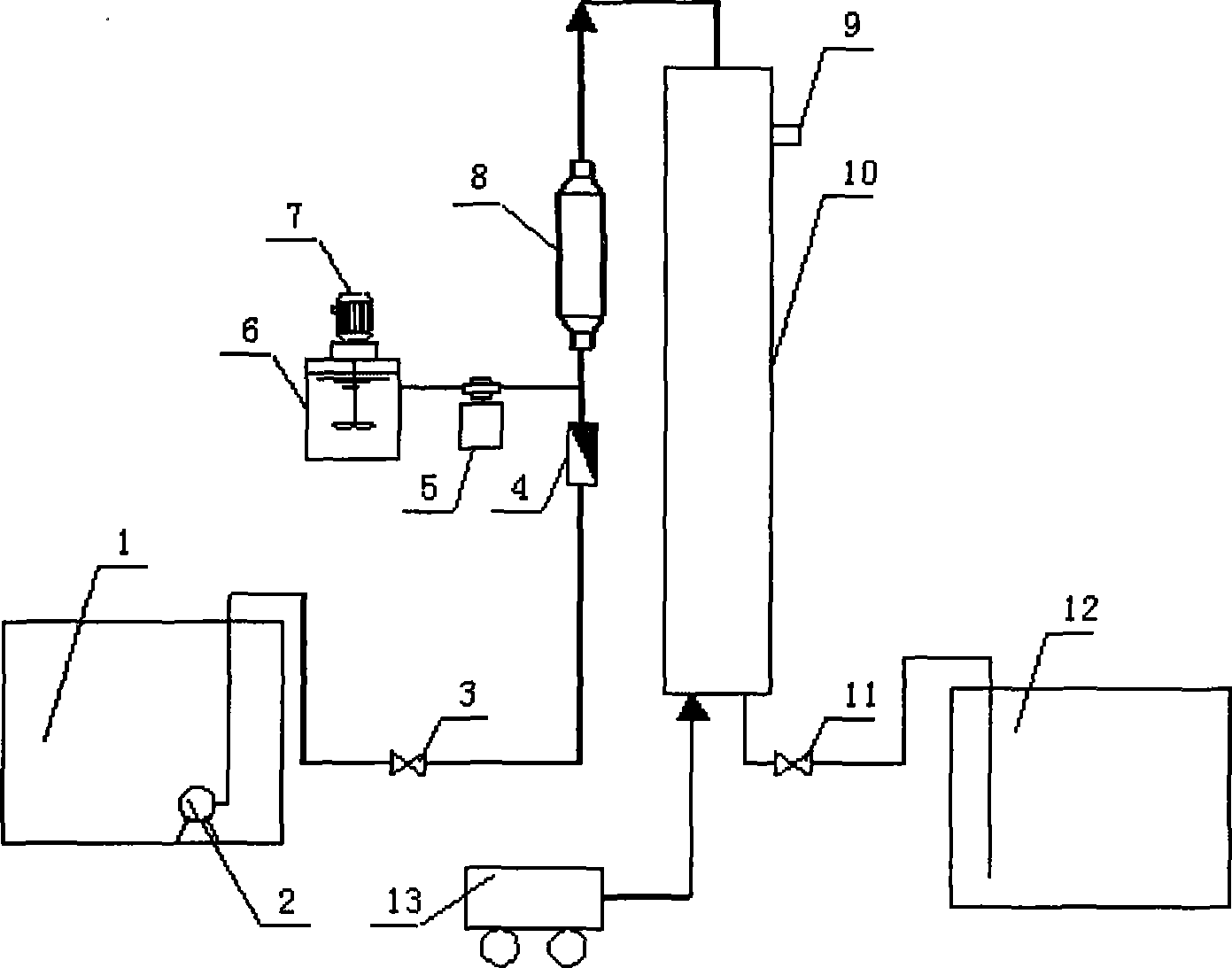

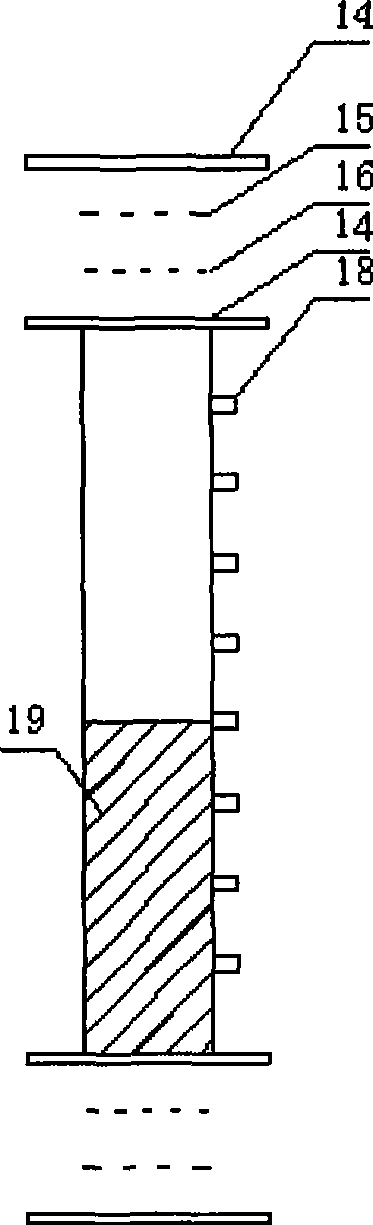

Micro-flocculation-terylene high stretch yarn fibrous globule filterantion and alga removal method and device thereof

InactiveCN101380534AGood removal effectOvercome the shortcomings of large dosage and large amount of sludge productionWater/sewage treatmentFiltration separationYarnFiber

The invention relates to a filter and algae removal method by micro flocculation-terylene high elater fiber balls and equipment thereof. The method comprises: (1) the water to be treated and the flocculant which is added by a wriggle pump are mixed in an inflow pipeline in front of a fiber ball filter column, the water after mixing enters the fiber ball filter column, the filler of the filter column is terylene high elater fiber ball filter material, and the fiber ball filter column carries out reverse washing of low intensity at the end of the filter period; the equipment comprises an original water tank, a water storage tank and a drug adding groove, the original water tank is communicated with a pipeline mixer through a valve flow meter by a lift pump; the drug adding groove is communicated with the pipeline mixer by the wriggle pump, and a stirrer is installed in the drug adding groove; the apopore of the pipeline mixer sends the water to the water storage tank by the fiber ball filter column, and the terylene high elater fiber ball filter material is installed at the middle part of the filter ball filter column. By the terylene high elater fiber ball filter material with the characters of high porosity, large specific surface area, fast filter speed and strong pollutant stopping ability and long filter period, the effect on removing algae and turbidity substances in water is very obvious.

Owner:DONGHUA UNIV

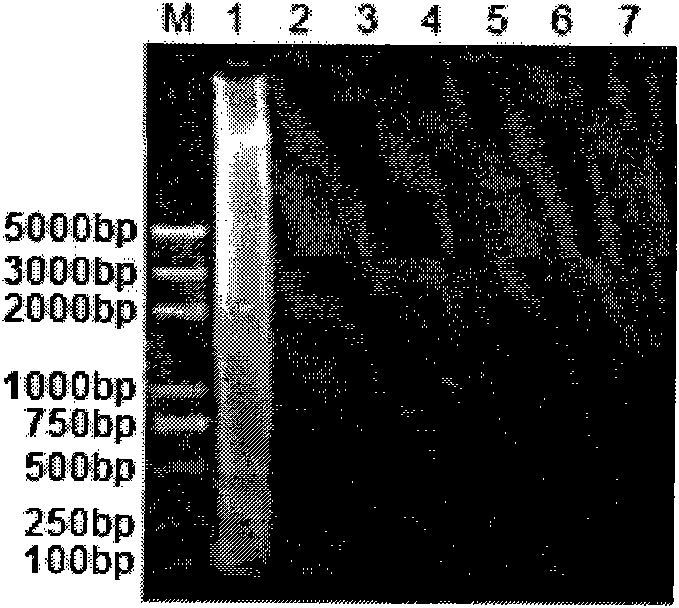

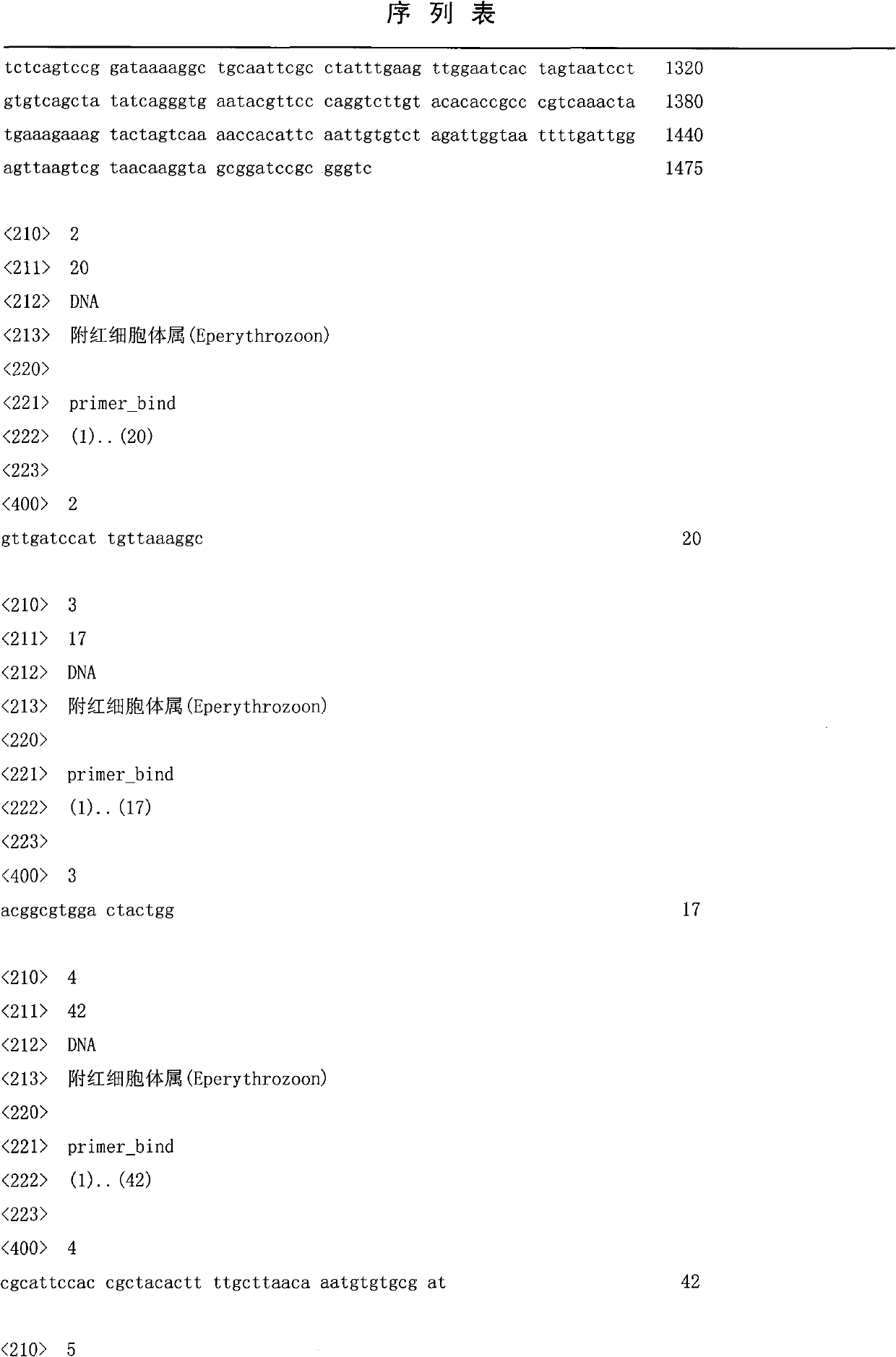

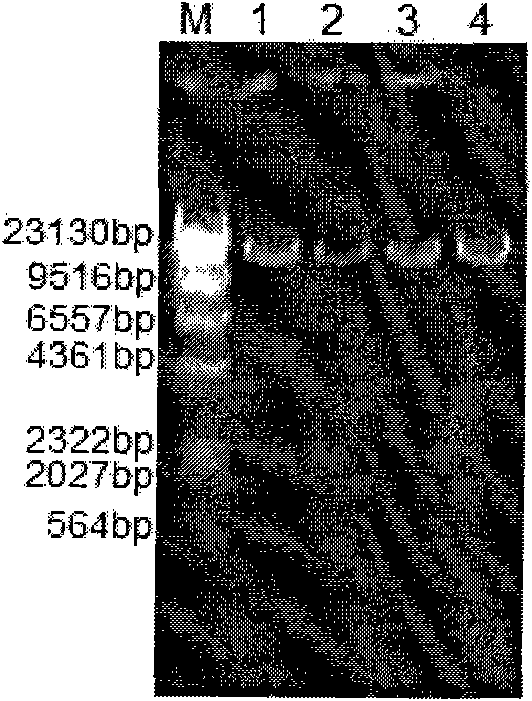

Loop-mediated isothermal amplification detection method of E. wenyoni

InactiveCN101948914AHigh sensitivityIncreased sensitivityMicrobiological testing/measurementWater bathsProtozoa

The invention belongs to the technical field of detection of parasite molecules, and in particular relates to a quick loop-mediated isothermal amplification detection method of E. wenyoni, which comprises the following steps: (1) designing three pairs of specific primers; (2) extracting total DNA of a blood sample; and (3) carrying out loop-mediated isothermal amplification reaction and analyzing the amplification product. By imaging on a gel imaging system and observing the result, E. wenyoni is positive if the amplification product is a stepped pattern formed by zones of different sizes; or SYBR Green I is added to the final product of amplification, and by visually observing the result under natural light, the E. wenyoni is positive if the amplification product turns to green yellow, and the E. wenyoni is negative if the amplification product is reddish brown. The invention has strong specificity and can be used for discriminating common blood protozoa, the sensitivity is high and is 10-100 times higher than that of common PCR, the detection is simple and quick, only one water bath is needed, and the result can be obtained in 1 hour.

Owner:HUAZHONG AGRI UNIV

Housing assembly, making method thereof and electronic device

ActiveCN110087420ANot corrodedIncreasing the thicknessOrnamental structuresCasings/cabinets/drawers detailsElaterEngineering

The invention provides a housing assembly, a making method thereof and an electronic device. The housing assembly comprises a substrate, a pattern layer, a barrier layer and a dip dyeing layer, wherein the pattern layer is arranged on the first surface of the substrate; the barrier layer is arranged on the surface, far away from the substrate, of the pattern layer and covers the exposed first surface; and the dip dyeing layer is arranged on the surface, far away from the substrate, of the barrier layer. Thus, through arranging the barrier layer between the pattern layer and the dip dyeing layer, dye molecules can be effectively prevented from impregnating into the pattern layer and the substrate during dip dyeing, and in a subsequent finished product state, the dye molecules can be prevented from impregnating into the pattern layer and the substrate for a long time, the gloss of the pattern layer and the strength of the substrate can be effectively ensured for a long time, and the pattern layer is ensured not to generate orange peel and fall; the thickness of the dip dyeing layer does not need to be increased, the dyeing uniformity of the dip dyeing layer is further effectively ensured, and the problem that the dip dyeing layer is likely to crack can be effectively prevented; and besides, bad phenomena of a noise point appearing on the dip dyeing layer do not happen.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Jean fabric

InactiveCN107718779AImprove dyeing effectWill not polluteLayered productsBiochemical treatment with enzymes/microorganismsFiberYarn

The invention provides a jean fabric. The jean fabric comprises a jean shell fabric and tweeds, wherein the jean shell fabric and the tweeds are processed with glue on a fabric laminating machine; thejean shell fabric is composed of 60-70% of cotton yarn, 28-32% of terylen and 1-5% of spandex; and the jean shell fabric is sequentially treated through biological enzyme pretreatment, dyeing, soap boiling and an antibacterial corrugation process. Fibers of the jean shell fabric contain lignins, and the lignins can obstruct dye molecules from entering the fibers, thereby causing poor dyeing performance of the fibers; laccase in this step can remove the lignins in the jean shell fabric, thereby improving the dyeing performance; and the residual enzyme washing liquid contains nutrient substances required by aquatic animals and plants and can not pollute water resources after being discharged, thereby protecting the natural environment.

Owner:东莞市卓能纺织服装有限公司

Production of dyed lyocell garments

InactiveUS6949126B2Improve performance against wet creasingIncrease valueTrousersReactive dyesCelluloseCross-link

Garments are constructed from lyocell fabric which has been resinated using a textile resin having just two groups per molecule which can reactively cross-link with cellulose molecules of the lyocell fabric then causticised by application under tension of an aqueous solution of sodium hydroxide, and the constructed garments are dyed in a garment dyeing operation. Garments can be produced by this route which retain a smooth, evenly-dyed appearance with unpuckered seams and minimal creasing and so present a desired formal look, as distinct from the casual look imparted by the effects of fibrillation normally produced when lyocell garments undergo garment dyeing.

Owner:LENZING AG

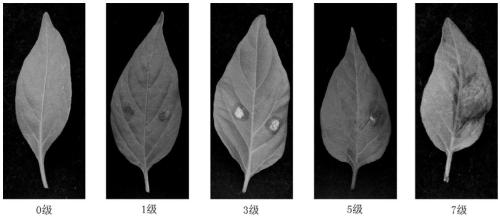

Method for quickly identifying resistance of single pepper plant to gellan anthracnose by using isolated leaves

InactiveCN109628549AImprove identification efficiencyImprove screening efficiencyMicrobiological testing/measurementBiological material analysisDiseaseElater

The invention provides a method for quickly identifying the resistance of a single pepper plant to gellan anthracnose by using isolated leaves, which comprises the following steps of: using isolated functional leaves with stems in a pepper seedling period as a sample to be detected; taking pathogenic bacteria of the coleobacteria anthracnose and inoculating the pathogenic bacteria to the back surfaces of the leaves of the sample to be detected; then placing the sample to be detected in an artificial climate box at a temperature of 28+ / -2 DEG C, carrying out dark culture for 48 hours to obtaina lesion sample, and measuring a lesion diameter of the lesion sample; wherein the sample to be detected is from a pepper plant at a 12-13 leaf seedling stage. The method has the advantages of simpleand rapid steps, stability, reliability and good repeatability, is particularly suitable for molecular marker development, disease resistance identification and genetic analysis of single pepper breeding plant (or strain) such as transgenic strains and the like, can well improve the disease resistance identification and screening efficiency of the pepper, and accelerates the breeding process.

Owner:NORTHWEST A & F UNIV

Easy-care pure cotton woven fabric

InactiveCN106120309AConvenient careImprove wrinkle resistanceVegetal fibresPolyethylene glycolElater

The invention relates to easy-care pure cotton woven fabric. The easy-care pure cotton woven fabric is characterized by comprising the following processing process: preparation of a finishing agent, pretreatment of fabric, double-dip double-nip, pre-drying and curing; during preparation of the finishing agent, fluorine-containing citric acid is adopted as a main finishing agent, and polyethylene glycol and polybasic acid are adopted as additives; the number average molecular weight of polyethylene glycol is 400-600; pretreatment of the fabric comprises a sizing technology including the specific content as follows: pure cotton warp is subjected to sizing treatment with a foam sizing technology, modified starch is taken as a sizing agent, and nano-silica is taken as an aid, so that the warp sizing permeability and evenness are improved. The easy-care pure cotton woven fabric has the advantages of comfortable and soft hand feeling, good moisture absorption and breathability, good dimensional stability, better crease resistance and certain water repellency and oil repellency, and is easy to care.

Owner:JIANGYIN XIANGFEI APPAREL

Method for processing water soft cotton knitted fabric

InactiveCN101818406BGood drapabilityGood flexibilityWeft knittingBleaching apparatusSurface finishFiber

The invention relates to a method for processing water soft cotton knitted fabric, which comprises the following steps of: preparation of grey yarns, enzyme washing of the grey yarns, weaving, boiling, dyeing, dehydration, drying, super-soft treatment, sizing and preshrinking. In the method, after the yarns are subjected to enzyme treatment, the fibers become porous and loose so that the yarns become soft and fluffy and the dyeing rate is improved, and fluffs on the surfaces of the yarns are removed so as to achieve the effects on surface finish and piling resistance and improve the drapability, softness and water absorbability of the fabric; and by combining the post super-soft treatment, polyurethane in finishing liquor can easily permeate into the yarns and produce cross-linking reaction with fiber molecules and other aid groups to form a three-dimensional netlike structure so as to endow the fabric with the characteristics of durable elasticity and dimensional stability and 'watersoft cotton' softness like water. The final finished fabric produced by the method has the advantages of soft and exquisite handfeel, strong gloss sense, surface finish and good resilience.

Owner:WUXI NATURAL GREEN FIBER TECH

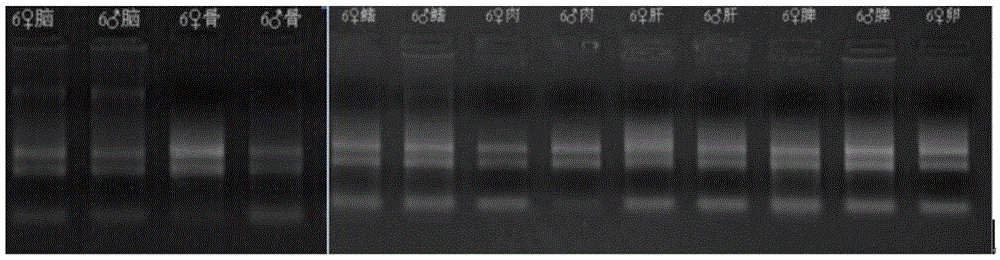

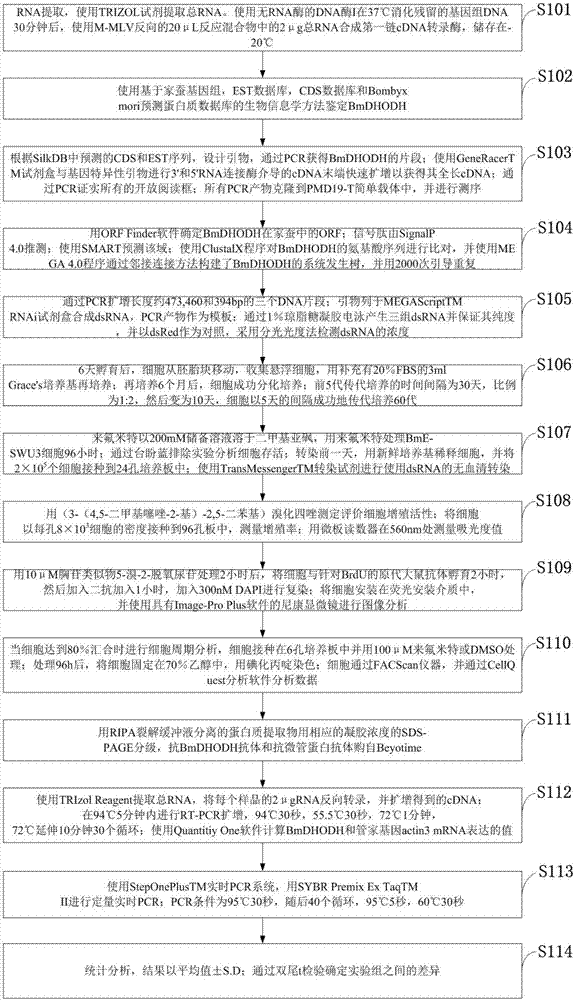

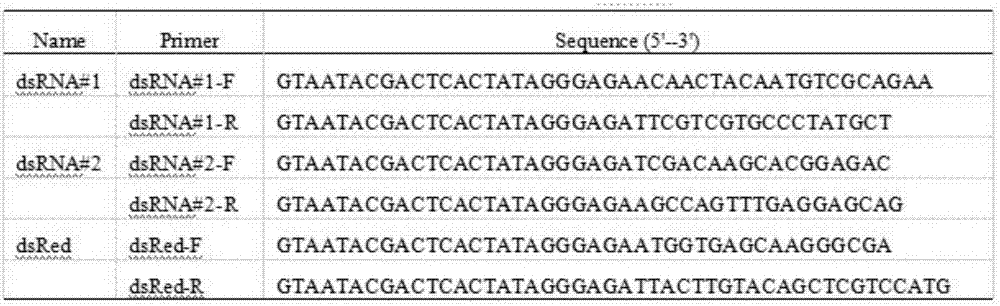

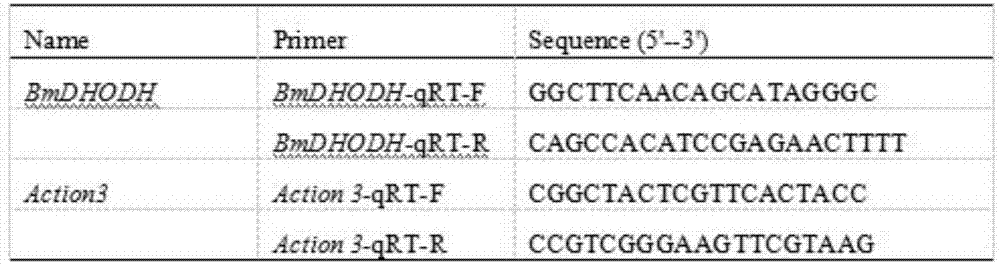

Molecular cloning and identifying method for silkworm gene

ActiveCN107384882AAffect growth and proliferationRich basic knowledgeMicrobiological testing/measurementOxidoreductasesPsocopteraTheoretical methods

The invention belongs to the field of biology and discloses a molecular cloning and identifying method for a silkworm gene. The sequence of the silkworm gene is SEQ ID NO:1; and the silkworm gene is named BmDHODH. The method disclosed by the invention has the advantages that leflunomide is used for treating silkworm cells and has great inhibitory effect on BmDHODH expression and cell proliferation; as a component in pyrimidine synthesis, BmDHODH is a necessary biological enzyme closely related with cell growth and proliferation, can become a new gene target for killing lepidoptera pests, provides new opinion for eco-friendly pest control and provides a new target and a new theoretical method for developing an environment-friendly pesticide; and as a biological model for the lepidoptera pests, basic knowledge of the lepidoptera pests can be enriched for silkworm BmDHODH, and a new method is provided for environment-friendly pest control.

Owner:SOUTHWEST UNIVERSITY

Lotus root silk fibre

InactiveCN1737223ABeautiful and long-lastingHas a health effectSuture equipmentsTourniquetsFiberTourniquet time

This invention relates to a lotus root fabric textile replication, which belongs to a new type green textile in present textile field. The lotus root fabric textile can be used for making operation stylolite, etamine, upper bleeding strip and tourniquet, characterized in that it can solve the problem of adhesion, demolition, degradation, allergic and so on. The invention does not cause tissue inflammation in inserted place and allergic reaction, and can penetrate and diffuse with muscle and bleed molecule in body; besides, it can automatically digest, absorb and biodegradation without clearing, so it is a spare piece of emergency injury process.

Owner:杨建年

Summer sleeping mat fabric with no harms to human bodies

InactiveCN107776115AChange variabilityChange the shortcomings such as poor strengthSynthetic resin layered productsCoatingsPolyesterHuman body

The invention relates to a summer sleeping mat fabric with no harms to human bodies. The summer sleeping mat fabric comprises a bottom layer (1), wherein a fixed layer (2) and an outer layer (3) are arranged at the outer part of the bottom layer in sequence; the outer layer (3) adopts an ultrahigh molecular weight polyethylene adhesive coating. A lining fabric layer is arranged on the back surfaceof the bottom layer; the lining fabric layer is formed by sinking and floating interweaving of warp yarns and weft yarns; the warp yarns and the weft yarns adopt 20D / 50S modal-coated polyester yarns;the warp yarns and the weft yarns are interwoven at intervals in a one-up and one-down manner to form plain weaves. According to the summer sleeping mat fabric provided by the invention, the elasticity and the strength are increased; the hand feeling and the size stability are improved. The summer sleeping mat fabric provided by the invention has no harms to the human bodies.

Owner:JIANGYIN HUAYIN CERAMIC ELECTROMECHANICAL TECH

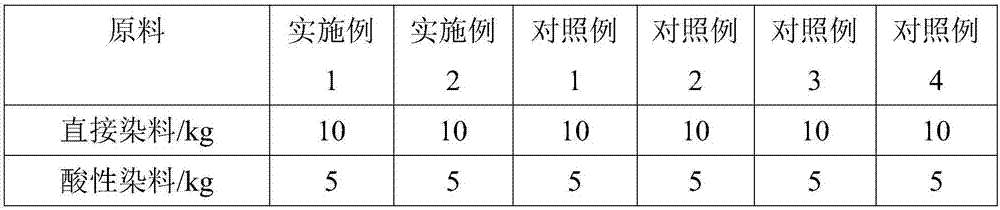

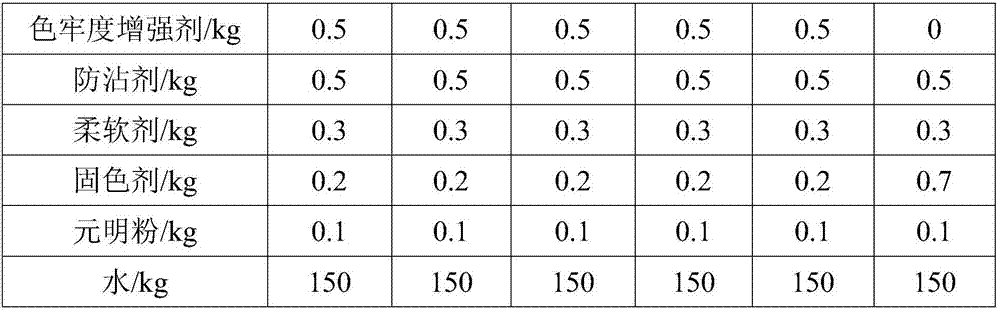

Color fastness enhancer for dyeing of wool-cotton blended yarn

The invention discloses a color fastness enhancer for dyeing of wool-cotton blended yarn and relates to the technical field of textile dyeing auxiliaries. The color fastness enhancer is prepared from raw materials in parts by weight as follows: 10-15 parts of polyglutamic acid, 5-10 parts of methoxypolyethylene glycols, 1-3 parts of hexakis(methoxymethyl)melamine, 1-3 parts of polyethylene oxide, 0.5-2 parts of turpentine oil, 0.5-2 parts of an ultramicro penetrating agent, 0.5-2 parts of hydrogenated castor oil, 0.1-0.5 parts of sepiolite fiber powder, 0.1-0.5 parts of sodium gluconate and 0.05-0.1 parts of nano-zinc oxide. The color fastness enhancer is good in water solubility and can be rapidly dissolved in an aqueous dye solution, so that adhesive force of dye molecules on wool-cotton fibers is enhanced, color fastness of wool-cotton blended fabric woven after dyeing is improved, and appearance use quality of the fabric is guaranteed.

Owner:ANHUI GOLDEN DIAMOND INTELLIGENT TECH CO LTD

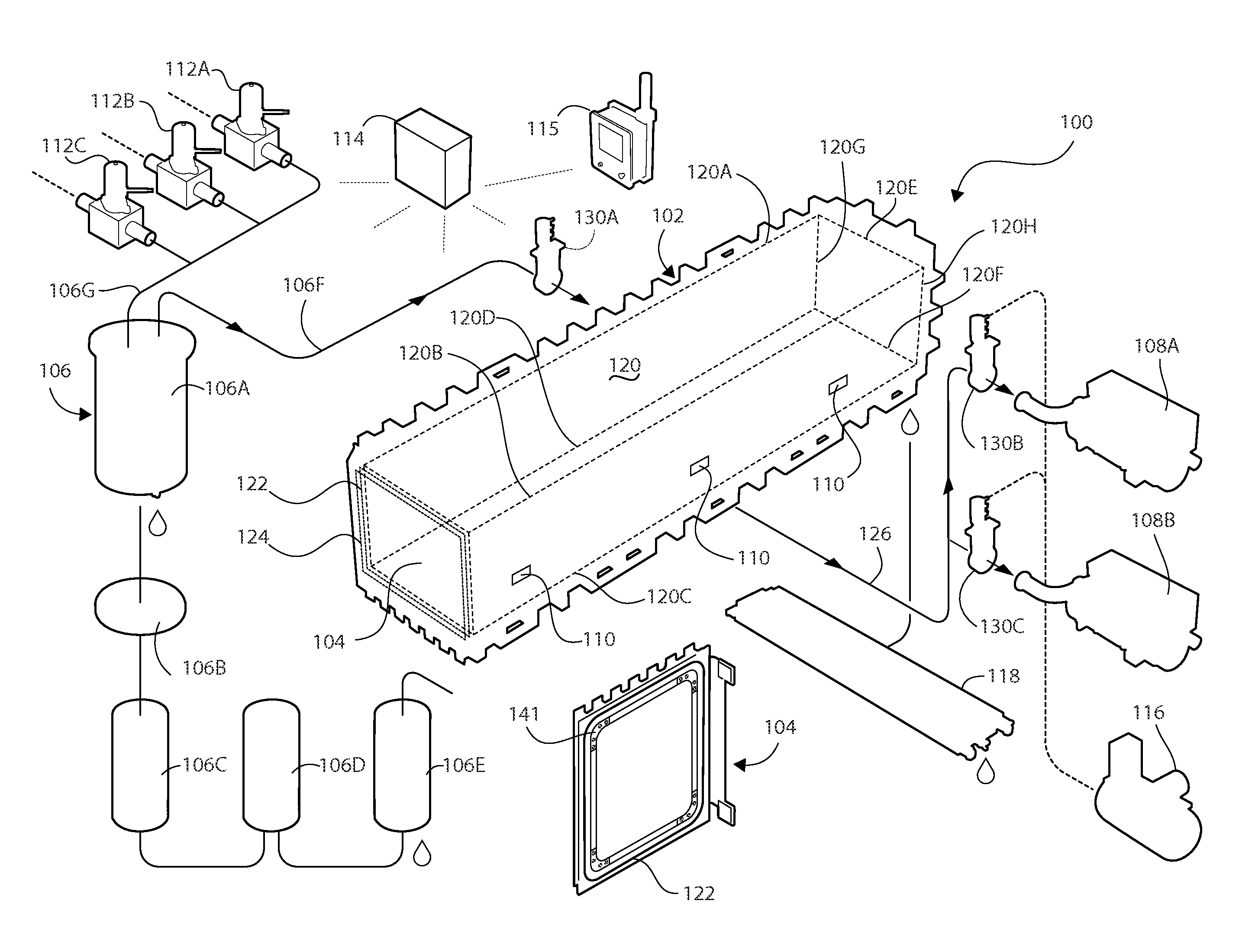

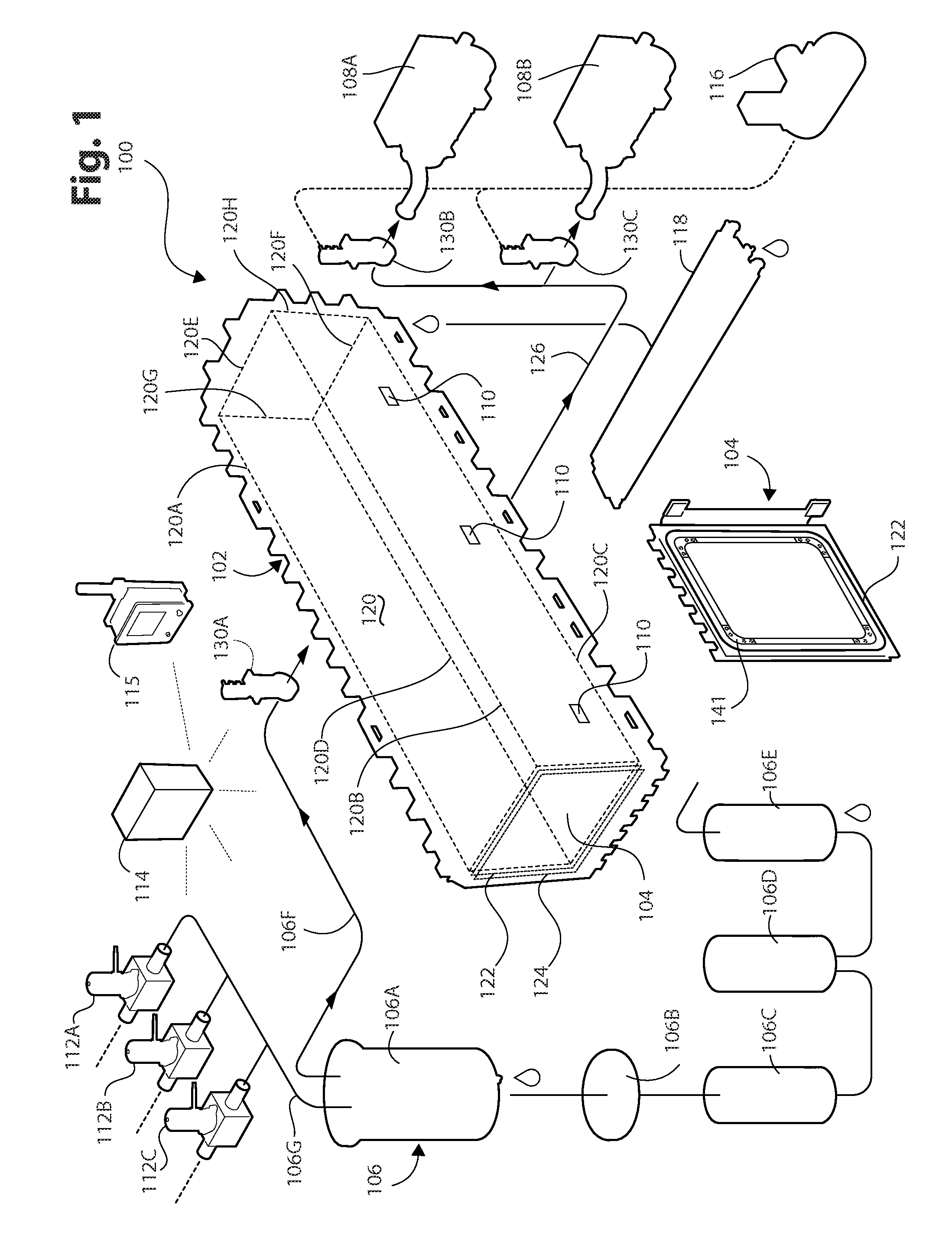

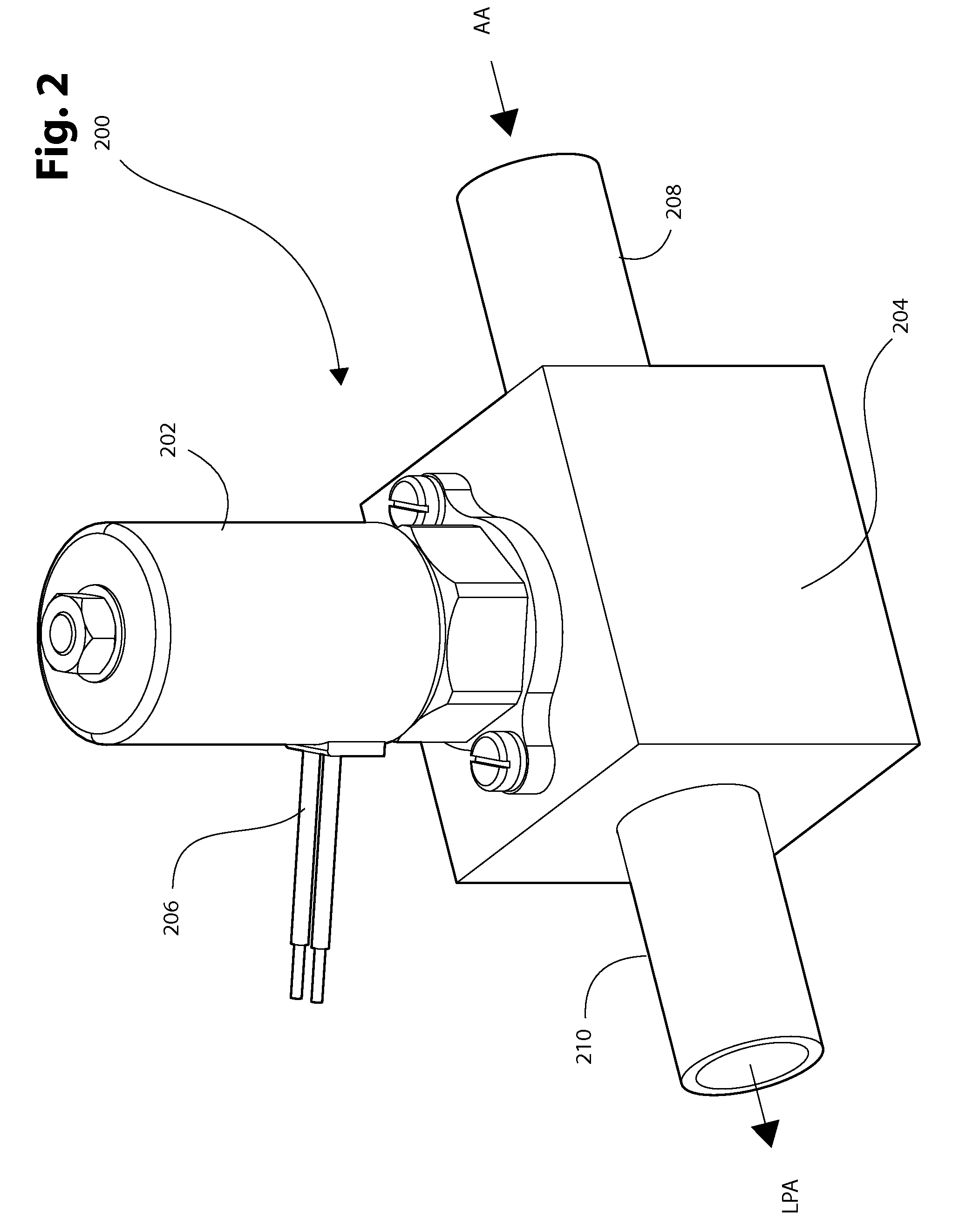

Systems and methods for controlled pervaporation in horticultural cellular tissue

InactiveUS8632737B2Reduce supplyPrevent tissueBioreactor/fermenter combinationsBiological substance pretreatmentsChilling injuryLife stage

A hypobaric apparatus and methods capable of inducing and maintaining in stored horticultural cellular tissue controlled pervaporation of undesired chemical compounds without reaching the boiling point of intracellular water molecules, comprising a hypobaric chamber constructed to provide a leak rate of less than 4.0 mm Hg per hour, sensors and regulators coupled to the chamber and to a controller to measure and regulate target correlates. Commodities processed, including processing storage periods longer than any known involving controlled atmosphere, exhibit an absence of low oxygen injury, high carbon dioxide injury, chilling injury, leaf abscission, leaf de-greening, fungal decay, bacterial decay, gravitational curving, geotropic curvatures, leaf epinasty, stem epinasty, flower fading, senescence, live invertebrates at any life stage, fumigant chemical compounds, volatile fungicides, volatile bactericides; no advance in ripening; minimal water loss.

Owner:ATLAS BIMETAL LABS

Tensile resistant pearl cotton

InactiveCN106335261AImprove tensile propertiesImprove protectionSynthetic resin layered productsLow-density polyethyleneMonoglyceride

The invention relates to tensile resistant pearl wool, which is characterized by comprising a tensile resistant layer and a pearl cotton base layer. The tensile resistant layer is arranged on the upper surface of the pearl cotton base layer. The pearl cotton base layer is prepared by steps of mixing molecular distilled monoglyceride and low-density polyvinyl ester and foaming. The tensile resistant layer is prepared by thermal synthesis of a film and a pearl cotton matrix, wherein the film is prepared from PET<12>, PE<147> and PET<12>. The invention has the following beneficial effects: as the tensile resistant layer is added to the pearl cotton, tensile resistance of the material is increased, and an article to be packaged can be better protected; and the product has a very wide application range.

Owner:ANHUI YILIN PLASTIC IND CO LTD

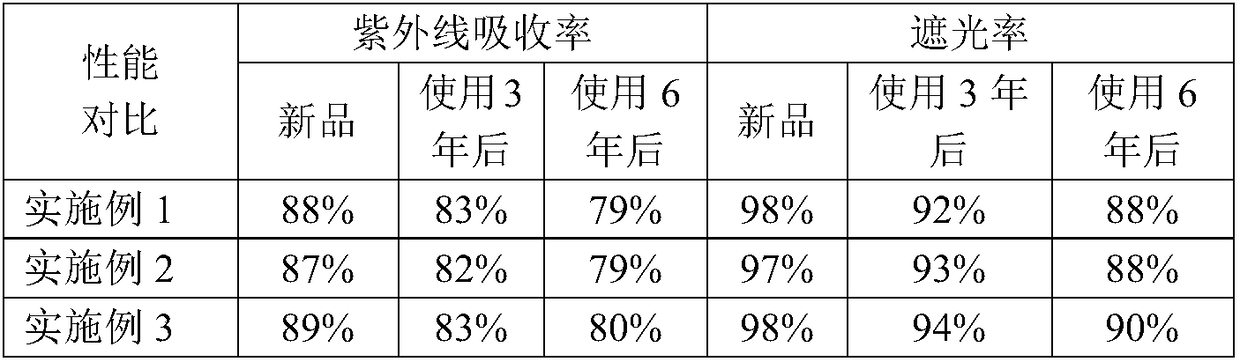

Anti-aging shading screen cloth

InactiveCN108327370AStrong UV resistanceStrong service lifeSynthetic resin layered productsDomestic netsPolyesterPolyolefin

The invention discloses a piece of anti-aging shading screen cloth. The cloth comprises a three-layer composite screen cloth structure: an outer anti-ultraviolet layer screen cloth, an inner anti-microbial layer screen cloth, and an intermediate elastic layer screen cloth; the outer anti-ultraviolet layer screen cloth comprises the following spinning materials in percentages by mass: 40-60% of polyester fiber, 10-20% of copper ion fiber, and the balance being corn fiber; the inner anti-microbial layer screen cloth comprises the following spinning materials in percentages by mass: 30-60% of polyester fiber, 10-20% of silver ion fiber, and the balance being anti-microbial vegetable fiber; the intermediate elastic layer screen cloth comprises the following spinning materials in percentages bymass: 20-40% of polyether ester elastic fiber, 30-50% of polyolefin elastic fiber, and the balance being a two-component composite crimped fiber. Compared with the prior art, the product is advantageous in that ultraviolet resistance is high, addition of other micromolecular anti-ultraviolet absorbents with easy volatile migration is avoided, chemical performance of the finished product is stable, generation of volatile migration is not easy, the product has lasting anti-ultraviolet absorption property and shading performance, and the product has long service life, aging resistance, and corrosion resistance.

Owner:苏州市欧贝遮阳科技有限公司

Production of highly oriented graphene oxide films and graphitic films derived therefrom

ActiveUS10005099B2Increase length and widthLarge grainMaterial nanotechnologyGraphitePolymer scienceElater

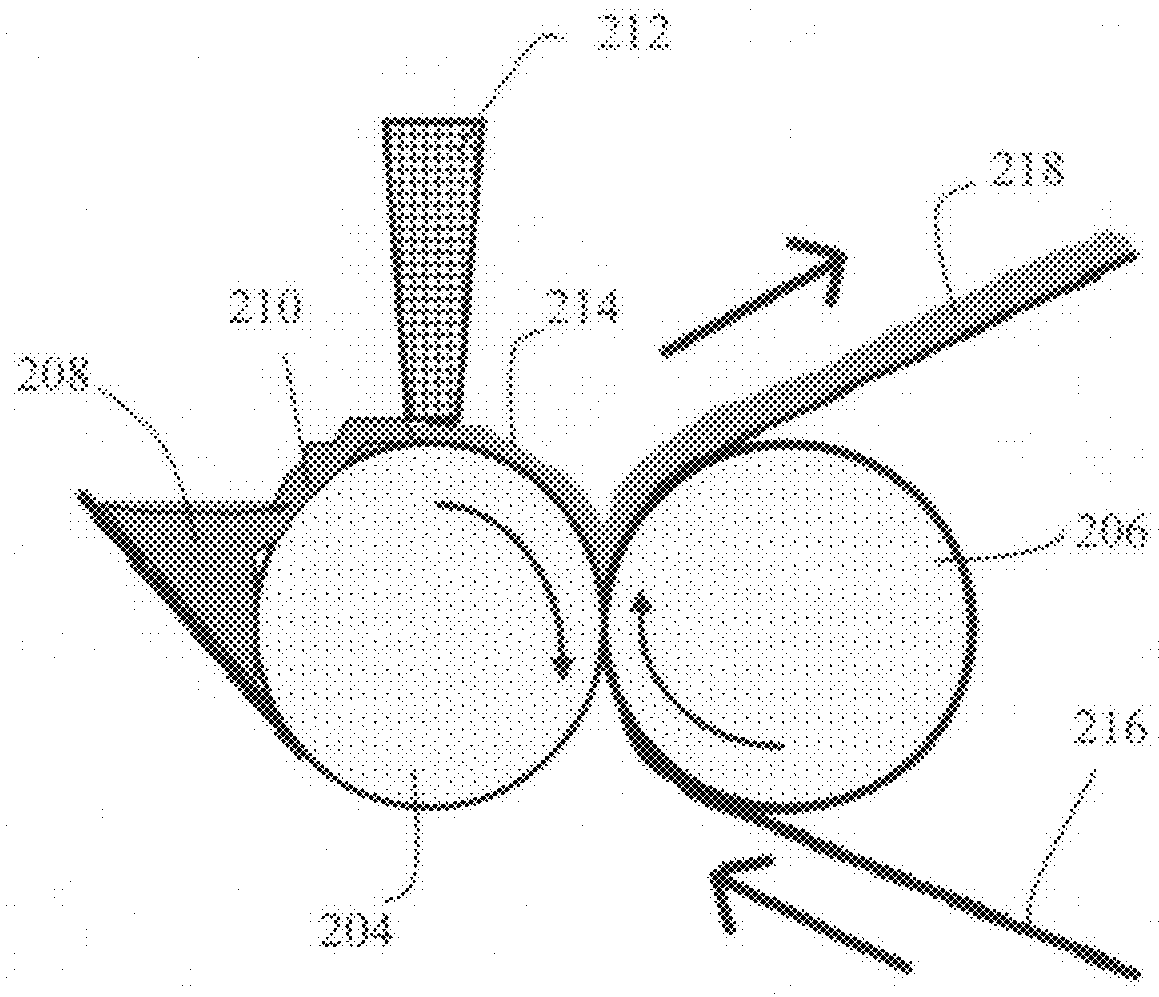

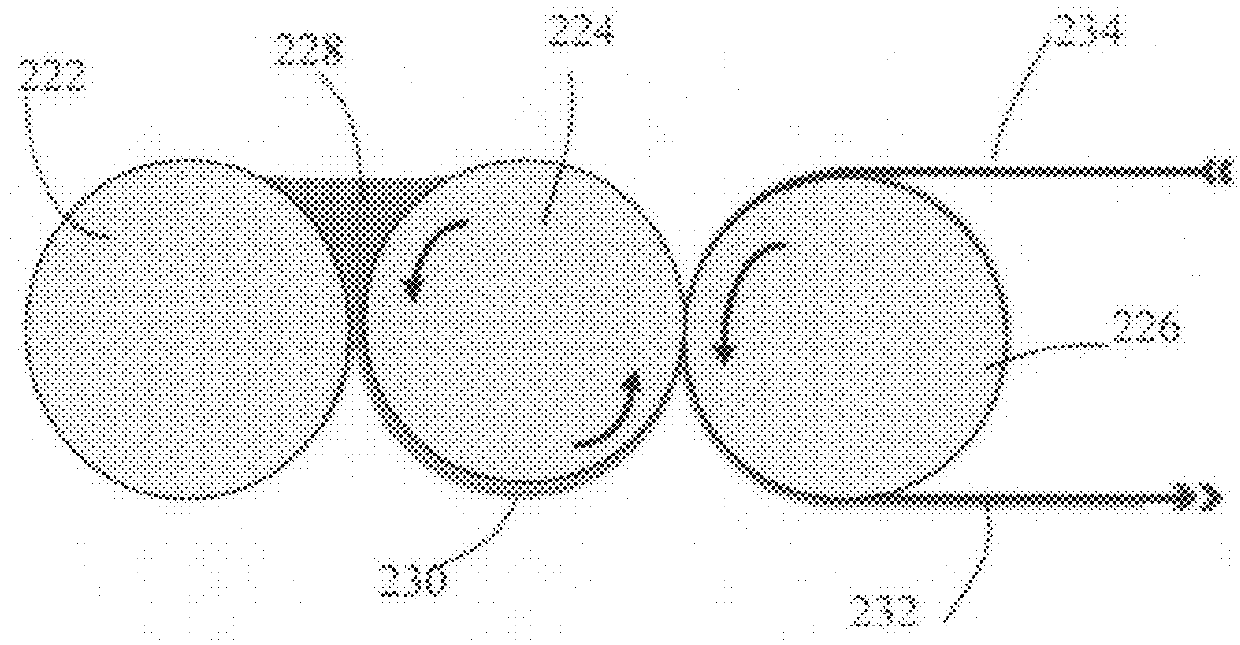

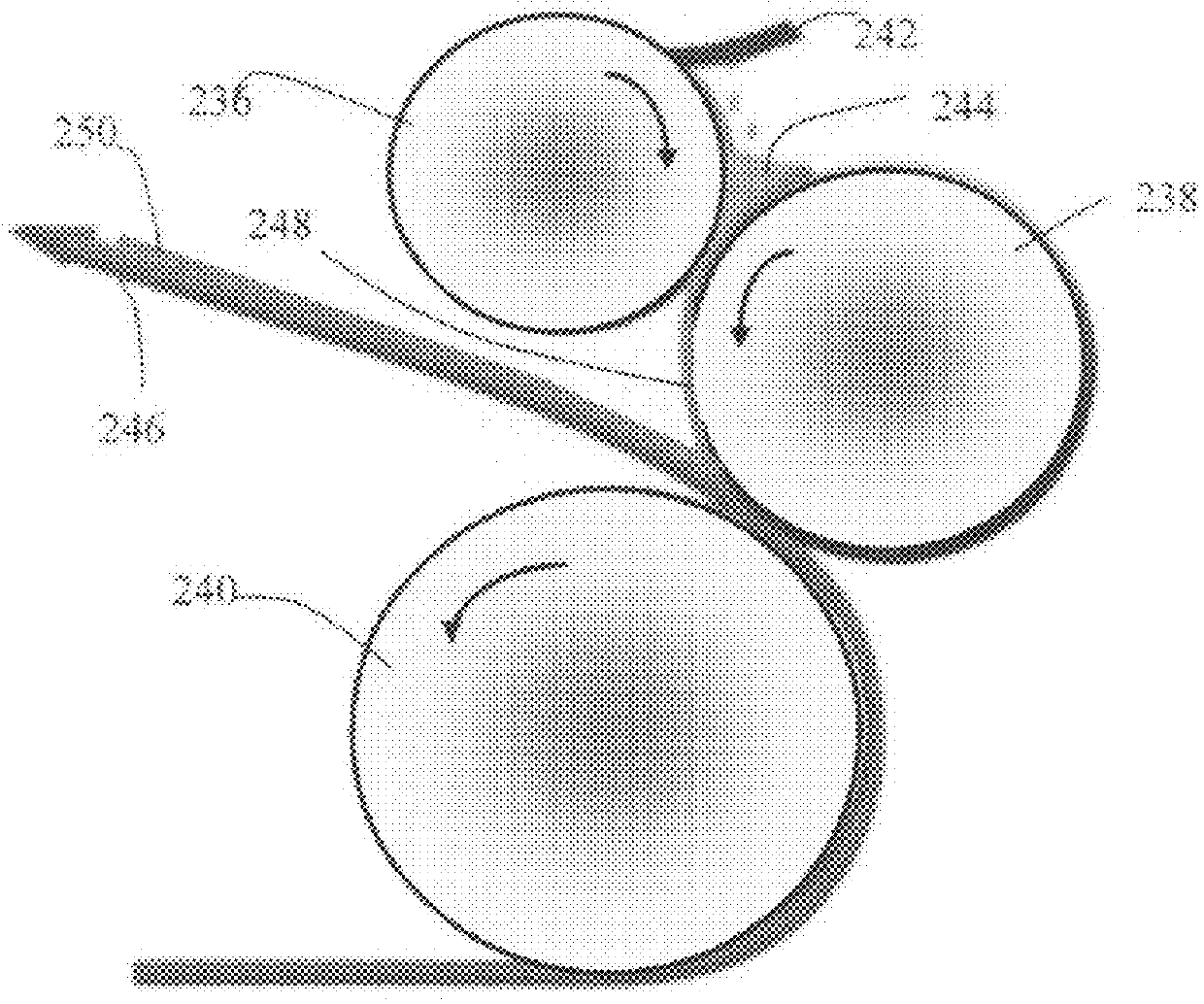

A process for producing a highly oriented graphene oxide (GO) film, comprising: (a) preparing either a GO dispersion having GO sheets dispersed in a fluid medium or a GO gel having GO molecules dissolved in a fluid medium; (b) dispensing the GO dispersion or gel onto a surface of an application roller rotating in a first direction to form an applicator layer of GO and transferring the applicator layer to a surface of a supporting film driven in a second direction opposite to the first direction to form a wet layer of GO on the supporting film; and (c) removing said fluid medium from the wet layer of GO to form a dried layer of GO having an inter-planar spacing d002 of 0.4 nm to 1.2 nm and an oxygen content no less than 5% by weight. This dried GO layer may be heat-treated to produce a graphitic film.

Owner:GLOBAL GRAPHENE GRP INC

High-antibacterial chromatophilous carpet yarn masterbatch and preparation method of high-antibacterial chromatophilous carpet yarn

ActiveCN102775743AEnsure nano silver contentWell mixedMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

The invention relates to a high-antibacterial chromatophilous carpet yarn masterbatch which has high antibacterial chromatophilous function and can kill the harmful single cell bacteria parasitized in the organic pollutants of carpet, and a preparation method of high-antibacterial chromatophilous carpet yarn. The carpet yarn masterbatch comprises the following components in percentage by weight: 1-5% of nano-silver, 52-56% of modified polyester chips (easy cationic dyeable polyester, ECDP), and 40-45% of polyethylene low molecular wax. The high-antibacterial chromatophilous carpet yarn masterbatch has the following advantages: firstly, the carpet yarn masterbatch has a broad spectrum of antimicrobial activity;, once the bacteria invade the carpet yarns, the nano-silver particles directly enter the bacteria and bind to the oxygen metabolism enzyme, so as to kill the bacteria, fungus, mycete, spores and other microorganisms in contact with the nano-silver particles; secondly, the carpet yarn masterbatch has strong bactericidal activity, because the silver (Ag) can kill more than 650 kinds of bacteria within several minutes, a very small amount of nano-silver particles at low concentration in the carpet yarns can quickly kill the pathogens; thirdly, the carpet yarn masterbatch has strong permeability, which can quickly penetrate organic pollutants to the depth of 2mm for sterilization and has good bactericidal effect on ordinary bacteria and stubborn bacteria; fourthly, the antimicrobial effect is lasting; and fifthly, the carpet yarn masterbatch is safe and non-toxic.

Owner:ZHEJIANG SITONG NEW MATERIAL TECH CO LTD

After finishing technology of woolen knitted fabric

InactiveCN106480622AImprove washing effectImprove permeabilitySucessive textile treatmentsLiquid/gas/vapor removalWorking fluidWarm water

The invention discloses an after finishing technology of a woolen knitted fabric. The technology comprises washing shrinkage treatment, softening treatment and drying treatment. The washing shrinkage treatment comprises the steps of selecting washing shrinkage agent KJF-10A which accounts for 3%-5% of the weight of a fabric, using warm water to stir the washing shrinkage agent evenly, adding the washing shrinkage agent into working liquid of 38-40 DEG C, soaking the working fluid for 15-20 min, and then washing the working fluid for 20-25 min; the softening treatment comprises the steps of adopting a bath ratio of 1:30-1:40 in the warm water, selecting softening smoothing agent A80 which accounts for 2%-4% of the weight of the fabric to soak for 20-30 min, and then conducting dehydration for 5-6 min; the drying treatment comprises the steps of conducting drying at 50-65 DEG C for 30-40 min. The after finishing technology of the woolen knitted fabric has the advantages that by adjusting components of detergent, the detergent still has activity in a low temperature state as that in a high temperature state, and thus the washing effect at a low temperature is constant or even better; meanwhile, softening agent with a structure of short chain segment and a small molecular is selected, and permeability of the softening agent at the low temperature is increased so as to guarantee the after finishing effect and achieve the purpose of reducing energy consumption and carbon discharge.

Owner:NANTONG YUEDA KNITTING GARMENT

Health bamboo vinegar paste

InactiveCN101934115AAvoid rednessAvoid itchingNervous disorderHydroxy compound active ingredientsHouttuyniaElater

The invention discloses a health bamboo vinegar paste prepared from special components by adding cordate houttuynia, abyssal chitin and tourmaline to a medicine core, adding a suitable amount of borneol powder to improve comfort and adding a great amount of starch. The starch is fully soaked with a mixed solution of bamboo vinegar liquid and chili liquid, dried and thinned so that the bamboo vinegar paste absorbing enough bamboo vinegar liquid molecules and chili liquid molecules can enhance the health function of a human body and suitably decrease the production cost. When the invention is in use, an adhesive plaster for synergistic use is convenient to use by adopting a sticky strip thereon, 2-3 rows of vent holes are evenly arranged on the periphery of the adhesive plaster so as to lessen skin irritation and avoid allergic symptoms, such as skin redness, itch, dermatitis, and the like and can satisfy assured use and health needs of most crowds.

Owner:张遂峰

Antibacterial and bacteriostatic nonwoven fabric formula

The invention discloses an antibacterial and bacteriostatic nonwoven fabric formula. The formula is characterized by comprising the following components: 46%-49% of polypropylene resin H5380-1 with amelt index value of 38; 46%-48% of polypropylene resin V30G with a melt index value of 22; and 5%-8% of water-soluble zinc antibacterial and bacteriostatic masterbatch. Through the above proportion, the melt value compatibility and fluidity of the components can be adjusted, so that water-soluble zinc antibacterial and bacteriostatic molecules can be smoothly and evenly fused into polypropylene resin, thus obtaining a mixed solution with good fluidity. The above proportion can ensure a smooth production process and avoid equipment damage.

Owner:SPRO MEDICAL PROD (XIAMEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com