Composite board and production method thereof

A technology of composite board and production method, which is applied in the field of building materials, can solve the problems of non-flammability, poor strength, and non-waterproof, etc., and achieve the effect of increasing strength and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

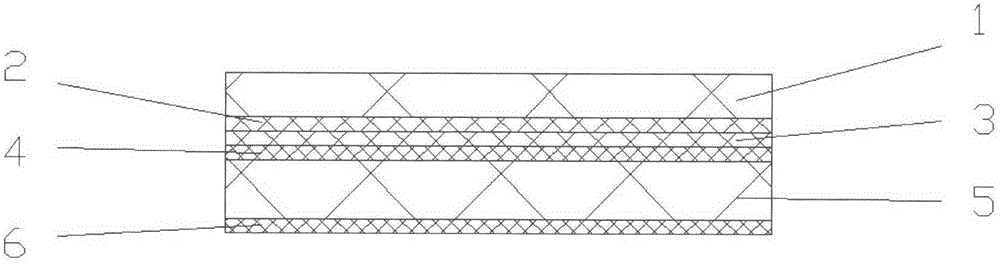

[0025] Embodiment one: if figure 1 The schematic structural diagram of the composite board of the present invention shown is a kind of oak tempered wood with a thickness of 0.6mm. The first layer: oak panel with a thickness of 0.45mm, with non-woven fabric on the back; the second layer: paper impregnated with high molecular weight glue with a thickness of 0.05mm; the third layer: kraft paper with a thickness of 0.2mm; the fourth layer: impregnated with a small molecular weight glue with a thickness of 0.1mm Adhesive paper, the fifth layer, 0.5mm thick poplar veneer, the sixth layer: 0.1mm thick small molecular weight glue impregnated paper.

[0026] The large molecular weight glue component includes melamine 50%-55%, plasticizer 35%-40%, formaldehyde 3%-5%; the small molecular weight glue component includes melamine 70%-82%, plasticizer 5%- 12%, formaldehyde 3%-6%; non-woven fabric or fiberglass mesh on the back of the surface layer can prevent cracking of the surface layer. ...

Embodiment 2

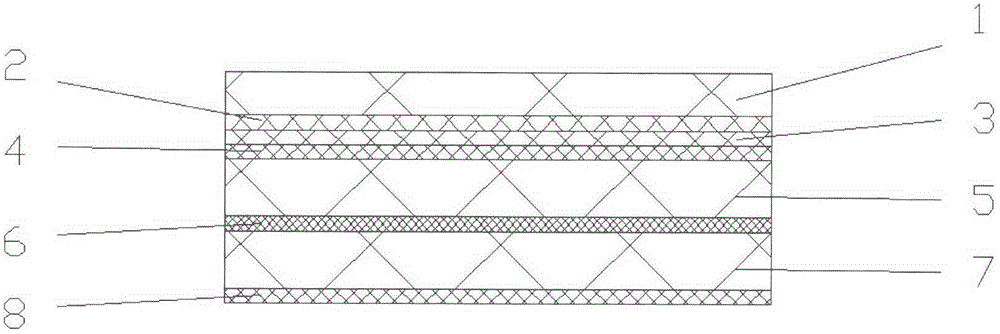

[0034] Embodiment two: if figure 2 The schematic structural diagram of the composite board of the present invention shown is a black walnut tempered wood with a thickness of 1.1 mm. The first layer: black walnut panel with a thickness of 0.5mm, and the back is bonded with non-woven fabric; the second layer: a thick 0.05mm high molecular weight glue impregnated paper; the third layer: a thick 0.2mm kraft paper; the fourth layer: a thick 0.1mm small molecular weight glue Adhesive paper, 5th layer: 0.8mm thick poplar veneer, 6th layer: 0.1mm thick small molecular weight glue impregnated paper, 7th layer: 0.8mm thick poplar veneer, 8th layer: 0.1mm thick small molecular weight glue impregnated Paper.

[0035] The large molecular weight glue component includes melamine 50%-55%, plasticizer 35%-40%, formaldehyde 3%-5%; the small molecular weight glue component includes melamine 70%-82%, plasticizer 5%- 12%, formaldehyde 3%-6%; the back of the 0.5mm black walnut panel is glued wit...

Embodiment 3

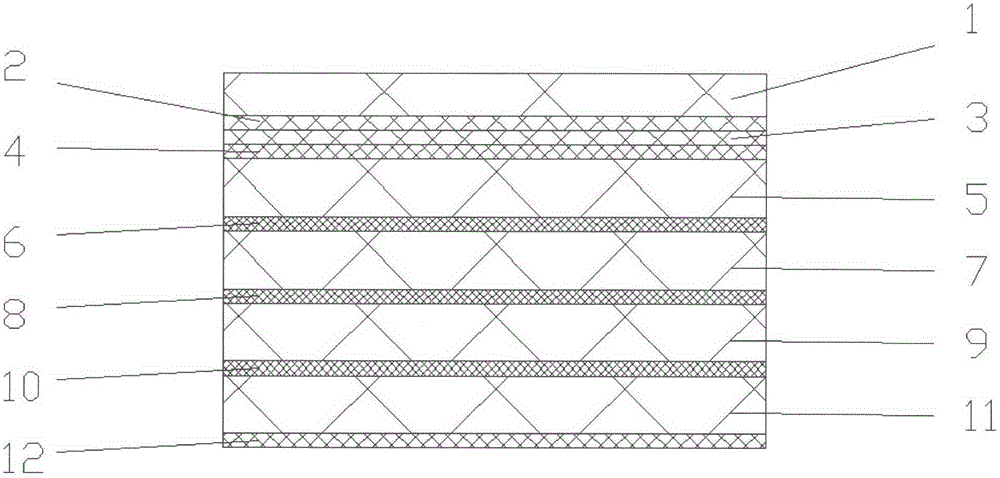

[0043] Embodiment three: as image 3 The schematic structural diagram of the composite board of the present invention shown is a black walnut tempered wood with a thickness of 2.1 mm. The first layer: black walnut panel with a thickness of 0.5mm, and the back is bonded with non-woven fabric; the second layer: a thick 0.05mm high molecular weight glue impregnated paper; the third layer: a thick 0.2mm kraft paper; the fourth layer: a thick 0.1mm small molecular weight glue Adhesive paper, 5th layer: 0.8mm thick poplar veneer, 6th layer: 0.1mm thick small molecular weight glue impregnated paper, 7th layer: 0.8mm thick poplar veneer, 8th layer: 0.1mm thick small molecular weight glue impregnated Paper, the ninth layer: 0.8mm thick poplar veneer, the tenth layer: 0.1mm thick small molecular weight glue impregnated paper, the eleventh layer: 0.8mm thick poplar veneer, the 12th layer: 0.1mm thick small molecular weight glue impregnated paper.

[0044] The large molecular weight glue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com