Anti-aging shading screen cloth

An anti-aging and mesh technology, which is applied in the field of sunshade mesh, can solve the problems of the anti-ultraviolet ability and light-shielding ability of the light-shading mesh, affecting the service life, and prone to aging. Strong service life and stable chemical properties of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

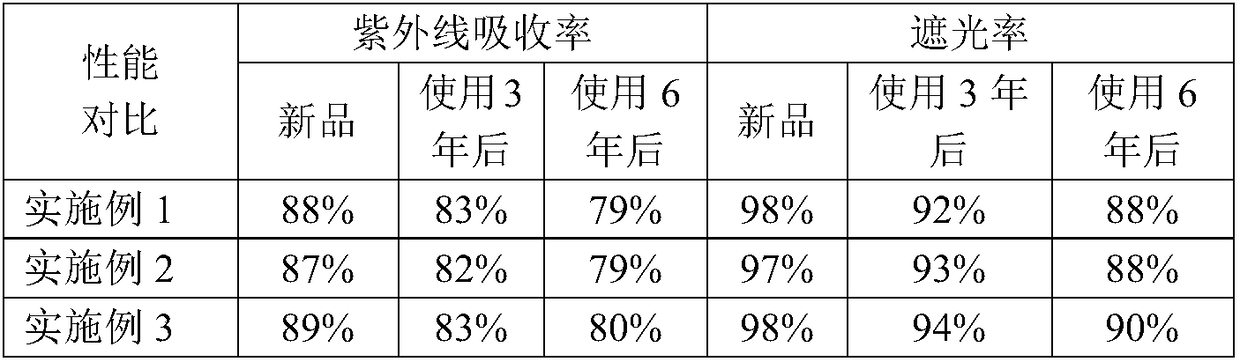

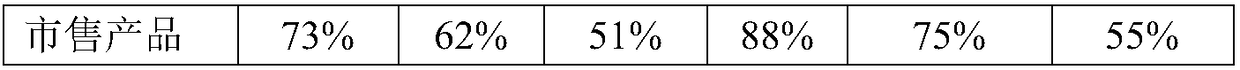

Examples

Embodiment 1

[0020] Anti-aging sunshade mesh, including three-layer composite mesh structure: outer anti-ultraviolet layer mesh, inner antibacterial layer mesh, middle elastic layer mesh;

[0021] The spinning material of the outer anti-ultraviolet layer mesh cloth includes by mass: 40% polyester fiber, 20% copper ion fiber, and corn fiber in the balance;

[0022] The spinning material of the inner antibacterial layer net cloth includes by mass: 30% polyester fiber, 20% silver ion fiber, and the antibacterial plant fiber of the balance;

[0023] The spun material of the mesh cloth of the middle elastic layer comprises, by mass: 20% of polyether ester elastic fibers, 50% of polyolefin elastic fibers, and the balance of bicomponent composite crimped fibers.

[0024] Wherein, the thickness of the outer anti-ultraviolet layer mesh is 0.1mm; the thickness of the inner antibacterial layer mesh is 0.3mm; the thickness of the middle elastic layer mesh is 0.2mm; the polyester fiber is polyester fil...

Embodiment 2

[0026] Anti-aging sunshade mesh, including three-layer composite mesh structure: outer anti-ultraviolet layer mesh, inner antibacterial layer mesh, middle elastic layer mesh;

[0027] The spinning material of the outer anti-ultraviolet layer mesh cloth includes by mass: 60% polyester fiber, 10% copper ion fiber, and corn fiber in the balance;

[0028] The spinning material of the inner antibacterial layer net cloth includes by mass: 60% polyester fiber, 10% silver ion fiber, and the antibacterial plant fiber of the balance;

[0029] The spun material of the mesh cloth of the middle elastic layer comprises, by mass: 40% of polyether ester elastic fibers, 30% of polyolefin elastic fibers, and the balance of bicomponent composite crimped fibers.

[0030] Wherein, the thickness of the outer anti-ultraviolet layer mesh is 0.3mm; the thickness of the inner antibacterial layer mesh is 0.2mm; the thickness of the middle elastic layer mesh is 0.4mm; the polyester fiber is polyester fil...

Embodiment 3

[0032] Anti-aging sunshade mesh, including three-layer composite mesh structure: outer anti-ultraviolet layer mesh, inner antibacterial layer mesh, middle elastic layer mesh;

[0033] The spinning material of the outer anti-ultraviolet layer net cloth includes by mass: 50% polyester fiber, 15% copper ion fiber, and corn fiber in the balance;

[0034] The spinning material of the inner antibacterial layer net cloth includes by mass: 45% polyester fiber, 15% silver ion fiber, and the antibacterial plant fiber of the balance;

[0035] The spun material of the mesh cloth of the middle elastic layer comprises, by mass: 30% of polyether ester elastic fibers, 40% of polyolefin elastic fibers, and the balance of bicomponent composite crimped fibers.

[0036] Wherein, the thickness of the outer anti-ultraviolet layer mesh is 0.2mm; the thickness of the inner antibacterial layer mesh is 0.25mm; the thickness of the middle elastic layer mesh is 0.3mm; the polyester fiber is polyester fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com