Yak wool dyeing method for anti-felting pretreatment of yak wool

A dyeing method, the technology of yak cashmere, which is applied in the field of yak cashmere dyeing, can solve the problems of inconspicuous effect, achieve the effects of improving dyeing activity, realizing low-temperature dyeing, and benefiting the dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

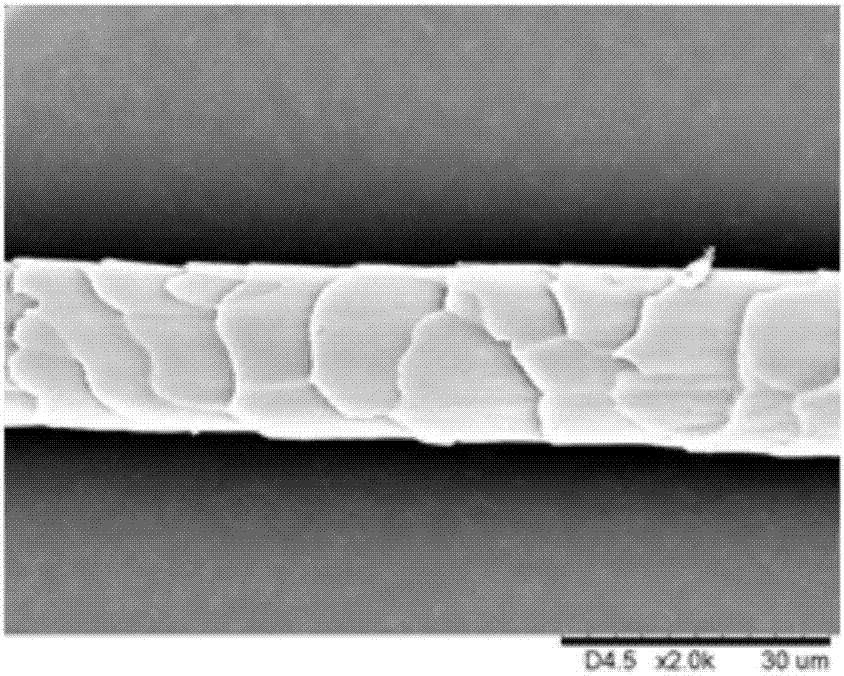

Image

Examples

Embodiment Construction

[0028] A yak wool dyeing method using yak wool anti-felting pretreatment according to the present invention will be further described in detail through specific examples below.

[0029] A method for dyeing yak cashmere by anti-felting pretreatment, comprising the steps of:

[0030] (1) Anti-felting pretreatment process

[0031] Pretreatment: place the yak wool in a solvent with a mass fraction of 1% alkyl polyoxyethylene ether (that is, Pingpingjiao), heat wash it for 20-40mim at an ambient temperature of 45°C, and finally wash it with ethanol and hot water to remove it. Fiber residual impurities;

[0032] Oxidation treatment of fibers: at room temperature, prepare a mixed solution of hydrogen peroxide and sodium pyrophosphate, and place the fibers in the mixed solution to react;

[0033] Oxidation treatment process conditions: the treatment bath is a solution containing 6% hydrogen peroxide with a mass concentration of 30%, sodium pyrophosphate 1-2g / L, pH 4.0, normal temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com