Method for dyeing wool fabric at low temperature

A low-temperature dyeing and fabric technology, applied in the field of dyeing and finishing, can solve the problem of wool damage and achieve the effect of optimizing pretreatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

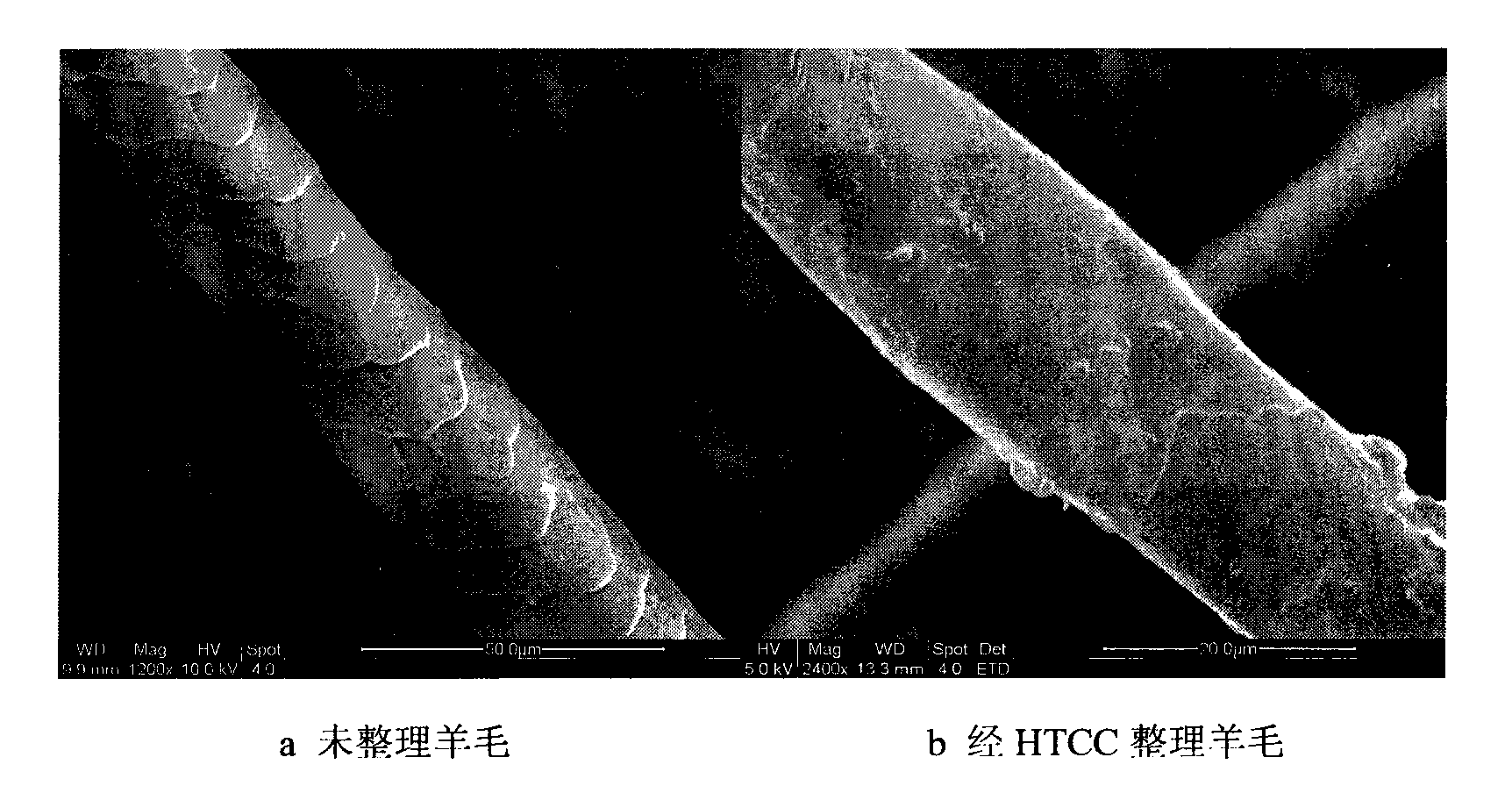

[0025] 1. HTCC finishing process of wool

[0026] Prepare 40mL of finishing solution with a pH of 3 and an HTCC concentration of 10g / L, heat to 50°C, put 2g of wool fabric into the finishing solution (bath ratio = 1:20), soak for 30min, dip in twice, wash with water, and wash at low temperature drying.

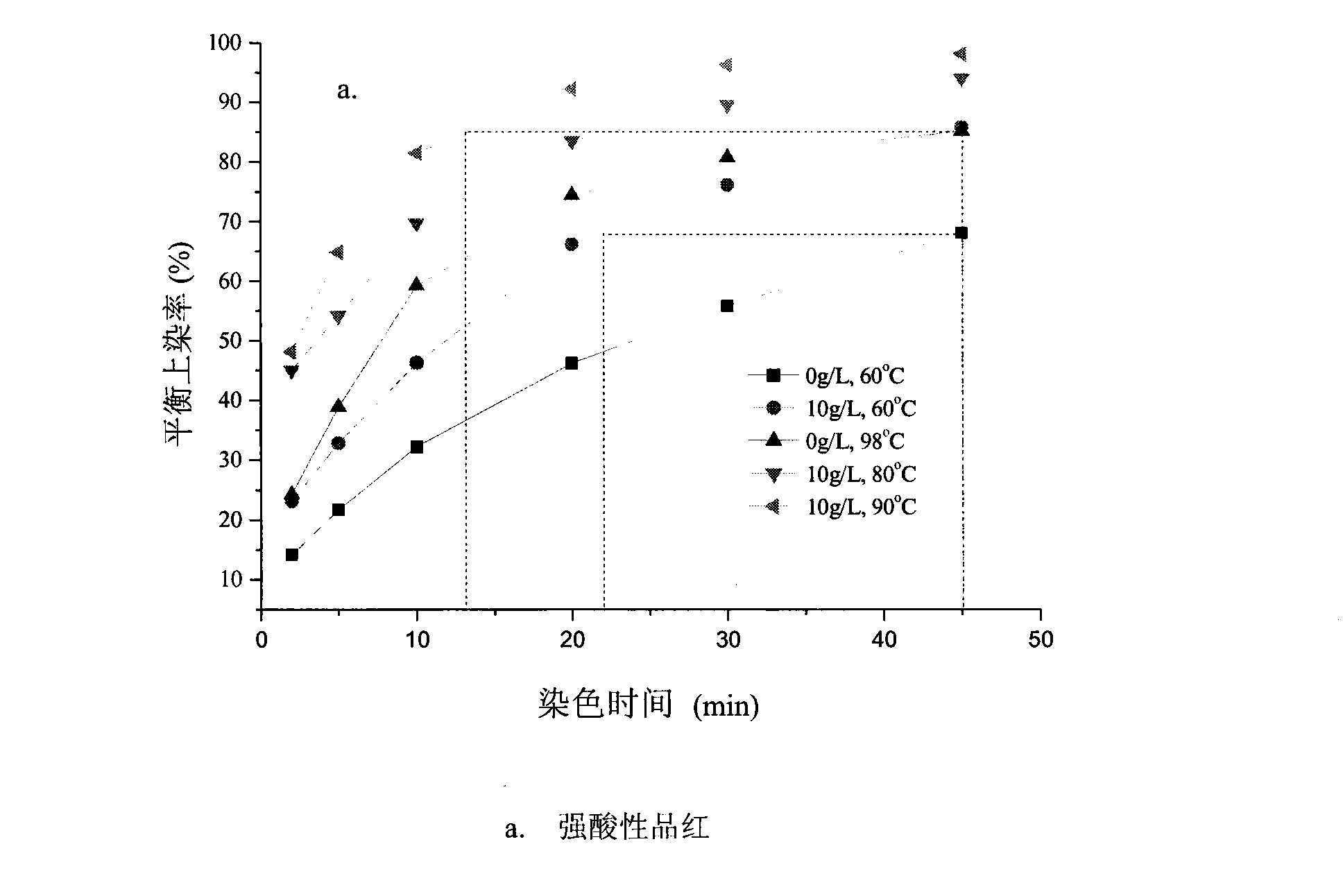

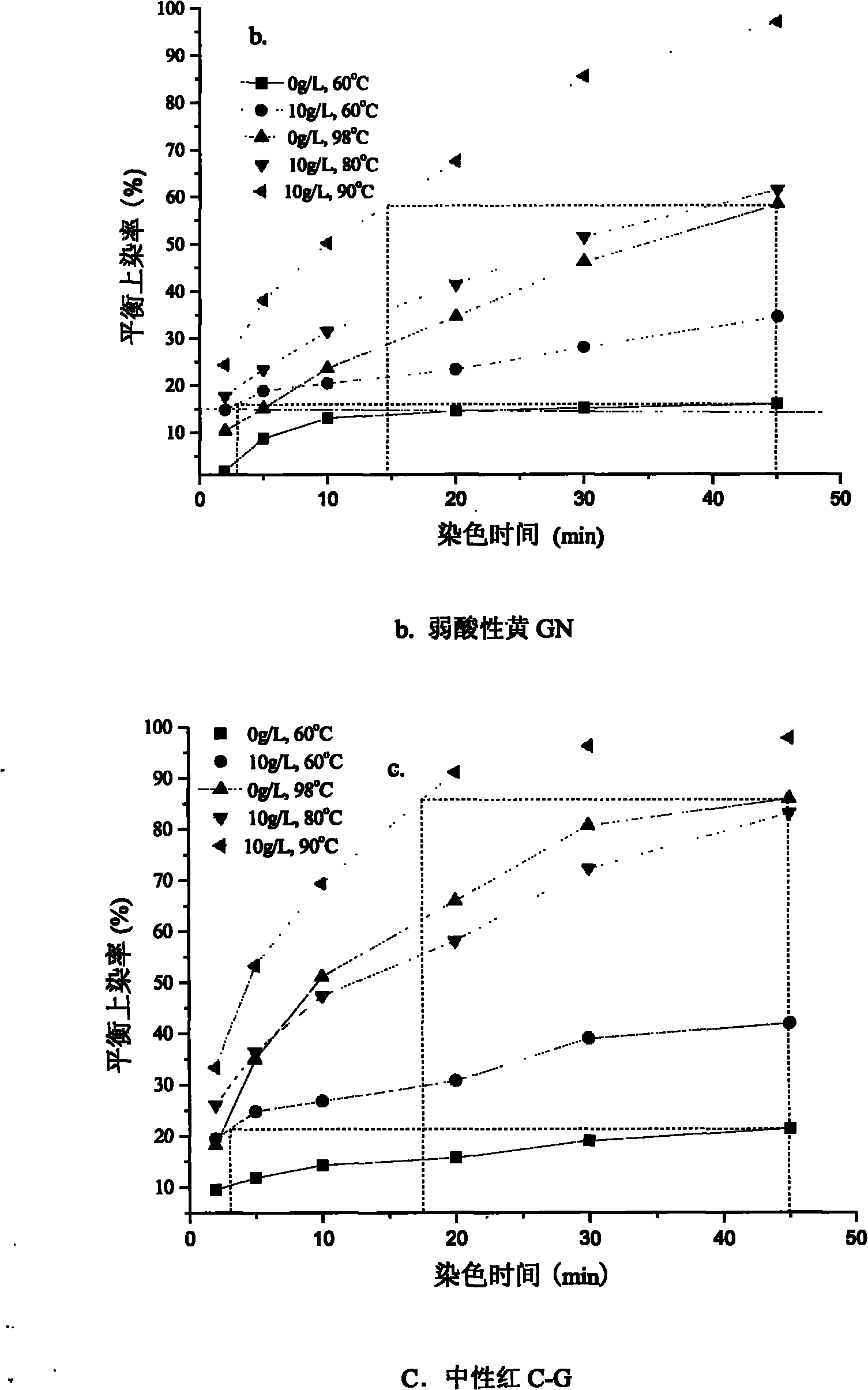

[0027] 2. Dyeing process

[0028] Prepare the dye solution according to the formula in the table below, heat the dye solution to 40°C and dye the wool fabric pretreated by HTCC, then raise the temperature to the specified temperature at a heating rate of 2°C / min, keep it warm for 45 minutes, cool to room temperature, wash and dry with water Dry.

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com