Micro-flocculation-terylene high stretch yarn fibrous globule filterantion and alga removal method and device thereof

A technology of polyester high elastic yarn and fiber ball filter material, which is applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of large dosage of coagulant, large amount of sludge, and clogging of filter beds. , to achieve the effect of good promotion and application prospects, significant algae removal effect, and strong pollution interception ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

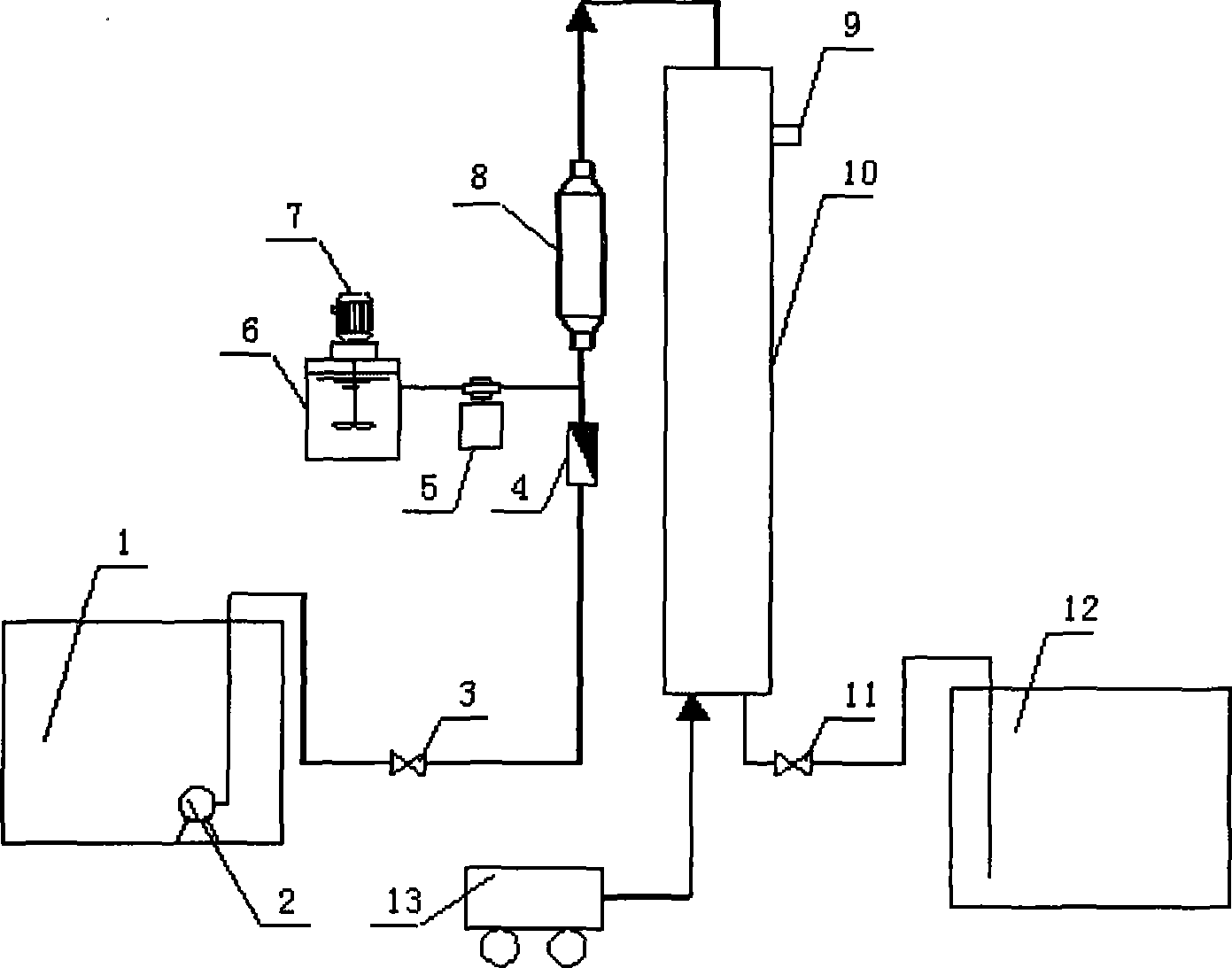

[0023] The waste water to be treated is sucked from the water tank by the lifting pump 2 through the raw water tank 1, and the flocculant is added by the peristaltic pump 5, and mixed with the sucked raw water in the pipeline mixer 8, and the water inlet mode of the pipeline mixer is lateral Water flows in so that the flocculant and waste water can be mixed quickly and effectively. The mixing time is 6-8 seconds. The mixed effluent directly enters the fiber ball filter column 10 through the connecting pipe, and the effluent enters the water storage tank 12.

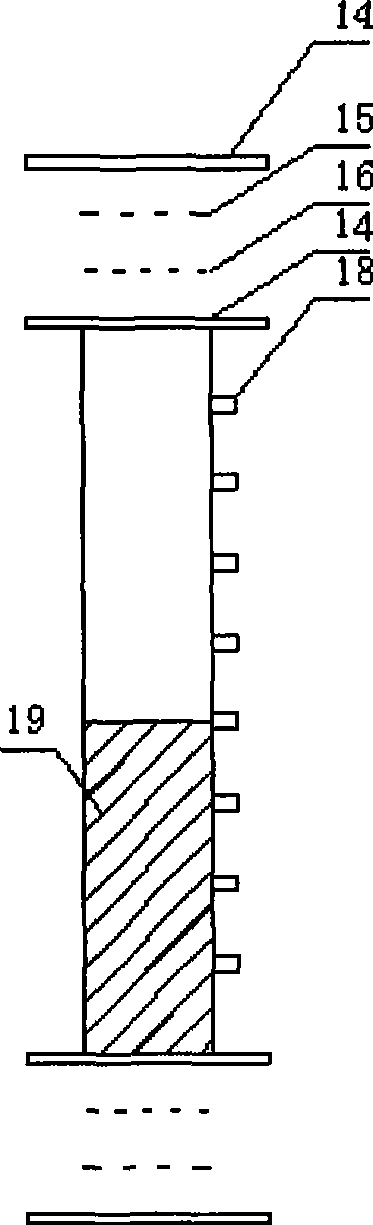

[0024] A micro-flocculation-polyester high-elastic fiber ball filter algae removal equipment, including a raw water tank 1, a water storage tank 12 and a dosing tank 6, wherein the raw water tank 1 is connected to a pipeline mixer 8 through a lift pump 2, a valve 3, a flow meter 4 The dosing tank 6 communicates with the pipeline mixer 8 through the peristaltic pump 5, and the agitator 7 is installed in the dosing tank 6; t...

Embodiment 2

[0026] The raw water for the test was taken from the lake of Songjiang University Town, and the total number of algae was 6.8×10 6 ~8×10 6 Between, the turbidity is 8 ~ 15NTU, the water is sucked from the water tank by the lifting pump 2 through the raw water tank 1, and the flocculant polyaluminum chloride (PAC) is added by the peristaltic pump 5, and the dosage is 15mg / L. It is mixed with the sucked raw water in the pipeline mixer 8. The water inlet method of the pipeline mixer adopts side flow water, so that the flocculant and waste water can be mixed quickly and effectively. The mixing time is 6-8s, and the mixed water is passed through the connecting pipeline. Directly enter the fiber ball filter column 5, the filtration rate is 15m / h, the filtration cycle is 9h, and the effluent enters the water storage tank 12.

[0027] After 5 months of practical investigation, it was found that the whole system was running well, and the total number of algae in the effluent could be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com