Superfine flat terylene low elater and technique for producing the same

A polyester low elastic yarn and production process technology, which is applied in the direction of rayon manufacturing, filament/thread forming, single-component polyester rayon, etc., can solve the experimental production that may be rare and the replacement of textile fabrics The speed is slow, the products cannot be mass-produced, etc., so as to achieve the effect of high added value, elegant luster and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

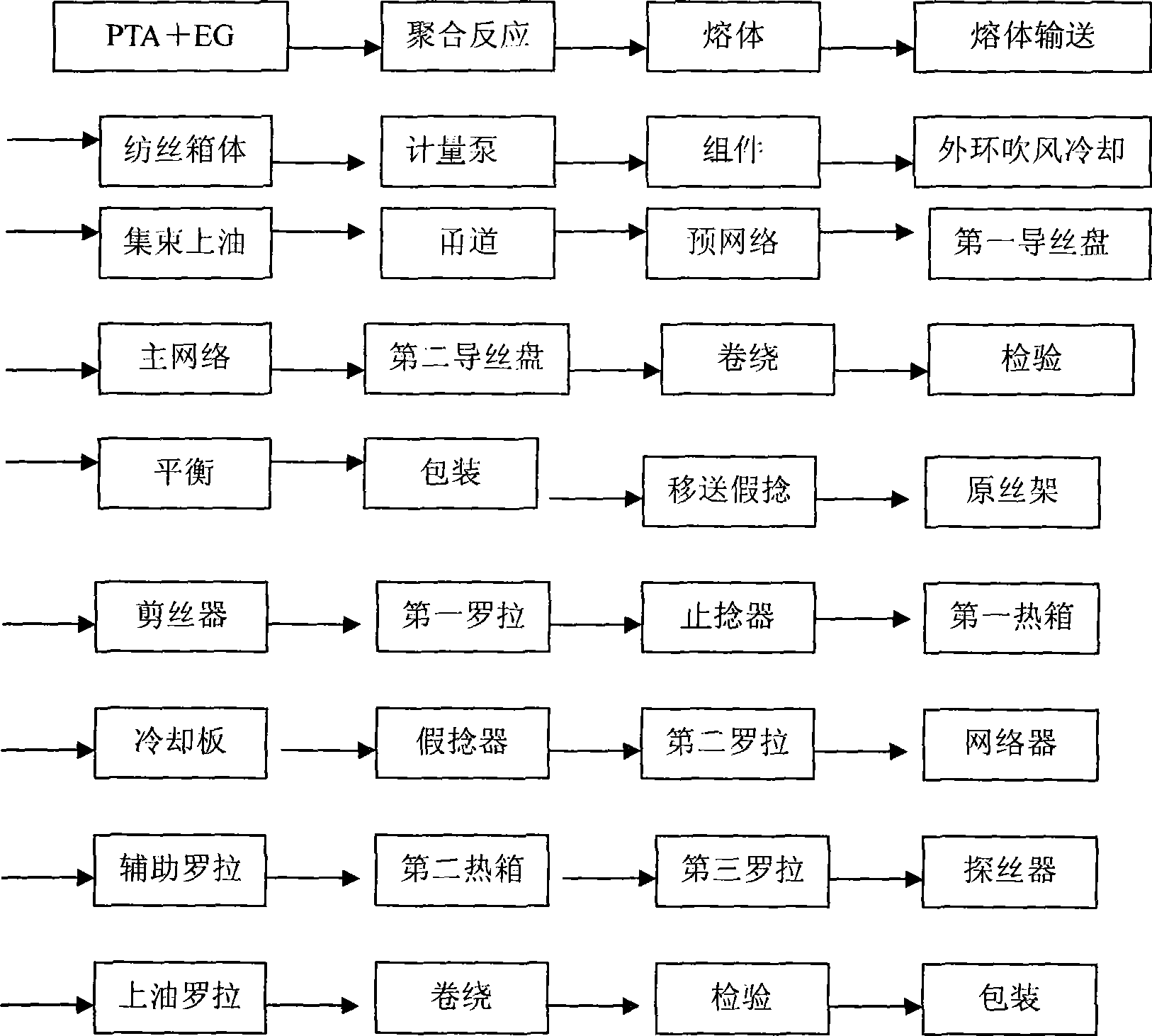

[0018] Describe the present invention in detail below in conjunction with accompanying drawing.

[0019] In the specific implementation process, the present invention adopts such as figure 1 The described technological process is produced, and the following requirements must be met in the production process:

[0020] 1. The spinneret is produced by a specially designed multi-hole spinneret with a high ratio of "one"-shaped spinneret holes with an aspect ratio ≥ 2 to ensure that the product has a similar rectangular cross-section.

[0021] 2. The outer ring blowing cooling forming method is used to cool and form the filaments sprayed from the spinneret.

[0022] 3. Winding Double-plate plying and winding of the thread. For example: during spinning and spinning production, the specification of the filament produced by POY veneer is 133dtex / 144f, and the product specification of the POY raw silk cake formed by winding is 266dtex / 288f.

[0023] 4. False twist adopts low-speed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com