Patents

Literature

165results about How to "No choice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photovoltaic EVA film resisting PID

ActiveCN103525321ALow costImprove performanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinEngineering

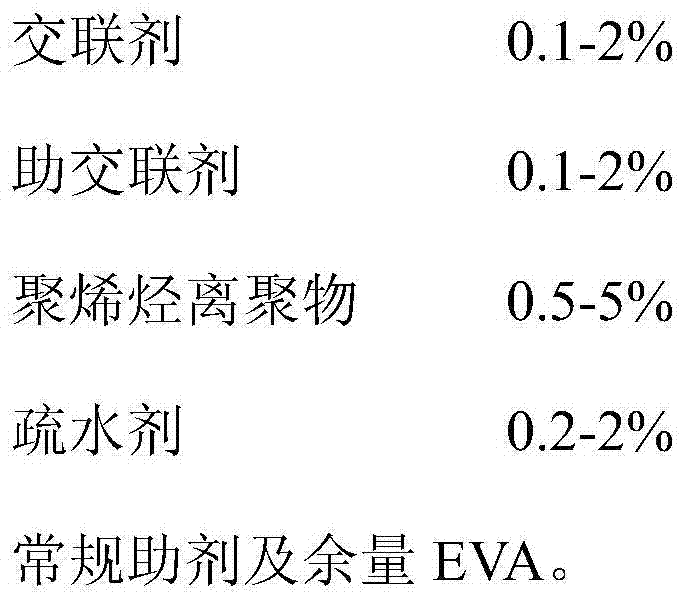

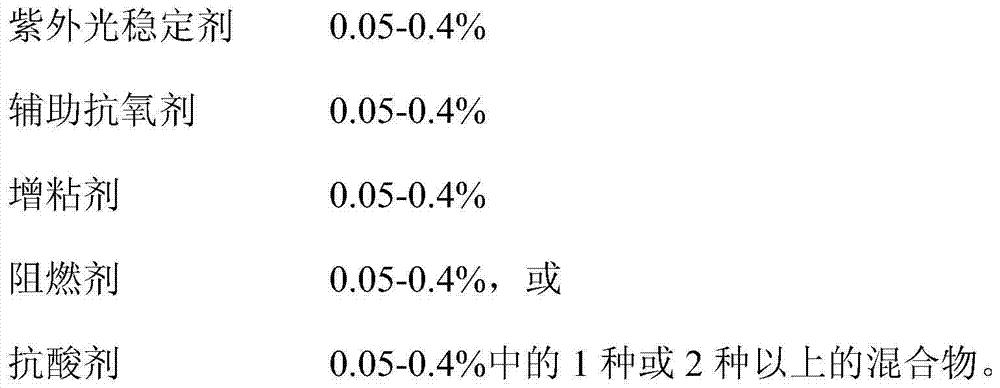

The invention relates to a photovoltaic EVA film resisting PID. The photovoltaic EVA film resisting the PID comprises the following components, by mass fraction, 0.05-5% of cross-linking agents, 0.05-5% of assistant crosslinker agents, 0.2-10% of polyolefin ionomer, 0.1-5% of hydrophobing agents, normal additives and the balance EVA. The photovoltaic EVA film resisting the PID is low in cost and high in performance, has no selectivity on battery pieces, the PID resistance performance is lasting and stable, and the photovoltaic EVA film resisting the PID can pass the PID standard test of IEC, has identical lasting PID resistance performance in a photovoltaic system, thoroughly eradicates the PID problem of components in an EVA level, and meets the demands of current and future component markets.

Owner:CSI SOLAR POWER GROUP CO LTD +2

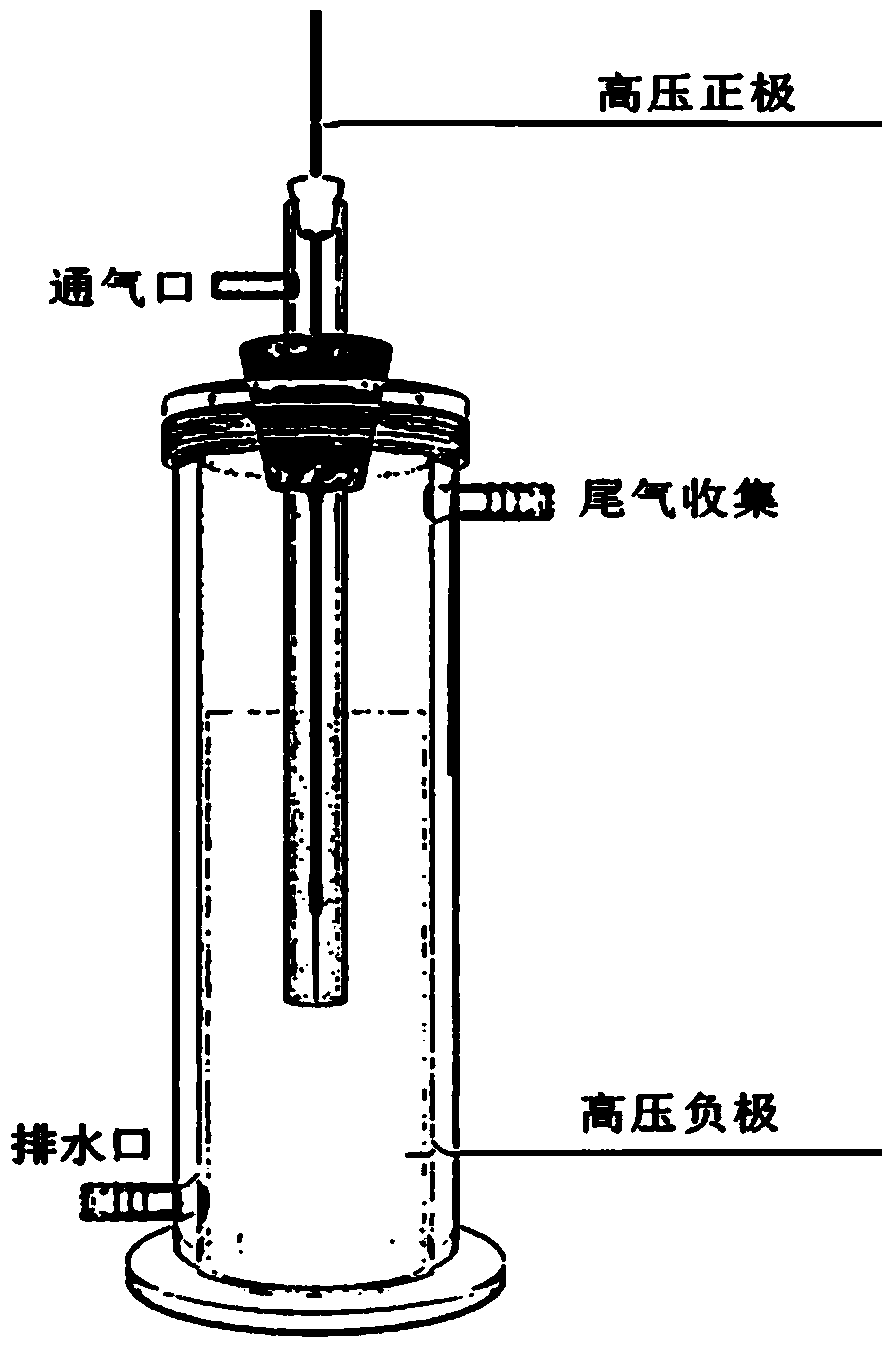

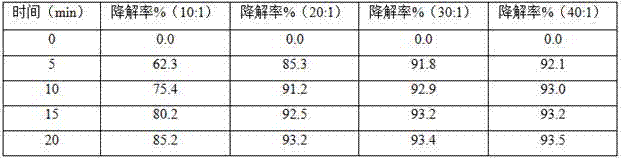

Device and method for degrading antibiotic wastewater by utilizing low temperature plasma in coordination with bismuth molybdate catalyst

InactiveCN103848484AImprove degradation rateHigh removal rateWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsCatalyst degradationBreather

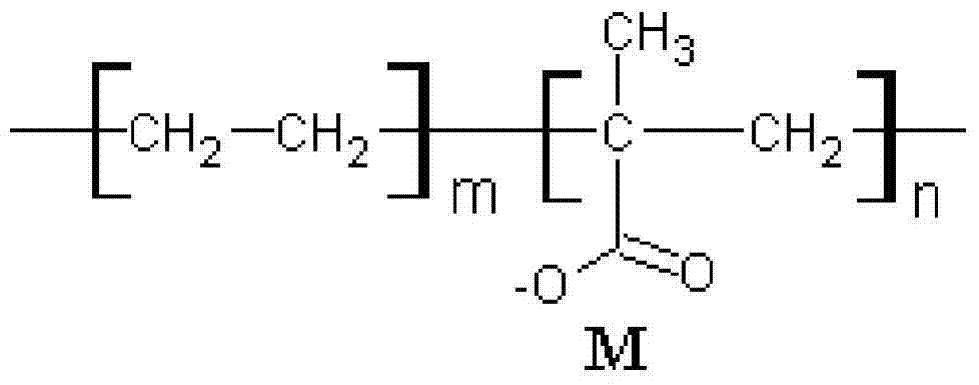

The invention discloses a device and a method for treating antibiotic wastewater by utilizing low temperature plasma in coordination with a bismuth molybdate catalyst. The device for treating the antibiotic wastewater by utilizing the low temperature plasma in coordination with the bismuth molybdate catalyst comprises a barrel-shaped reactor, a breather pipe, a high voltage electrode, an alternating current high voltage power supply, an air pump and a stirrer, wherein the breather pipe is arranged inside the barrel-shaped reactor and is coaxial with the barrel-shaped reactor, the high voltage electrode is suspended inside the breather pipe, the lower port of the breather pipe is arranged at the lower bottom part inside the barrel-shaped reactor, the upper part of the breather pipe is arranged outside the barrel-shaped reactor, an air inlet is formed in the side wall of the upper part of the breather pipe, the air inlet is communicated with the outlet of the air pump by virtue of a pipeline; the alternating current high voltage power supply is respectively connected to the high voltage electrode and grounded, and the stirrer is arranged at the lower part of the barrel-shaped reactor. The device for treating the antibiotic wastewater by utilizing the low temperature plasma in coordination with the bismuth molybdate catalyst has the characteristics of simple design, low equipment investment and no secondary pollution and can be applied to the filed of treatment on antibiotic wastewater and organic wastewater difficult to be biochemically degraded, wherein a degradation reaction temperature can be increased by fully utilizing heat produced in a discharge process.

Owner:NANJING UNIV

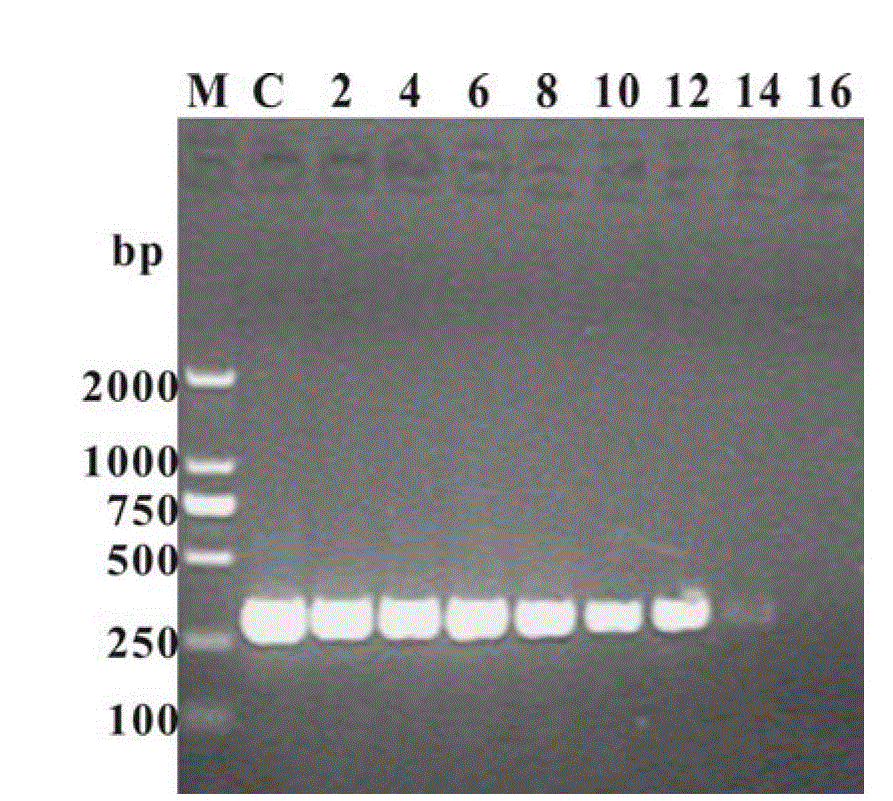

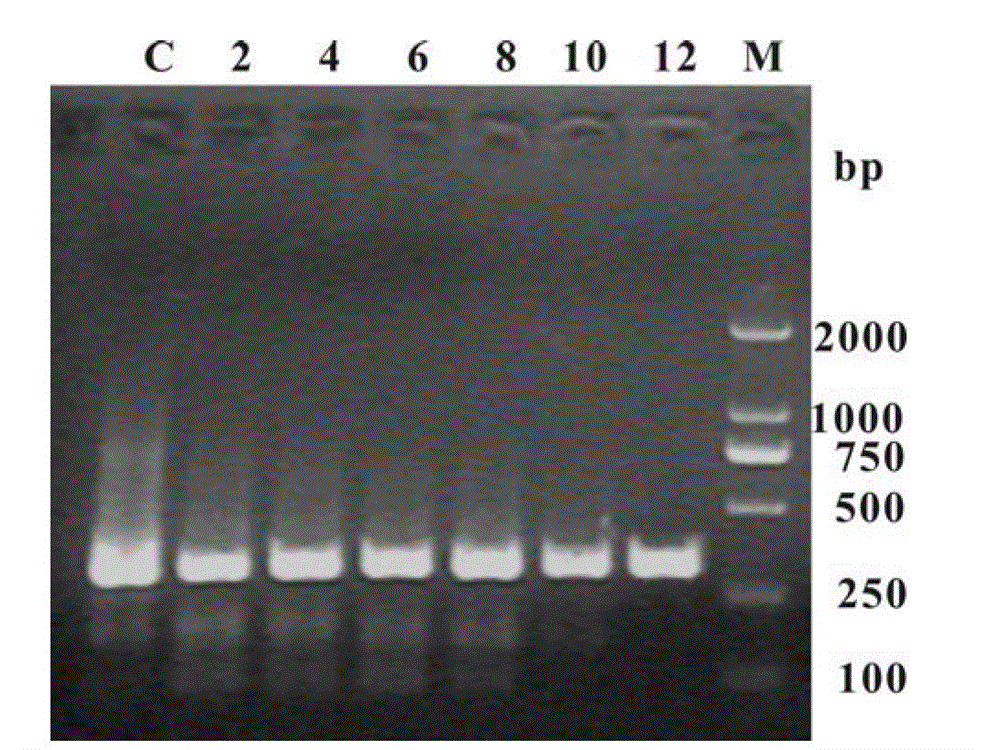

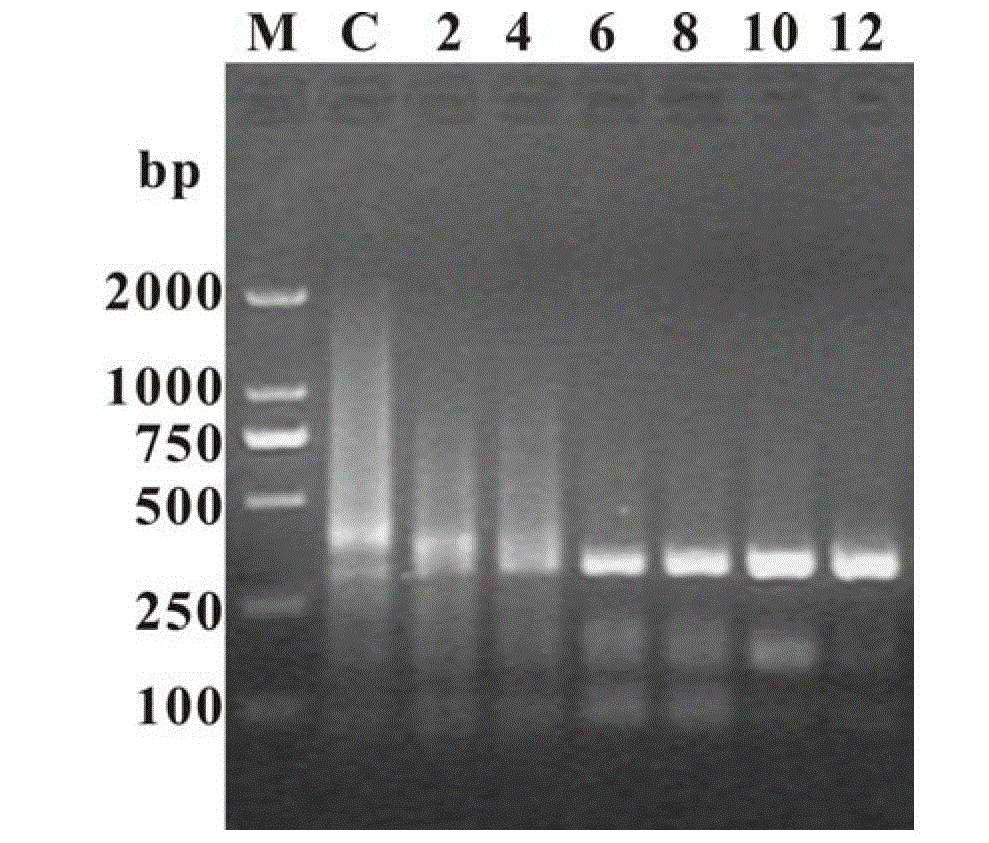

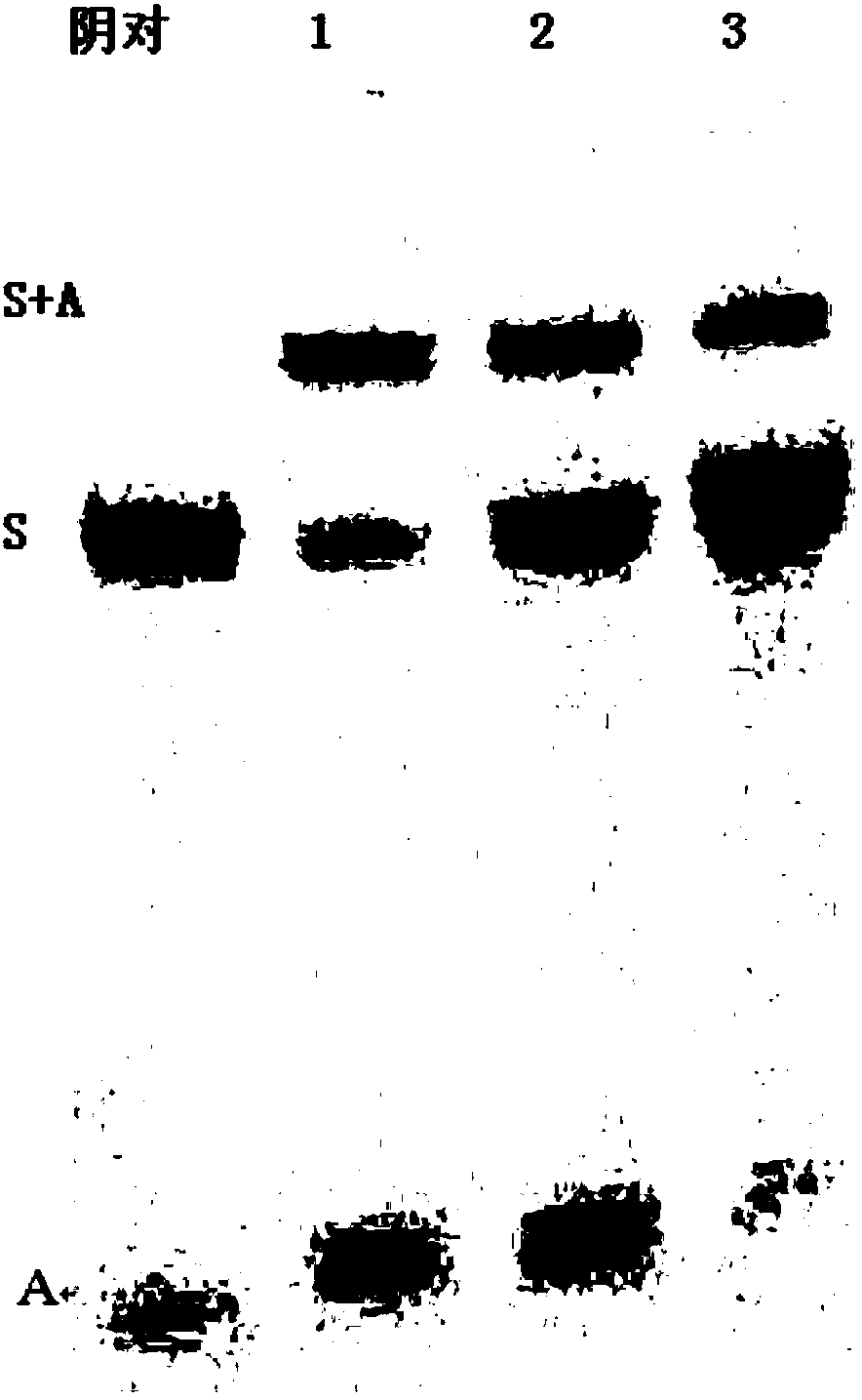

Application of graphene in polymerase chain reaction as reinforcing agent

An application of graphene in polymerase chain reaction as a reinforcing agent relates to a graphene material. An improved Hummers method is utilized to synthesize graphite oxide, and hydrazine hydrate is utilized to synthesize graphene. A plasmid is used as a template to carry out polymerase chain reaction and multi-round polymerase chain reaction, the graphene can increase the specificity of the polymerase chain reaction within 14 mu gmL-1, and a target product with strong specificity can even be obtained through 8-round polymerase chain reaction. A clinical blood sample deoxyribonucleic acid (DNA) is taken as a template to carry out the polymerase chain reaction, and a polymerase chain reaction (PCR) reaction system which is added with the graphene can obtain a product with single specificity and can still obtain the target product with the strong specificity within a scope between 25 DEG C and primer annealing temperature. The amplification products which are added with the graphene do not influence the primer sequence and length through sequencing tests, and the graphene can be used as a polymerase chain reaction reinforcing agent with good performance for polymerase chain reaction.

Owner:XIAMEN UNIV

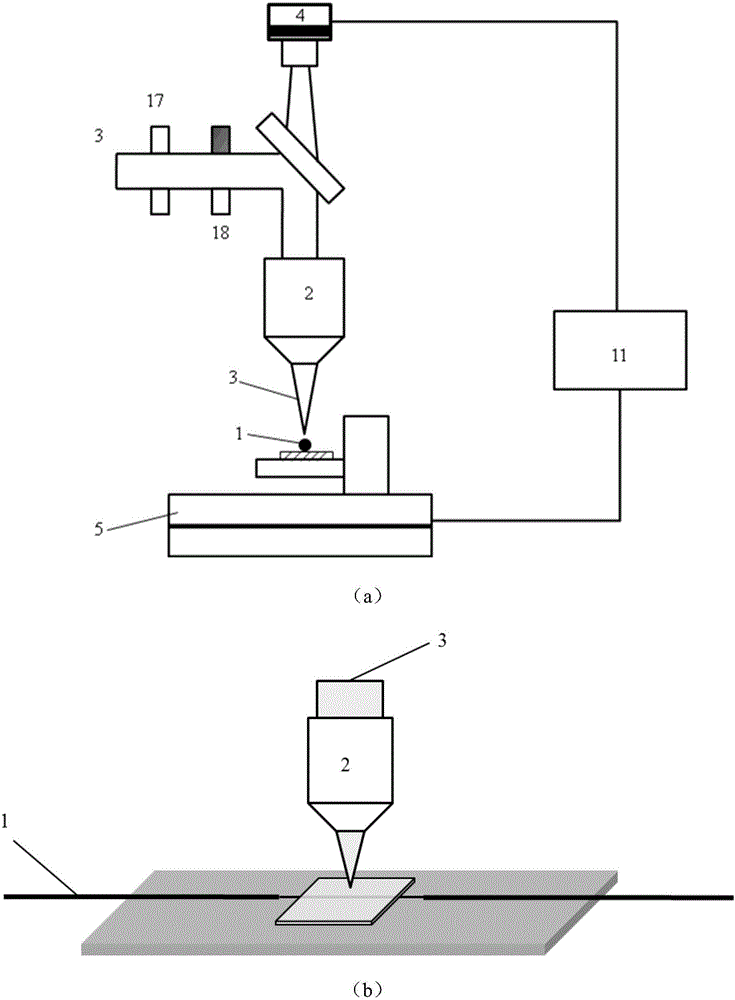

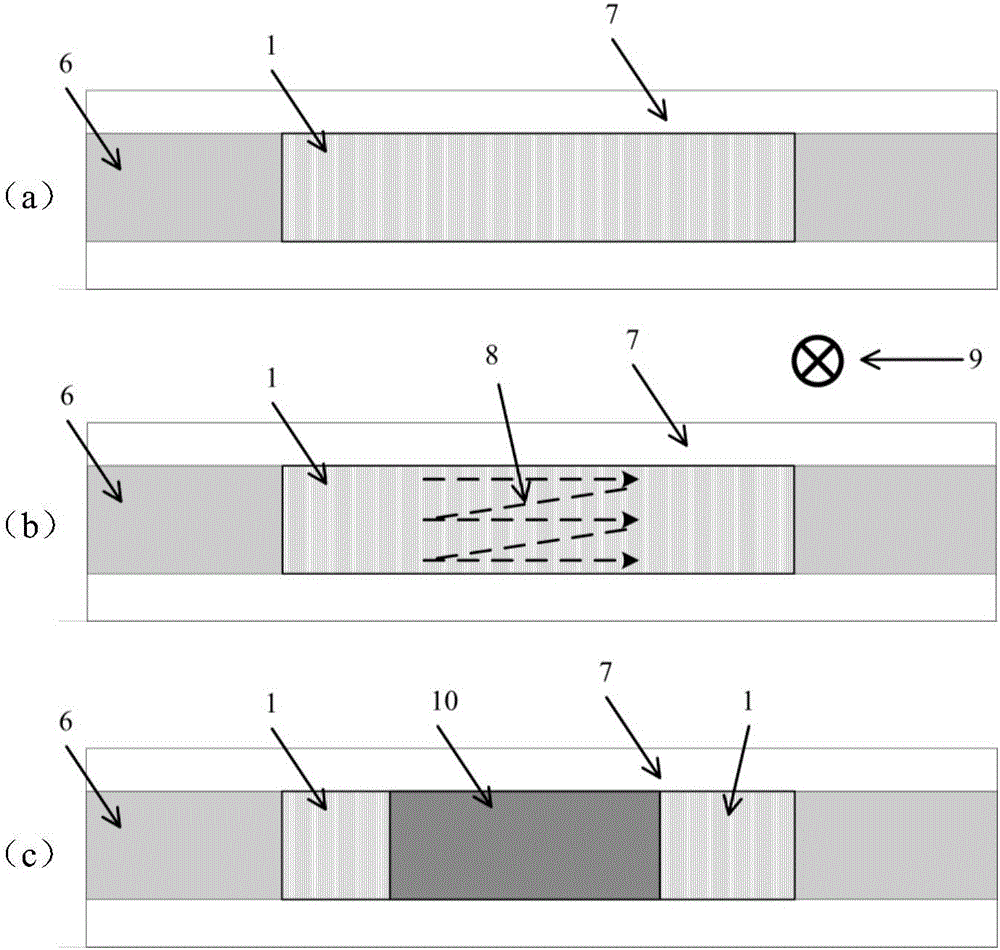

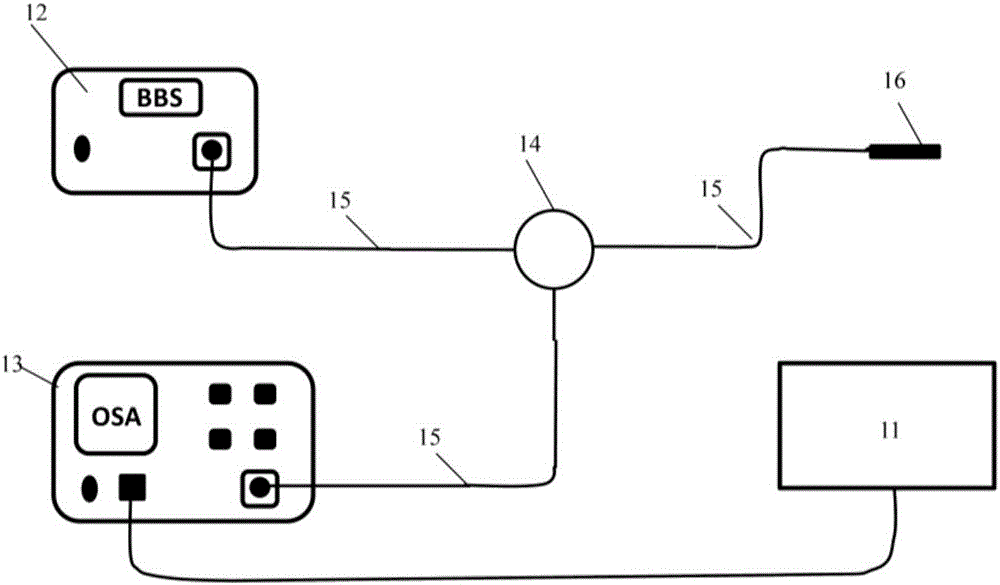

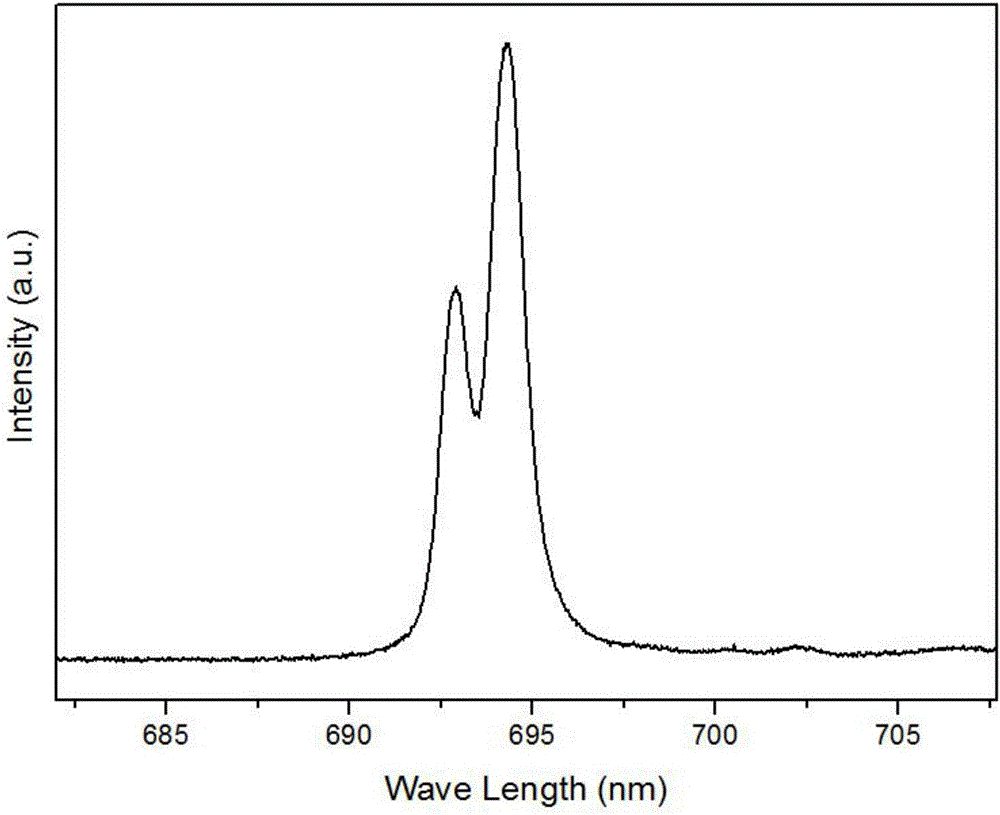

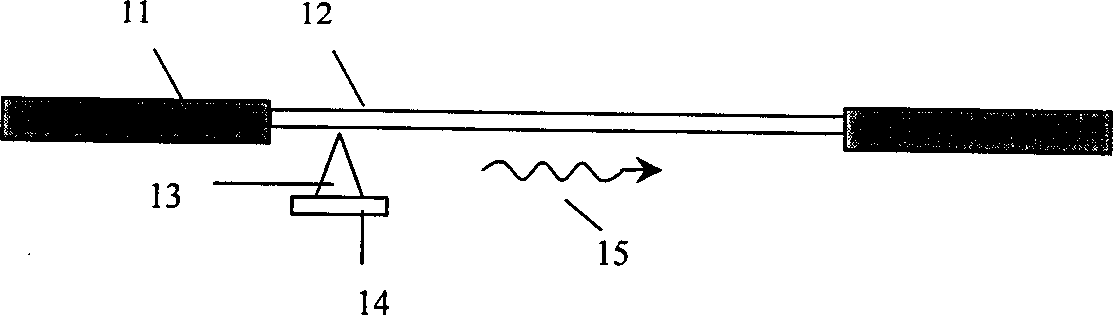

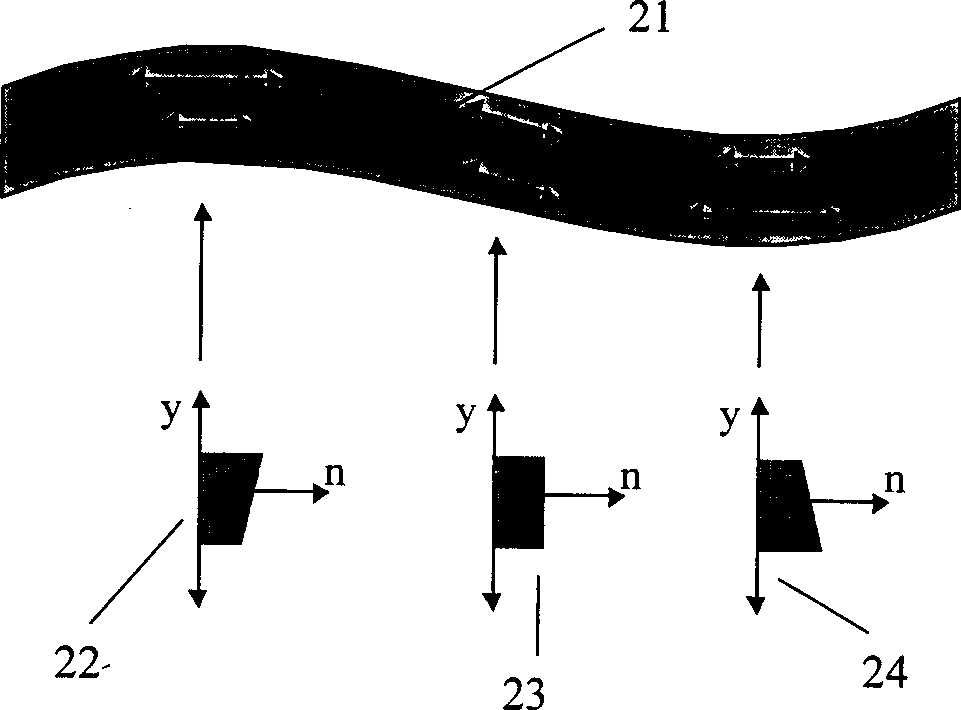

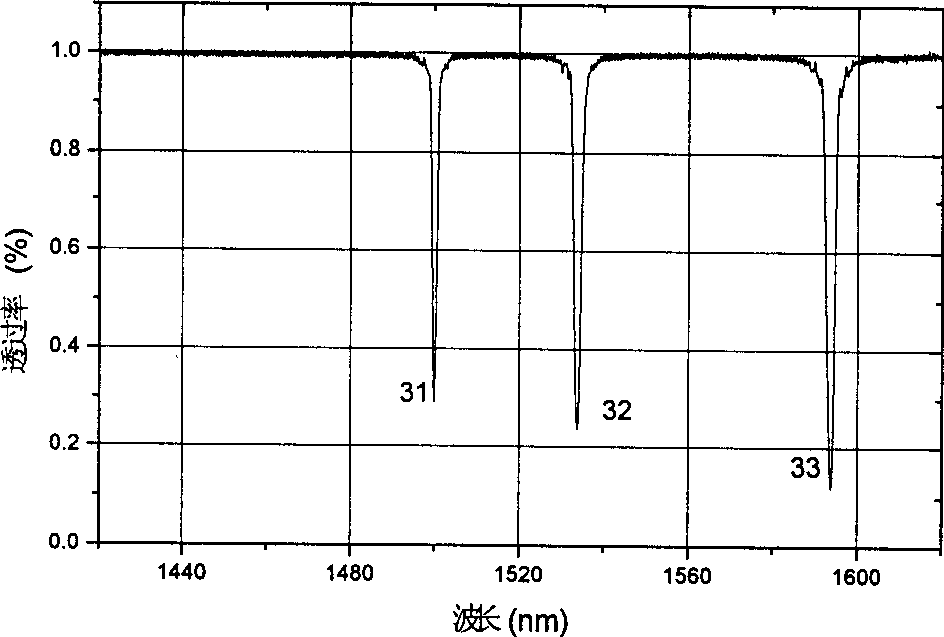

Method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing

ActiveCN106291802AEasy to operatePrecise length controlCladded optical fibreOptical waveguide light guideGratingPhase shifted

The invention provides a method for preparing phase shift optical fiber bragg grating based on femtosecond laser direct writing. The method comprises the following steps: performing fixed point radiation or scanning in a fiber core area of the optical fiber bragg grating of an ordinary structure by using focused femtosecond laser, forming one or more areas with changed refractive indexes in the fiber core area of the optical fiber bragg grating of the ordinary structure, and forming a phase shift structure, thereby obtaining the phase shift optical fiber bragg grating. Compared with the prior art, the method is relatively simple in processing procedure, high in processing speed and applicable to optical fiber of different materials, and precision control of phase shift within 0-2pi can be achieved. The phase shift optical fiber bragg grating prepared by using the method provided by the invention can be applied to fields of sensation, optical fiber laser and the like.

Owner:XI AN JIAOTONG UNIV +1

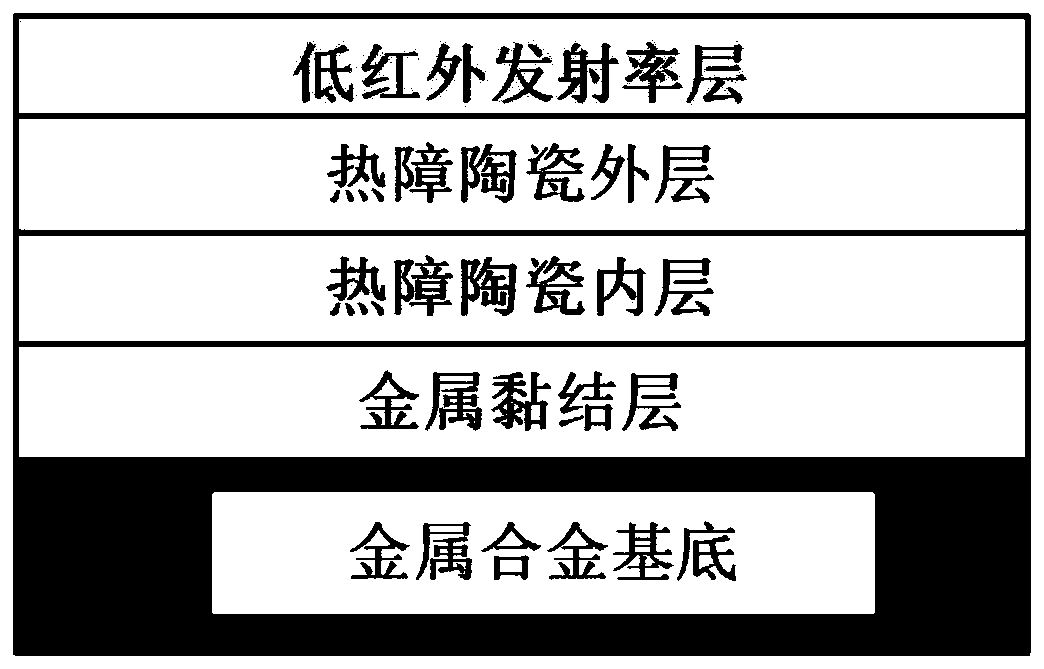

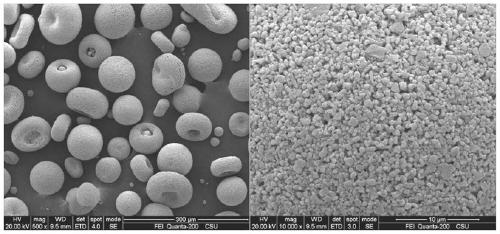

Double-layer thermal barrier/high-temperature low-infrared emissivity integrated coating, metal composite material with coating and preparation method thereof

ActiveCN110055486AGood oxygen barrier effectStop the spreadMolten spray coatingSuperimposed coating processEmissivityAlloy

The invention discloses a double-layer thermal barrier / high-temperature low-infrared emissivity integrated coating which is of a multilayer superposition structure. The multilayer superposition structure sequentially comprises a metal bonding layer, a thermal barrier ceramic inner layer, a thermal barrier ceramic outer layer and a low-infrared emissivity layer from inside to outside, and the thermal barrier ceramic inner layer is La2Zr2O7-8YSZ mixture layer, wherein the mass fraction of La2Zr2O7 powder in the mixture is not more than 45%, the thermal barrier ceramic outer layer is a rare earthzirconate layer, and the low-infrared emissivity layer is a Bi2O3-Al2O3-ZrO2-CaO-SiO2 glass coating comprising conductive phase AuPt alloy powder. The invention also provides a metal composite material with the coating and a preparation method thereof. The integrated coating has the characteristics of heat insulation performance, high-temperature low infrared emissivity, excellent thermal shock resistance and the like.

Owner:NAT UNIV OF DEFENSE TECH

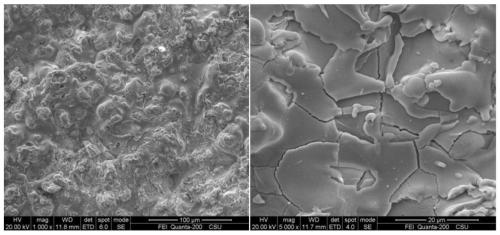

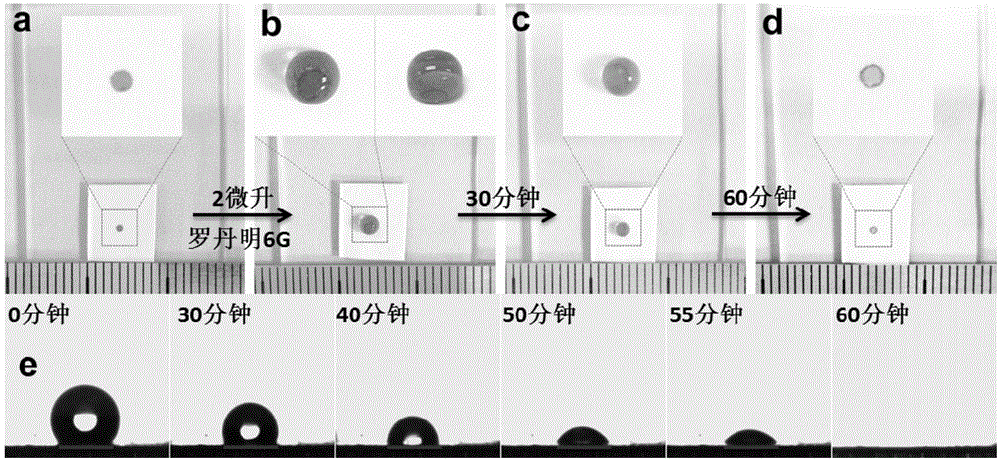

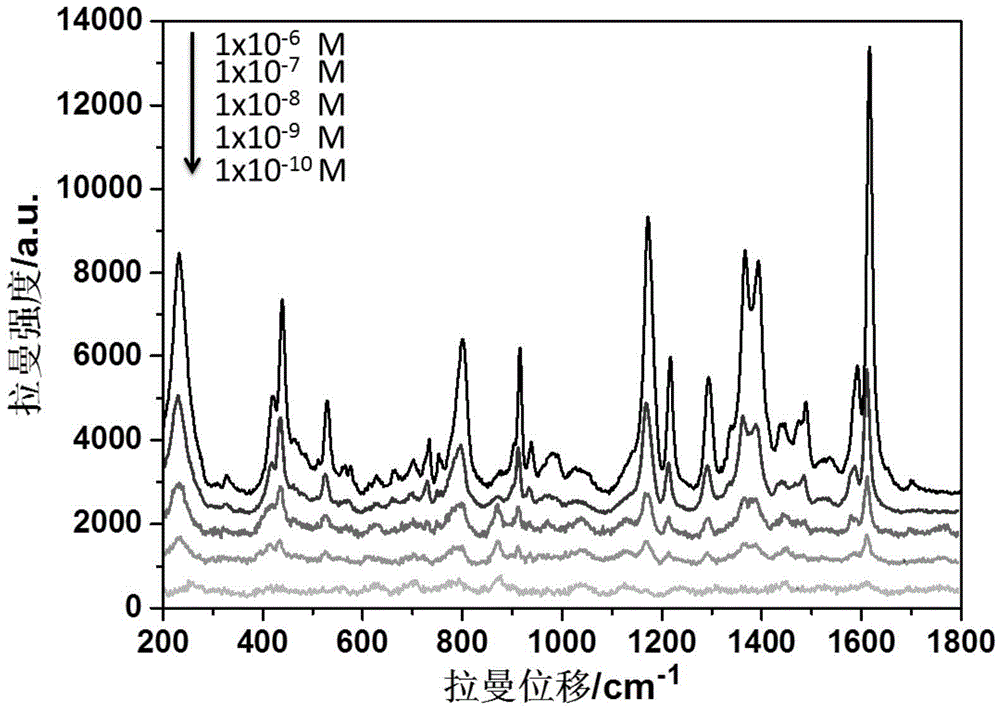

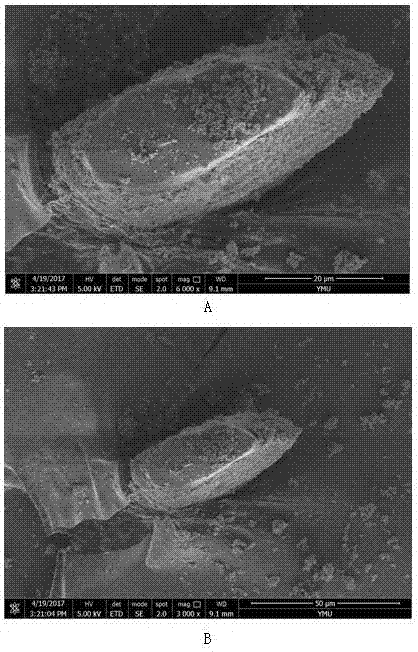

Surface enhanced Raman scattering substrate, preparation method and applications thereof

The invention provides a surface enhanced Raman scattering substrate, which comprises a polylactic acid electrostatic spin film and nano metal particles on the surface or in the inner of the polylactic acid electrostatic spin film, wherein the nano metal particles carry positive charges. The surface enhanced Raman scattering substrate has the advantages of high enhancing ability, good repeatability, long storage period, and capability of enriching articles to be detected. The invention also provides a preparation method of the surface enhanced Raman scattering substrate. The preparation method comprises the following steps: (1) dissolving polylactic acid into an organic solvent to obtain a spinning liquid, and using the spinning liquid to carry out electrostatic spinning to obtain a polylactic acid electrostatic spin film; (2) arranging nano metal particles on the surface and in the inner of the obtained polylactic acid electrostatic spin film through a spotting mode so as to obtain the surface enhanced Raman scattering substrate. The preparation method is simple and is suitable for massive production. The prepared surface enhanced Raman scattering substrate can be applied to food analysis, environment analysis, etc.

Owner:SHENZHEN INST OF ADVANCED TECH

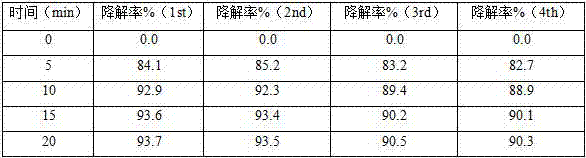

Method for rapidly degrading antibiotics

ActiveCN107285452AEasy to operateReduce energy consumptionOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsChemistryLight source

The invention discloses a method for rapidly degrading antibiotics. According to the method, by utilizing an MIL-101(Fe) / TiO2 composite material as a catalyst, persulfate can be greatly catalyzed and activated under a normal temperature and weak light source to rapidly generate a large quantity of sulfate radical free radicals so as to degrade the antibiotics; a composite material is easy to recycle, can remain a relatively good activating effect after being repeated used and is a green environment-friendly material; according to the method, equipment is simple and convenient to operate, the energy consumption is saved, the catalysis time is short, and extremely high degradation effect on the antibiotics can be achieved under relatively weak natural light in severe-haze and light-deficient areas; and the method has great application prospects in the degradation of the antibiotics.

Owner:KUNMING UNIV OF SCI & TECH

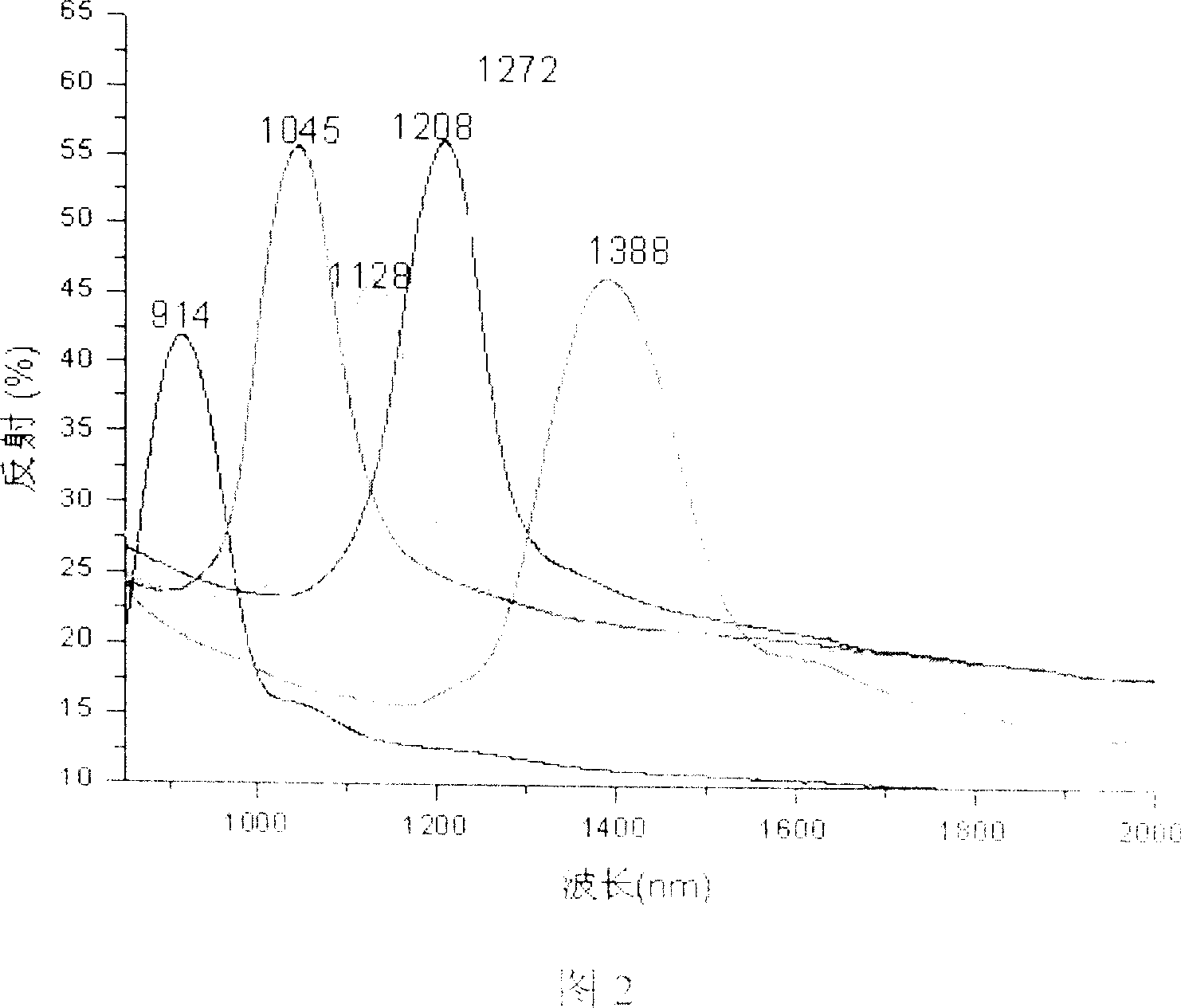

Polymer colloid photon crystal film with photon band-gap position at near infrared region and its preparing method and use

InactiveCN101033299ANo specific choiceNo choiceReflecting/signal paintsPhotonic bandgapLatex particle

The invention relates to a kind of polymer colloidal photon crystal membrane with large sized photon band-gap locate in the near-infrared area and its preparation and application. It covers the large sized monodisperse polymer latex particle emulsion on the substrate to achieve cyclical orderly arranged three-dimensional photonic crystal membrane which is spelled with the large sized monodisperse polymer latex particles in the form of face-center cube. The monodisperse polymer latex particle is achieved from the process of polymerization of numbers of the polymer latex particles with hard core-soft shell structure. The size of the monodisperse polymer latex particle ranges from 400 to 1200nm, and the polydispersity index is less than or equal to 0.005. According to the size of monodisperse polymer latex particles, the photonic band gap of the latex photonic crystal membrane can be distributed in the near infrared different band of 800~30000nm.

Owner:INST OF CHEM CHINESE ACAD OF SCI

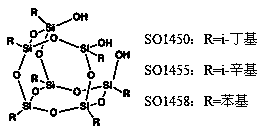

Capacity increasing method for nano particle modified carbon fiber sizing agent

The invention discloses a capacity increasing method for a nano particle modified carbon fiber sizing agent. The capacity increasing method comprises steps as follows: (1), nano particles, POSS (polyhedral oligomeric silsesquioxane) and a catalyst are dissolved in an organic solvent and subjected to ultrasonic treatment for 5-20 min, and a nano particle dispersion liquid is obtained; (2), the nano particle dispersion liquid in the step (1) is uniformly mixed with epoxy resin and an emulsifier, an organic solvent in the mixture is removed through distillation under reduced pressure, and a corresponding sizing agent emulsion is prepared with a phase inversion method. POSS and the nano particles are introduced into the sizing agent simultaneously, advantages of POSS and the nano particles can be combined, and the problems of poor compatibility and high probability of agglomeration and demulsification of the nano particles in the sizing agent can be solved; besides, in comparison with traditional coating modification and coupling agent modification, the treatment method adopting POSS as a capacity increasing agent is simple, and more excellent heat resistance is acquired.

Owner:HARBIN INST OF TECH

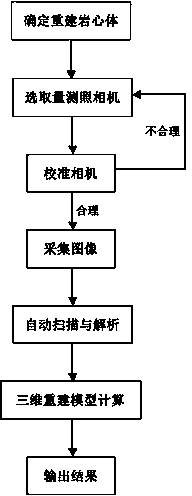

Rock core shape-preserving three-dimensional reconstruction method

InactiveCN104063899AKeep the status quoLow cost3D modellingHigh performance computationCharacterization methods

The invention relates to a rock core shape-preserving three-dimensional reconstruction method. The method comprises the steps that holographic image information of the contour of a rock core is obtained through multi-angle shooting of a calibrated measurement camera, and then a high-density point cloud on the surface of the rock core is obtained by means of scanning analysis of a high-performance computer on images according to the dense curve modeling technology; gridding and automatic filling of the surface of the rock core are completed through effective determination of the point cloud, and therefore the three-dimensional reconstruction of the rock core is completed. Compared with a traditional rock core characterization method, a large amount of three-dimensional information of the rock core with the original shape can be obtained instantly, no rock core shape selectivity exists, no special handling is needed, the original shape of the rock core can be well kept, the cost is low, operation is convenient and fast, the degree of automation is high, on-site quantitative analysis can be carried out on a coring site, the defects of existing methods are effectively overcome, and the rock core shape-preserving three-dimensional reconstruction method is efficient, fast, low in cost, accurate and reliable.

Owner:CENT SOUTH UNIV

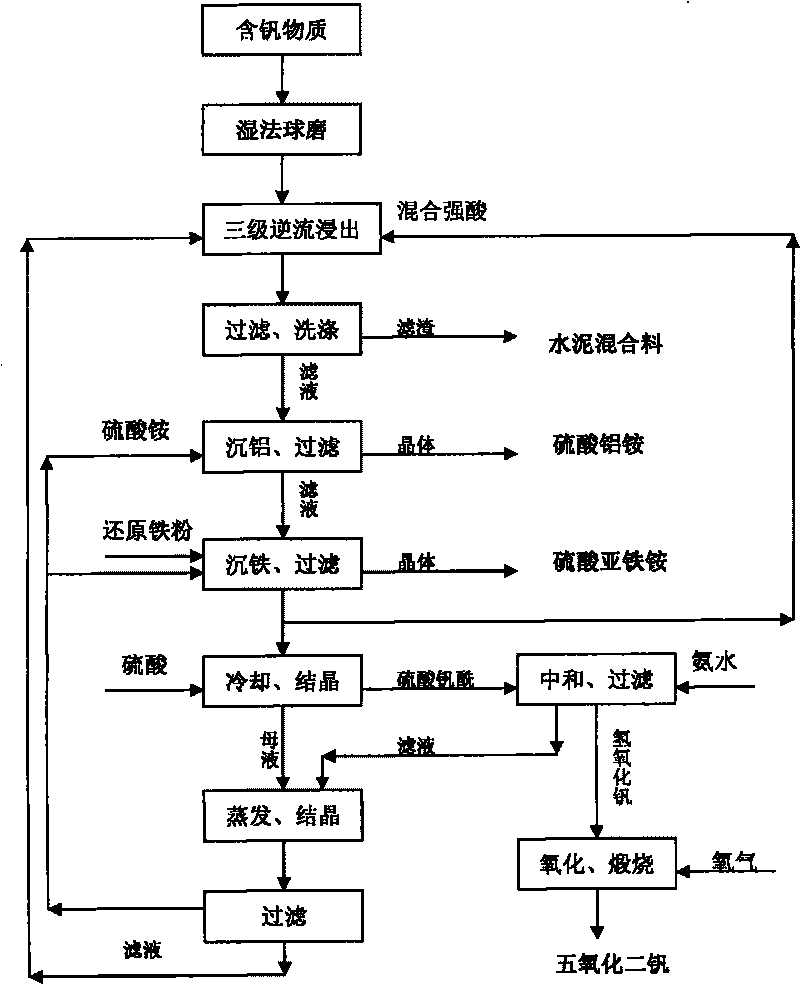

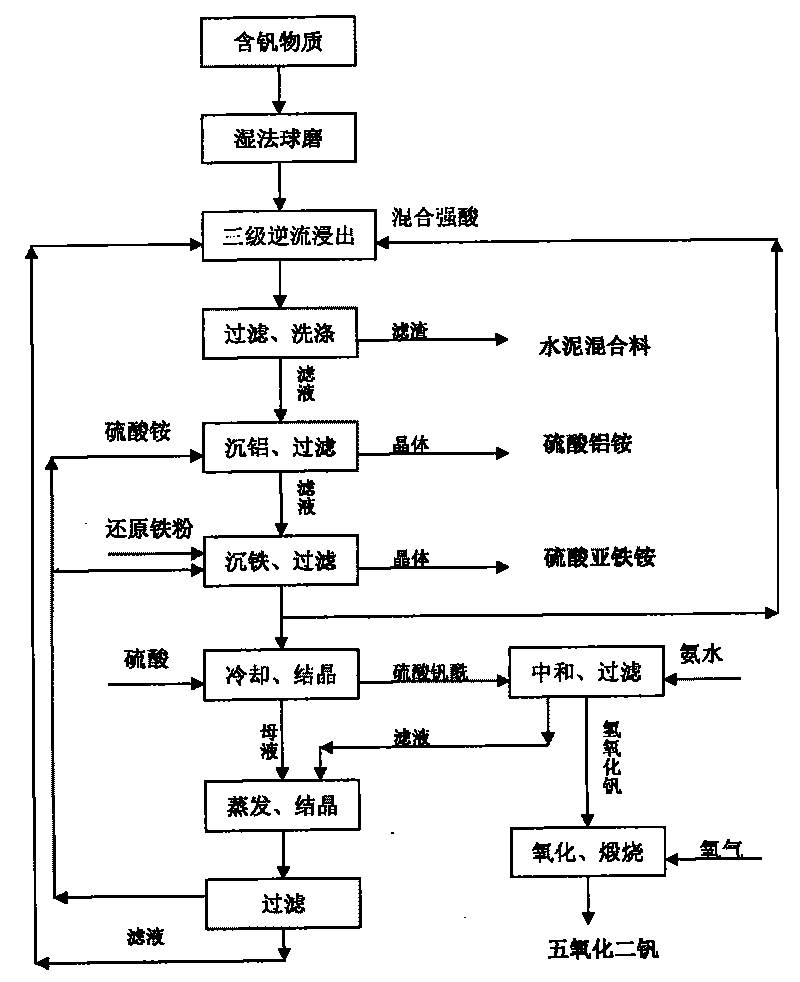

Method for cleanly extracting vanadium pentexide from vanadium containing material

ActiveCN101723458AHigh yieldRealize comprehensive utilizationVanadium oxidesPhosphateAluminum ammonium sulfate

The invention relates to a method for cleanly extracting vanadium pentexide from a vanadium containing material. The method is characterized in that: the vanadium containing material is milled by the wet method, and then mixed with a certain weight amount of sulfuric acid, vanadic acid, water, sulfuric acid or phosphoric acid salt having certain association; under conditions of set temperature and set time, performing three-stage reflux leaching reaction of the mixture; adding ammonia sulfate and reducing iron powder to reaction leach solution in sequence to obtain aluminum ammonium sulfate crystals and ammonium ferrous sulfate crystals respectively; adding sulfuric acid to the solution in which aluminum and iron are separated out, cooling the solution for crystallization to obtain vanadium sulfate acyl crystals, and returning the mother liquor to extract vanadium ores; performing the neutralization reaction of the vanadium sulfate acyl crystals and ammonia water to obtain a precipitate of vanadium hydroxide, and returning the solution of ammonia sulfate to precipitate the aluminum and iron; and calcining the vanadium hydroxide and oxygen gas at a high temperature of over 300 DEG C to obtain the vanadium pentexide. The method has the advantages of short process flow, less energy consumption, high vanadium yield, low production cost, environmental protection, and comprehensive utilization of valuable metallic elements in ores.

Owner:河南龙宇钒业有限公司

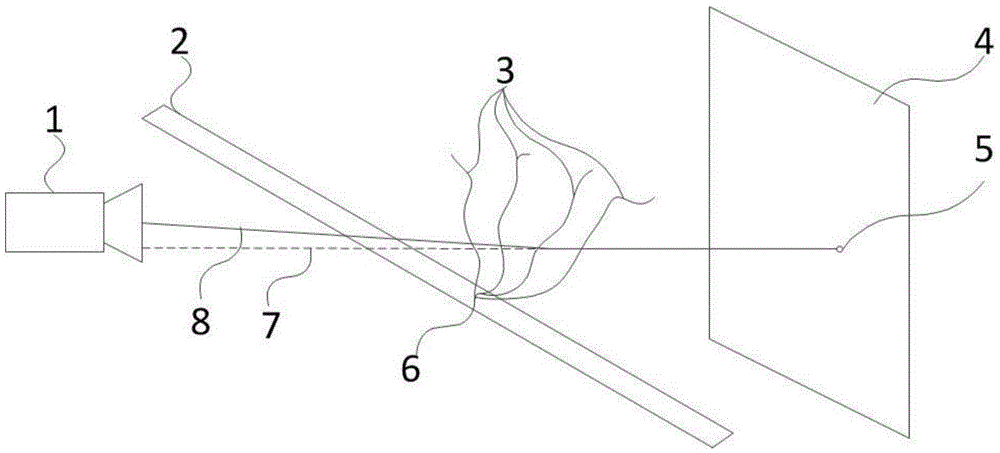

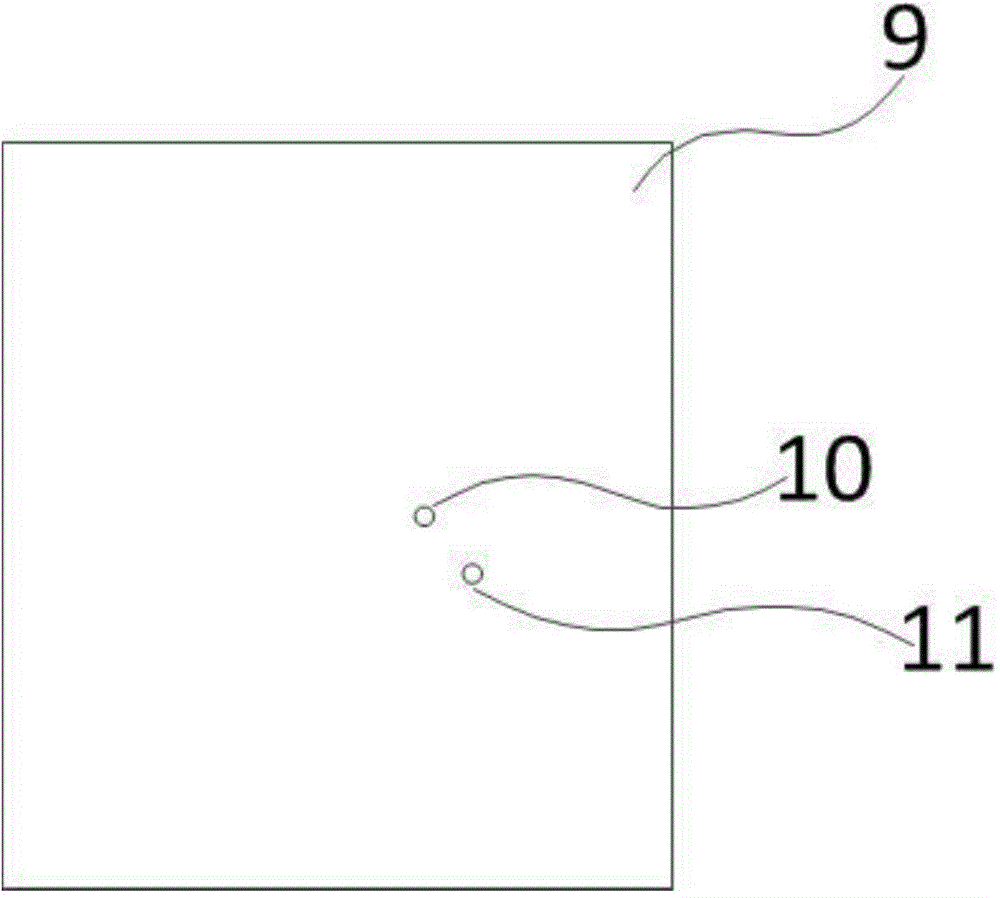

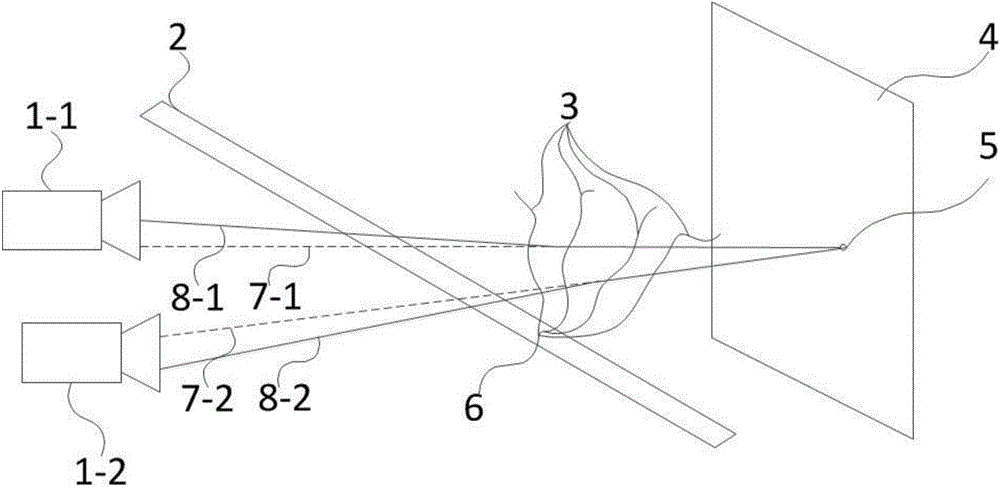

Gas leakage monitoring device based on background schlieren technology, and gas leakage monitoring method based on background schlieren technology

InactiveCN104155071ASimple structureNo choicePhase-affecting property measurementsFluid-tightness measurement using lightRefractive indexEngineering

The present invention relates to a gas leakage monitoring device based on a background schlieren technology, and a gas leakage monitoring method based on the background schlieren technology. According to the present invention, based on the background schlieren technology, by comparing the two background photographs which are acquired at the different times or are acquired at the same time but at the different angles, and by the displacement of a lot of points on the photographs, the gradient change of an air refractive index in an area is detected, an air refractive index gradient change area caused by the gas leakage is identified, and the gas leakage is determined whether to occur, thereby determining the position of a leakage point. The device and method of the present invention are simple in structure, can monitor the gas leakage and search the leakage point in a large-range open environment and a complicated pipe network system, do not have selectivity to the gas types, and can monitor the all gas leakage.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Organic waste water ozone oxidation catalyst and preparation method and application thereof

InactiveCN110152682AImprove biodegradabilityPromote decompositionWater treatment compoundsWater contaminantsActivated carbonChemistry

The invention provides an organic waste water ozone oxidation catalyst and a preparation method and application thereof. The organic waste water ozone oxidation catalyst comprises the following raw materials in parts by mass: 0.6-1.2 parts of active metals, 20-26 parts of titanium dioxide, 41-45 parts of aluminum oxide, 14-20 parts of manganese dioxide and 8.2-9.6 parts of activated carbon, wherein the active metals comprise titanium, copper, zinc, nickel and manganese. The mass ratio of titanium, copper, zinc, nickel and manganese is 1.2:3:2:1.6:2.2.

Owner:TONGREN UNIV

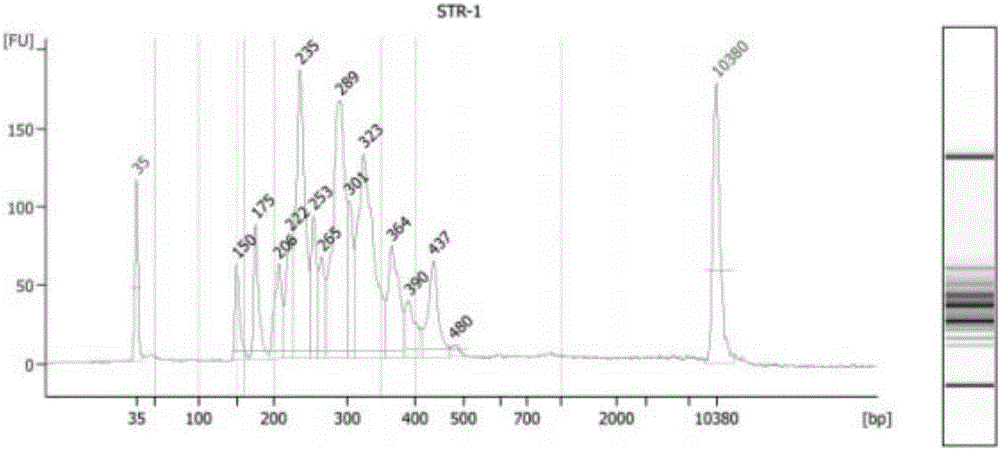

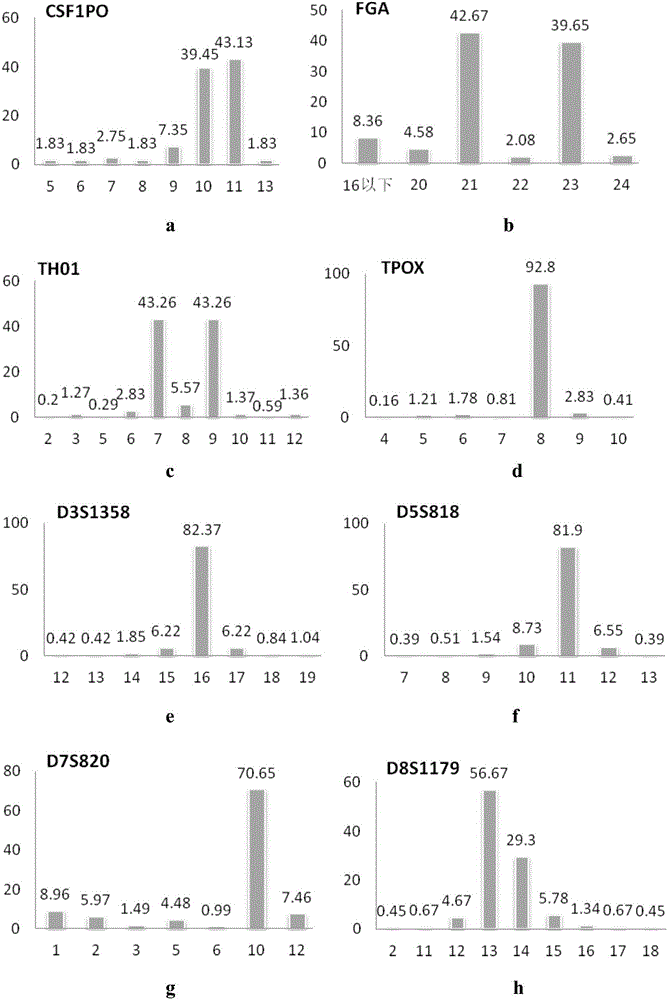

DNA library construction method for high-throughput sequencing

ActiveCN106350590AShorten the timeLow costMicrobiological testing/measurementLibrary creationAgricultural scienceTest sample

The invention discloses a DNA library construction method for high-throughput sequencing. The DNA library construction method includes the steps of carrying out multiple PCR (polymerase chain reaction) to a DNA template obtained from a to-be-tested sample through multiple pairs of fusion primers, then recycling PCR products to obtain a sequencing library. The multiple pairs of fusion primers respectively aim at different target fragments of the DNA template, and each fusion primer comprises specificity primer sequence aiming at the target fragment and linker sequence for sequencing. The multiple PCR is carried out on reaction conditions: reacting at 95 DEG C for 2 minutes; reacting within 38 cycles, wherein each cycle includes processes of preserving at the temperature of 95 DEG C for 30 seconds, cooling to the temperature from 76 DEG C to 55-58 DEG C slowly at the speed of 0.1 DEG C each second, holding the temperature for 20 seconds once cooling to the temperature of 58 DEG C, and then preserving at 72 DEG C for 30 seconds; after that, preserving at 72 DEG C for 2 minutes, and finally preserving at 4 DEG C. The invention further discloses application of the library construction method in testing STR locus and paternity identification on the basis of high-throughput sequencing.

Owner:承启医学(深圳)科技有限公司

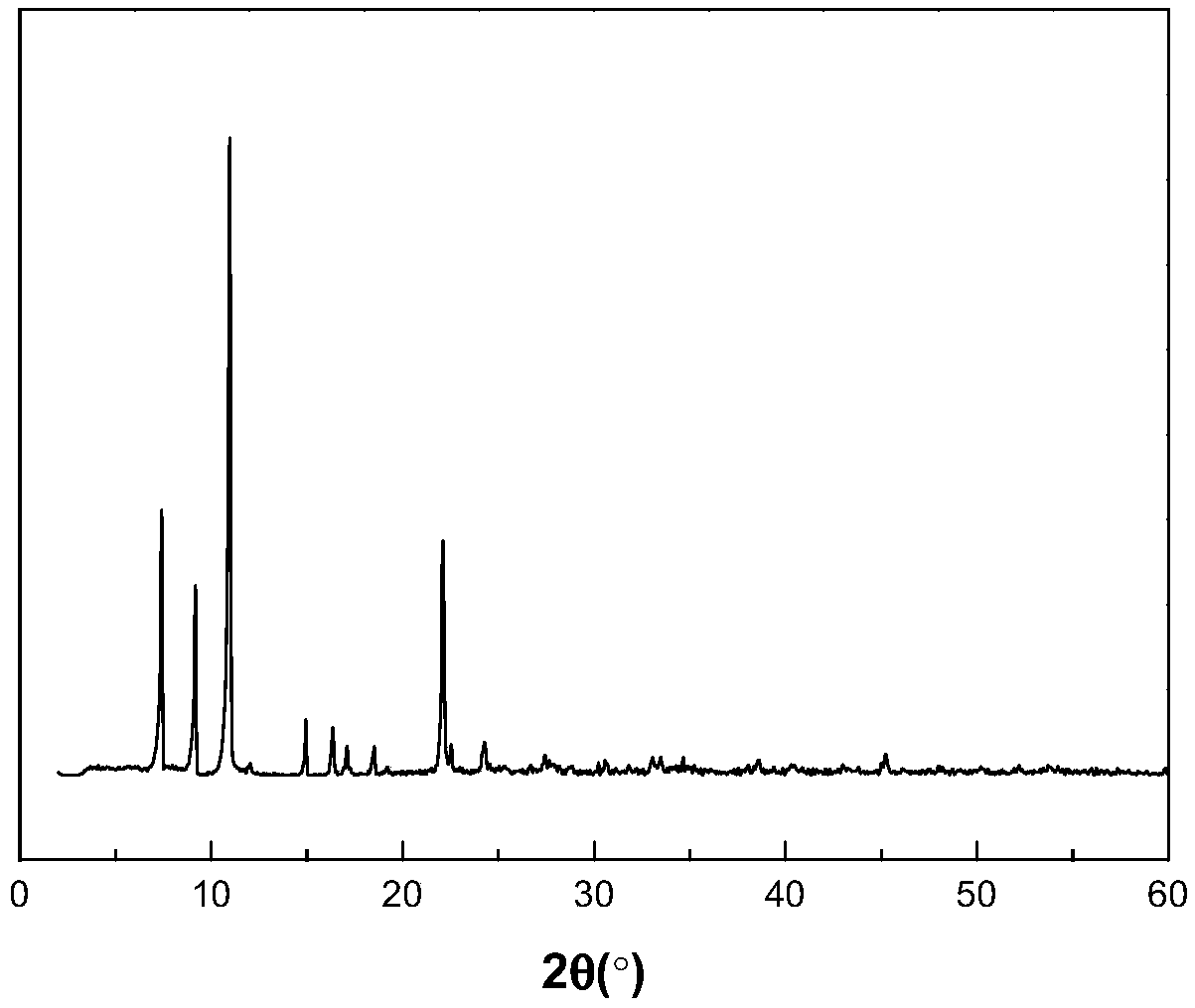

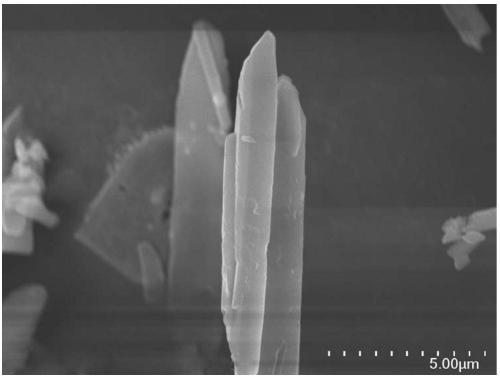

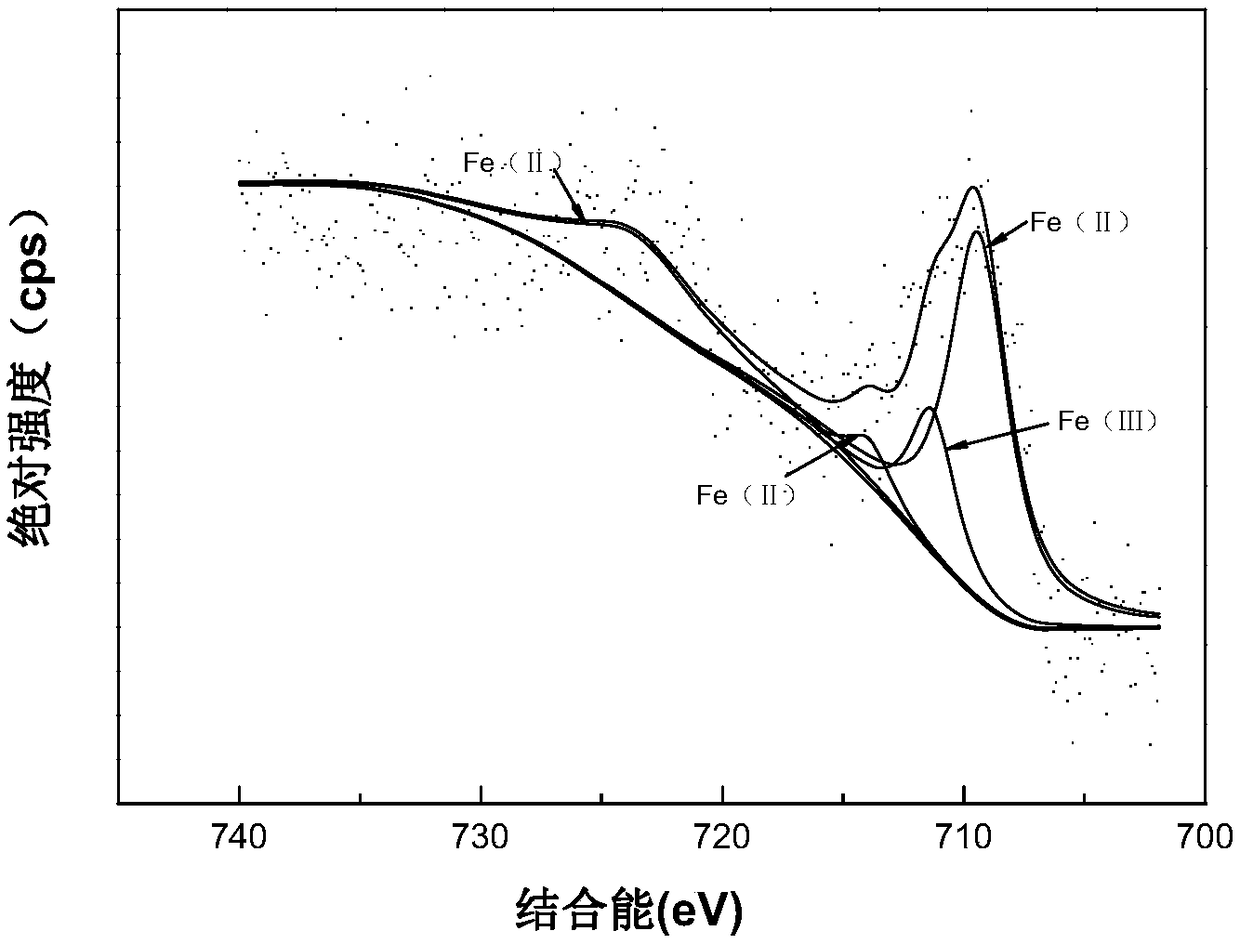

Ferrous-base metal organic framework material, normal-pressure synthesis method thereof and method of catalytically activating persulfate to treat organic pollutants

ActiveCN109482233ALower requirementEasy for macro synthesisOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsSulfate radicalsSynthesis methods

The invention discloses a ferrous-base metal organic framework material, a normal-pressure synthesis method thereof and a method of catalytically activating persulfate to treat organic pollutants. Themethod includes: successfully synthesizing a heterogeneous catalyst high-proportion ferrous-base metal organic framework material (Fe(II)-MOFs); utilizing the characteristic that the metal organic framework is high in active site and catalytic activity to catalytically activate sulfate at normal temperature to generate sulfate radical to degrade persistent organic pollutants. The catalyst is easyto be recycled, still has good activating effect after being reutilized for several times and is an environment-friendly material. The method is suitable for various persistent organic pollutants, high in durability, short in catalysis time, convenient in operation, capable of having good degradation effect within a wide pH value range and great in application prospect of degrading the persistentorganic pollutants.

Owner:广东仁安生态有限公司

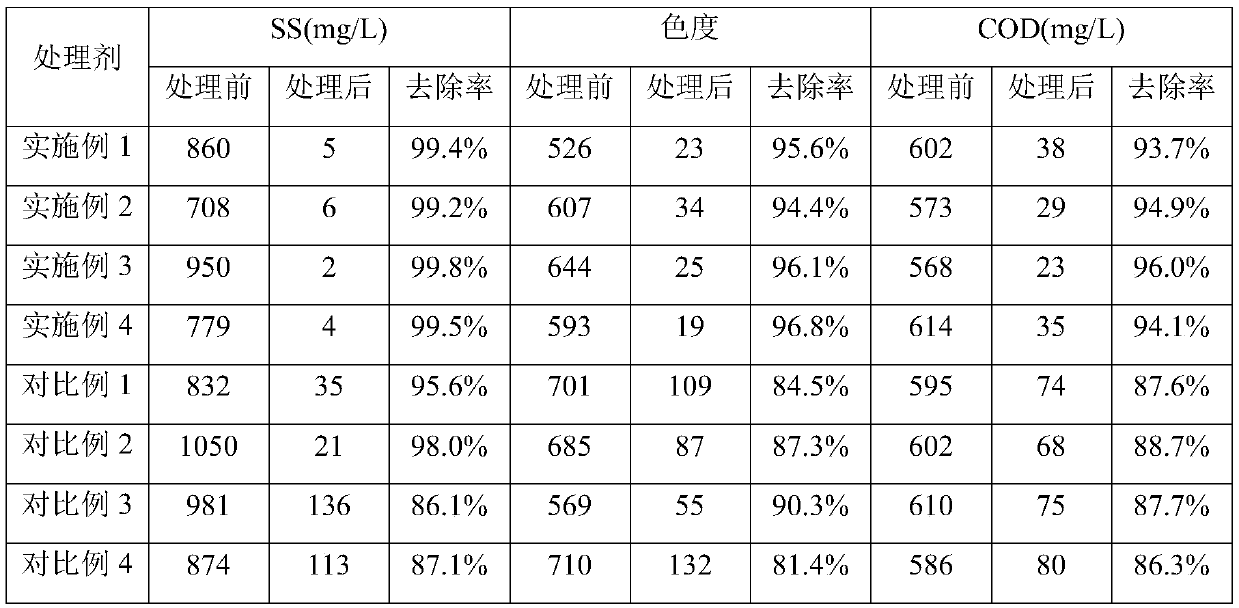

Composite flocculant for treating printing and dyeing wastewater

ActiveCN109734145AGood nucleation effectRealize separation and removalWater contaminantsWaste water treatment from textile industryFiberPolyvinyl alcohol

The invention discloses a composite flocculant for treating printing and dyeing wastewater. The composite flocculant for treating the printing and dyeing wastewater is prepared from the following rawmaterials in parts by weight: 15-25 parts of activated carbon fibers, 4-11 parts of acrylamide, 2-9 parts of sodium carboxymethyl cellulose, 5-17 parts of polyvinyl alcohol, 3-6 parts of a crosslinking agent, 0.003-0.006 part of an initiator, 3-5 parts of a polyethyleneimine-cellulose composite material, 10-15 parts of starch xanthate and 25-36 parts of modified bentonite. The composite flocculantprovided by the invention does not contain components which are complicated, have radiation and easily cause secondary pollution, all the used raw materials are natural, environment-friendly, low inprice and easy to obtain, the preparation method is simple, the feeding amount is small, the composite flocculant has multiple effects of flocculation sedimentation, adsorption decolorization, deodorization and the like, the sedimentation rate is high, the removal rates of organic matters, dye molecules and heavy metals are high, the structure and properties are stable, and the application range is wide.

Owner:XINXIANG UNIV

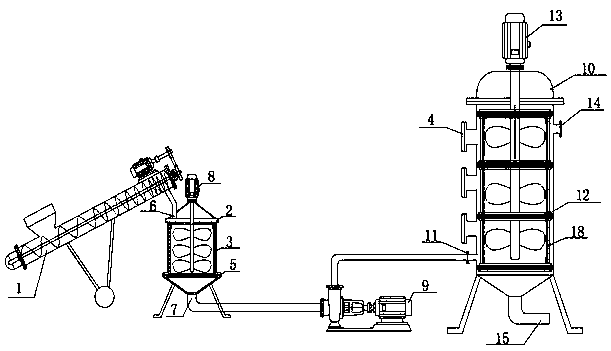

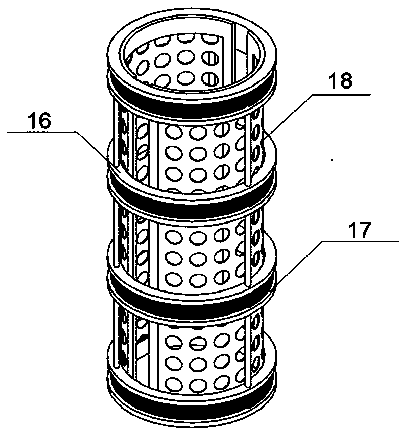

Method and device for removing impurities from phosphogypsum through electromagnetic reinforcement

The invention discloses a method and device for removing impurities from phosphogypsum through electromagnetic reinforcement. The method comprises the steps: adding the phosphogypsum and an organic extractant into an acid immersion tank through a spiral material lifter, performing mixing with concentrated sulfuric acid so as to prepare phosphogypsum slurry, performing heating and stirring so as tomake the slurry uniform and the impurities in the phosphogypsum be leached completely, applying an electric field on the mixed slurry so as to release the impurities wrapped and adsorbed on the surface of the phosphogypsum sufficiently, sending the phosphogypsum slurry obtained after electric disassociation to a water washing tower, applying an electric field and a magnetic field on the water washing tower so as to achieve directional migration of metal, heavy metal and radioactive metal ions in the phosphogypsum slurry under the action of an electric field force under stirring, and finally performing deposition on the surface of an electrode so as to realize separation from the phosphogypsum slurry. The method and device have wide applicability and no selectivity to the content of the phosphorus gypsum impurities, a short processing time, low energy consumption, high treatment efficiency and no secondary pollution are achieved, and the metal, heavy metal and radioactive elements in phosphogypsum can be separated and recovered effectively, so that recycling use of resources is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Hydrotalcite magnetite composite water treatment material

InactiveCN104261547AWill not cause secondary pollutionLow priceWater/sewage treatment by irradiationWater treatment compoundsChemical oxygen demandMagnetite

The invention discloses a hydrotalcite magnetite composite water treatment material for catalyzing, degrading and treating wastewater. The hydrotalcite magnetite composite water treatment material is prepared by the following method which comprises the following steps: mixing a mixed alkali solution of NaOH and Na2CO3 and a mixed saline solution of Mg(NO3)2 and Al(NO3)3 under the condition that the pH value is 10-11 and stirring the two solutions to obtain a mixed liquid; carrying out thermostatic reaction on the mixed liquid for 3-5 hours at a temperature of 60-100 DEG C, aging, centrifuging and washing to obtain precipitates; adding the magnetite into precipitates, mixing, adding ethanol, dispersing, then washing and drying to obtain the hydrotalcite magnetite composite water treatment material. The hydrotalcite magnetite composite water treatment material has the benefits that the hydrotalcite magnetite composite water treatment material has strong oxidability and is free from selectivity, starting matters and intermediate products can be removed when organic matters are removed, and the effect of removing COD (Chemical Oxygen Demands), TOC (Total Organic Carbon), total nitrogen, total phosphorus, algal cells and the like is good; the magnetite in the composite material is very favorable for recycling the material; the effects of treating domestic sewage, factory wastewater and especially treating the water bloom phenomenon are excellent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

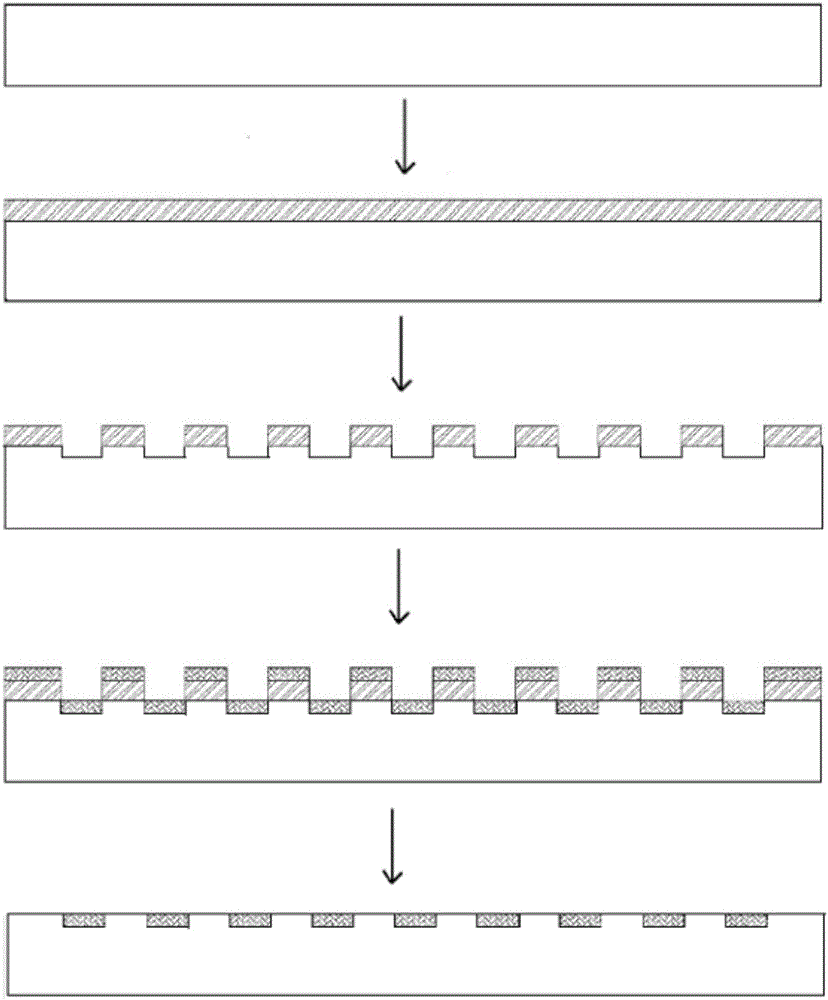

Shielding optical window and preparation method thereof

InactiveCN105887032AExcellent firmness and wear resistanceReduce performanceMagnetic/electric field screeningVacuum evaporation coatingCoatingMetal precipitation

The invention discloses a shielding optical window and a preparation method thereof. The method comprises the steps of (1) cleaning a substrate; (2) coating the substrate with a protective layer; (3) etching the protective layer and the substrate; (4) carrying out sputtering coating on the surface of the etched substrate; and (5) removing the protective layer to obtain the shielding optical window. According to the method for preparing the shielding optical window, metal precipitation is not required, and the material of the substrate is not required.

Owner:CHINA BUILDING MATERIALS ACAD

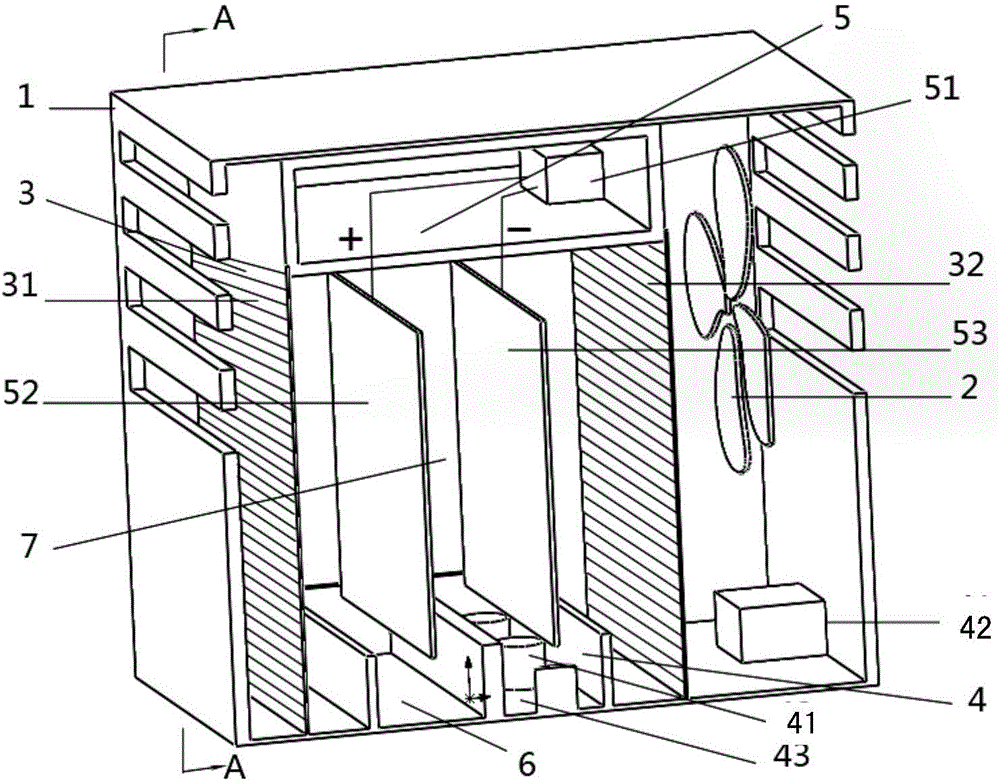

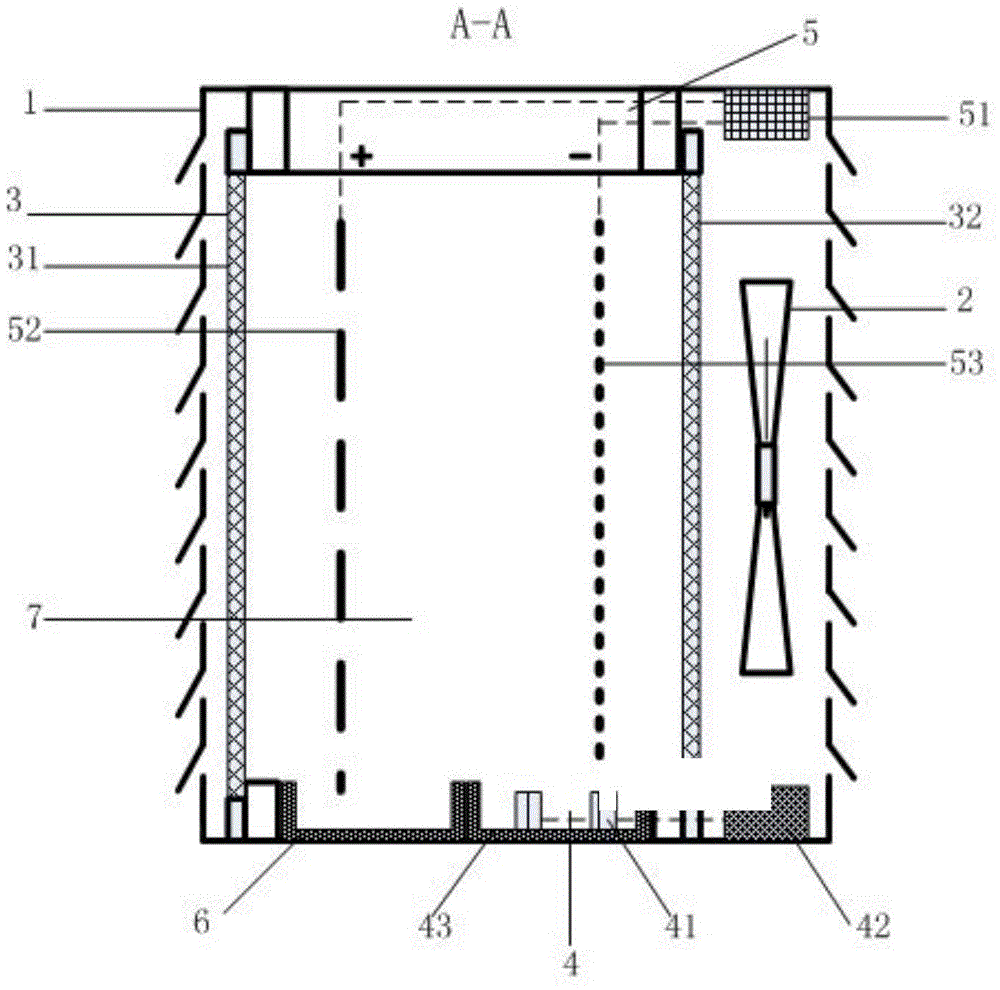

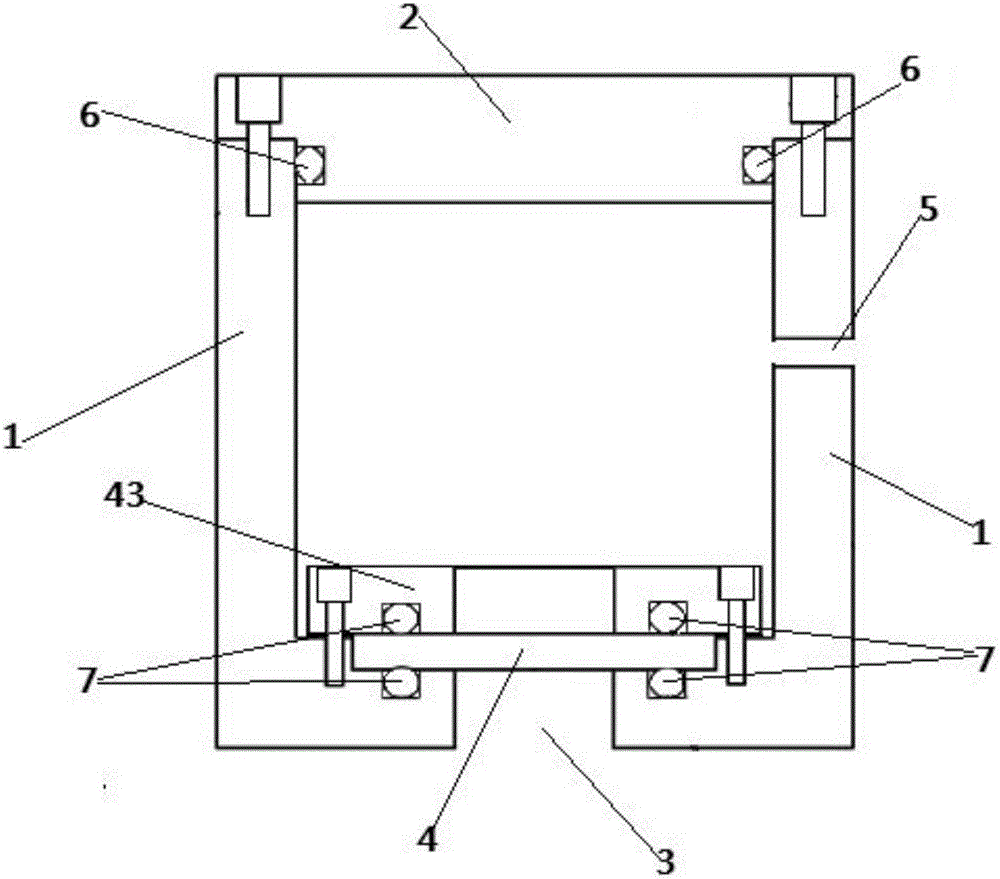

Air purifier

The invention discloses an air purifier. The air purifier comprises a purifier casing, an air inlet fan, a filter net, a water mist generator, an electrostatic device and a sewage storage box, wherein the air inlet fan is mounted on the inner side of an air inlet or an air outlet of the purifier casing; the filter net comprises a front filter net body and a back filter net body which are mounted on inner sides of the air outlet and the air inlet of the purifier casing respectively, and the front filter net body, the back filter net body and the purifier casing form an airtight cavity; the water mist generator is mounted at the bottom of the airtight cavity, is used for generating small water mist particles with high concentration and enables the cavity to be full of the particles; the electrostatic device is mounted in the purifier and matched with the water mist generator to enable the water mist particles to be charged; the sewage storage box is mounted at the bottom of the purifier. The air purifier has the benefits as follows: the filtering effect is good; charged water mist is collected into the sewage storage box after adsorbing dust, and the air purifier is easy to clean and convenient to use; no consumable is used, core filter components are not required to be replaced frequently, and the using cost is reduced.

Owner:ZHEJIANG UNIV CITY COLLEGE

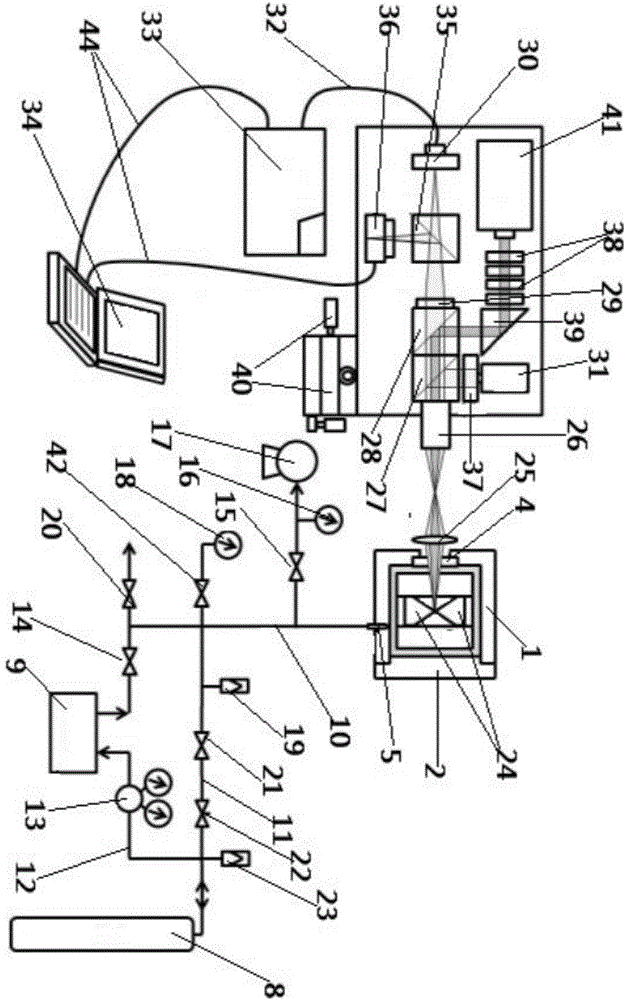

High-pressure packaging container and high-pressure in-situ gas compression packaging and pressure monitoring system

InactiveCN106764397AStable and controllable pressureIncrease success rateVessel wallsPressure vesselsPressure transmissionEngineering

The invention discloses a high-pressure packaging container, and a high-pressure in-situ gas compression packaging and pressure monitoring system. The system comprises the high-pressure packaging container, a high-pressure in-situ gas compression packaging system and a high-pressure in-situ gas monitoring system, wherein the high-pressure in-situ gas compression packaging system can package both a plurality of inert gas pressure transmission media and a plurality gaseous-state samples; the high-pressure in-situ gas monitoring system can precisely calibrate ultrahigh pressure; the high-pressure packaging container is provided with an optics observation window and a high-pressure gas inlet, so that high pressure generated during the packaging process of the gaseous-state samples or the inert gas pressure transmission media can be monitored, the situation that pressure in the high-pressure packaging container is stable and controllable during the packaging process is ensured, and the problems that the packaging of the gaseous-state samples or the inert gas pressure transmission media fails caused by uncontrollable pressure in the high-pressure packaging container and a diamond anvil cell press is damaged are avoided to further increase the success rate of a high-pressure in-situ experiment.

Owner:JILIN UNIV

Method for producing nutritious soilless culture base material

InactiveCN1545853AStrong exchange abilityImprove breathabilityAgriculture gas emission reductionCultivating equipmentsNitrogenPotassium

The invention discloses a process for preparing nutrition-containing soilless cultivation base material which comprises, stock preparation, calcinations, acid conventional processing, purification, replacing some substance in the zeolite aperture by means of dynamic reaction, cleaning again, adsorbing potassium sulphate, boric acid and other nourishing material completely in the zeolite, cleaning again, adjusting pH by charging acid, drying and packaging.

Owner:高显会

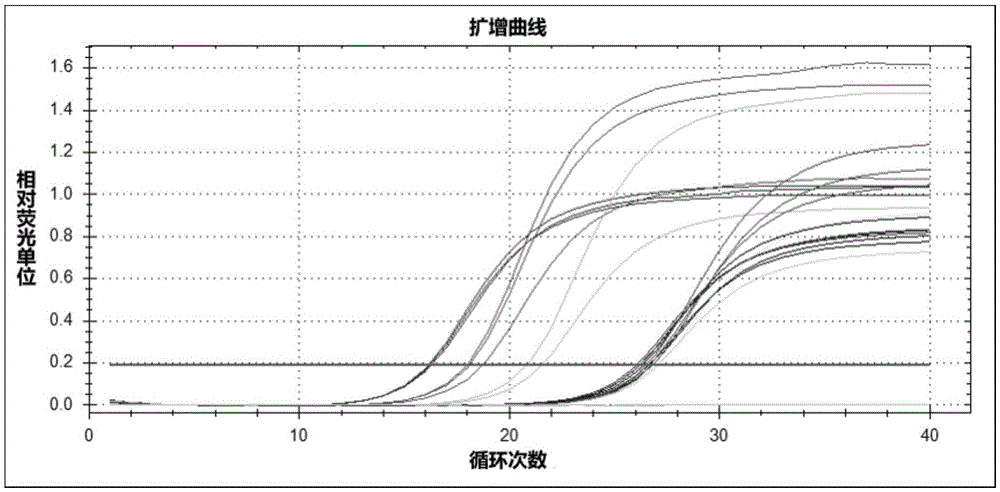

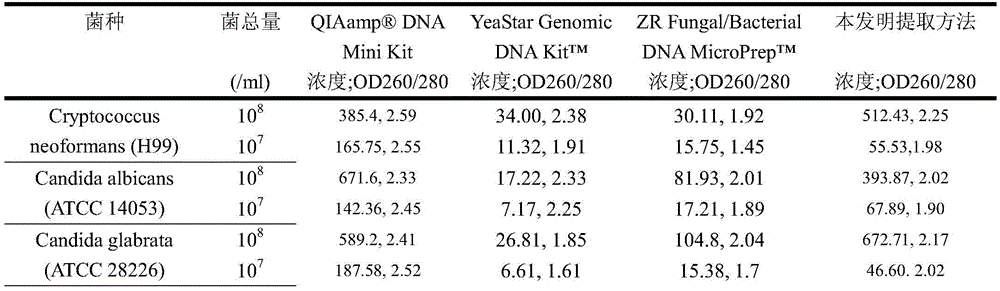

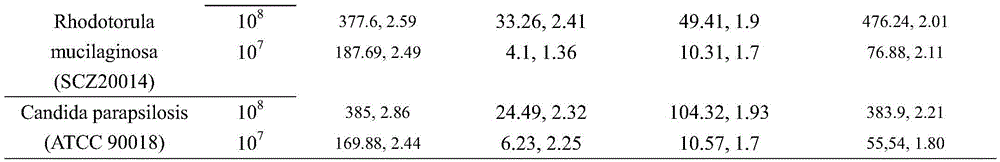

Instrument-free yeast-like fungus DNA extraction method used for nucleic acid amplification

ActiveCN105624152AGood cracking effectShorten the timeMicrobiological testing/measurementDNA preparationSyringeBiology

The invention relates to the field of fungi molecular biology, in particular to an instrument-free yeast-like fungus DNA extraction method used for nucleic acid amplification. According to the method, two yeast wall breaking methods, namely, the chemical lysis method and the enzymatic lysis method, are ingeniously integrated, DNA extraction is completed within 1.5-3 hours through the combination with a suction device, a filter device and a nucleic acid extraction syringe without power supply devices, and the method is the only efficient instrument-free yeast-like fungus DNA extraction method at present. The extraction method has the advantages of being rapid, simple, convenient to use, sensitive, free of toxin, low in cost and the like, and can be suitable for most yeast-like fungi.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY +1

Novel use of formaldehyde in preparation of drug for animals

InactiveCN1704047APrevent diseaseReduce dosageOrganic active ingredientsAntiinfectivesDigestive canalAntibiotic Y

Provided is a novel use of formaldehyde in preparing pharmaceuticals for prevention and cure of animal diseases caused by pathogenic microorganisms through infection of digestive canal by means of digestive tract administration, wherein formaldehyde can deactivate pathogenic microorganisms and their toxins, make it lose pathogenicity while keeping the antigenicity. The invention realizes the advantages of broad spectrum, quick and sure effects, small dosage, less administration, lower price and removal of drug resistance and medicinal residual produced by the application of antibiotics.

Owner:关中田

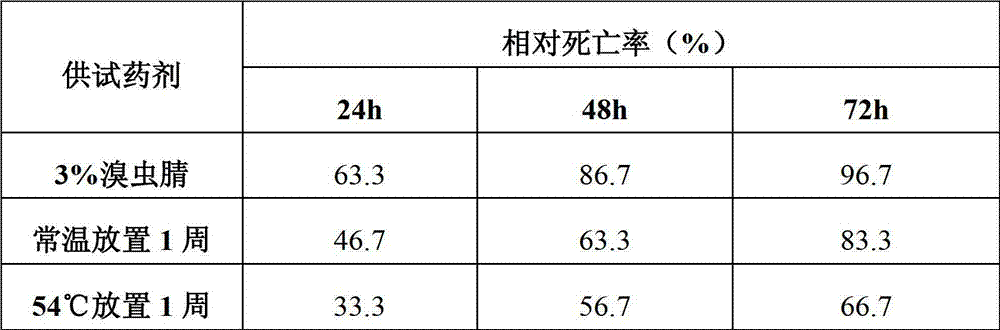

Powder type blattaria bait

The invention discloses a powder type blattaria bait. The bait agent comprises the components of pesticide original medicine, a composite feeding stimulant, a preservative agent and a filling agent, wherein by weight percent, the pesticide is 1.0-3.0 percent, the composite feeding stimulant is 80.0-85.0 percent, the preservative agent is 0.5 percent and the filling agent is the rest. The bait has the characteristics of inexpensive materials, simplicity in manufacturing, convenience in scattering and good population control effect, and has no harm to human, domestic animals and the environment.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI

Automobile rear view mirror lens and its preparation method

InactiveCN101241195ANo choiceImprove efficiencyOptical viewingOptical elementsHigh volume manufacturingEngineering

An automobile rear view mirror lens and producing method thereof are disclosed, pertaining to automobile parts technique field. The invented automobile rear view mirror lens is composed of a blue glass sheet and an aluminum or chromium plated film on one side of the glass sheet. The producing method are: producing a blue glass plate by using the floating method, cutting the glass plate to produce the rear view mirror glass base sheet, plating an aluminum film or a chromium film thereon by a normal vacuum plating process, and obtaining the invented product. The positive effects of the invention are: the two techniques which are producing color glass plate by the floating method and plating on the glass plate are matured, techniques with low costs are combined together, so that blue rear view lens with a cost which is only 30145604210f the cost of the traditional products is produced. And the products has no selectivity to optical spectrum, has good evenness, and reflectance ratio thereof can be controlled at optimal value (40%). The production period is short, the production efficiency is high, and it is suitable for mass production. The invented products create conditions for mounting rear view mirrors which are viewed as high-grade products on normal automobiles.

Owner:长春博信光电子有限公司

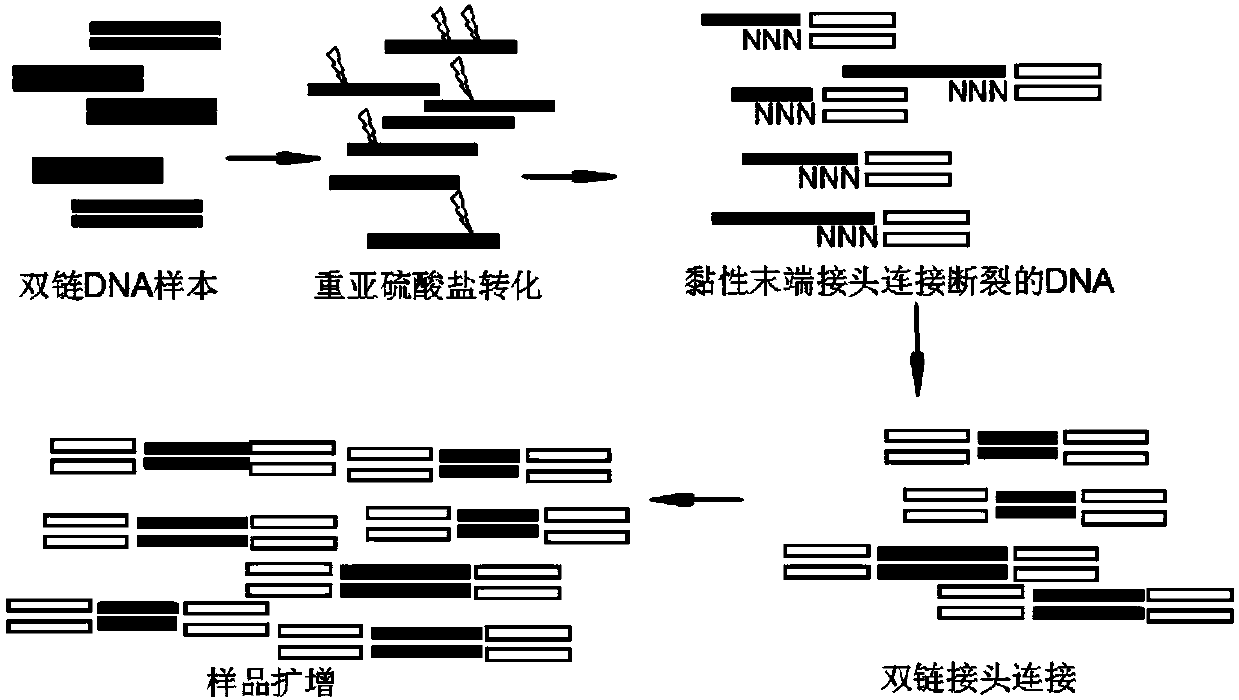

Novel methylation library-establishing kit and application thereof

InactiveCN107904667AReduce lossesImprove accuracyMicrobiological testing/measurementLibrary creationDna breakageA-DNA

The invention relates to the technical field of molecular biology and particularly relates to a novel methylation library-establishing kit and an application thereof. The novel methylation library-establishing kit at least comprises a bisulfate conversion reagent, a sticky end joint, ligase, a DNA extending reagent and a DNA amplifying reagent. The novel methylation library-establishing kit can beapplied to a sample with a low initial mass (as low as 6pg) and suitable for genome DNA with relatively poor mass extracted from FFPE samples and the like, so that the loss of sample information caused by DNA breakage during drug treatment is greatly reduced; and a double-chain DNA joint with a sticky end can be directly introduced by virtue of relatively economic and practical common ligase, sothat the accuracy of data can be improved, the diversity of samples can be preserved to a great extent, and the library deviation property caused by human factors can be reduced.

Owner:SHANGHAI MAJORBIO BIO PHARM TECH

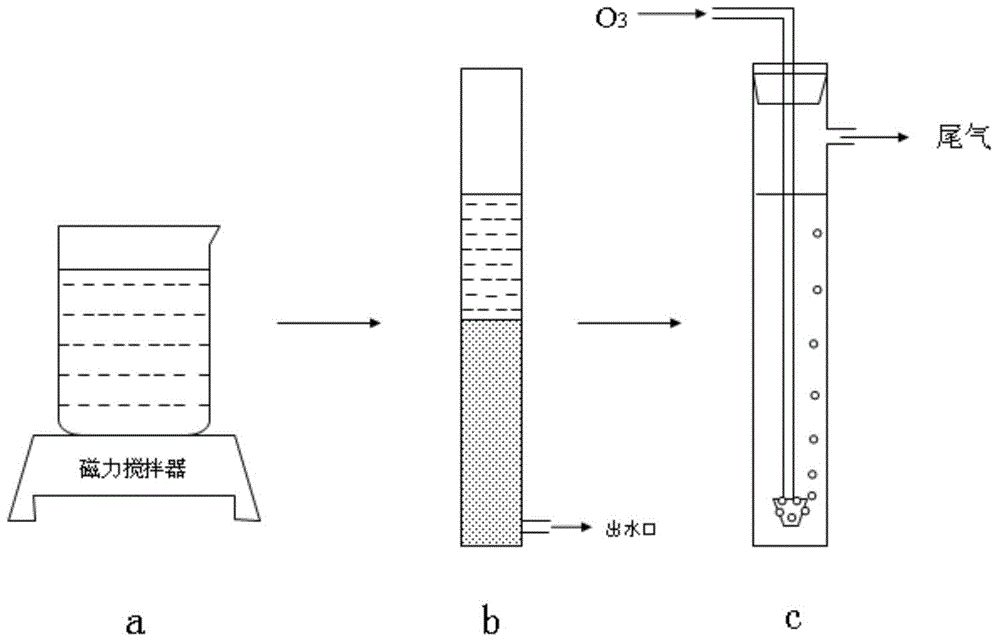

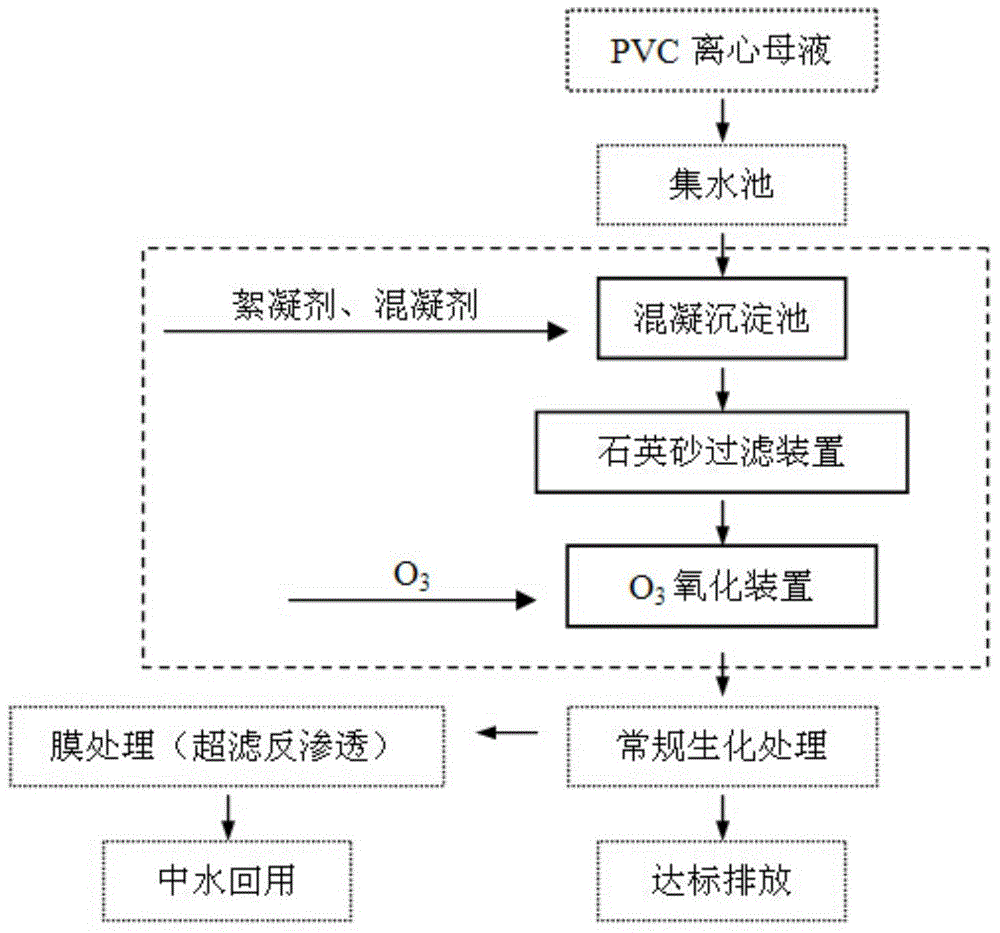

Polyvinyl chloride centrifugal mother liquor wastewater pretreatment method

InactiveCN105036463AReduce contentStrong oxidation abilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationPretreatment methodPolyvinyl chloride

The invention provides a polyvinyl chloride centrifugal mother liquor wastewater pretreatment method, and belongs to the technical field of wastewater treatment. The method adopts a flocculation deposition-quartz sand filtration-ozone oxidation combination mode to treat PVA in PVC centrifugal mother liquor wastewater. Te method comprises the following steps: adding a coagulant and a coagulant aid to the mother liquor wastewater to carry out flocculation deposition, filtering by using a quartz sand filtering column, carrying out ozone aeration treatment on the obtained filtrate, and allowing treated wastewater to directly enter a routine biological treatment system. The method has the advantages of substantial effect, low cost and simple operation, allows disadvantages of other treatment units to be made up through combining all treatment units, and can be widely used in pretreatment of the PVC centrifugal mother liquor wastewater.

Owner:JILIN UNIV

Process for preparing optical fibre based on single-mode optical fibre to implement different performance of acousto-optic filter

InactiveCN1346990AChange performanceCoupling Conversion Efficiency ImprovementOptical light guidesEngineeringAcousto-optics

A process based on single-mode transmitting optical fibre for preparing the optical fibre to implement different performance of acousto-optic filter includes using a commercially available optical fibre for transmission purpose, determining needed external diameter and etching speed, and etching the optical fibre by controlling etch time to change its refractivity in acousto-optical action region. Its advantages are simple process, easy control, high effect, no damage to core of optical fibre, and low loss of optical fibre.

Owner:TSINGHUA UNIV

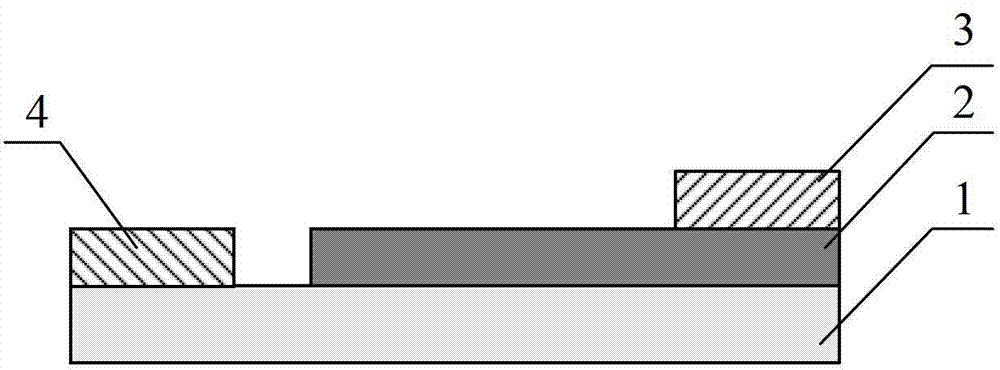

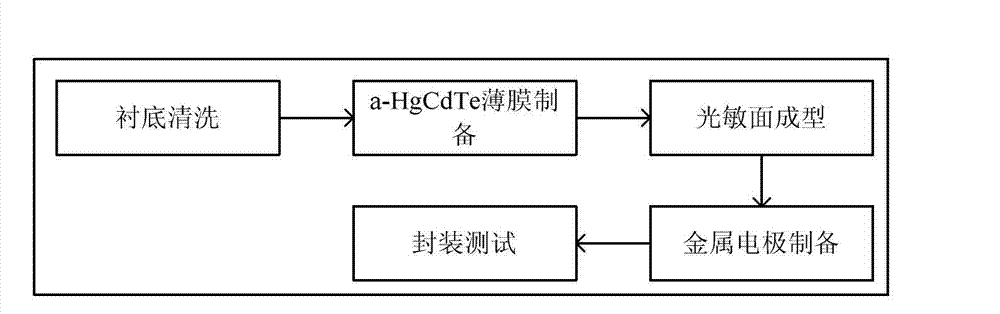

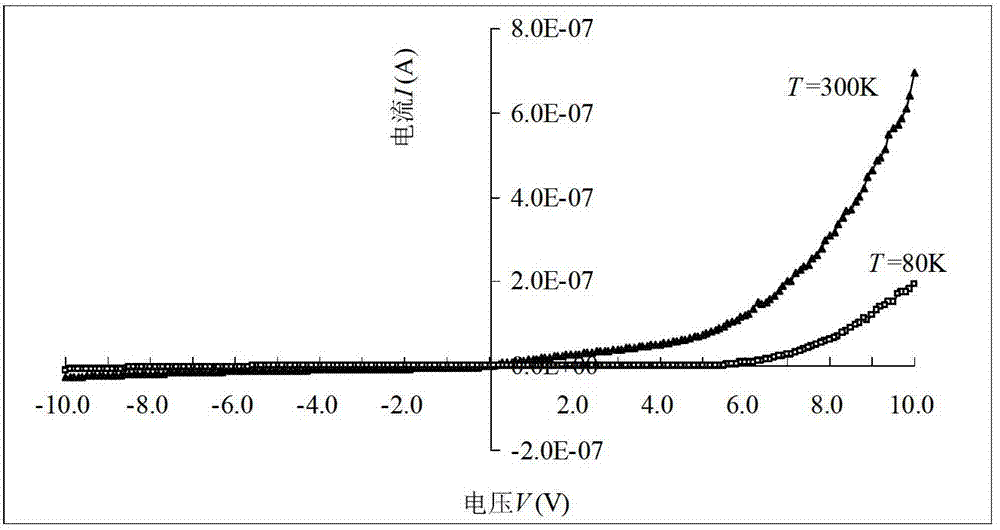

Amorphous tellurium-cadmium-mercury/crystalline silicon heterojunction infrared-detector and manufacturing method thereof

InactiveCN102903783AGood lattice matchingNo choiceFinal product manufacturePhotovoltaic energy generationHeterojunctionWorking temperature

The invention relates to an amorphous tellurium-cadmium-mercury / crystalline silicon heterojunction infrared-detector, which is characterized by being composed of a crystalline silicon substrate, amorphous tellurium-cadmium-mercury, a first metal electrode and a second metal electrode, wherein the amorphous tellurium-cadmium-mercury and the crystalline silicon substrate form heterojunction, the first metal electrode is connected with the amorphous tellurium-cadmium-mercury, and the second metal electrode is connected with the crystalline silicon substrate. The preparation process comprises the following steps of substrate cleaning, amorphous tellurium-cadmium-mercury film preparation, photosensitive surface forming, metal electrode preparation and package test; or substrate cleaning, second metal electrode preparation, amorphous tellurium-cadmium-mercury film preparation, photosensitive surface forming, first metal electrode preparation and package test. The amorphous semiconductor material has no selectivity for the substrate, the lattice matching performance between materials forming heterojunction is better, and the significant photoelectric response exists. The optimum working temperature of the detector is close to room temperature, two stages of semiconductors are utilized for refrigeration, and the weight, the power consumption and the manufacturing cost of the infrared detector assembly are reduced.

Owner:KUNMING INST OF PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com