Hydrotalcite magnetite composite water treatment material

A composite material and hydrotalcite technology, applied in the field of water treatment, can solve the problems of limiting the further application of homogeneous systems, low utilization rate of hydrogen peroxide, high treatment cost, etc., to achieve recycling and reuse, low price and fast reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to Mg(N0 3 ) 2 , A1(N0 3 ) 3 The molar total ratio of 2 weighs 4.8g of NaOH, 12.7g of Na 2 C0 3 Dissolve in 150ml of distilled water to make a mixed alkali solution, weigh 15.4g of Mg(N0 3 ) 2 and 11.3g of A1 (N0 3 ) 3 Dissolve in 150ml of distilled water to form a mixed salt solution, mix and stir the mixed alkali solution and the mixed salt solution at a pH value of 10-11 to obtain a mixed solution; the mixing process is preferably dropwise. React the mixture at a constant temperature of 60-100°C for 3-5h, age, centrifuge, and wash to obtain a precipitate; add 2g of magnetite to the precipitate to mix, add 2ml of 95% ethanol to disperse, wash again, and dry at 60°C to obtain Hydrotalcite-magnetite composites.

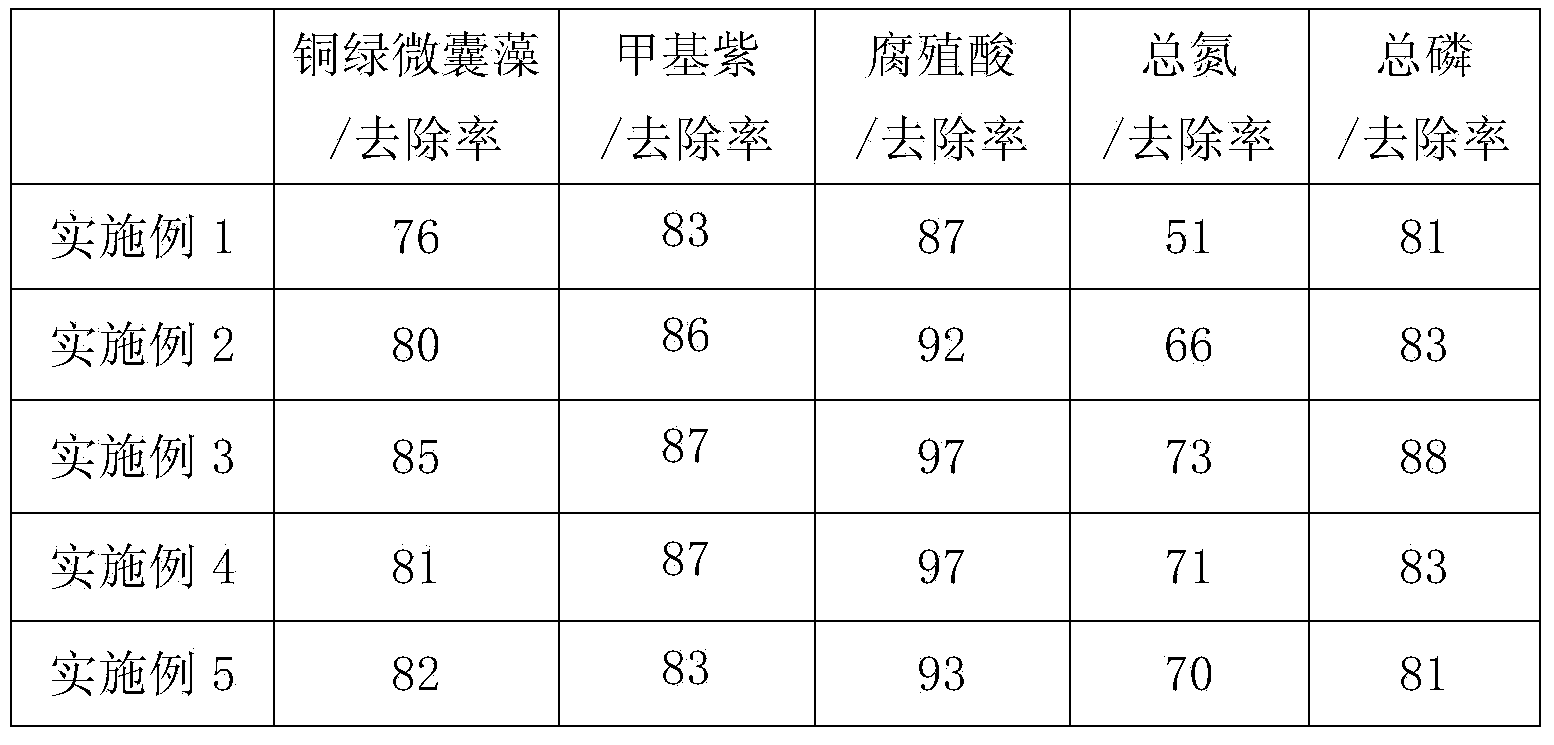

[0035] The hydrotalcite-magnetite composite material obtained in this example degrades Microcystis aeruginosa. Weigh 0.125g of the hydrotalcite-magnetite composite material and add it to 250ml of Microcystis aeruginosa suspension with a mass c...

Embodiment 2

[0039] According to Mg(N0 3 ) 2 , A1(N0 3 ) 3 The molar total ratio of 2.5 weighs 4.8g of NaOH, 12.7g of Na 2 C0 3 Dissolve in 150ml of distilled water to make a mixed alkali solution, weigh 19.3g of Mg(N0 3 ) 2 and 11.3g of A1 (N0 3 ) 3 Dissolve in 150ml of distilled water to form a mixed salt solution, mix and stir the mixed alkali solution and the mixed salt solution at a pH value of 10-11 to obtain a mixed solution; the mixing process is preferably dropwise. React the mixture at a constant temperature of 60-100°C for 3-5h, age, centrifuge, and wash to obtain a precipitate; add 2g of magnetite to the precipitate to mix, add 2ml of 95% ethanol to disperse, wash again, and dry at 60°C to obtain Hydrotalcite-magnetite composites.

Embodiment 3

[0041] According to Mg(N0 3 ) 2 , A1(N0 3 ) 3 The molar total ratio of 3 weighs 4.8g of NaOH, 12.7g of Na 2 C0 3 Dissolve in 150ml of distilled water to make a mixed alkali solution, weigh 23.1g of Mg(N0 3 ) 2 and 11.3g of A1 (N0 3 ) 3 Dissolve in 150ml of distilled water to form a mixed salt solution, mix and stir the mixed alkali solution and the mixed salt solution at a pH value of 10-11 to obtain a mixed solution; the mixing process is preferably dropwise. React the mixture at a constant temperature of 60-100°C for 3-5h, age, centrifuge, and wash to obtain a precipitate; add 2g of magnetite to the precipitate to mix, add 2ml of 95% ethanol to disperse, wash again, and dry at 60°C to obtain Hydrotalcite Magnetite Composite No. 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com