High-pressure packaging container and high-pressure in-situ gas compression packaging and pressure monitoring system

A gas compression and packaging system technology, applied in pressure vessels, equipment into pressure vessels, container filling methods, etc., can solve problems such as increased experimental difficulty, damage to diamond anvils, and packaging failures, and achieves high adaptability and reliability. Flexibility, increased success rate, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

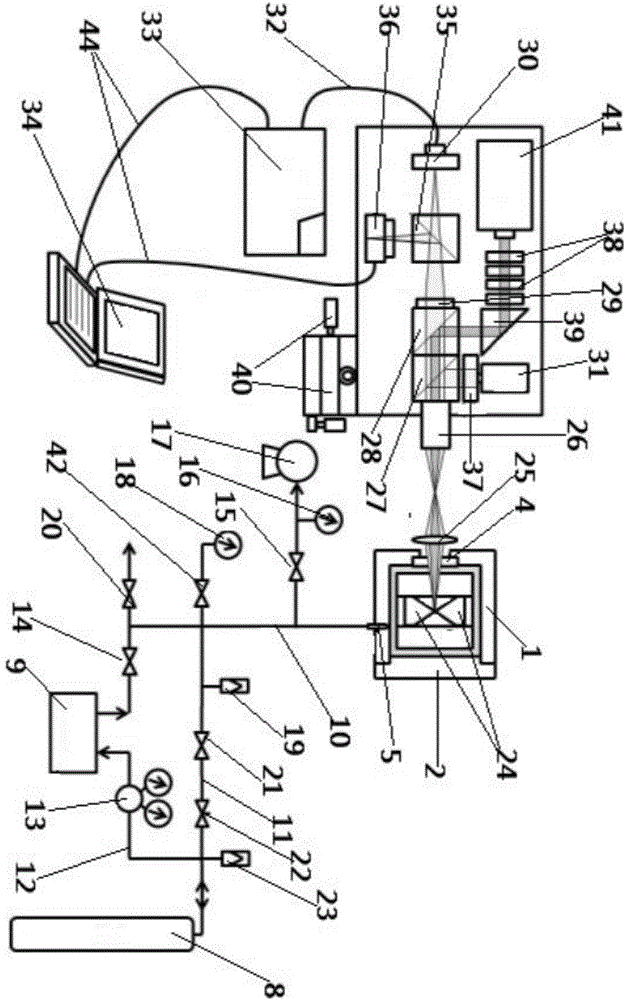

[0056] In this embodiment, using the high-pressure in-situ gas compression packaging and pressure monitoring system of the present invention, argon gas is filled into the sample cavity of the diamond counter-anvil press as a pressure transmission medium, and the pressure in the sample cavity is monitored with a ruby pressure calibration system , the specific operation process is as follows:

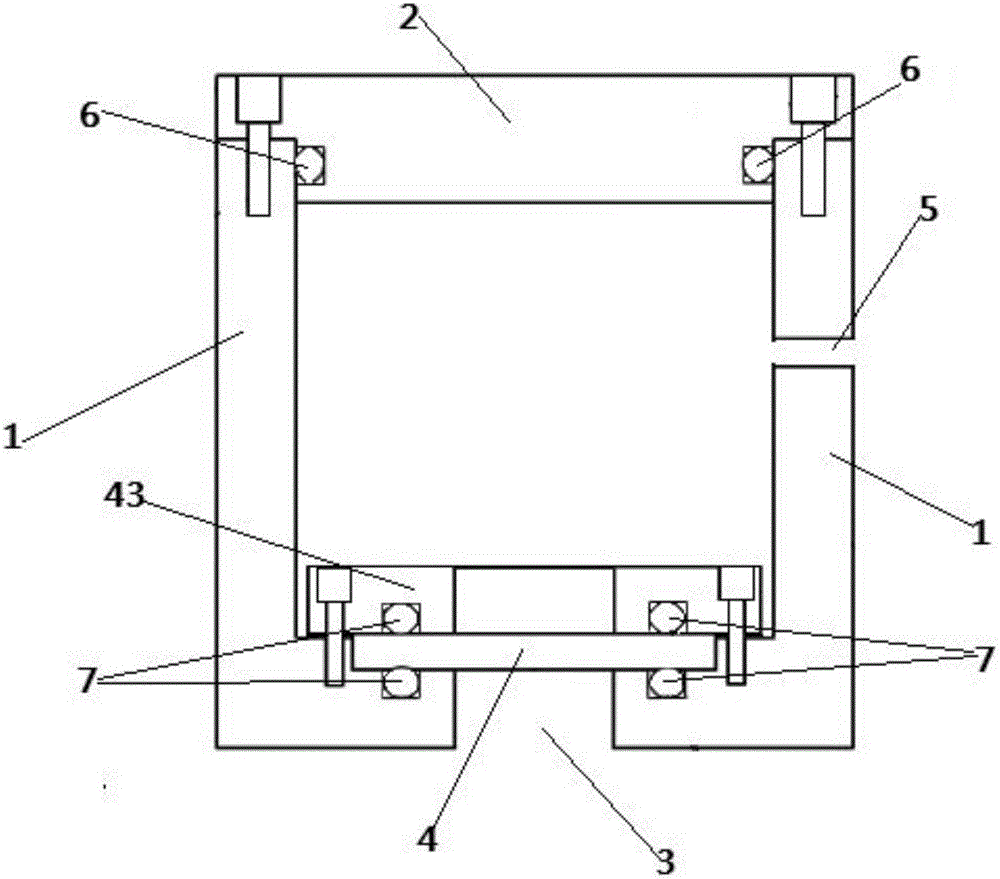

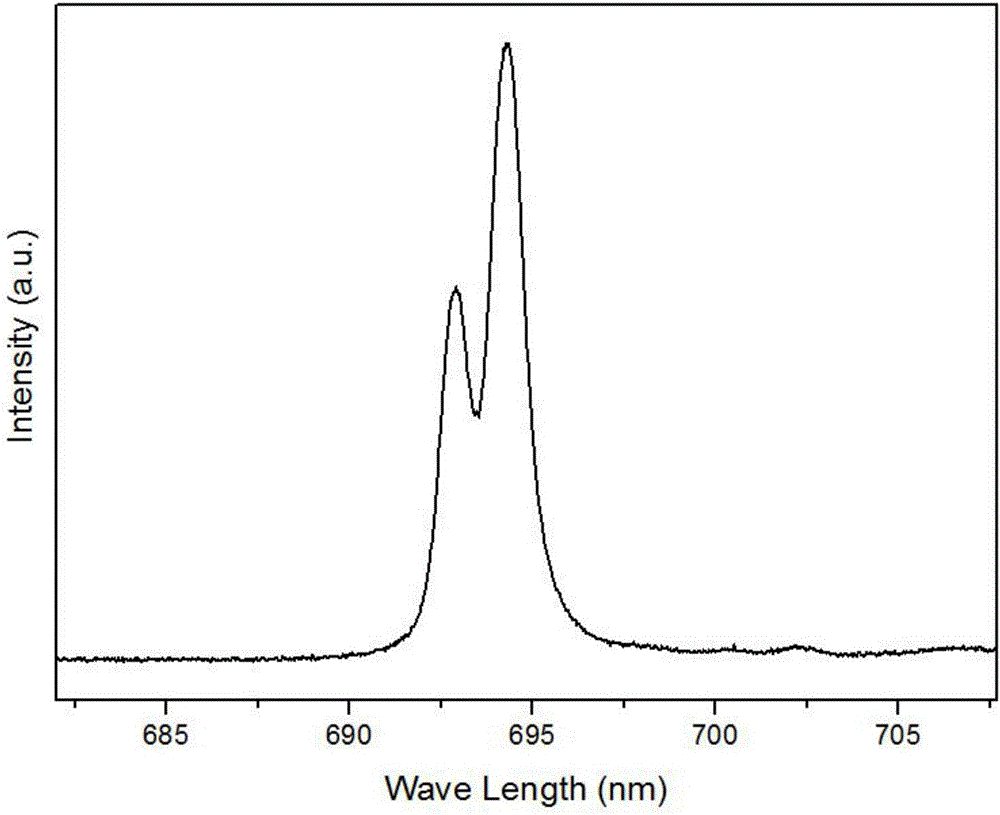

[0057] In this example, the diameter of the anvil surface of the diamond counter-anvil press device used is 500 μm, a T301 stainless steel foil with a thickness of 0.25 mm is pre-pressed to 40 μm, and a tungsten carbide needle is used to punch a diameter of 160 μm in the center of the indentation. The hole is used as the sample cavity, and the experimental sample is loaded into the sample cavity, and at the same time, ruby microspheres with a diameter of 10 μm are loaded to calibrate the pressure in the sample cavity; the diamond counter anvil device is sealed, and the diamond counter ...

Embodiment 2

[0067] In this embodiment, using the high-pressure in-situ gas compression packaging and pressure monitoring system of the present invention, hydrogen sulfide is filled into the sample cavity of the diamond counter-anvil press as an experimental sample, and the pressure in the sample cavity is monitored with a ruby pressure calibration system. The specific operation process is as follows:

[0068] In this embodiment, the diameter of the anvil surface of the diamond counter anvil press device used is 300 μm. Pre-press a square metal rhenium foil of 5mm×5mm, use an EDM to form a hole with a diameter of 100 μm in the center of the indentation as the sample cavity, and fill it with ruby microspheres with a diameter of 5 μm to calibrate the sample cavity Seal the diamond counter-anvil device, pack the diamond counter-anvil into a high-pressure packaging container, and seal the high-pressure packaging container. Switch the imaging / measurement switching device to the "cut-in" st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com