A kind of grouting and sealing method for brick gas channel

A technology of gas channel and grouting machine, which is applied in the direction of preventing/repairing the leakage of bricklaying, can solve the problems of easy falling off, pressure control, cracks cannot be sealed, etc., to achieve stable and controllable pressure, short time consumption, lower mud The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

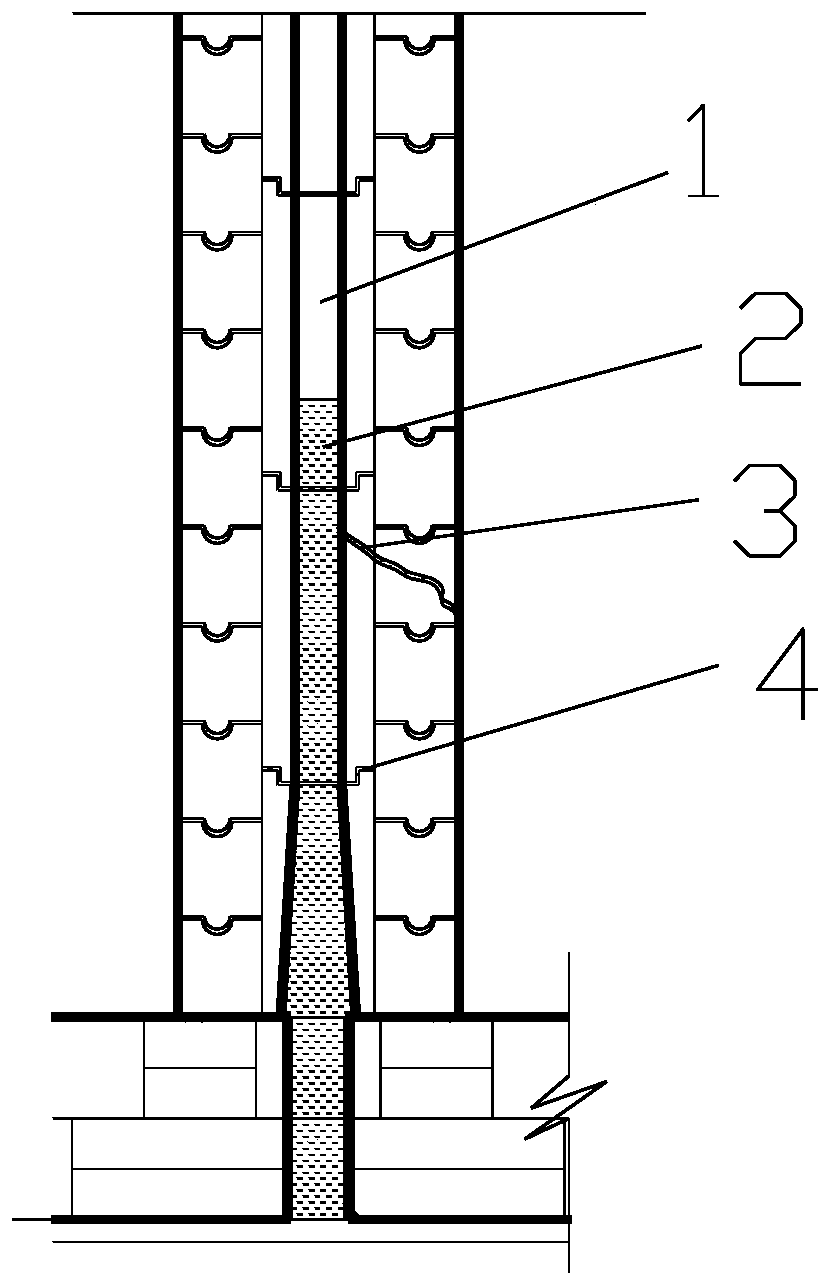

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0022] like figure 1 Shown, a kind of method for grouting and sealing of brick gas channel of the present invention comprises the following steps:

[0023] 1) Confirmation of the sealing range and calculation of the sealing parameters; firstly, confirm the part that needs to be sealed in the coke oven brick gas channel 1, and then determine the required height of the mud 2 in the brick gas channel 1, and calculate the required height when reaching the height. The volume of the mud 2 that needs to be pressed in; the mud 2 is pressed in quantitatively by the gear pump, and the working time of the gear pump is calculated according to the volume of the mud 2 required and the output flow of the gear pump;

[0024] 2) Preparation before sealing operation; prepare the mud 2 used for sealing the brick gas channel, the specific gravity of the mud 2 is 1.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com