Vibration-crushing micro-pill machine

A pelletizing machine and crushing technology, which is used in the direction of making medicines into special physical or taking forms, can solve the problems of high operator level requirements, difficult control, dust pollution, etc., and improve the operability. performance, low preparation cost, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

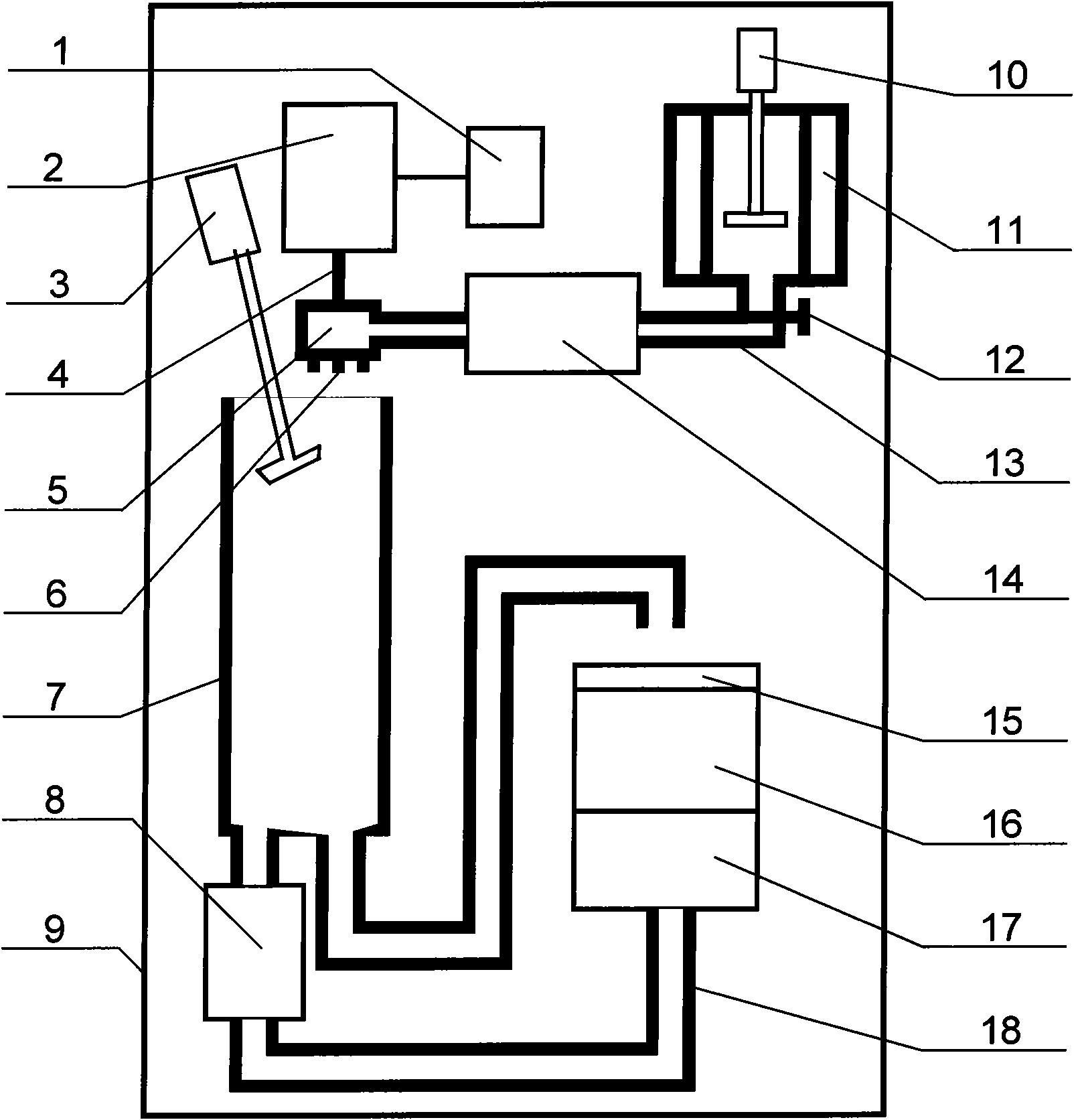

[0040] The following combination figure 1 , figure 2 , image 3 and an embodiment to describe the present invention in detail.

[0041] figure 1 The overall structure of the dripping pill machine in the present invention is shown.

[0042] The pellet machine of the present invention includes a housing 9 and a liquid storage tank 11 arranged in the housing 9, a dropping pill system, a cooling cycle device, a pellet collector, a control circuit, and the like.

[0043] The outer wall of the liquid storage tank 11 is provided with a sandwich layer, a heater and a temperature sensor are arranged in the sandwich layer, and an electric valve 12 is provided at the lower part;

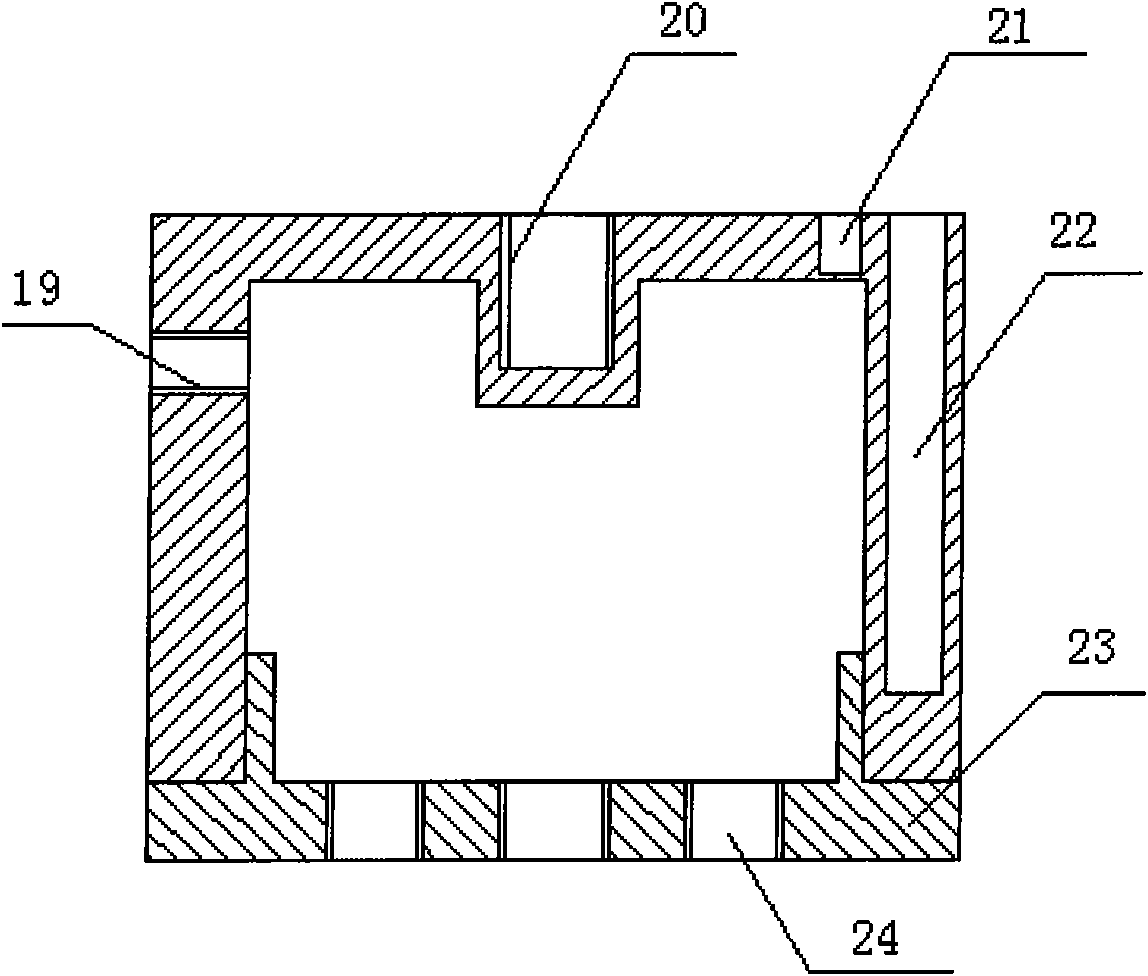

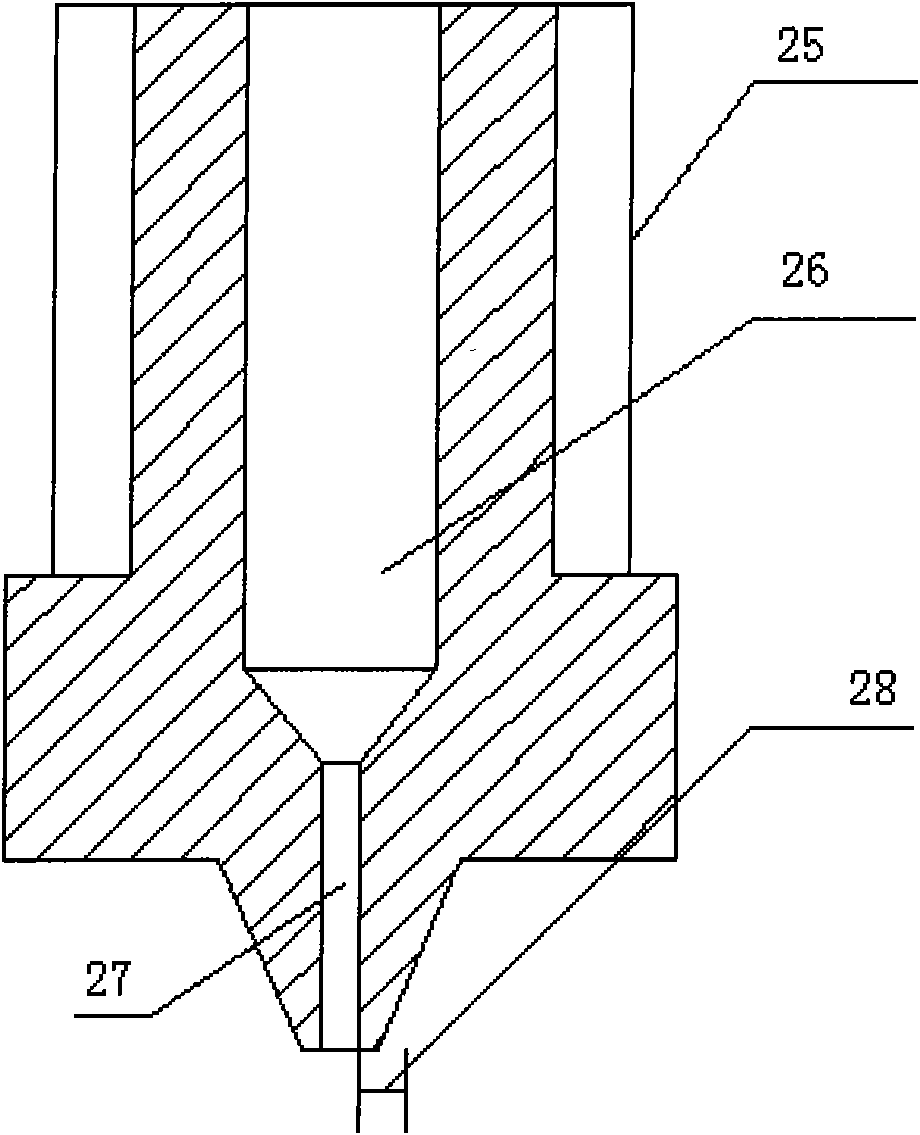

[0044] The dripping pill system includes a dripper 5, a vibrator 2, and a gear pump 14. figure 2 It is a schematic diagram of dripper 5 . The side wall of the dripper 5 is provided with a liquid inlet threaded hole 19 and a heater insertion hole 22, its upper end is provided with a threaded hole 20 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com