Patents

Literature

763results about How to "Short time consuming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphics and text information releasing and generating method and graphics and text information releasing and generating device

ActiveCN103885951AMeets requirementsImprove click-through rateAdvertisementsWebsite content managementGraphicsTemplate library

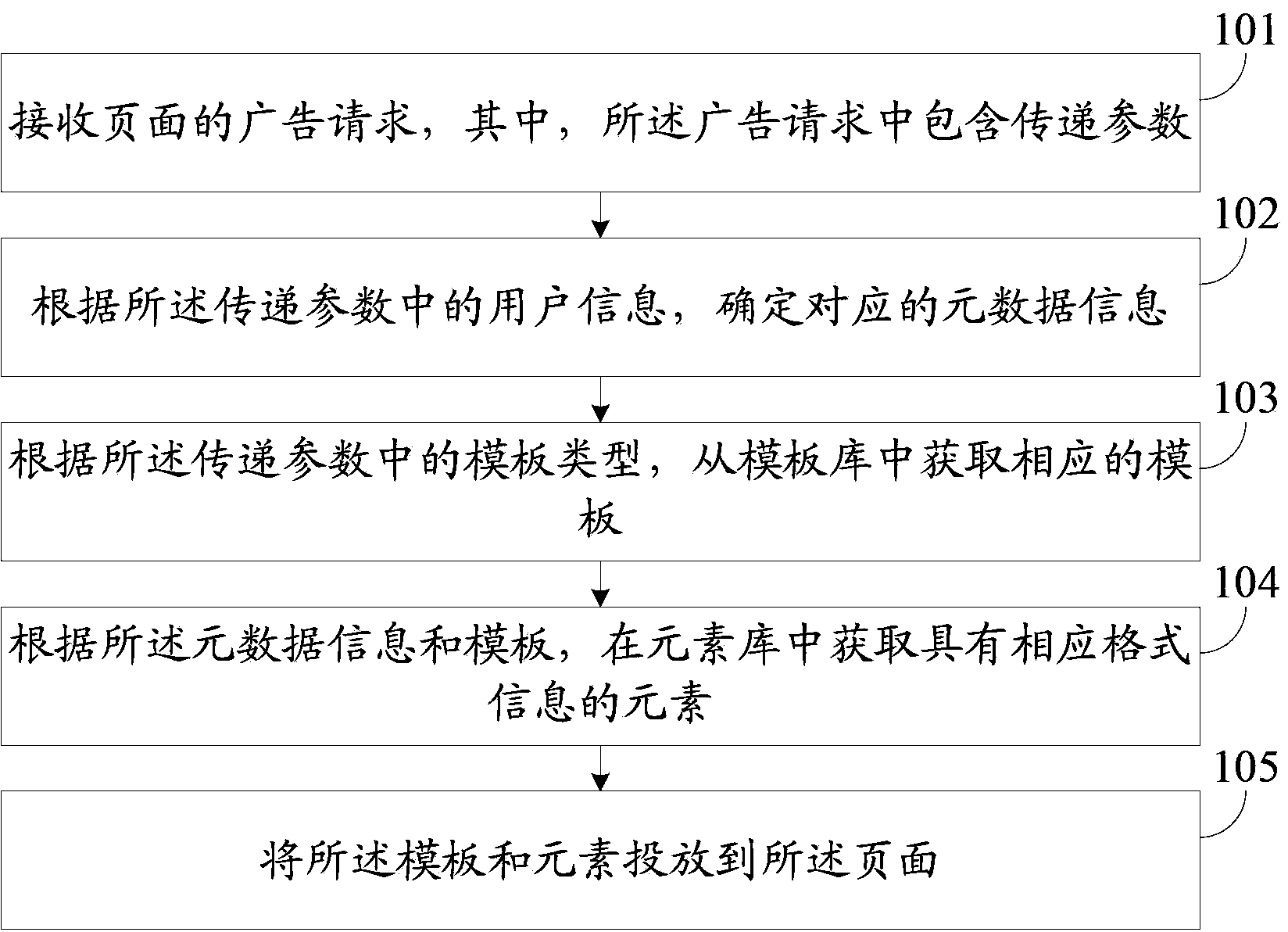

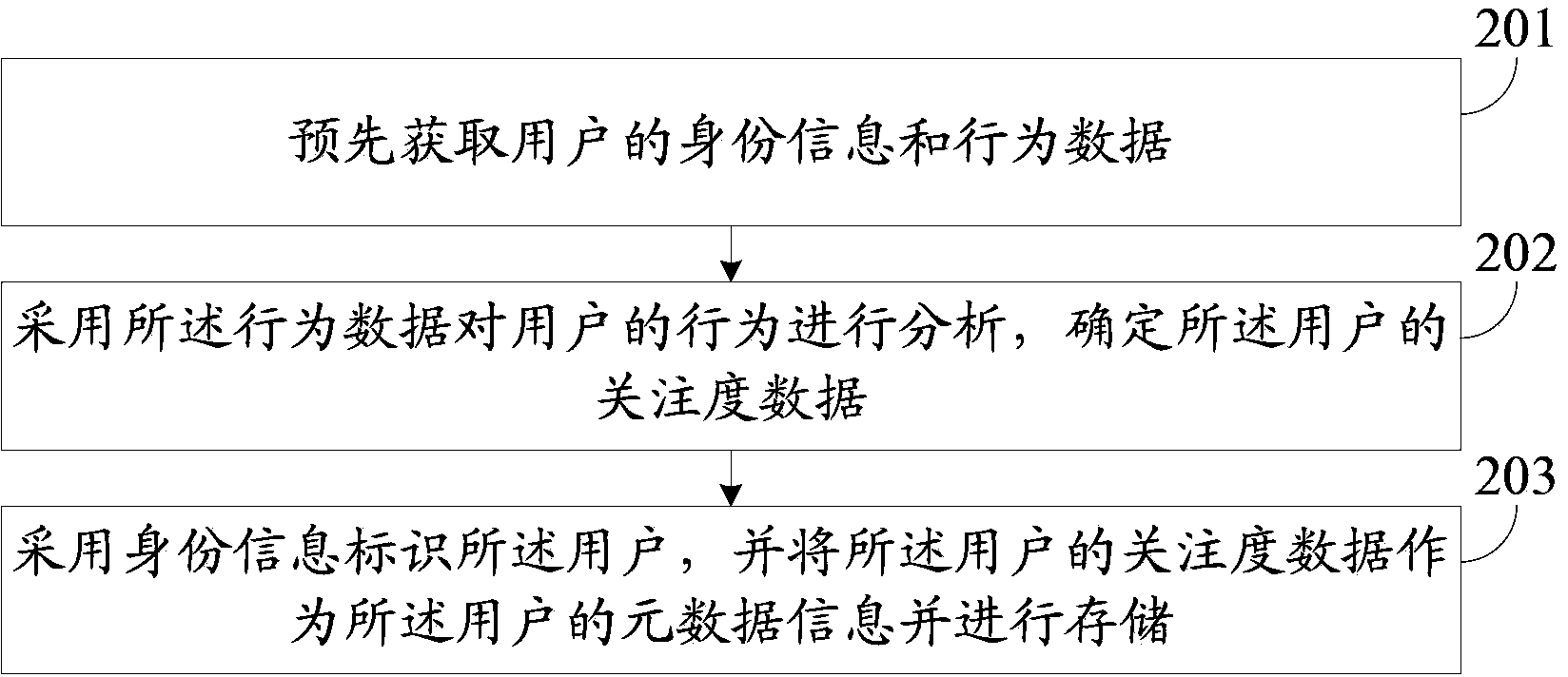

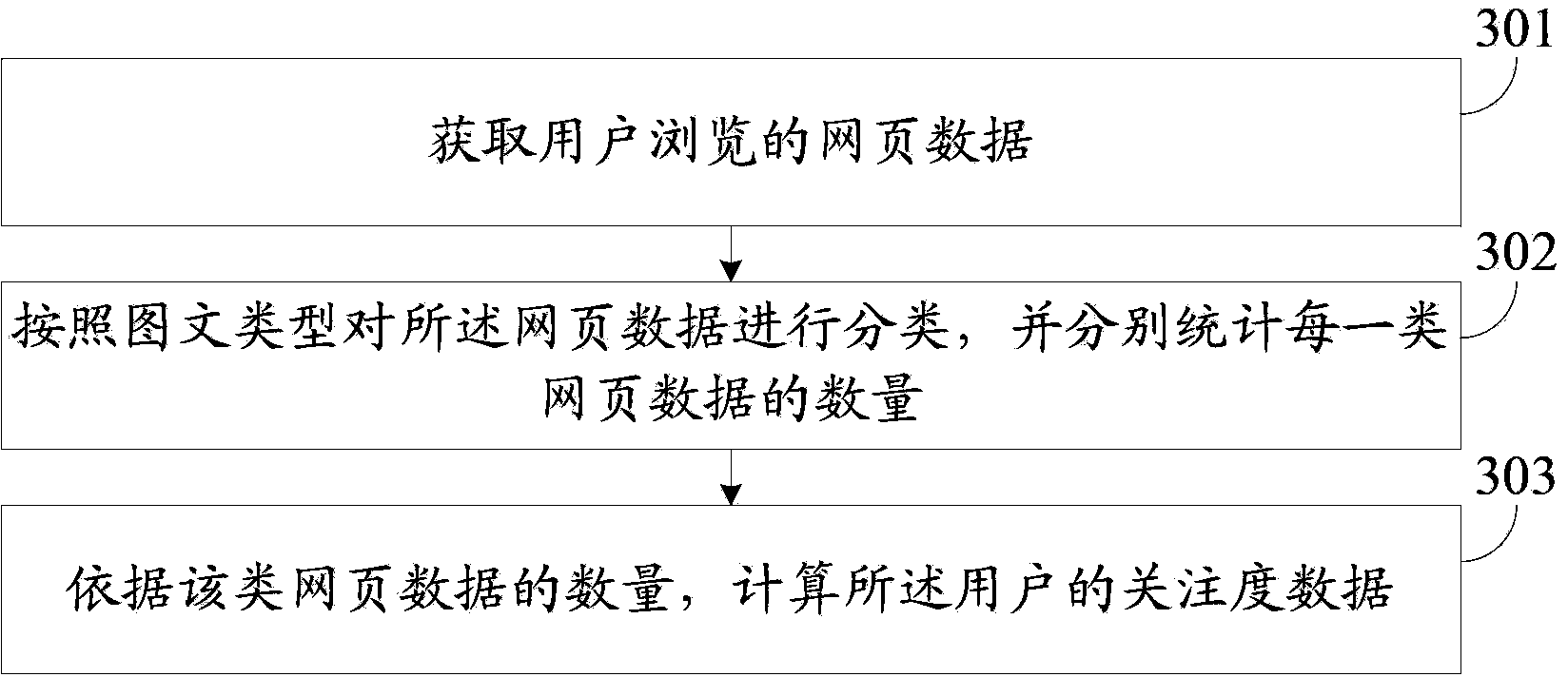

The invention provides a graphics and text information releasing and generating method and a graphics and text information releasing and generating device. The problems that a graphics and text information updating and manufacturing process is quite troublesome, consumed time is long, and the efficiency is low are solved. The graphics and text information releasing and generating method comprises the following steps of receiving a graphics and text information request, which comprises pass parameters, of a page; determining corresponding metadata information according to user information in the pass parameters; acquiring a corresponding template from a template library according to a template type in the pass parameters; acquiring elements with corresponding format information from an element library which is stored with a plurality of elements with different format information according to the metadata information and the template; and releasing the template and the element to the page. A plurality of templates in different types are stored in the template library; and the types of the templates correspond to the format information of the elements in the element library.

Owner:ALIBABA GRP HLDG LTD

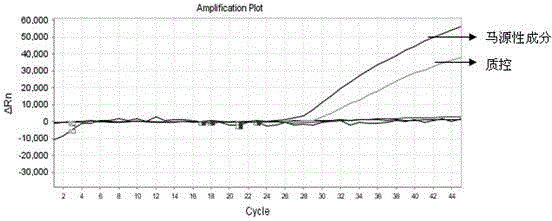

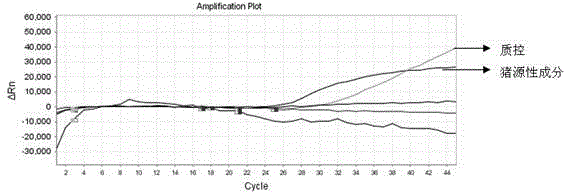

Primer and probe composition for distinguishing various animal sources in colla corii asini, kit and multiple real-time fluorescence quantification PCR detection method

ActiveCN104531884AStrong specificityHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyColla corii asini

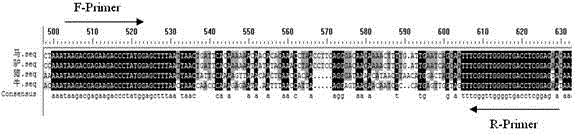

The invention discloses a primer and probe composition for distinguishing various animal sources in colla corii asini. The composition is good in specificity and high in sensitivity. The invention further discloses a kit comprising a probe and a primer. The kit can distinguish donkey, horse, cow and pig source ingredients in the colla corii asini at the same time, and is high in accuracy, high in throughput and convenient to use. The invention further discloses a multiple real-time fluorescence quantification PCR detection method for distinguishing various animal sources in the colla corii asini. The method can qualitatively detect donkey, horse, cow and pig source ingredients in the colla corii asini at the same time, and is applicable to animal hide and skin detection, applicable to animal source detection on deep-processed colla corii asini as well, and is convenient and fast to implement.

Owner:BIOTECH RES CENT SHANDONG ACADEMY OF AGRI SCI

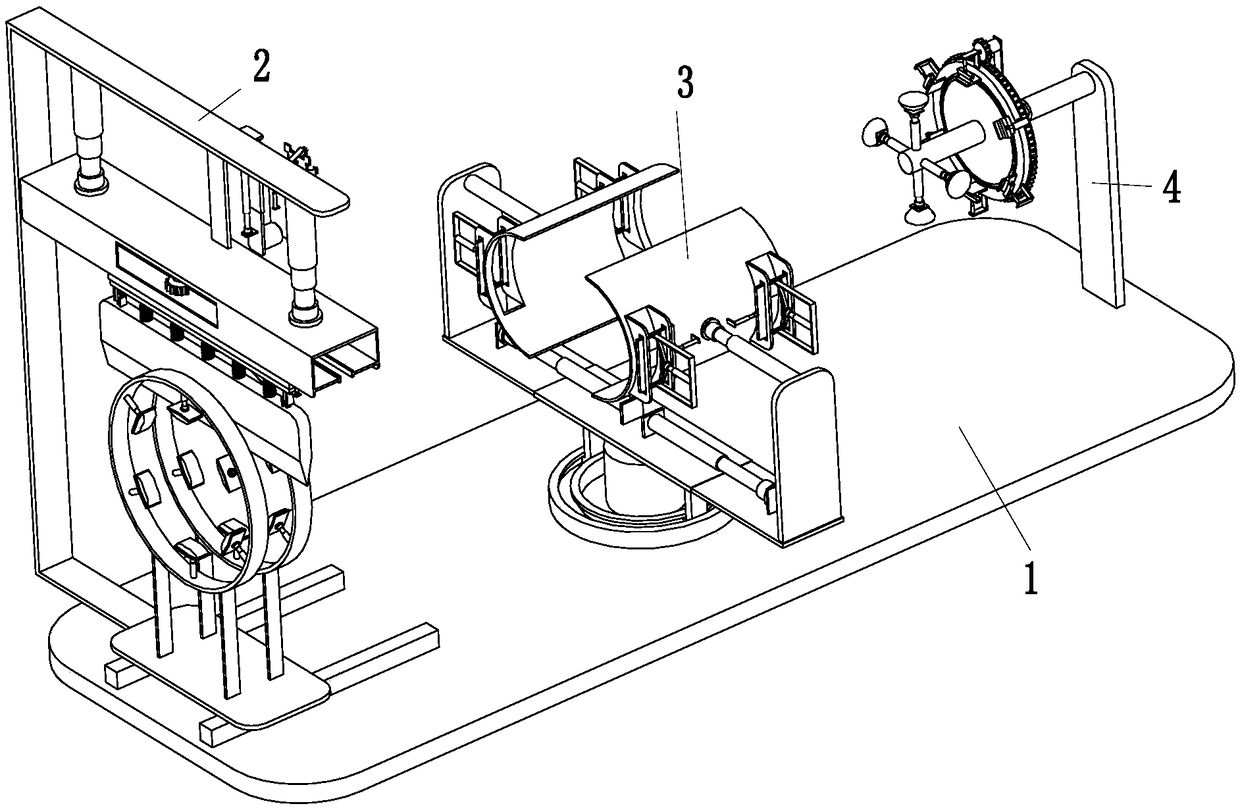

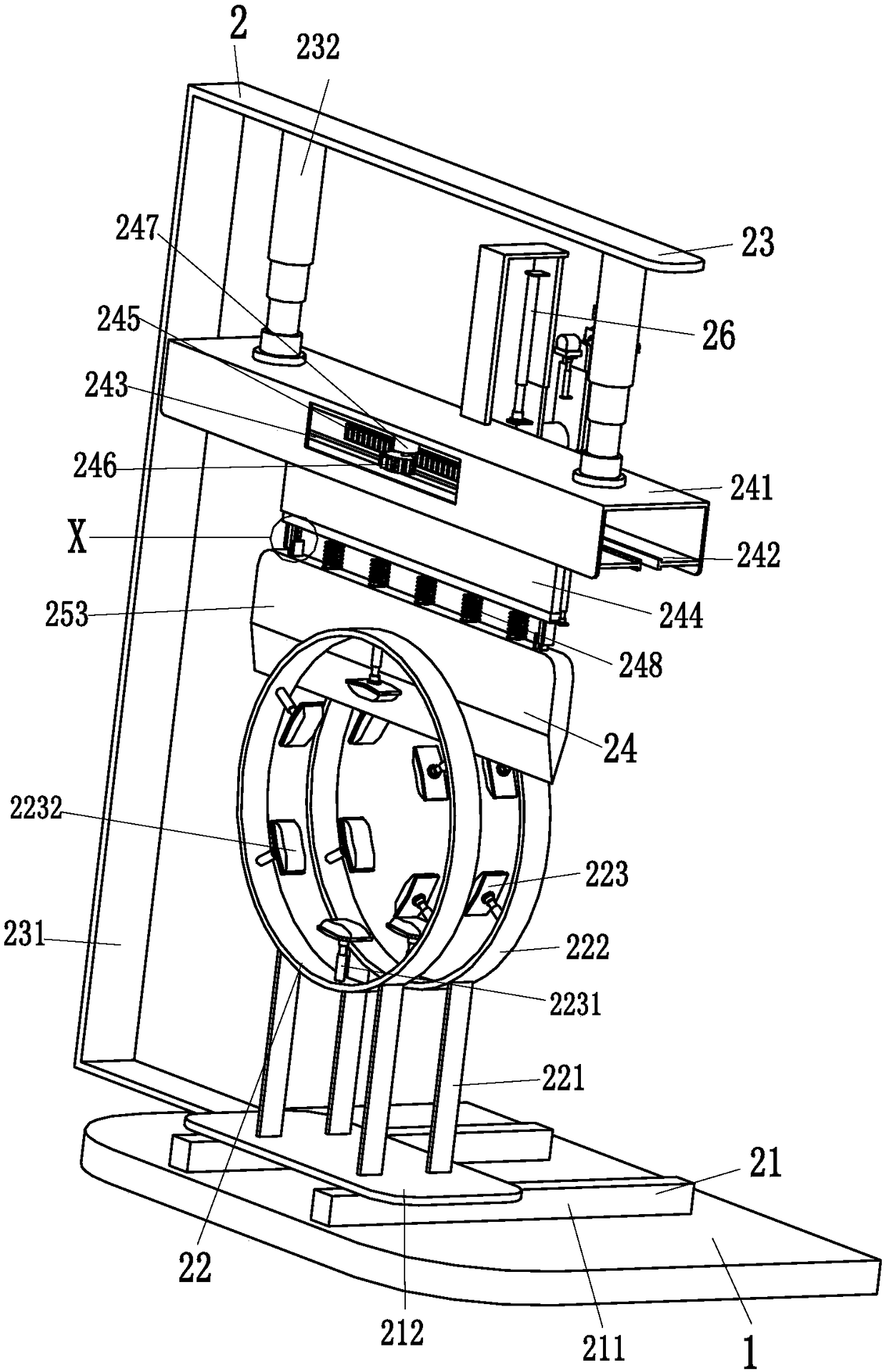

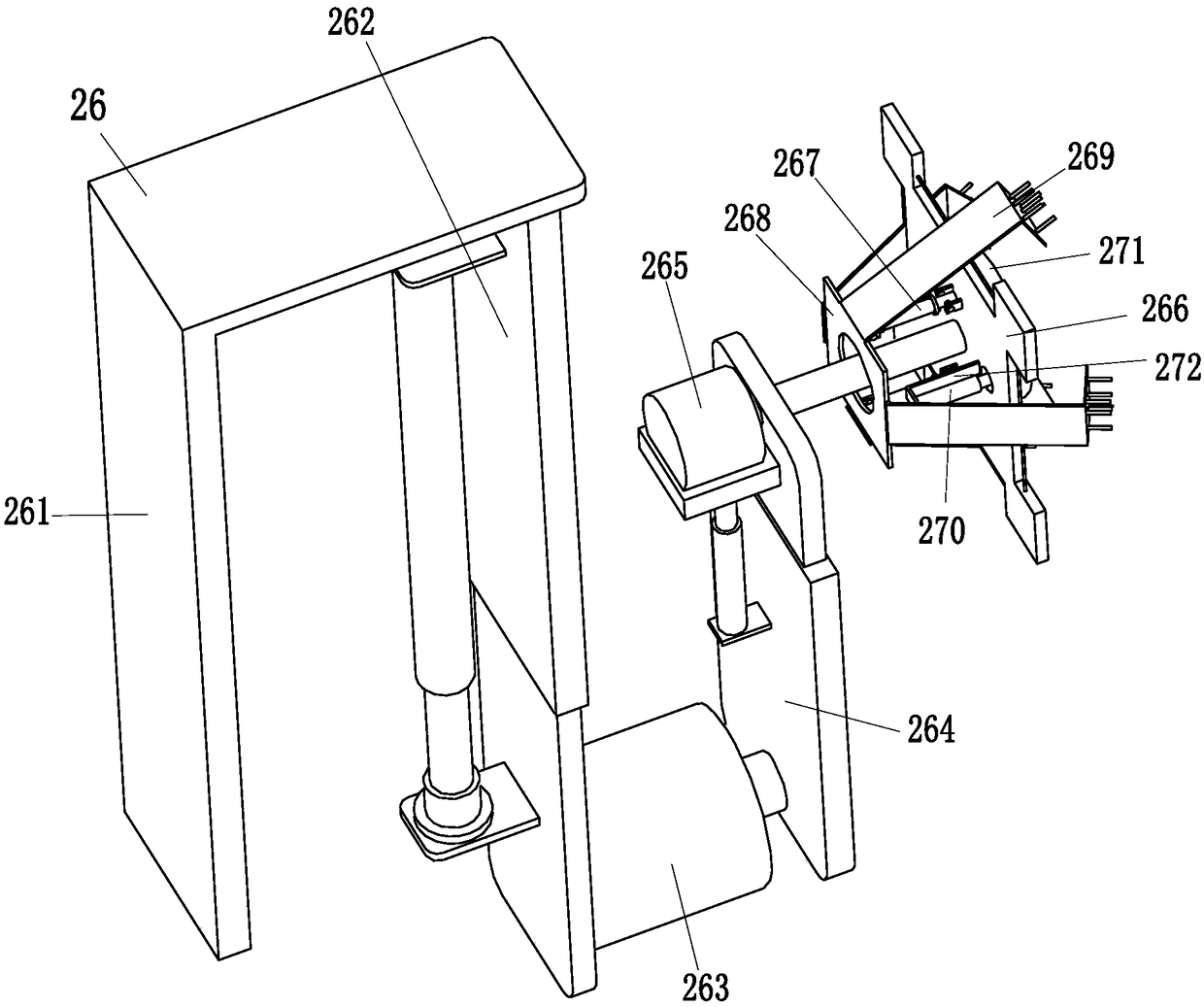

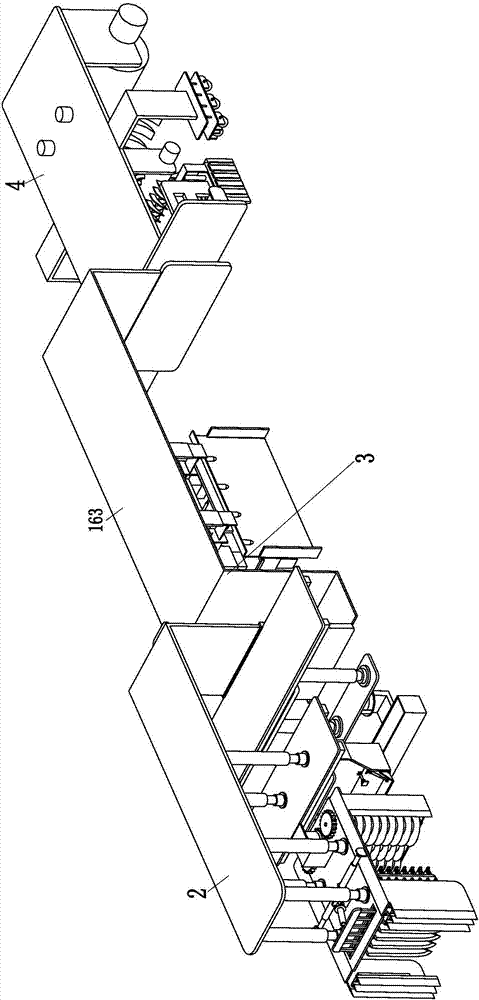

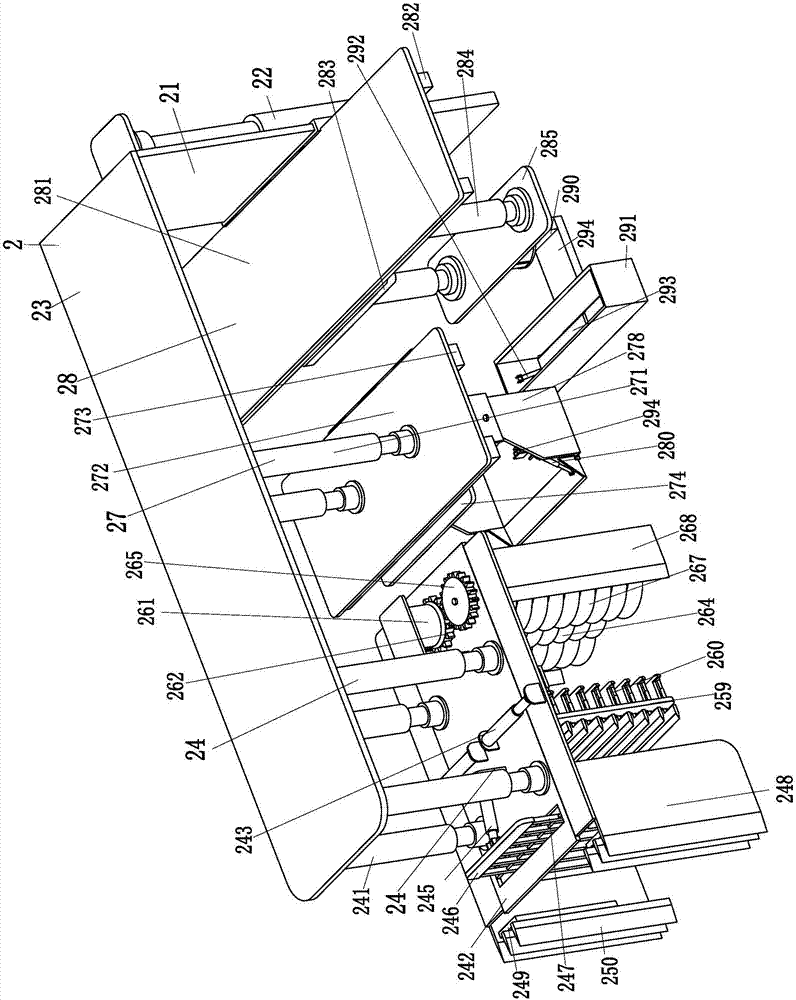

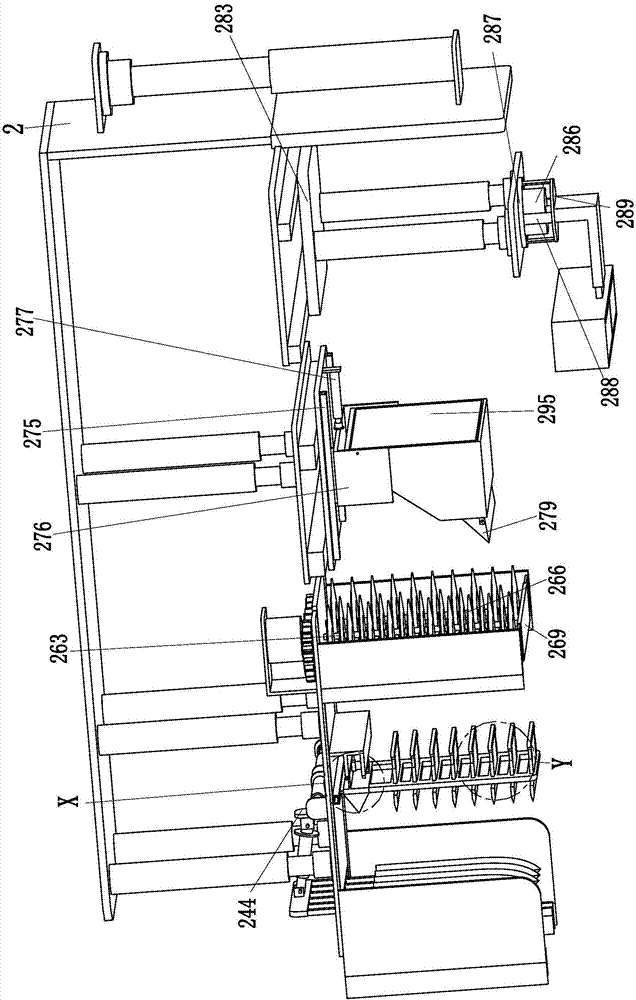

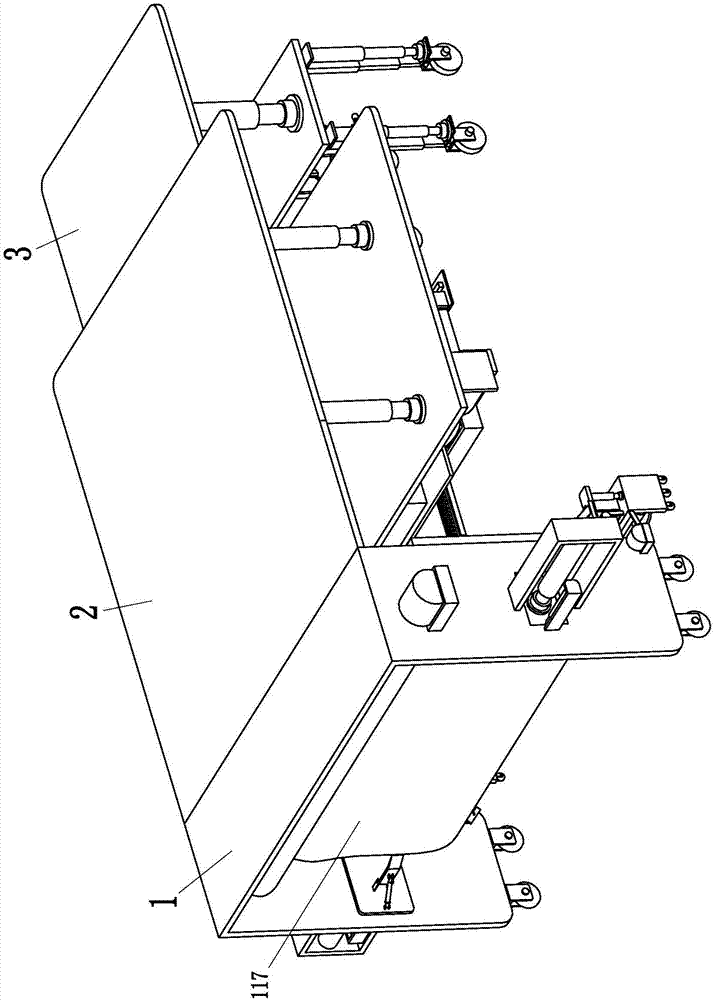

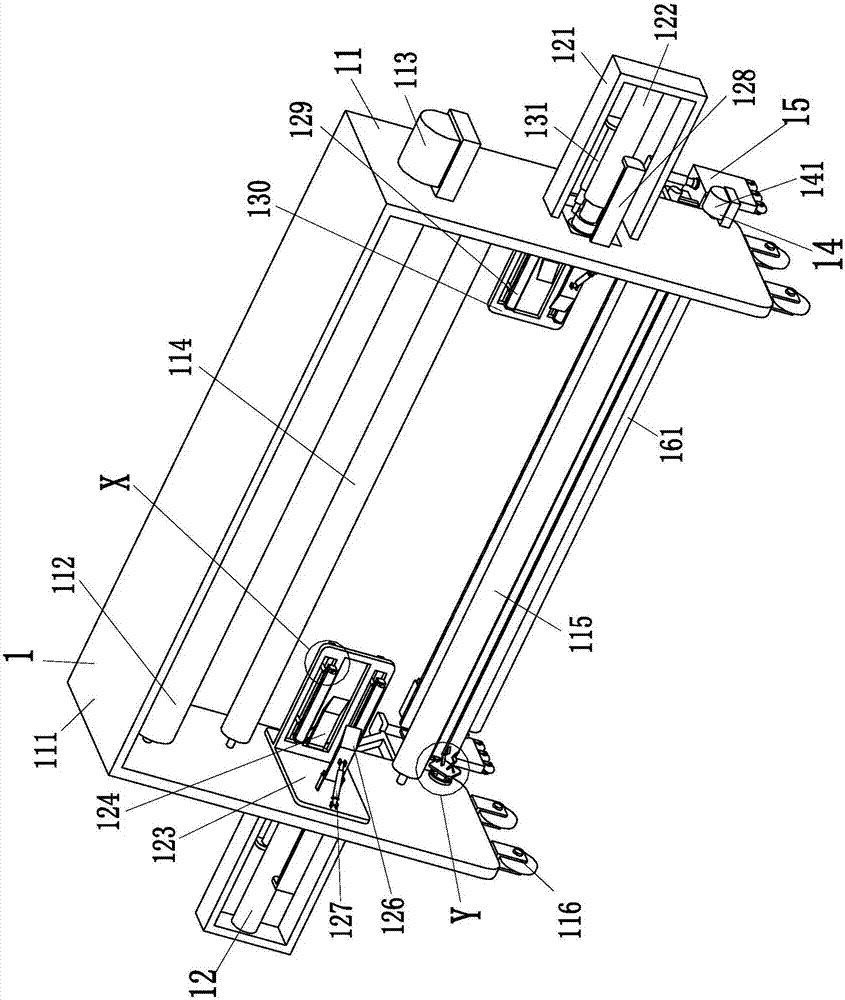

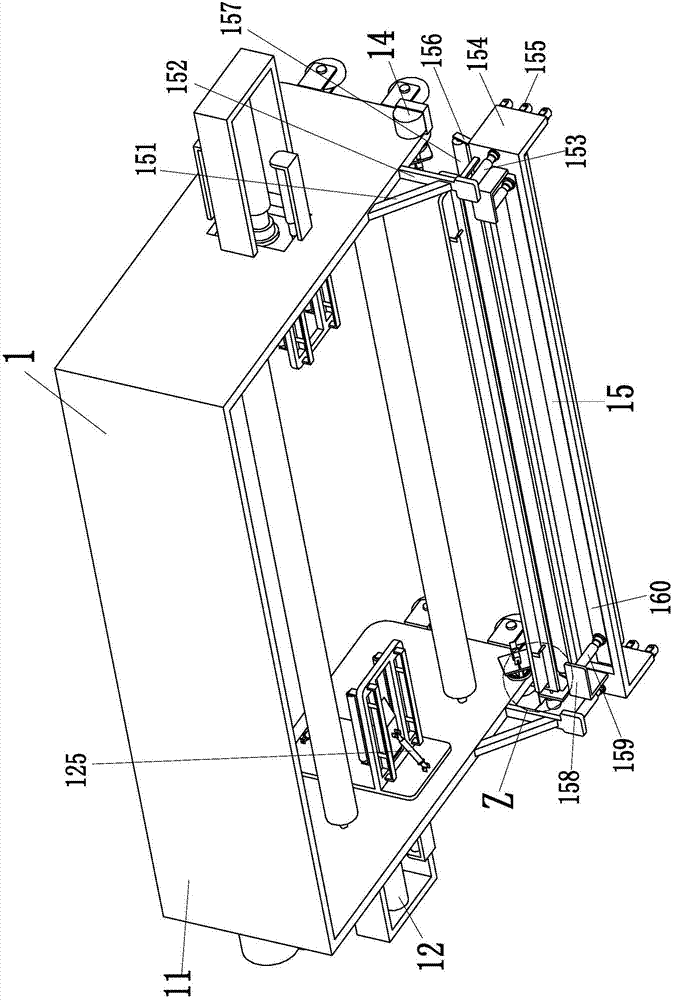

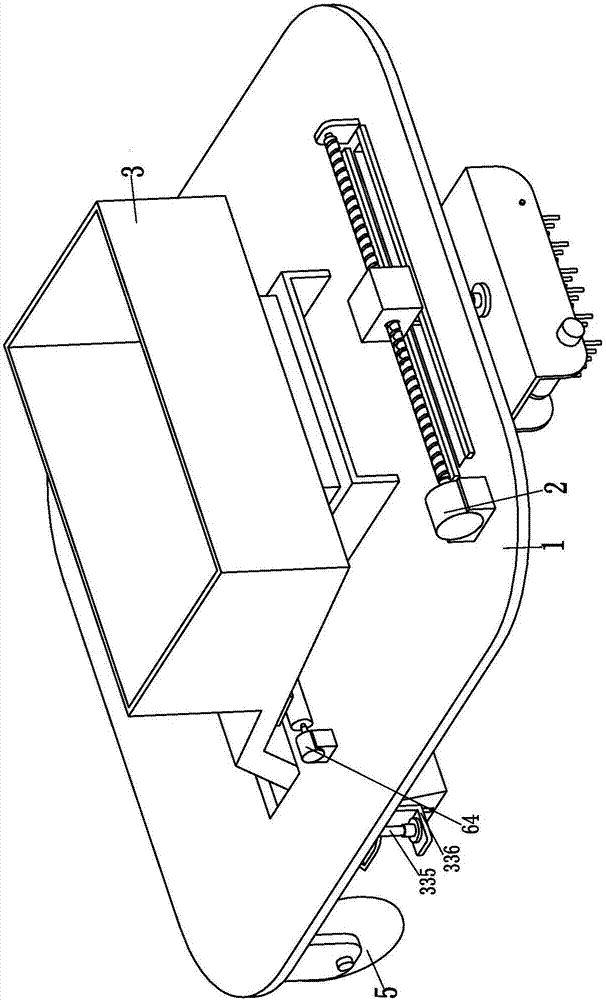

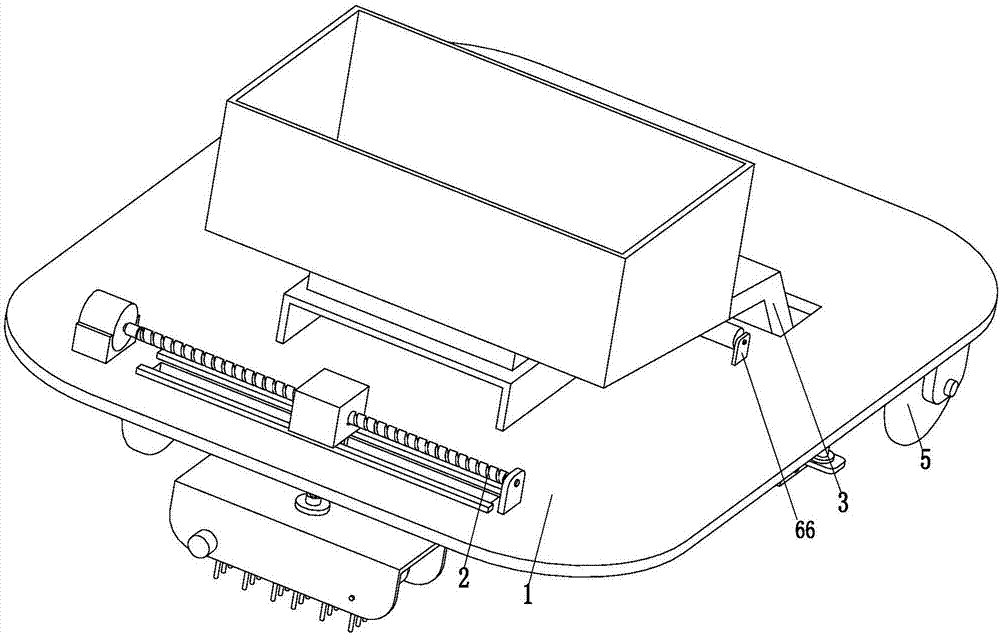

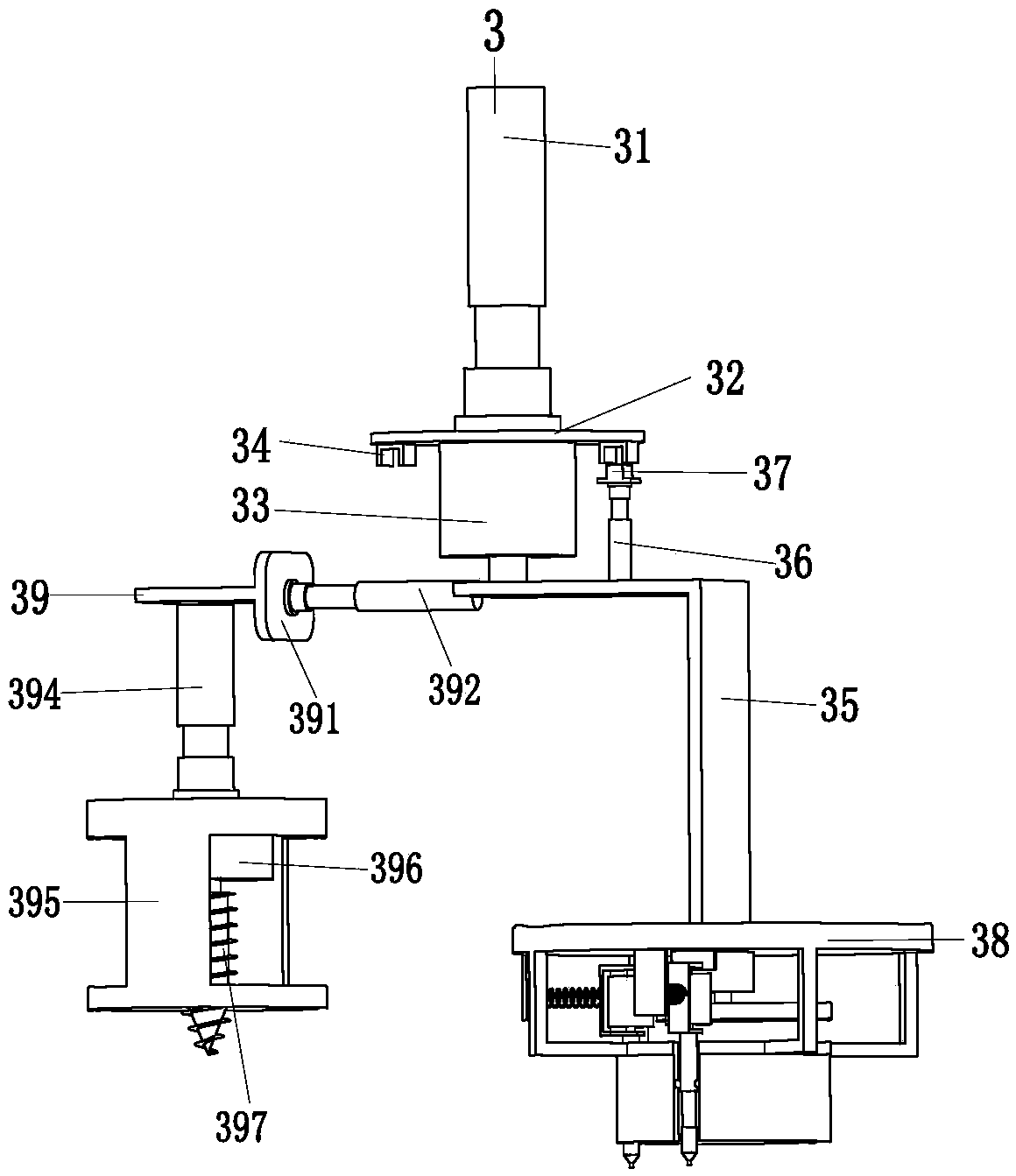

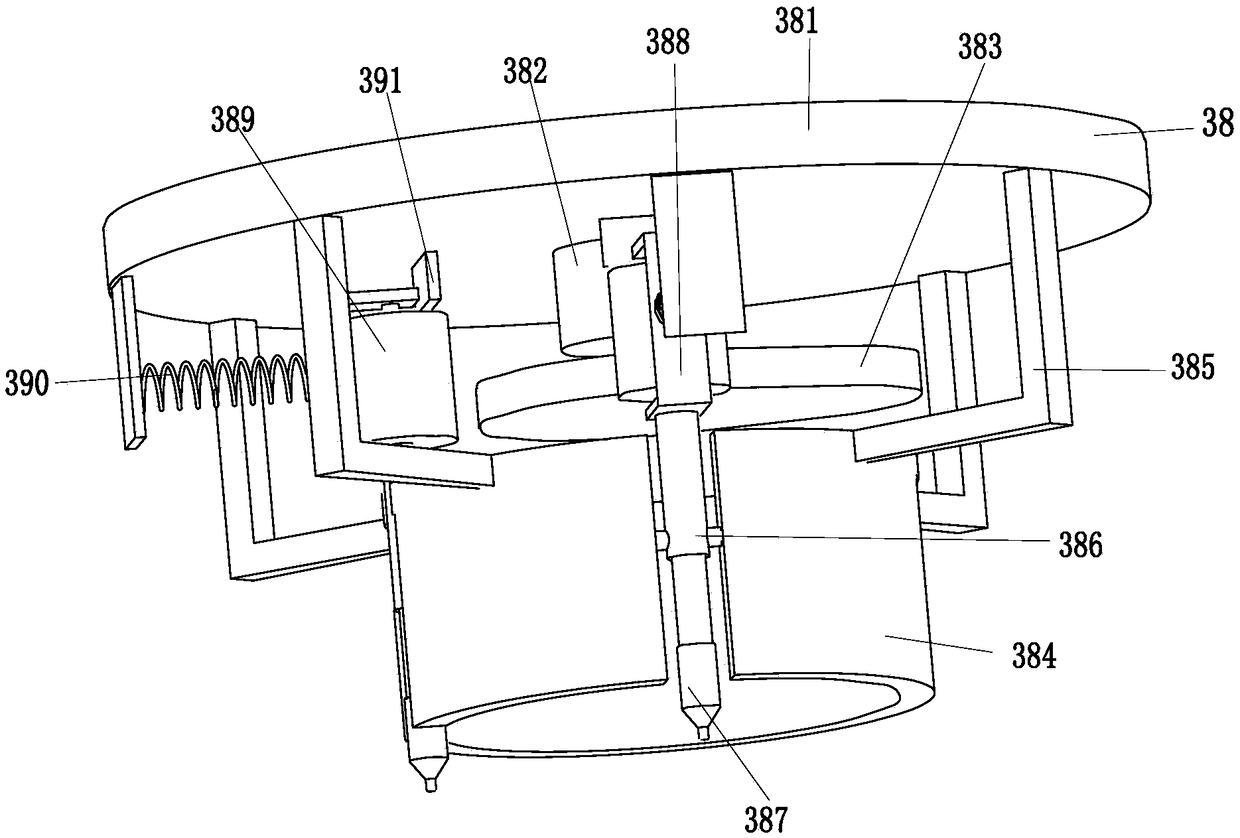

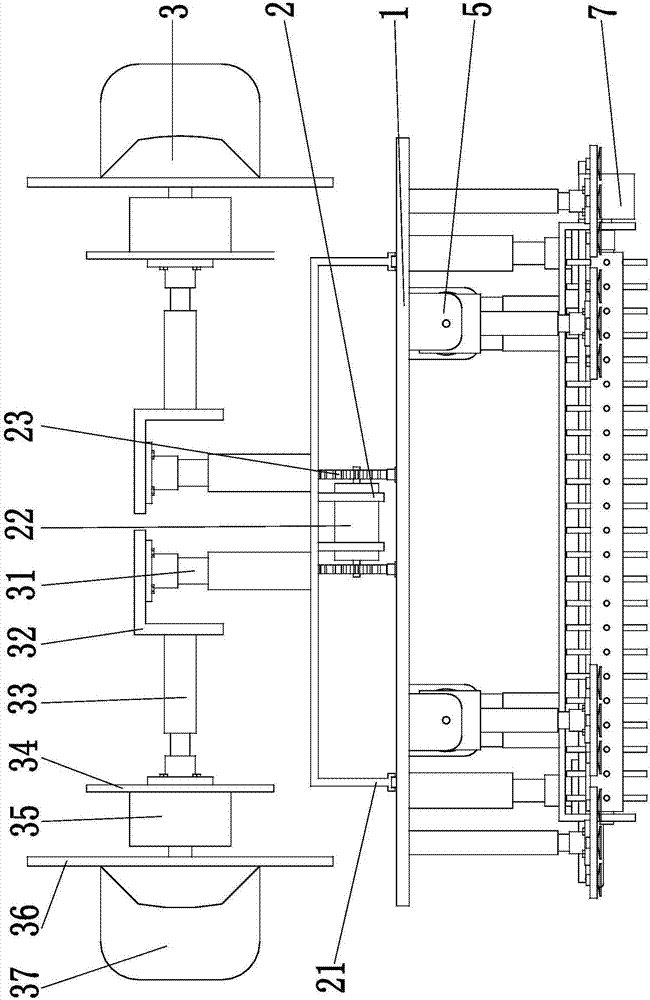

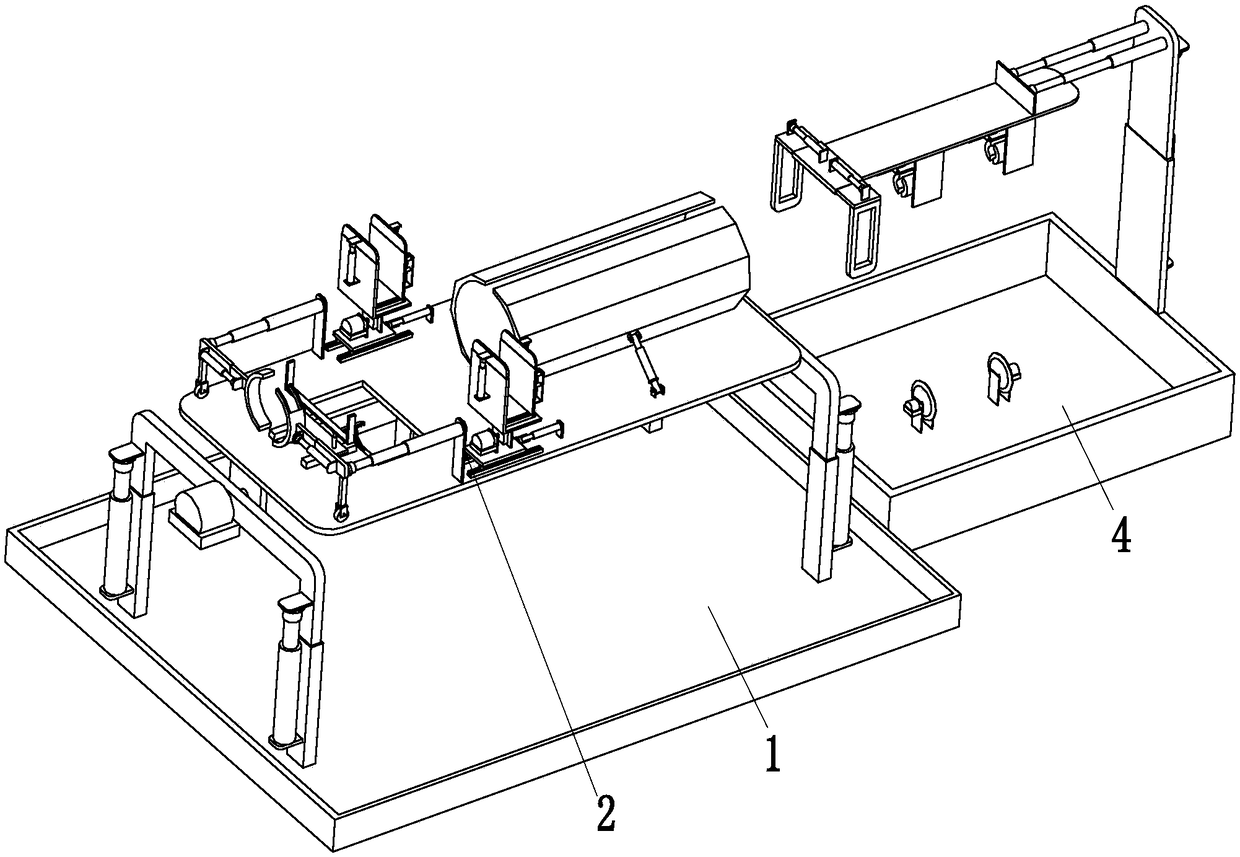

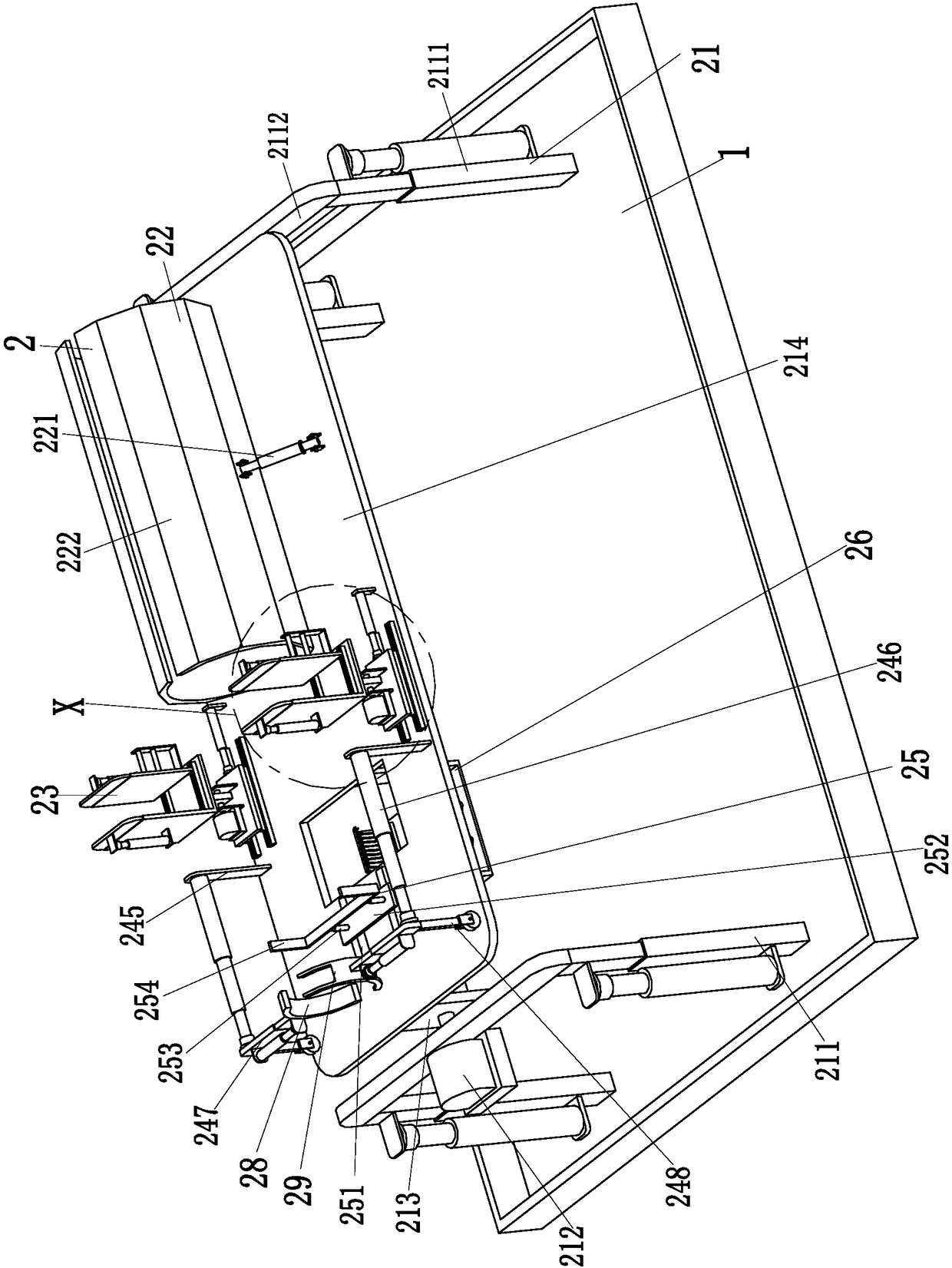

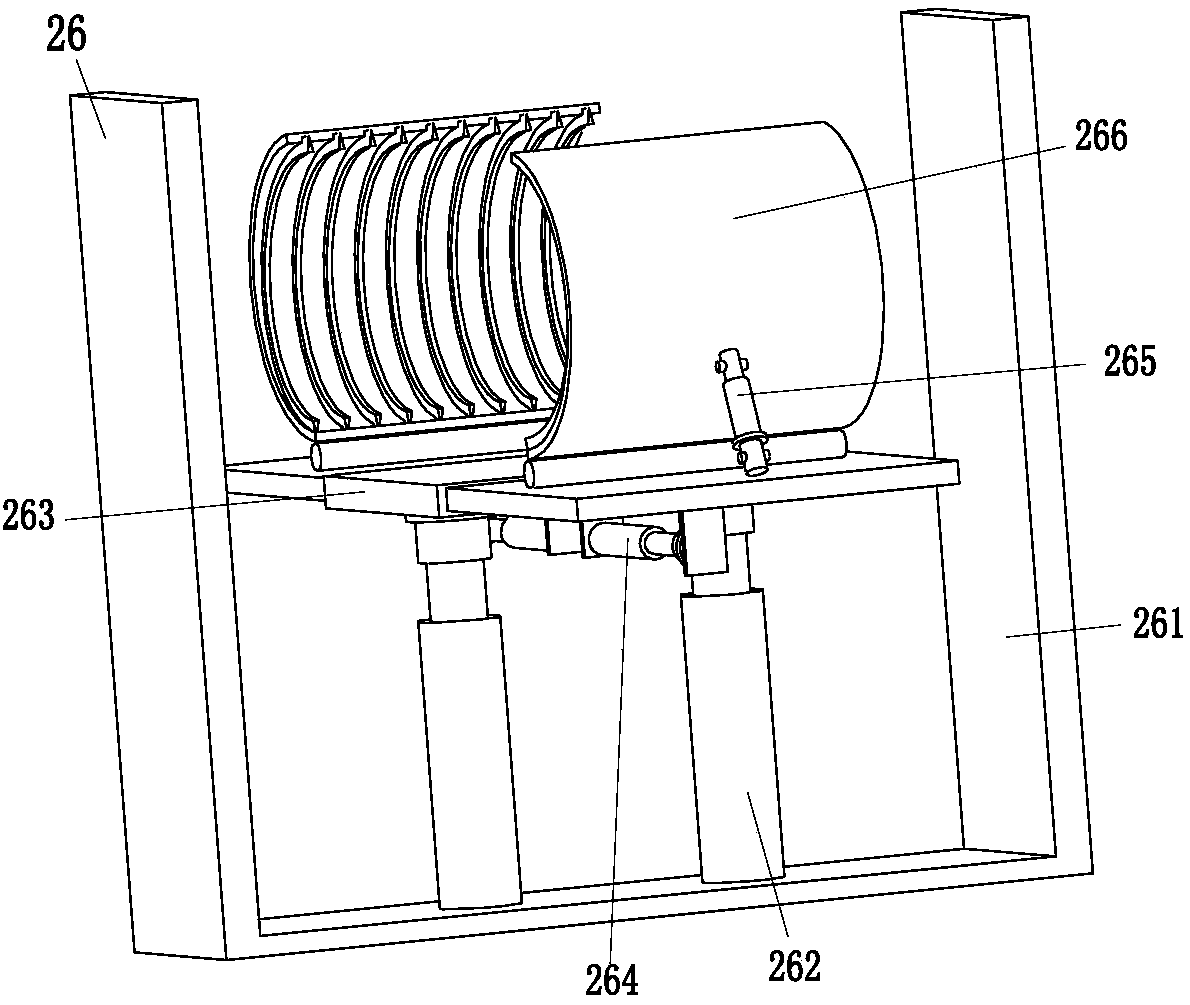

Machining equipment for communication cable

ActiveCN108515564AEasy to operateShort costEdge grinding machinesMetal working apparatusMachining processMotherboard

The invention relates to machining equipment for a communication cable. The machining equipment comprises a main plate, a cutting and deburring device, a middle limiting device and an end limiting device, the cutting and deburring device is installed at the front end of the main plate, the middle limiting device is installed in the middle of the main plate, and the end limiting device is installedat the back end of the main plate. According to the machining equipment for the communication cable, the problems that in the existing communication cable sleeve machining process, communication cable sleeves need to be manually limited and then cut, the process is tedious and complex, when the communication cable sleeves are limited, workers need to grab the communication cable sleeves with different structures in different modes, manual grabbing is single and unstable, when cutting is conducted, sleeve openings are likely to be uneven due to the fact that the positions are prone to deviating when manual cutting is conducted, burrs can be generated after cutting, the time consumed by the process is long, the labor intensity is high, and the efficiency is low can be solved, and the automatic limiting and cutting functions on the communication cable sleeves can be achieved.

Owner:以太龙精密机械江苏有限公司

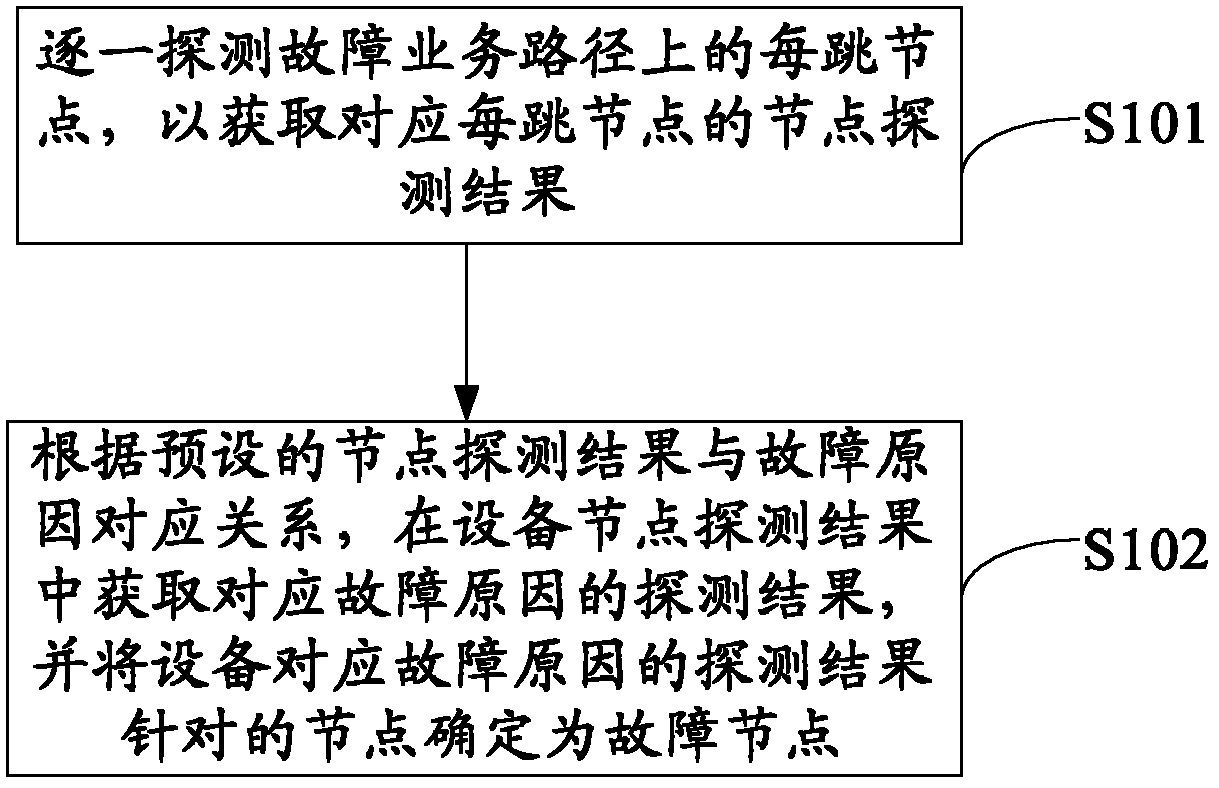

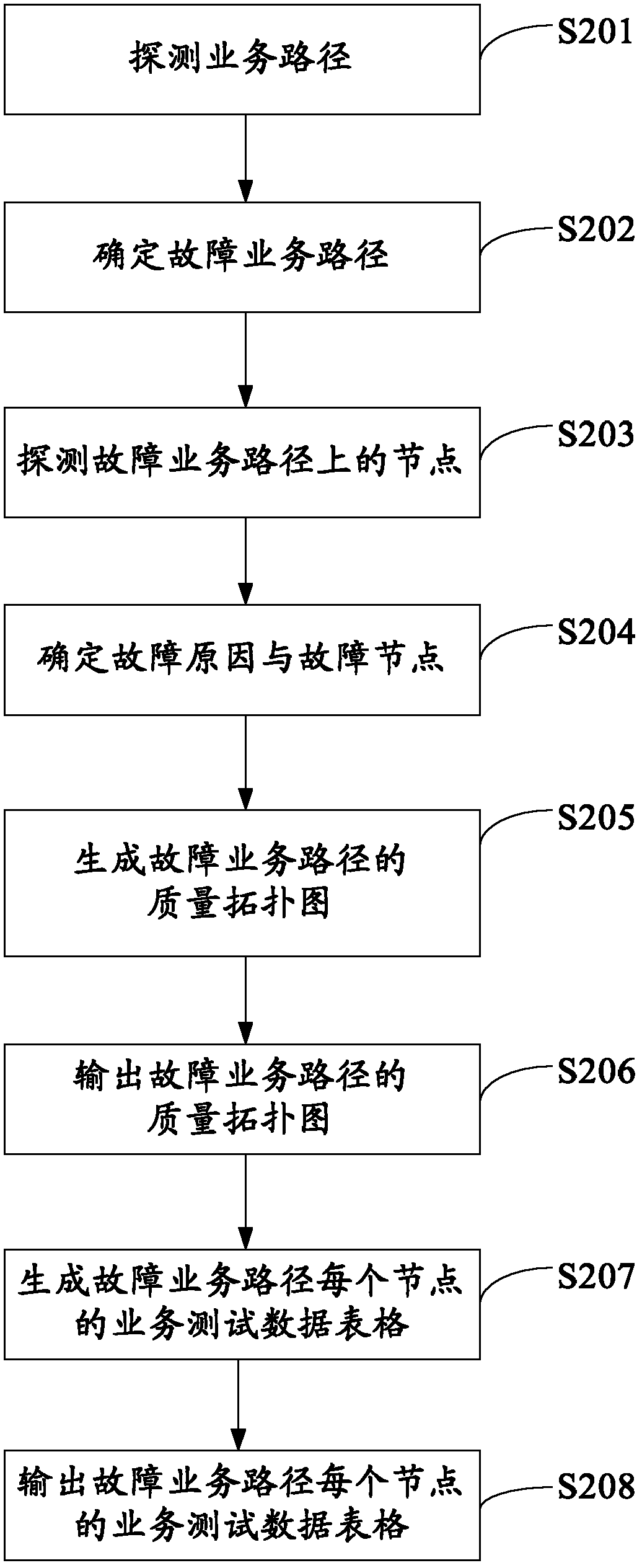

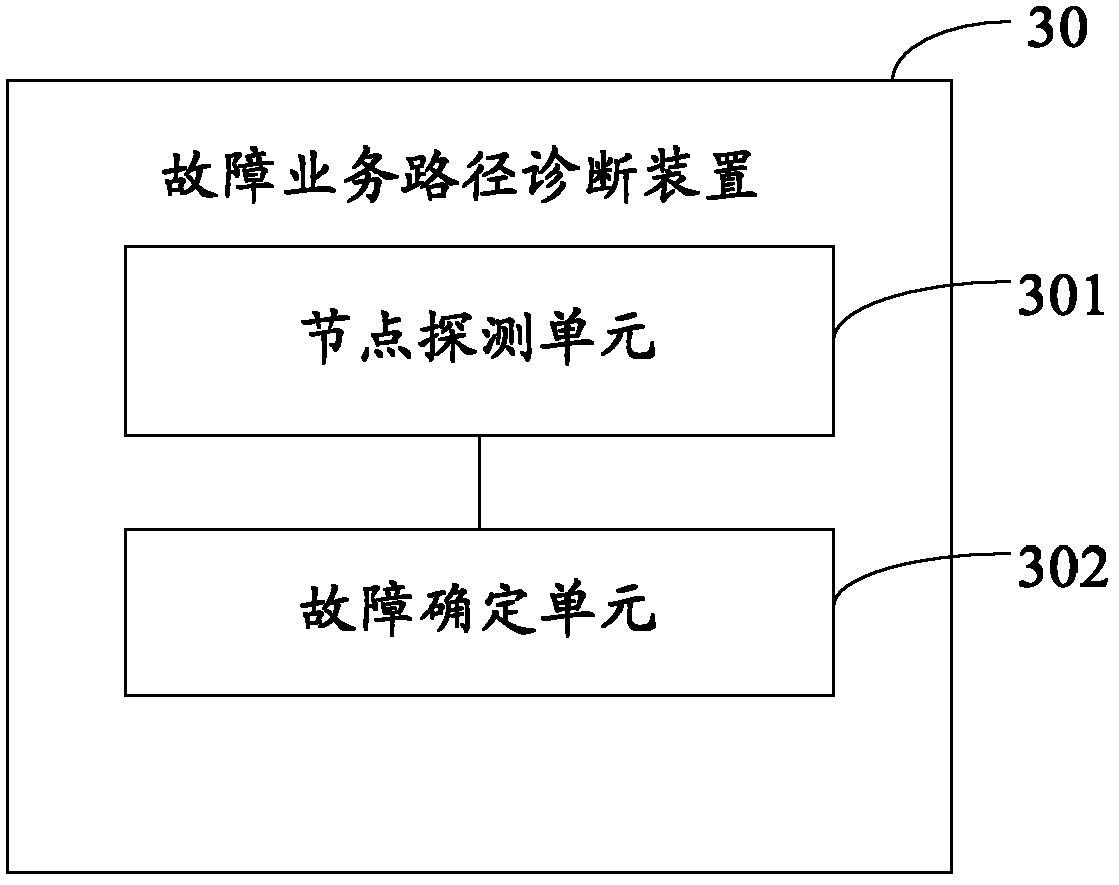

Failure service path diagnosis method and device

ActiveCN102611568AQuick fixShort time consumingData switching networksDiagnosis methodsPerformed Diagnosis

Owner:启东市远福蔬果专业合作社

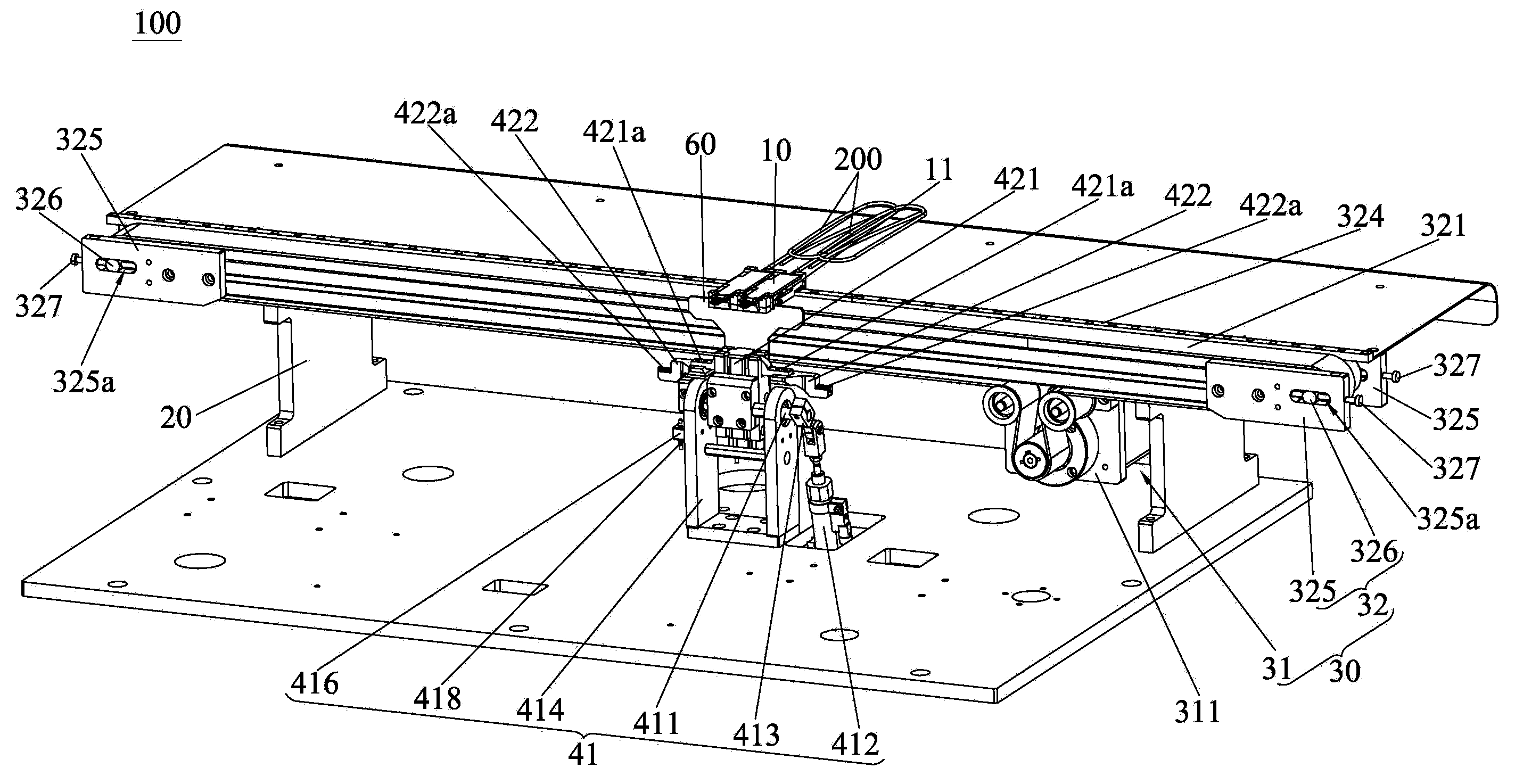

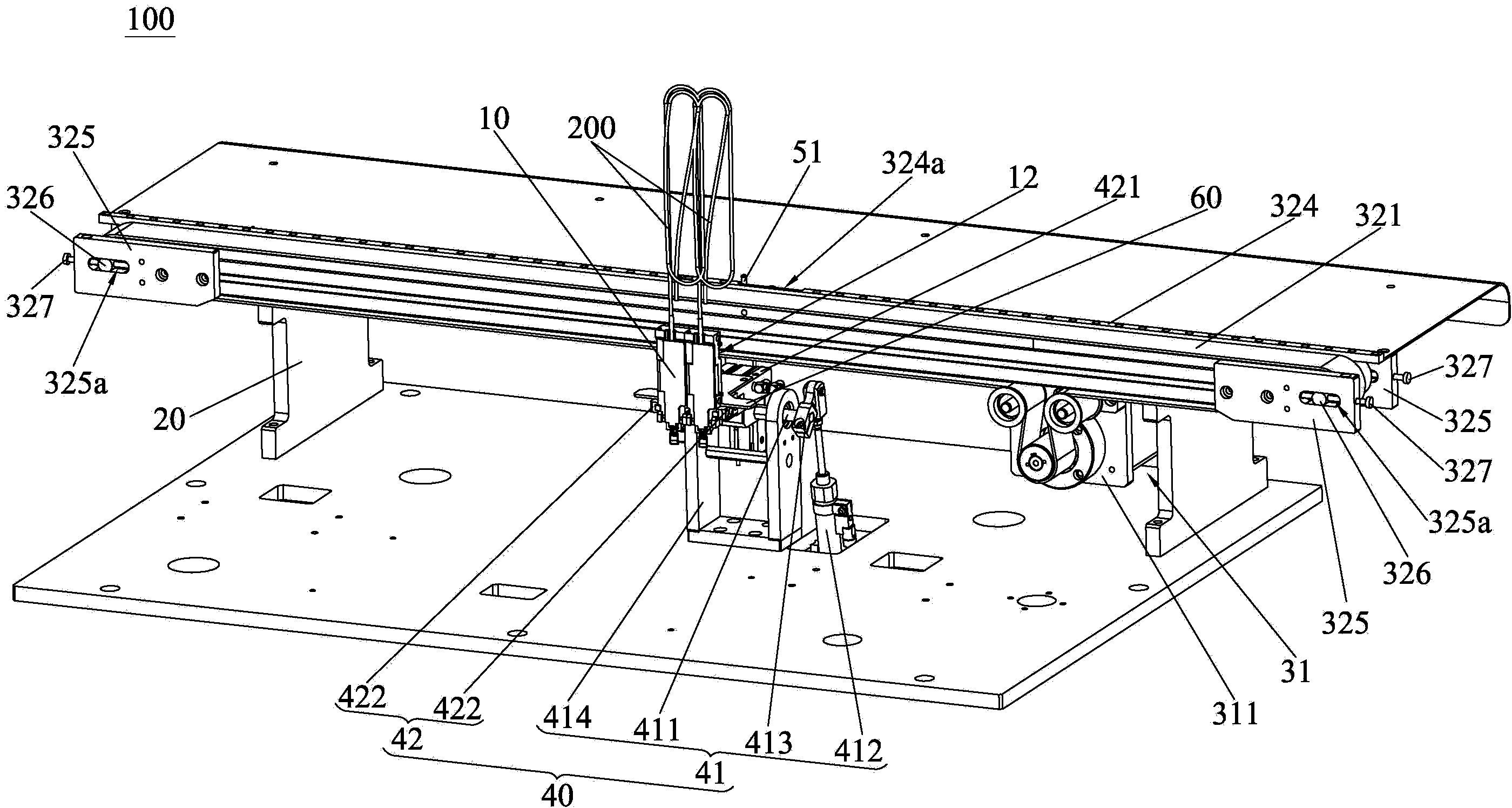

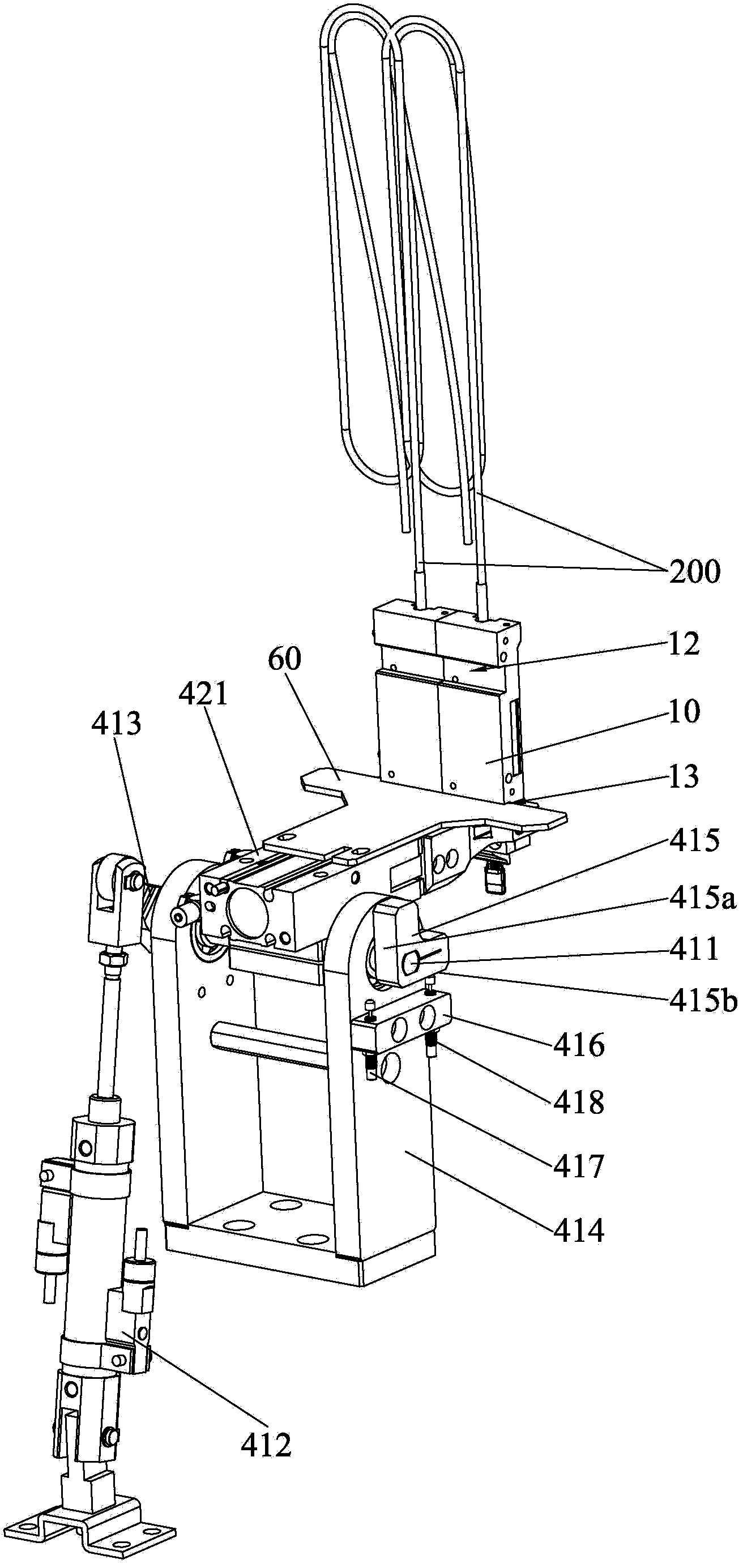

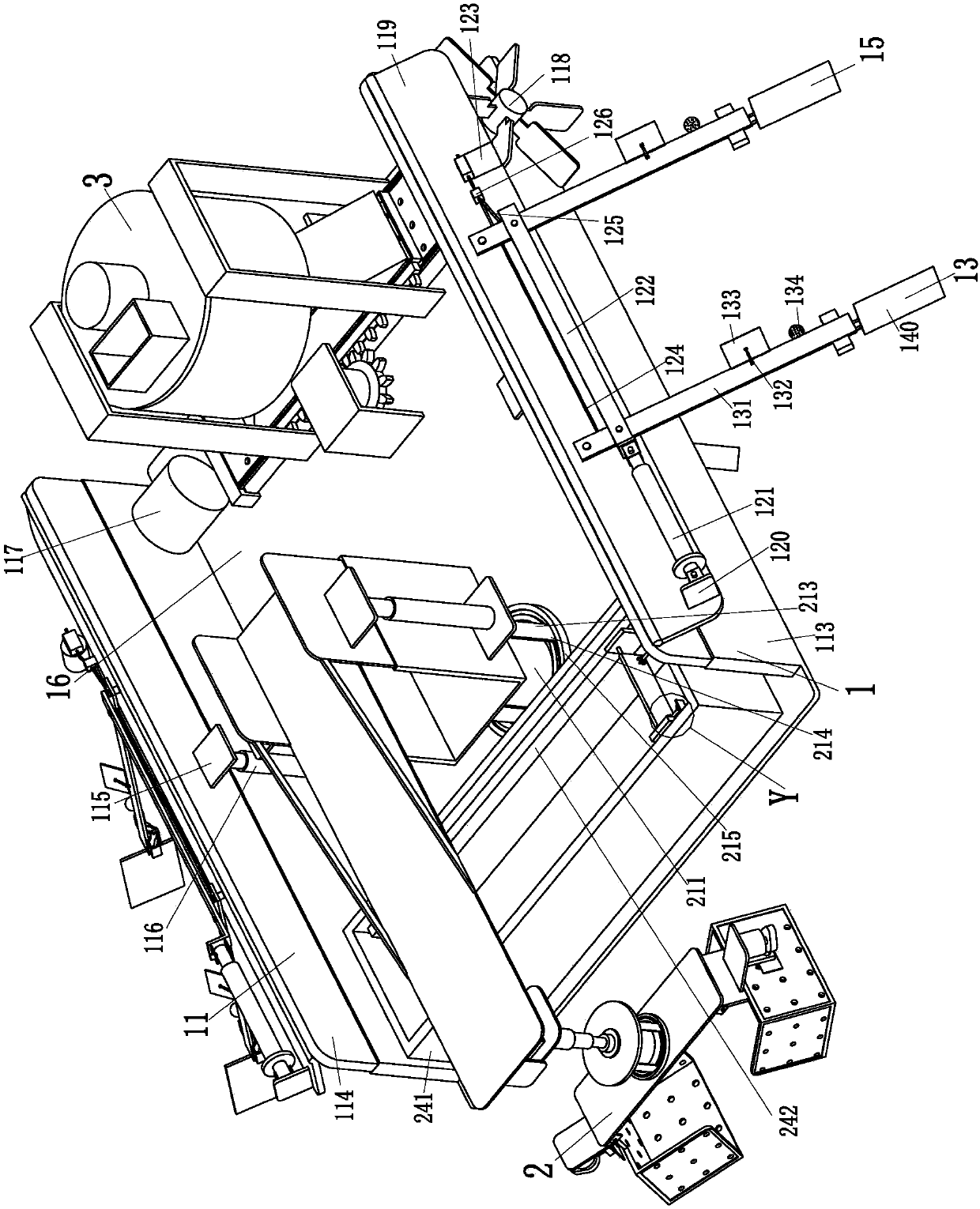

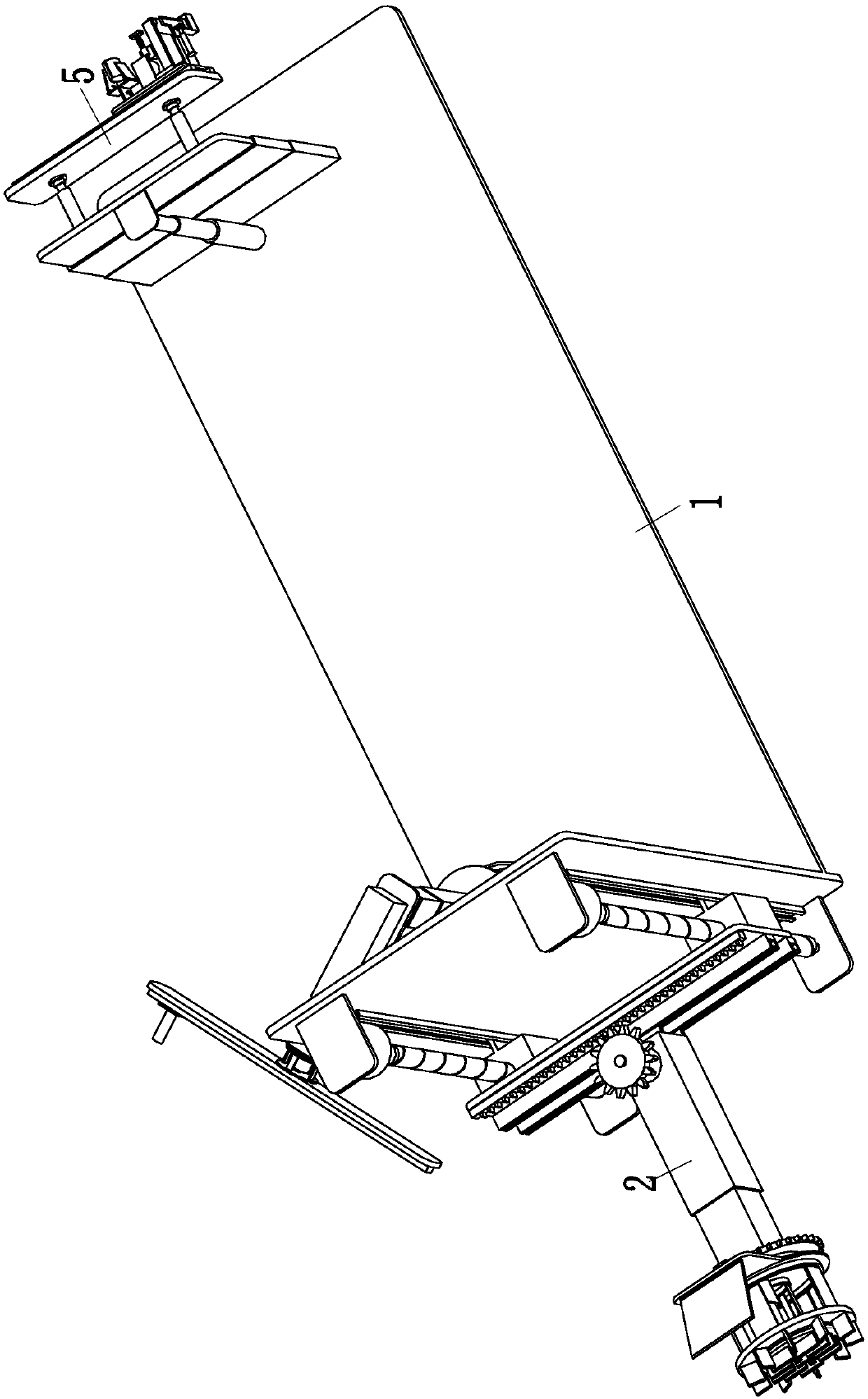

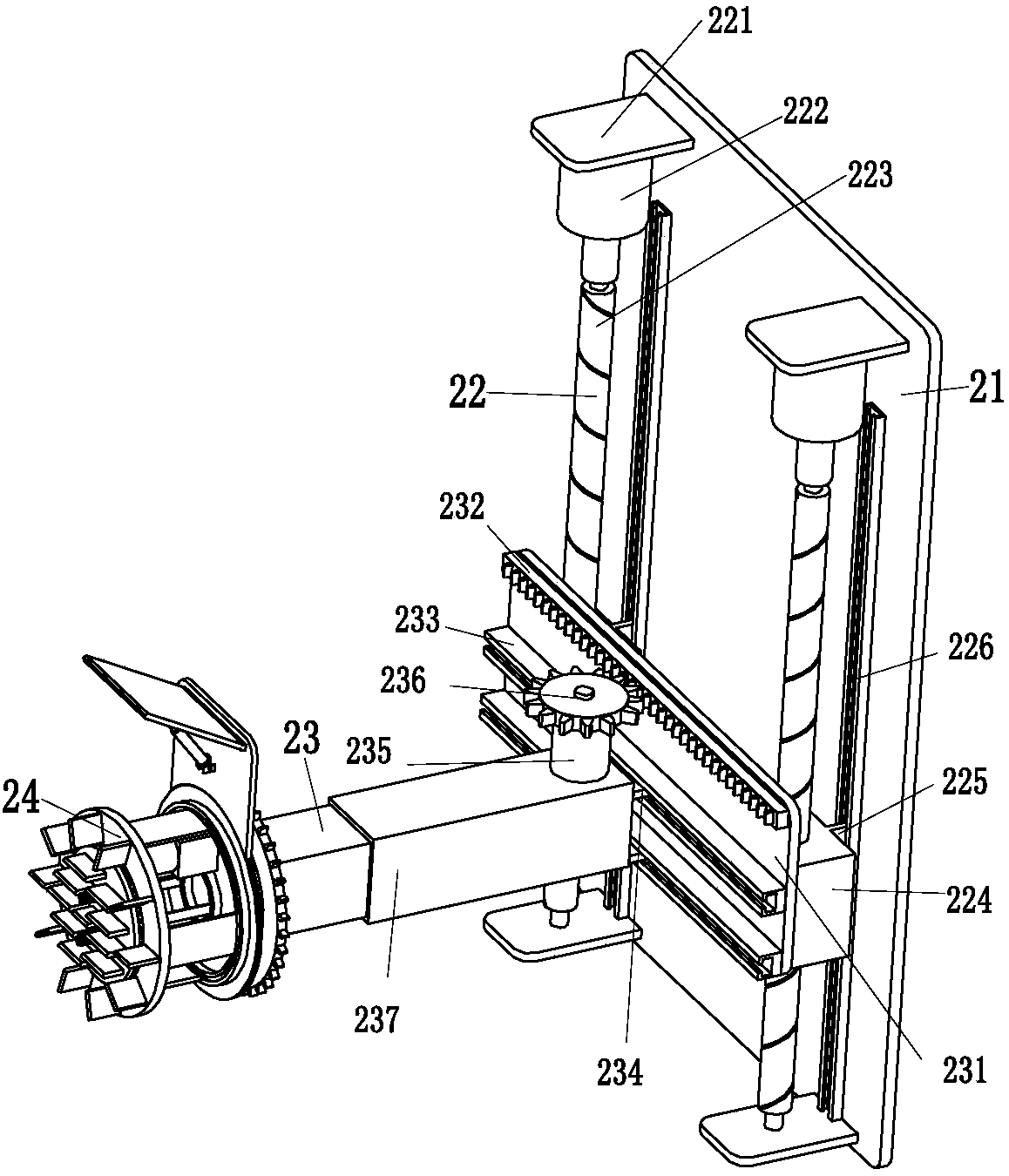

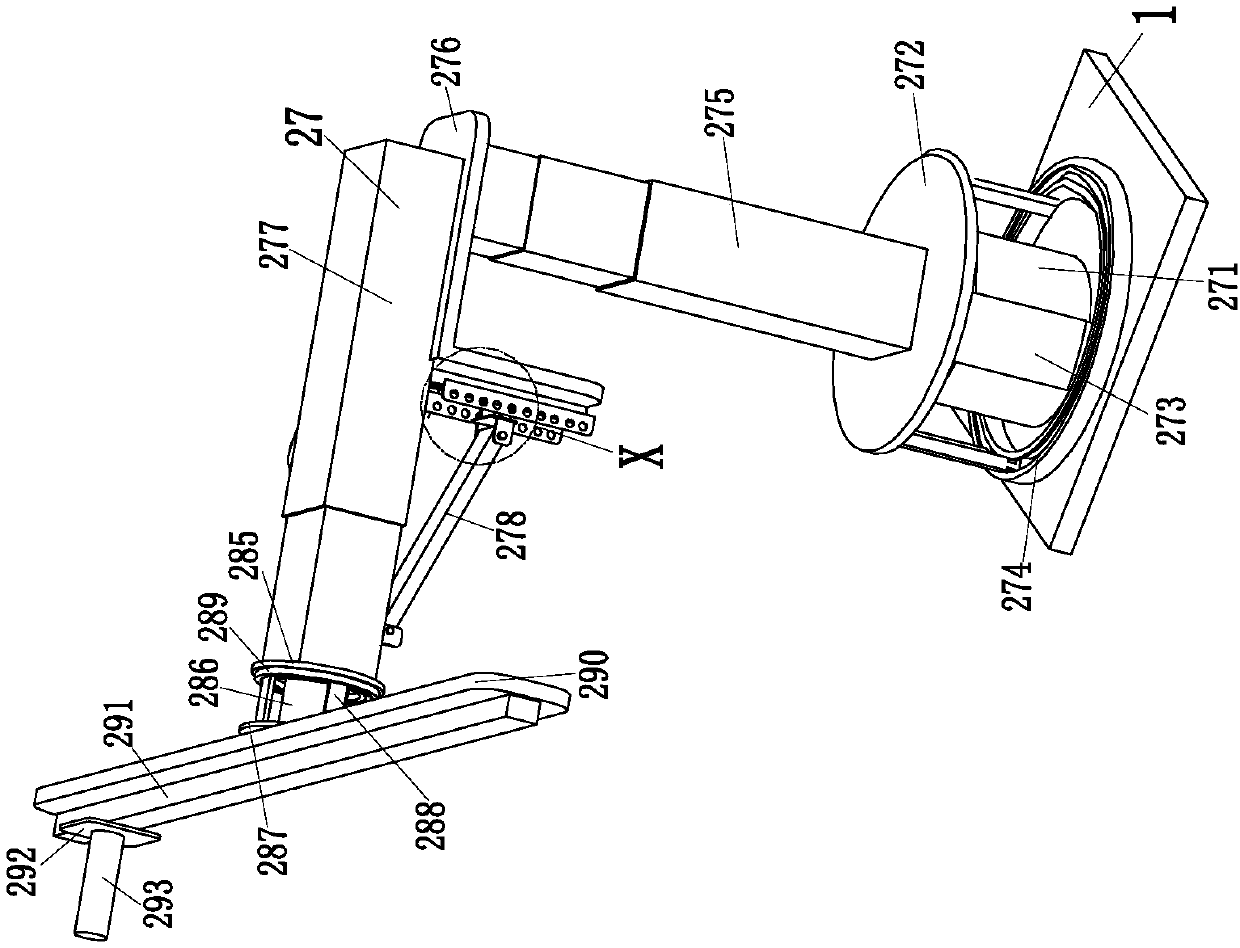

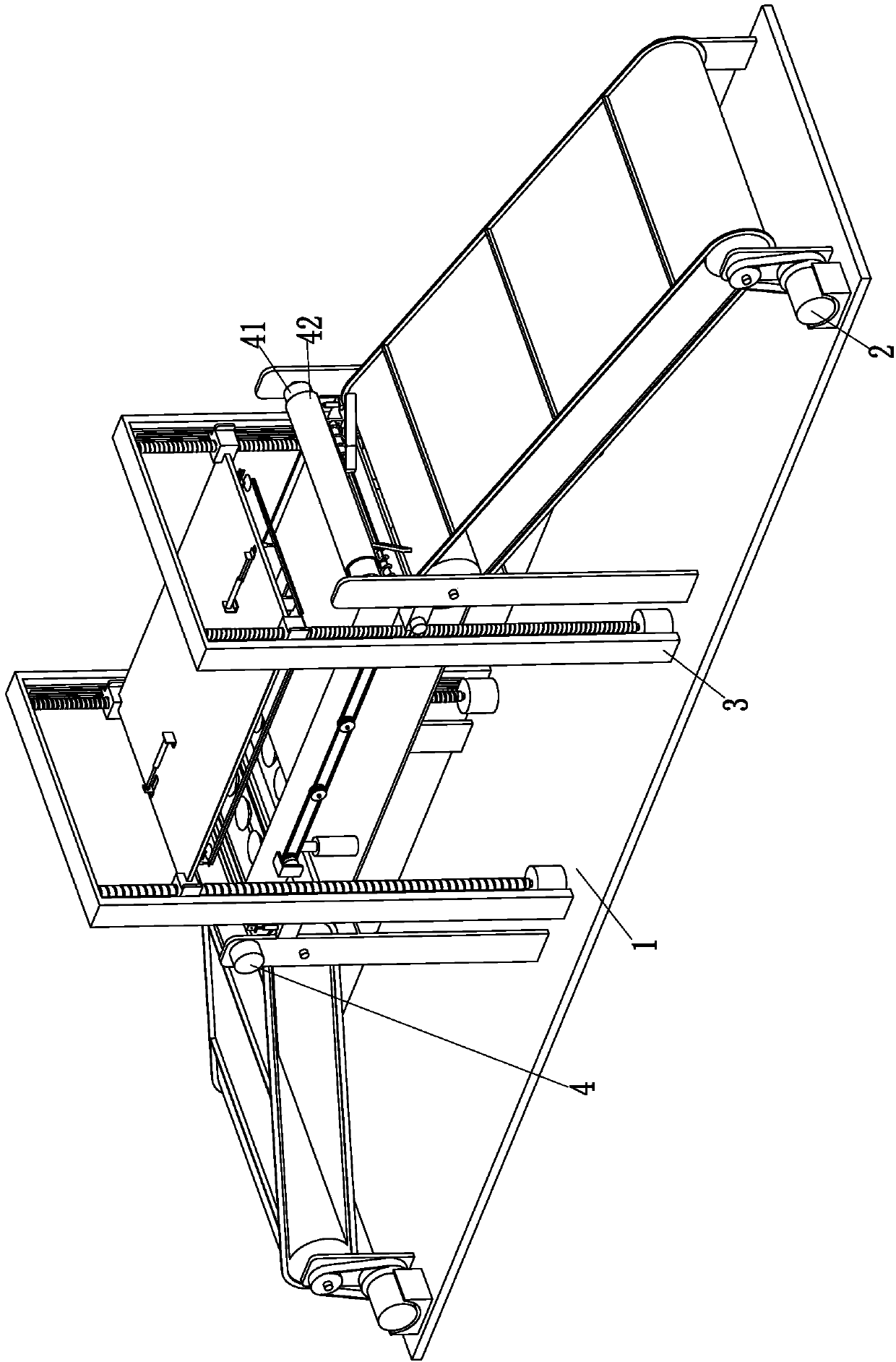

Feeding device

ActiveCN104139979AFlip blockPass smoothlyConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses a feeding device. The feeding device comprises a jig, a rack, a first conveying mechanism and second conveying mechanisms, wherein the first conveying mechanism comprises a conveying driving assembly and a bearing guide assembly which are arranged on the rack, the bearing guide assembly comprises a bearing conveying piece and a guide rail which are arranged on the rack and are in parallel with each other, the jig loaded with a workpiece is born by the bearing conveying piece and is in sliding fit with the guide rail, and the conveying driving assembly is associated with the jig or the bearing conveying piece to drive the jig to move along a direction in parallel with the guide rail; at least one clamping station is distributed on the rack along a direction in parallel with the guide rail, any clamping station is correspondingly provided with a second conveying mechanism, each second conveying mechanism comprises a turnover assembly and at least one clamping assembly which are arranged on the rack, the clamping assembly is connected to the turnover assembly, an avoiding part which is distributed along the pivoting direction of the clamping assembly and is used for avoiding the turnover action of the jig is arranged at the clamping station on the guide rail, the clamping assembly is provided with an auxiliary guide rail corresponding to the avoiding part, and the jig is in sliding fit with the auxiliary guide rail.

Owner:苏州科昂泰材料科技有限公司

Human body anti-AQP4 autoantibodies detection material and preparation method thereof

ActiveCN107022548AEasy to useLower requirementDisease diagnosisBiological testingHuman bodyAutoantibody

The invention provides a human body anti-AQP4 autoantibodies detection material and a preparation method thereof. The preparation method comprises the steps of firstly acquiring M1 and M23 subtype AQP4 overall length target genes, dyeing into an HEK293 cell, and building an HEK293 / pCI-neo-M1-AQP4 cell and an HEK293 / pCI-neo-M23-AQP4 cell expressing M1 and M23 subtype AQP4; extracting an AQP4-cell membrane complex of the cells; finally curing the AQP4-cell membrane complex on a carrier, and obtaining the human body anti-AQP4 autoantibodies detection material. According to the human body anti-AQP4 autoantibodies detection material and the preparation method thereof provided by the invention, the extracted AQP4-cell membrane complex is used as a detection material, so that the intrinsic protein amount causing background coloration can be reduced; compared with a method for using the cell as the detection material for carrying out immunofluorescence detection, the detection sensitivity and the specificity are further increased, a detection result is easier and clear to judge, and the AQP4 autoantibodies of a patient can be simply, conveniently and quickly detected.

Owner:SHAANXI MYBIOTECH CO LTD

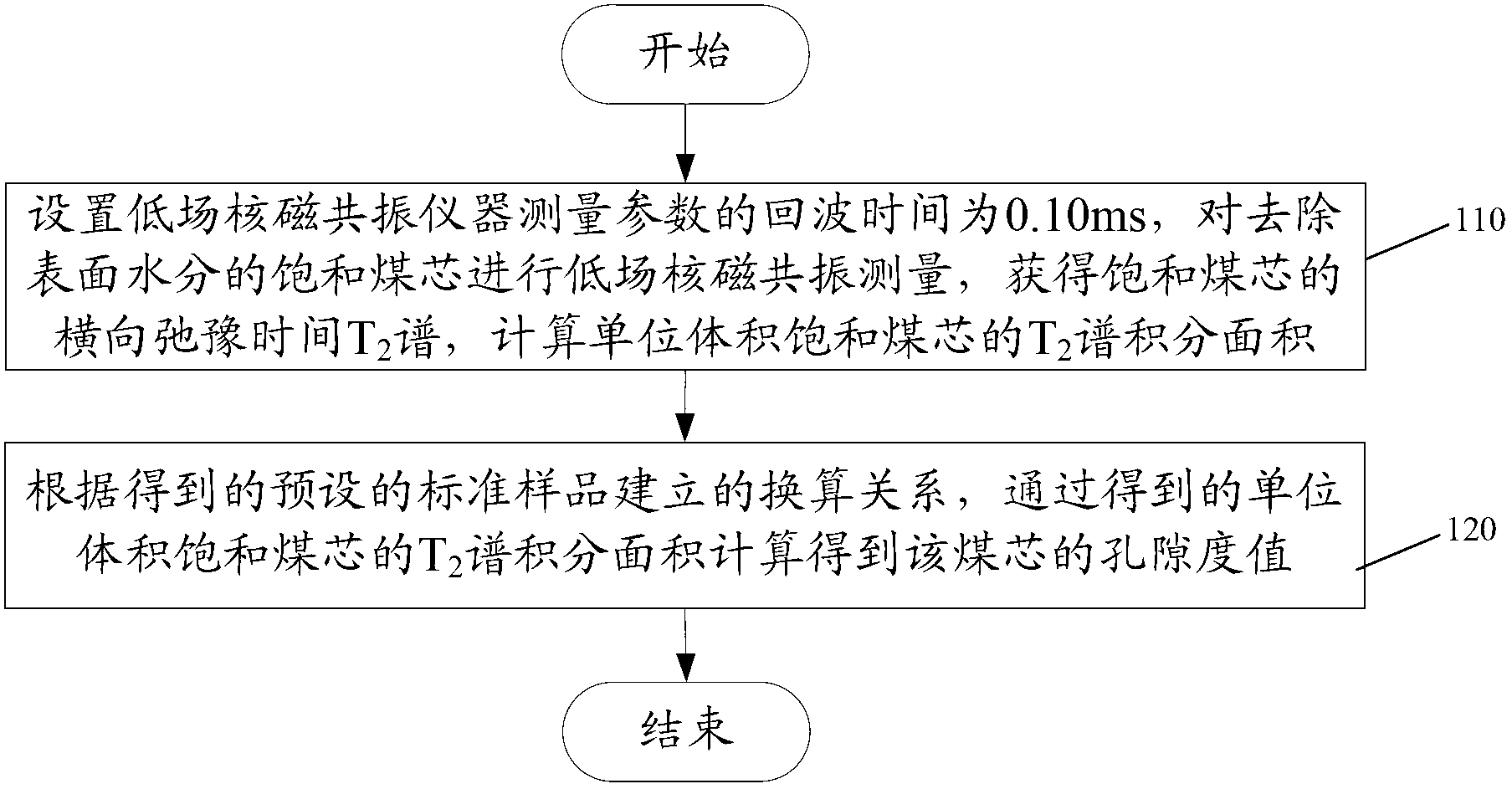

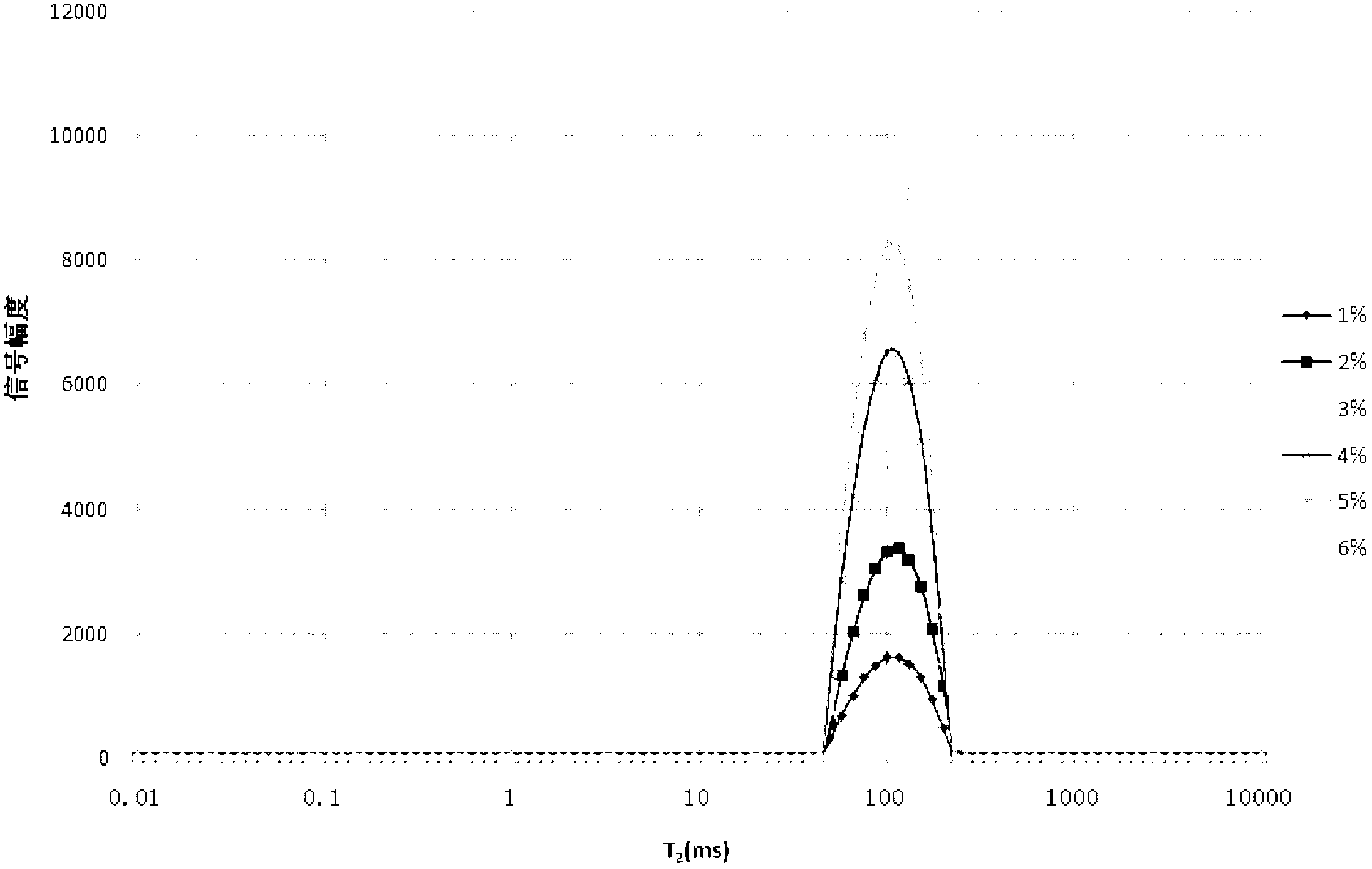

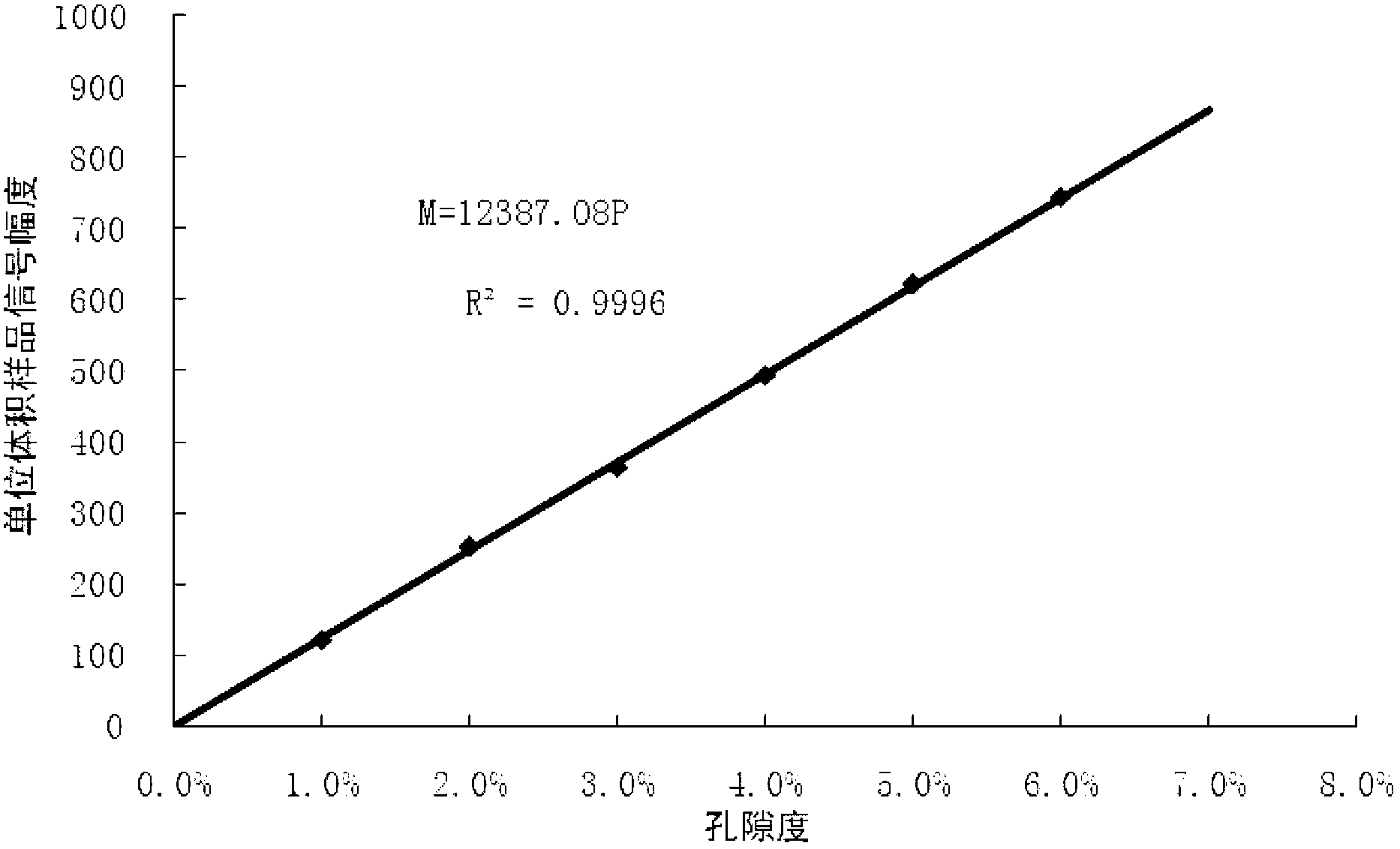

Method for measuring porosity of coal core

ActiveCN103018148AImprove detection accuracyShort time consumingPermeability/surface area analysisSurface moisturePorosity

The invention discloses a method for measuring the porosity of a coal core. The method comprises the following steps of setting echo of measuring parameters of a low-field nuclear magnetic resonance instrument to be 0.10 microseconds; carrying out low-field nuclear magnetic resonance measurement on the saturated coal core after surface moisture is removed so as to obtain a spectrum T2 of transverse relaxation time of the saturated coal core; calculating an integral area of the spectrum T2of the saturated coal core in unit volume; and calculating to obtain a porosity value of the coal core through the integral area of the spectrum T2of the saturated coal core in the unit volume according to conversion relation established by an obtained preset standard sample. With the adoption of the method provided by the invention, the porosity of a core hole is reflected by a signal generated by moisture in a sample hole in a low-field nuclear magnetic resonance manner, so that the detection precision is high, and the consumed time is short.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment

InactiveCN107989092AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringTelecommunications cableEngineering

The invention relates to ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment. The equipment comprises a lifting plate, a soil cutting device, a groutingdevice and a backfilling device, wherein the soil cutting device is mounted at the front end of the lifting plate; the grouting device is mounted at the lower end of the lifting plate; and the backfilling device is mounted at the rear end of the lifting plate. By means of the ditching, layer laying and backfilling combined telecommunication cable mechanical laying equipment, the problems can be solved that in the existing cable direct burying processes, workers need to perform ditching, manual grouting and layer laying, and backfilling and soil rolling; during ditching, the workers need to perform ditching with the help of tools, and the later-stage backfilling effect is affected due to different sizes of soil blocks which are manually cut; and during layer laying, the ditch bottoms needsto be subjected to manual grouting and rolling, cement plates need to be subjected to external grouting and solidification and then delivered to the appointed positions to be mounted during groutingof the side surfaces, cut soil needs to be subjected to manual backfilling and then beating and pressing, and the soil is not compact during manual pressing due to different cut soil blocks, and the functions of automatic ditching, layer laying and backfilling of telecommunication cables can be achieved.

Owner:黄正秀

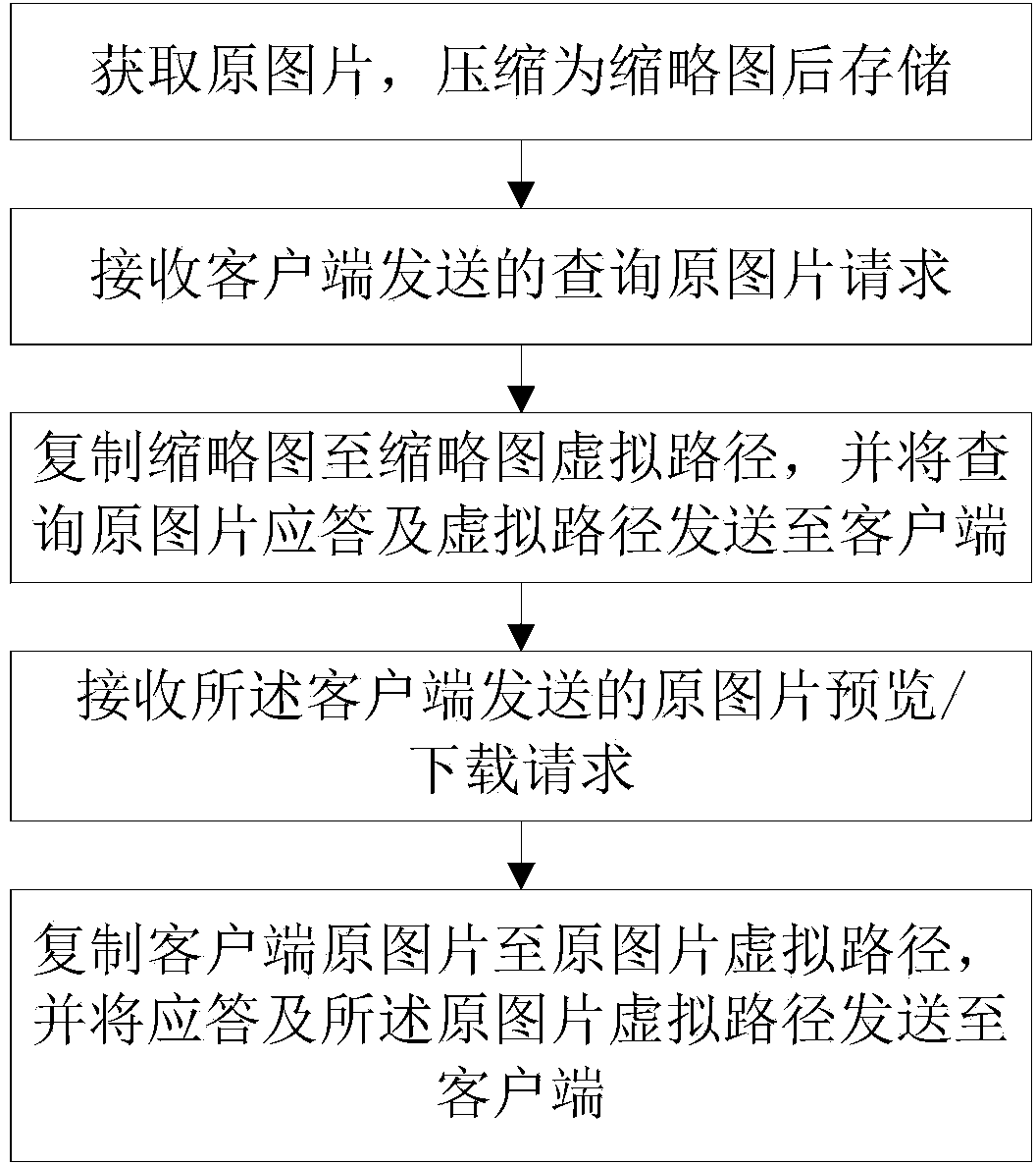

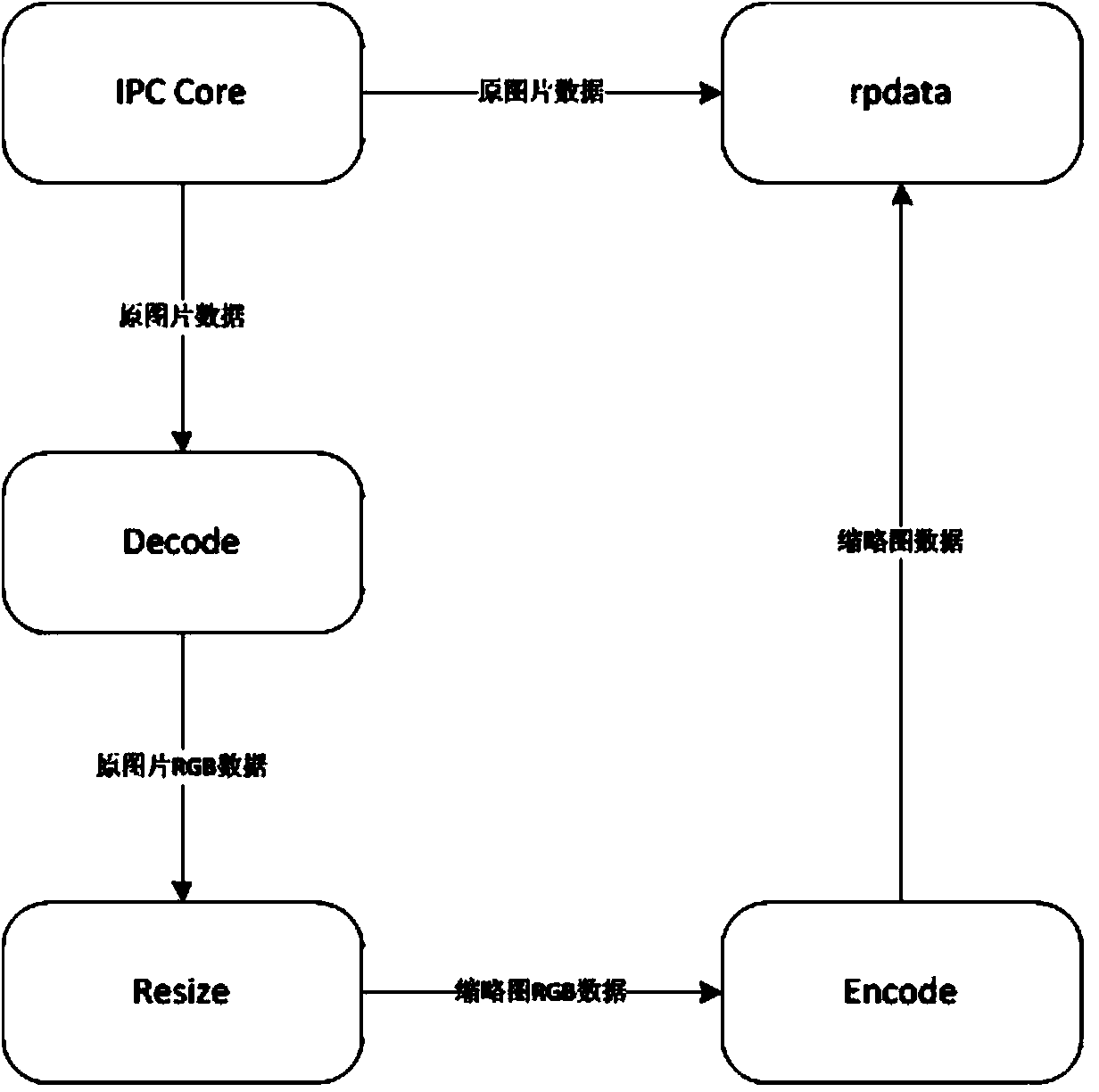

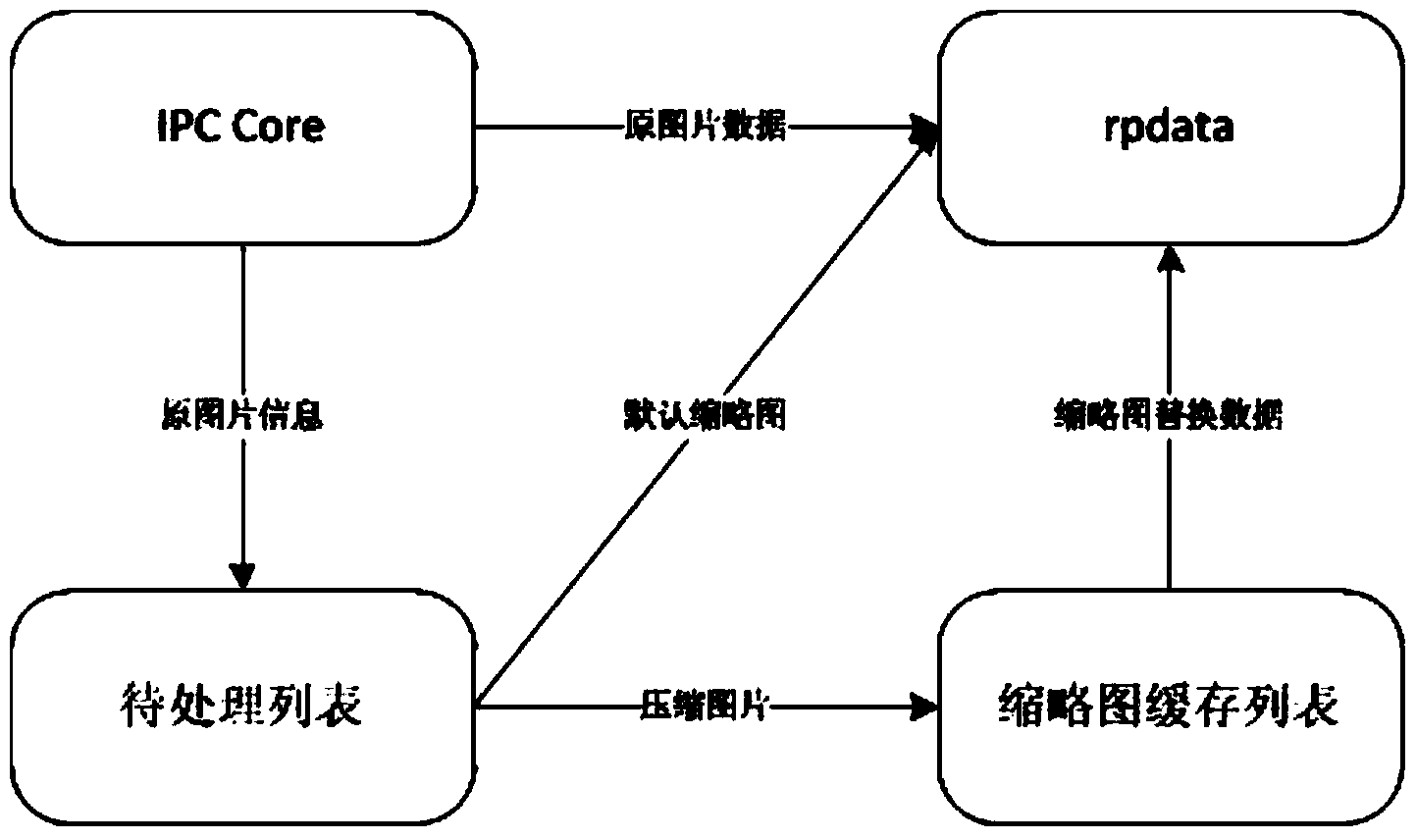

Image processing and previewing method and system

ActiveCN104243923AShorten the timeImprove experienceClosed circuit television systemsSelective content distributionVirtual memoryImaging processing

The invention provides an image processing and previewing method and system. For the request for inquiring an original image, a thumbnail corresponding to the original image is copied to a thumbnail virtual route, and the thumbnail virtual route is sent to a client side; for the request for previewing / downloading of the original image, the original image needing to be previewed / downloaded by the client side is copied to an original image virtual route, and the original image virtual route is sent to the client side; unrecognizable image files in a monitoring video are mapped to a virtual route in a virtual memory disk mode so that the client side can preview thumbnails instantly, a user selects the original image needing to be loaded, the time is saved for the user, and the user experience is improved. The thumbnails obtained through compression are saved temporarily in a buffer queue, and when a CPU is idle, the thumbnails are saved in a storage device in sequence; in this way, the occupied CPU can be reduced, and the situation that a system operates slowly or breaks down is avoided.

Owner:SUZHOU KEDA TECH

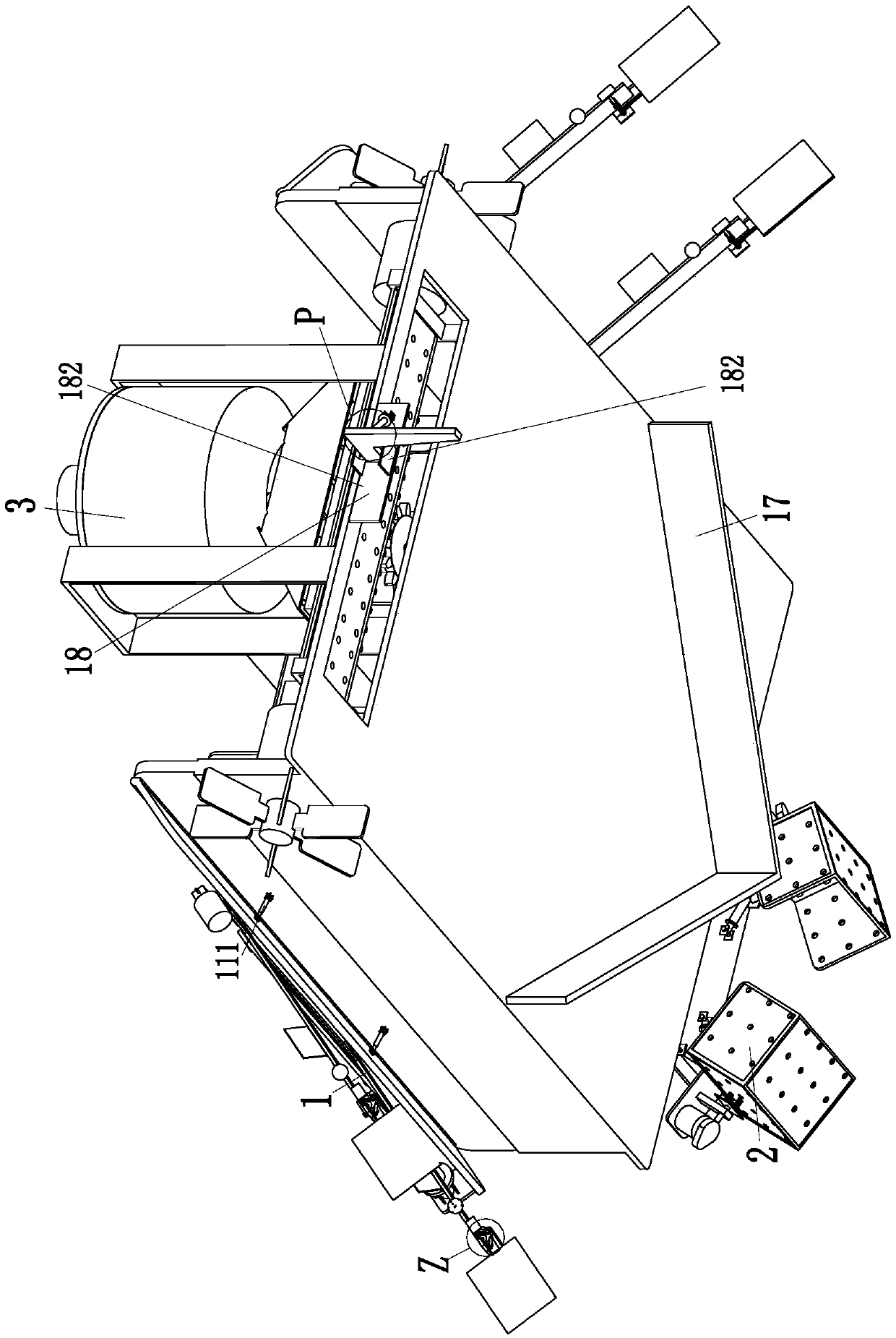

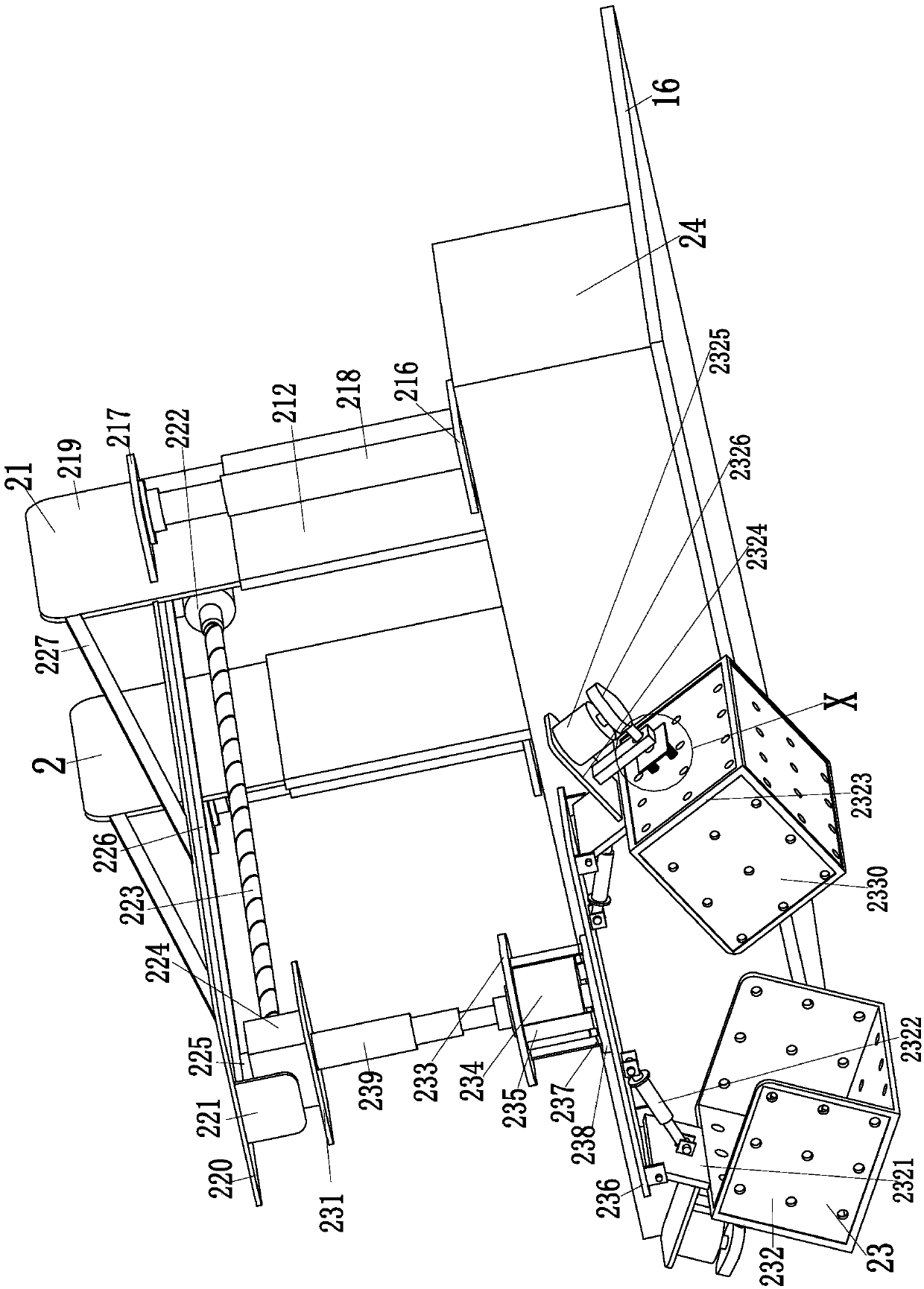

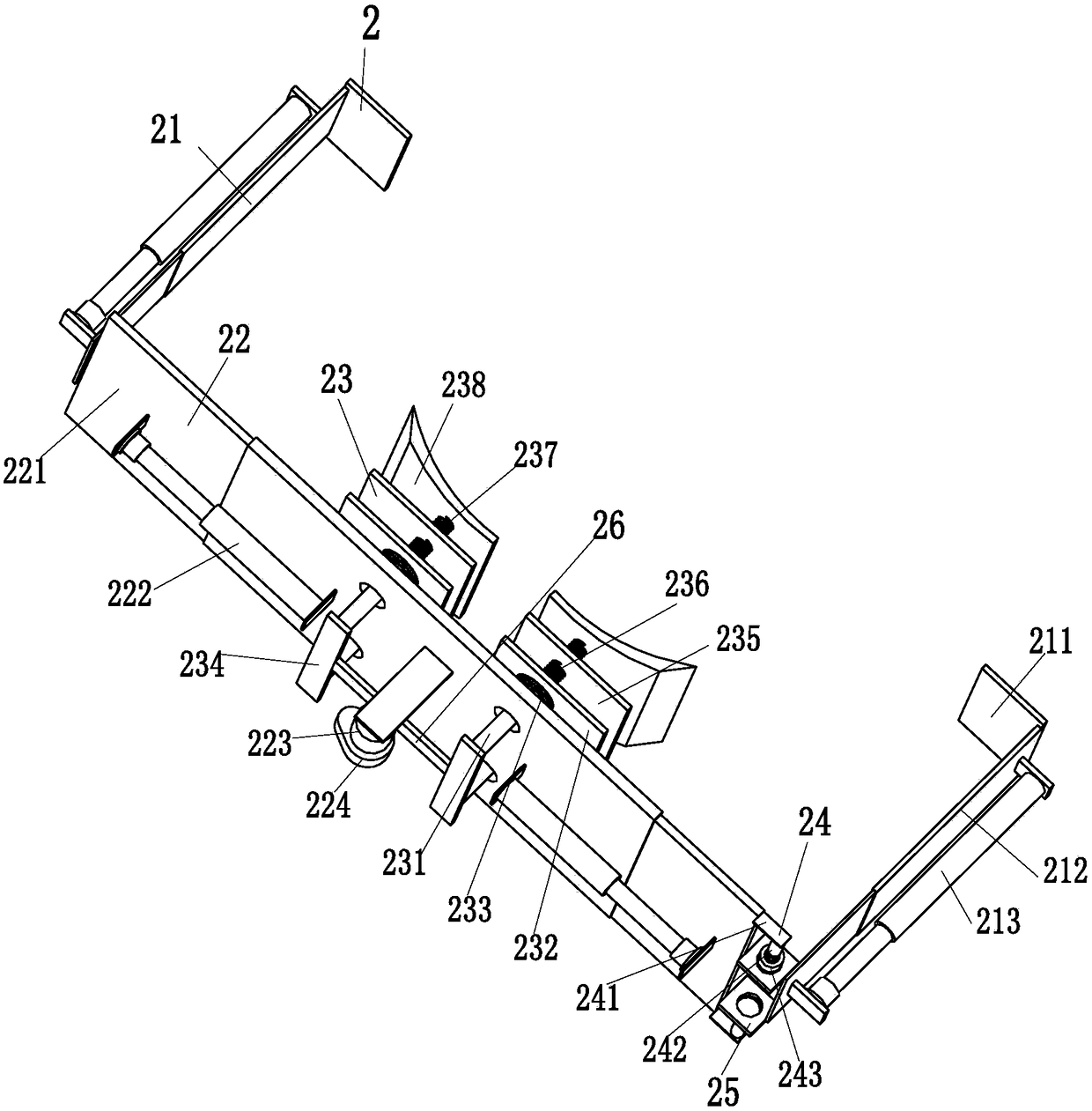

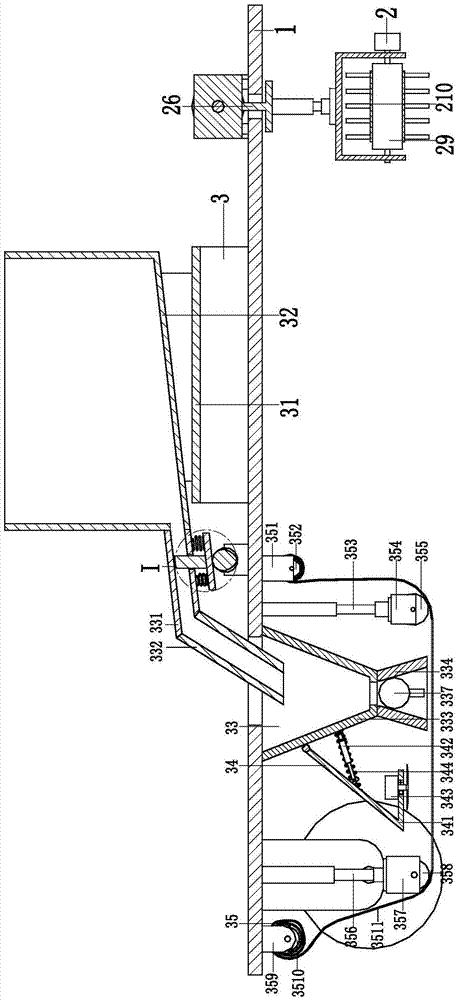

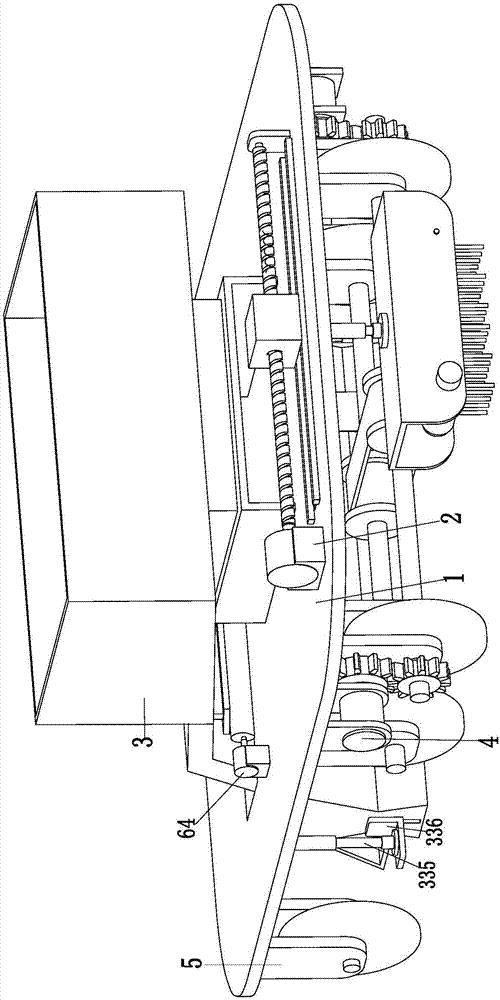

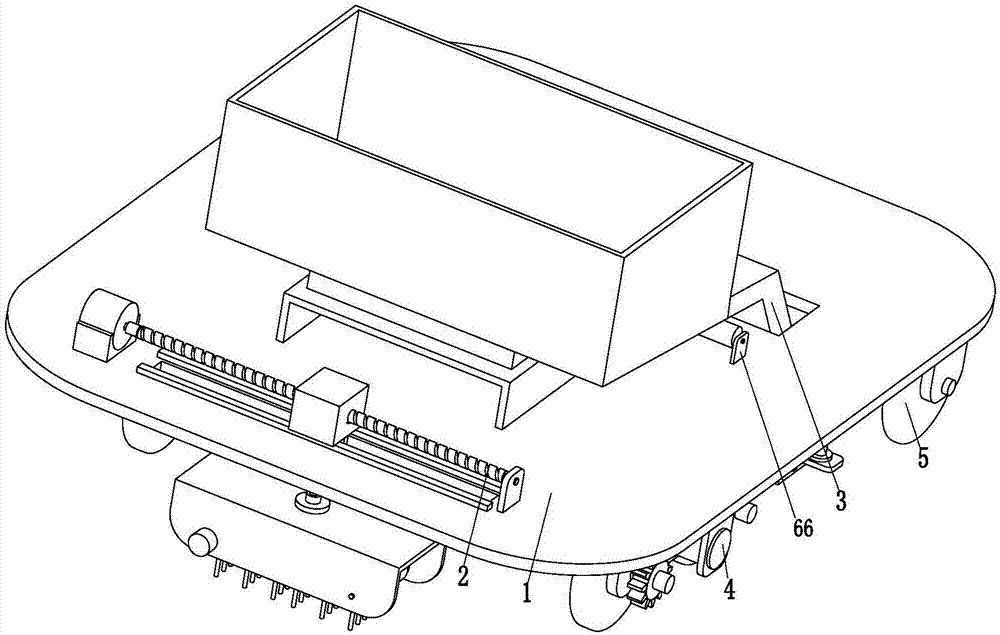

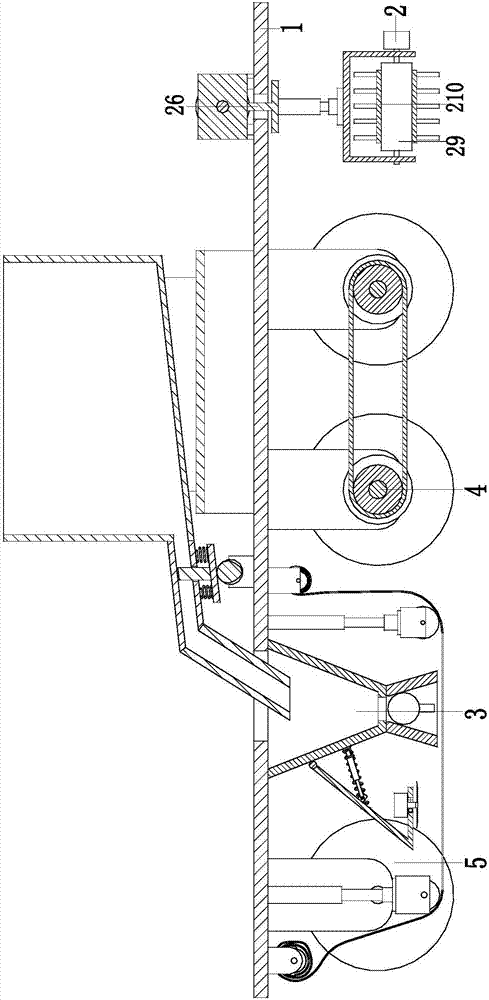

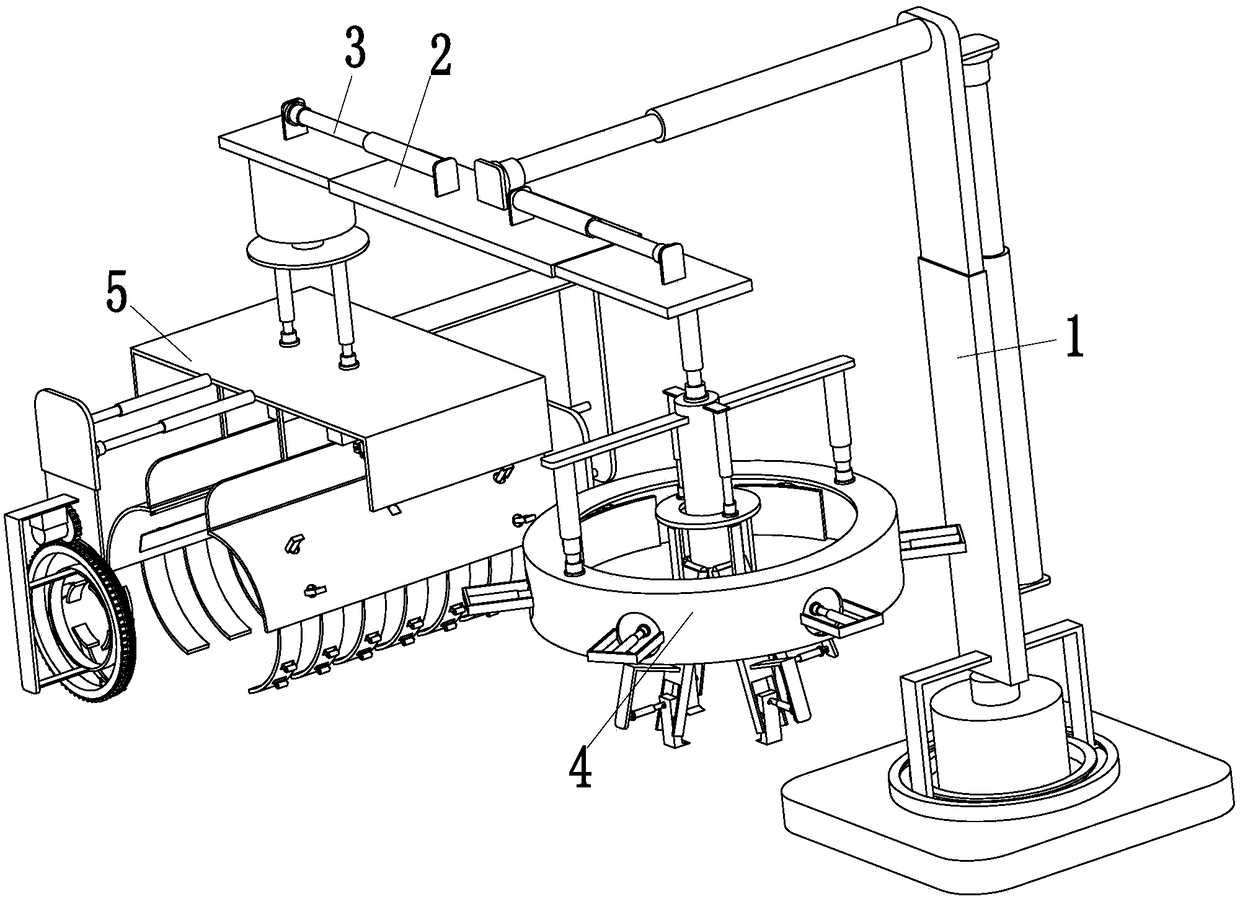

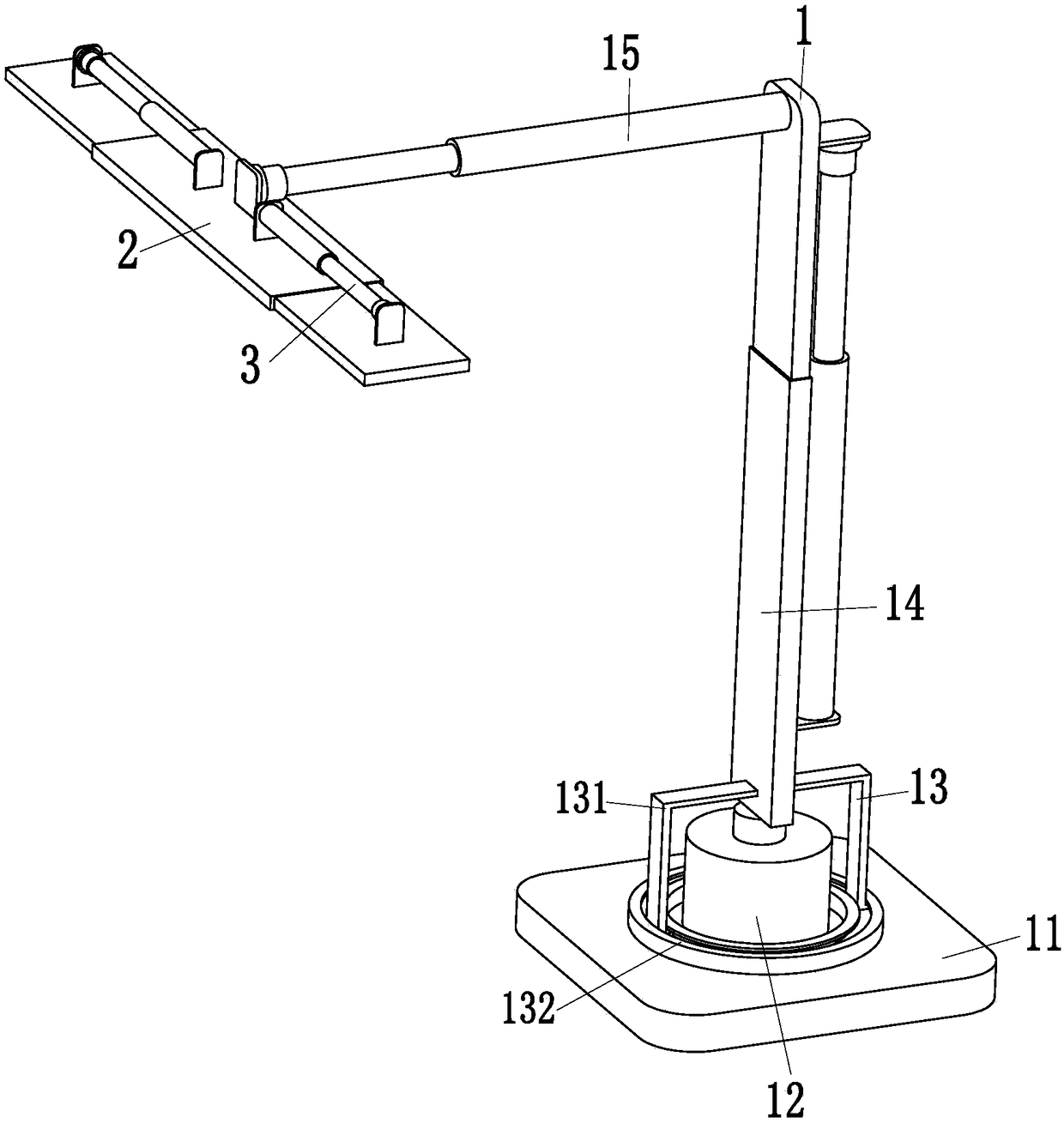

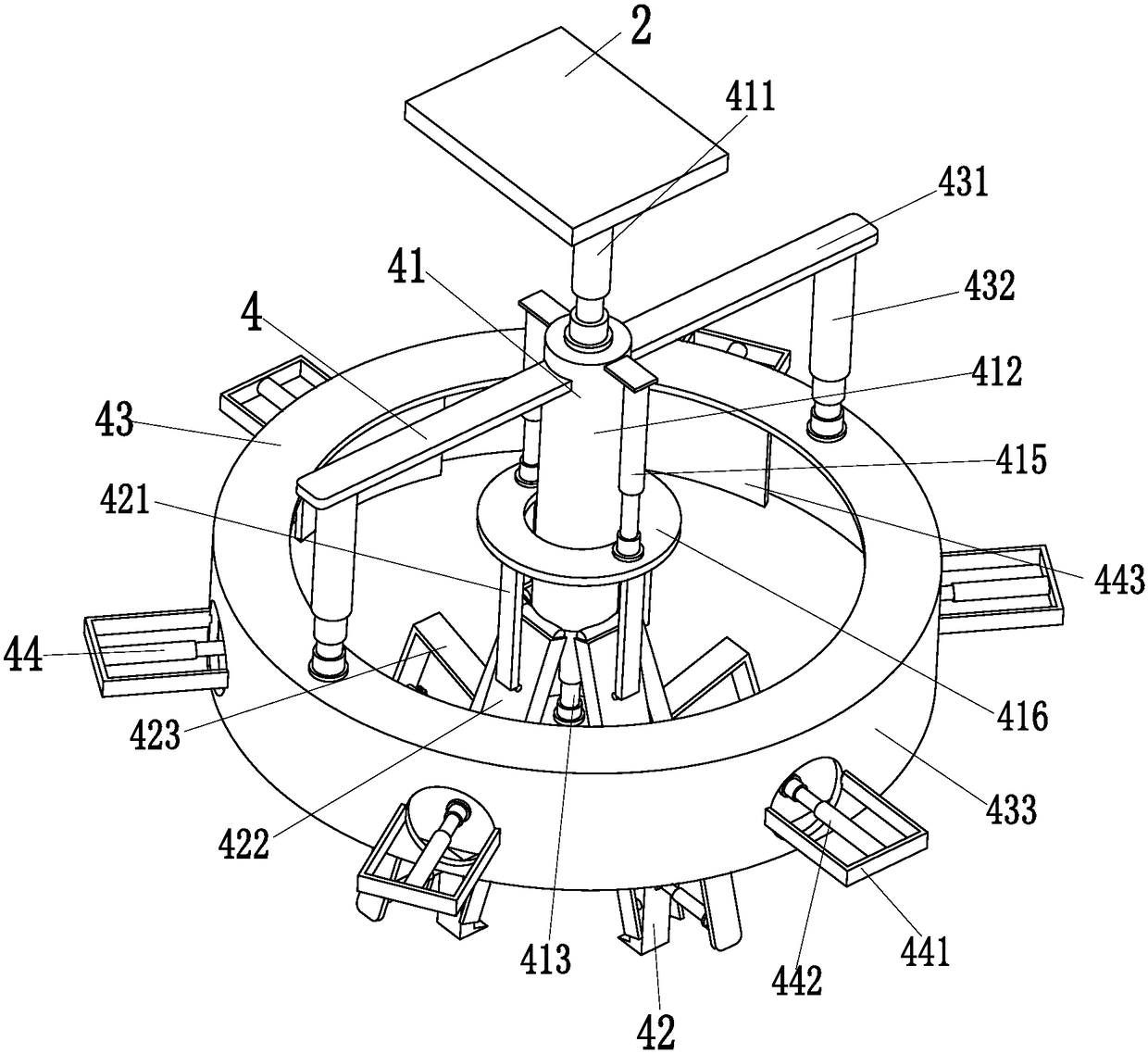

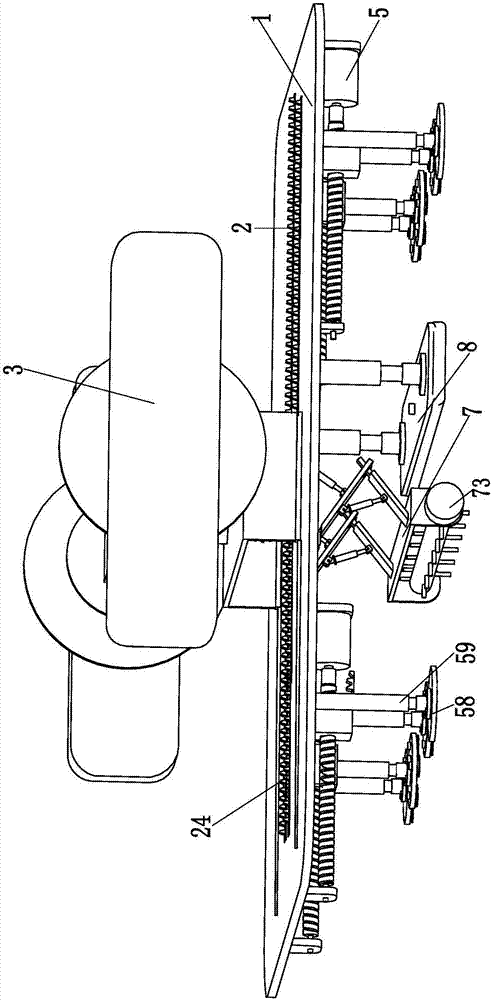

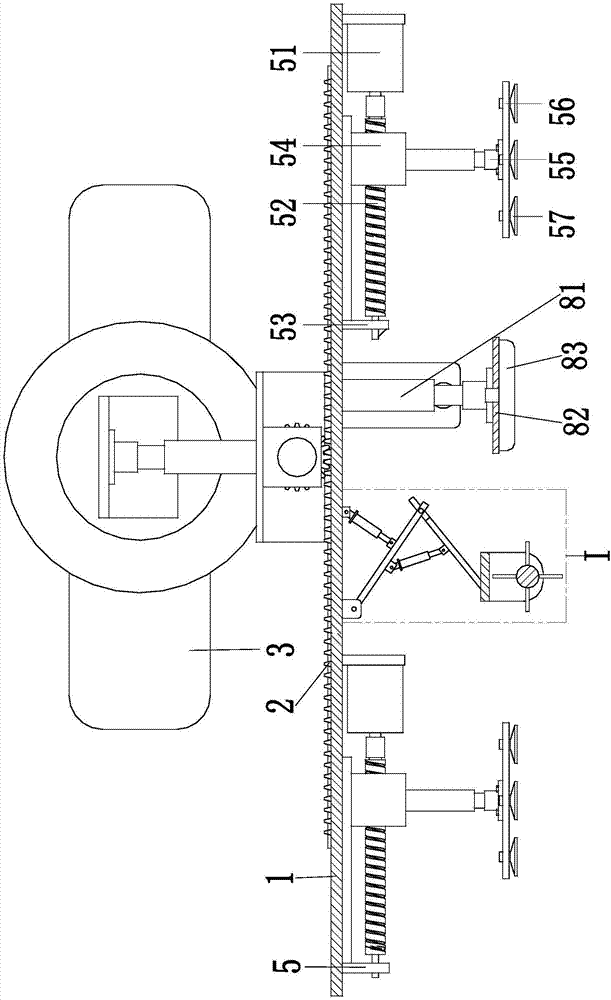

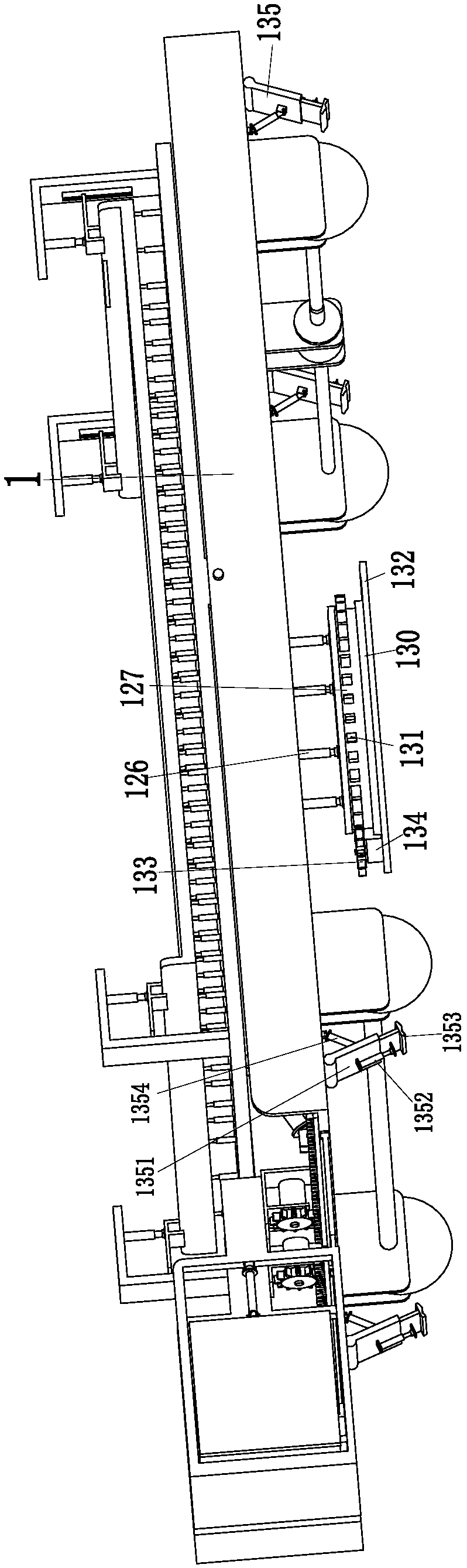

Aquaculture feed-scattering fishing boat capable of salvaging dead fish rubbish and achieving uniform oxygen and deodorization

The invention relates to an aquaculture feed-scattering fishing boat capable of salvaging dead fish rubbish and achieving uniform oxygen and deodorization. The aquaculture feed-scattering fishing boatcomprises a boat body device, a salvaging device and a feed-scattering device, wherein the salvaging device is installed on the front side of the upper end of the board body device, and the feed-scattering device is installed on the rear side of the upper end of the boat body device. The problem can be solved that a user salvages dead fish rubbish in river water while rowing in the process of artificial salvaging and then artificial feed scattering in lake water through an existing fishing boat, the process is complicated and inconvenient, and the operation that workers perform salvaging andfeed scattering while rowing makes the fishing boat unstable, causes that the user falls into water and accordingly causes potential safety hazards. Generally, the user puts an oxygen aeration pump atthe center of a lake to perform manual feed scattering, feed scattering is not uniform, the process is complicated, the consumed time is long, the problems such as high labor intensity and low efficiency are caused, and the functions of automatic salvaging and feed scattering of the fishing boat can be achieved.

Owner:潘军

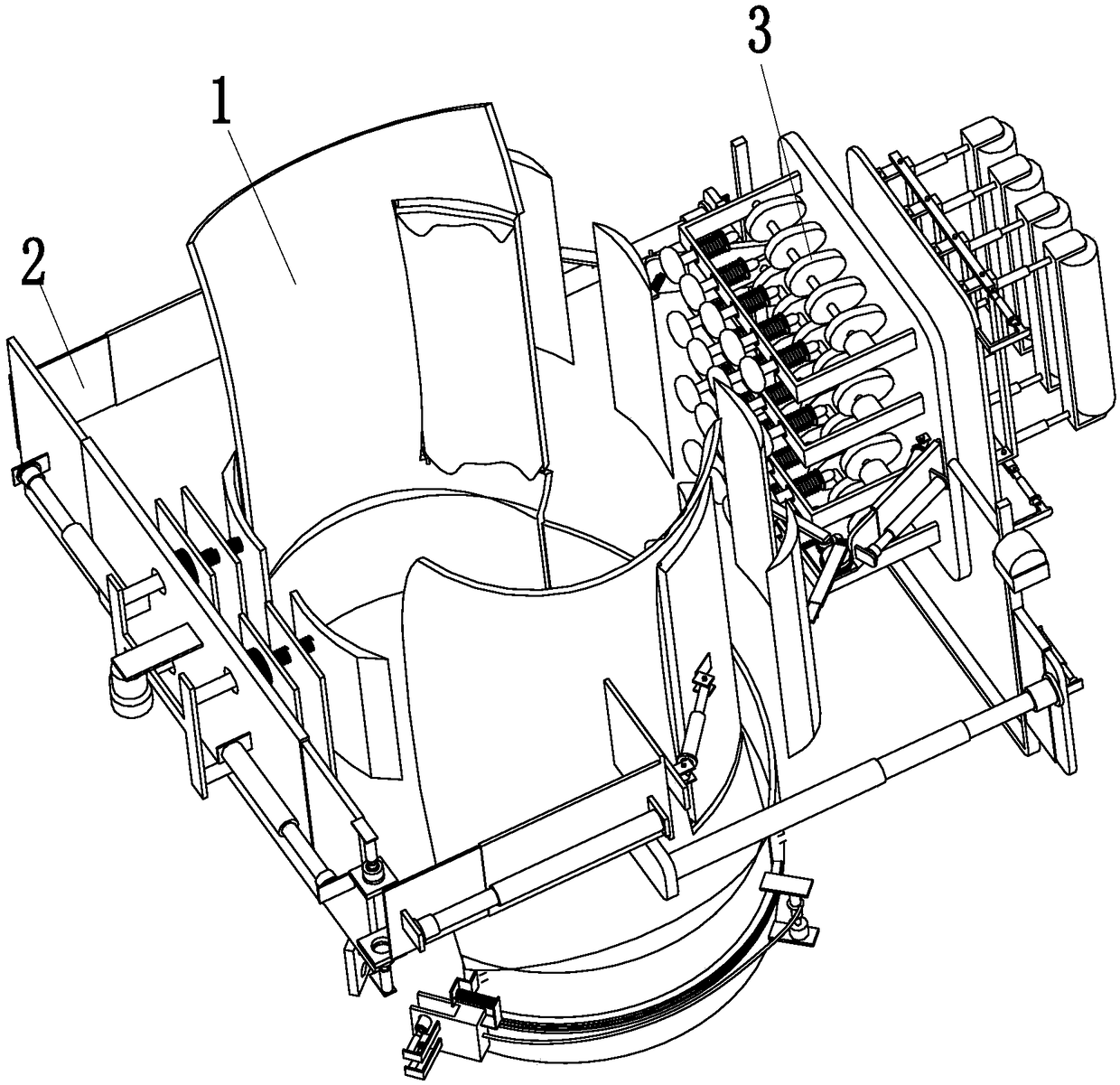

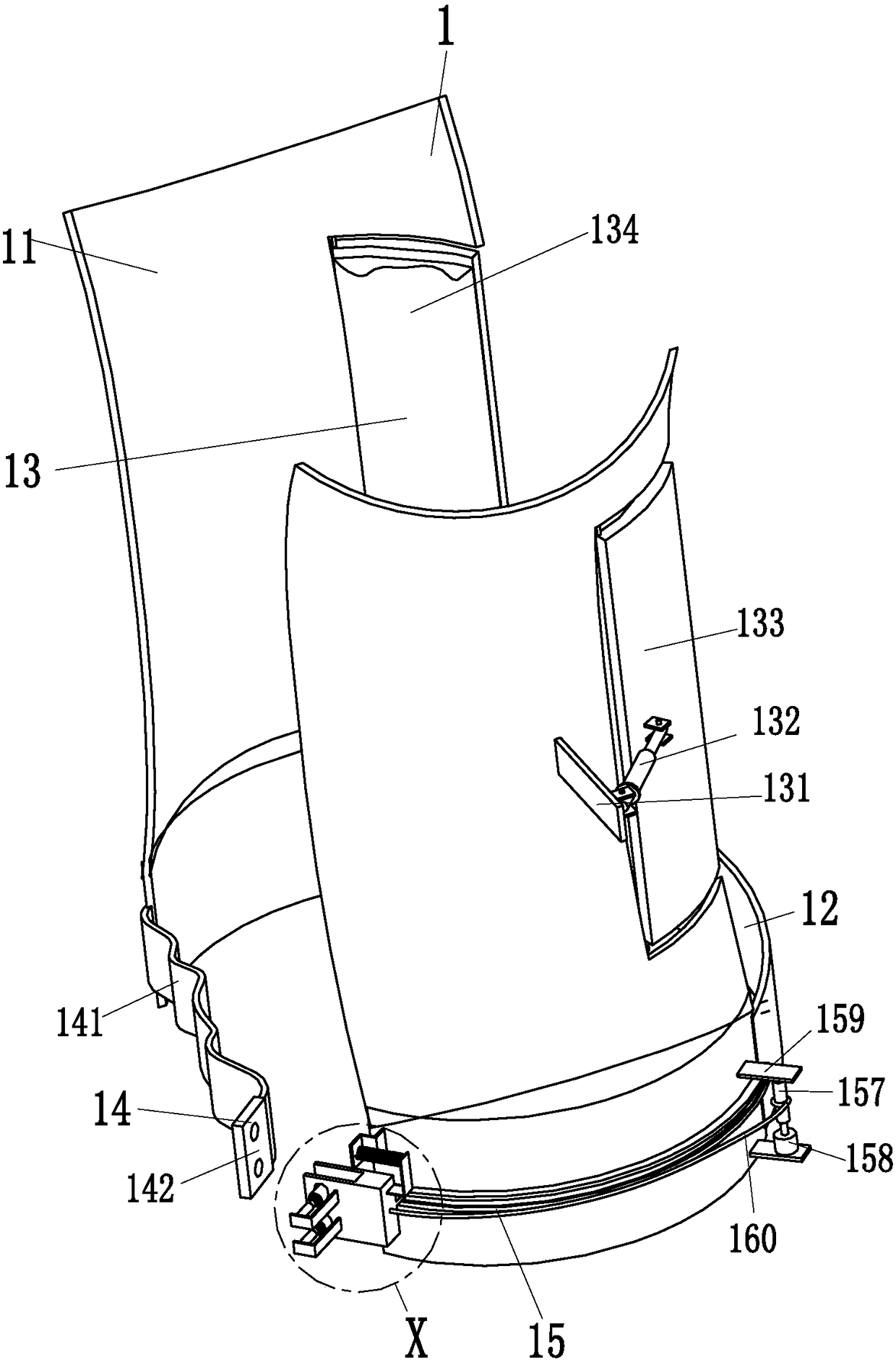

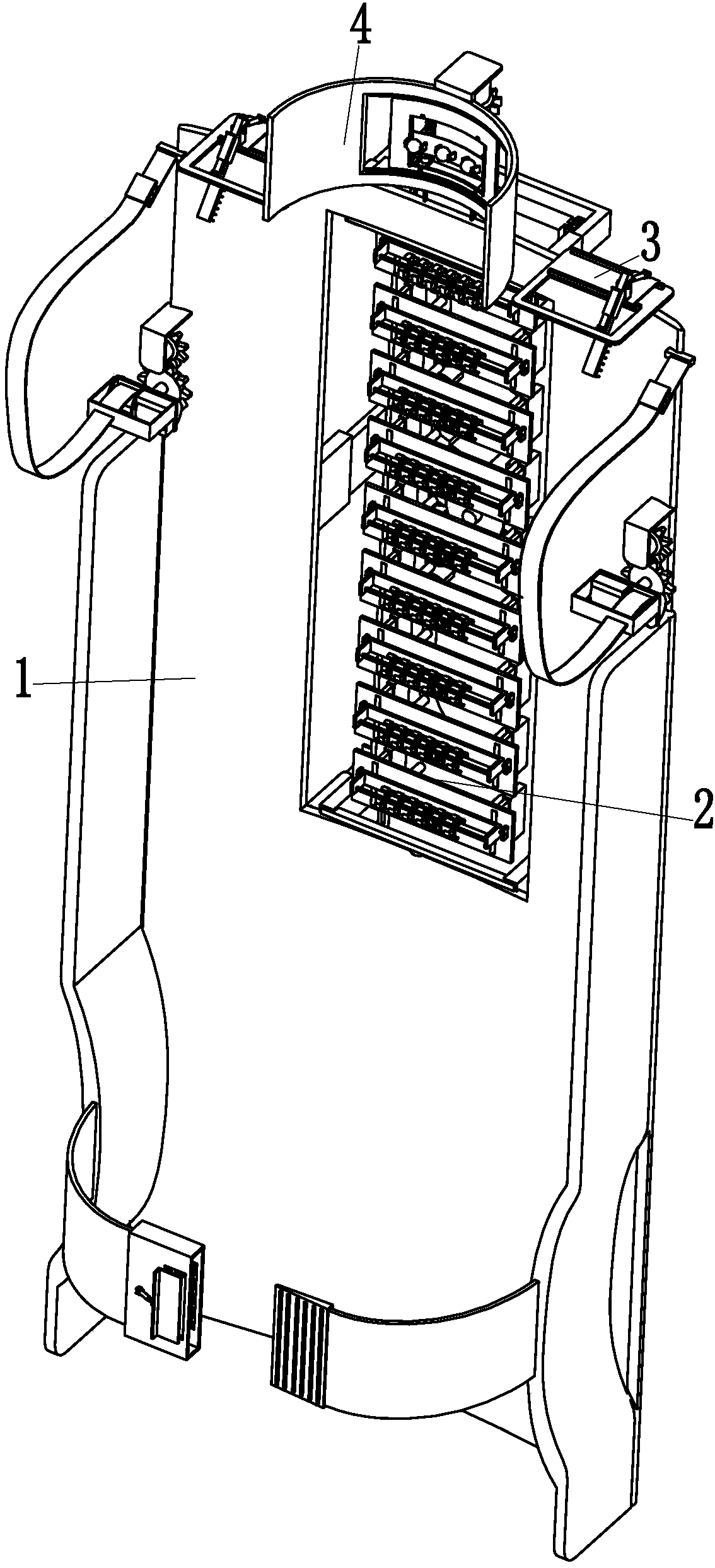

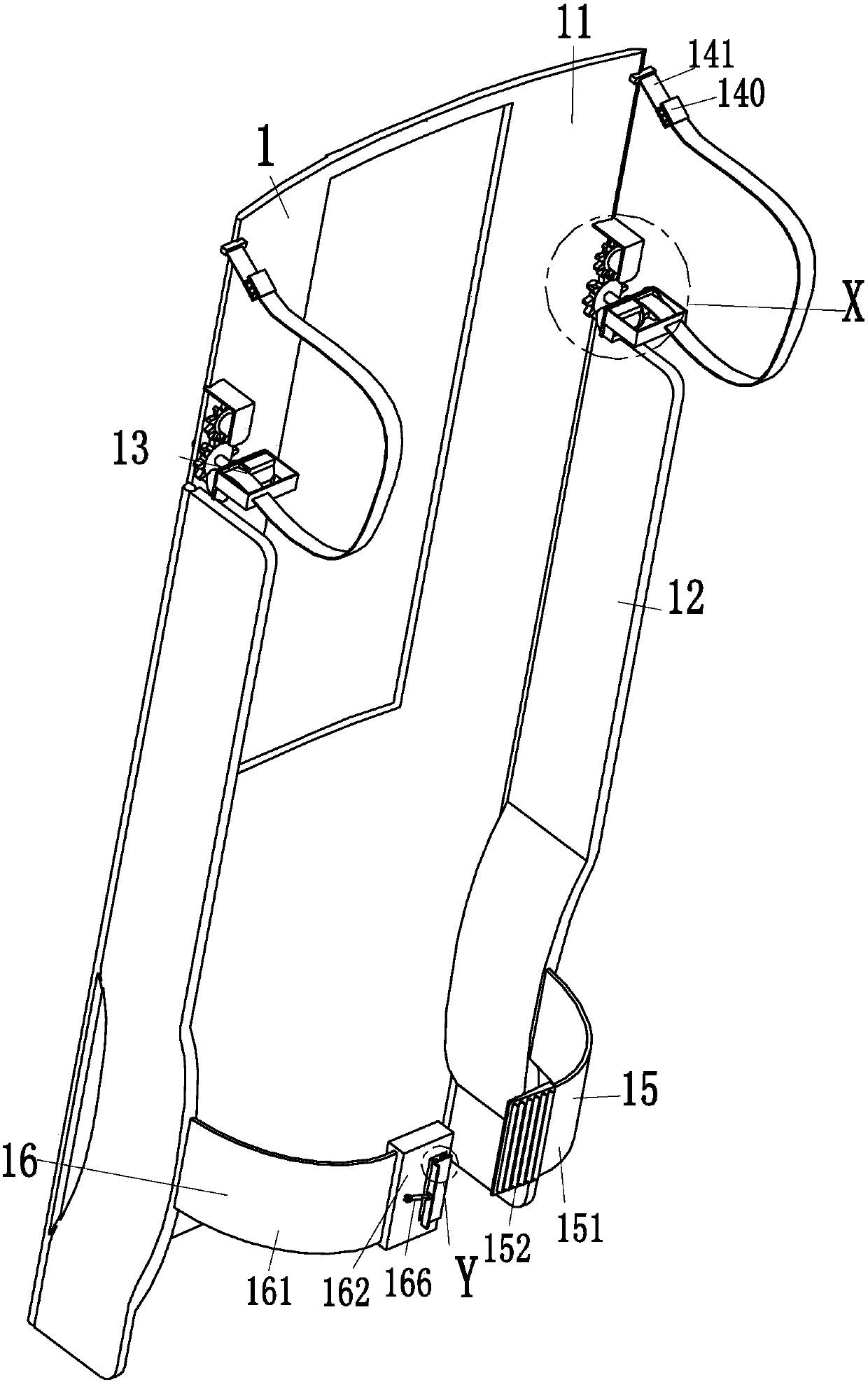

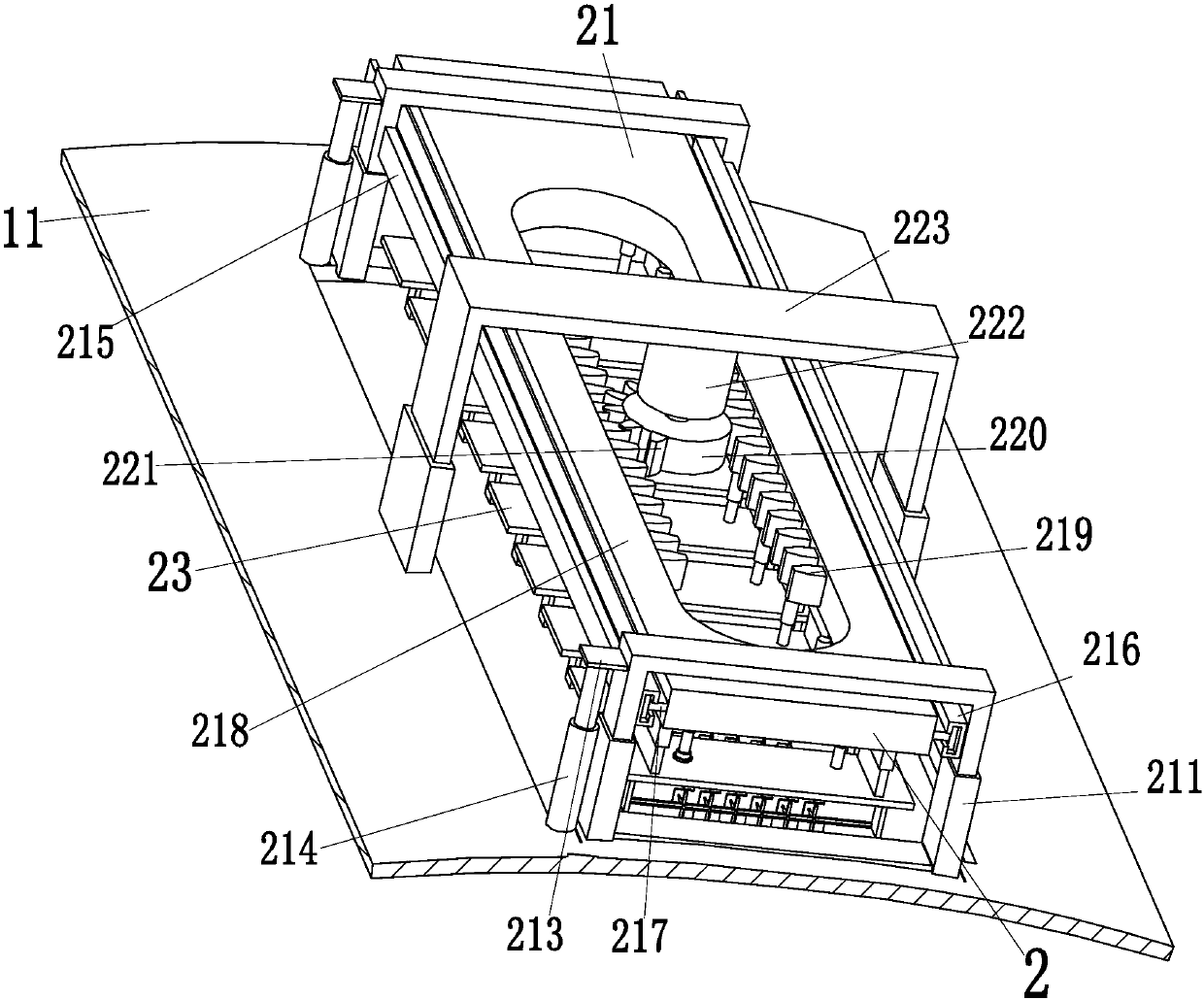

Special medical rehabilitation health-care apparatus for waist of human body

InactiveCN108378970AEnsure safetyMassage evenlyVibration massageRoller massageHuman bodyPhysical medicine and rehabilitation

The invention relates to a special medical rehabilitation health-care apparatus for the waist of a human body. The special medical rehabilitation health-care apparatus for the waist of the human bodycomprises a correcting device, a beating device and a waist massaging device, wherein the beating device is mounted at the front end of the correcting device; and the waist massaging device is mountedat the rear end of the correcting device. By the special medical rehabilitation health-care apparatus for the waist of the human body, the problems that people need to successively correct and massage the waist in an existing human body waist correcting and massaging process, in the correcting process, people cannot massage the waist, during massaging, workers require to successively beat the belly, massage the waist and massage two sides of the waist, simultaneous massaging is not allowed, after long-time massaging, the workers feel sour on hands easily, thus, the massaging force in the later period is not enough, the massaging effect cannot be achieved, after long-time massaging, the waists and hands of the workers are injured easily to cause potential safety hazards, the time consumedin the process is long, the labor intensity is high, the efficiency is low and the like are solved, and functions of automated correction and multifunctional massaging on the waist of the human body can be fulfilled.

Owner:绍兴集知汇信息科技有限公司

Architectural decoration device capable of automatically caulking indoor ceramic tile gaps

The invention relates to an architectural decoration device capable of automatically caulking indoor ceramic tile gaps. The architectural decoration device comprises a facing device, a gluing device,and an edge pressing device; the front end of the gluing device is provided with the facing device, and the rear end of the gluing device is installed at the front end of the edge pressing device. Thearchitectural decoration device capable of automatically caulking the indoor ceramic tile gaps solves the problems that when seams are traditionally ornamented, manual work is required to paste masking papers, and personnel need to inject glue and press edges by tools; when the masking papers are pasted, the personnel need to paste the masking papers manually, edges are pasted raggedly, and people may cut their hands during cutting the masking papers by the tools; during working, the papers may be folded, and the personnel need to straighten the folded masking papers to work; during gluing bya seam beauty agent, the personnel need to put a seam beauty agent in a seam ornamenting gun and then glue the gaps, and the personnel may cut the hands due to improper operation during cutting a rubber nozzle laterally; and during edge pressing, the personnel need to vigorously press the gaps after gluing by an edge pressing ball. The architectural decoration device capable of automatically caulking indoor the ceramic tile gaps can achieves the functions of automatic pasting paper, gluing, and edge pressing for ceramic tile gaps.

Owner:吴凡

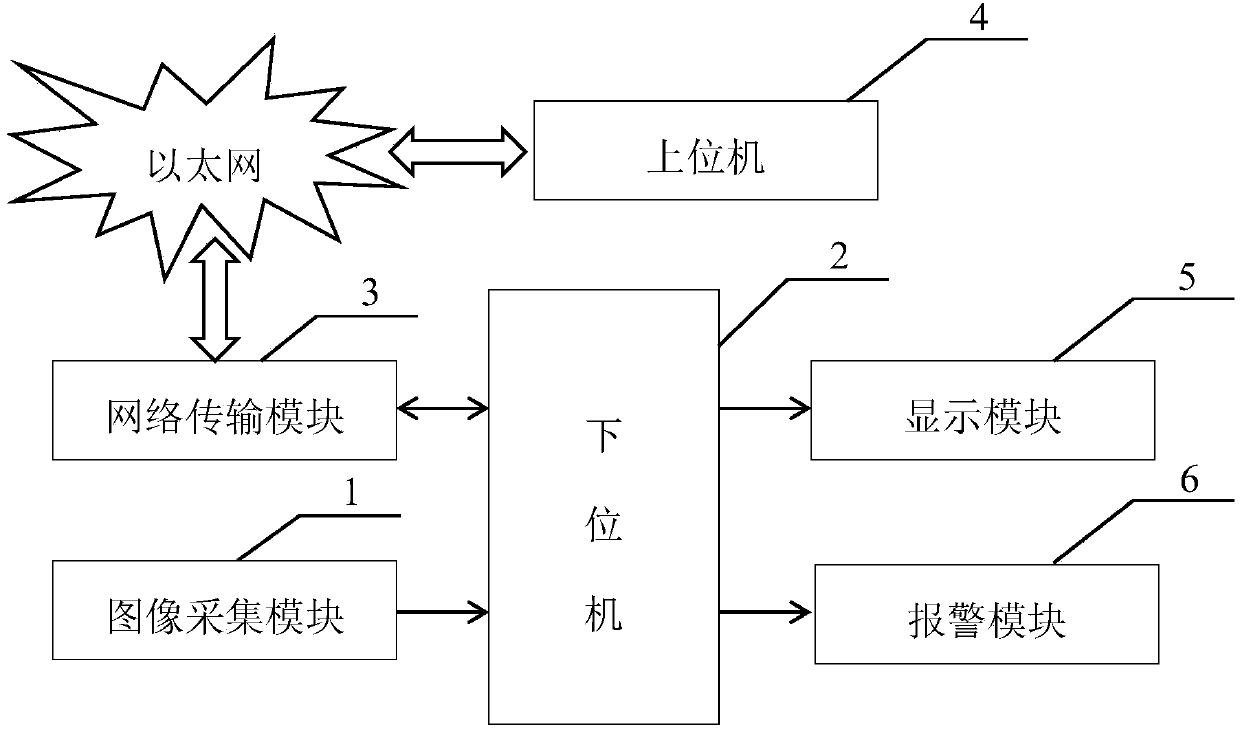

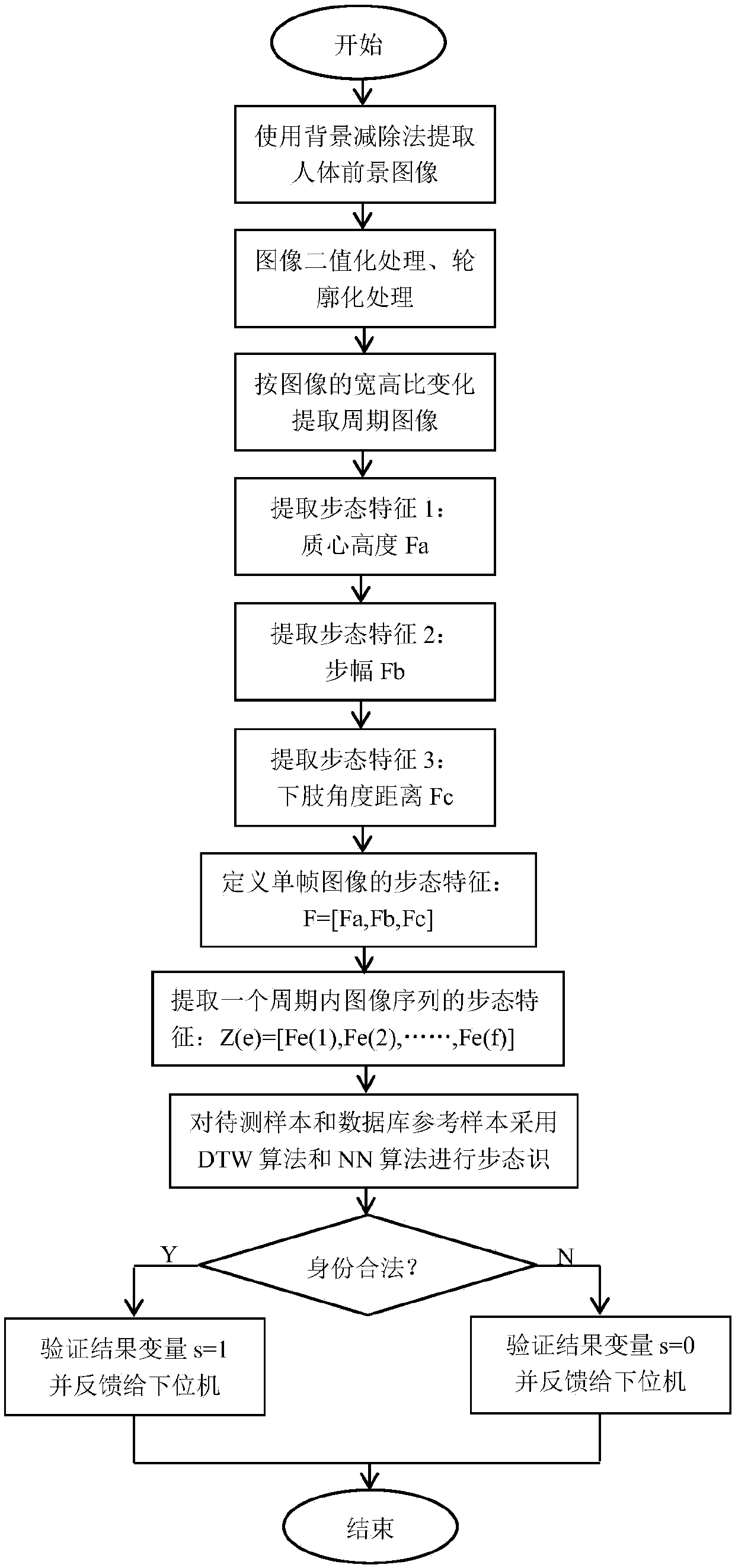

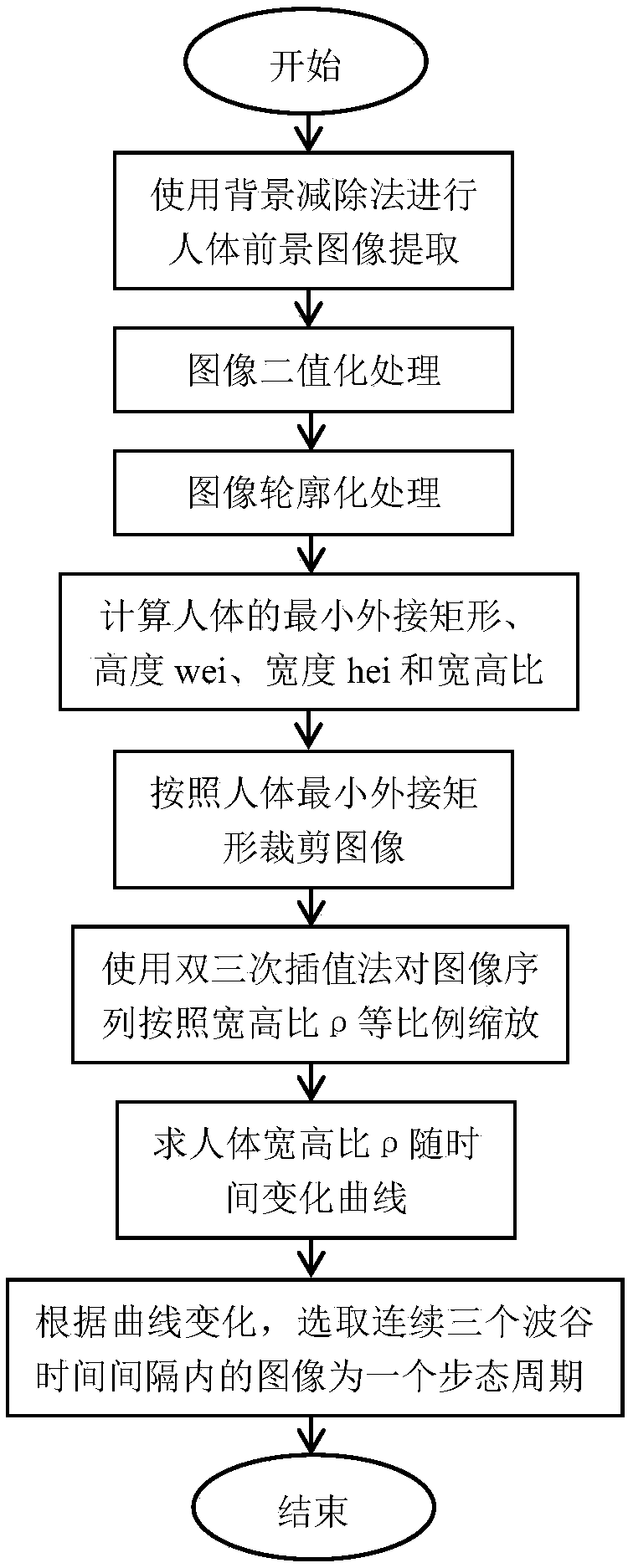

Video monitoring system and real-time gait recognition method

ActiveCN107766819AHighly consistentEasy gait feature extractionImage analysisCharacter and pattern recognitionVideo monitoringMinimum bounding rectangle

The invention provides a video monitoring system and a real-time gait recognition method. In the process of image preprocessing, an extracted binary contour image is cut according to the minimum bounding rectangle thereof, and the image is scaled according to the maximum image height of all the image frames under the condition that the aspect ratio is kept unchanged. Therefore, all the preprocessed image frames are consistent in height, the aspect ratio before and after image processing is the same, and gait feature extraction is easier. According to the gait recognition method, both the static and dynamic characteristics of human gait are taken into account, the centroid height, the stride and the change rate of angular distance of the lower limb contour are extracted as gait features, and the gait differences of different individuals are comprehensively reflected. Through the method, the video monitoring system shortens the recognition time on the basis of ensuring high recognition rate. Moreover, the video monitoring system has better robustness to the clothing change of users, and is especially suitable for real-time user identity recognition in a video monitoring environment.

Owner:SHAANXI INST OF INT TRADE & COMMERCE

Automatic road line maker used for physical-training environmental-friendly air-permeable plastic runway construction

InactiveCN107326790ASolve the underlineSmooth linesRoad cleaningRoads maintainenceEnvironmental resistanceMachine building

The invention relates to an automatic marking machine for the construction of an environment-friendly and breathable plastic runway for sports training. Wheel, cleaning device and marking device are used in conjunction with each other to complete the automatic marking process of the plastic runway. The present invention can solve the problem of manually cleaning the ground of the plastic runway that needs to be marked in the marking process of the existing plastic runway. The existing marking equipment cannot automatically adjust the output of the marking paint according to the actual marking requirements. Unevenness. In the marking process, it is necessary to manually use isolation tools to isolate the marking paint. The natural air drying of the marking paint takes a long time, and the labor intensity and work efficiency are low. The function of automatic marking of the plastic track can be realized.

Owner:冒俊

On-site construction road line marker of composite wear-resistant resin plastic runway

InactiveCN107320942ASmooth linesNo manual operationSki bindingsWater-skiingWear resistantEngineering

The invention relates to an on-site construction road line marker of composite wear-resistant resin plastic runway. The on-site construction road line marker of composite wear-resistant resin plastic runway comprises a bottom plate; the front end of the bottom plate is provided with a cleaning device; the middle part of the bottom plate is provided with a line maker; the lower end of the bottom plate is provided with a moving device; two auxiliary wheels are symmetrically arranged on the back side of the lower end of the bottom plate. Plastic runway automatic line drawing is realized via interaction cooperation of the moving device, the cleaning device, and the liner maker. The on-site construction road line marker is capable of solving difficult problems in the prior art that labour is needed by cleaning of plastic runway after line drawing, labour is needed to push conventional line makers to perform line drawing, automatic adjustment of the output quality of line draying paint is impossible to realize by conventional line makers, line drawing is uniform, labour is needed to isolating line drawing paint using isolating tools in line drawing process, natural airing time of line drawing paint is long, labout intensity is high, and working efficiency is low, and is capable of realizing automatic line drawing of plastic runway.

Owner:冒俊

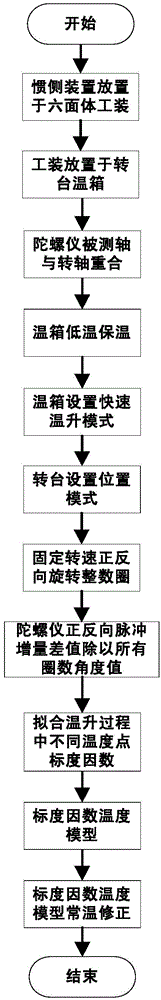

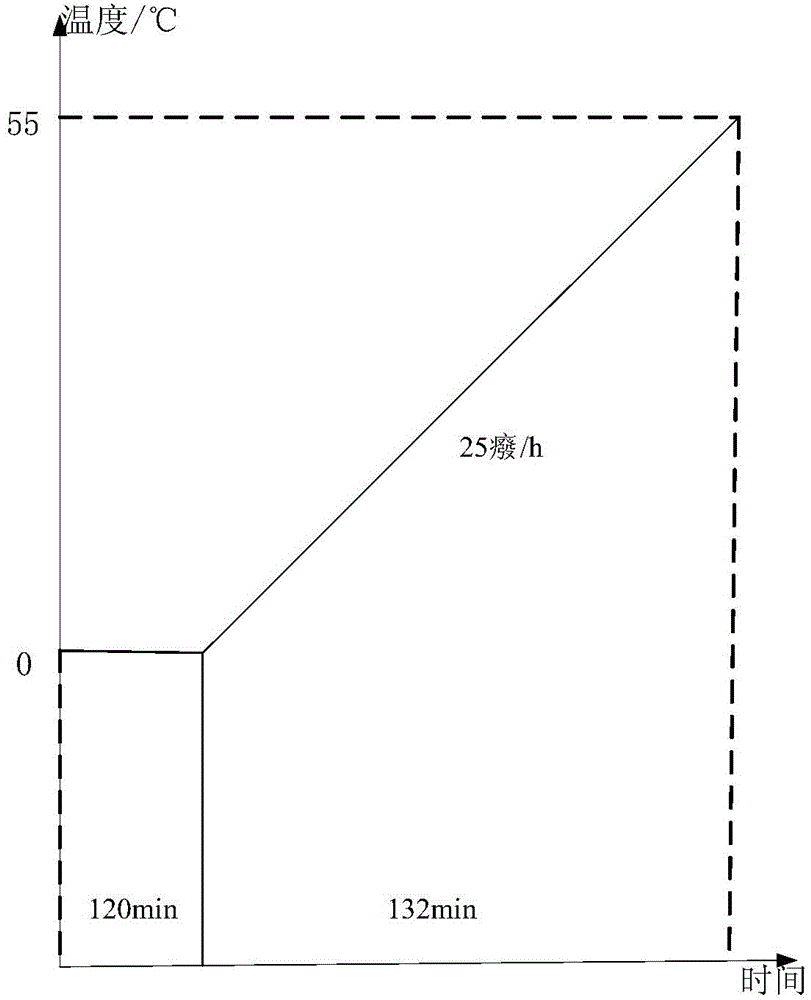

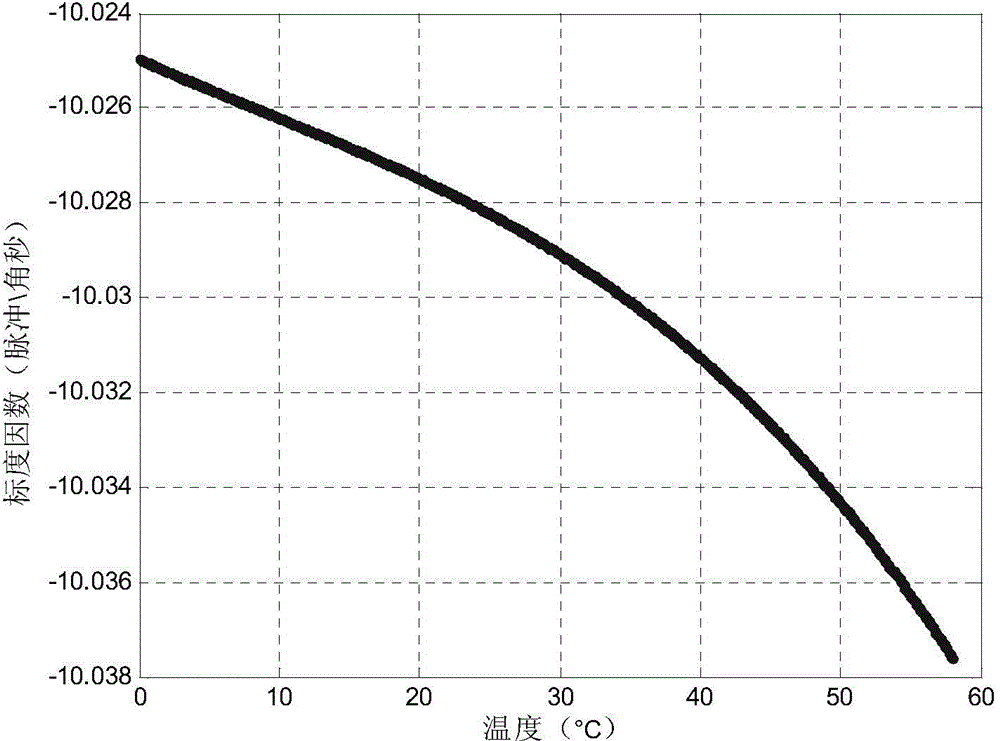

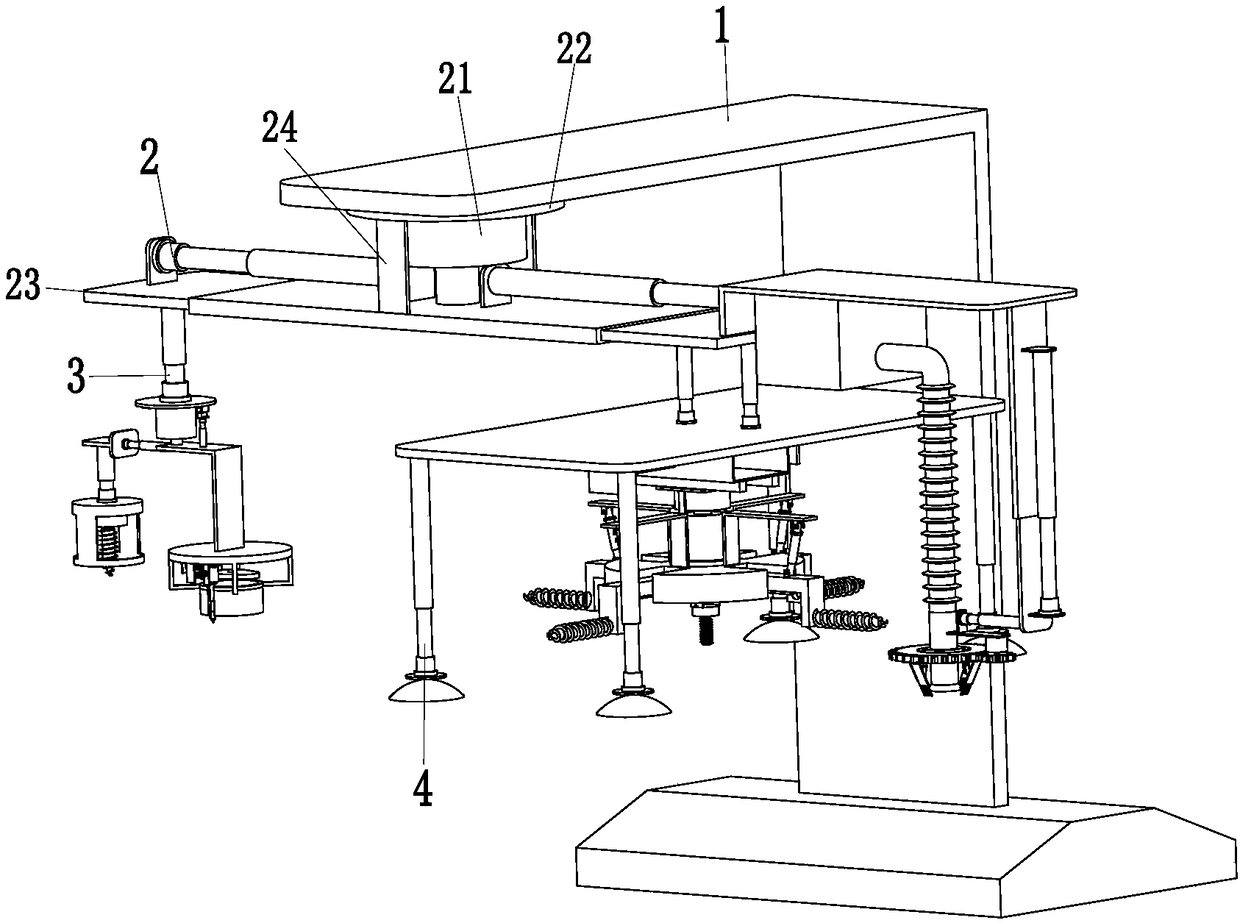

Optical cable gyroscope scale factor temperature modeling method of inertia measurement device

ActiveCN104596545AShort time consumingAccurate modelingMeasurement devicesMeasurement deviceEngineering

The invention provides an optical cable gyroscope scale factor temperature modeling method of an inertia measurement device. A temperature model of an optical cable gyroscope scale factor is obtained by adopting a constant angle calibrating method in a rapid temperature change environment of a temperature box. The method comprises the following steps that firstly, an inertia measurement device is arranged on a rotary platform temperature box by a hexahedron tool so that a tested shaft of a gyroscope is consistent with a rotary platform shaft; low-temperature-point heat preservation is set in the temperature box and the heat preservation time meets a gyroscope optical path temperature to reach heat balance; a rapid temperature rise mode is set by the temperature box from a low temperature point to a high temperature point; the rotary platform is set to a position mode and the rotary platform rotates for integral circles in front and back directions at a constant rotary speed; angle values of all the rotation circles are divided by a pulse increment value output by two times of rotation in the front and back directions of the gyroscope to obtain a scale factor; and a plurality of groups of scale factors under different temperature points are obtained in a rapid temperature rise process of the temperature box, and are subjected to least square fit to obtain a scale factor temperature model. The modeling method has short operation time and an accurate model; and the rapid and accurate modeling of the optical cable gyroscope scale factors in the inertia measurement device can be realized better.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

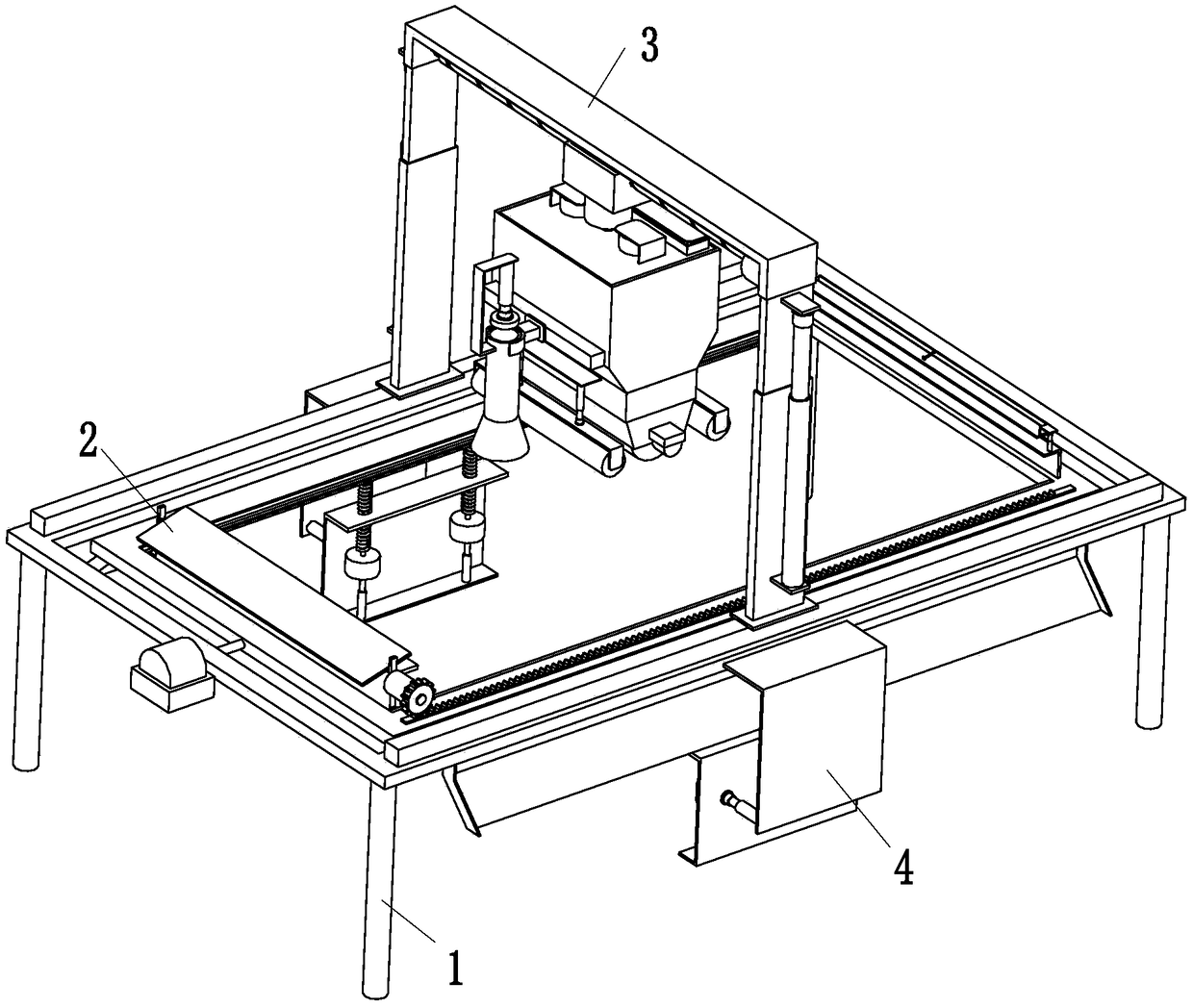

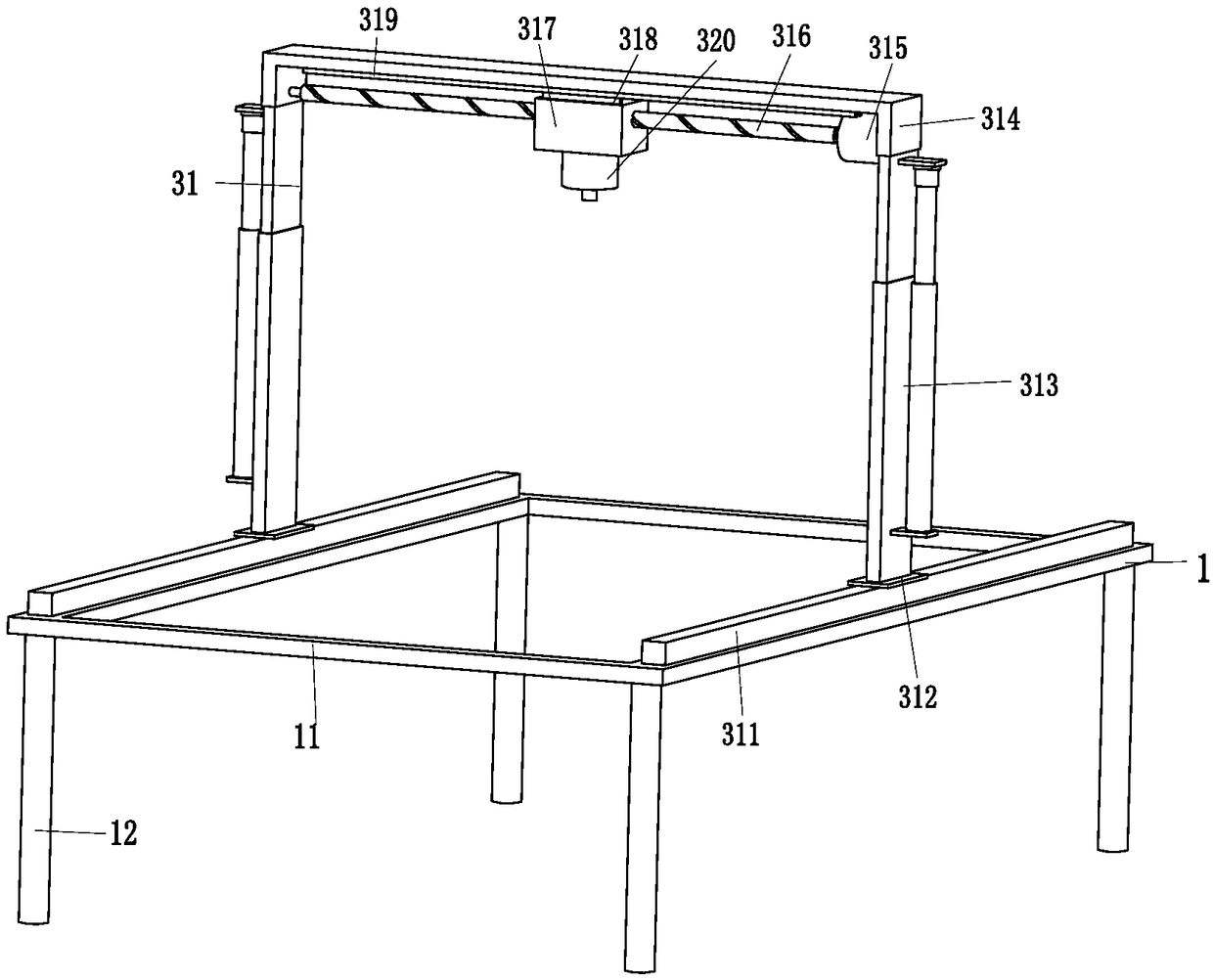

Automatic aluminum-plastic panel drilling and machining system and automatic aluminum-plastic panel drilling technology thereof

ActiveCN108941655AShort costEasy to operateLarge fixed membersOther workshop equipmentMachining systemDrill cuttings

The invention relates to an automatic aluminum-plastic panel drilling and machining system and an automatic aluminum-plastic panel drilling technology thereof. The automatic aluminum-plastic panel drilling and machining system comprises a supporting seat, a rotating device, a marking and boring device and a drilling device; the rotating device is mounted on the front side of the upper end of the supporting seat; the marking and boring device is mounted at the left end of the rotating device; and the drilling device is mounted at the right end of the rotating device. The problems that an existing aluminum-plastic panel drilling process requires manual drilling on an aluminum-plastic panel, personnel are required for marking and boring before drilling, the middle position of the aluminum-plastic panel is not easy to mark by the personnel, the personnel may slightly deviate from the drilling position when drilling with a tool, the personnel need to replace different drill bits for drilling according to different drilling sizes during drilling, the personnel cannot accurately drill into the drilling position when drilling with the tool, drill cuttings generated after the drilling cannot be discharged in time, the time consumed is long, the labor intensity is high, the efficiency is low, and the like can be solved. The functions of automatic marking, boring, drilling and chip removal of the aluminum-plastic panel can be realized.

Owner:深圳市精盛源精密模具有限公司

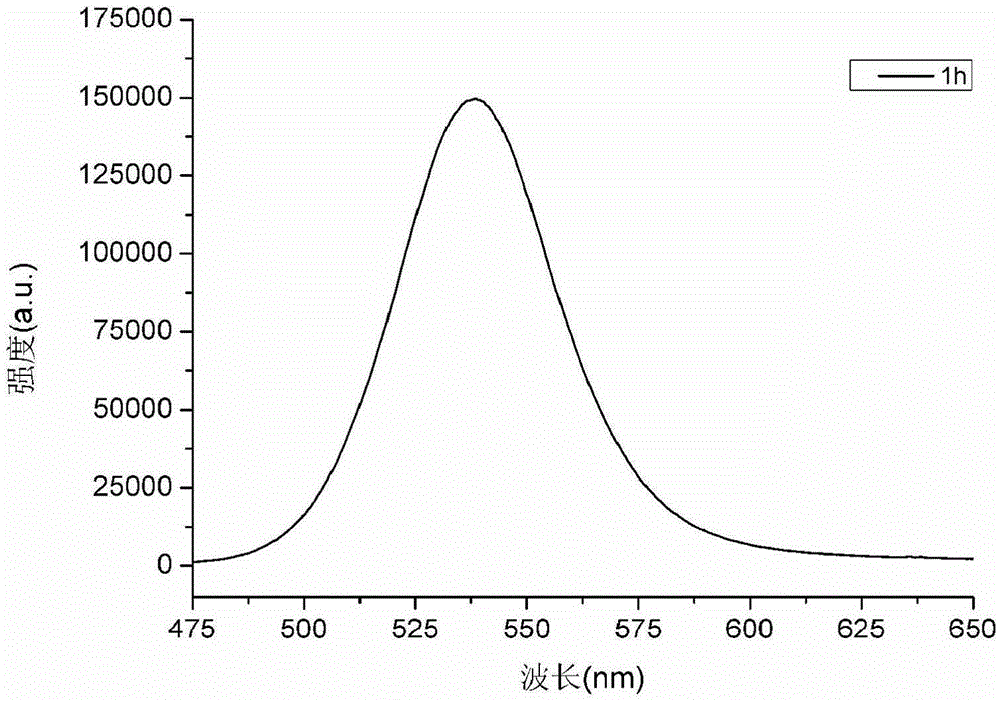

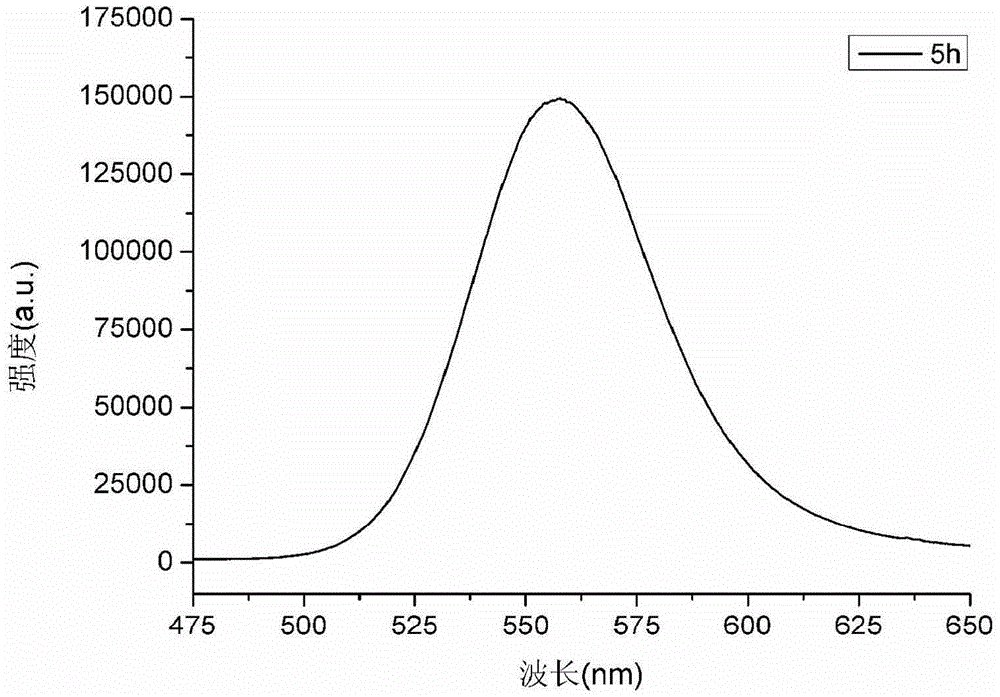

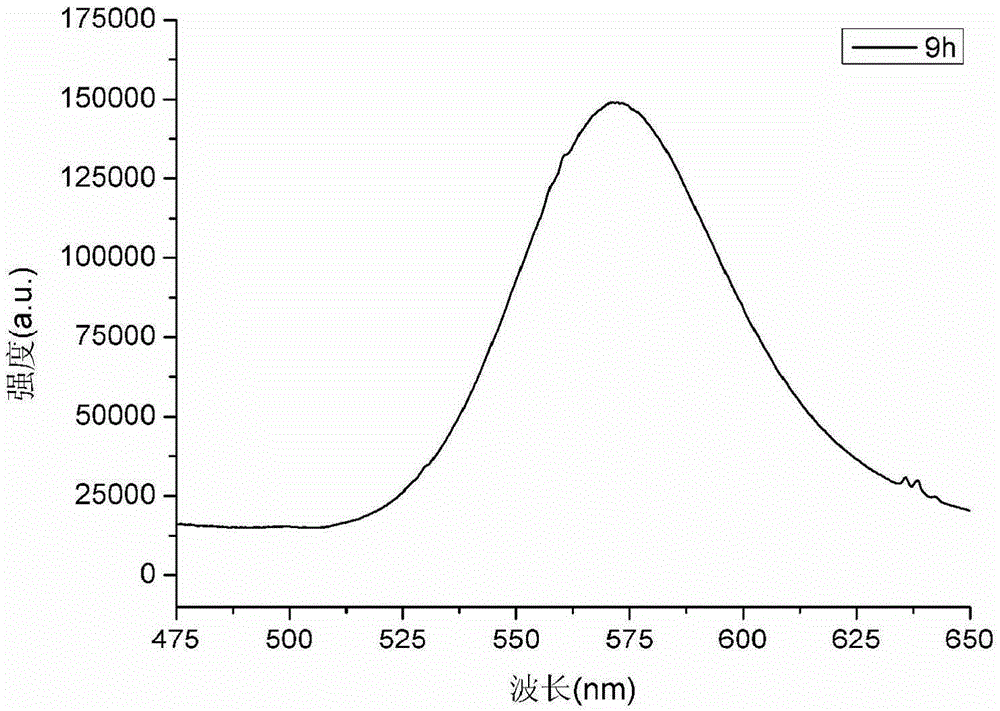

Preparation method of PDMS film with thermosensitivity

InactiveCN105348550AGood film formingGood light stabilityLuminescent compositionsAnhydrous ethanolQuantum dot

A preparation method of a PDMS film with thermosensitivity comprises the following steps: carrying out rotary evaporative concentration on aqueous-phase cadmium telluride quantum dots prepared by a hydrothermal method, carrying out purification treatment by settling with isopropanol, dispersing the purified product in anhydrous ethanol, uniformly dispersing the cadmium telluride quantum dots in a PDMS prepolymer through the affinity interaction between the PDMS prepolymer and aqueous-phase quantum dots, mixing and curing by adding a curing agent, so as to obtain optically transparent PDMS film with thermosensitivity. The raw materials used in the invention are easily available, required experimental equipment is simple, and the technological process is easy to master. By the preparation method, a thermosensitive PDMS film having uniform euphotic layer and with good film-forming ability can be prepared.

Owner:XI AN JIAOTONG UNIV

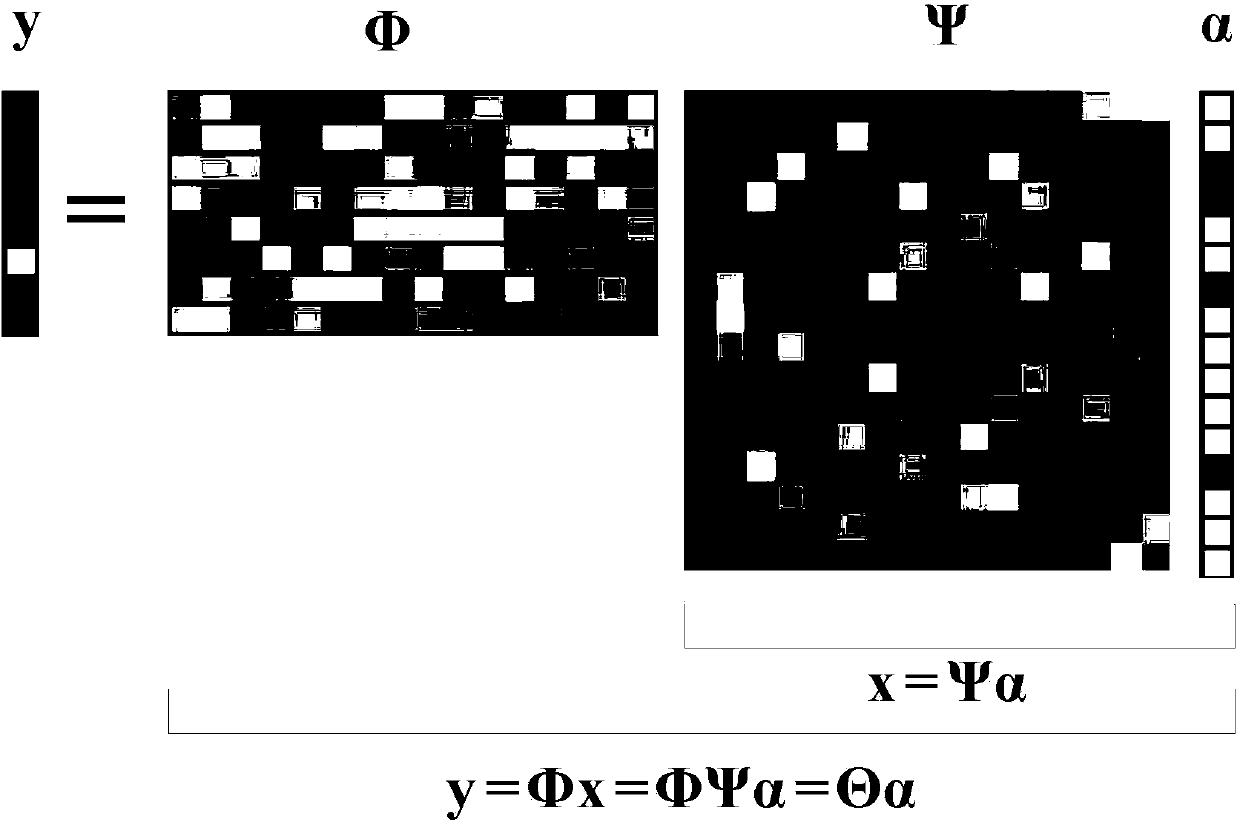

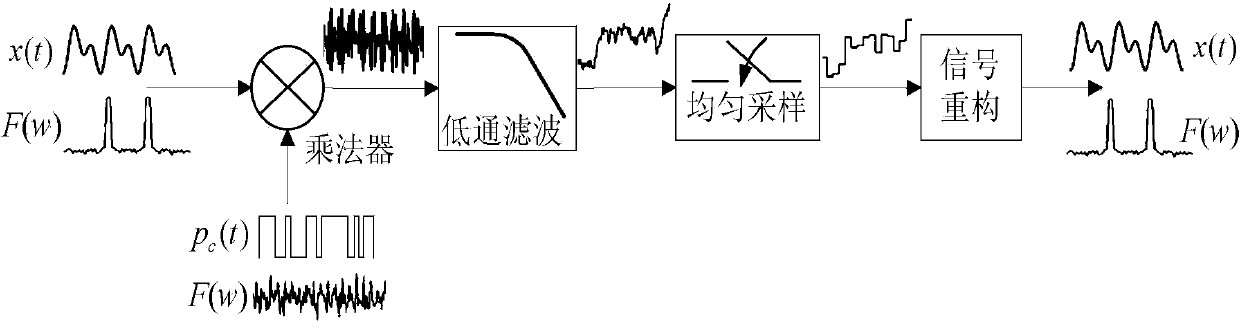

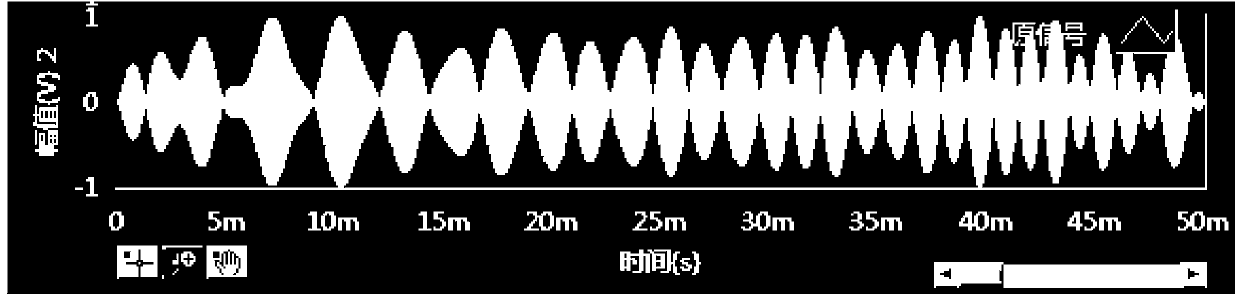

Signal reconstruction method for frequency domain sparse signals

The invention belongs to the technical field of signal processing, and relates to a signal reconstruction method for frequency domain sparse signals. The signal reconstruction method aims to solve the problems that in an existing method, the calculation amount is large, a long time is consumed, a large data memory space is needed, the power consumption is large, the real-time performance is poor and the efficiency is low. According to the signal reconstruction method, based on the symmetry of a discrete Fourier transformation matrix and some characteristics of matrix operation, the method of calculating a sensing matrix in a compressed sensing model is improved, a new method of calculating the sensing matrix is designed and then introduced into fast Fourier transformation, and therefore the calculation amount is decreased and the speed is increased. The signal reconstruction method can be applied to the field of signal processing.

Owner:HARBIN INST OF TECH

Medical orthopedics department back massage device for different parts of human back

InactiveCN107789105AMassage evenlyImprove comfortVibration massageRoller massageHuman bodyMulti site

The invention relates to a medical orthopedic back massage device for different parts of the back of the human body, including a rectification device, a spine massage device, two shoulder massage devices and a neck massage device, and a spine massage device is installed at the rear end of the correction device Two shoulder massage devices are installed symmetrically on the upper side of the left and right ends of the correction device, and a neck massage device is installed on the upper end of the correction device. The present invention can solve the problem that in the existing massage process, massagers need to massage the parts of the human body one by one. The process is cumbersome and complicated. During the massage process, the personnel need to use force to massage various parts of the human body. Too much force or too little force will affect the actual effect of massage , People can only do a small range of movements in the designated position during massage. People may not be able to massage while correcting their back. The manual massage process takes a long time, labor intensity is high and efficiency is low. It can be realized on the human body at the same time. Multi-part massage function.

Owner:储高鹏

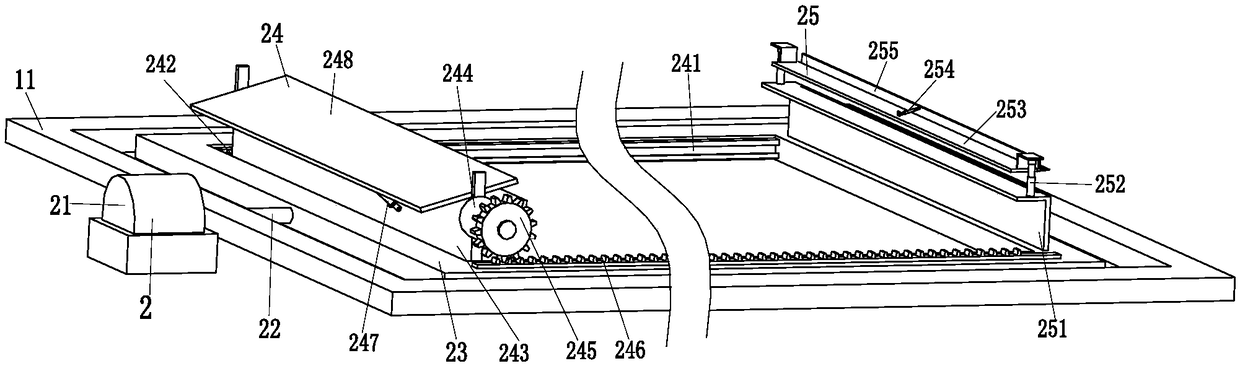

Aluminum-plastic panel coating processing system and aluminum-plastic panel coating technology

ActiveCN108816638AEasy to operateShort costLiquid surface applicatorsSpraying apparatusAluminiumEngineering

The invention relates to an aluminum-plastic panel coating processing system and an aluminum-plastic panel coating technology. The system comprises a support, a hold-down gear, a coating device and two discharging devices. The coating device is installed at the upper end of the support; the hold-down gear is arranged below the coating device; the hold-down gear is installed on the support; and left and right ends of the support are provided with the two discharging devices. In existing coating process, aluminium strips in coils need to be firstly fixed and then manually coated, and the processis tedious and complicated; existing equipment cannot stably fix the aluminium strips in coils and the aluminium strips in coils are not easy to stay in a tighten state for a long time; it is required to coat with various coatings of required thickness during coating; manual coating is not uniform, and residual coatings cannot be recovered timely; concave positions of a coating cannot be filled or leveled up timely; time consumption is high; labor intensity is high; and efficiency is low. By the use of the system and the technology of the invention, the above problems can be solved, and the function of automatically clamping and coating the aluminium strips in coils can be achieved.

Owner:力同铝业(山东)有限公司

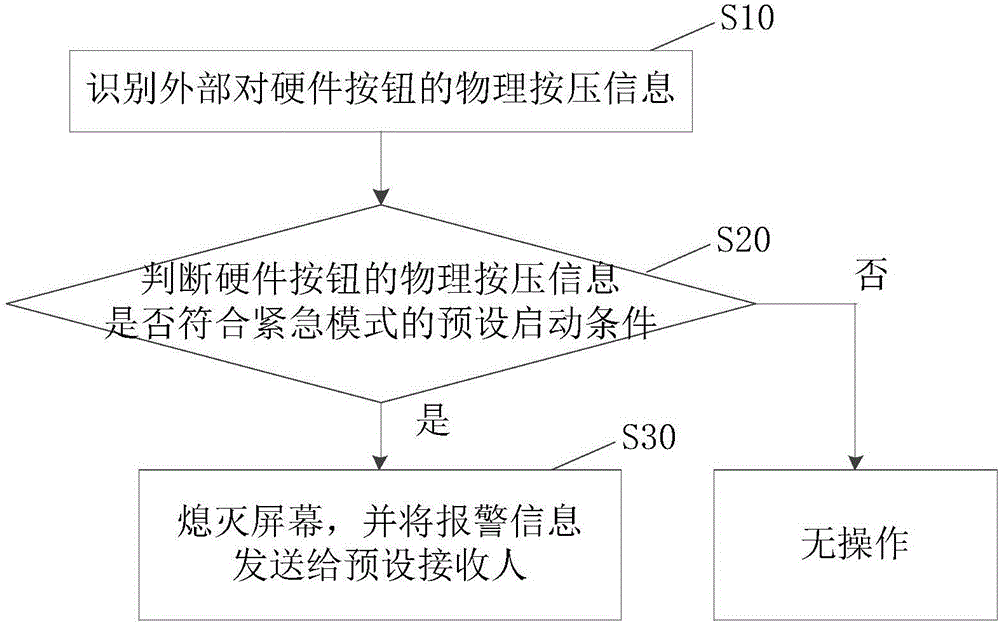

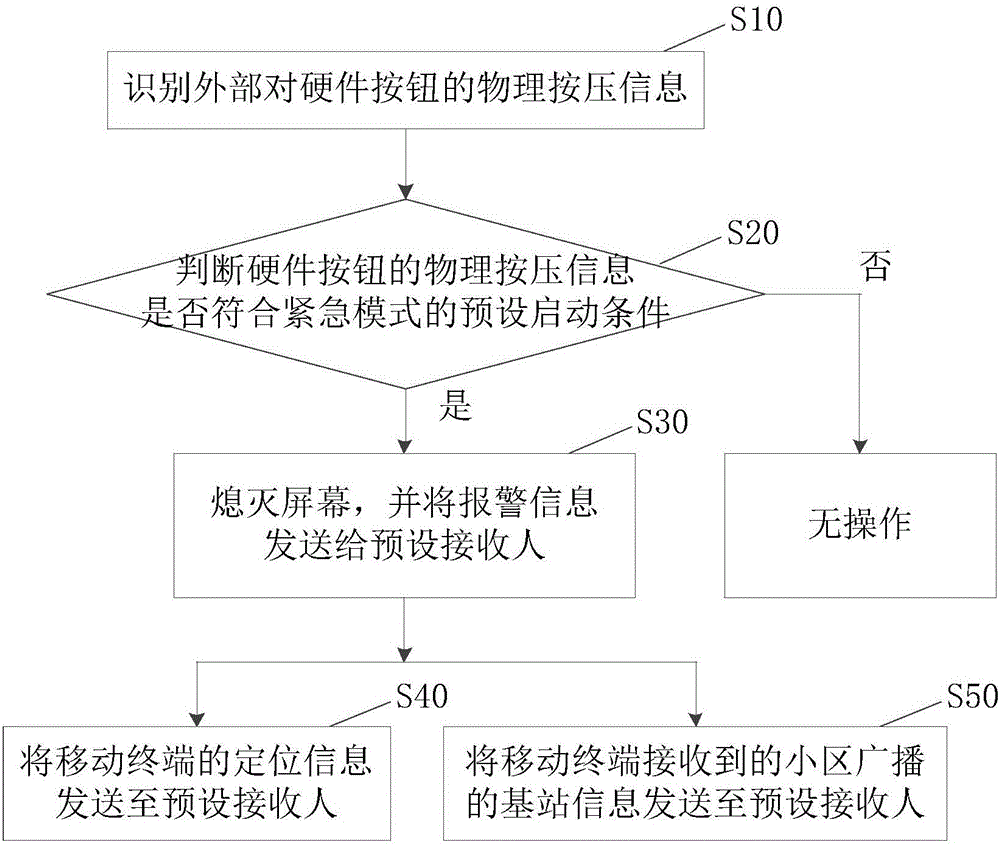

Method and device for alarming through mobile terminal, and mobile terminal

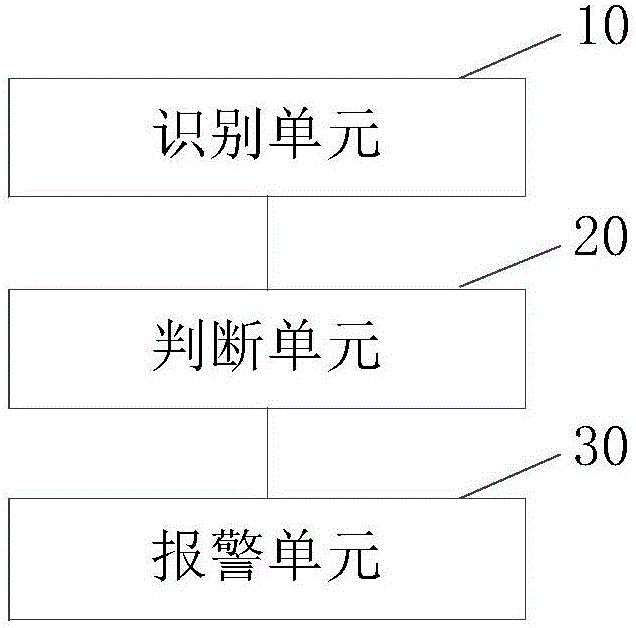

InactiveCN105898052AReduce threat levelAlarm behavior is stealthySubstation equipmentComputer terminalComputer science

The invention discloses a method and a device for alarming through a mobile terminal, and a mobile terminal. The mobile terminal includes hardware buttons. The method comprises the following steps: identifying external physical pressure information of the hardware buttons; judging whether the physical pressure information of the hardware buttons meets the starting conditions in an emergency state; and if the physical pressure information of the hardware buttons meets the starting conditions in an emergency state, putting out the screen, and sending alarm information to a default recipient. The alarm information is sent to the default recipient under the condition that the screen of the mobile terminal is put out, there is neither bright screen nor the behavior of looking down on a mobile phone to draw the attention of kidnappers, the alarming behavior is relatively hidden, and the degree of threat of the site to the personal safety is reduced. Alarm information can be sent to a default recipient through a predetermined button or a combination of predetermined buttons, the process is simple and takes a short time, and people can seek help easily.

Owner:LETV HLDG BEIJING CO LTD +1

Building external wall decorating material construction device capable of automatically smoothening and caulking cement fiber board

InactiveCN108035523AGuaranteed smoothnessEnsure safetyBuilding constructionsFiberArchitectural engineering

The invention relates to a building external wall decorating material construction device capable of automatically smoothening and caulking a cement fiber board. The building external wall decoratingmaterial construction device comprises a movable platform, a smoothening marking device and a caulking device, the smoothening marking device is mounted at the front end of the movable platform, and the caulking device is mounted at the rear end of the movable platform. The building external wall decorating material construction device can solve the problems that an external wall needs to be manually smoothened and marked and panels need to be manually caulked in an existing cement external wall hanging board mounting process, staff needs to perform smoothening and marking treatment by the aidof a ladder when the external wall is smoothened and marked, the staff needs to manually move the ladder and then climb again to perform operation when a next position is smoothened, the ladder is unstable, the staff possibly falls down to cause potential safety hazards, the staff needs to perform caulking, rolling and scraping during caulking, gaps are not easily filled with glue in manual caulking, manual rolling depression is uneven, the glue cannot be completely shoveled off and the like. The external wall can be automatically smoothened, and the space among the panels can be caulked.

Owner:刘静

Battery machining robot

ActiveCN108466273ANo manual operationEasy to operatePrimary cell manufactureAssembling battery machinesButton batteryBlurred vision

The invention relates to a battery machining robot. The battery machining robot comprises an adjusting device, a two-way telescopic plate, two symmetric air cylinders, a button battery clamping deviceand a cylindrical battery clamping device; the front end of the adjusting device is installed at the upper end of the two-way telescopic plate, the two symmetric air cylinders are installed in the middle of the two-way telescopic plate, and the top ends of the symmetrical air cylinders are installed at the outer ends of the two-way telescopic plate through flanges; and the button battery clampingdevice is installed on the right side of the lower end of the two-way telescopic plate, and the cylindrical battery clamping device is installed on the left side of the lower end of the two-way telescopic plate. According to the battery machining robot, the problems that in the present process of producing batteries, people need to grab the different types of batteries, when the button battery isgrabbed, due to the fact that the button battery is relatively small, jumping and flying of the button battery are prone to occurrence during grabbing by people, and people possibly have blurred vision and then miss grabbing the button battery during long-term grabbing, and in addition, when a cylindrical battery is grabbed, people usually grab the middle part of the cylindrical battery, and thenthe grabbed cylindrical battery possibly falls off due to sweating of hands can be solved.

Owner:JIAXING HENGWEI BATTERY

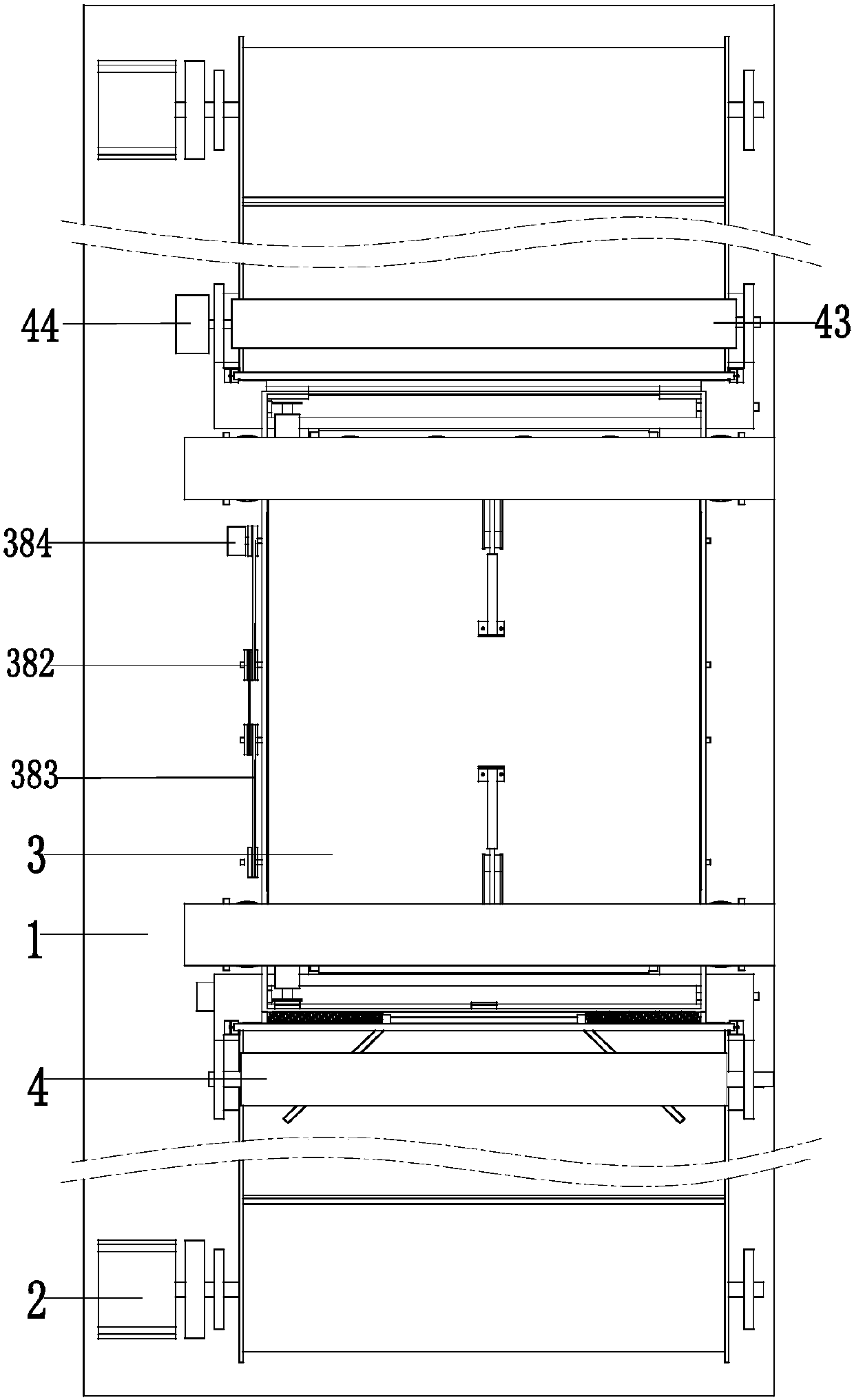

Automatic sweeping equipment for stepping type escalator

ActiveCN106984593ANo manual operationShort time consumingFlexible article cleaningCleaning using toolsProtective glassesEngineering

Owner:聊城赛大工业设计有限公司

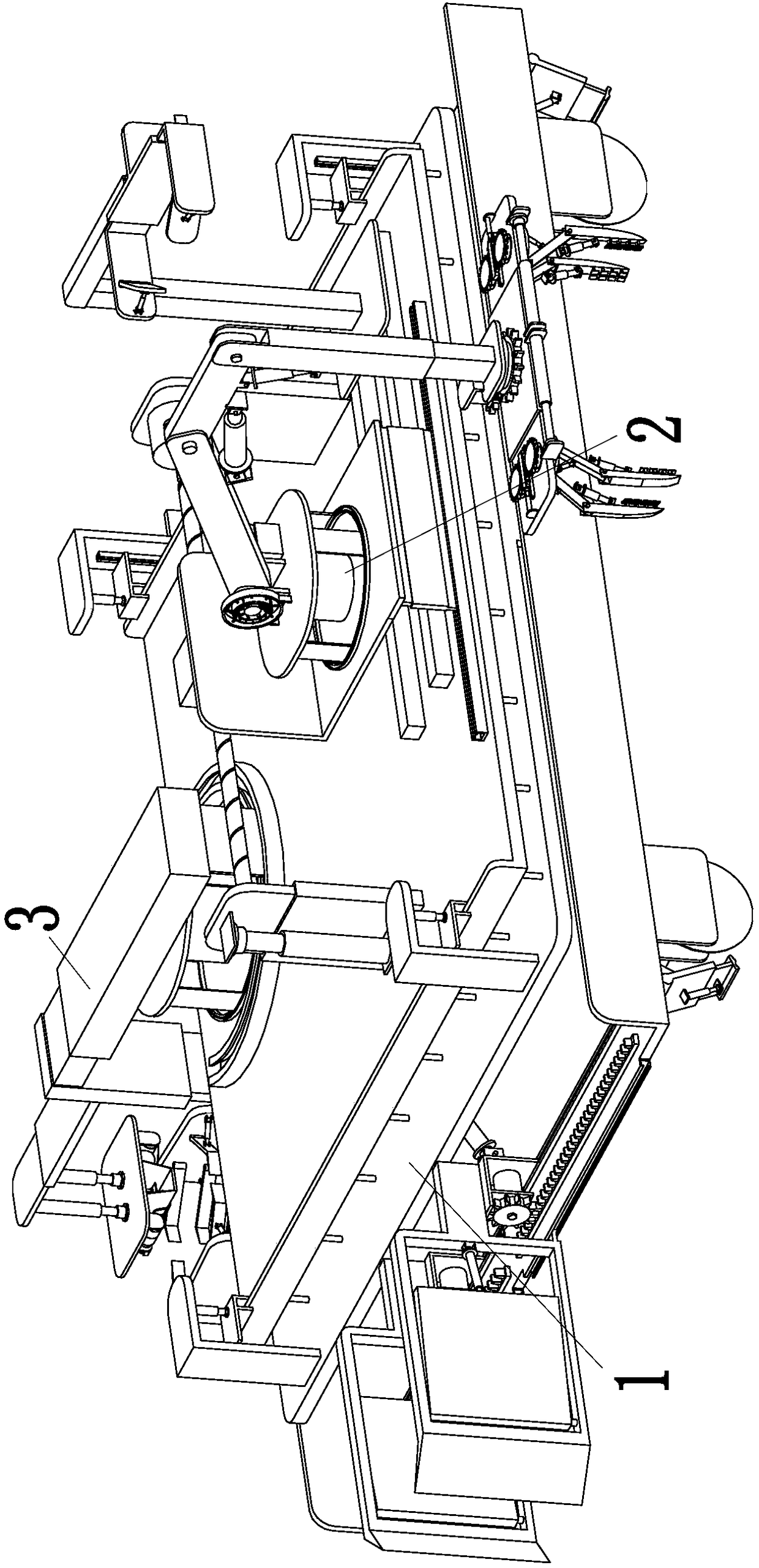

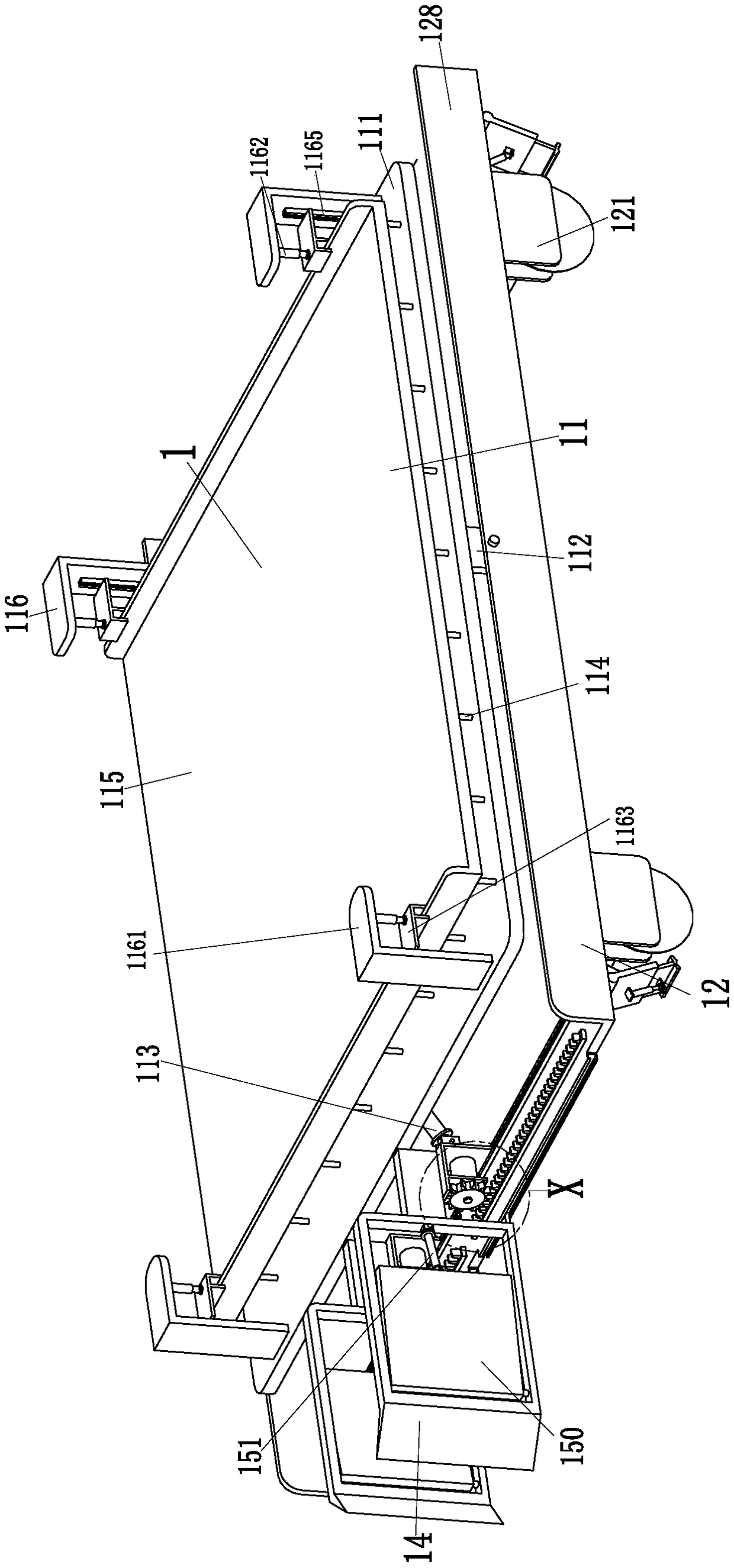

Unmanned storage logistics robot capable of achieving full-automatic moving, stacking and bar code sticking

InactiveCN108146950AEnsure safetySave spaceStorage devicesConveyor partsEngineeringMechanical engineering

The invention relates to an unmanned storage logistics robot capable of achieving full-automatic moving, stacking and bar code sticking. The robot comprises a moving device, a stacking device and a bar code sticking device. The stacking device is installed on the right side of the upper end of the moving device, and the bar code sticking device is installed on the left side of the upper end of themoving device. The problems that in existing storage logistics, workers need to stack cargos and stick bar codes to cargos respectively, workers possibly need to place cargos to designated positionsthrough ladders during stacking, workers need to rotate directions to stick bar codes to cargos in an aligned mode during bar code sticking, a cart is needed by workers to assist in cargo transportation and is likely to collide cargos since the warehouse area is not large during carrying, meanwhile, the cart cannot turn since the area is not large enough during turning so as to affect later-periodwork, the cart affects work of the device due to inclination when moving uphill and downhill, the time consumed in the process is long, and the labor intensity is large are solved, and the functionsof automatic moving, stacking and bar code sticking in a warehouse can be achieved.

Owner:刘静

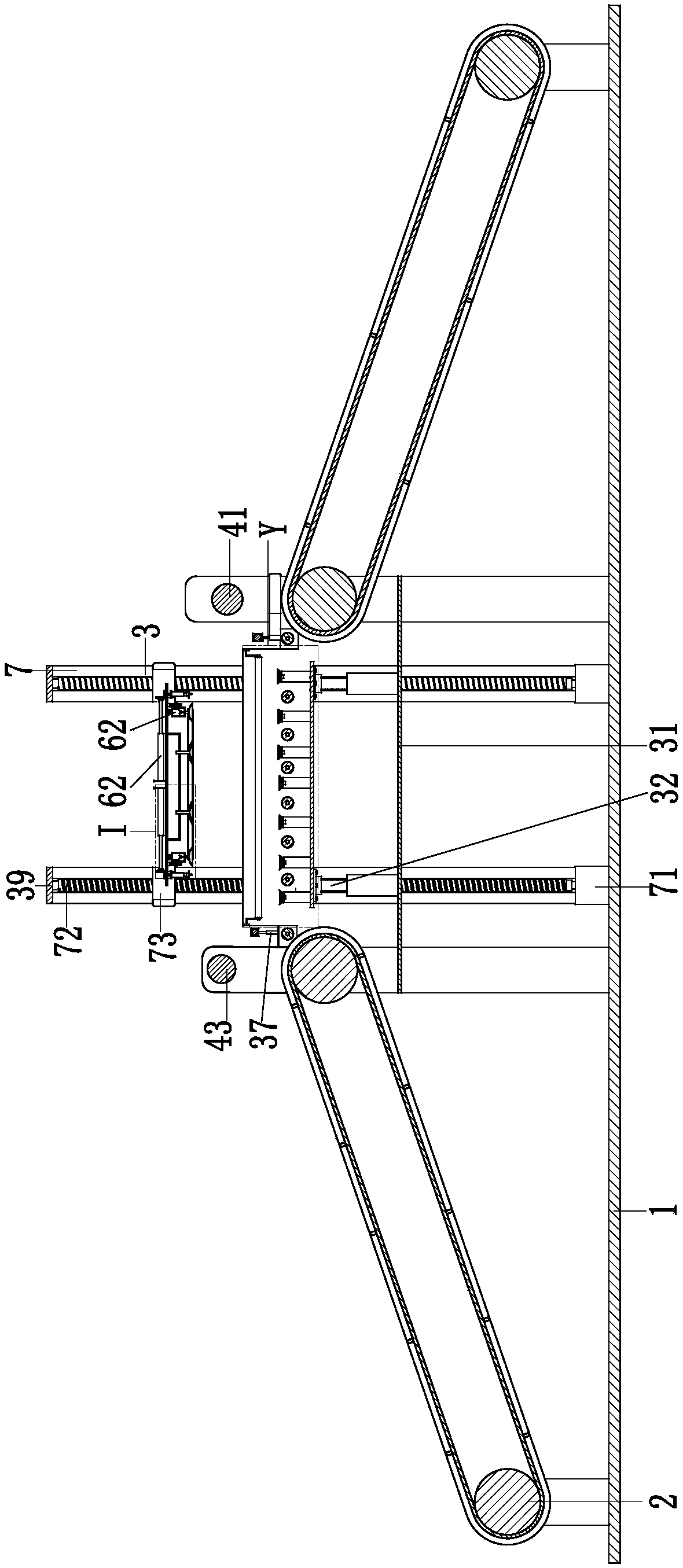

Automatic laminating processing equipment of container house flat color steel plate

ActiveCN107757045AHigh precisionImprove stabilityLamination ancillary operationsLaminationSteel platesEngineering

The invention relates to automatic laminating processing equipment of a container house flat color steel plate. The automatic laminating processing equipment of the container house flat color steel plate comprises a bottom plate; two conveying devices are symmetrically arranged on the bottom plate; a winding device is arranged between the two conveying devices; a conveying and laminating device isarranged between the two conveying devices; and the two conveying devices, the winding device and the conveying and laminating device are cooperatively used to finish the automatic laminating processof the color steel plate. The automatic laminating processing equipment of the container house flat color steel plate can solve the problems that the existing flat color steel plate laminating equipment cannot laminate the upper end and the lower end of the flat color steel plate in the laminating process of the existing flat color steel plate, the flat color steel plate is liable to move under the action of an external force in laminating processing process of the existing laminating processing equipment by the flat color steel plate laminating equipment, the flat color steel plates with different sizes need to be adjusted manually during laminating processing, the precision degree is slow, the labor intensity is large, the time consumption is high, the stability is low, the working efficiency is low and the like, and can realize the function of automatically laminating the container house flat color steel plate.

Owner:新沂市新南环保产业技术研究院有限公司

Disposable syringe medical treatment apparatus

The invention relates to a disposable syringe medical treatment apparatus. The disposable syringe medical treatment apparatus comprises a main box, a needle cylinder separating device and a needle head cutting device, the needle cylinder separating device is installed at the upper end of the main box, and the needle head cutting device is installed at the rear end of the main box. The disposable syringe medical treatment apparatus can solve the problems that by means of an existing damaging type syringe, a needle cylinder needs to be manually separated from a needle head, then the needle headis pinched off, when the syringe is separated, all parts need to be separated after the syringe is manually limited, when the needle head is separated, the chance is that the potential safety hazard is caused when the hand is punctured by the needle head due to misoperation, the manual separating efficiency is low, a piston part in the needle cylinder needs to be manually taken out, since the needle cylinder is small in size, manual separation is not easy, when the needle head is pinched off, since the needle head is fine and small, manual pinch-off is not easy, the time consumed in the process is long, the labor intensity is large, and the efficiency is low; the functions of targetedly separating a disposable needle cylinder and cutting the needle head can be achieved.

Owner:绍兴集知汇信息科技有限公司

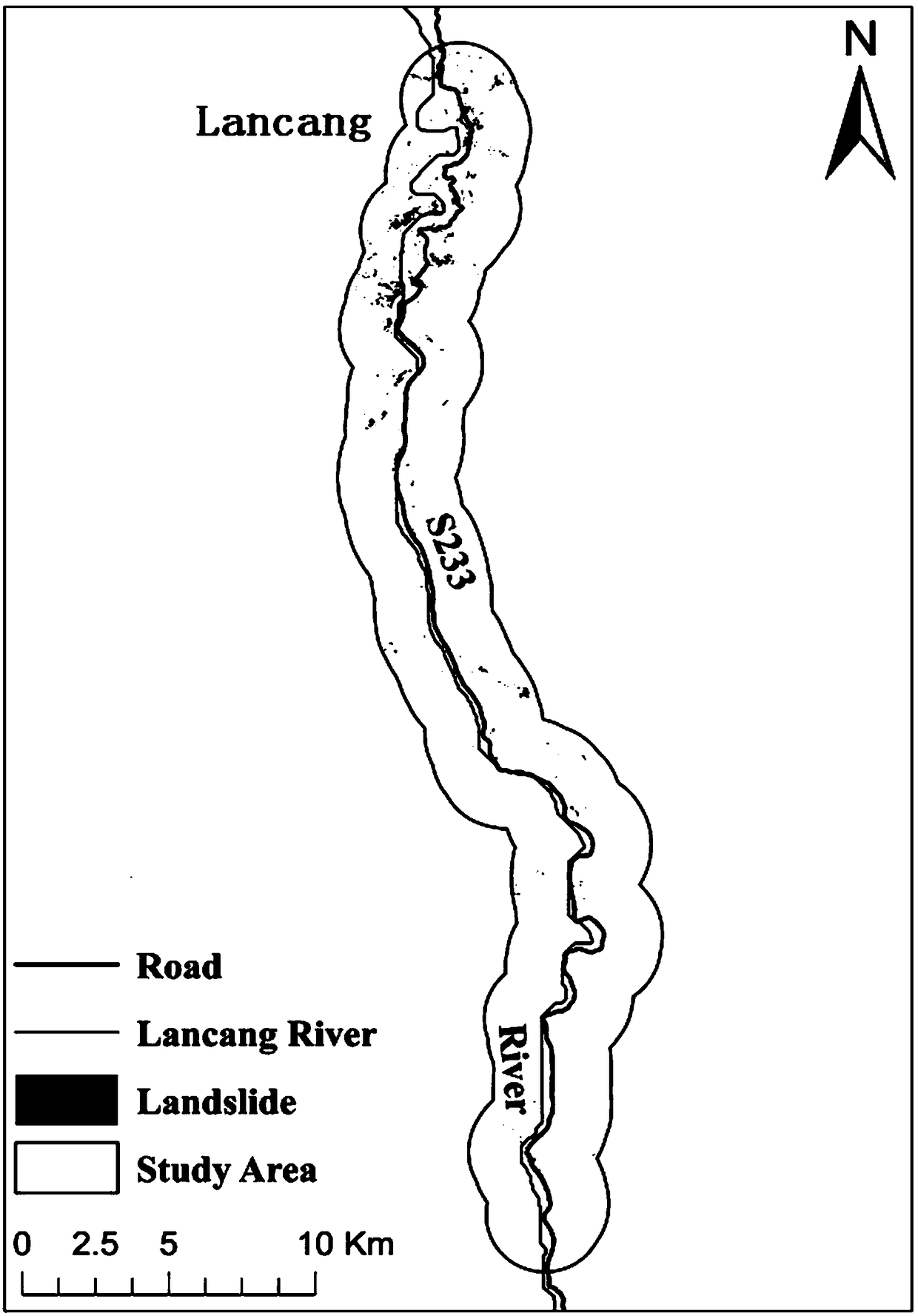

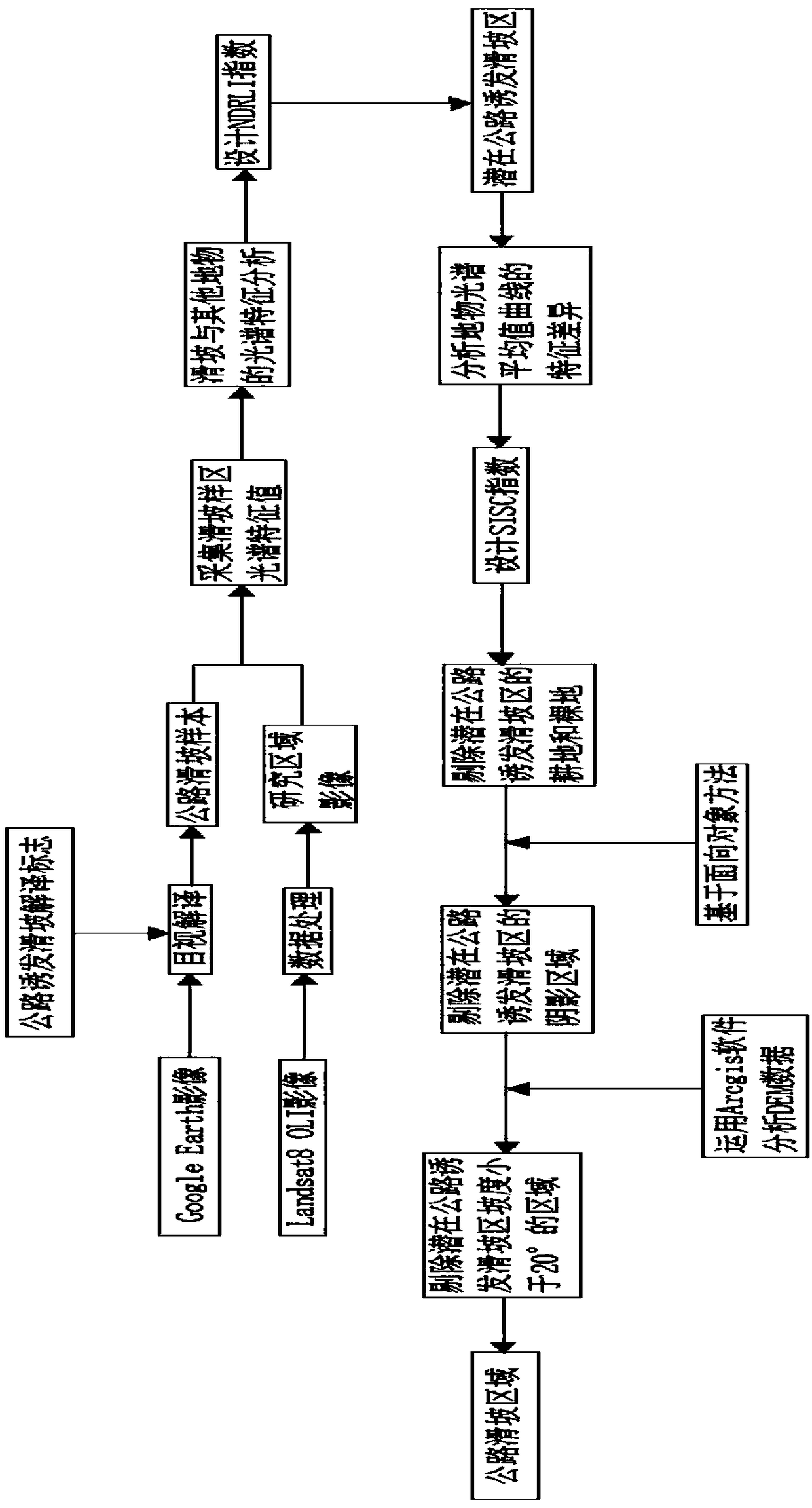

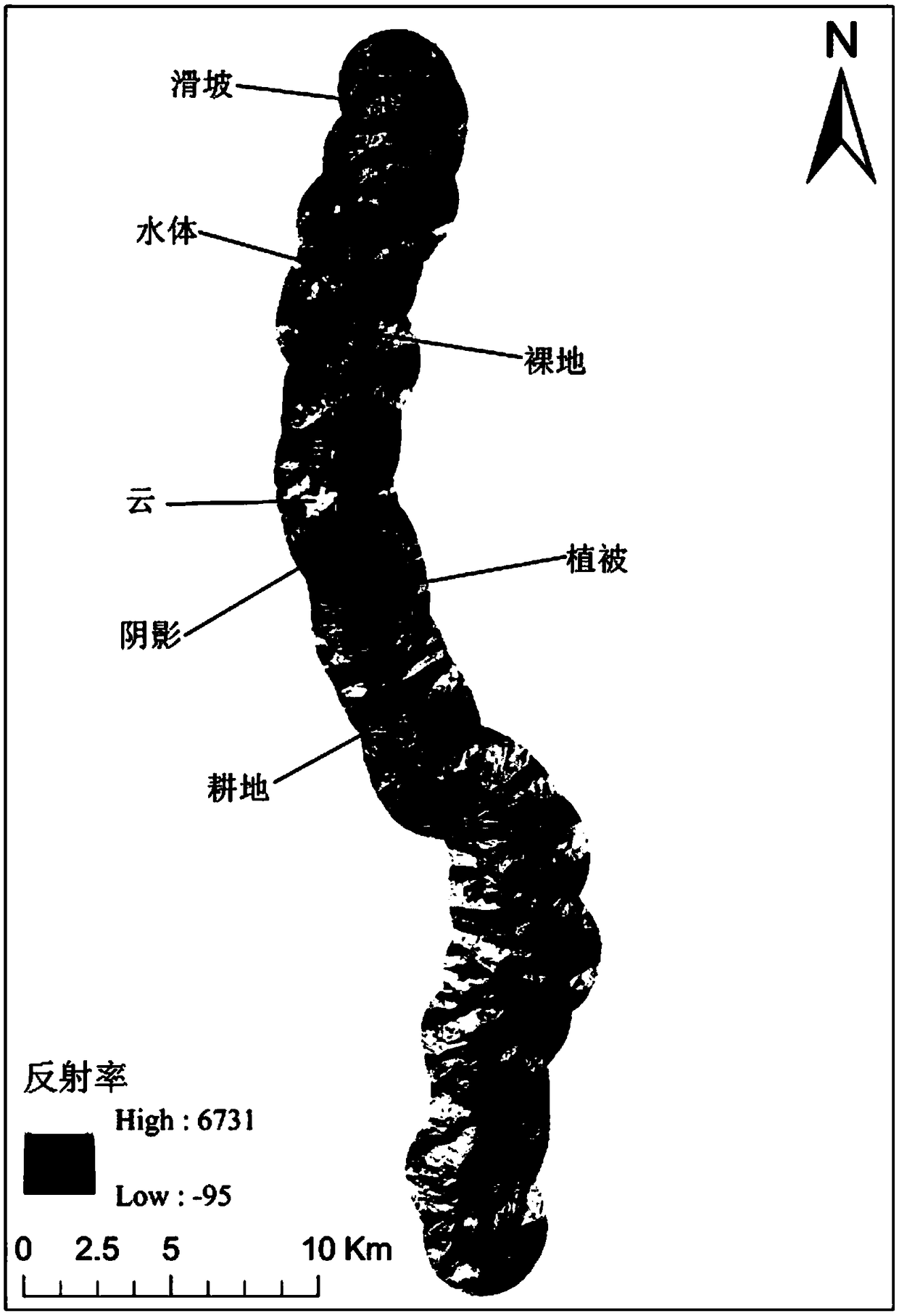

Fast extraction method of highway landslide area

The invention relates to the technical field of landslide research, in particular to a fast extraction method of a highway landslide area. The fast extraction method includes: acquiring a highway landslide sample and a study area image; acquiring a landslide sample area spectrum characteristic value; designing a new remote sensing index NDRLI; determining a potential highway-induced landslide area; designing a spectral curve shape index SISC; eliminating the water, cultivated lands, bare lands, shadow areas, building lands and land features with the slope less than 20 degrees in the potentialhighway-induced landslide area; and finally obtaining the highway landslide. Compared with the existing common methods, the invention has the advantages of small workload, short consumption time, highefficiency, easy data acquisition and high classification accuracy, provides a scientific basis for studying and analyzing the landslide disaster along the highway, and has the prospect of large-scale promotion and application.

Owner:GUANGXI TEACHERS EDUCATION UNIV

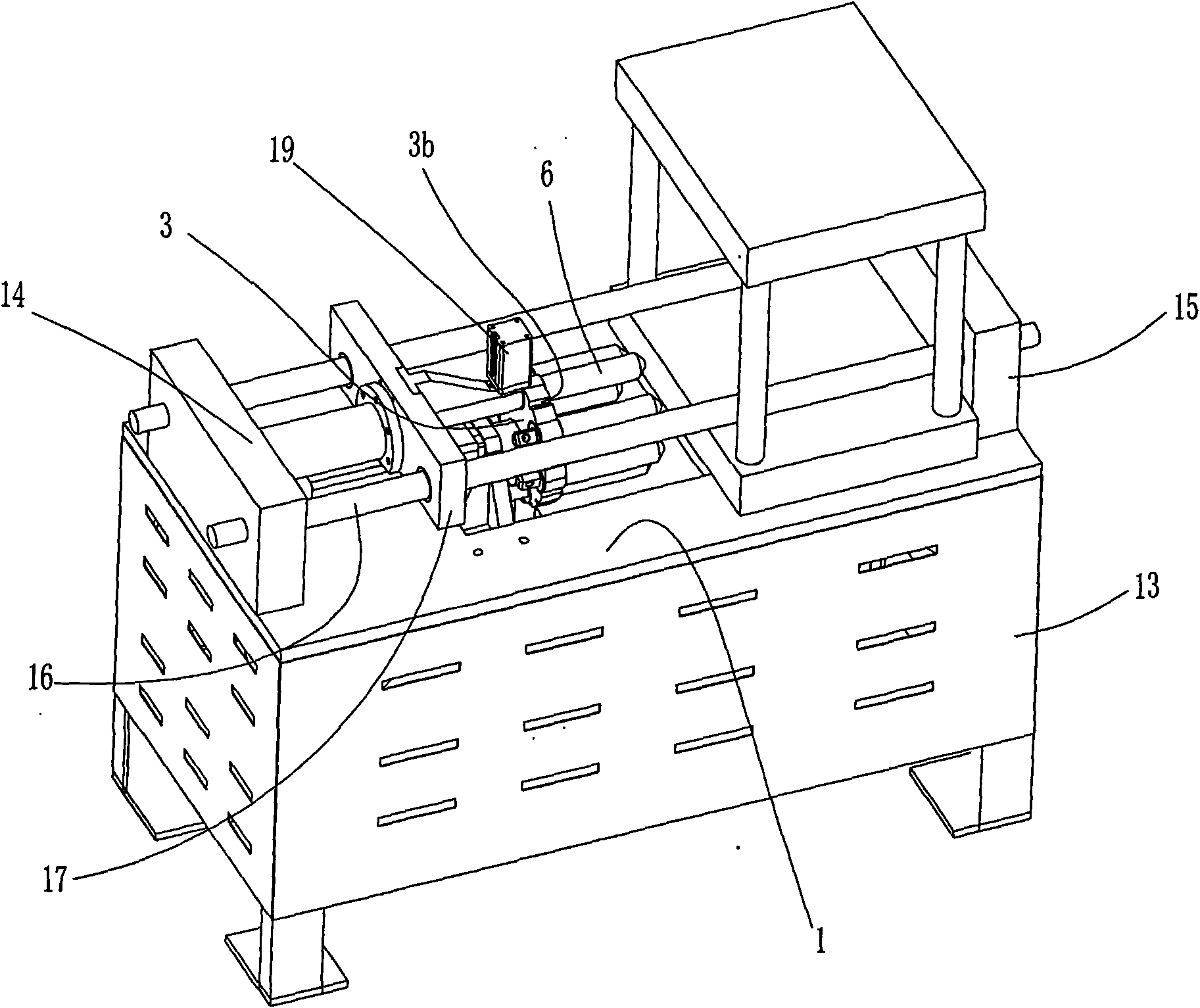

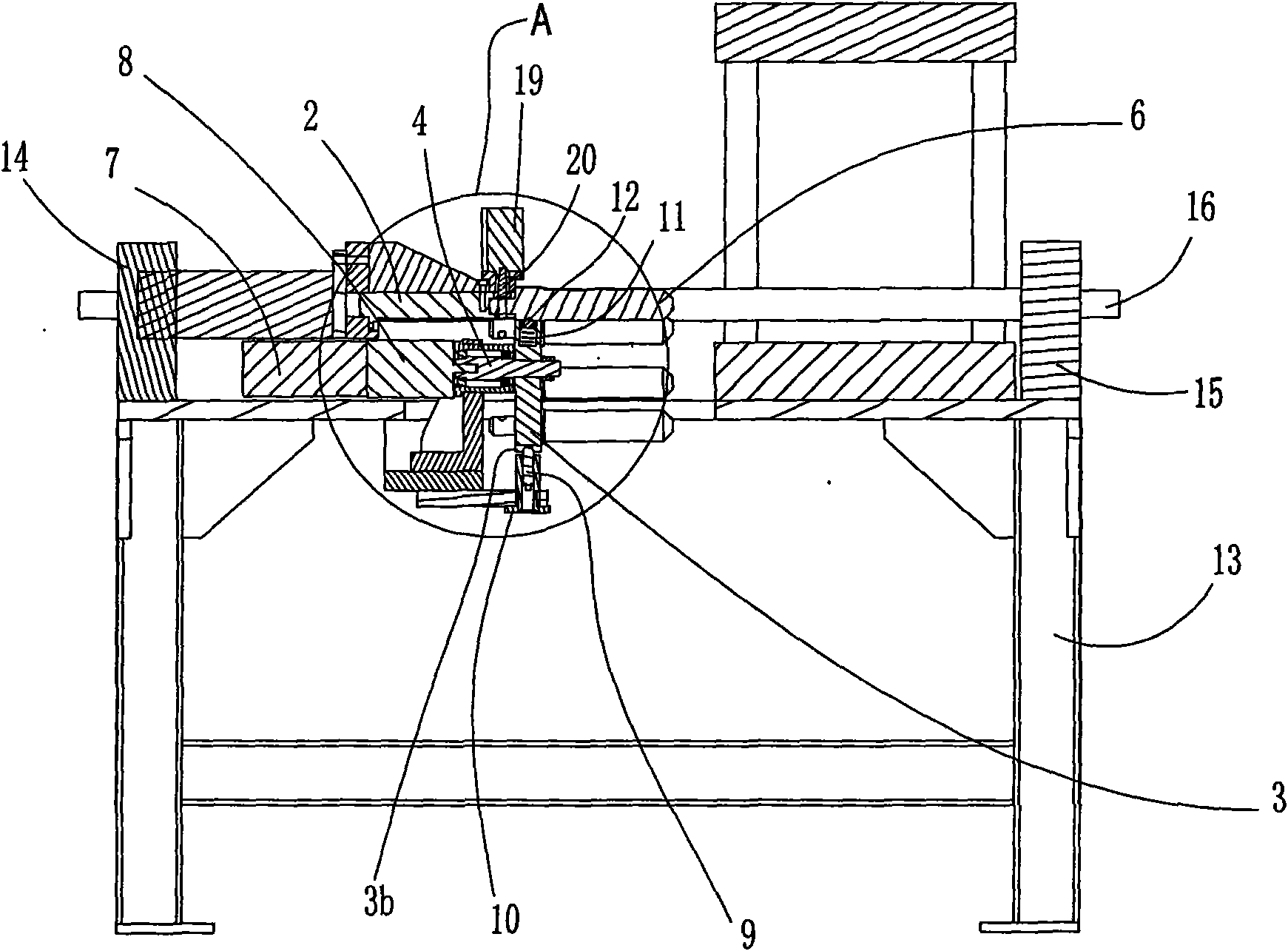

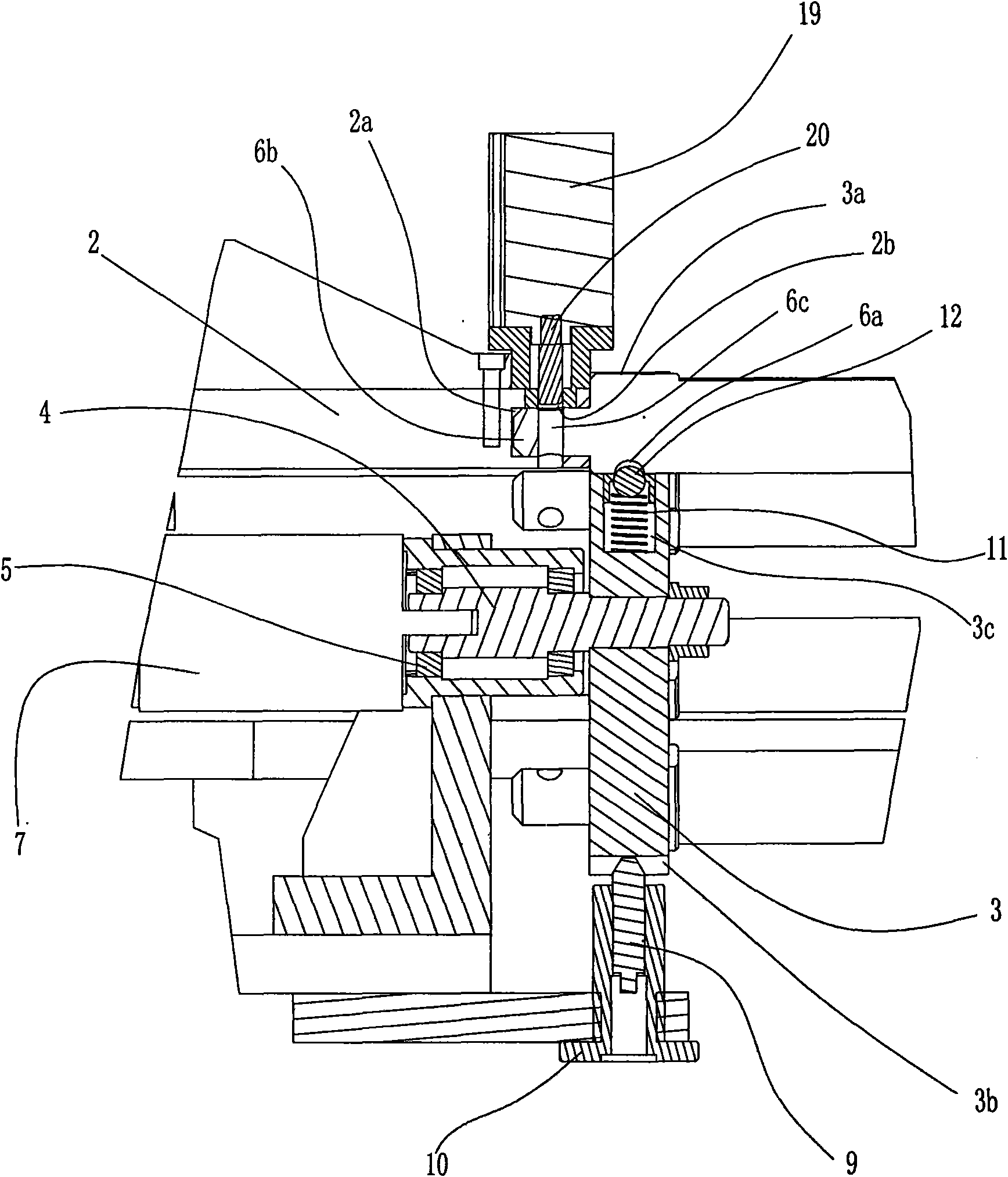

Turntable type automatic tube expander

The invention discloses a turntable type automatic tube expander, which comprises a stander, a tube blank fixing mechanism arranged at one end of the stander, a tube expanding head driving device fixedly arranged at the other end of the stander, and a push rod connected with the tube expanding head driving device, wherein a round turntable is arranged between the tube blank fixing mechanism and the tube expanding head driving device, the center of the round turntable is fixedly connected with one end of a center shaft, and the other end of the center shaft is sleeved with a bearing fixed on the stander; and the turntable is provided with at least two tube expanding head fixing holes which are positioned on a concentric circle which intersects with the extending part of the push rod and takes the center of the round turntable as the center of a circle, a tube expanding head required by tube blank processing is movably inserted in the tube expanding head fixing holes, and the head of the push rod and the tail of the tube expanding head are provided with connecting mechanisms matched with each other. Compared with the prior art, the turntable type automatic tube expander has the advantages of simple and reasonable structure, less floor space and high working efficiency.

Owner:NINGBO SHUNJIANG AUTO PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com