Turntable type automatic tube expander

A pipe expanding machine and a rotary table type technology, which is applied in the field of pipe expanding machines, can solve the problems of large area of the pipe expanding machine, reduced production efficiency, long time required, etc., and achieves easy implementation, improved work efficiency, and short time consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

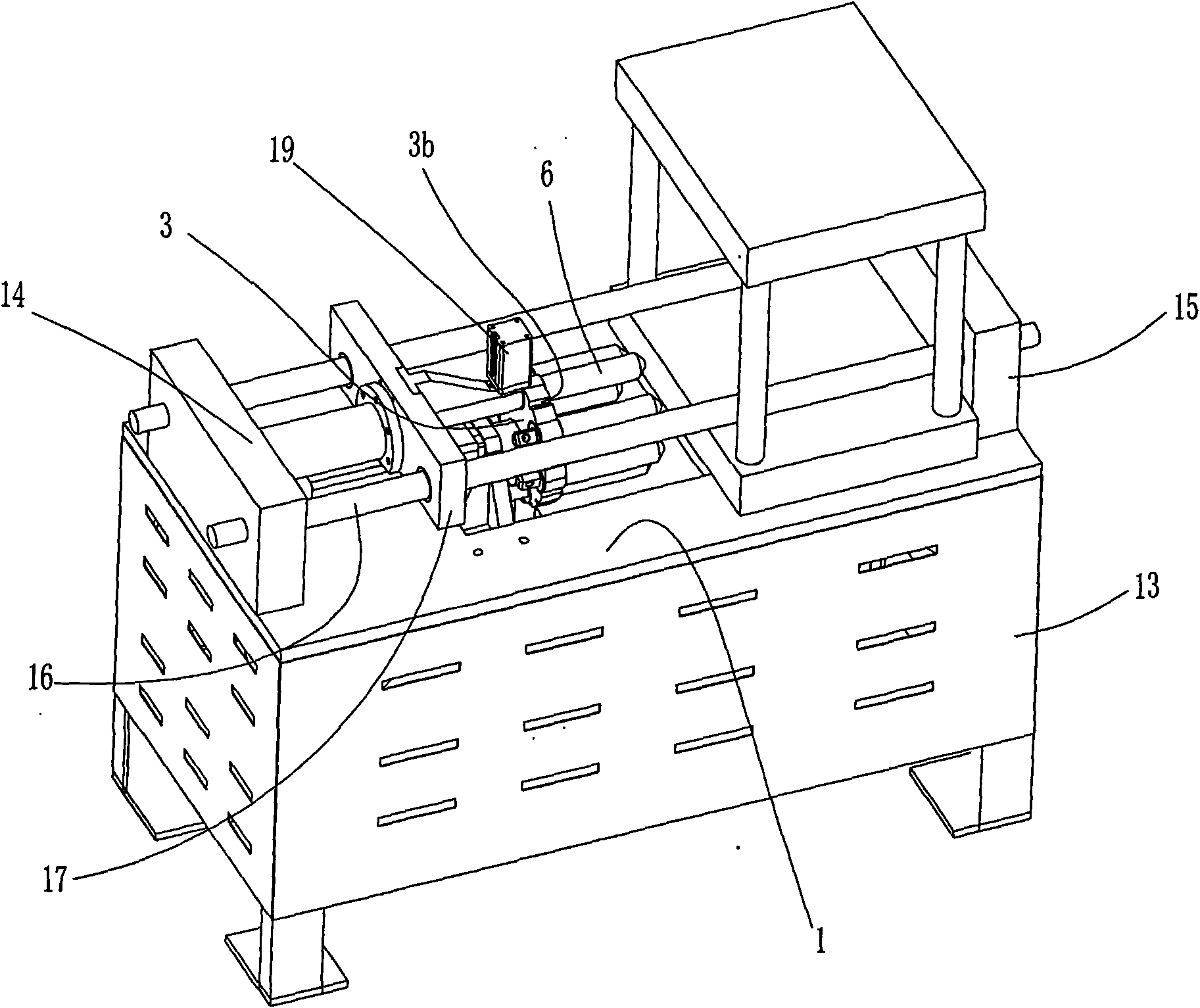

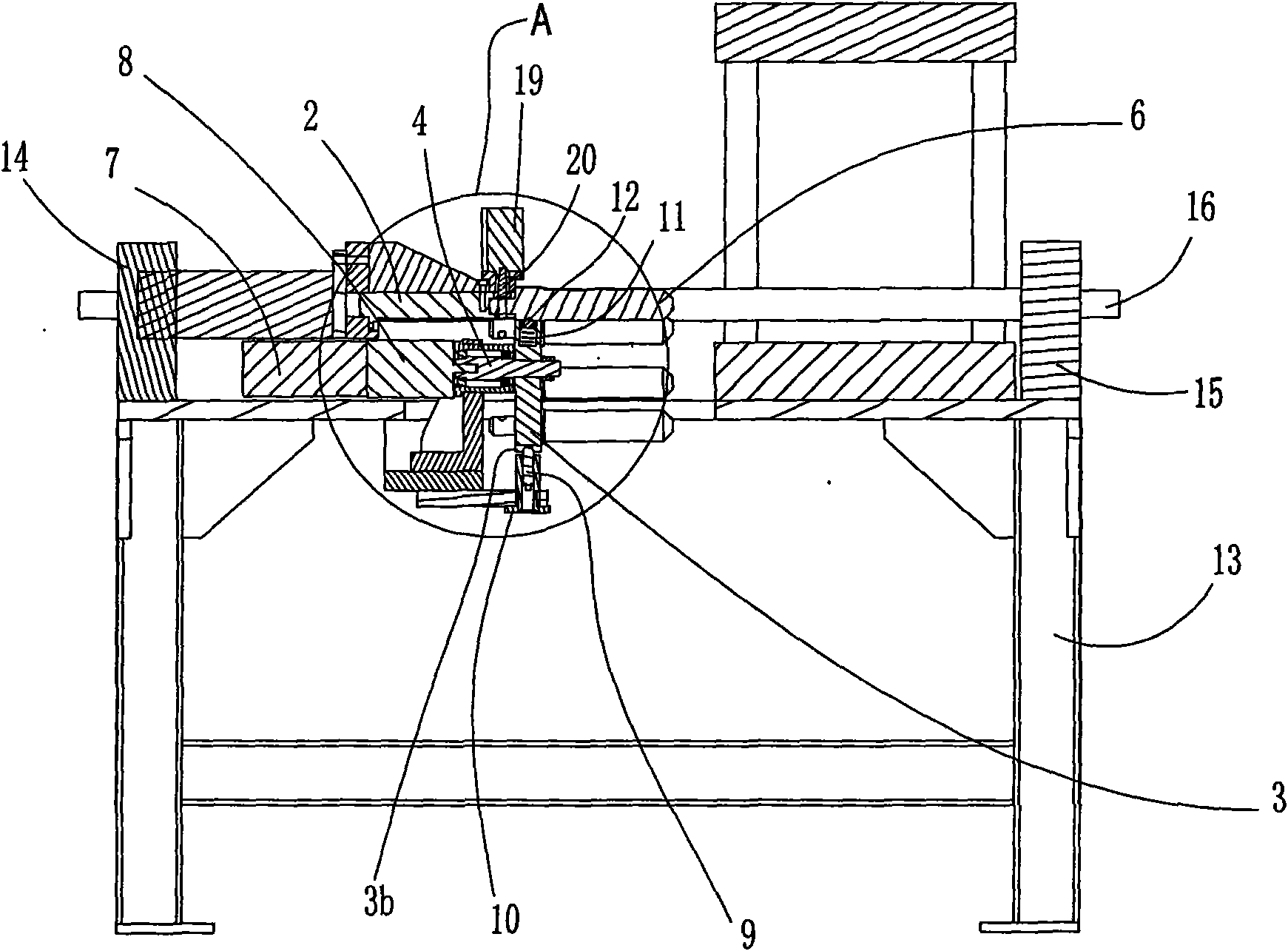

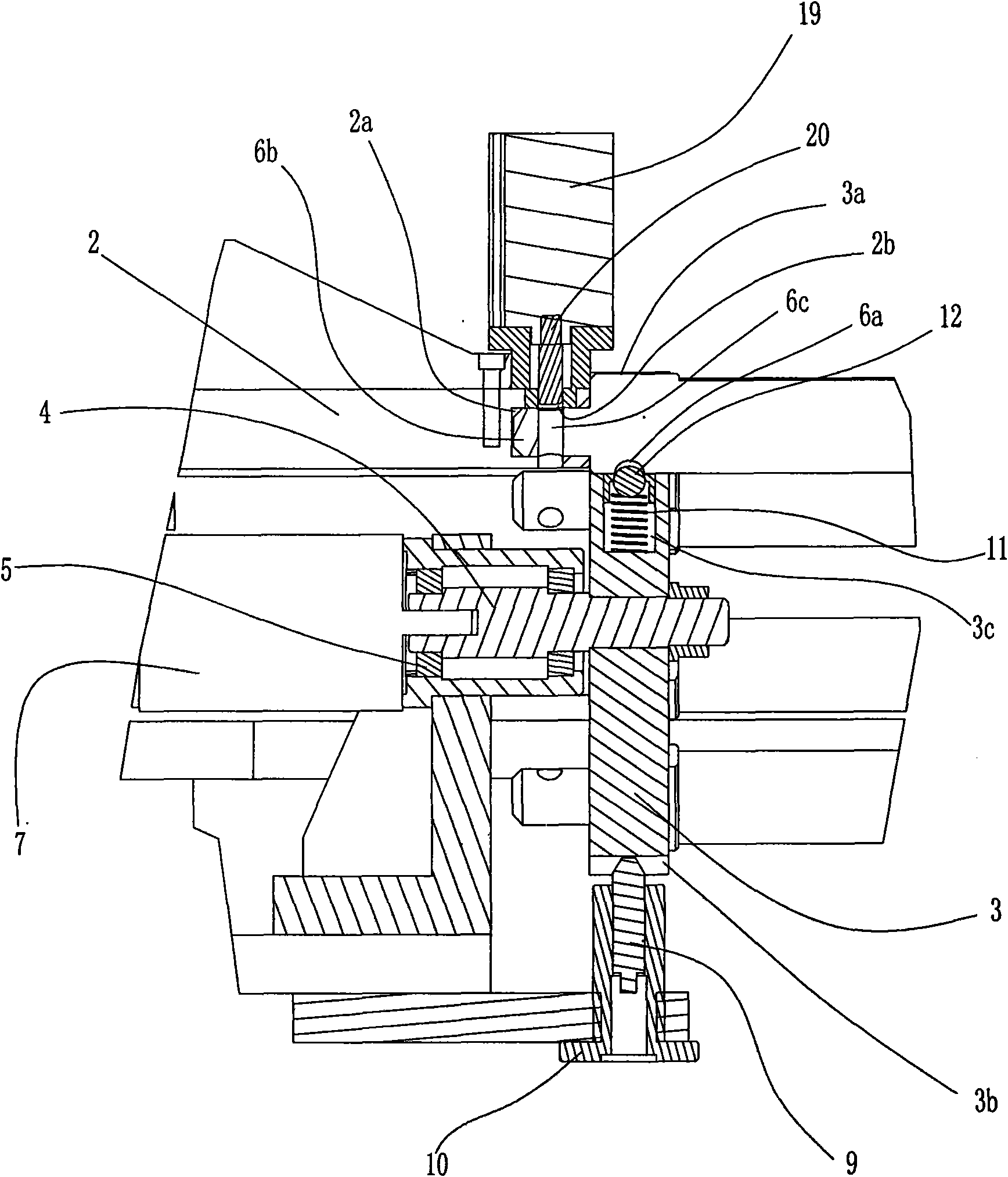

[0017] Such as Figures 1 to 3 As shown, the description of the icon numbers: frame 1, push rod 2, groove 2a, second hole 2b, circular turntable 3, expansion head fixing hole 3a, turntable positioning groove 3b, accommodation groove 3c, central axis 4, Bearing 5, pipe expansion head 6, pipe expansion head positioning groove 6a, narrowing part 6b, first hole 6c, servo motor 7, planetary gearbox 8, positioning pin 9, positioning pin oil cylinder 10, spring 11, positioning steel ball 12, Frame body 13, left guide rod fixed seat 14, right guide rod fixed seat 15, guide rod 16, pipe expanding head driving device fixed seat 17, latch oil cylinder 19, latch 20.

[0018] In the embodiment shown in the figure, a rotary table-type automatic pipe expanding machine includes a frame 1, a pipe blank fixing mechanism arranged at one end of the frame 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com