Patents

Literature

1370 results about "Signal reconstruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In signal processing, reconstruction usually means the determination of an original continuous signal from a sequence of equally spaced samples. This article takes a generalized abstract mathematical approach to signal sampling and reconstruction. For a more practical approach based on band-limited signals, see Whittaker–Shannon interpolation formula.

Parallel and adaptive signal processing

InactiveUS8055095B2Reduce energy consumptionReduce data volumeImage enhancementRecognisation of pattern in signalsStandard stateSelf adaptive

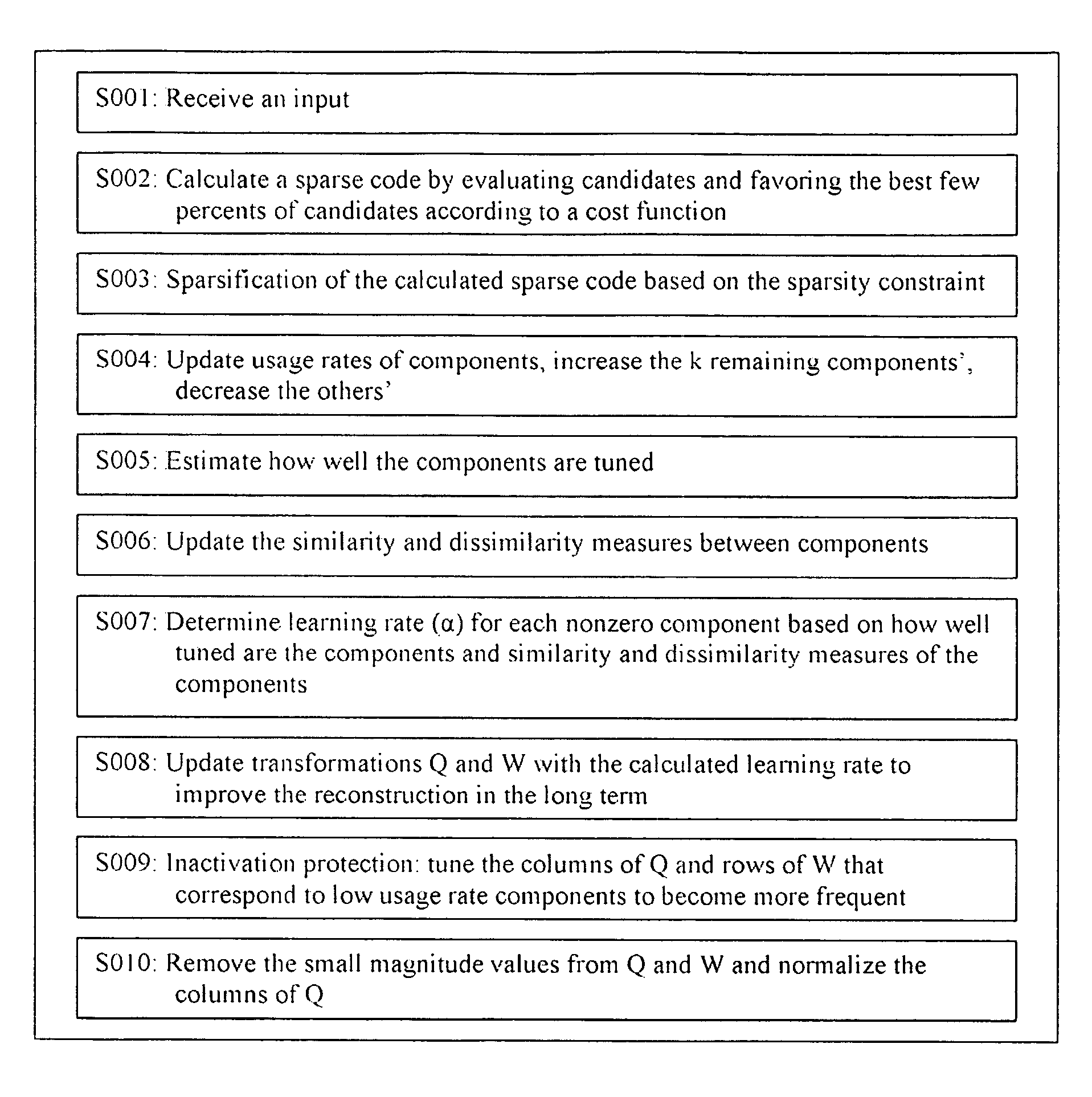

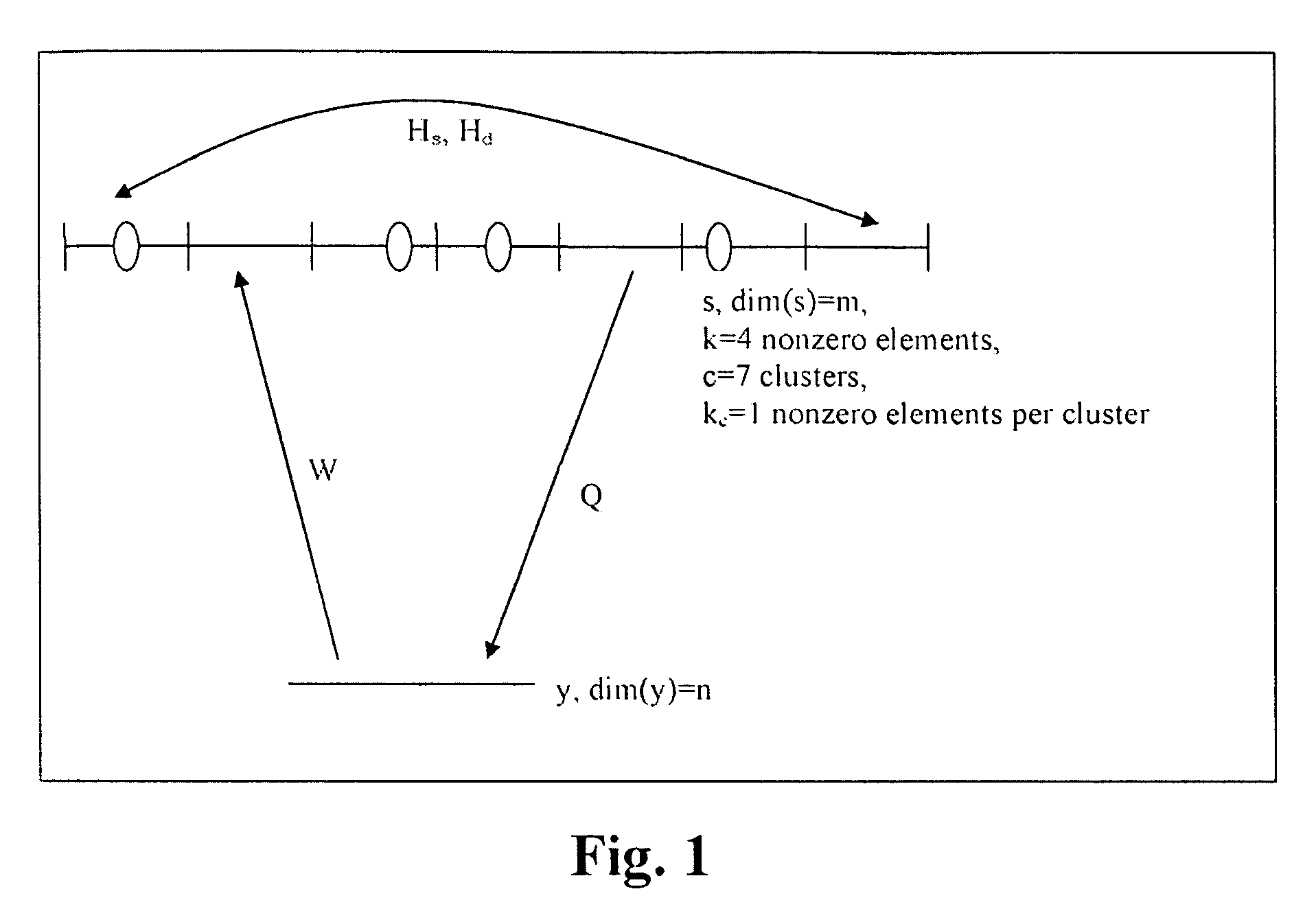

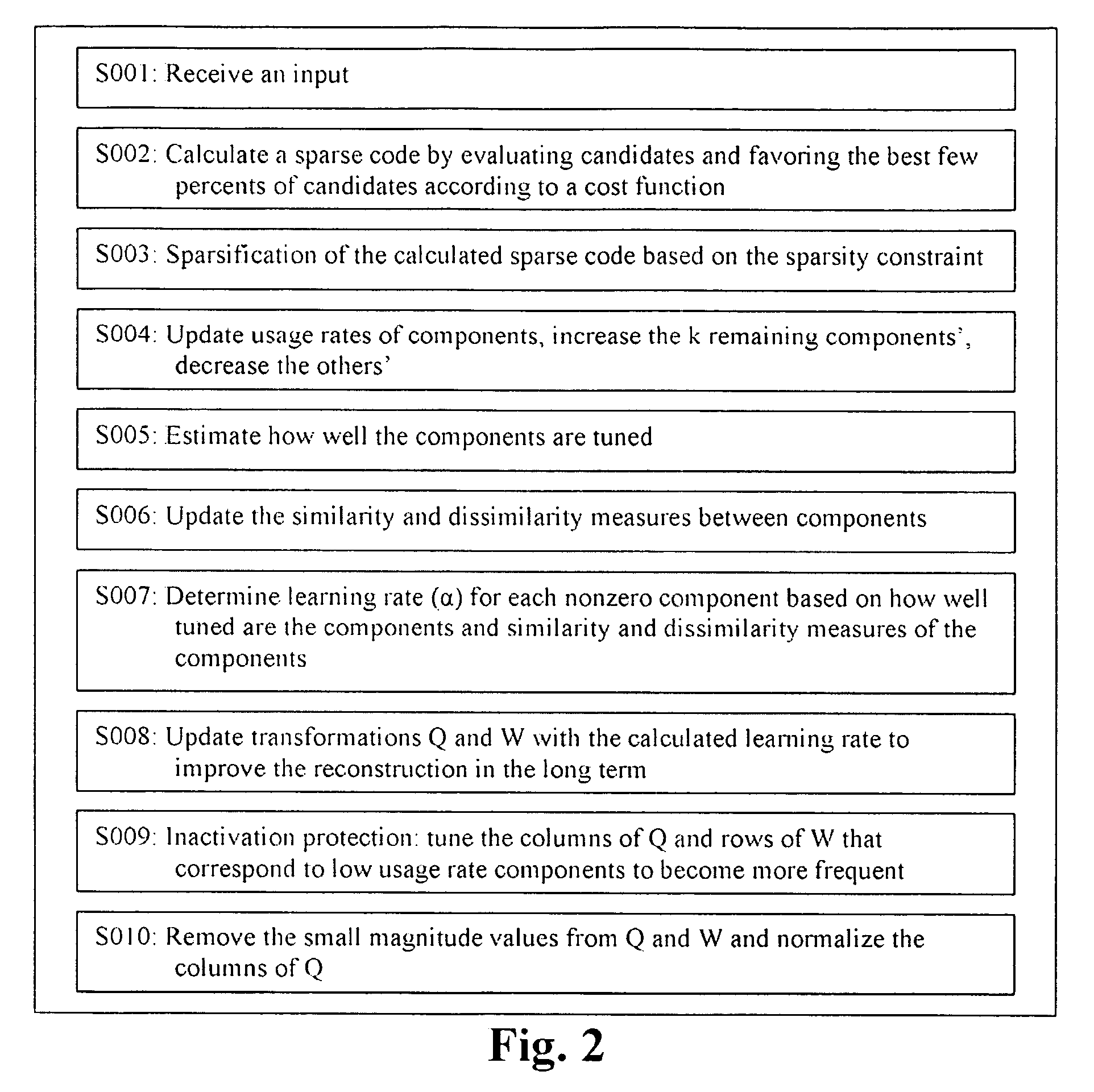

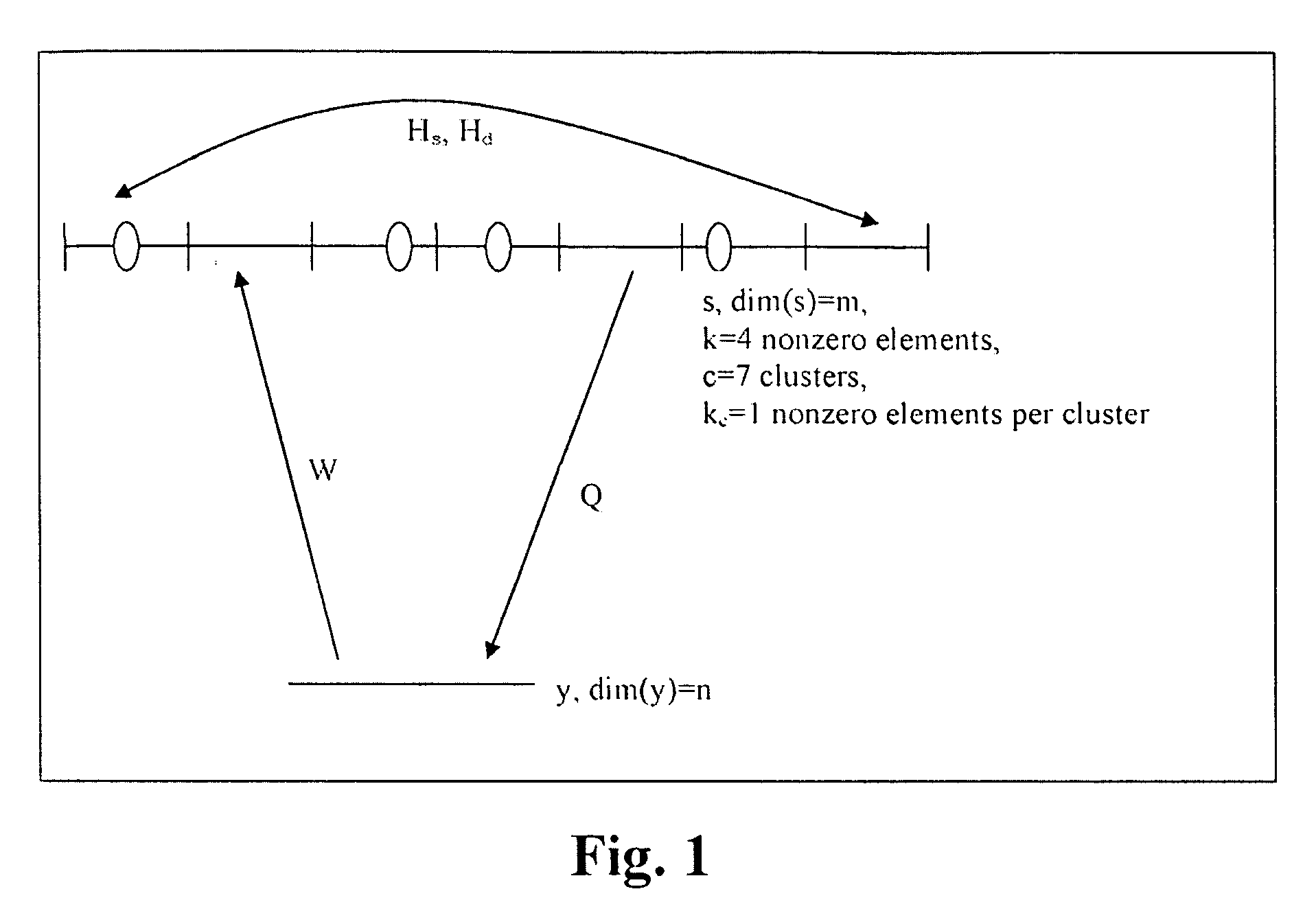

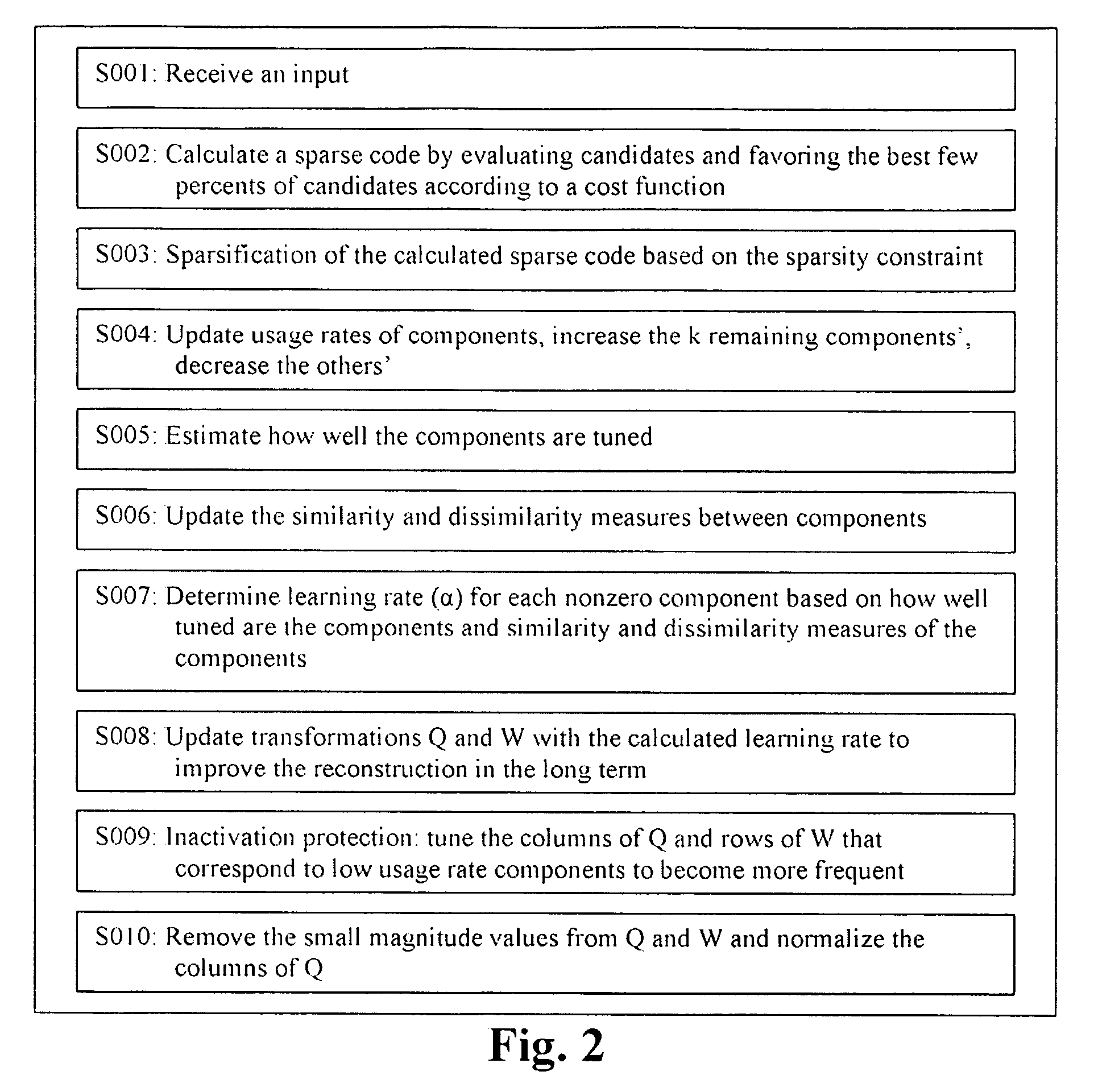

A method and apparatus for parallel and adaptive signal reconstruction from a multitude of signal measurements. Algorithms and hardware are disclosed to denoise the measured signals, to compress the measured signals, and to reconstruct the signal from fewer measurements than standard state-of-the-art methods require. A parallel hardware design is disclosed in which the methods that are described can be efficiently executed.

Owner:SPARSENSE

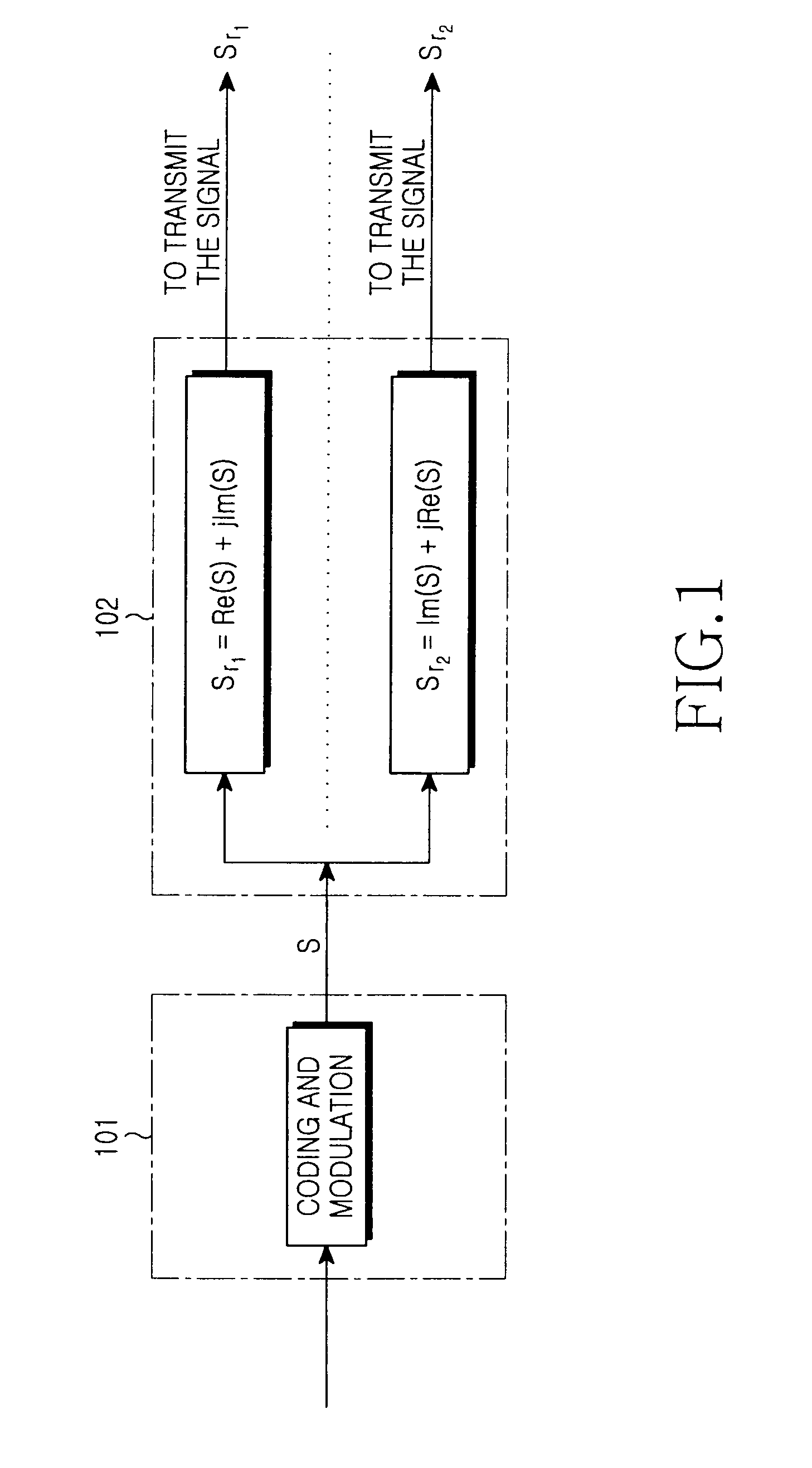

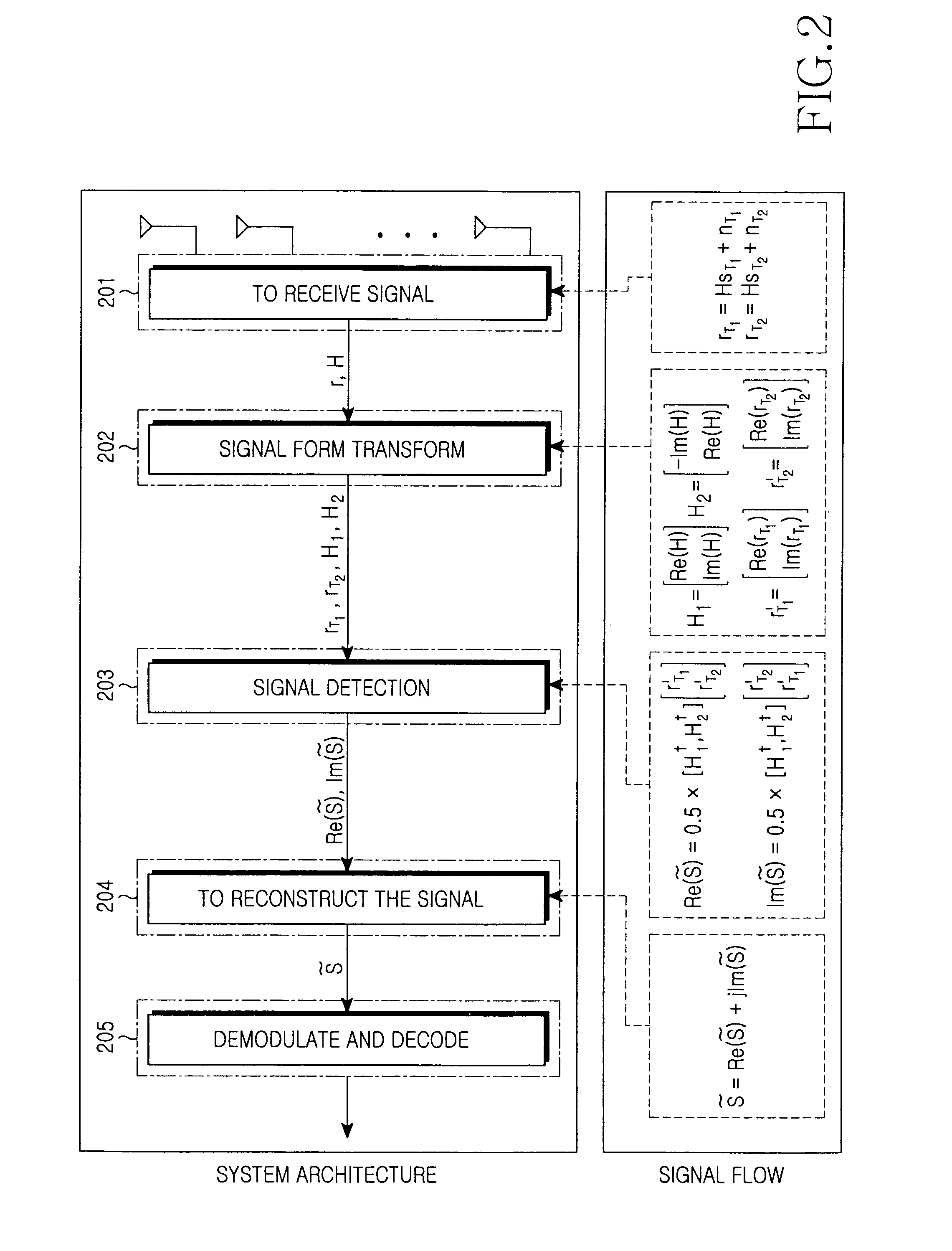

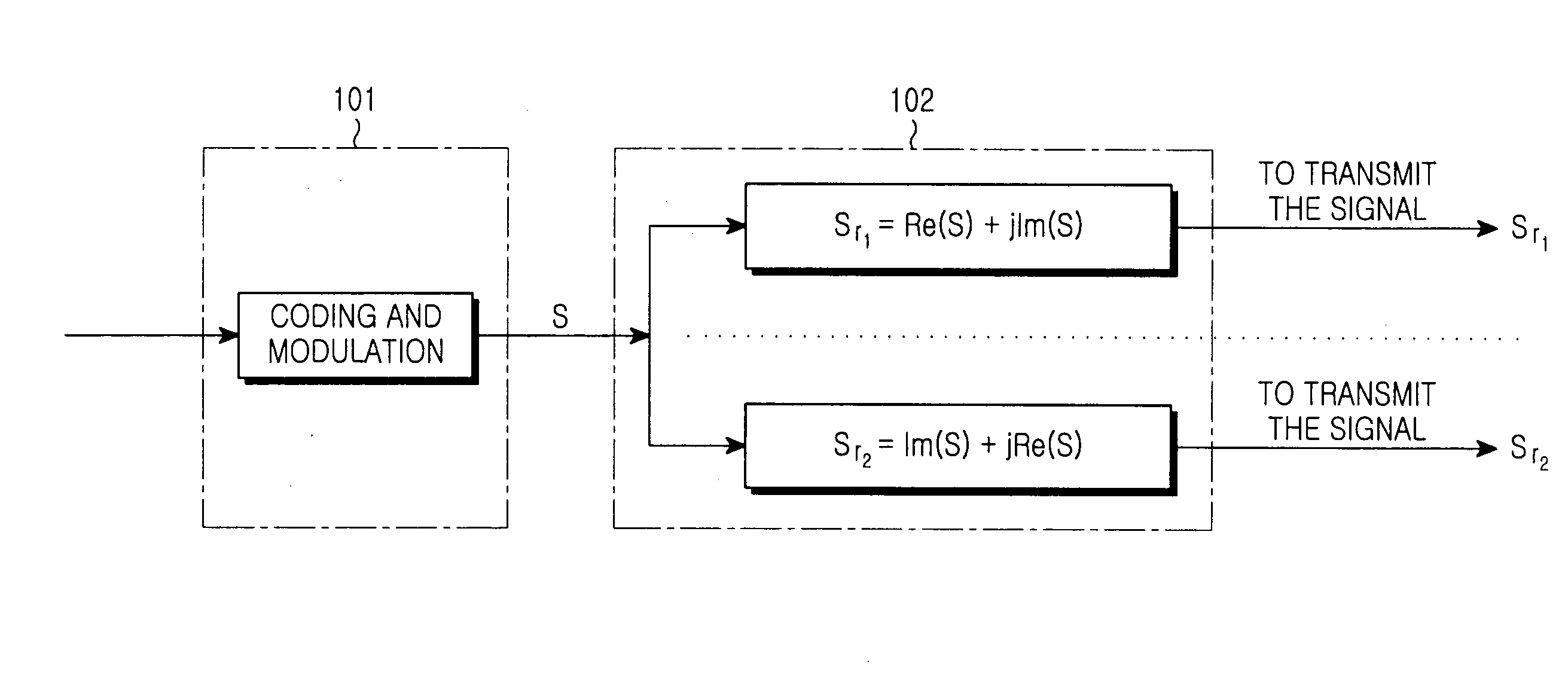

Multiple-antenna space multiplexing system using enhancement signal detection and method thereof

ActiveUS8199863B2Easy to detectPerformanceMultiplex communicationLine-faulsts/interference reductionMultiplexingComputer science

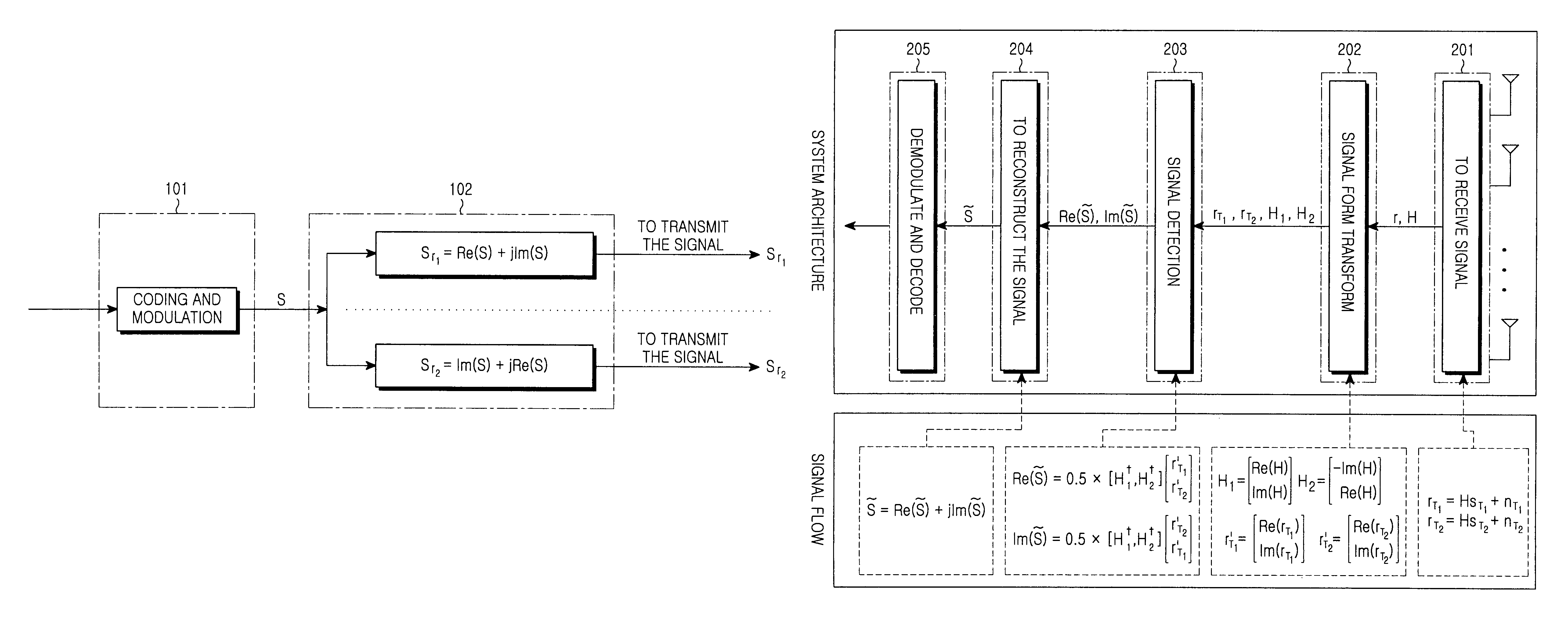

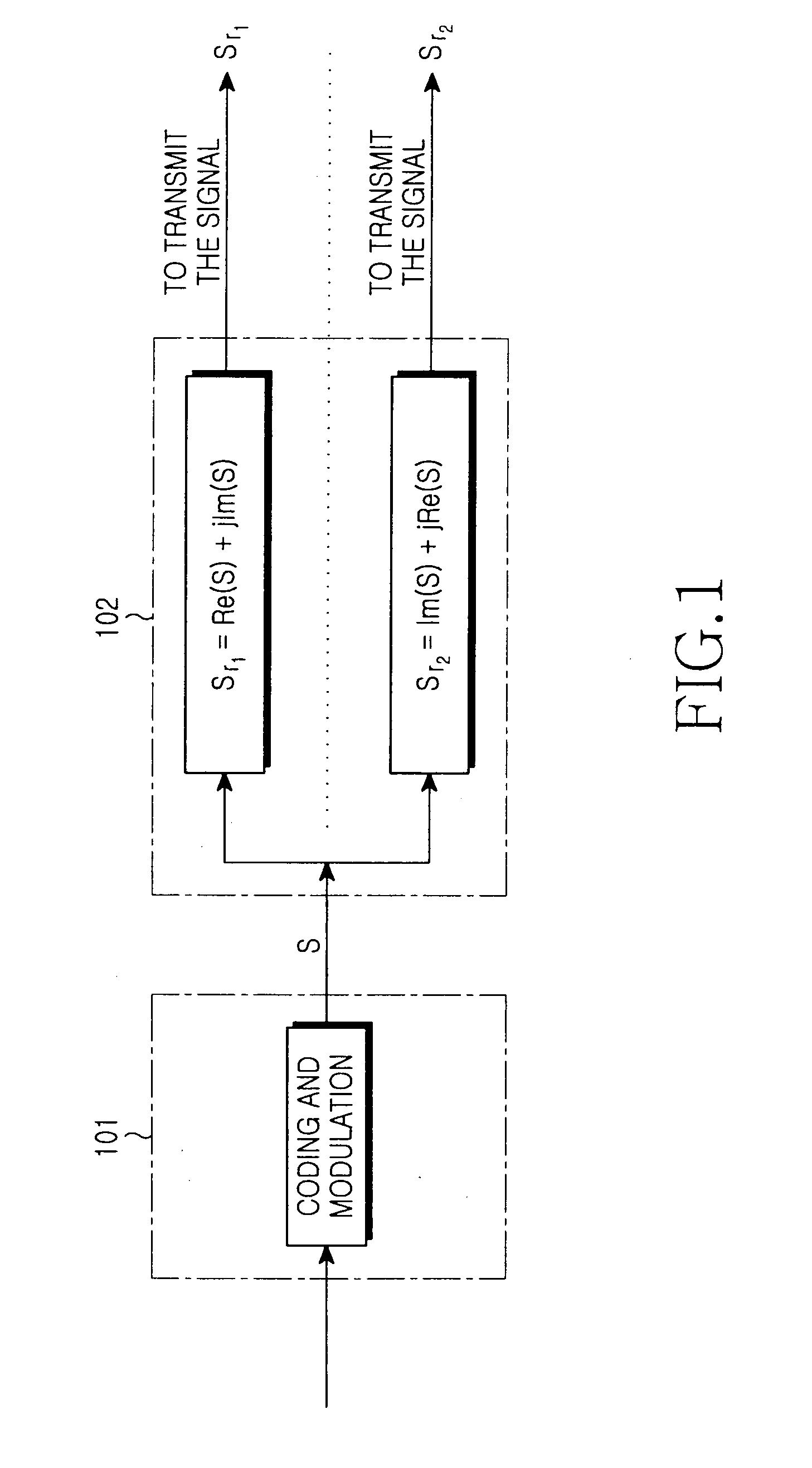

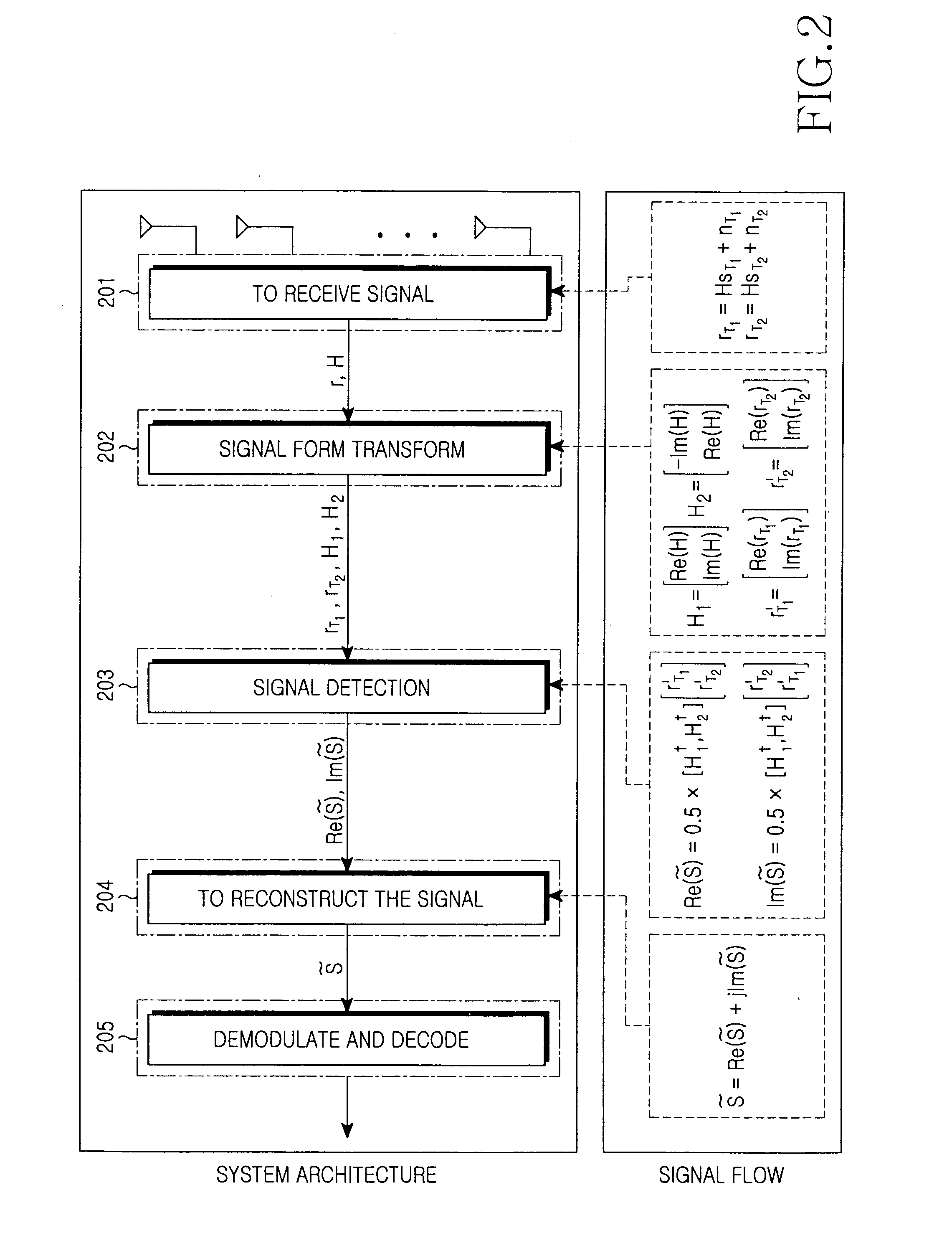

The multiple-antenna space multiplexing system using enhancement signal detection comprising: a code modulation module for coding and modulating bit information; a signal transmission module for transmitting the modulated signals; a signal reception module for receiving the signals; a signal form transform module for transforming form of a channel matrix H and the received signal vector r; a signal detection module for detecting the received signals; a signal reconstruction module for reconstructing the detection results of in the signal detection module, and obtaining a detected signal; a demodulation decoding module for demodulating and decoding the output of the signal reconstruction module, and outputting bit information. Compared with the conventional detection methods, the system performance is improved in considering the realization complexity.

Owner:SAMSUNG ELECTRONICS CO LTD +1

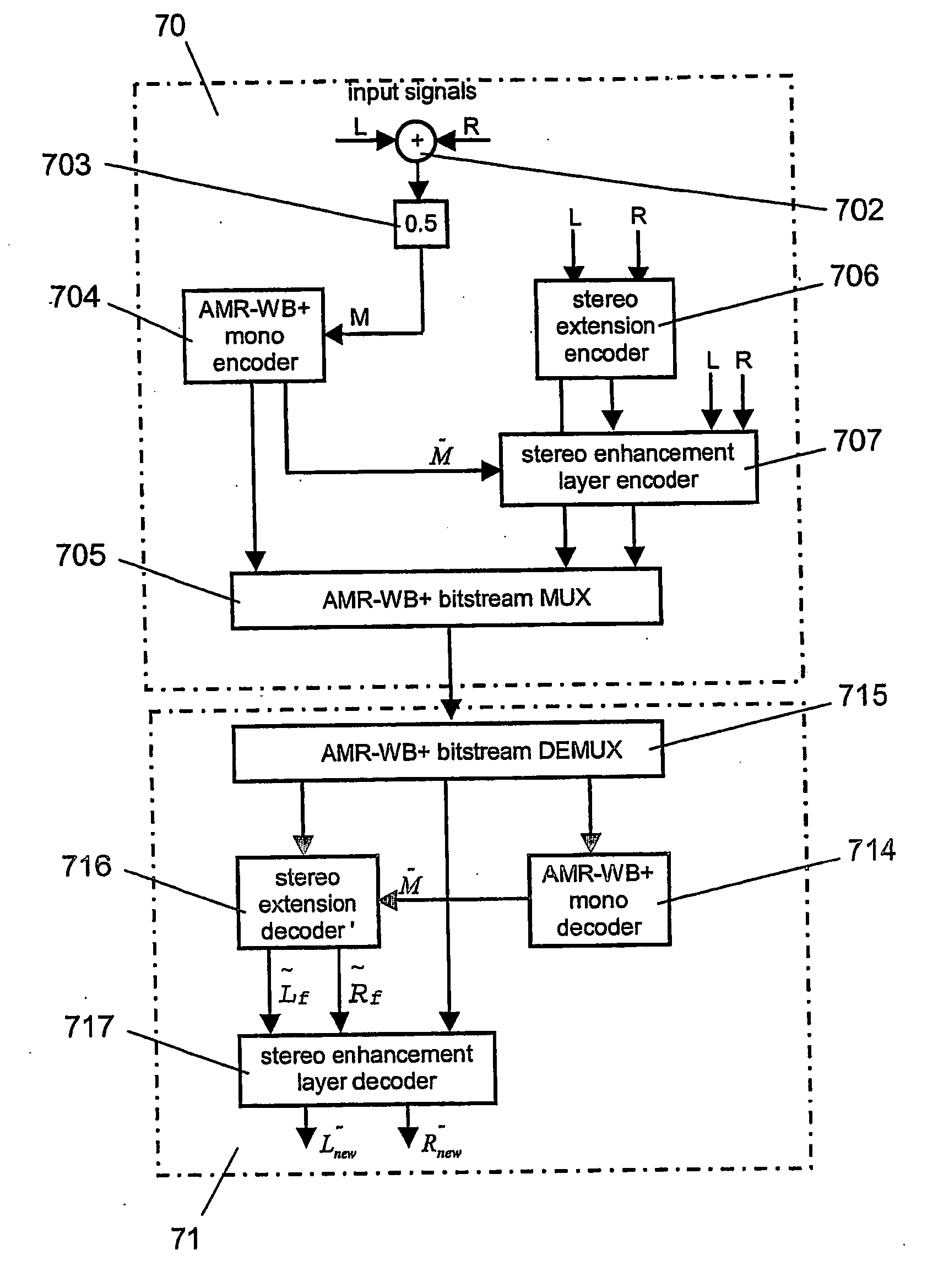

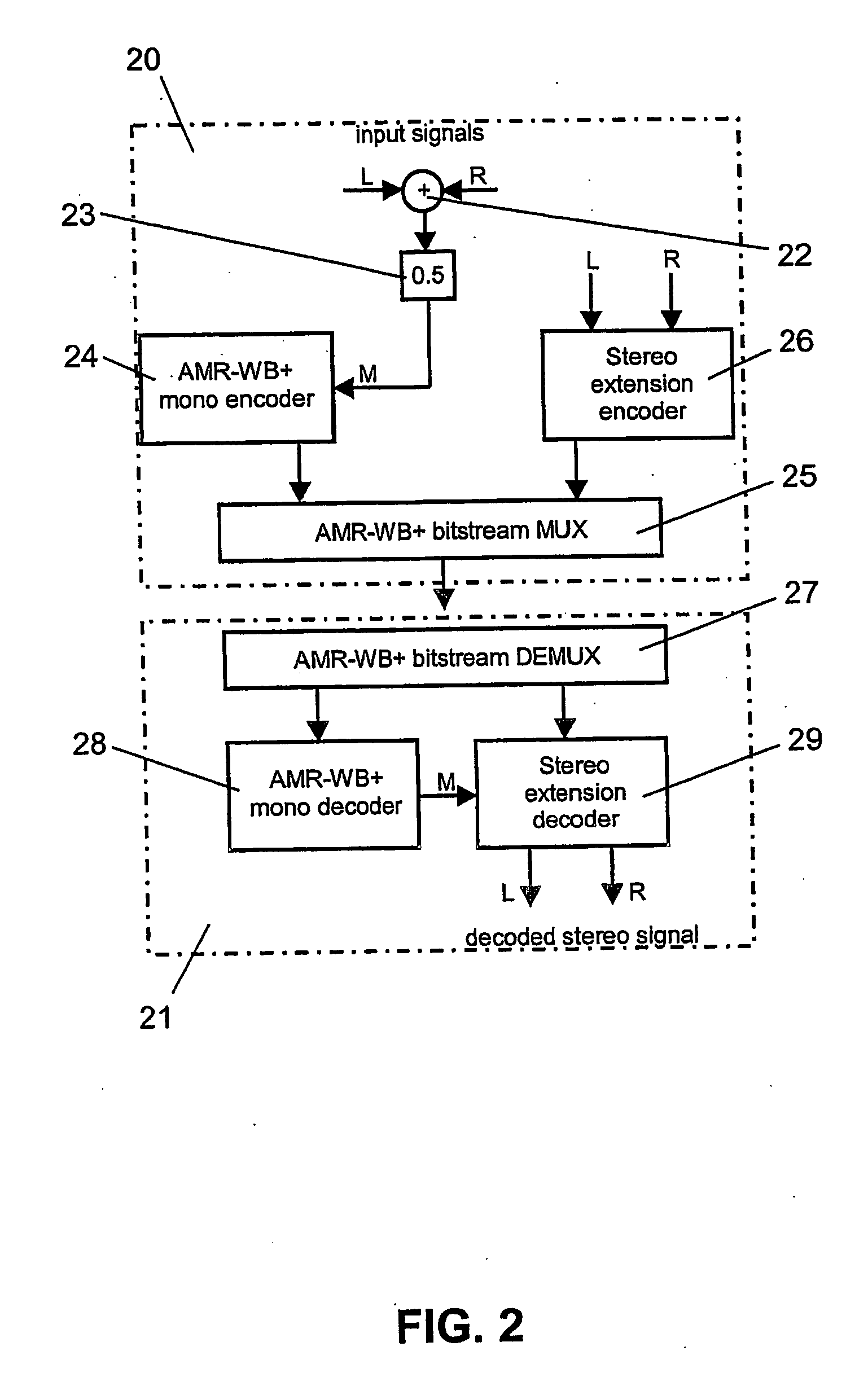

Support of a multichannel audio extension

InactiveUS20070165869A1Efficient multichannel audio codingReduce computational complexitySpeech analysisTwo-channel systemsFrequency bandAudio signal

The invention relates to methods and units supporting a multichannel audio extension. In order to allow an efficient extension requiring a low computational complexity, it is proposed that at an encoding end, at least state information is provided as side information for a provided mono audio signal (M) generated out of a multichannel audio signal. The state information indicates for each of a plurality of frequency bands how a predetermined or equally provided gain value is to be applied in the frequency domain to the mono audio signal (M) for obtaining first and a second channel signals (L,R) of a reconstructed multichannel audio signal.

Owner:CORE WIRELESS LICENSING R L

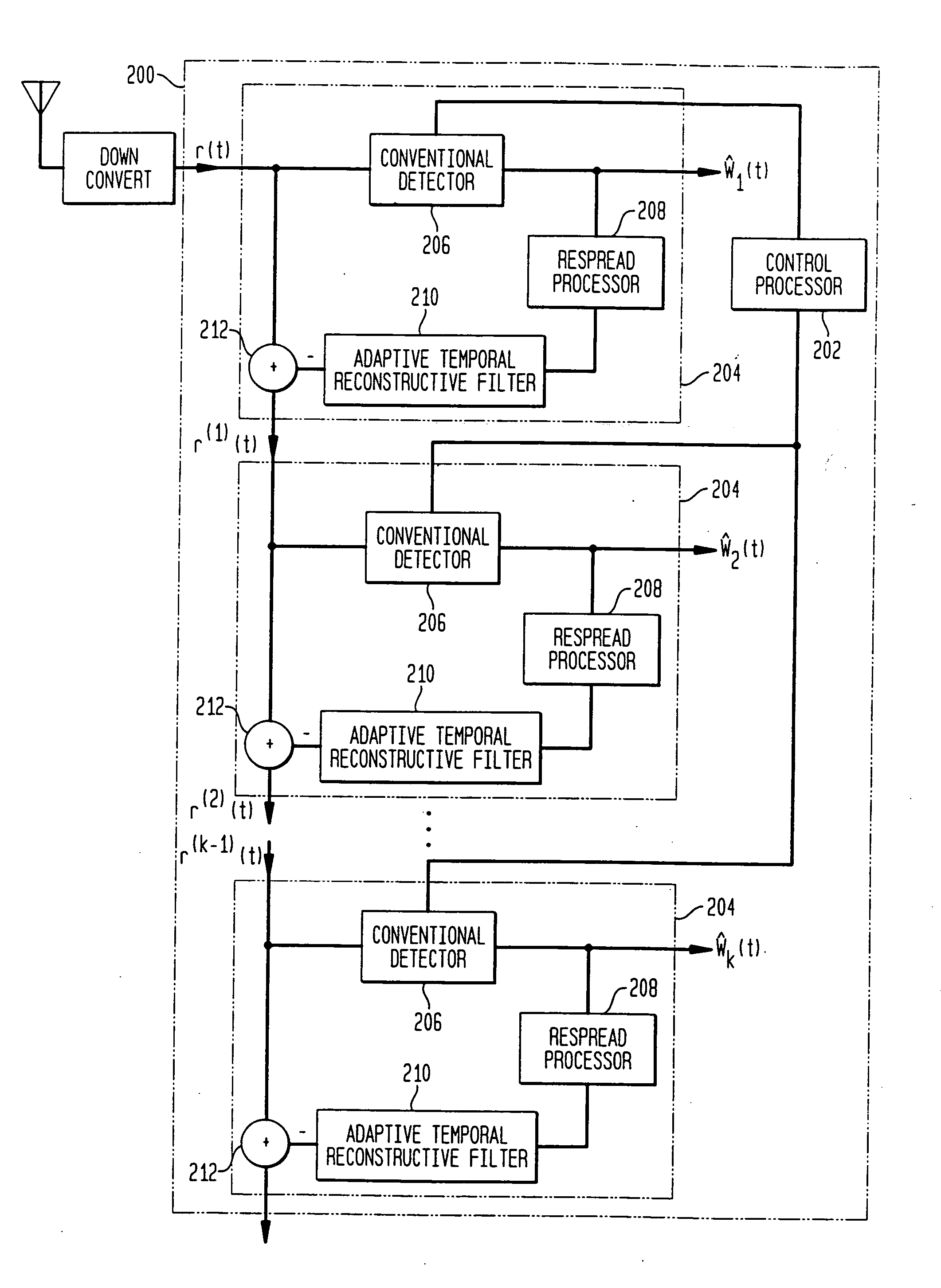

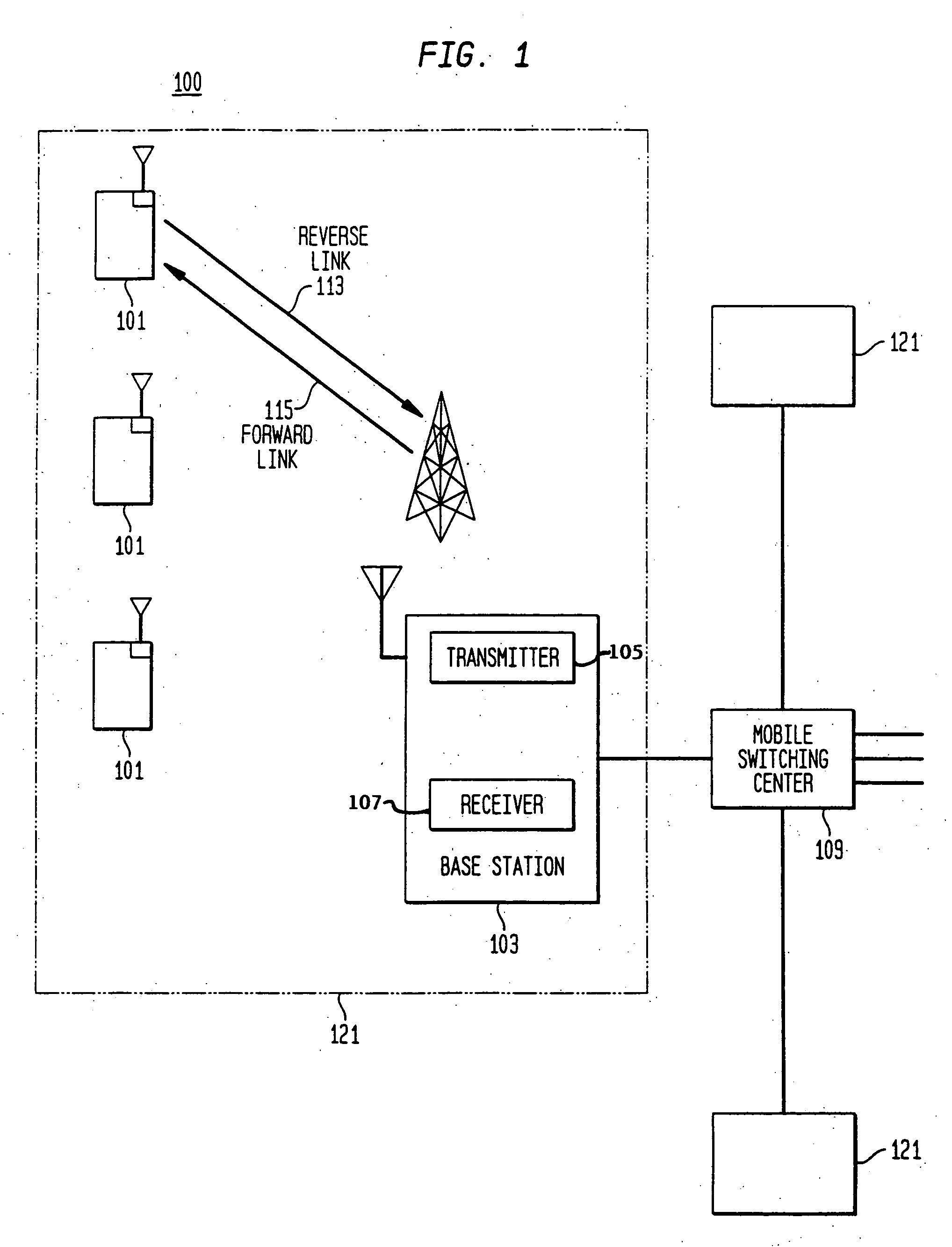

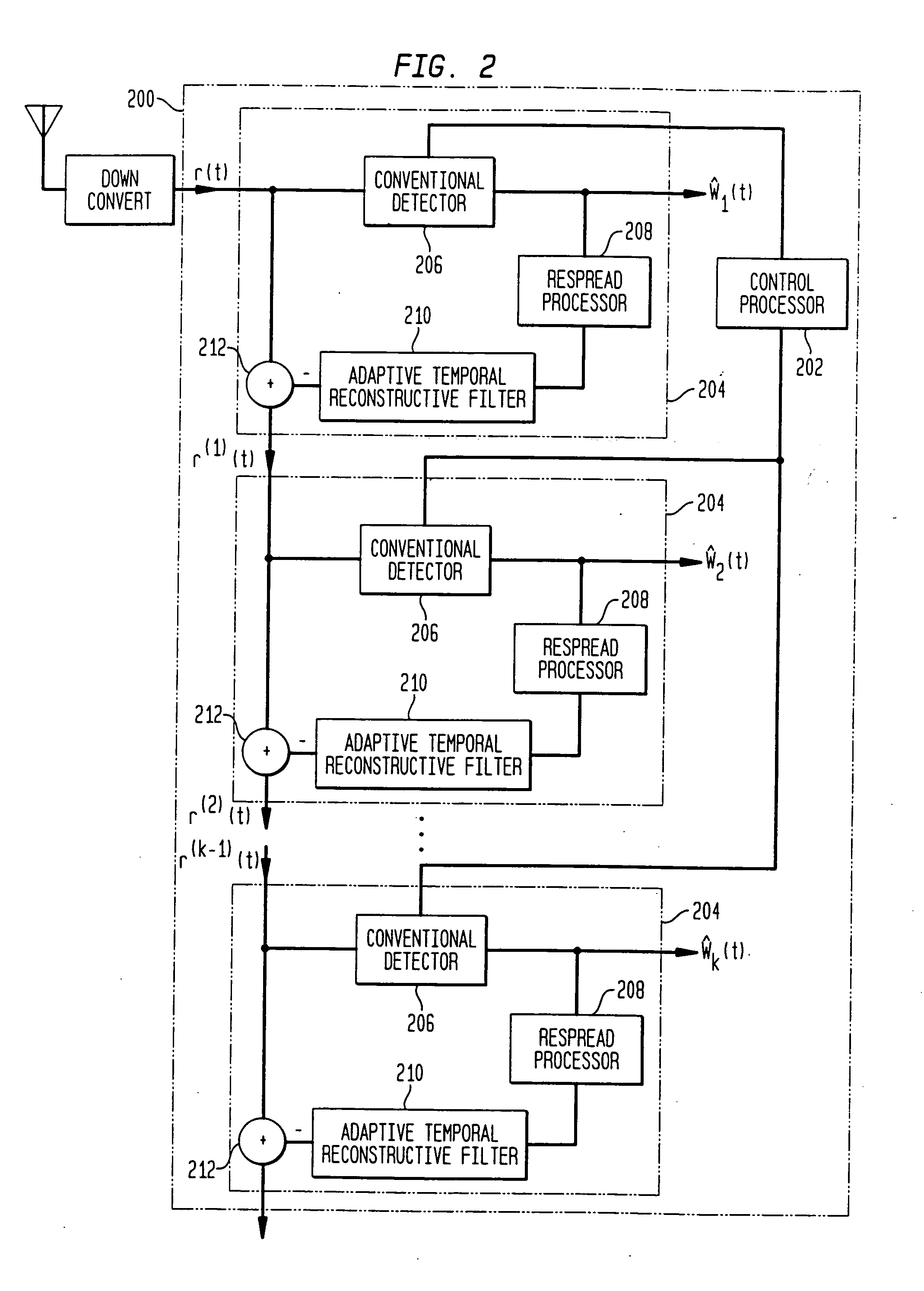

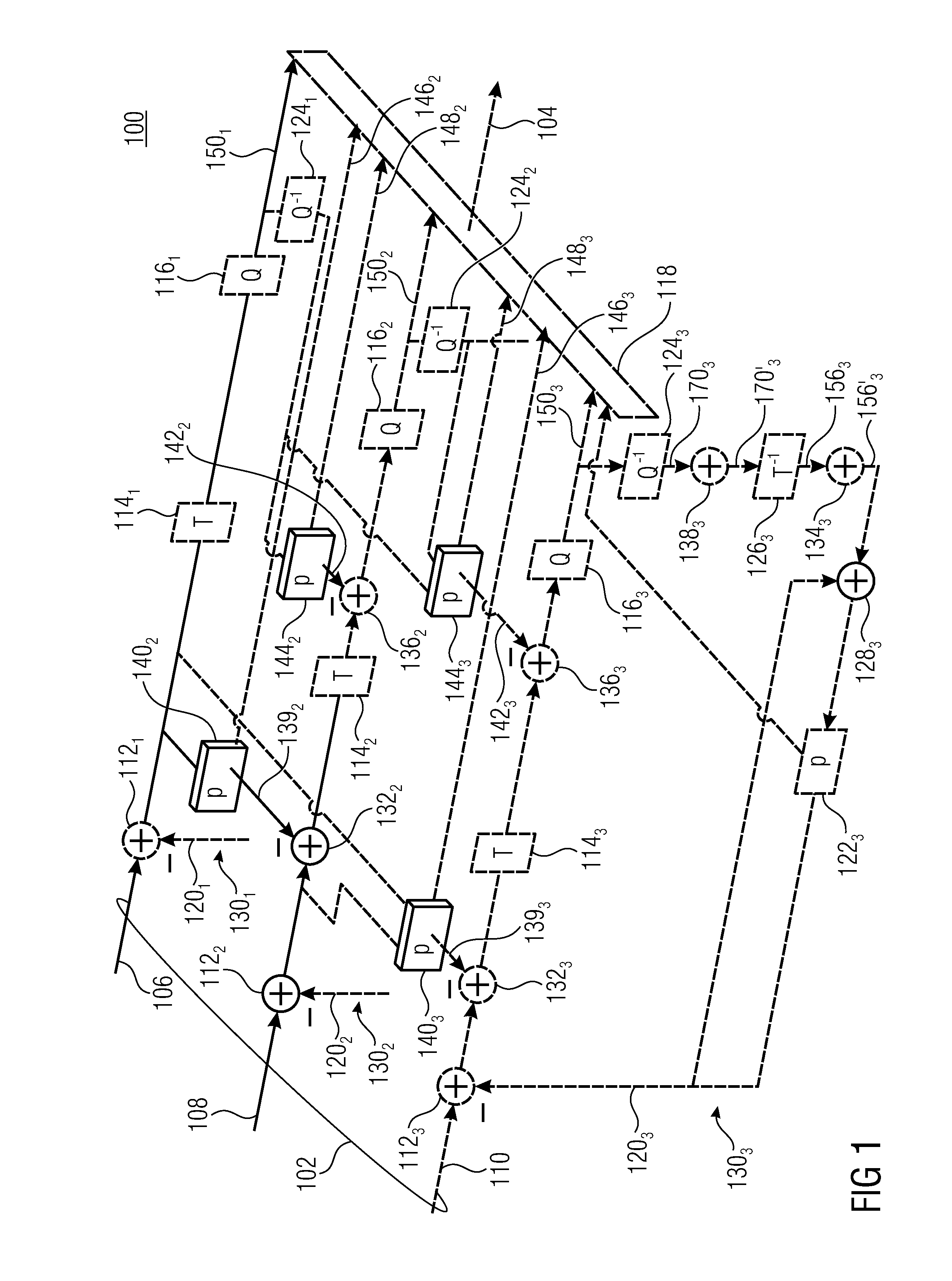

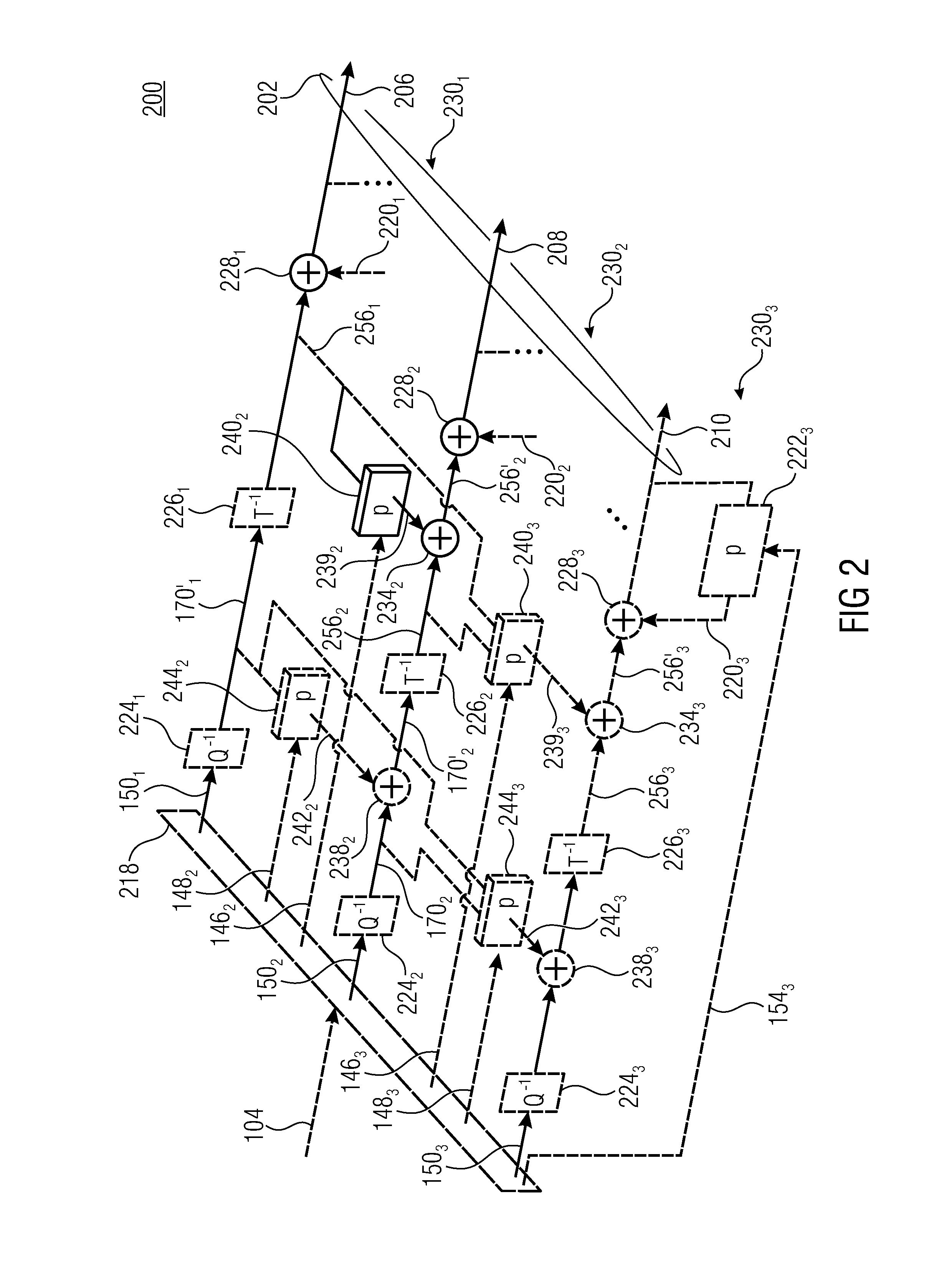

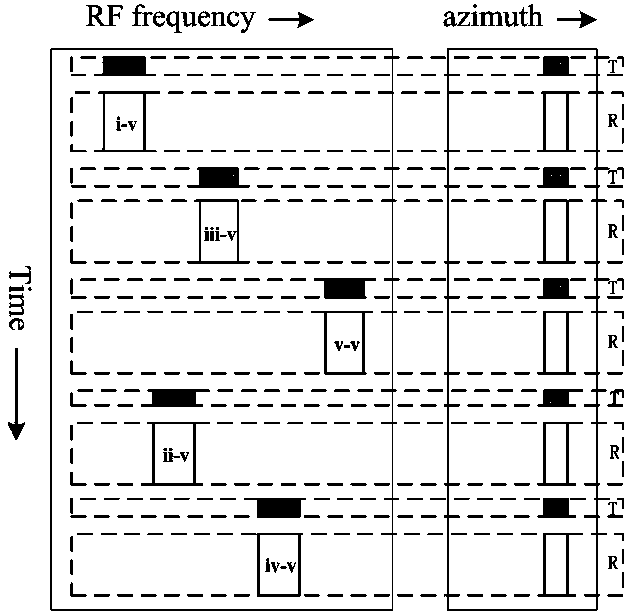

Combined adaptive spatio-temporal processing and multi-user detection for CDMA wireless systems

ActiveUS20050128985A1Reduce cancellationAccurate estimateRadio transmissionWireless commuication servicesEngineeringCo-channel interference

Methods and systems in a wireless receiver for enabling the reception of input signals at varied power levels in the presence of co-channel interference utilizing combinations of space-time adaptive processing (STAP), interference cancellation multi-user detection (MUD), and combined STAP / MUD techniques. In MUD, code, timing, and possibly channel information of multiple users are jointly used to better detect each individual user. The novel combination of adaptive signal reconstruction techniques with interference cancellation MUD techniques provides accurate temporal cancellation of interference with minimal interference residuals. Additional methods and systems extend adaptive signal reconstruction techniques to take Doppler spread into account. STAP techniques permit a wireless receiver to exploit multiple antenna elements to form beams in the direction of the desired signal and nulls in the direction of the interfering signals. The combined STAP-MUD methods and systems increase the probability of successful user detection by taking advantage of the benefits of each reception method. An additional method and system utilizes STAP techniques in the case where no pilot signal is available. This method compares the outputs of various hypothesized STAP solutions.

Owner:NYTELL SOFTWARE LLC

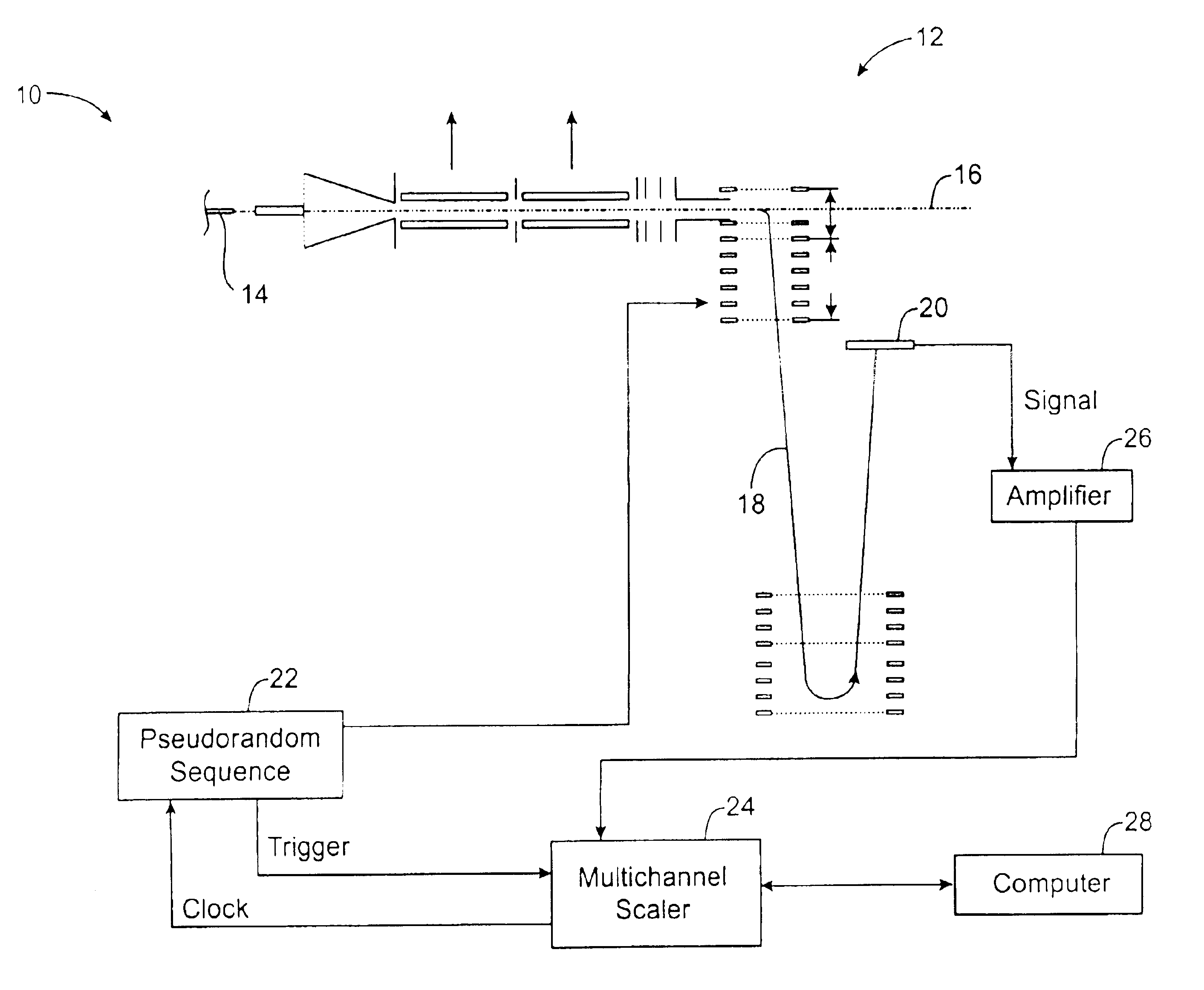

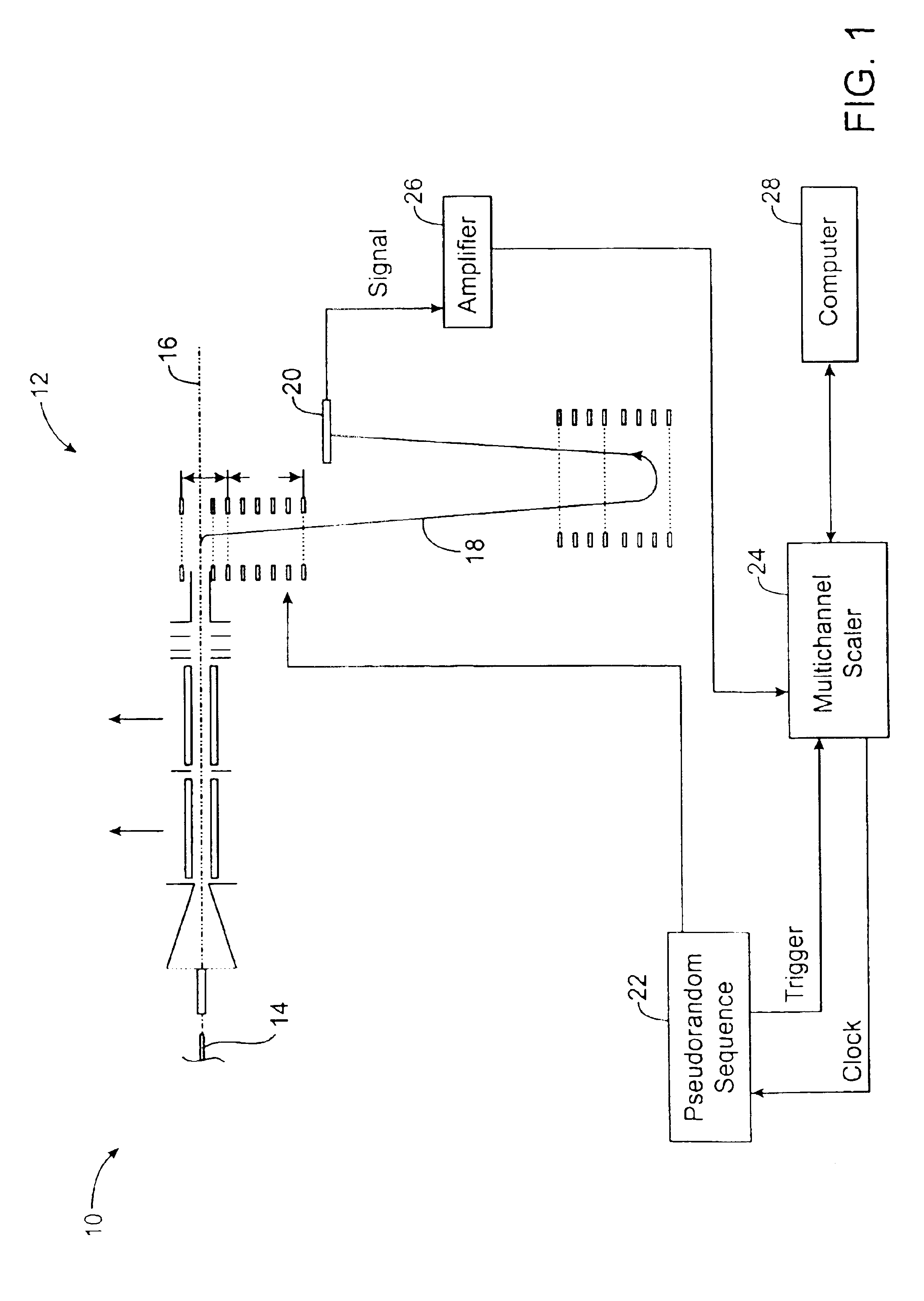

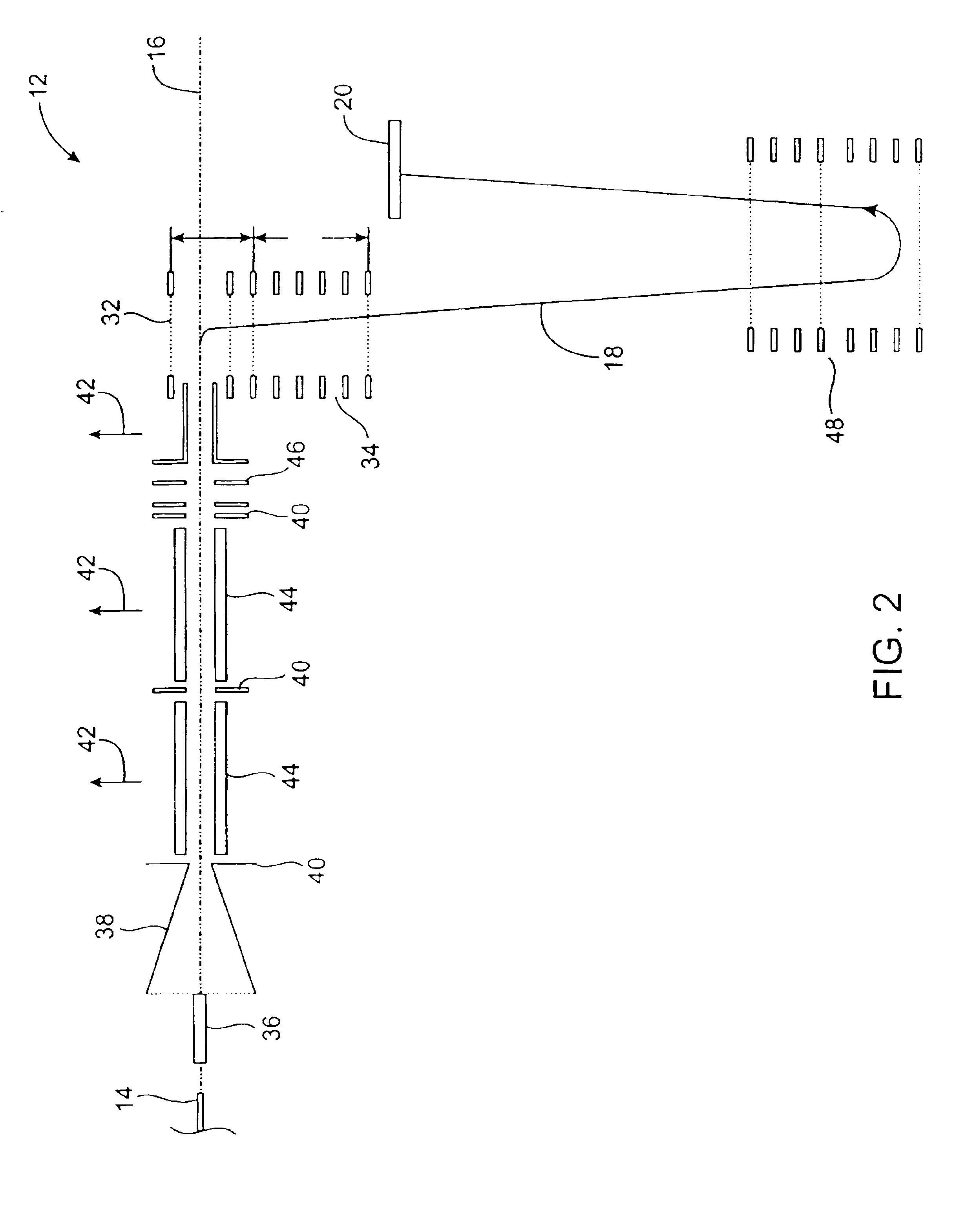

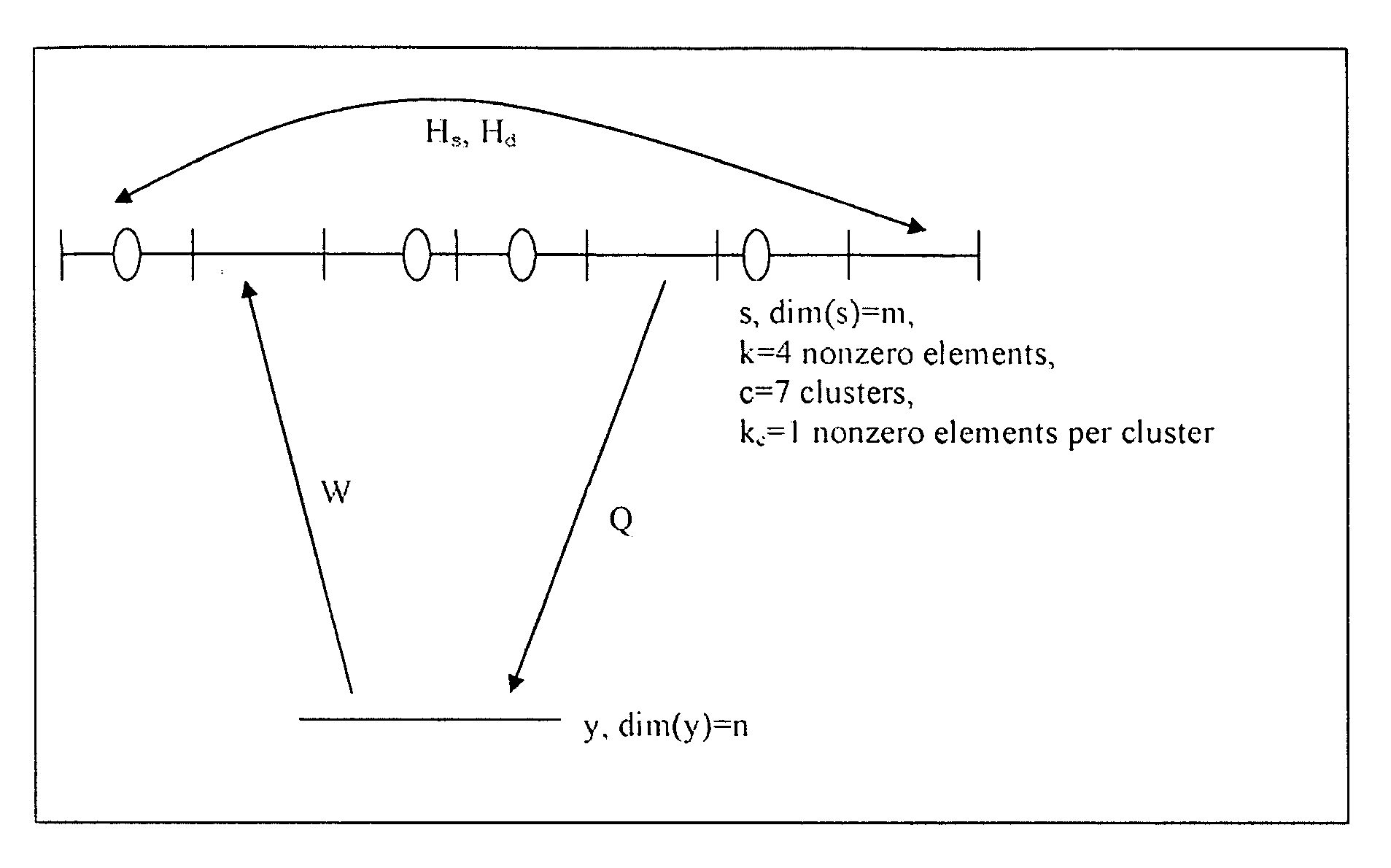

Multiplexed orthogonal time-of-flight mass spectrometer

InactiveUS6900431B2Time-of-flight spectrometersParticle spectrometer methodsHadamard transformTime-of-flight mass spectrometry

A mass spectrometer and associated methods analyze an ion beam by accumulating ions for a sequence of time periods, and driving the accumulated ions in pulses. Differing quantities of ions can be accumulated in the sequential pulses according to a psuedo-random sequence, and the slower ions are overtaken by the faster ions of a subsequent pulse. A mass spectrum may be reconstructed from an overlapping ion detector signal using an inverse of a weighted simplex matrix or inverse Hadamard transform techniques.

Owner:NORVIEL VERN

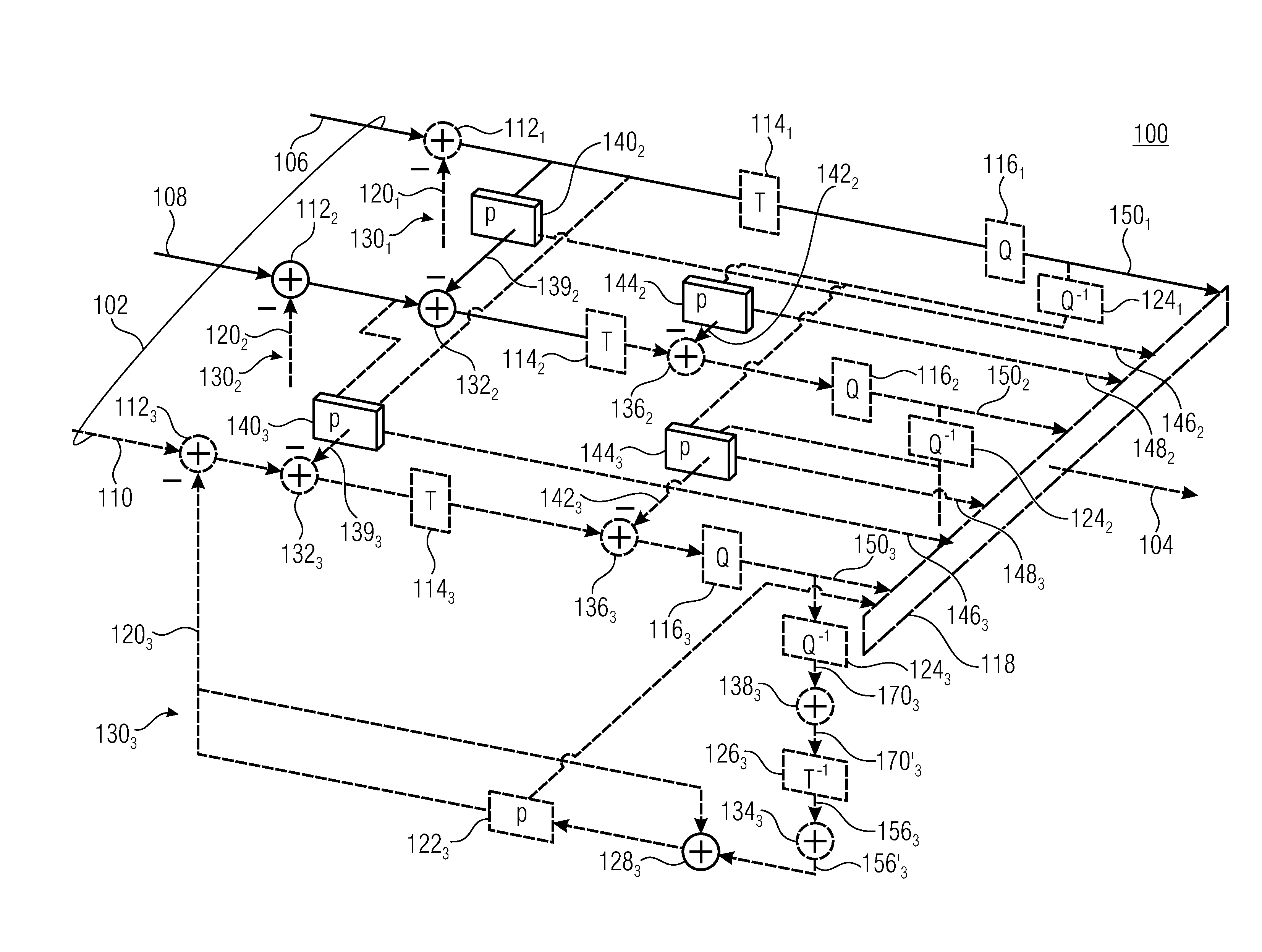

Parallel and adaptive signal processing

InactiveUS20090185636A1Reduces required bandwidthLow costImage enhancementRecognisation of pattern in signalsSignal processingSignal reconstruction

A method and apparatus for parallel and adaptive signal reconstruction from a multitude of signal measurements. Algorithms and hardware are disclosed to denoise the measured signals, to compress the measured signals, and to reconstruct the signal from fewer measurements than standard state-of-the-art methods require. A parallel hardware design is disclosed in which the methods that are described can be efficiently executed.

Owner:SPARSENSE

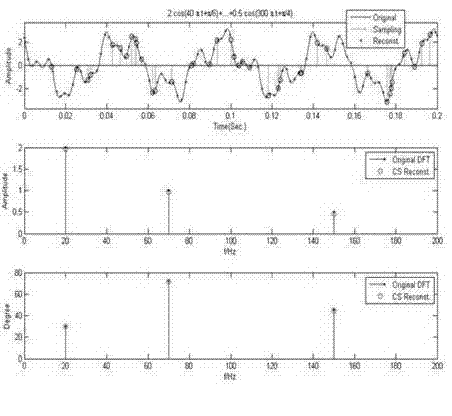

Sparse sampling and signal compressive sensing reconstruction method

InactiveCN103595414AFew samplesReduce the number of samplesCode conversionNMR - Nuclear magnetic resonanceReconstruction method

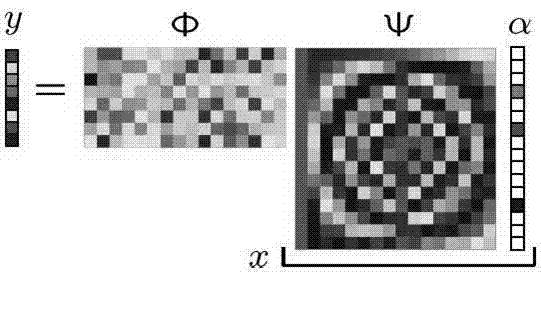

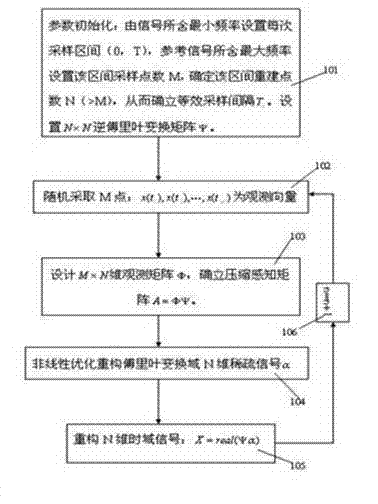

The invention discloses a sparse sampling and signal compressive sensing reconstruction method. The method comprises: establishing a signal sampling interval of each time, sampling point number, and the number of points recovering, establishing random sparse sampling lower than a Nyquist sampling theorem value; and designing a measurement matrix by random sampling timing sequence values, designing a transformation matrix of a sparse expression domain of signals, determining a compressive sensing matrix, and separated compressive sensing optimizing signal reconstruction in a nonlinear manner. The method is based on rationality of objective world rules, and makes full use of signal sparsity, uses transformation space to describe the signals, and establishes theoretical framework of new signal description and processing, so under the condition that information is not lost is ensured, signals are sampled by speed much lower than required speed of a Shannon's sampling theorem. Simultaneously, signals can be recovered completely, that is, sampling of signals is converted into sampling of information. The invention provides a whole set of complete method. The method can be used in one-dimensional and multidimensional signals, and can process audio frequency, videos, nuclear magnetic resonance, and other signals.

Owner:HUNAN INT ECONOMICS UNIV

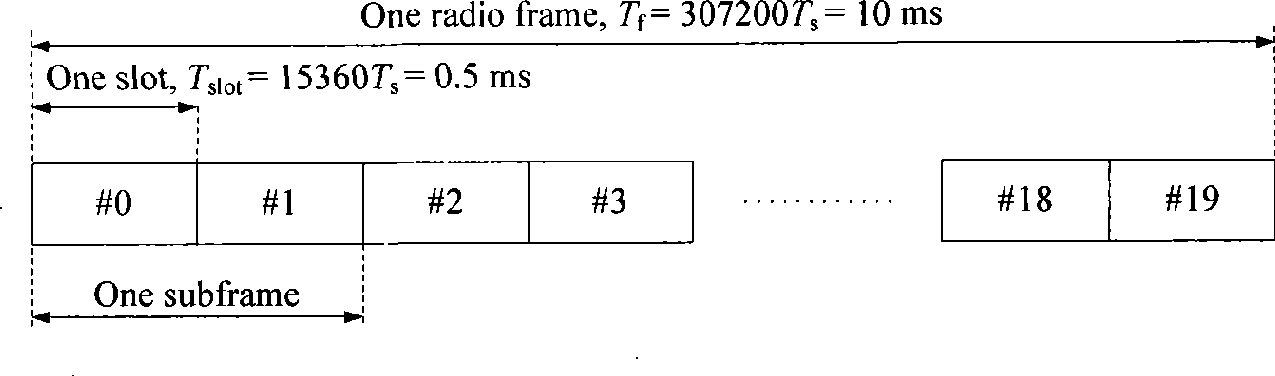

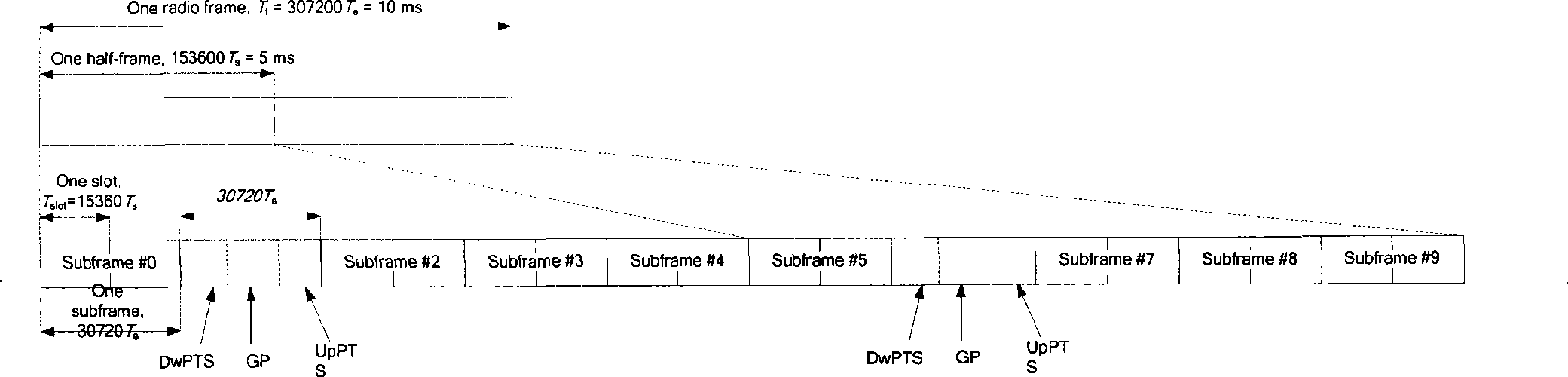

Radio communication timing synchronization method, cell searching method and system

ActiveCN101388723ARealization of cell searchReduce processing complexityRadio transmission for post communicationOrthogonal multiplexTime domainSignal quality

The invention discloses a method for timing and synchronizing wireless communication, a method for searching districts and a system thereof. The method fully utilizes the time domain repetitiveness of a main synchronizing signal in a 5ms period and comprises: firstly, adopting predetermined step length sliding time domain cross-correlation to realize blind timing coarse synchronization with low complexity and without local synchronizing signal reconstruction, simultaneously, using normalized correlation processing to resist strong interference, finally, realizing timing fine synchronization with high precision, and correcting receiver integer multiple residual frequency deviation simultaneously. The method can realize timing and synchronization rapidly and accurately in particular in environment with low signal to interference and noise ratio, thereby realizing district searching in a long term evolution wireless communication system. The method can realize downlink timing and synchronization when the signal quality is in the sensitivity position of a terminal receiver and in the environment with strong interference.

Owner:RDA CHONGQING MICROELECTRONICS TECH CO LTD

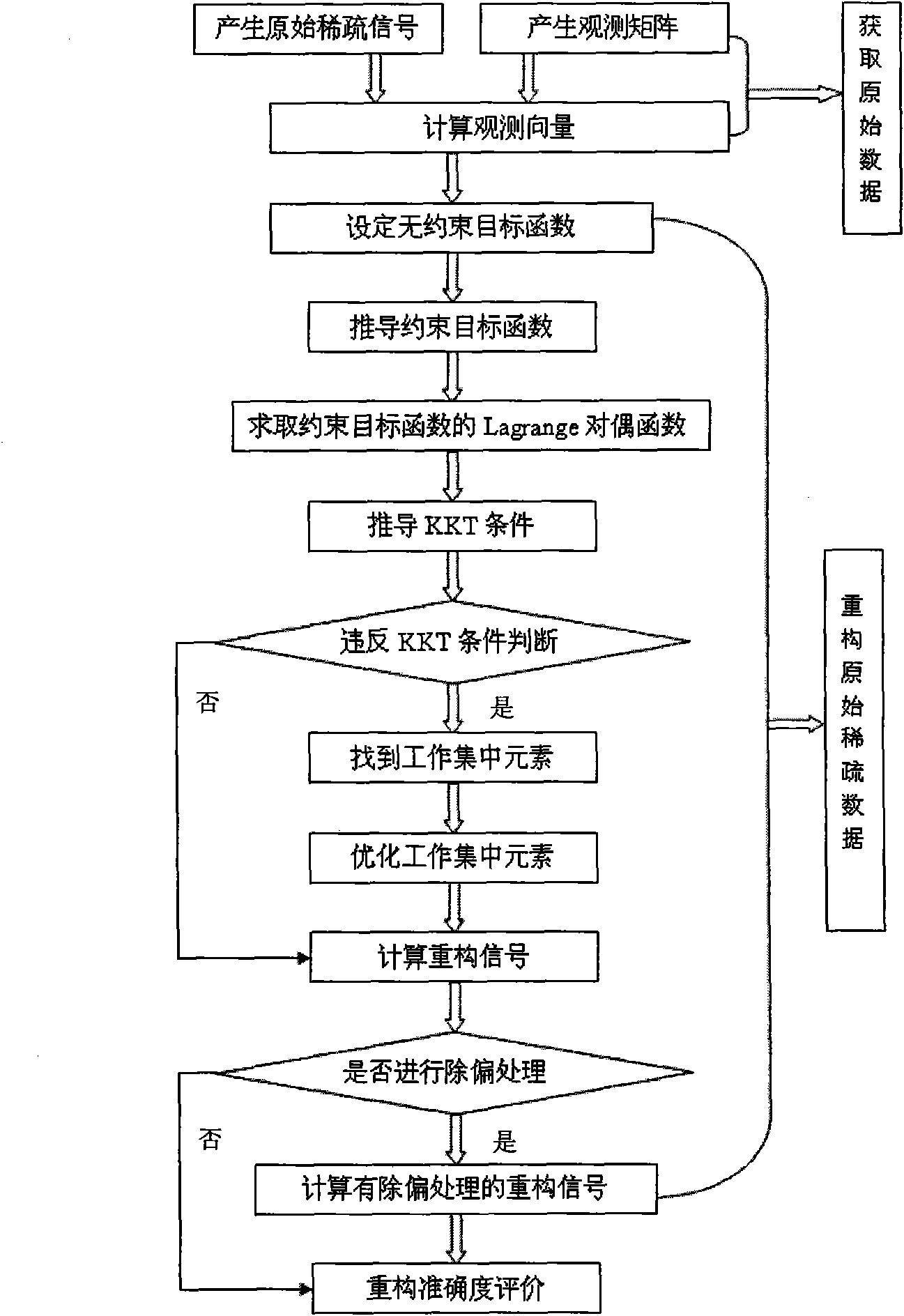

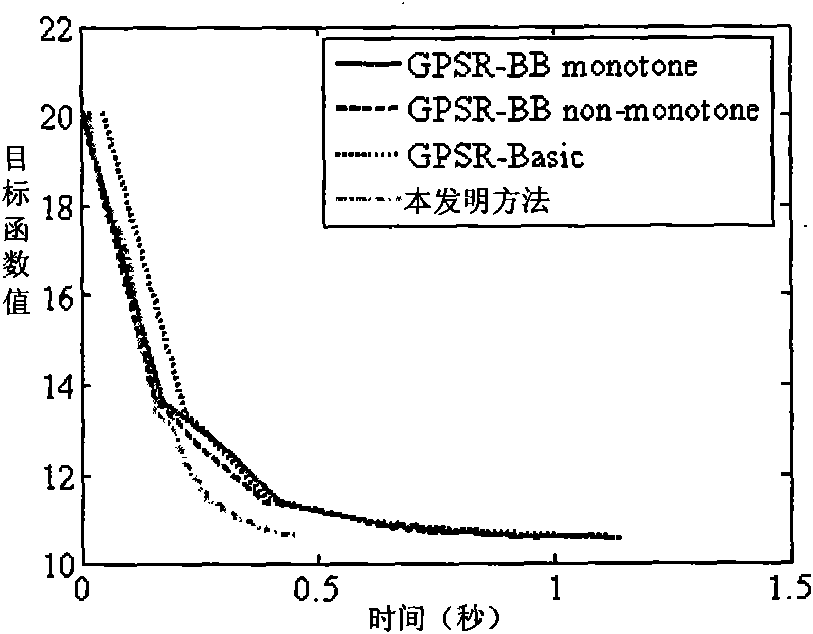

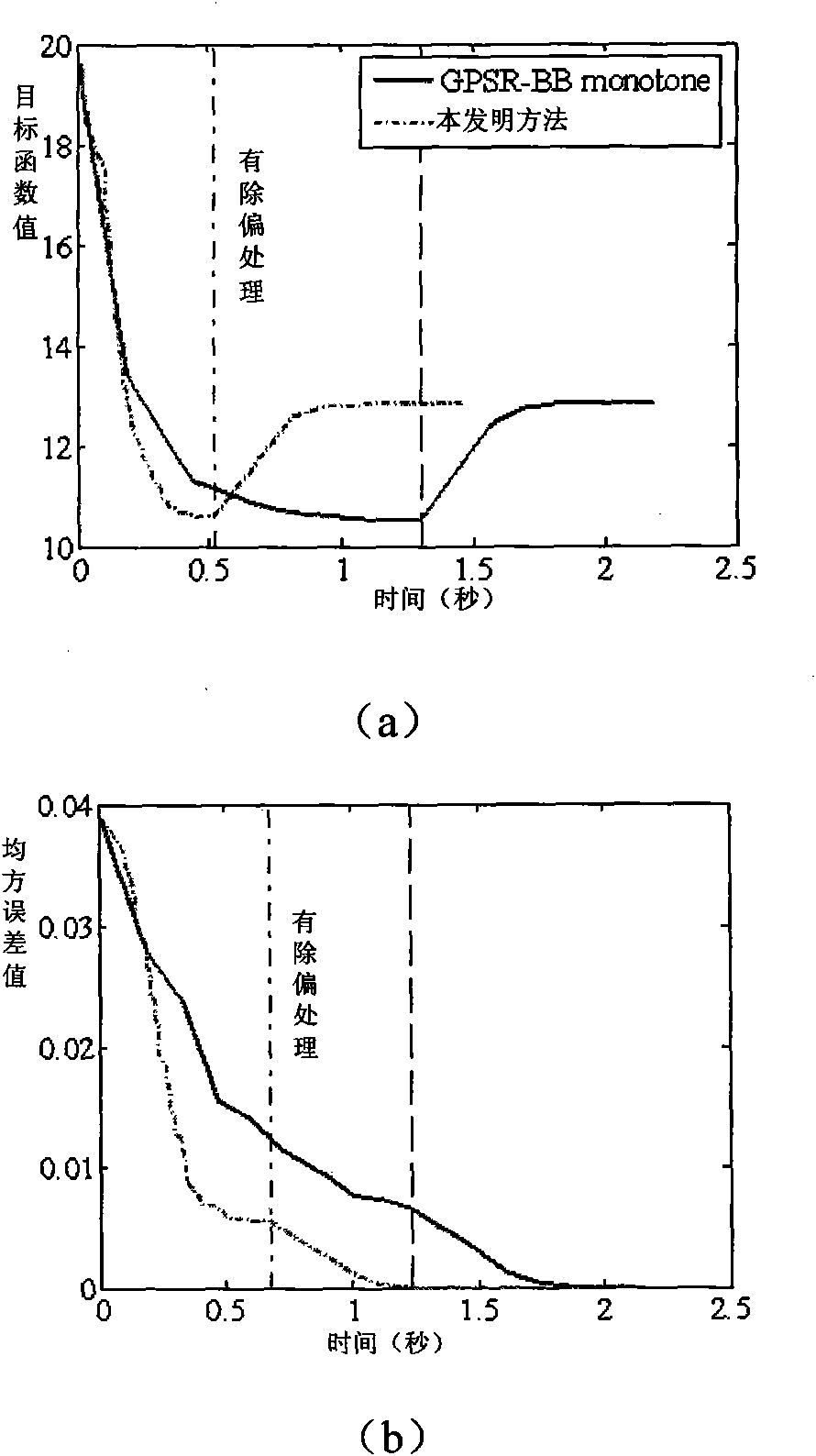

Reconstruction method of sparse signal

InactiveCN101640541ASave storage spaceFast convergenceCode conversionComplex mathematical operationsMean squareSequential minimal optimization

The invention discloses a reconstruction method of sparse signal, mainly solving the problem of low rate of raw sparse signal reconstructed from observation vectors. Utilizing the decomposability of aconstrained object function, the method decomposes the problem of optimizing the constrained object function into a series of small constrained object functions for optimization to improve the reconstruction rate, comprising a raw data acquisition part, a raw sparse signal reconstruction part and a reconstruction accuracy evaluation part, wherein the raw data acquisition part comprises raw sparsesignal generation, matrix observation and vector observation; the raw sparse signal reconstruction part mainly comprises setting unconstrained object function, deducing constrained object function, decomposing the constrained object function by a sequential minimal optimization method, calculating reconstruction signal and debiasing reconstruction signal; the reconstruction accuracy evaluation isto compare the magnitude of the error of mean square. The reconstruction method can improve the reconstruction rate on the premise of ensuring reconstruction accuracy rate and be used for solving theproblem of sparse signal reconstruction in the fields of compressed sensing and the like.

Owner:XIDIAN UNIV

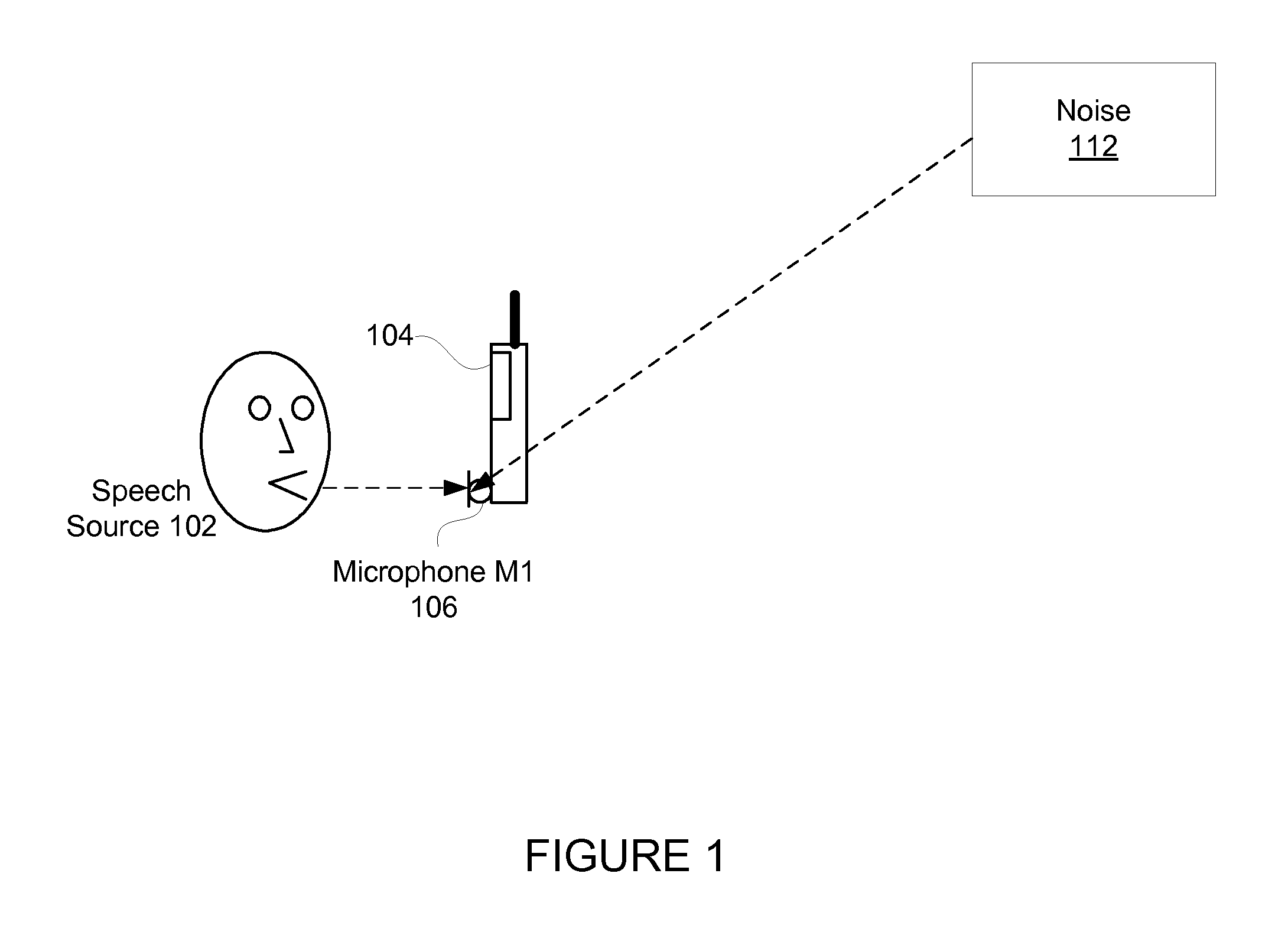

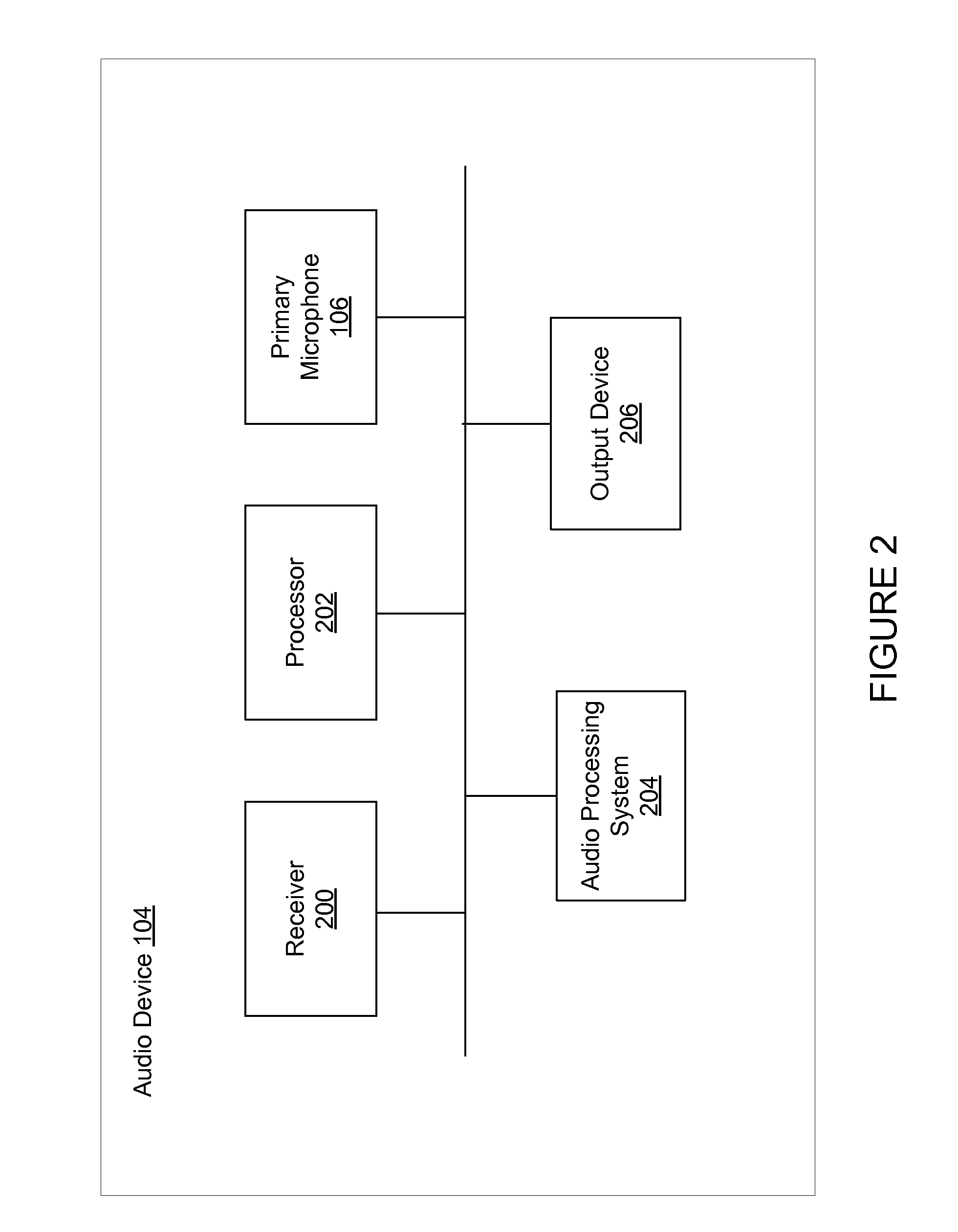

Monaural Noise Suppression Based on Computational Auditory Scene Analysis

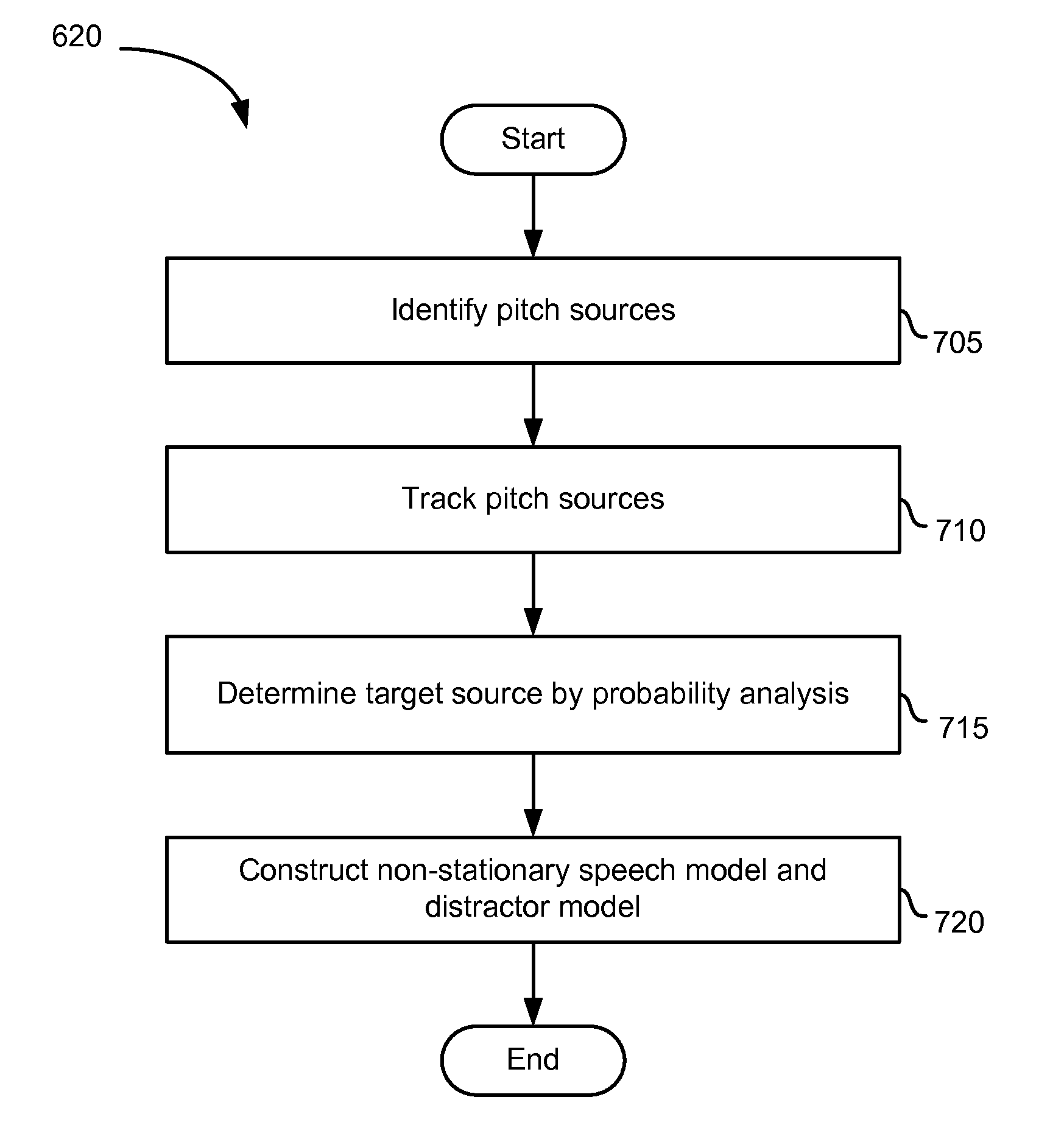

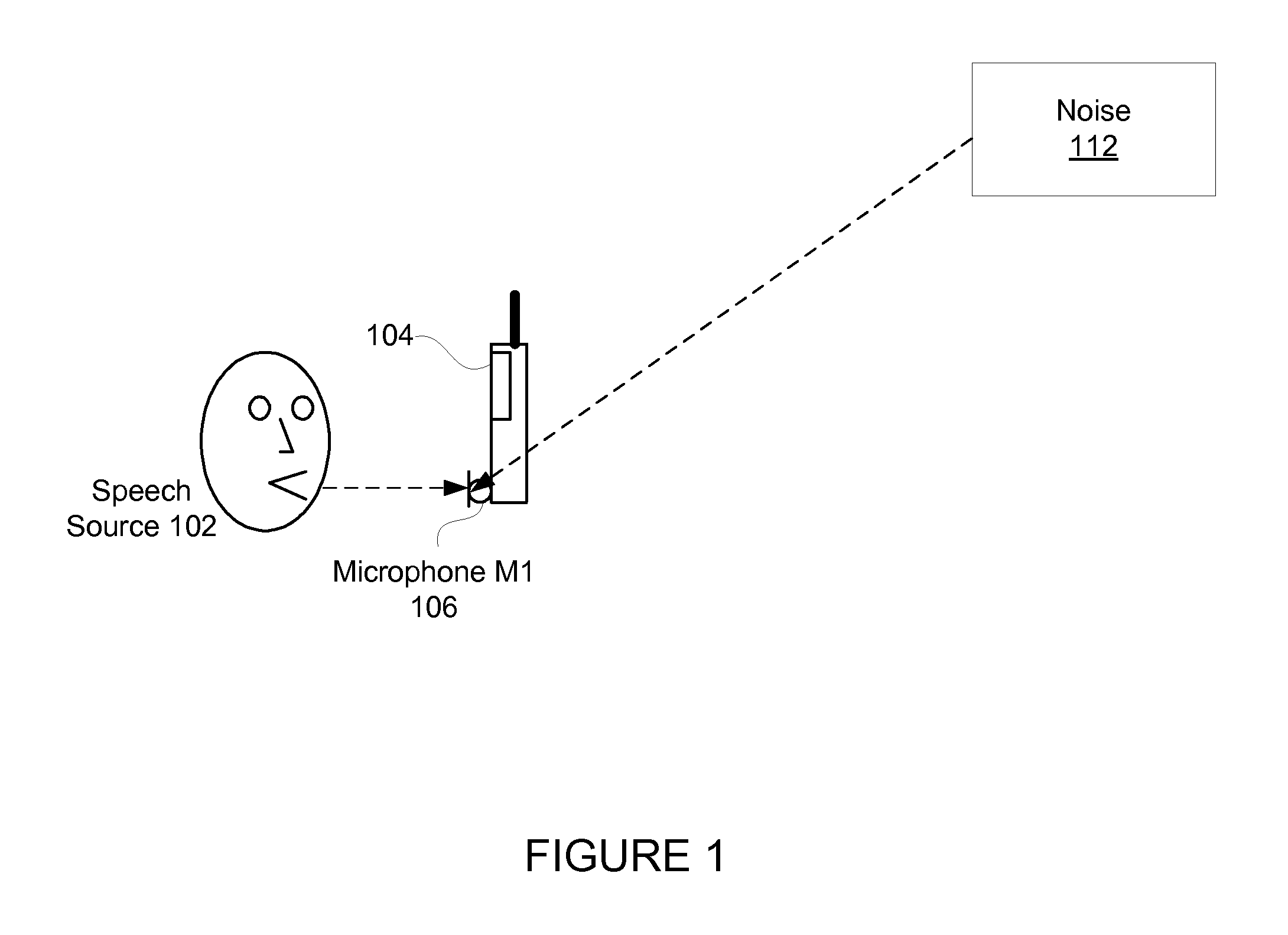

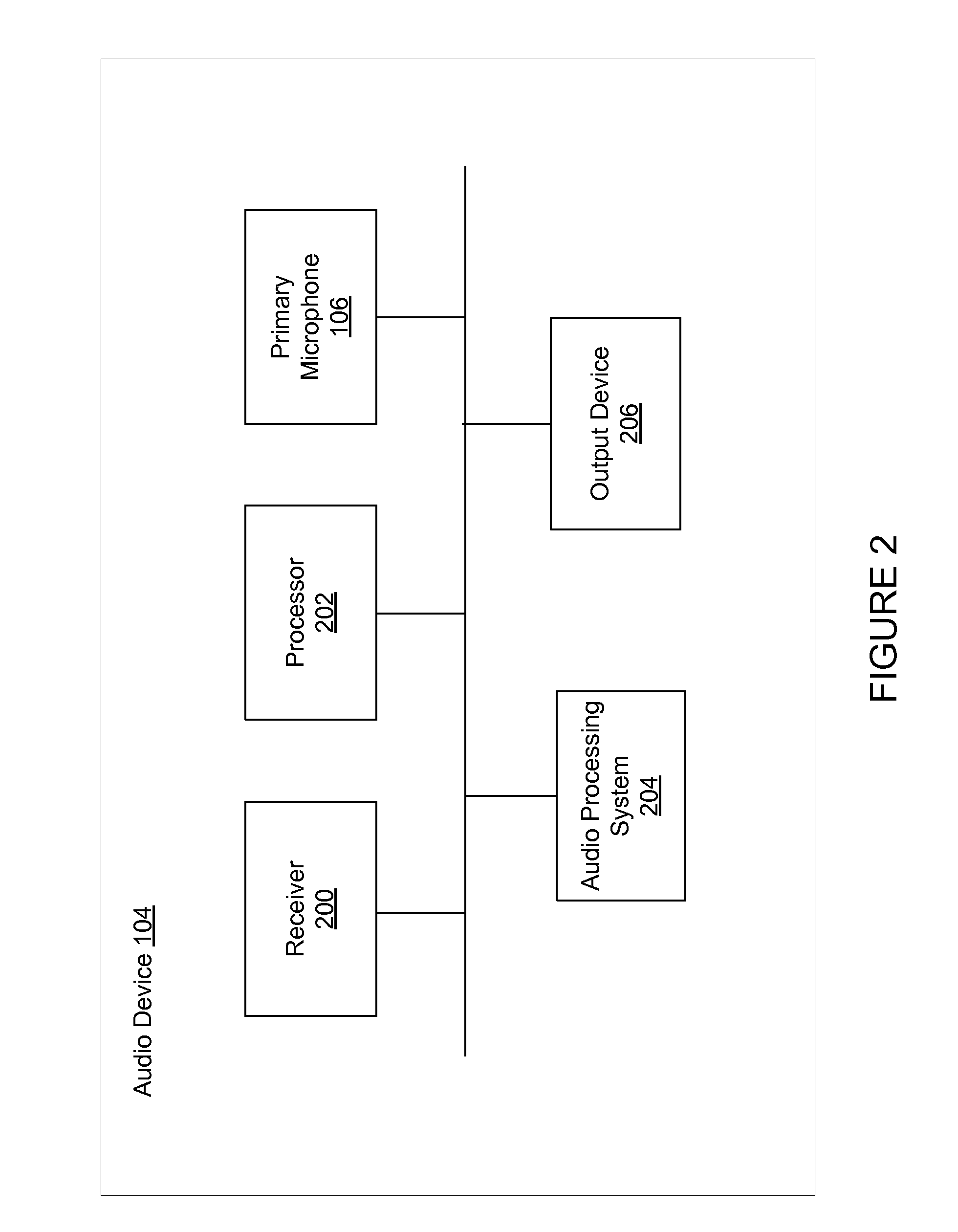

The present technology provides a robust noise suppression system which may concurrently reduce noise and echo components in an acoustic signal while limiting the level of speech distortion. An acoustic signal may be received and transformed to cochlear domain sub-band signals. Features such as pitch may be identified and tracked within the sub-band signals. Initial speech and noise models may be then be estimated at least in part from a probability analysis based on the tracked pitch sources. Speech and noise models may be resolved from the initial speech and noise models and noise reduction may be performed on the sub-band signals and an acoustic signal may be reconstructed from the noise-reduced sub-band signals.

Owner:KNOWLES ELECTRONICS INC

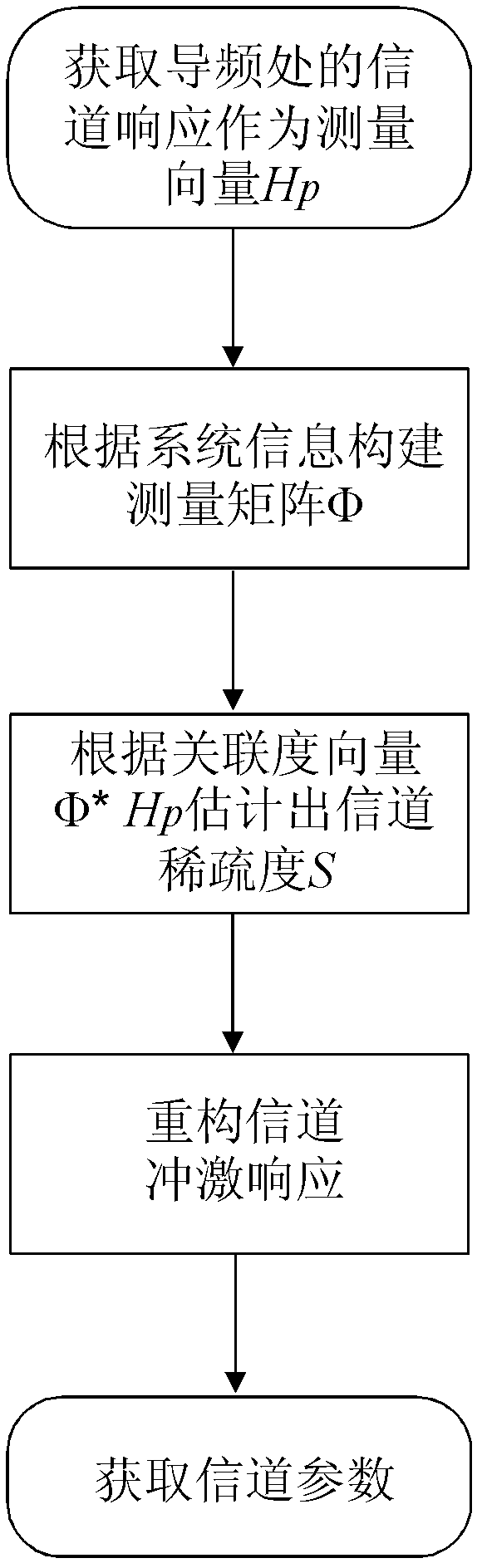

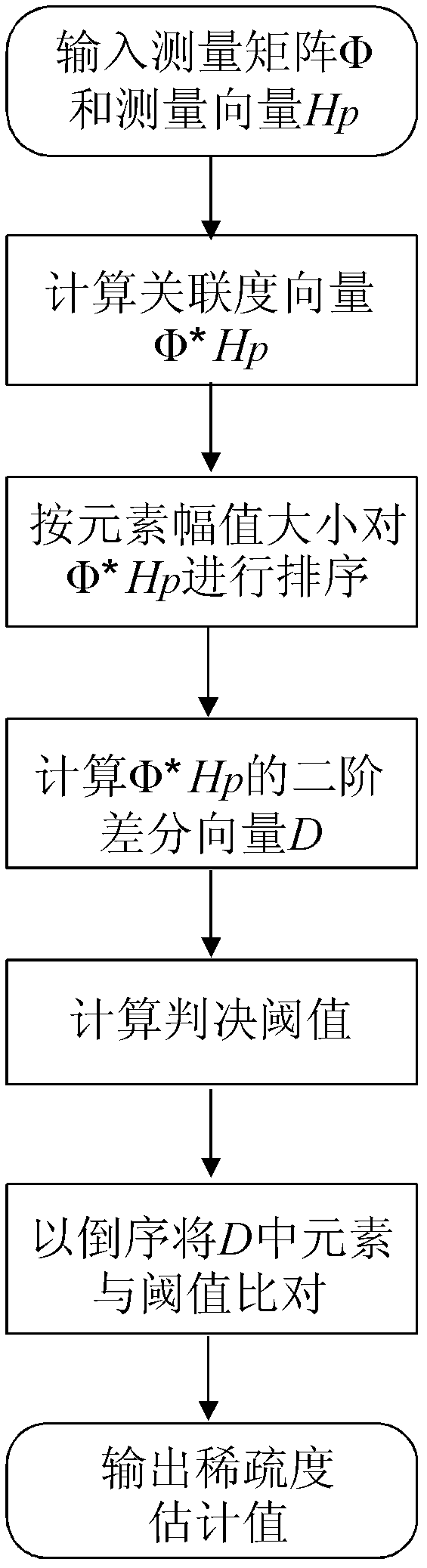

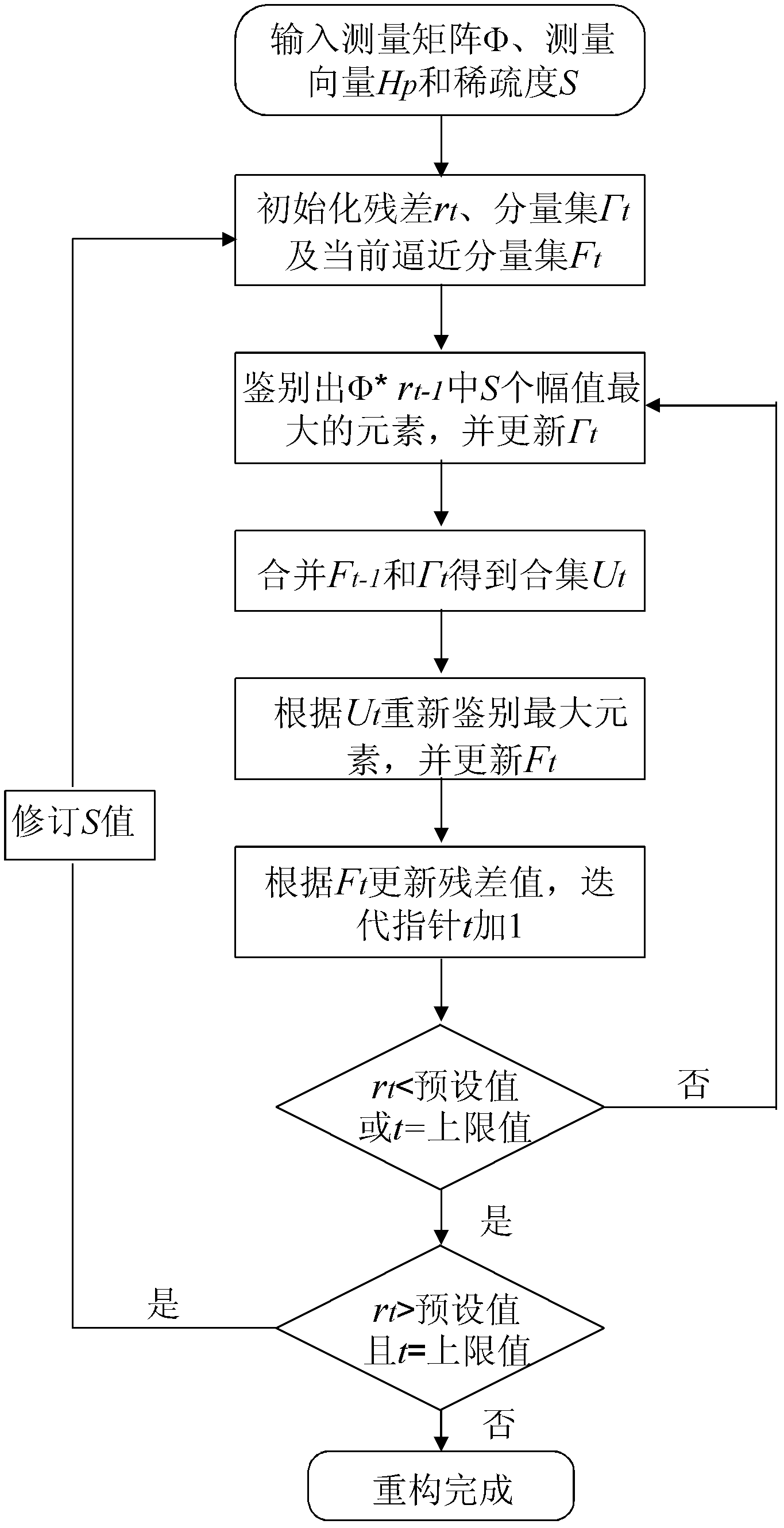

Compressed sensing wireless communication channel estimation method based on sparsity self-adapting

InactiveCN102497337AImprove spectrum utilizationReduce the number of pilotsBaseband system detailsMulti-frequency code systemsChannel impulse responseEstimation methods

The invention belongs to the field of wireless communication channel estimation, particularly relates to a compressed sensing wireless communication channel estimation method based on sparsity self-adapting, which includes the ssteps: (1) collecting demodulated receiving signals and calculating channel response of a pilot frequency position; (2) constructing a measurement matrix phi required by signal reconstruction; (3) calculating an association degree vector and sequencing elements of the vector; (4) calculating second difference vector of a novel association degree vector after sequencing and setting a threshold value I for judging sparsity of signals; (5) estimating sparsity S of channel impulse response; (6) comparing the threshold value I with the last element of a vector D sequentially, and a coefficient value corresponding to the first element larger than the threshold value is the estimated sparsity S of the signals; and (7) reconstructing the signals. The channel estimation method breaks a bottleneck of a traditional compressed sensing algorithm that the sparsity of the signals must be known, and signal reconstruction of sparsity self-adapting is achieved.

Owner:TIANJIN UNIV

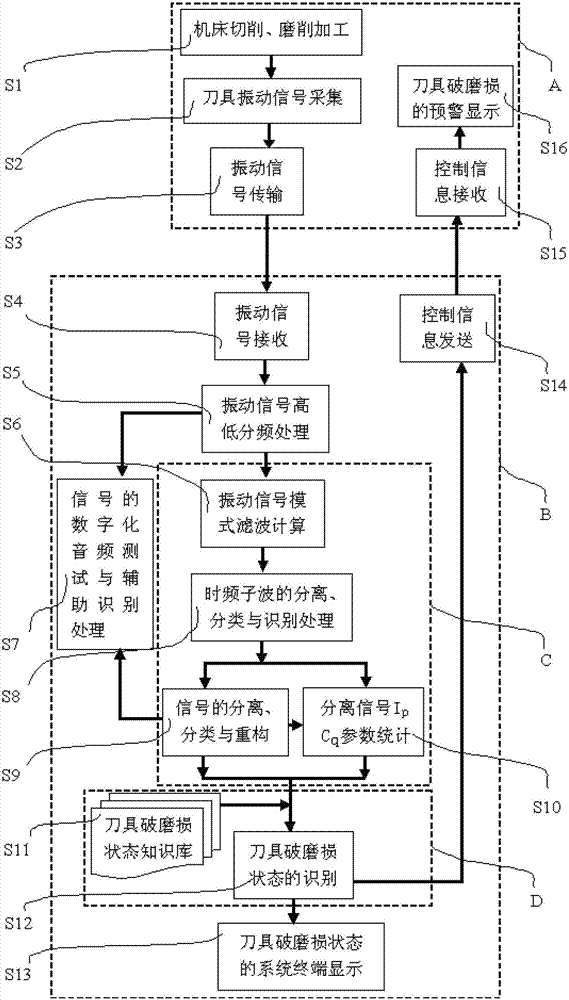

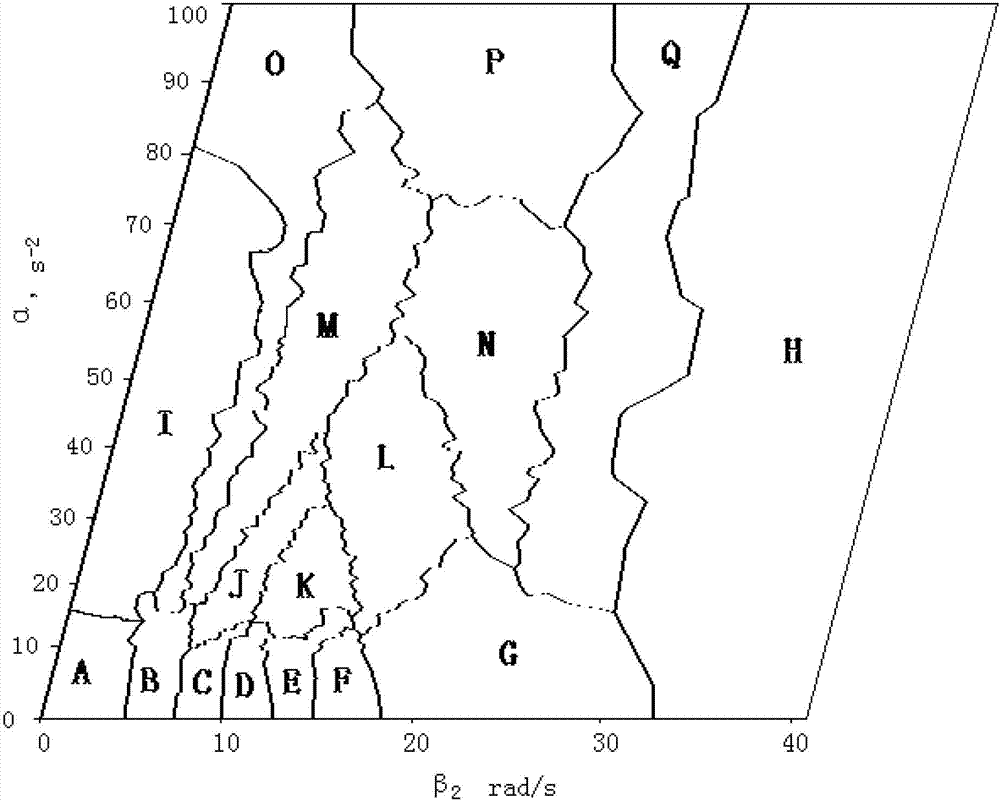

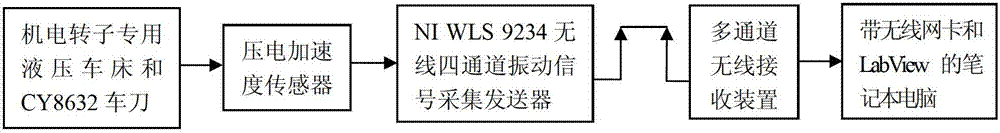

Cutter damage and abrasion state detecting method and cutter damage and abrasion state detecting system

ActiveCN102765010ARealize online dynamic monitoringHigh precisionMeasurement/indication equipmentsProduction rateFeature extraction

The invention relates to a cutter damage and abrasion state detecting method, which comprises the following steps that 1, vibration signals in the cutter cutting and grinding processes are measured; 2, the vibration signals are subjected to mode filtering calculation; 3, time-frequency wavelets of the vibration signals are subjected to classification sorting and feature extractions; and 4, the time-frequency wavelets are subjected to classification, collection and signal separation processing, various kinds of time-frequency wavelets are subjected to signal reconstruction, the kurtosis index (Cq) and the peak index (Ip) of various kinds of signals are then counted, the cutter damage and abrasion state and the machine tool operation state are detected under the dynamic distribution condition of a Cq-Iq plane according to various kinds of separation signal index parameters, and the identification detection and the quantitative early warning and forecast of the cutter damage and abrasion state are realized. Through single monitoring equipment, the detection of the cutter damage and abrasion state is realized, the signal identification stability is good, the mechanical processing production safety is ensured, the precision of processing parts is improved, and the production rate and the utilization rate of a machine tool are improved.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

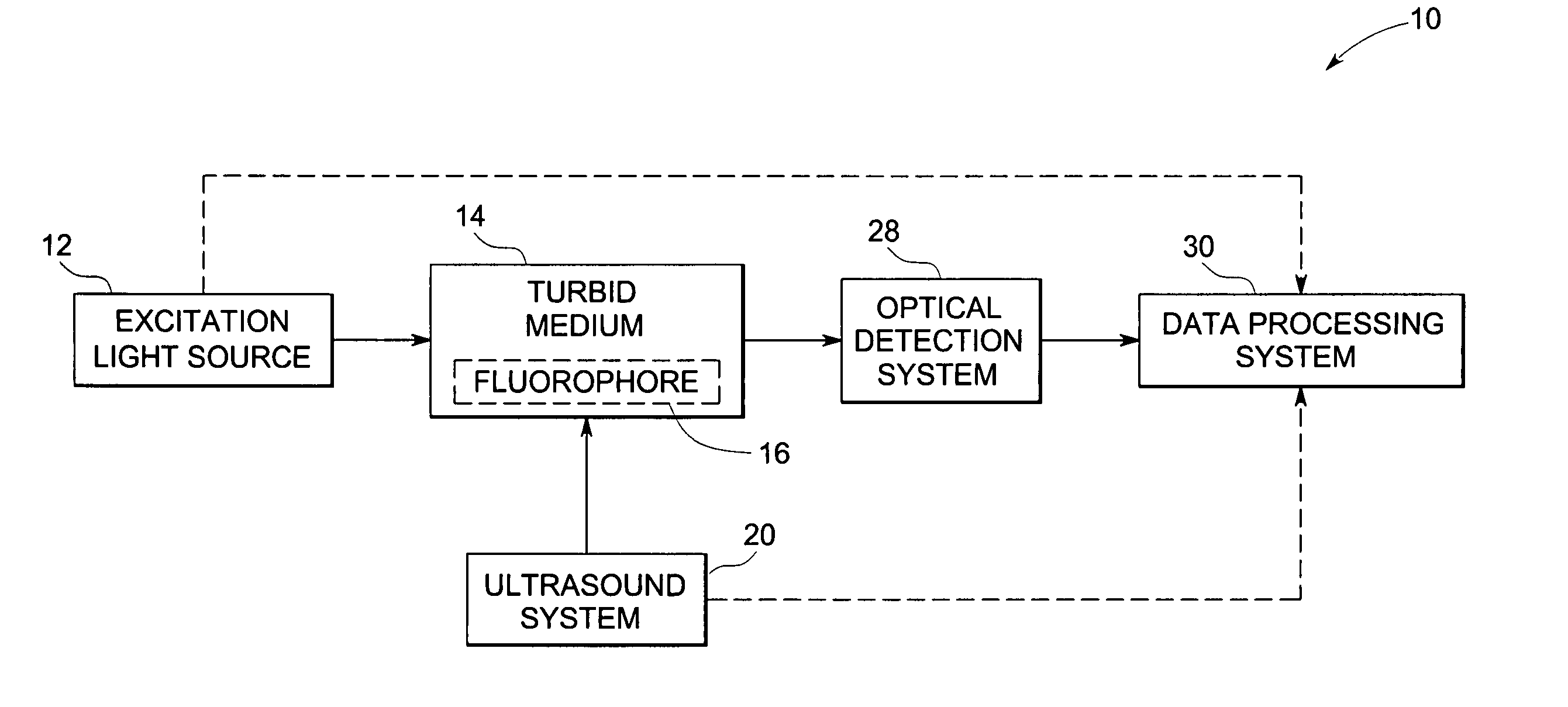

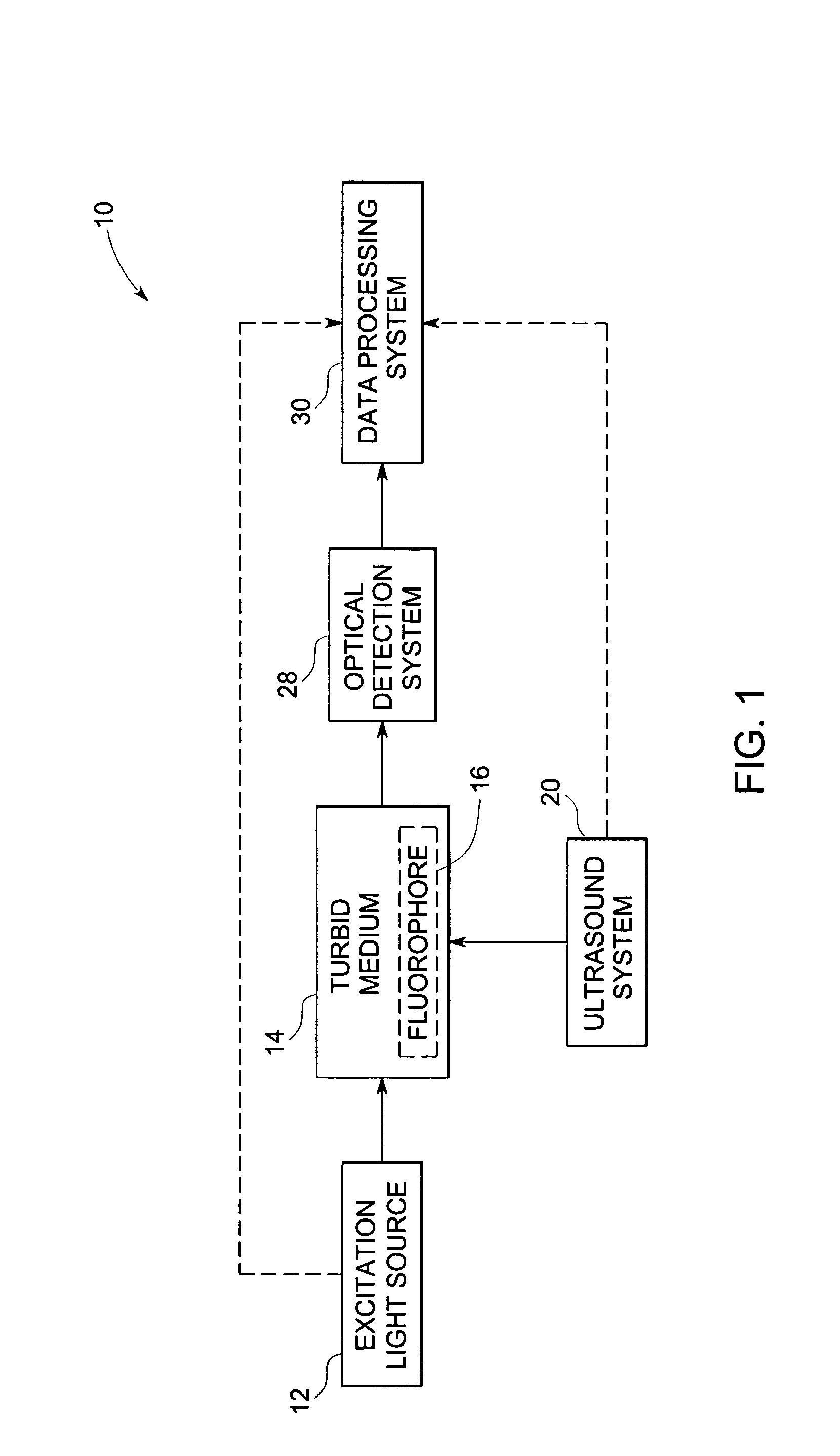

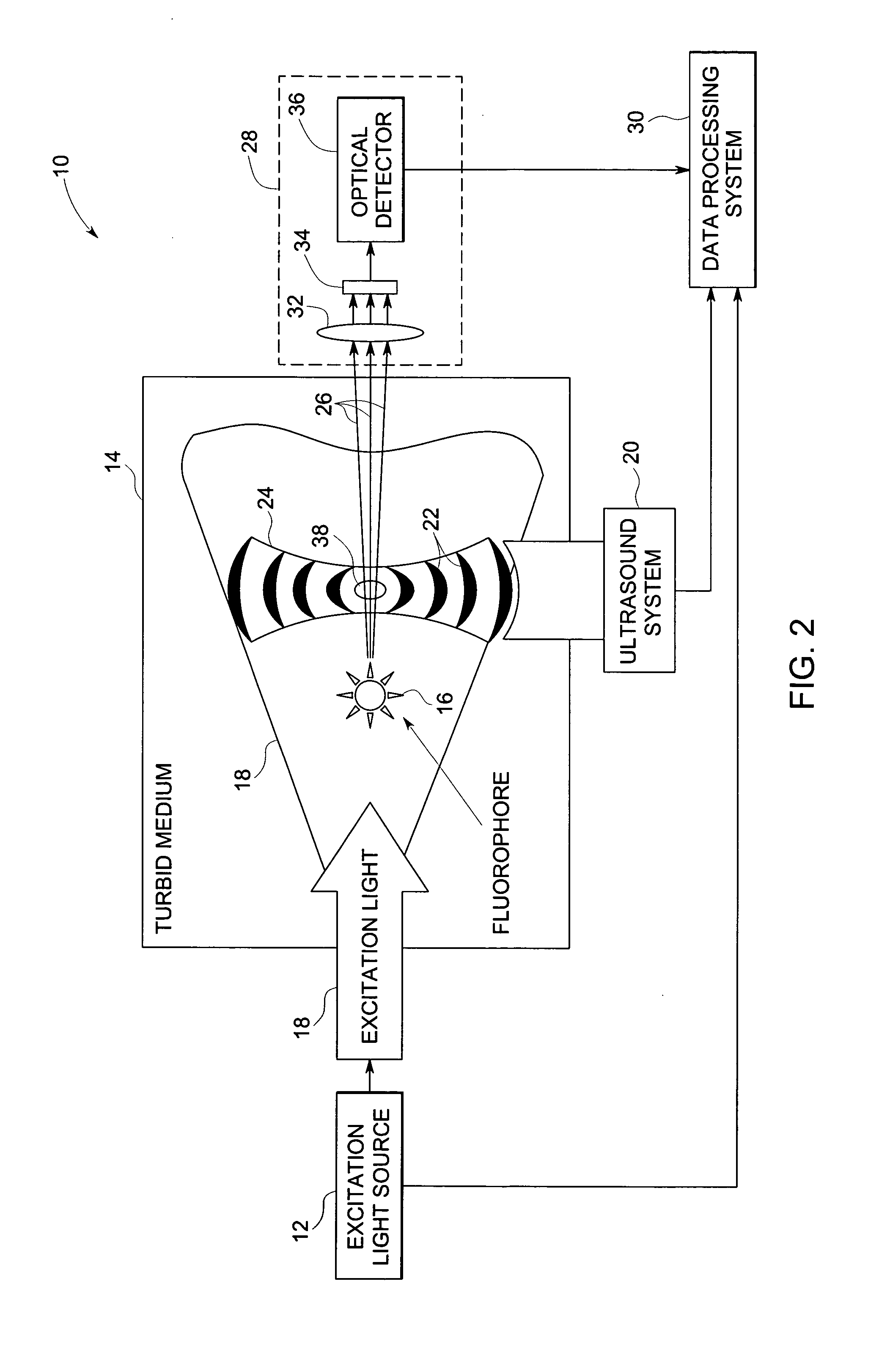

System and method for imaging based on ultrasonic tagging of light

ActiveUS20060058685A1Ultrasonic/sonic/infrasonic diagnosticsDiagnostics using vibrationsUltrasonic beamLight irradiation

A technique is provided for imaging based on localization of fluorescence in a medium. The technique includes illuminating the medium with an excitation light to excite fluorescence, scanning the medium at a plurality of locations via an ultrasonic beam, modulating a portion of the emitted light from the fluorescence via the ultrasonic beam at each of the plurality of locations, differentially detecting the modulated light at a boundary of the medium, and reconstructing an image from the detected signal.

Owner:GENERAL ELECTRIC CO

Inter-component prediction

ActiveUS20160029035A1Improve coding efficiencyEnabling changeColor television with pulse code modulationColor television with bandwidth reductionData streamComputer science

Reconstructing a second component signal relating to a second component of a multi-component picture from a spatially corresponding portion of a reconstructed first component signal and a correction signal derived from a data stream for the second component promises increased coding efficiency over a broader range of multi-component picture content. By including the spatially corresponding portion of the reconstructed first component signal into the reconstruction of the second component signal, any remaining inter-component redundancies / correlations present such as still present despite a possibly a priori performed component space transformation, or present because of having been introduced by such a priori performed component space transformation, for example, may readily be removed by way of the inter-component redundancy / correlation reduction of the second component signal.

Owner:GE VIDEO COMPRESSION LLC

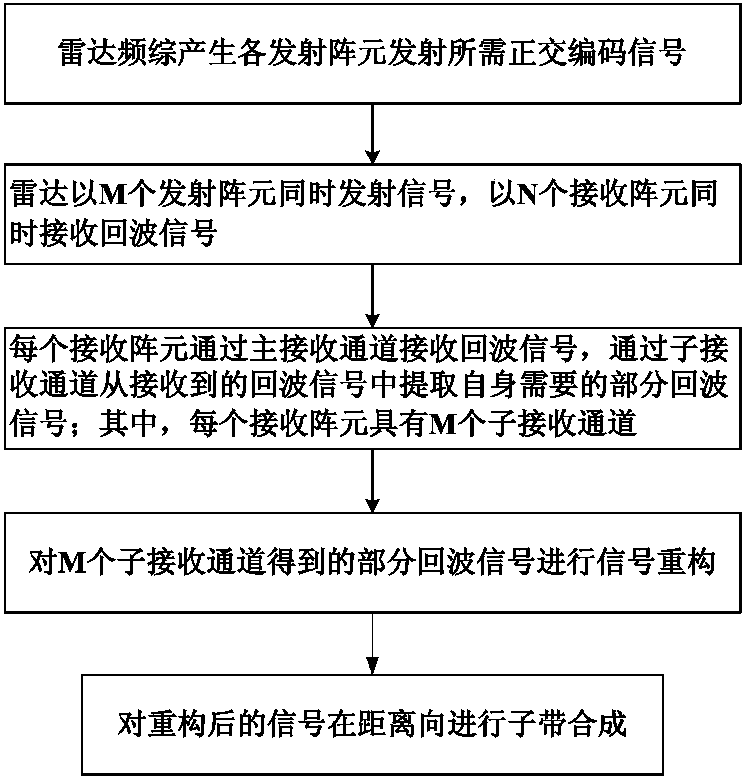

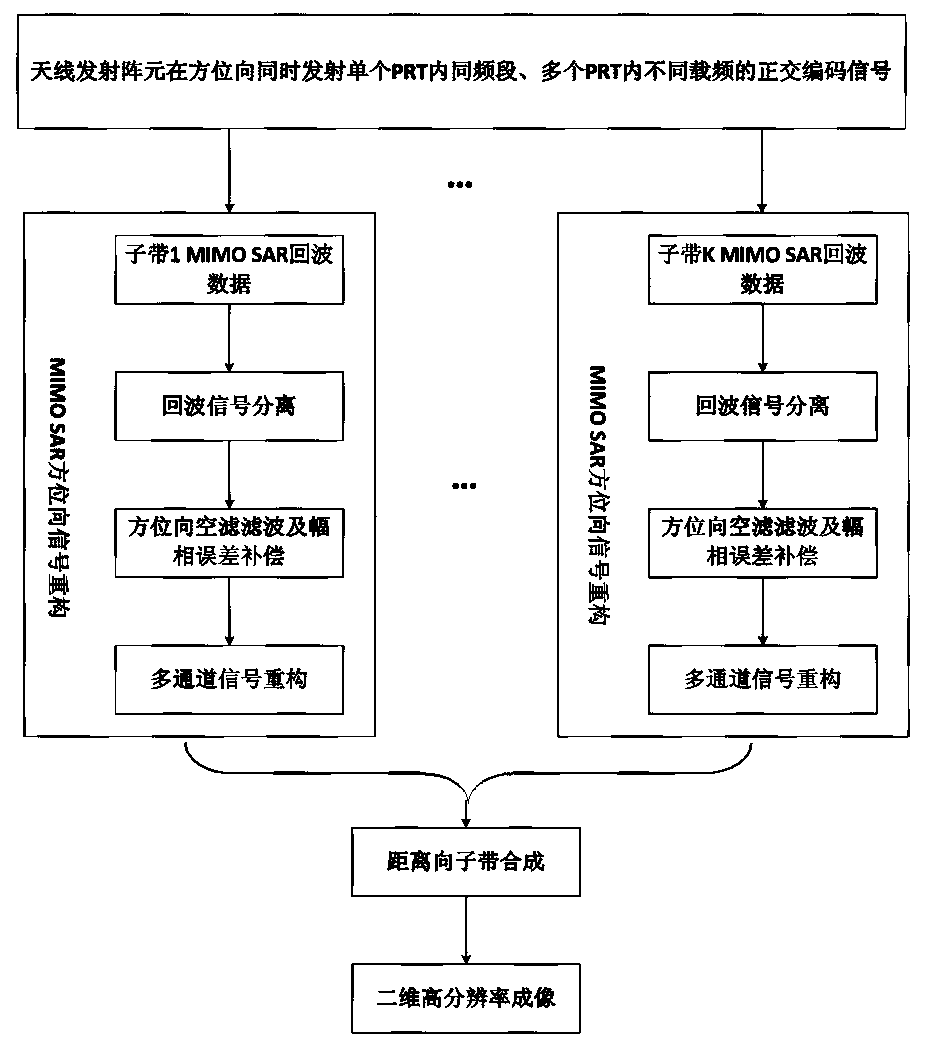

Method for designing multiple-input-multiple-output synthetic aperture radar system on basis of sub-band synthesis

ActiveCN104166141AWork lessWork around limitationsRadio wave reradiation/reflectionSystems designRadar waveforms

The invention relates to a method for designing a multiple-input-multiple-output synthetic aperture radar (MIMOSAR) system on the basis of sub-band synthesis. The method includes the steps that a radar waveform generating module generates quadrature encoding signals needed for transmission of various transmitting array elements; according to radar, M transmitting array elements are used for transmitting signals at the same time, and N receiving array elements are used for receiving echo signals simultaneously; each receiving array element receives the echo signals through a main reception channel, extracts a part of the echo signals as required from the echo signals received by the main reception channel through minor reception channels and is provided with the M minor reception channels; signal reconstruction is carried out on the part of the echo signals obtained by the M minor reception channels of each receiving array element; sub-band synthesis is conducted on the reconstructed signals in a distance. The orientation multi-aperture MIMOSAR system based on a sub-pulse linear frequency modulation stepping system namely sub-band synthesis is adopted, the instantaneous operation bandwidth and sampling rate of the MIMOSAR system are reduced manyfold, and remote high-resolution wide-observation-band imaging can be achieved in an SAR mode.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

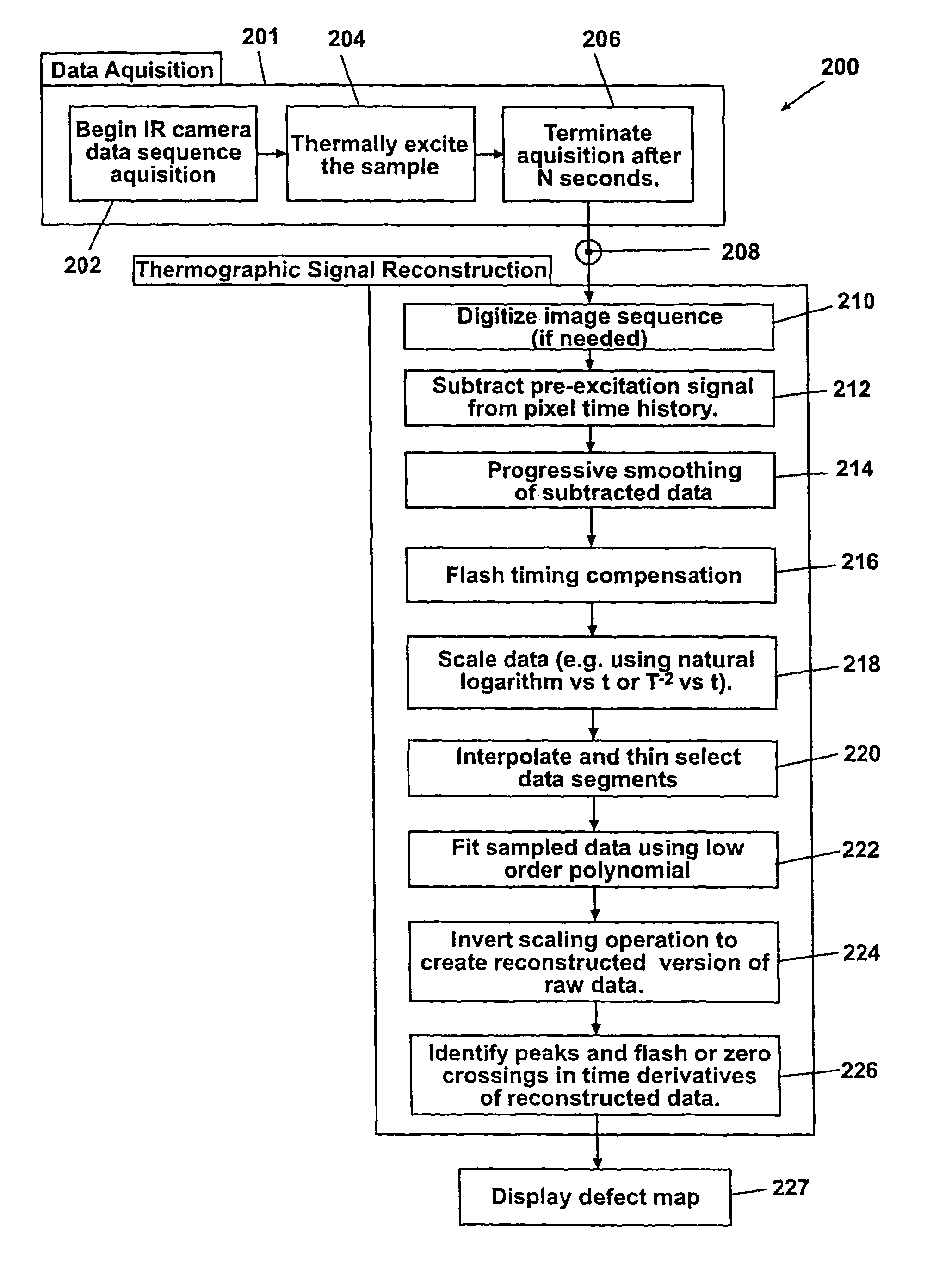

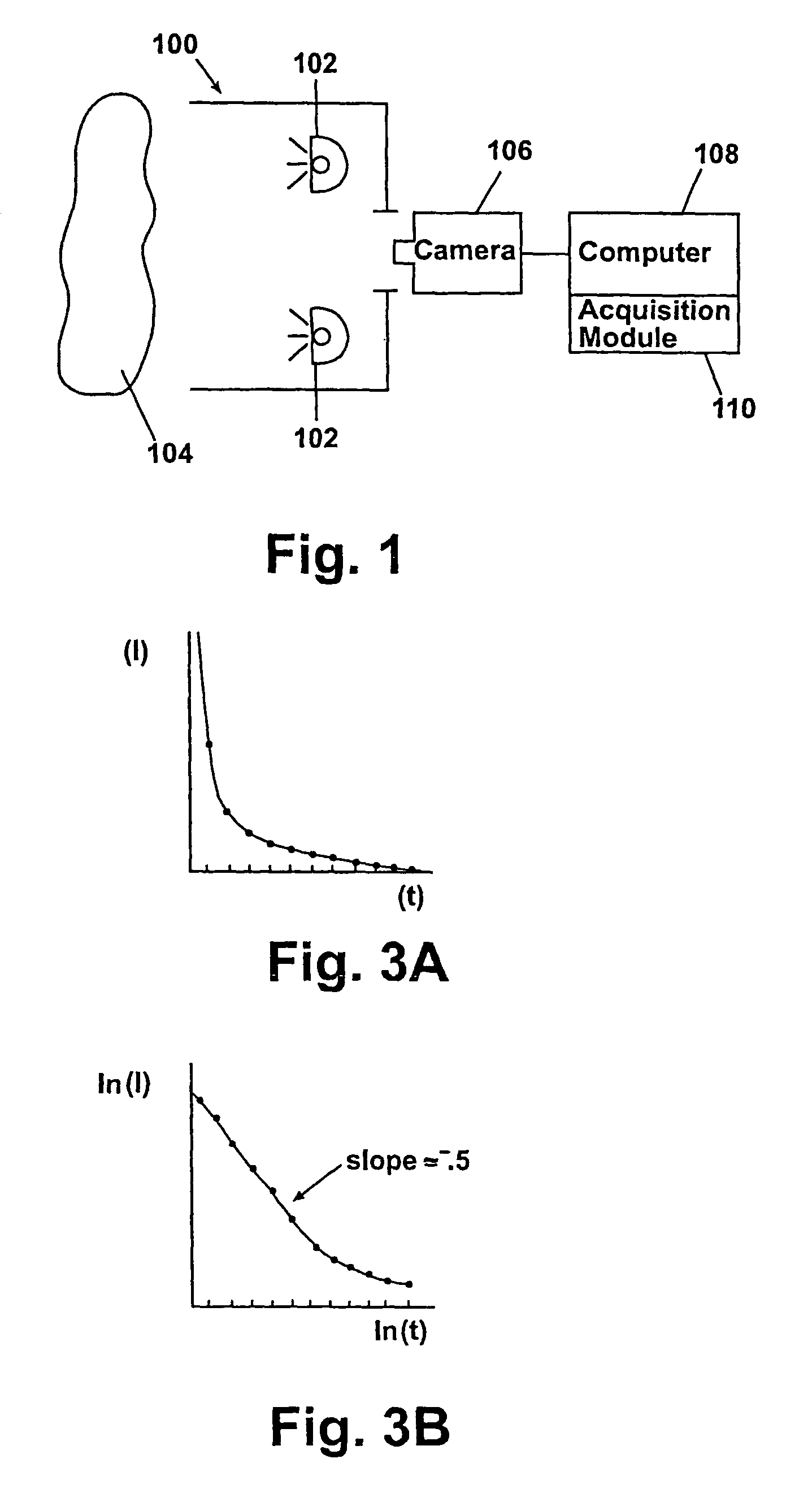

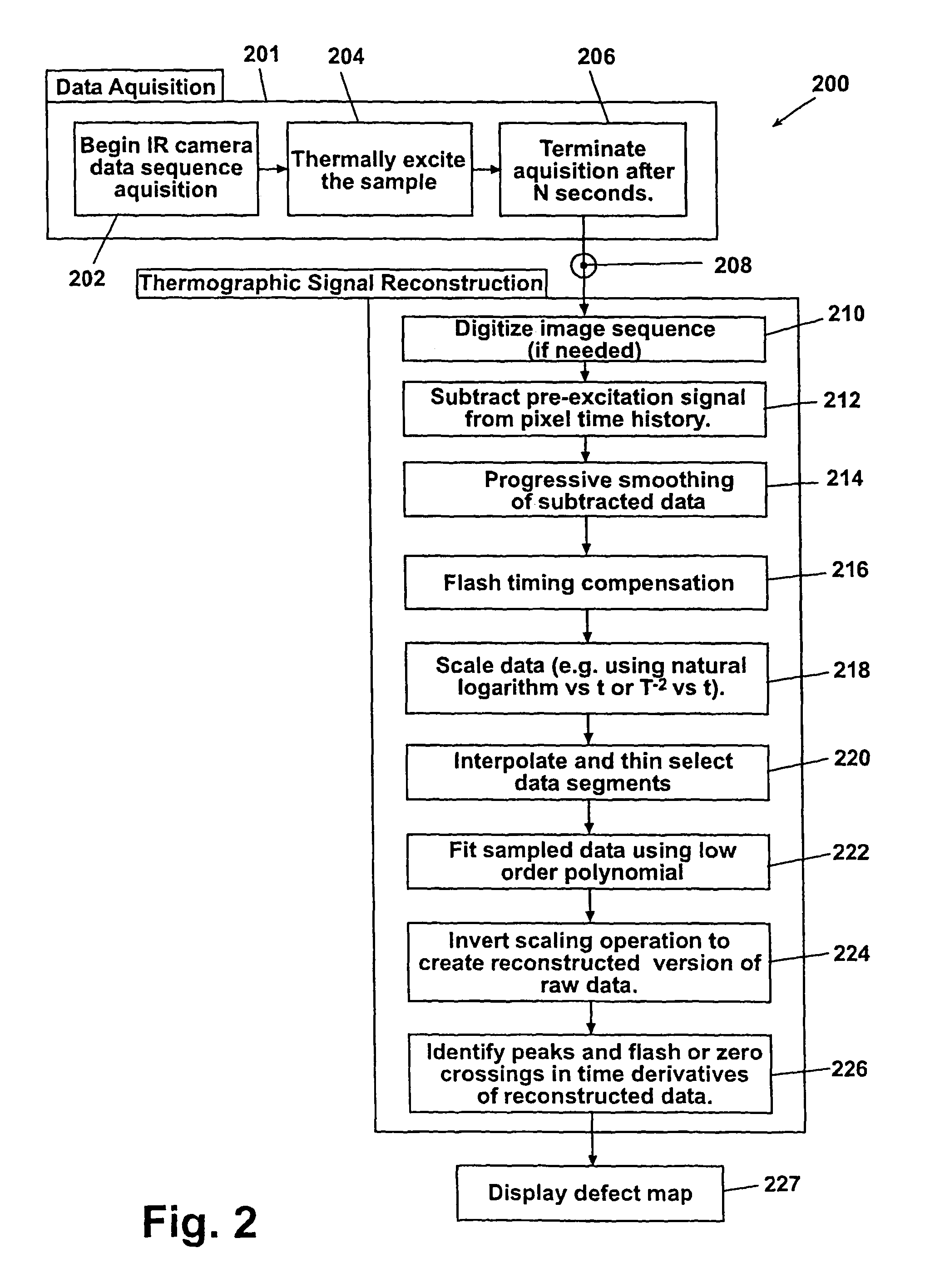

System for generating thermographic images using thermographic signal reconstruction

ActiveUS7724925B2Small sizeReduce complexityCharacter and pattern recognitionMaterial flaws investigationThermographySignal reconstruction

A method for compiling thermographic data including obtaining data indicative of a monotonically changing characteristic of a specimen, sequencing the data or a surrogate of the data into a plurality of groups, categorizing, within each group, the frequency distribution of an attribute of the data or an attribute of said surrogate data, and compiling, from one or more groups, a collection of two or more of the frequency distributions.

Owner:THERMAL WAVE IMAGING INC

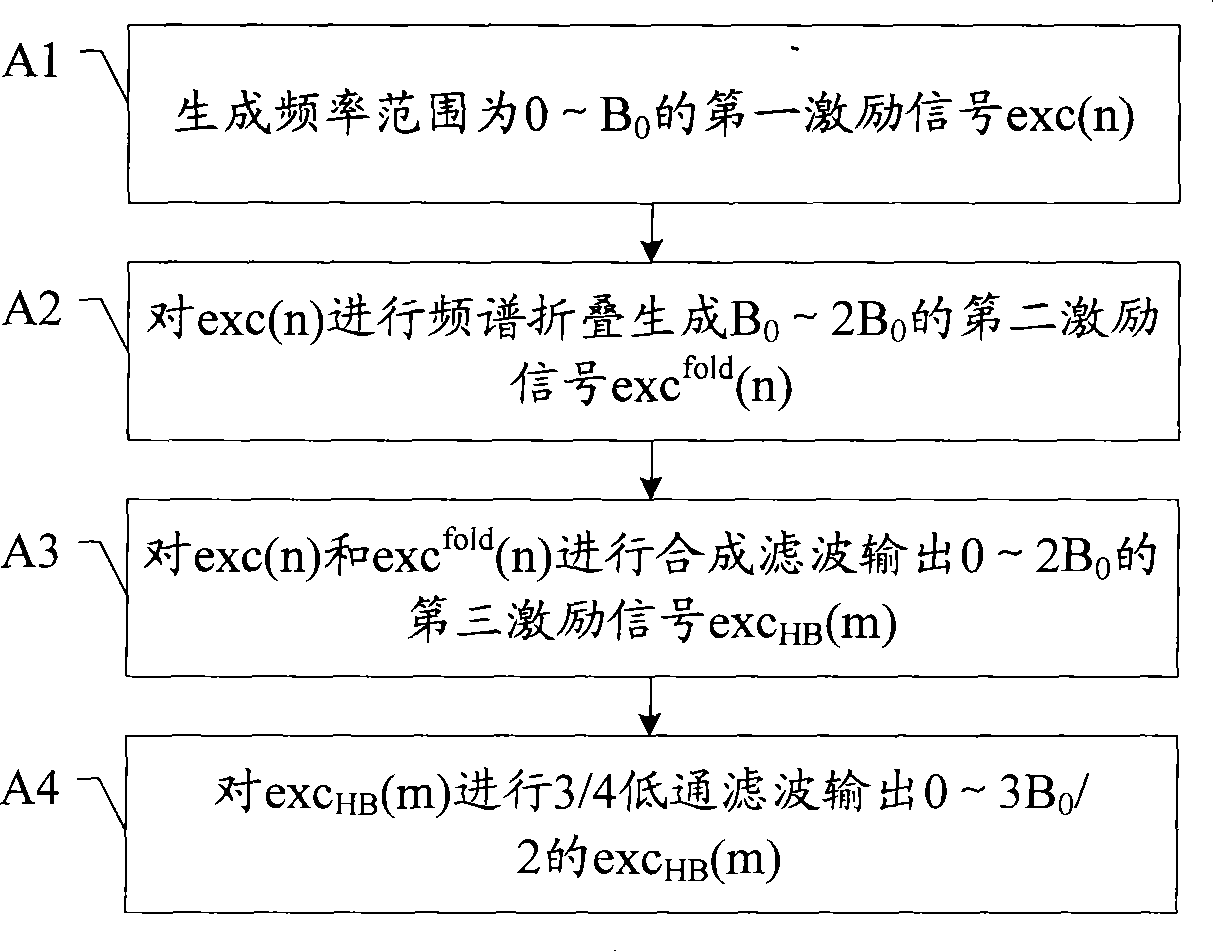

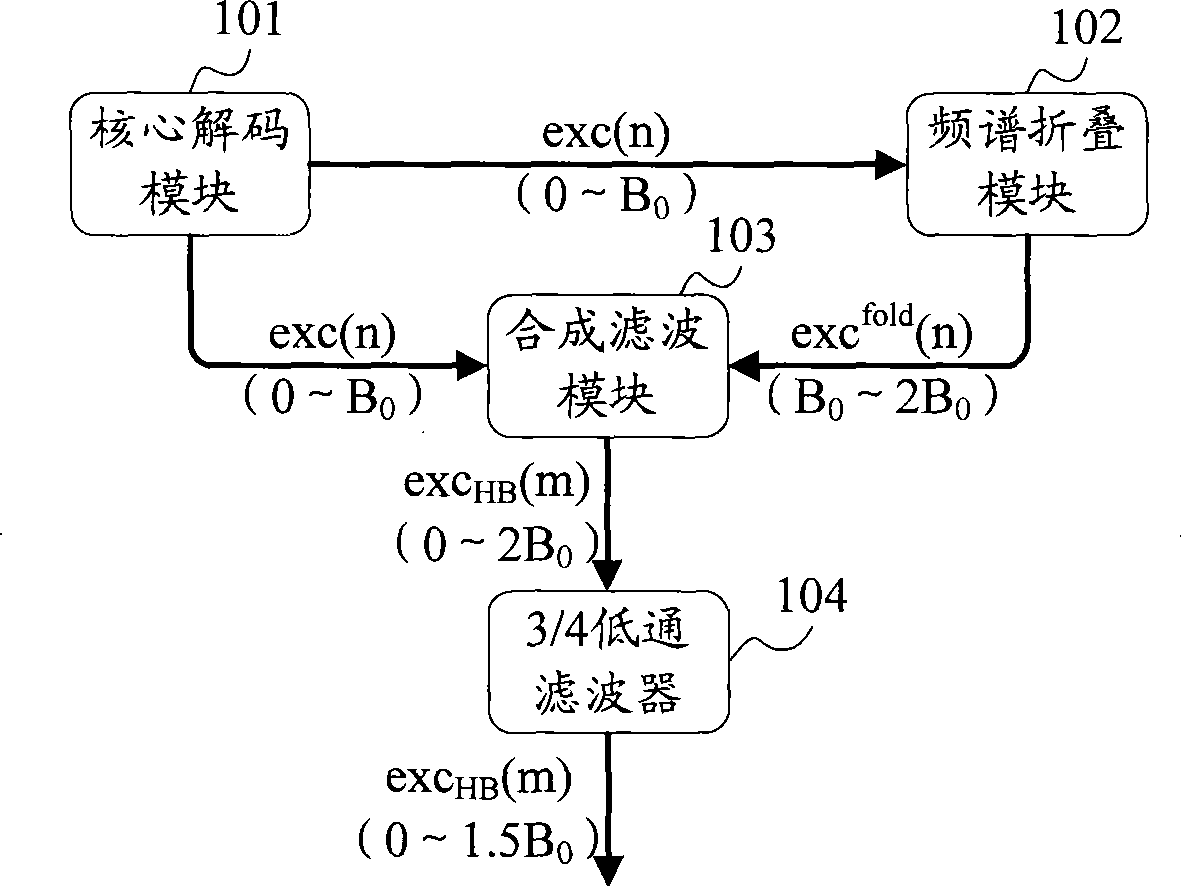

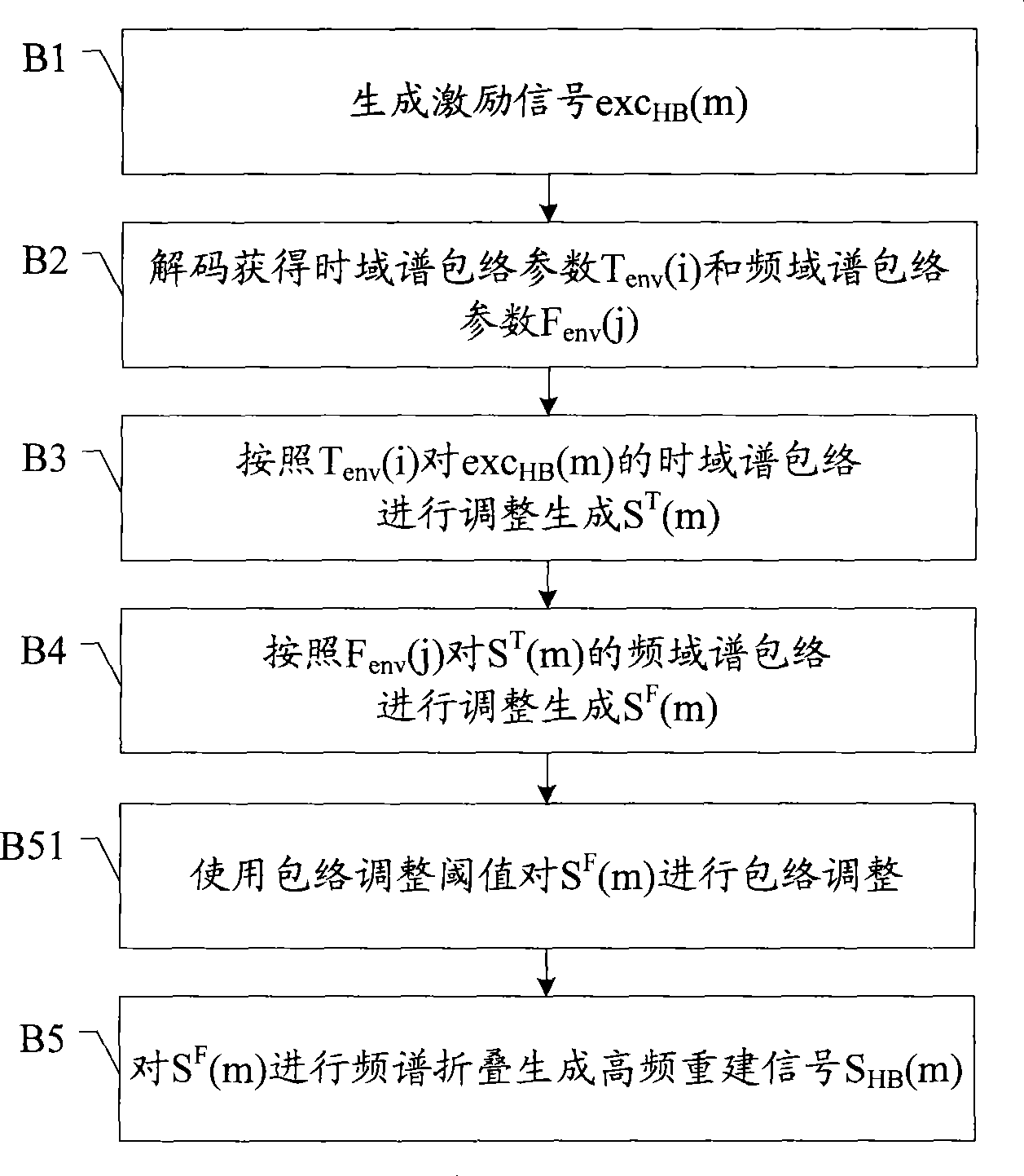

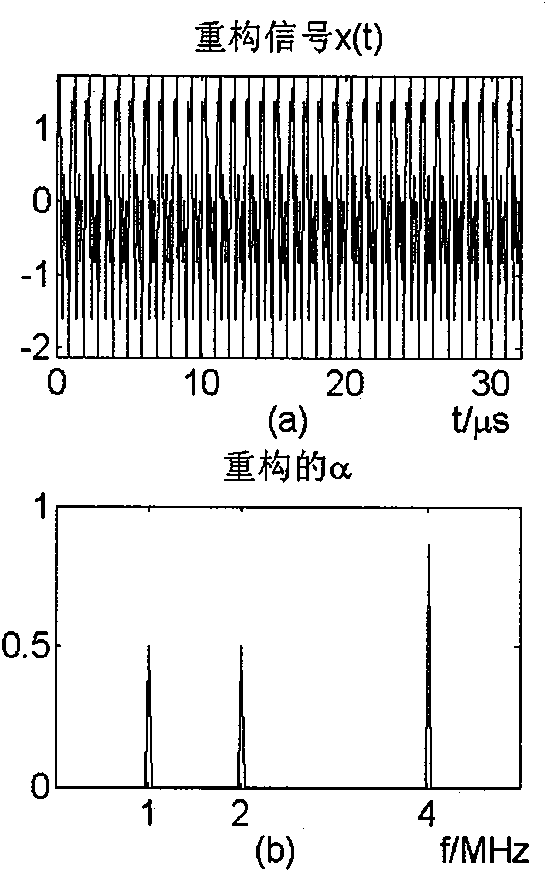

Excitation signal generation in bandwidth spreading and signal reconstruction method and apparatus

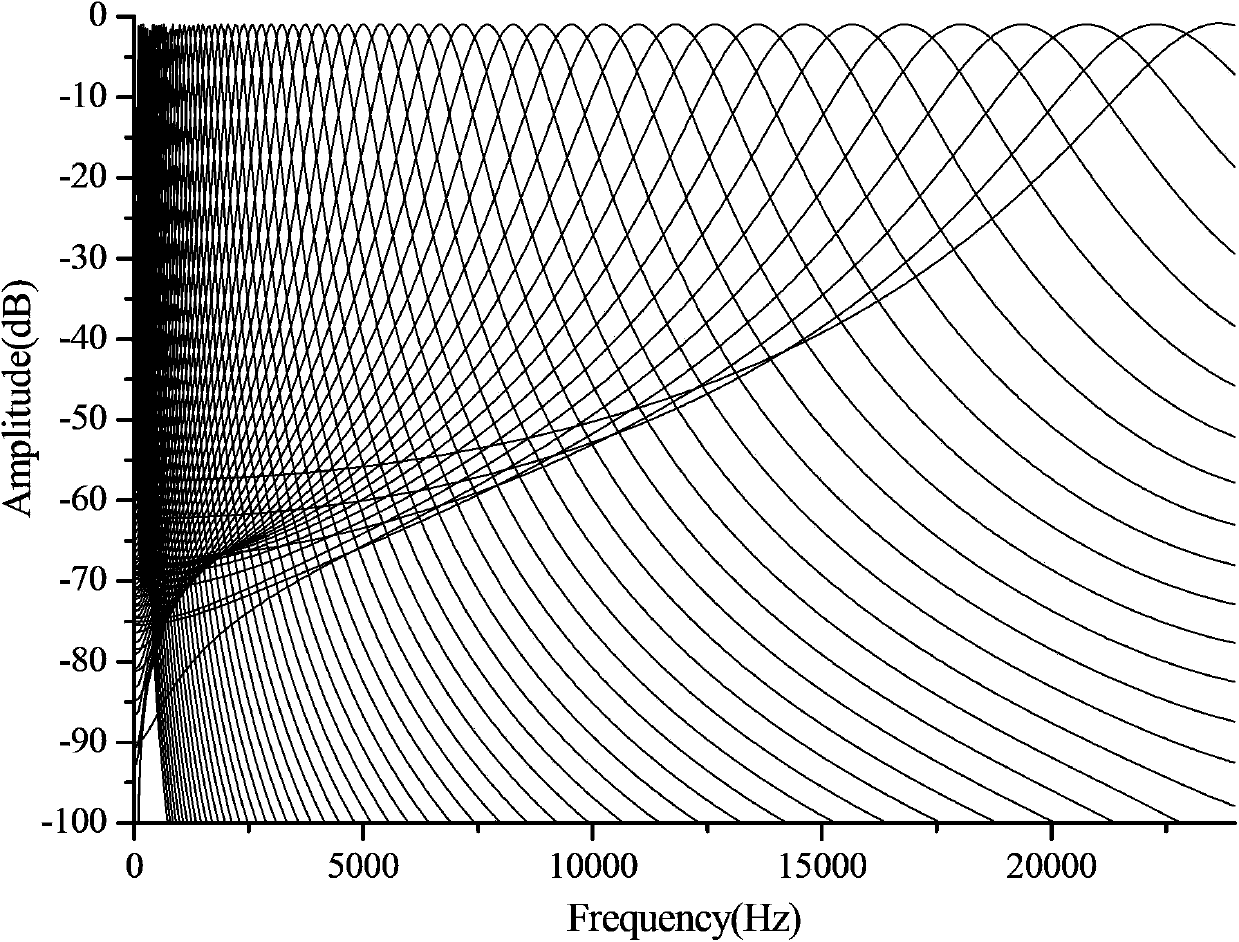

InactiveCN101458930AImprove scalabilityImprove continuitySpeech analysisUltra-widebandFrequency spectrum

The invention discloses a method for generating exciting signals in bandwidth extension, which processes narrow-band low frequency signals via frequency spectrum folding and synthesis to generate required high frequency exciting signals. The invention further provides a reconstruction method for the high frequency signals in bandwidth extension and a device thereof. The technical scheme utilizes low frequency signals to generate high frequency signals, and is based on the harmonic characteristic of low and high frequency spectrums of the signals, therefore, the method can extend speech and music signals effectively, and the frequency spectrum folding method can confirm the signal frequency spectrum continuity of high and low frequencies at joint part. Tests prove that the technical scheme is suitable for extending ultra wideband signals of 7 to 14 kHz.

Owner:HUAWEI TECH CO LTD +1

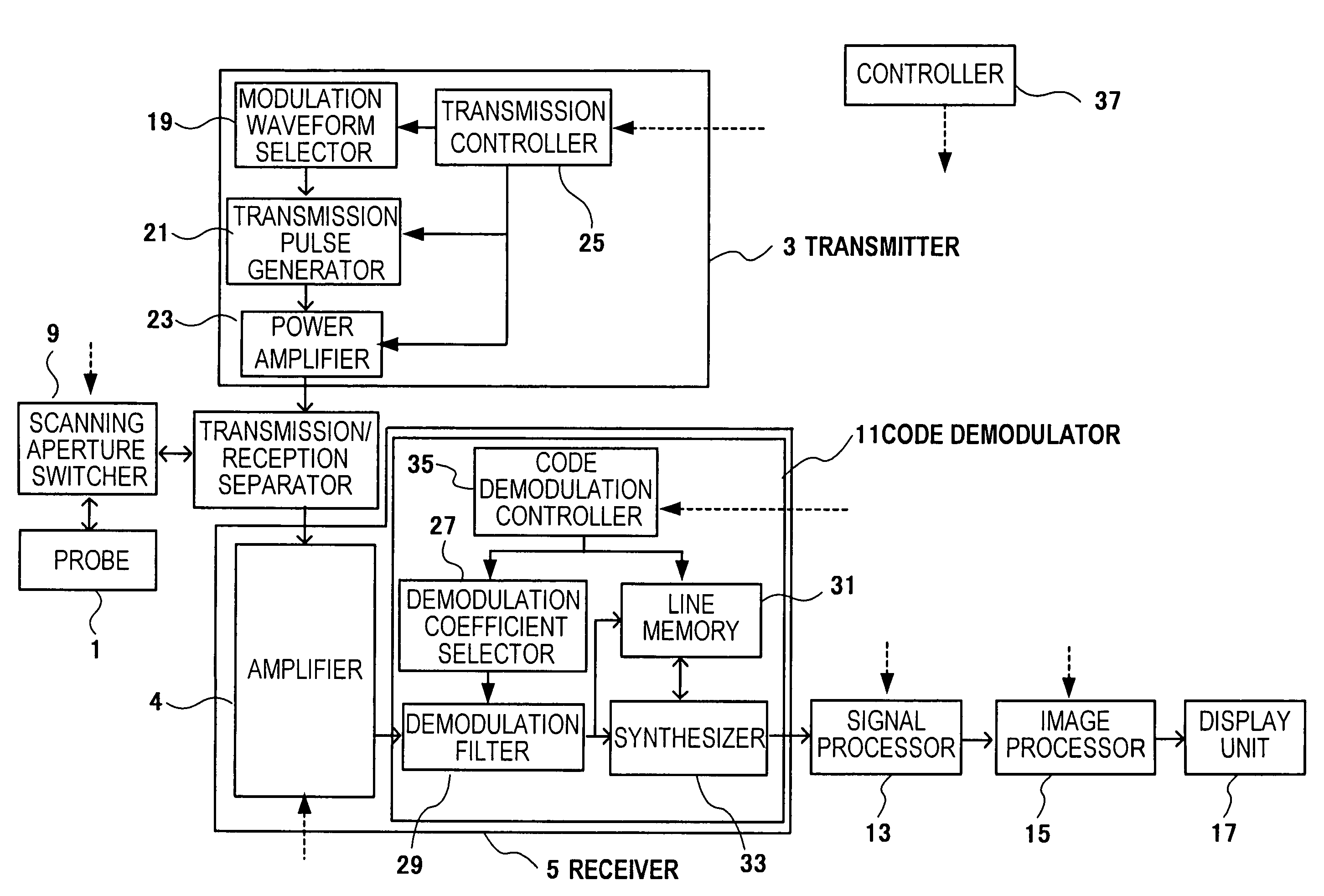

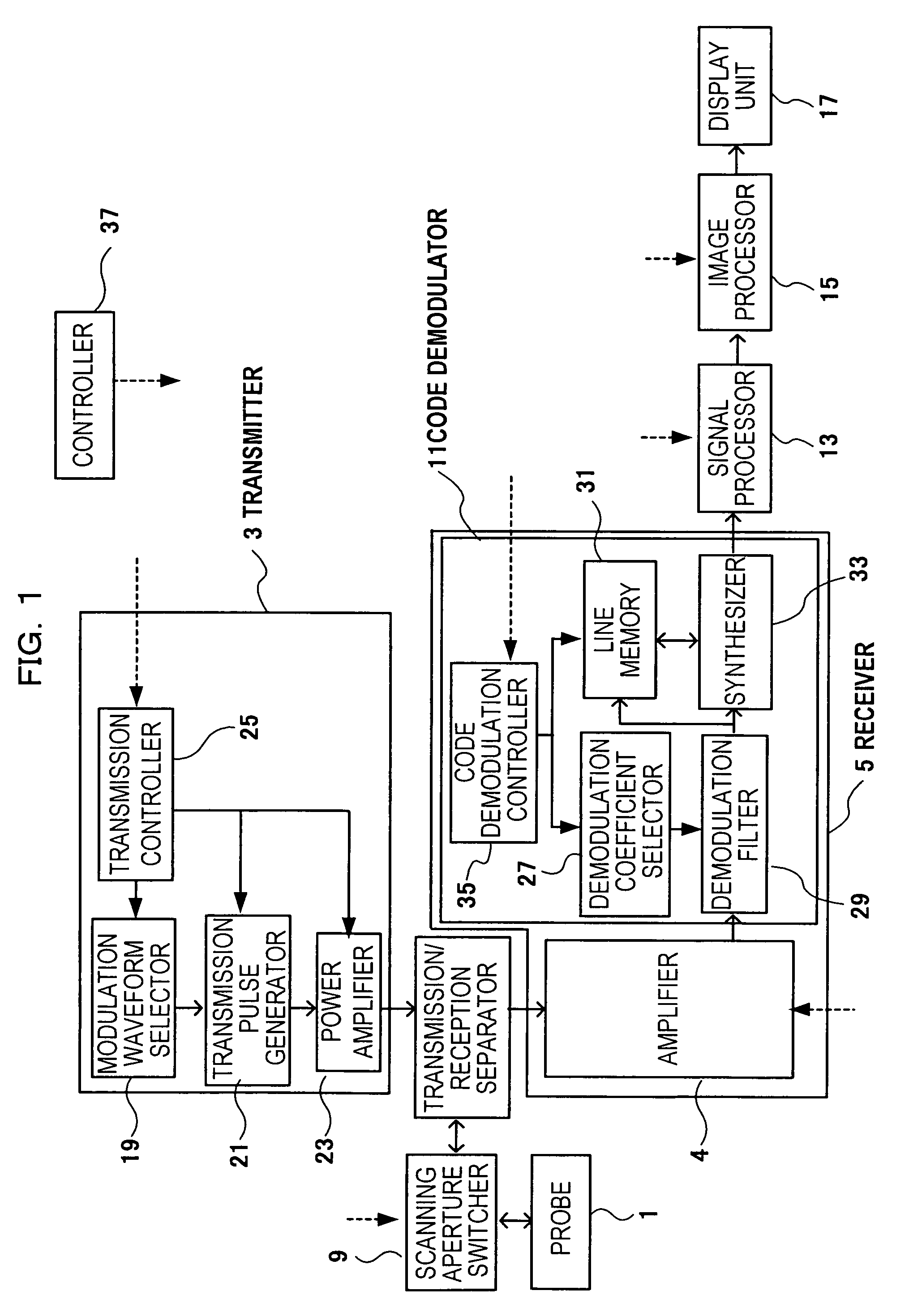

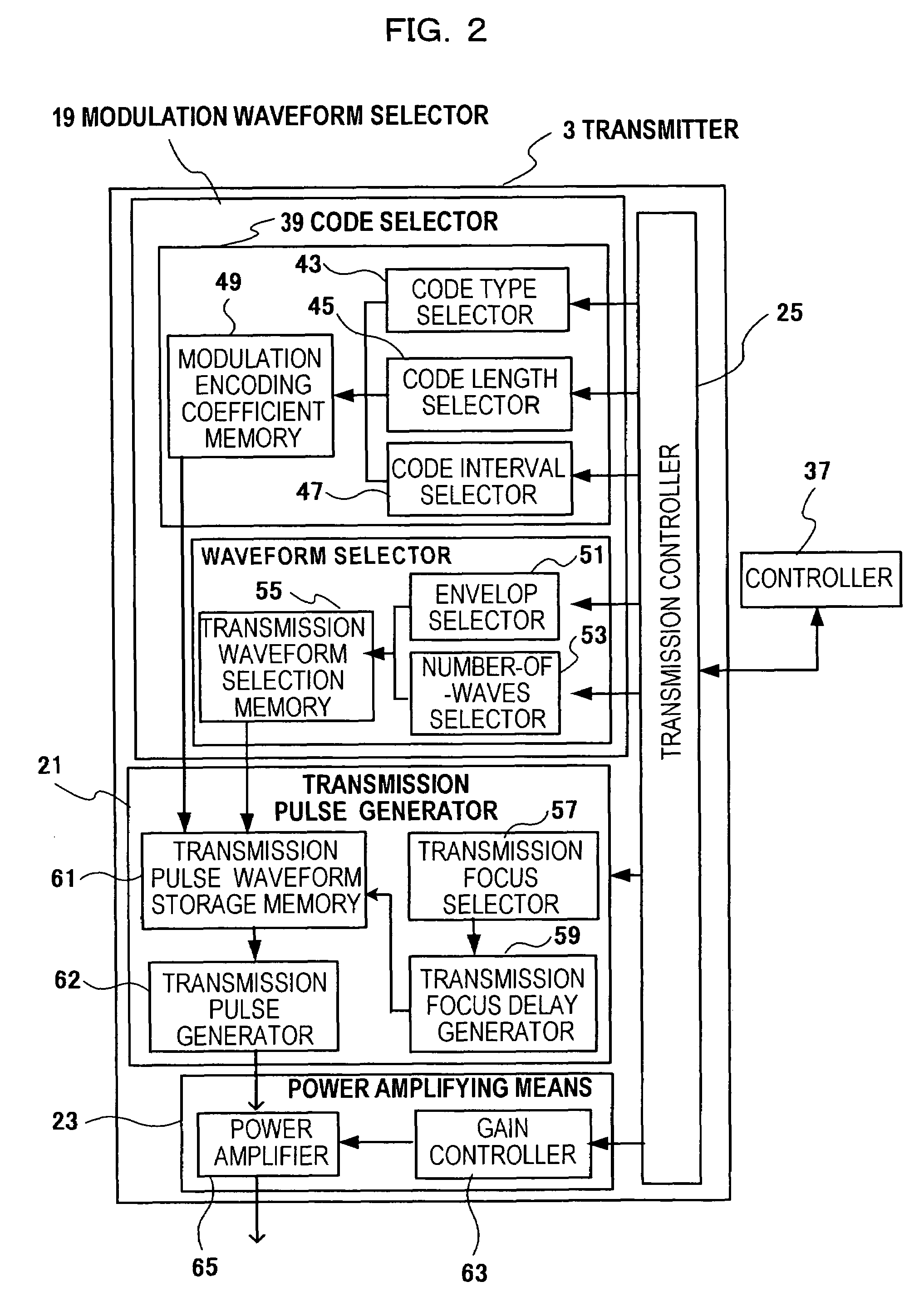

Ultrasonographic method and ultrasonographic device

InactiveUS7354400B2Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasonic beamSonification

An ultrasonographic method includes: a first encoding transmission / reception step for transmitting an ultrasonic beam encoded by an encoding set consisting of a plurality of modulation codes in which at least two are in complementary relationship and demodulating reception signals corresponding to the ultrasonic beam; a step for obtaining a first synthesis signal by synthesizing the demodulation signals demodulated by the first encoding transmission / reception step; a second encoding transmission / reception step for transmitting an ultrasonic beam encoded by a reverse encoding set consisting of a plurality of modulation codes in which the arrangement order of modulation codes of the encoding set is reversed and demodulating the reception signals corresponding to the ultrasonic beam; a step for obtaining a second synthesis signal by synthesizing the demodulated signals demodulated by the second encoding transmission / reception step; a step for obtaining a third synthesis signal by synthesizing the first synthesis signal and the second synthesis signal; and a step for reconstructing the ultrasonograph according to the third synthesis signal.

Owner:HITACHI MEDICAL CORP

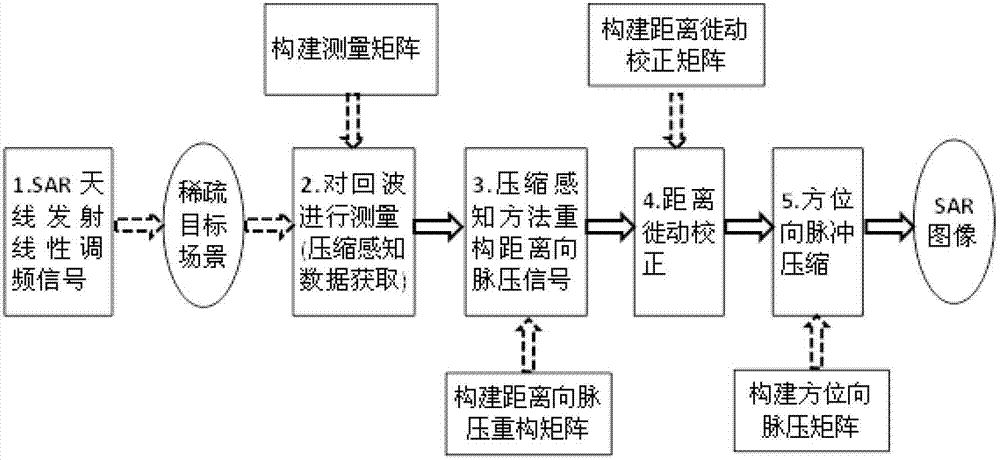

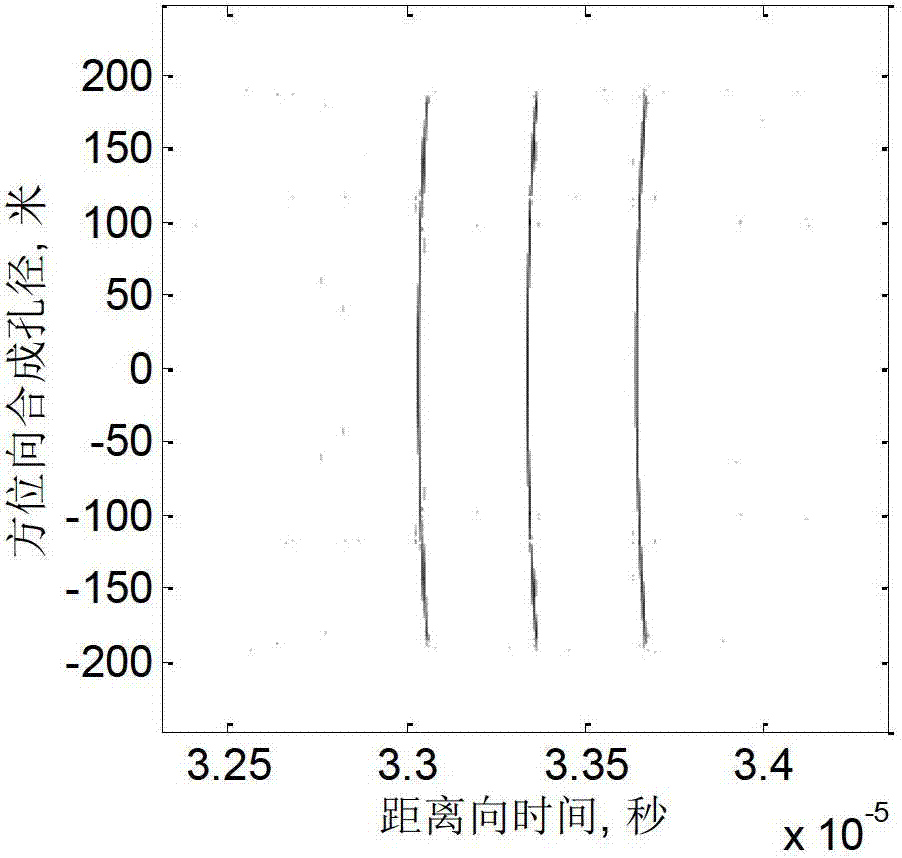

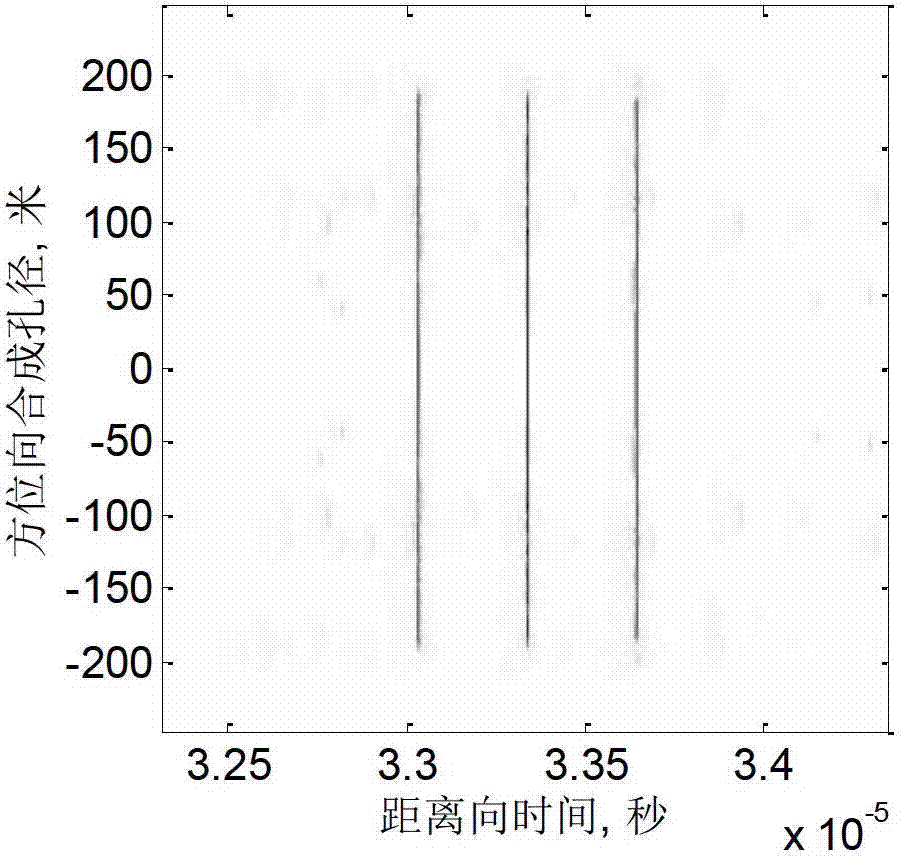

Compressed sensing synthetic aperture radar (SAR) imaging method based on fractional order fourier transformation

InactiveCN102879782AReduce the amount of measurement dataRelieve the pressure of signal storage and transmissionRadio wave reradiation/reflectionSynthetic aperture sonarDimension measurement

The invention provides a compressed sensing synthetic aperture radar (SAR) imaging method based on fractional order fourier transformation, and belongs to the technical field of microwave imaging. For a sparse target scene, a system emits a linear frequency modulation pulse signal; by adopting a method for projecting an echo signal to a low-dimension measurement matrix, measurement data which are much smaller than those required by a Nyquist sampling principle are acquired; due to the echo signal, after a reconstruction matrix is constructed by a simplified fractional order fourier transformation domain sparse mode and a data acquisition mode, a calculated distance pulse pressure result is optimized by a compressed sensing signal reconstruction method and is subjected to distance migration correction and direction pulse pressure to obtain a target scene imaging result. By the imaging method, the measurement data amount of a target scene with a sparse characteristic can be greatly reduced; and pressure on data storage and data transmission can be effectively relieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

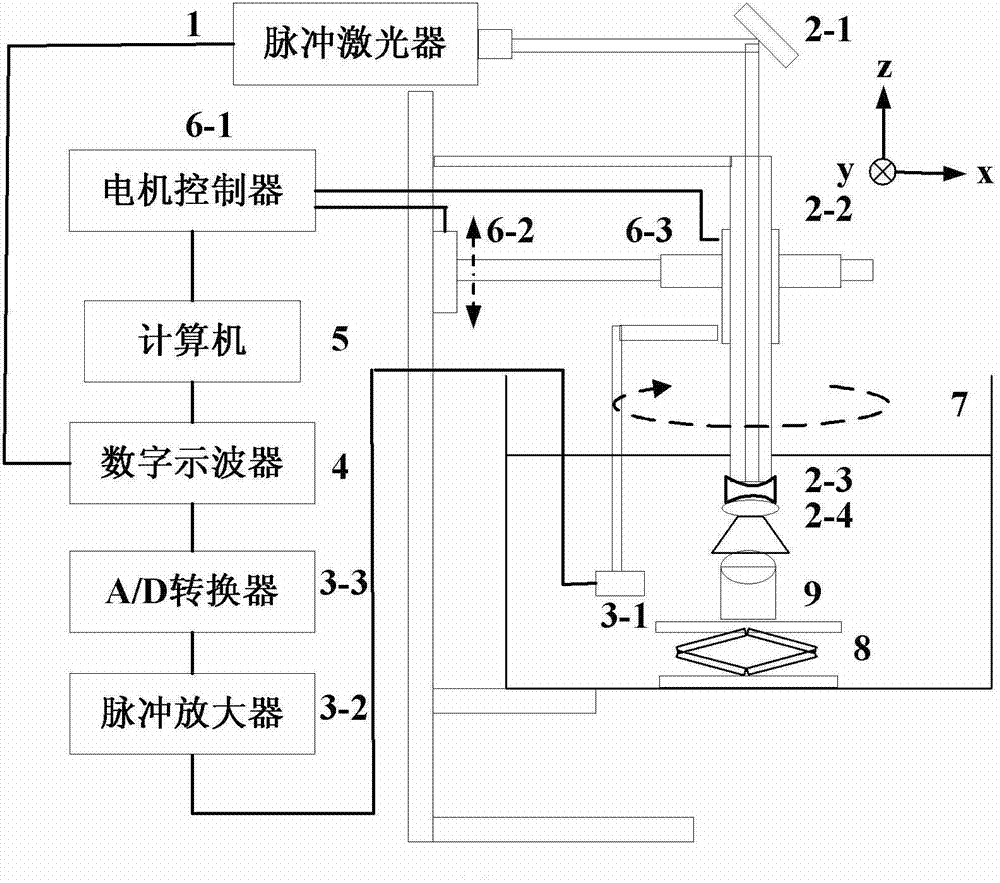

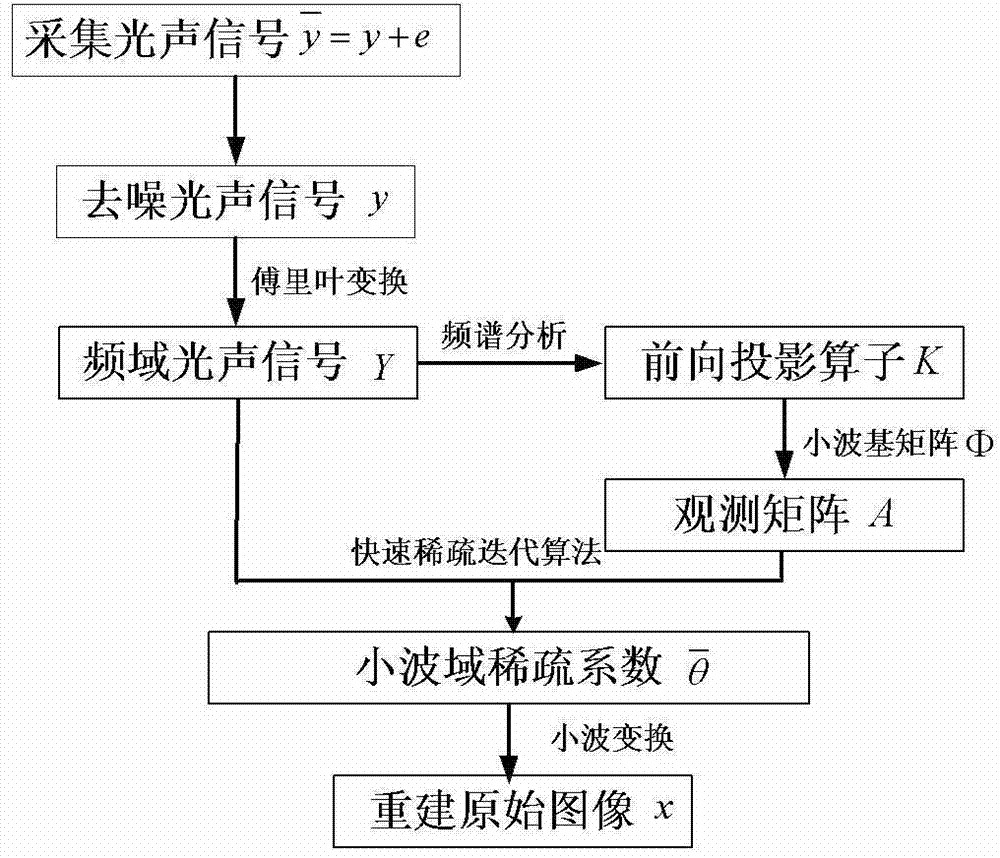

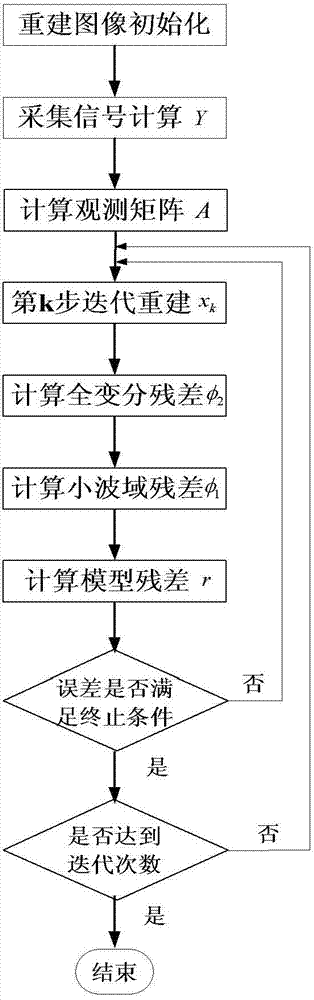

Photoacoustic tomography device and method based on limited-angle scanning

ActiveCN102727259AImprove reliabilityReduce hardware costsTomographyThinning algorithmDigital signal

The invention relates to the technical field of photoacoustic imaging and discloses a rapid photoacoustic tomography device and a rapid photoacoustic tomography method based on limited-angle scanning. The method comprises the following steps of: transmitting pulse laser into an imaging sample to generate a photoacoustic signal, acquiring the photoacoustic signal at a limited position on an arc through an ultrasonic detector unit, amplifying the signal through a signal amplifier, converting the photoacoustic signal into an electric signal through an analog / digital (A / D) converter, and finally transmitting the electric signal to an oscilloscope to finish digital signal acquisition; inputting the photoacoustic signal of the imaging sample into a computer, performing filtering and Fourier transform processing on the photoacoustic signal through the computer, extracting the frequency domain information of the photoacoustic signal according to experiment conditions, establishing a forward projection operator and a measurement matrix, and performing reconstruction imaging on the signal based on a quick thinning algorithm through the computer. The method and the device have the advantages of short signal acquisition time, high reconstruction speed, convenience in operation, high adaptability, high expansibility and the like.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

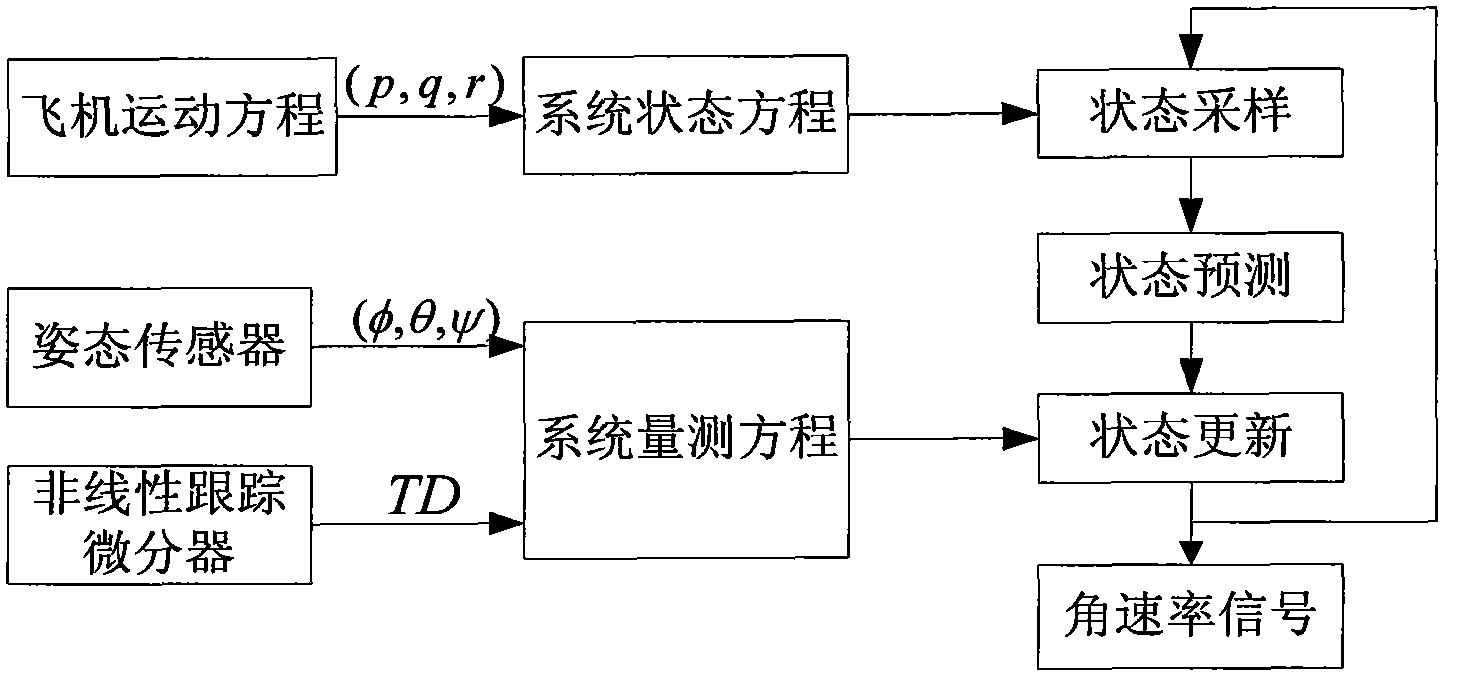

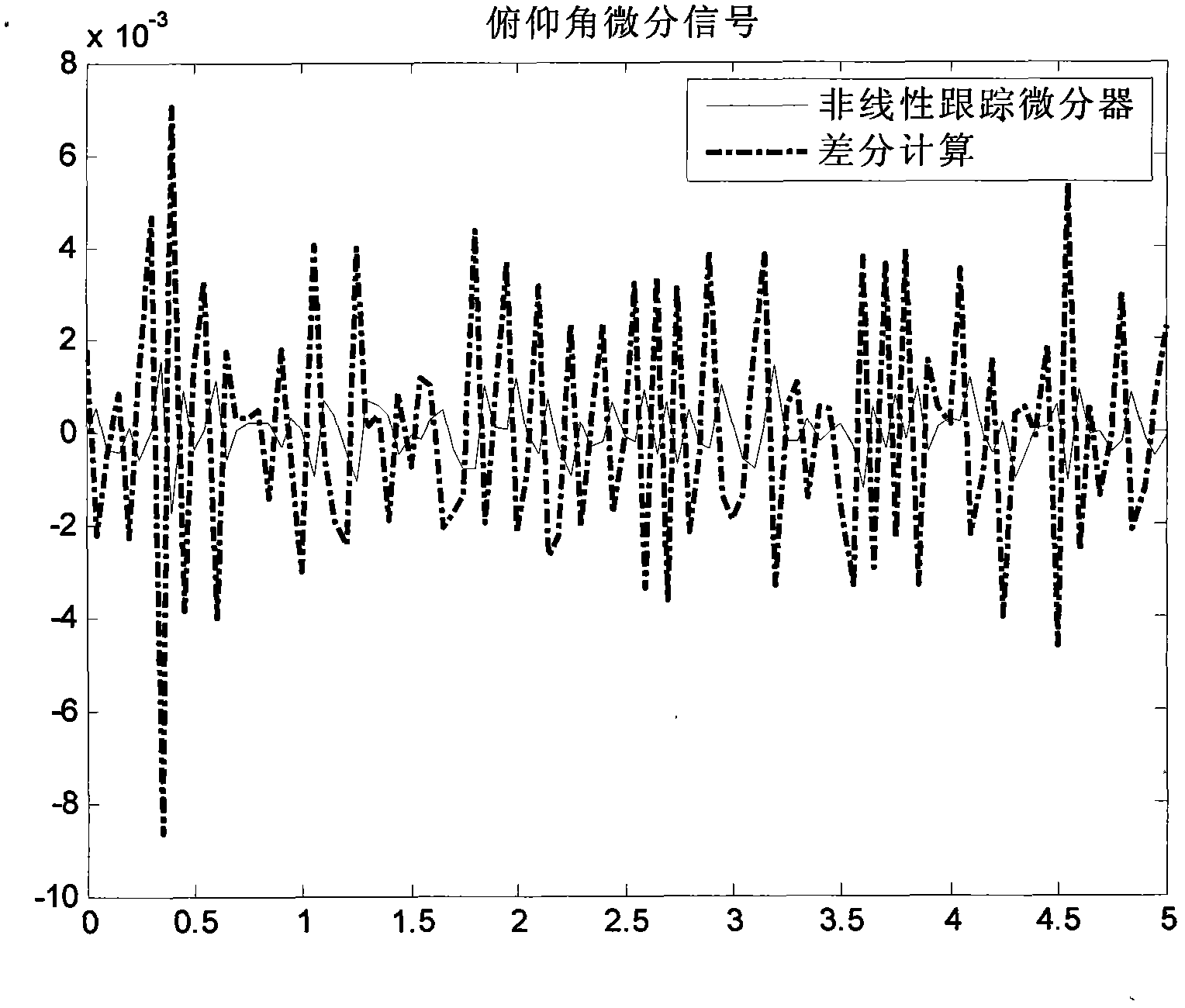

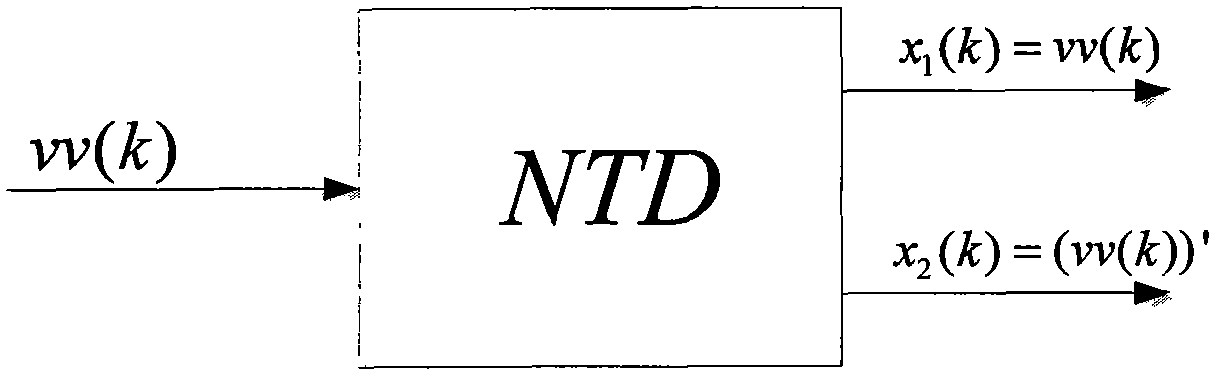

Airplane angular rate signal reconstruction method based on unscented kalman filter

InactiveCN103363993AThe result is accurateNavigational calculation instrumentsJet aeroplaneDifferentiator

The invention discloses an airplane angular rate signal reconstruction method based on unscented kalman filter. The method comprises the following steps of: (1), denoising an attitude angle measurement signal containing measurement noise through a nonlinear tracking differentiator to obtain a differential signal of an attitude angle, and constructing a virtual measurement equation; (2), constructing a state equation of a system on the basis of natural characteristics of an airplane and according to tri-axial angular rate signals and torque characteristics of the airplane; and (3), reconstructing an angular rate signal of the system by selecting the unscented kalman filter technology as the processing manner because both the state equation and the measurement equation are nonlinear and the estimation precision can be influenced by traditional operation for linearizing a nonlinear equation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multiple-antenna space multiplexing system using enhancement signal detection

ActiveUS20100104047A1Improve bit error rate performanceEasy to detectMultiplex communicationLine-faulsts/interference reductionMultiplexingComputer science

The multiple-antenna space multiplexing system using enhancement signal detection comprising: a code modulation module for coding and modulating bit information; a signal transmission module for transmitting the modulated signals; a signal reception module for receiving the signals; a signal form transform module for transforming form of a channel matrix H and the received signal vector r; a signal detection module for detecting the received signals; a signal reconstruction module for reconstructing the detection results of in the signal detection module, and obtaining a detected signal; a demodulation decoding module for demodulating and decoding the output of the signal reconstruction module, and outputting bit information. Compared with the conventional detection methods, the system performance is improved in considering the realization complexity.

Owner:SAMSUNG ELECTRONICS CO LTD +1

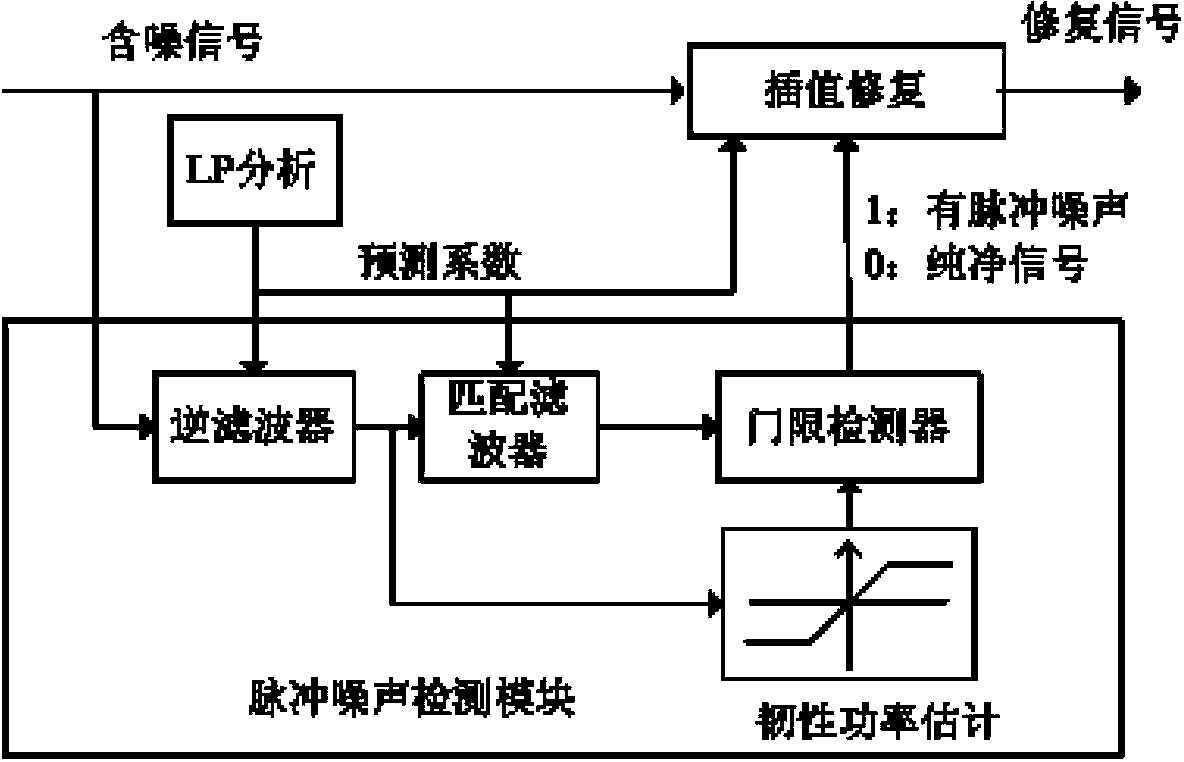

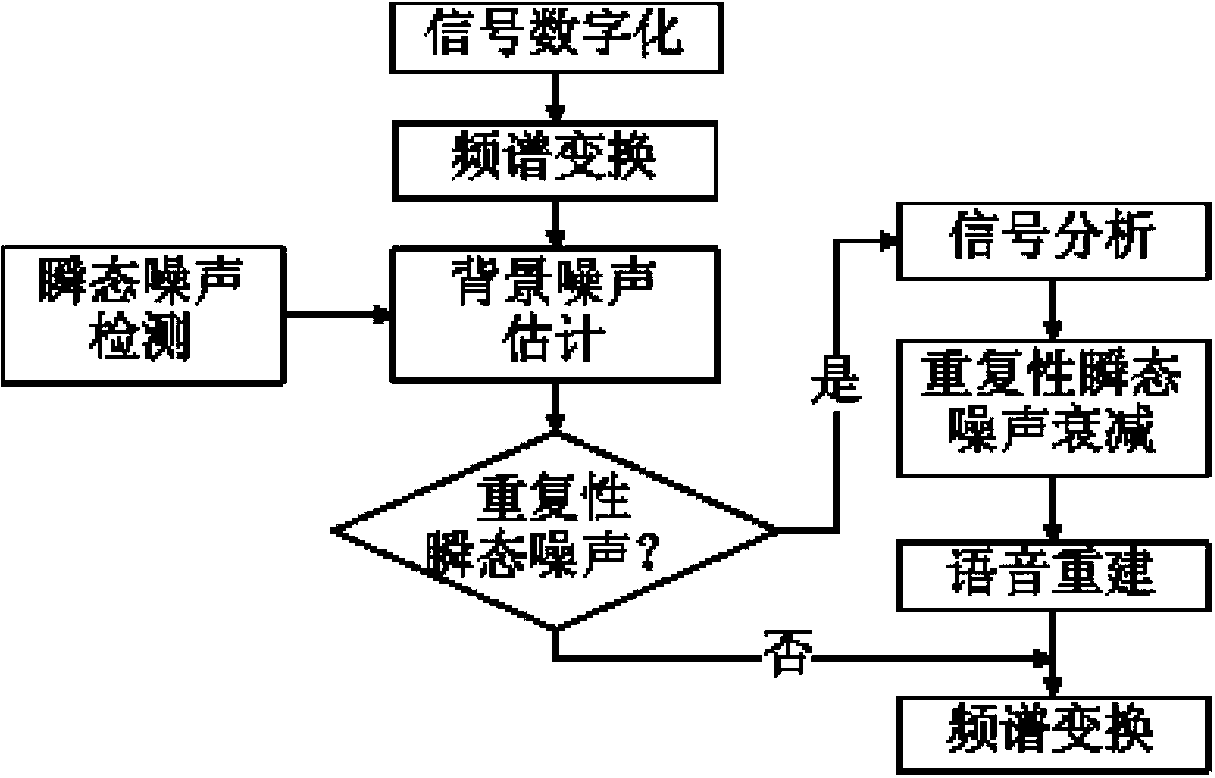

Method for suppressing transient noise in voice

The invention discloses a method for suppressing transient noise in voice, and belongs to the technical field of signal processing. The method for suppressing transient noise in voice is characterized by comprising a gamma through frequency cepstrum coefficient extraction module, a transient noise detection module and a voice signal reconstruction module, wherein the input end of the gamma through frequency cepstrum coefficient extraction module receives a voice signal containing noise, the output end of the gamma through frequency cepstrum coefficient extraction module is connected with the input end of the transient noise detection module, the output end of the transient noise detection module is connected with the input end of the voice signal reconstruction module, the input end of the voice signal reconstruction module receives the voice signal containing noise and is also connected with the output end of the transient noise detection module, and the voice signal reconstruction module outputs the voice with noise removed.

Owner:DALIAN UNIV OF TECH

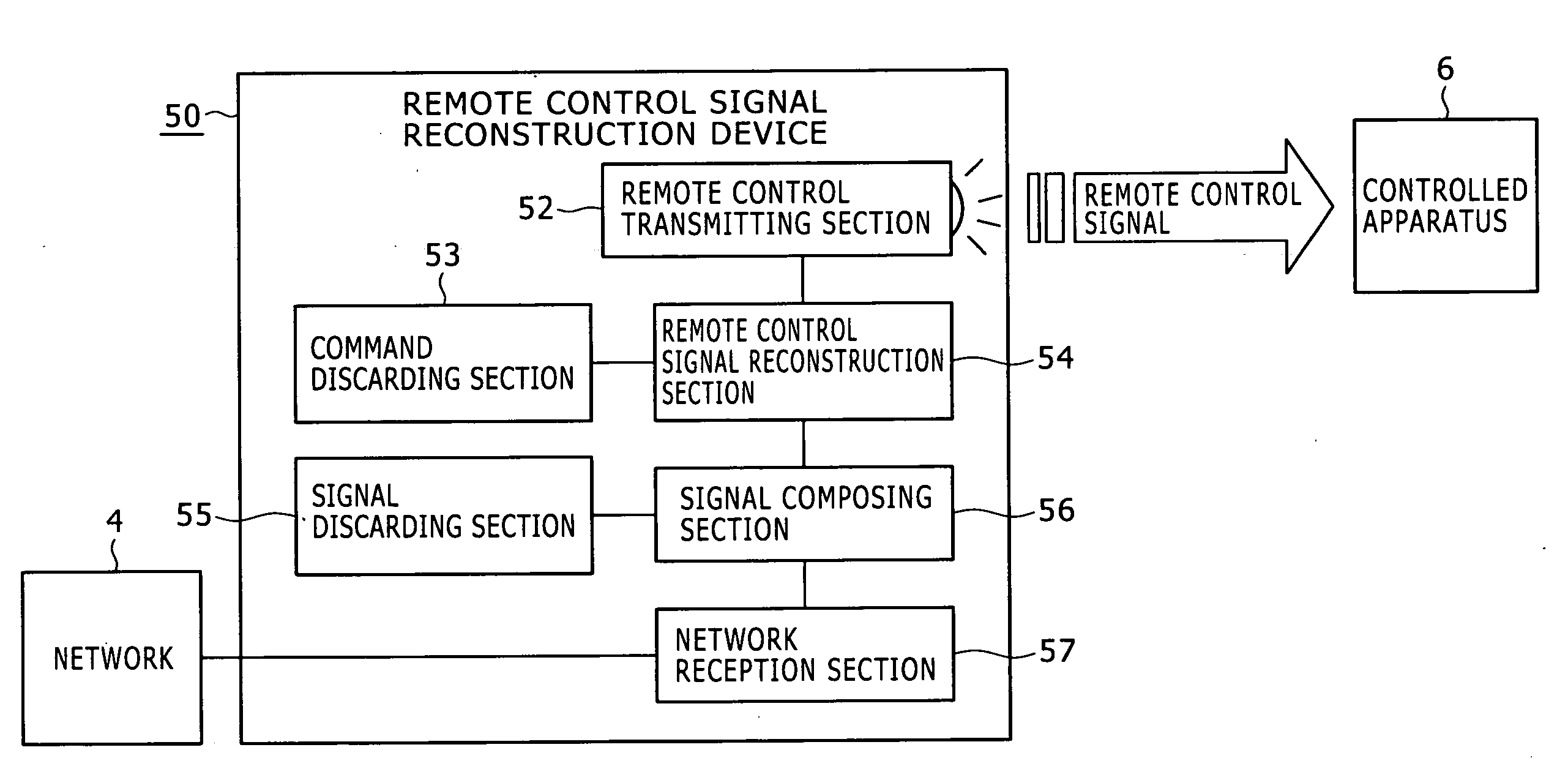

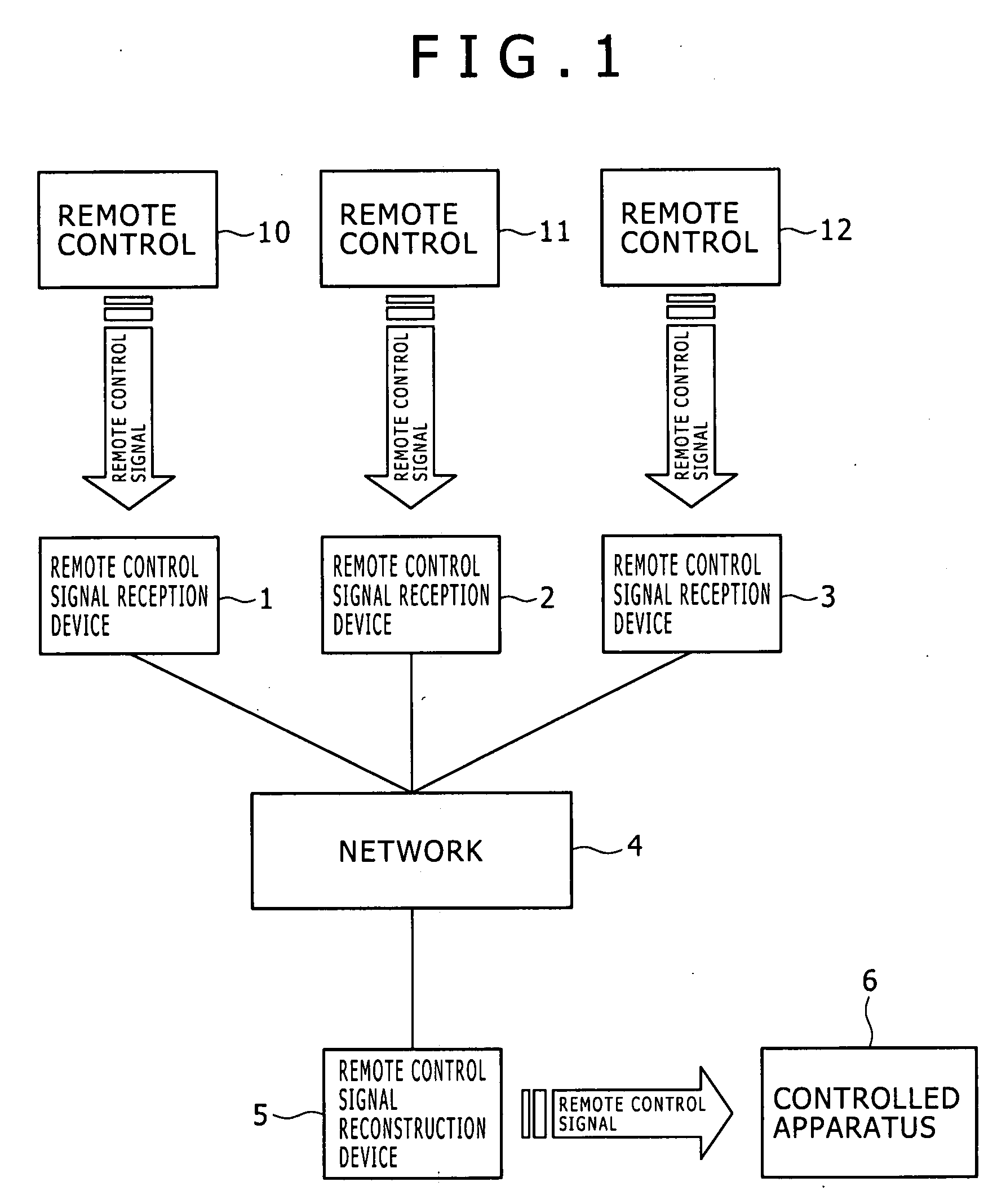

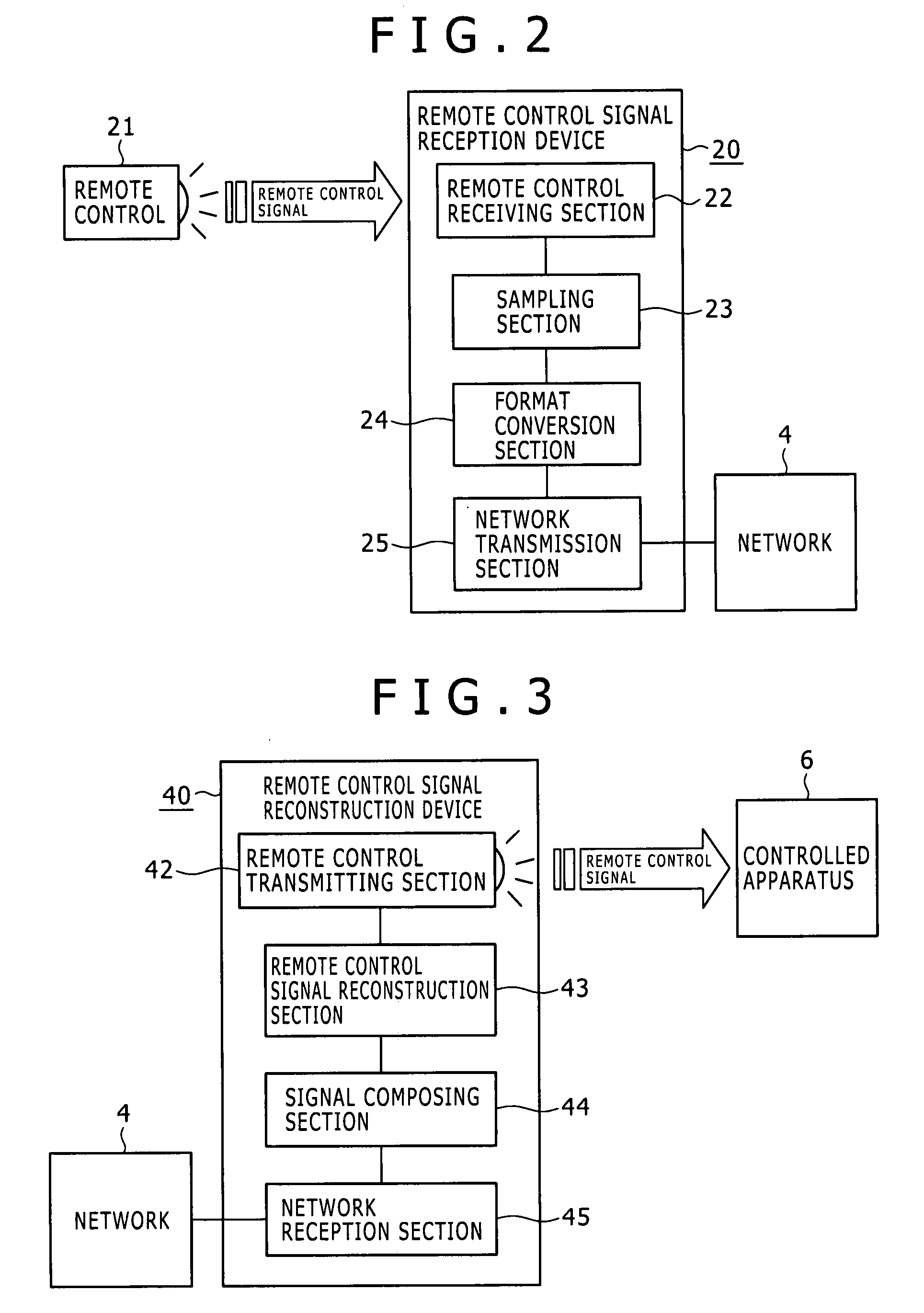

Remote control signal transfer system

InactiveUS20070229300A1Easy to optimizeAppropriately transferredElectric signal transmission systemsNon-electrical signal transmission systemsRemote controlTransfer system

A remote control signal transfer system for transferring a remote control signal sent by a remote control toward a controlled apparatus via a transmission medium, the system including: one or more remote control signal reception devices each installed at a separate place; and one or more remote control signal reconstruction devices each installed for a separate one of the one or more controlled apparatuses. Each remote control signal reception devices subjects a remote control signal obtained from a remote control receiving section to sampling, and transmits resultant data to the transmission medium. Each more remote control signal reconstruction devices composes the remote control signals received from any one or more of the remote control signal reception devices via the transmission medium into a single composed signal, and outputs the single composed signal to the corresponding controlled apparatus via a single remote control transmitting section.

Owner:SONY CORP

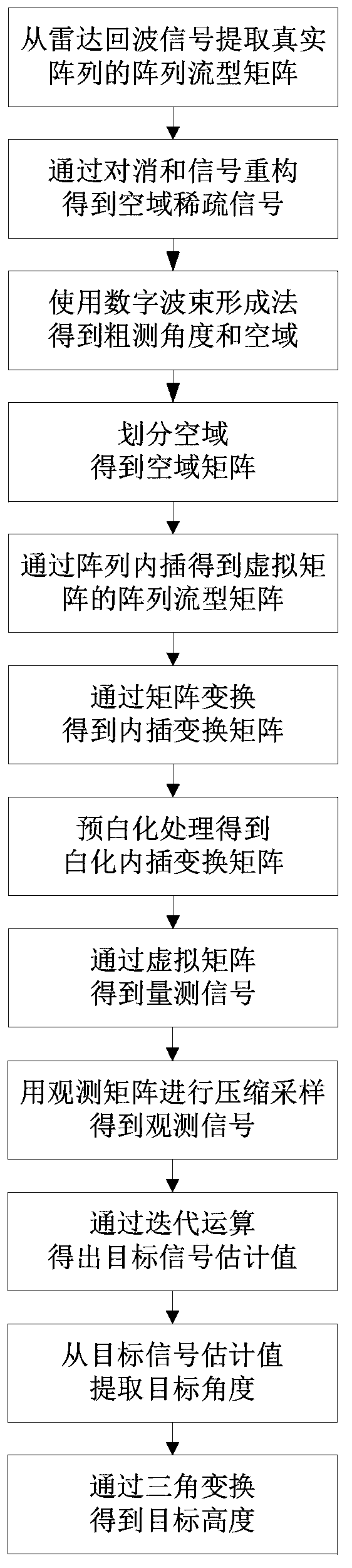

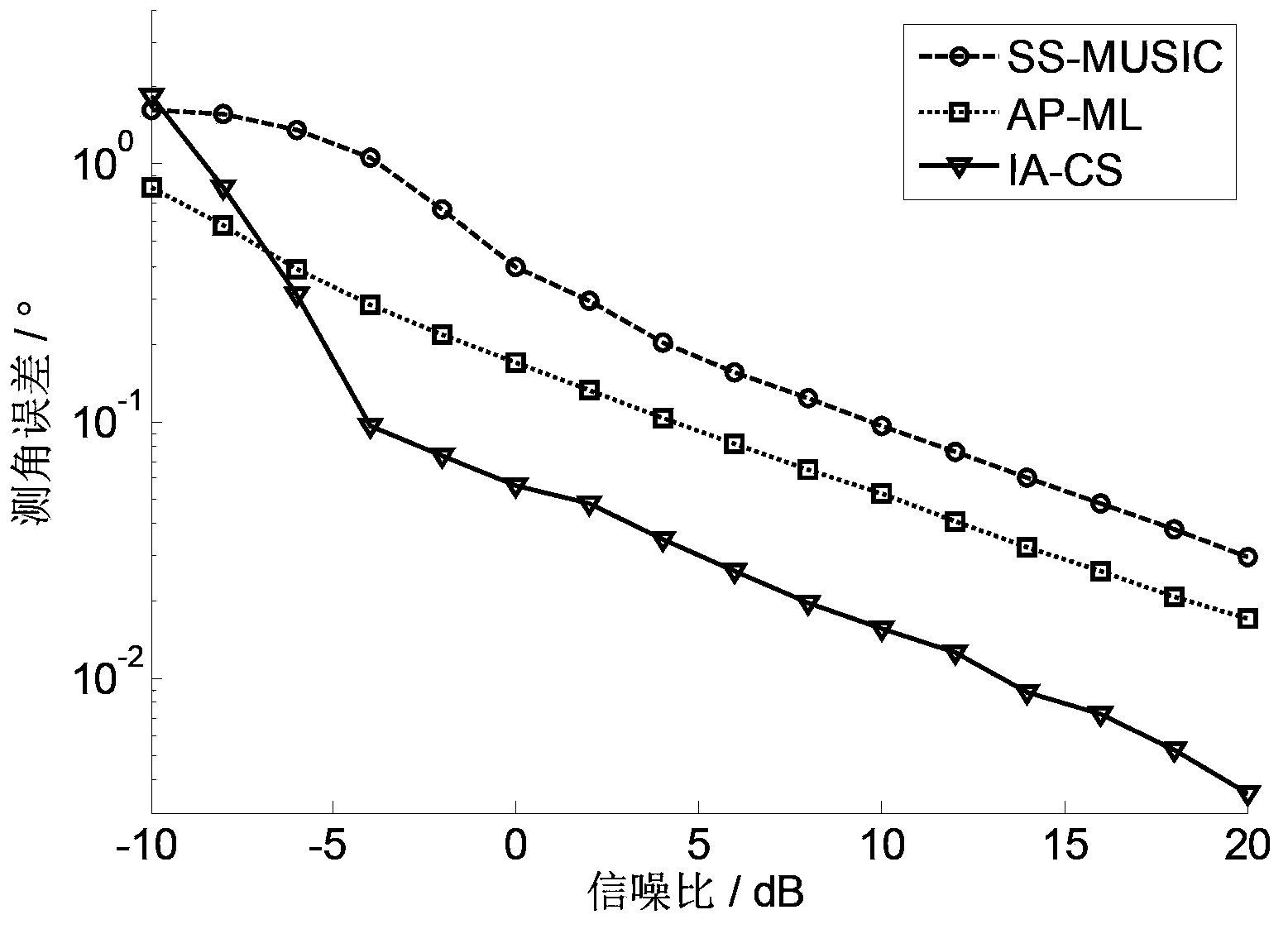

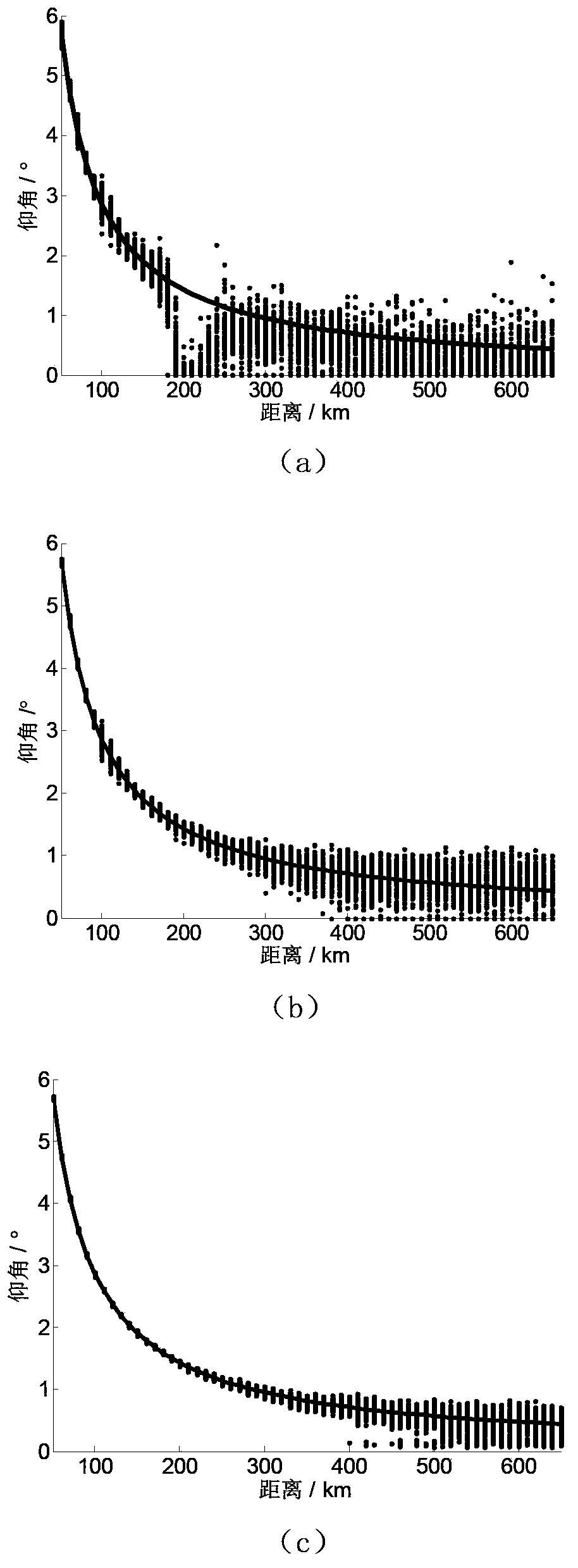

Meter wave radar height measurement method based on array interpolation compression perception

ActiveCN103353595AReduce sidelobeImprove performanceWave based measurement systemsTarget signalRadar

The invention discloses a height measurement method based on an array interpolation compression perception. The height measurement method mainly aims at solving a low elevation height measurement problem under a multipath environment, and especially under low signal to noise ratio and less snapshot environments. The method comprises the following steps of extracting a target signal from a radar echo; acquiring a spatial-domain sparse signal through cancellation and signal reconstruction; using a wave beam formation method to obtain a rough measurement target angle; according to the rough measurement angle, acquiring the spatial domain and dividing the spatial domain; using the array interpolation to acquire a virtual array; according to a matrix transformation relation, acquiring an interpolation transformation matrix and carrying out prewhitening processing on the interpolation transformation matrix; using a whitening interpolation transformation matrix and an observation matrix to acquire an observation signal; using a whitening interpolation transformation matrix and observation signal iteration operation to acquire a target signal estimation value; extracting a target angle from the target signal estimation value so as to acquire a target height. By using the method of the invention, sampling points of the target signal and computation intensity are obviously reduced; sidelobes of a signal power spectrum and a space spectrum are effectively reduced; the method can be used in target tracking.

Owner:XIDIAN UNIV

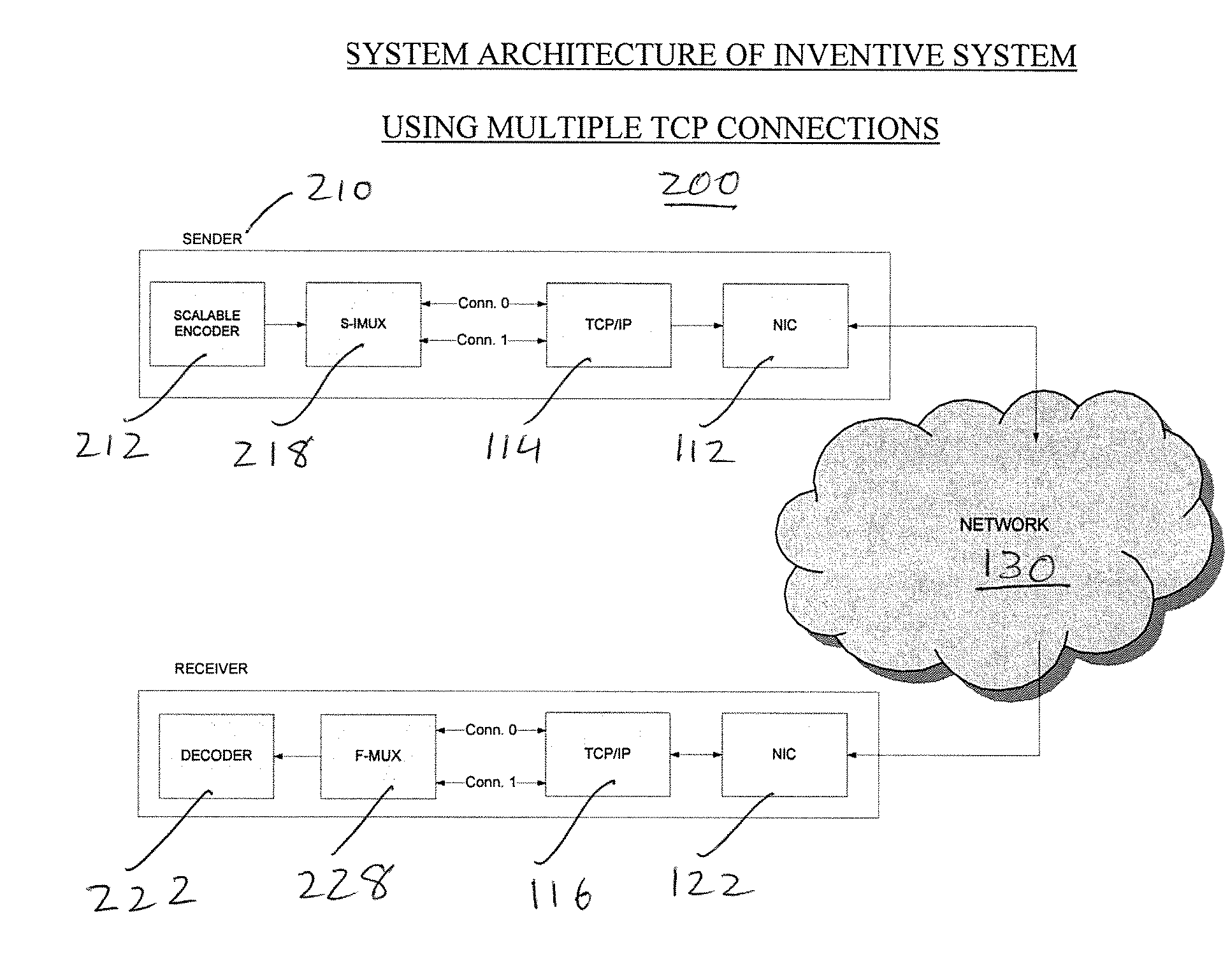

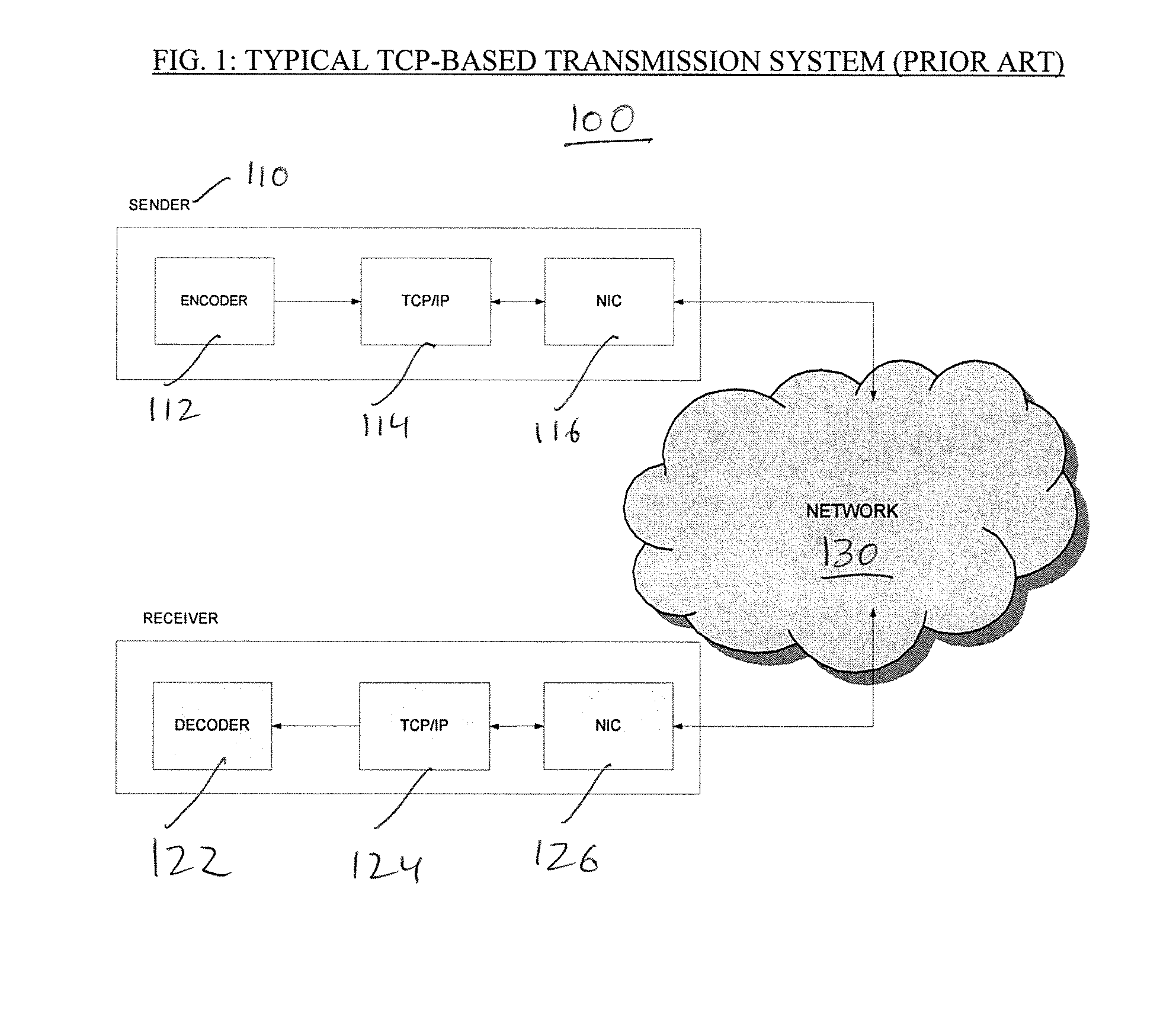

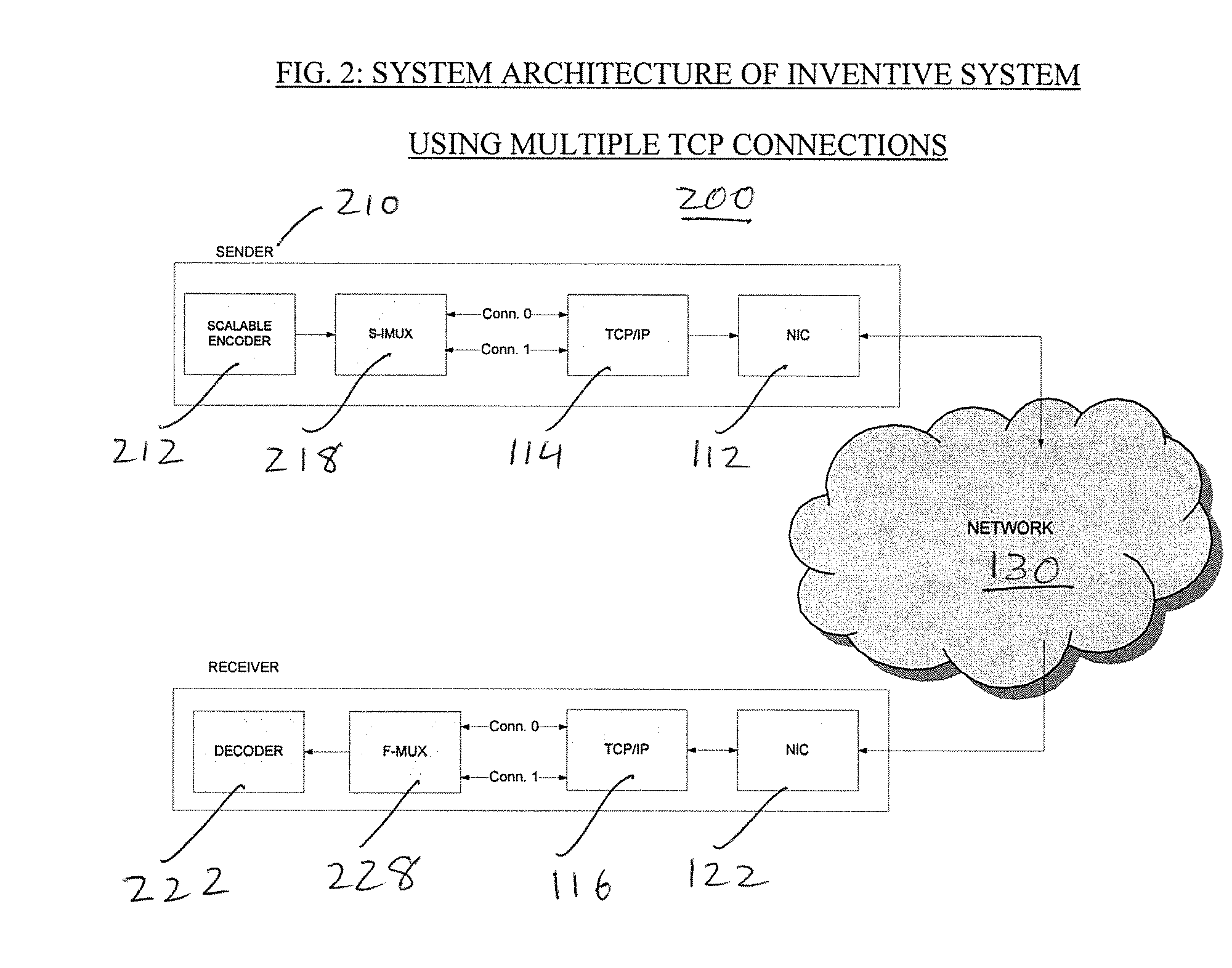

System and method for low-delay, interactive communication using multiple TCP connections and scalable coding

InactiveUS20080130658A1Low latency packet deliveryOvercome limitationsData switching by path configurationLatency (engineering)Low delay

Systems and methods for communication of scaleable-coded audiovisual signals over multiple TCP / IP connections are provided. The sender schedules and prioritizes transmission of individual scalable-coded data packets over the plurality of TCP connections according to their relative importance in the scalable coding structure for signal reconstruction quality and according to receiver feedback. Low-latency packet delivery over the multiple TCP / IP connections is maintained by avoiding transmission or retransmission of packets that are less important for reconstructed media quality.

Owner:VIDYO

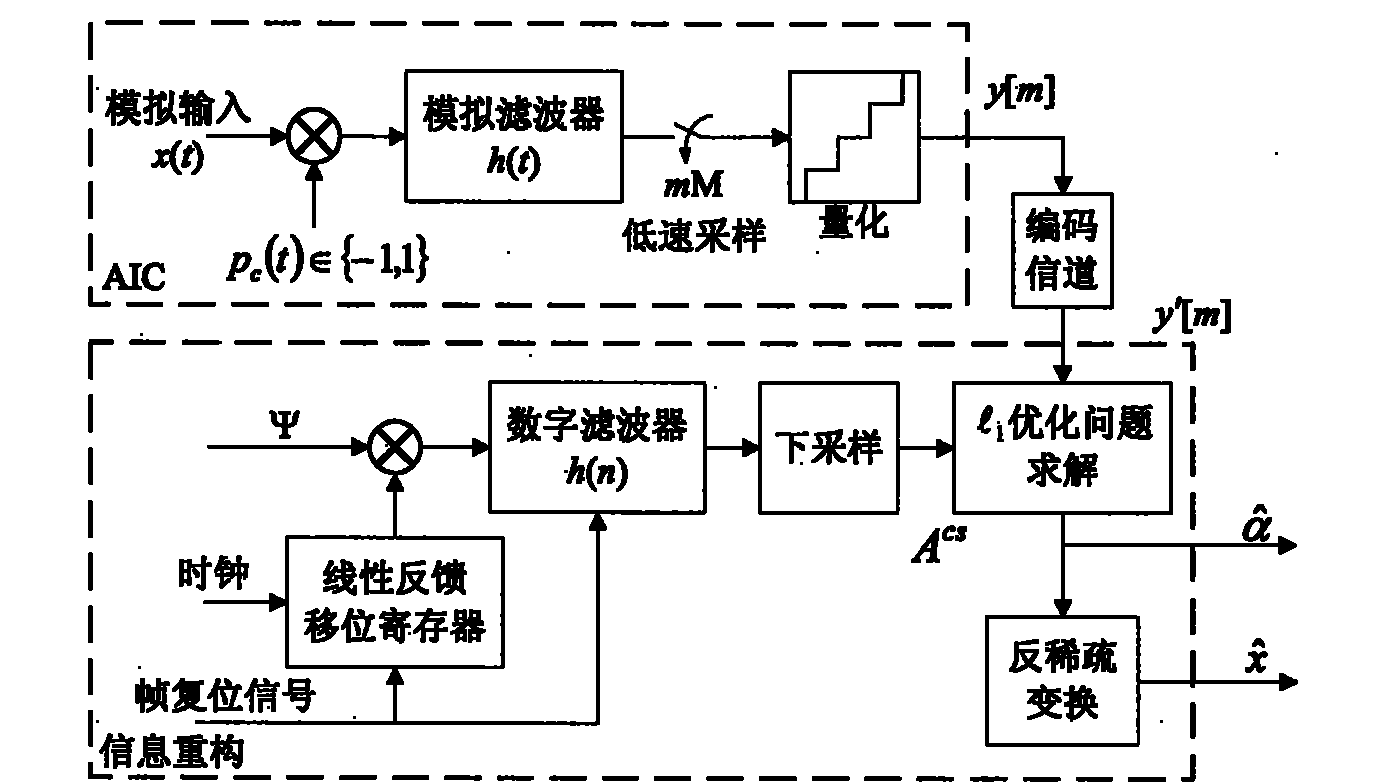

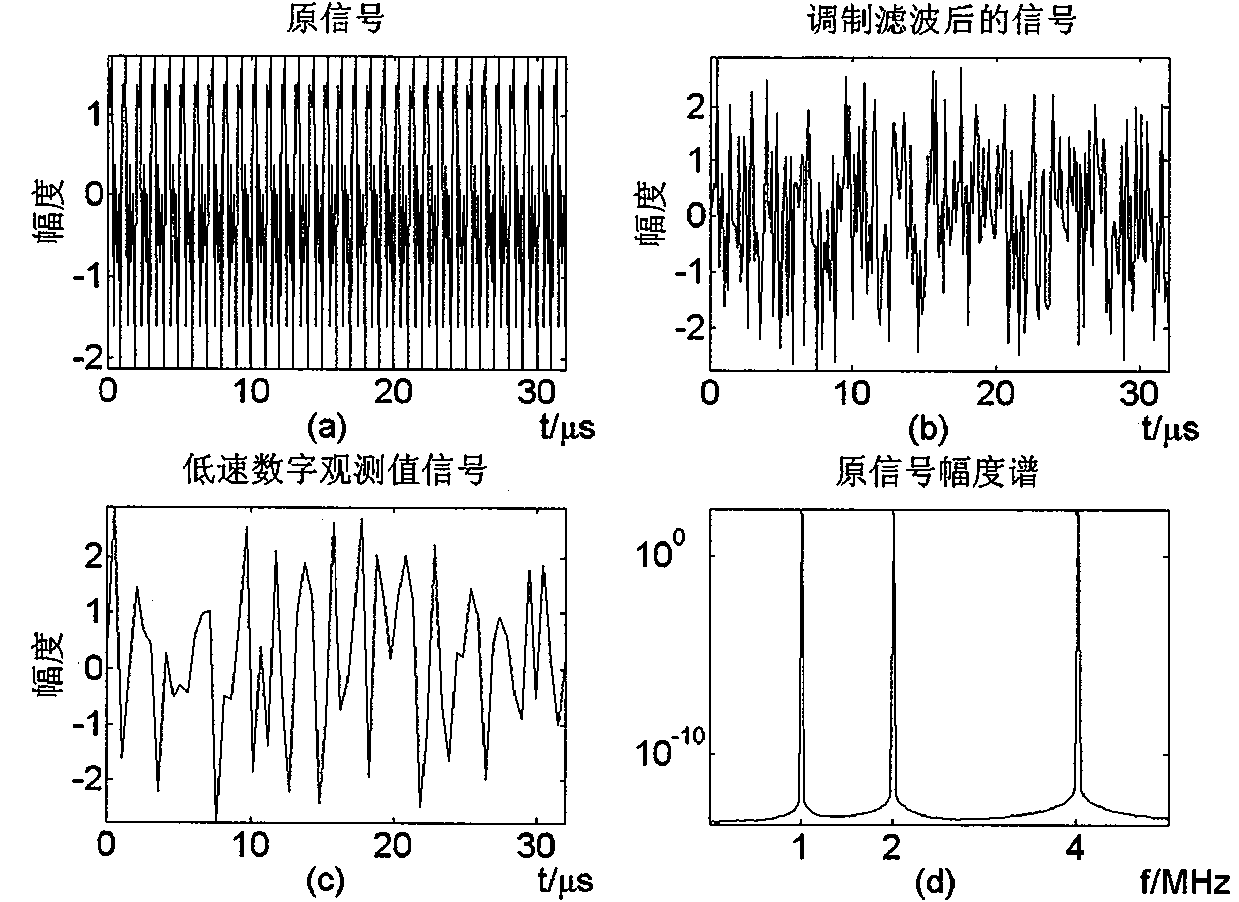

Signal reconstruction technical scheme for sampling with rate lower than Nyquist rate

InactiveCN101867387AAvoid time costReduce computing costTransmitter/receiver shaping networksFilter (signal processing)Digital filter

The invention relates to a signal reconstruction technical scheme for sampling with rate lower than nyquist rate. The signal reconstruction scheme comprises the following steps of: firstly, solving a transformation basic matrix (signals x to be reconstructed thereon are sparse on the transformation basic matrix), modulating the transformation basic matrix with a cutting sequence, filtering by means of a digital filter, sampling the filtered signals, then generating compressive sensing arithmetic operators, and finally obtaining reconstructed signals by solving an optimized problem through the sparse inverse transformation. The invention aims to provide the signal reconstruction technical scheme for sampling with rate lower than the Nyquist rate, satisfy the needs for people in solving the contradictions between the increasingly widening signal bandwidth as well as the increasingly quickening sampling frequency and the requirements for reducing processing time and various costs reduce the signal sampling frequency and data transmission and storage cost, further remarkably shorten the signal processing time and reduce the computational expense, and accurately reconstruct signals.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

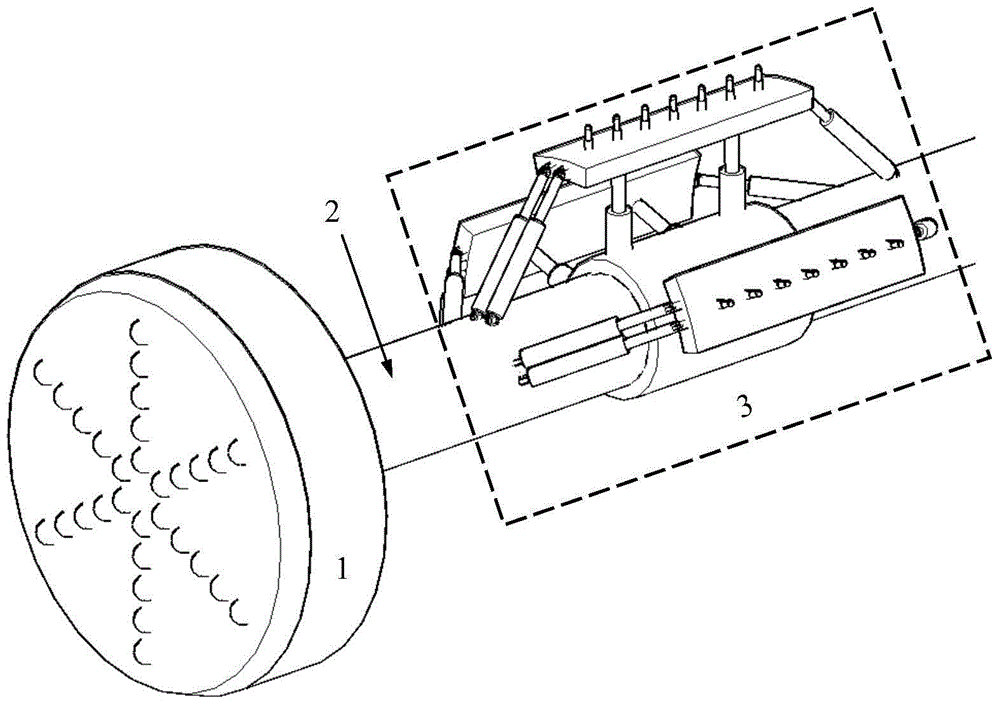

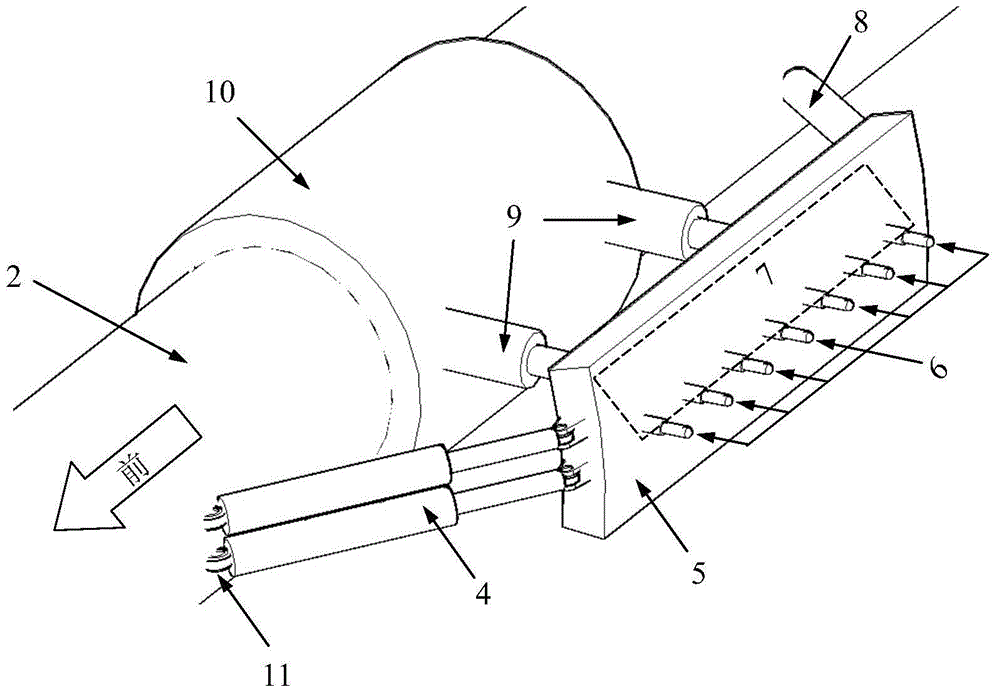

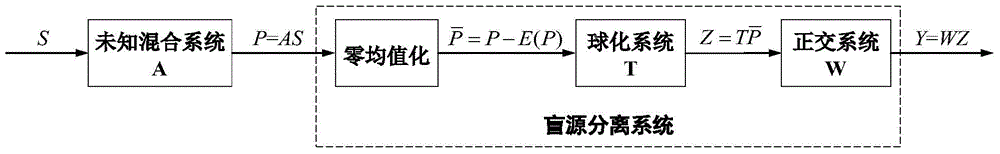

Tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method

ActiveCN104678427ADoes not affect normal workflowQuick layoutSeismologySensor arrayIndependent component analysis

The invention discloses a tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method. The device comprises a seismic source sensor array, a receiving sensor and a supporting device thereof, a noise sensor, and a multichannel seismic wave data collecting instrument, wherein the multichannel seismic wave data collecting instrument is connected with the seismic source sensor array, the receiving sensor and the noise sensor and receives seismic wave signals and noise signals of a noise source. Aiming at the special situation of the construction tunnel of a tunnel boring machine, the device adopts a seismic source signal blind source separation method based on an independent component analysis theory, a seismic source signal reconstruction method and a method for performing powerful interference signal degeneration on receiving sensor signals to finally obtain geological conditions in front of a working surface of the tunnel boring machine and the surrounding rock mass of a tunnel and corresponding mechanical parameters, can realize the advanced prediction of geological anomalous bodies, can further be used for evaluating the quality of surrounding rocks of a region to be excavated, and provides reference for the optimization of tunnel boring machine operating parameters and guarantee of construction safety.

Owner:山东百廿慧通工程科技有限公司

Monaural noise suppression based on computational auditory scene analysis

Owner:KNOWLES ELECTRONICS INC

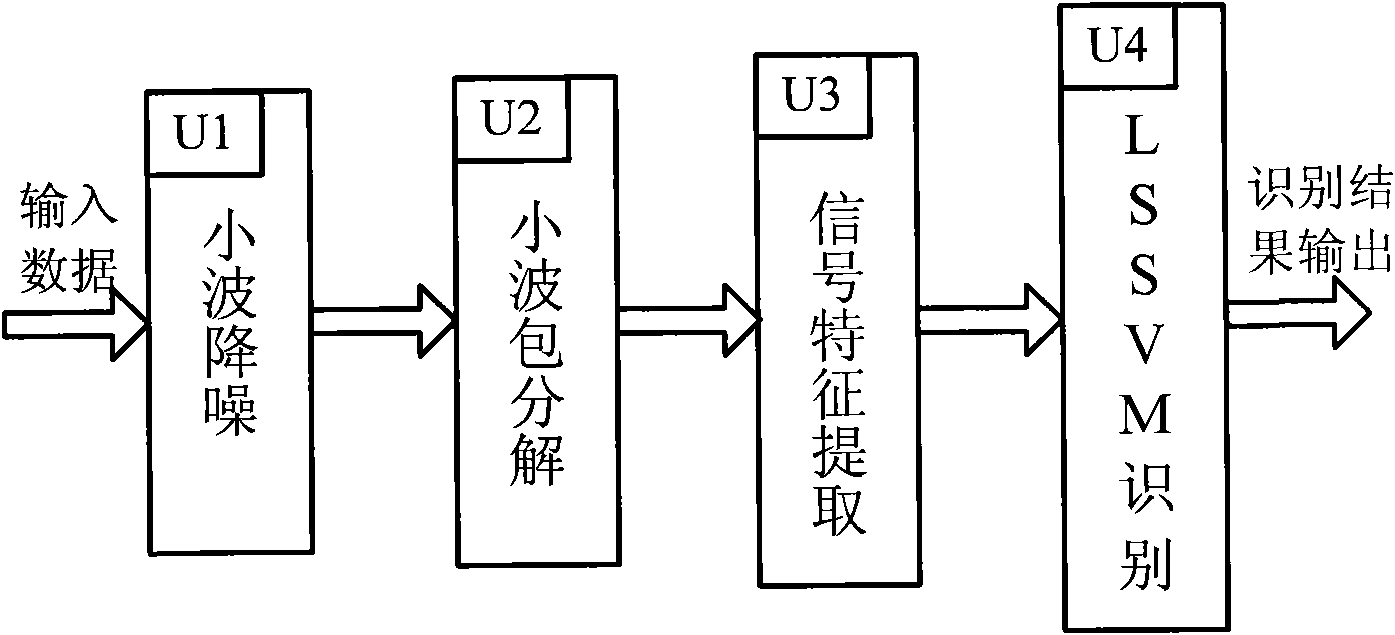

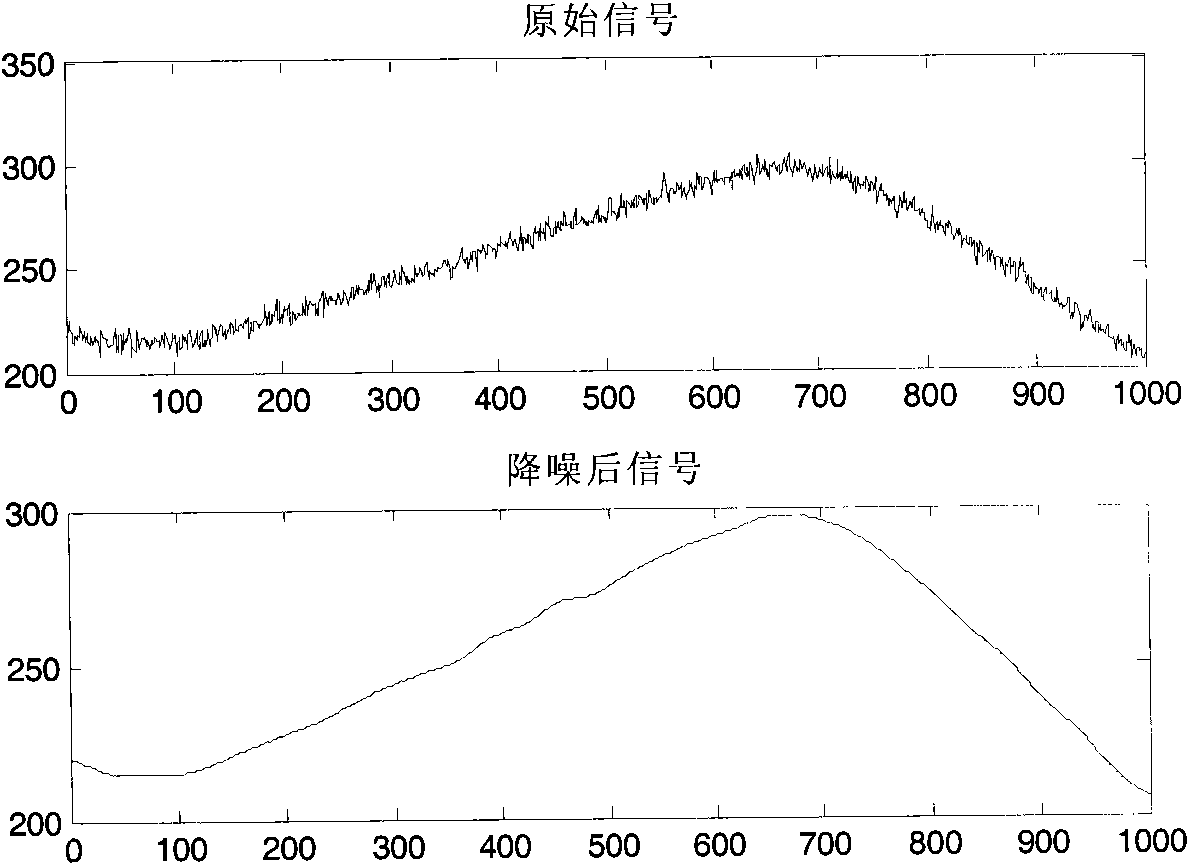

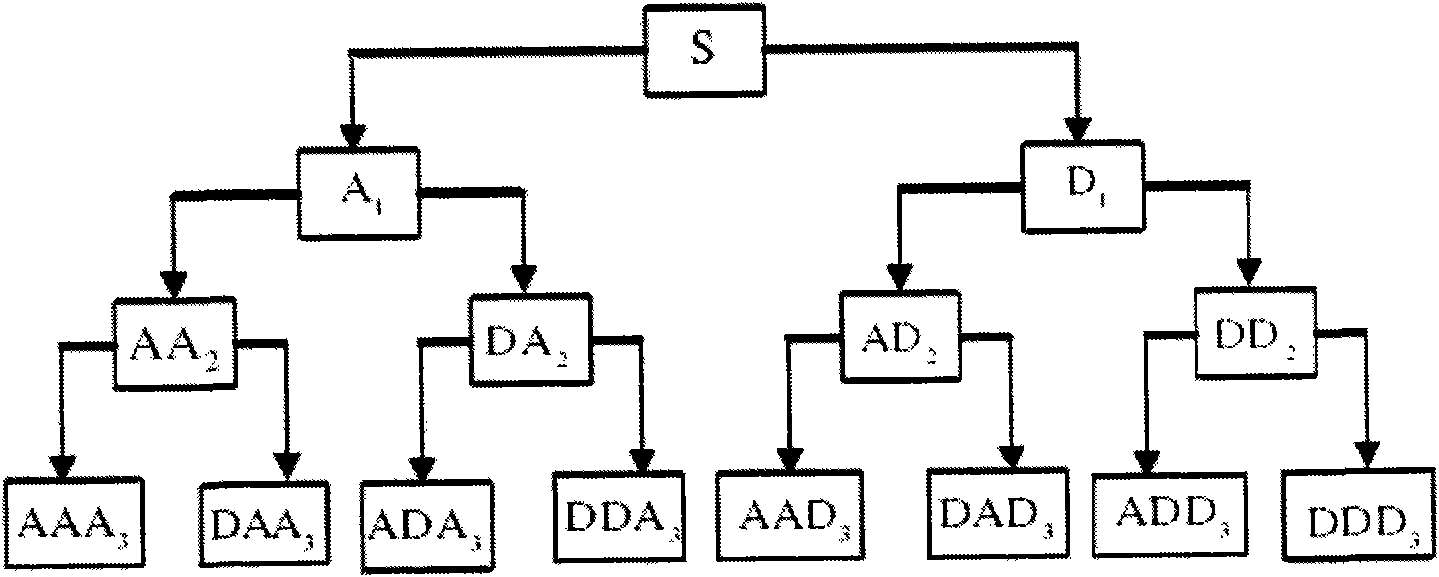

Signal identification and classification method

InactiveCN101832471AAccurate removalThe principle of the method is simpleComputing modelsPipeline systemsDecompositionCharacteristic space

The invention provides a signal identification and classification method. The method comprises the followings steps of: carrying out noise reduction on initial data containing higher noise by utilizing a wavelet transform method, decomposing signals into high-frequency information and low-frequency information in data analysis, carrying out noise cancelling on the signals by adopting a soft thresholding method and then carrying out signal reconstruction; carrying out further decomposition on the high-frequency part which is not detailedly classified by multiscale analysis while inheriting allthe favorable time-frequency localization advantages of the wavelet transform; analyzing the signals within different frequency bands after multi-layered decomposition by utilizing the wavelet packettransform to extract out characteristic information reflecting a system state; transforming the characteristic vectors of input signals into a high-dimensional characteristic space through non-lineartransform and then solving for an optimal linear classification plane in the high-dimensional characteristic space. The invention overcomes the defects of difficult determination of a network structure, low convergence rate, requirement on large quantities of data samples during training, and the like in neural network learning and enables the neural network learning to be with the characteristics of high precision and strong real time in the aspect of practical application of engineering.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com