Polyvinyl chloride centrifugal mother liquor wastewater pretreatment method

A polyvinyl chloride, centrifugal mother liquor technology, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of improved biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

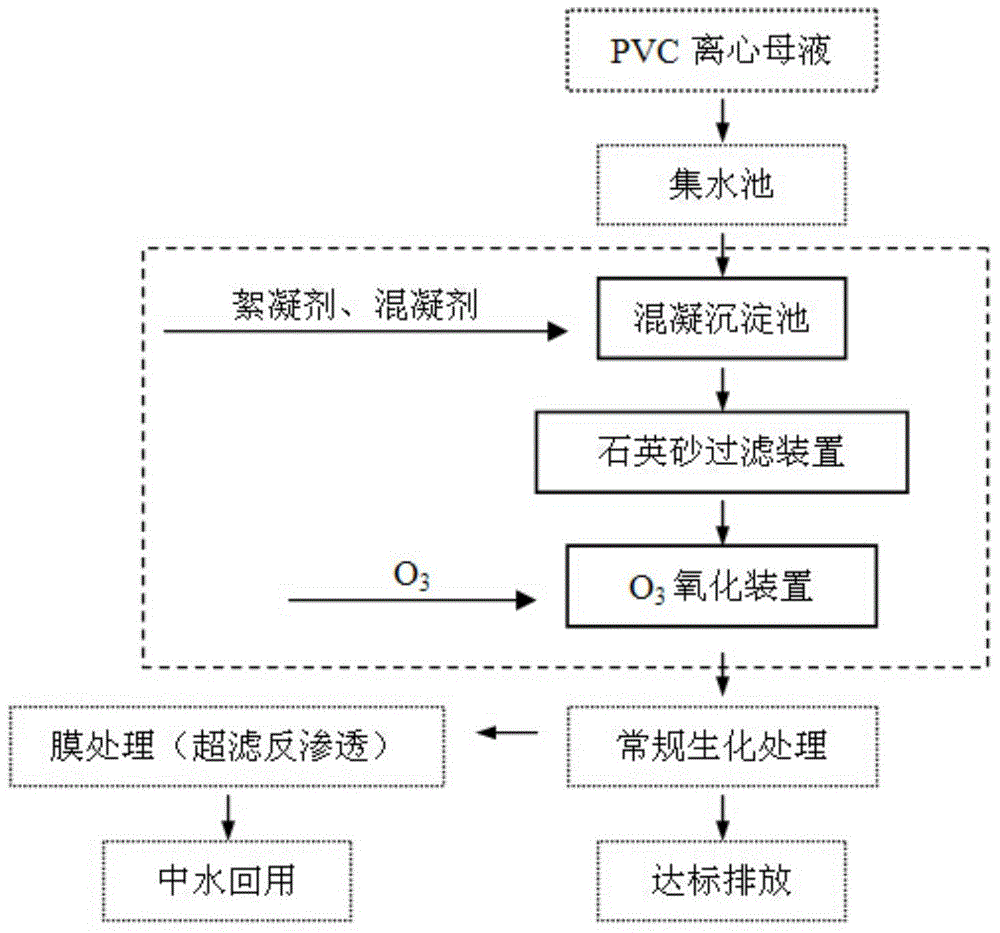

[0023] The PVC centrifugal mother liquor discharged from the PVC polymerization section of a chlor-alkali enterprise in Northeast China was used for experiments. The initial COD of the waste water was 101mg / L, the PVA was 3mg / L, and the turbidity was 89FAU. COD was measured by American Hach COD digestion instrument (DRB200, American Hach) and portable spectrophotometer (DR2800, American Hach), PVA was measured by boric acid-potassium iodide spectrophotometry (DR2800, American Hach), BOD 5 The American Hach BOD rapid tester (BODTrack II, American Hach) was used for measurement, and the turbidity was measured by a portable water quality monitor (DR820DR850, American Hach).

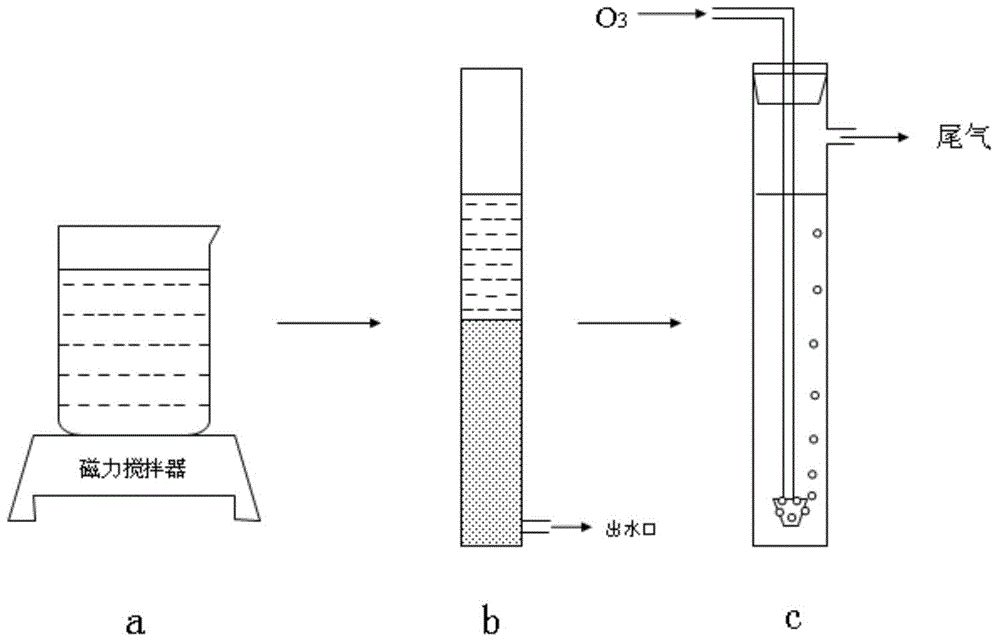

[0024] Sieve out the quartz sand with a particle size between 0.8mm and 1.0mm, wash and dry it with tap water, and put it into a glass column. The diameter of the filter column is 5cm, and the height of the quartz sand is 20cm. Add 0.1g of Al to 1L of wastewater 2 (SO 4 ) 3 18H 2 O and 0.004g of PAM, adj...

Embodiment 2

[0026]Experiments were carried out by using a PVA solution prepared by dissolving PVA particles with a molecular weight of 1750±50 in distilled water and mixing the mother liquor wastewater collected from the PVC polymerization section of the chlor-alkali enterprise. The initial COD of the wastewater is 133mg / L, the PVA is 29mg / L, and the turbidity is 75FAU. After processing according to the combination technology described in Example 1, the PVA concentration is about 0.5mg / L, the removal rate is close to 100%, the removal rate of COD can reach 56%, and the removal rate of BOD 5 / COD increased from 0.13 to 0.41, and the turbidity after treatment was 0.

Embodiment 3

[0028] Experiments were carried out by using a PVA solution prepared by dissolving PVA particles with a molecular weight of 1750±50 in distilled water and mixing the mother liquor wastewater collected from the PVC polymerization section of the chlor-alkali enterprise. The initial COD of the wastewater is 396mg / L, the PVA is 50mg / L, and the turbidity is 45FAU. According to the combination technology described in Example 1, the PVA concentration after treatment is about 8mg / L, and the removal rate is about 84%, while the removal rate of COD can reach 79%, and the turbidity after treatment is reduced to 0, BOD 5 / COD increased from 0.007 to 0.26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com