Capacity increasing method for nano particle modified carbon fiber sizing agent

A technology of nano-particles and modified carbon, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of poor compatibility and easy agglomeration, and achieve the effects of improving heat resistance, simple operation and improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

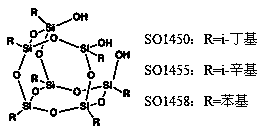

[0036] Specific embodiment one: The compatibilization method for nanoparticle modified carbon fiber sizing agent provided in this embodiment is divided into the following two steps:

[0037] One, 100 parts by mass of nano-SiO 2 and 10 parts by mass of SO1458POSS were dissolved in acetone, and ultrasonically dispersed for 15 minutes to obtain nano-SiO 2 Dispersion, the dispersion was spread on a glass slide for contact angle measurement as Figure 2-3 shown. Depend on figure 2 It can be seen that POSS forms a film on the glass surface, and the contact angle of water is 90°; image 3 It can be seen that the dispersion liquid forms a film on the glass surface, and the contact angle of water is 130°.

[0038] 2. Mix the dispersion liquid in the first step with epoxy resin and emulsifier evenly to control the nano-SiO 2 The mass ratio of the mixture of SO1458POSS to epoxy resin and emulsifier is 15:100:50, the organic solvent is removed by distillation under reduced pressure,...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the amount of SO1458POSS in step 1 is 50 parts by mass, and other contents are the same as Embodiment 1. Depend on Figure 4 It can be seen that the dispersion liquid forms a film on the glass surface, and the contact angle of water is 139°.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, SiO 2 The consumption of is 50 mass parts, and other content is identical with specific embodiment one. Depend on Figure 6 It can be seen that for different proportions of nano-SiO 2 It can be seen from the thermogravimetric analysis of the sizing agent of POSS that the introduction of POSS can improve the nano-SiO 2 Heat resistance properties of modified carbon fiber sizing agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com