Surface enhanced Raman scattering substrate, preparation method and applications thereof

A surface-enhanced Raman and substrate technology, which is applied in Raman scattering, textiles, papermaking, non-woven fabrics, etc., can solve the problems of limited applications, achieve the effect of improving the detection limit, wide application, and suitable for large-scale batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for preparing a surface-enhanced Raman scattering substrate, comprising the following steps:

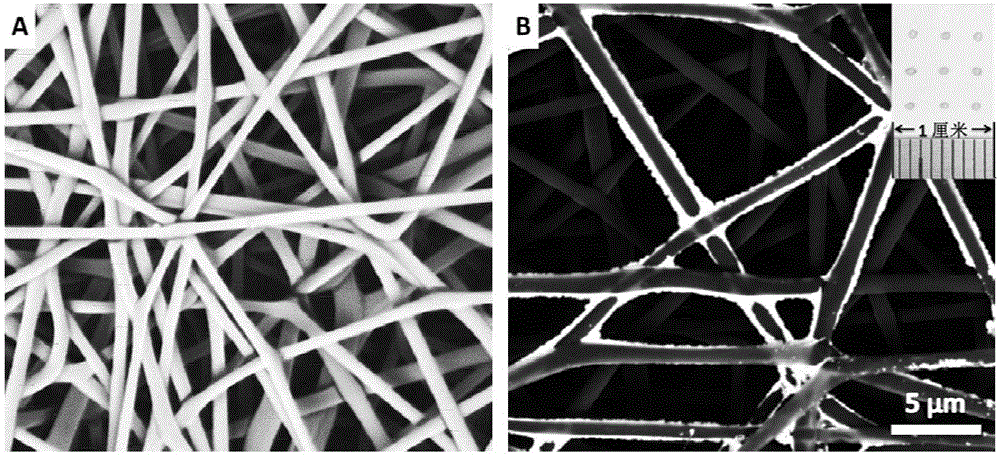

[0065] (1) Preparation of polylactic acid electrospun film: Weigh 0.5 g of L-type polylactic acid and dissolve it in a mixed solution of 5 ml of dichloromethane and N,N-dimethylformamide (4:1 by volume) , and magnetically stirred at room temperature for 12 hours to obtain a uniform spinning solution, wherein the concentration of L-type polylactic acid was 0.1 g / mL.

[0066] Then, transfer the spinning solution into a 5 mL medical syringe and fix it on a small syringe pump, and connect the pump head tube with a 6-gauge stainless steel needle. The needle is connected to the high-voltage positive electrode with an alligator clip. Below the needle is a grounded roller collector covered with a layer of aluminum foil as a collection device. The distance between the needle and the aluminum foil is 15 cm. The humidity in the spinning machine is controlled by a dehumidifier, ...

Embodiment 2

[0072] A method for preparing a surface-enhanced Raman scattering substrate, comprising the following steps:

[0073] (1) Preparation of polylactic acid electrospun film: Weigh 1 g of L-type polylactic acid and dissolve it in a mixed solution of 5 ml of dichloromethane and N,N-dimethylformamide (6:1 by volume) , and magnetically stirred at room temperature for 12 hours to obtain a uniform spinning solution, wherein the concentration of L-type polylactic acid was 0.2 g / mL.

[0074] Then, transfer the spinning solution into a 5 mL medical syringe and fix it on a small syringe pump, and connect the pump head tube with a 6-gauge stainless steel needle. The needle is connected to the high-voltage positive electrode with an alligator clip. Below the needle is a grounded roller collector covered with a layer of aluminum foil as a collection device. The distance between the needle and the aluminum foil is 15 cm. The humidity in the spinning machine is controlled by a dehumidifier, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com