Method for rapidly degrading antibiotics

A rapid degradation, antibiotic technology, applied in chemical instruments and methods, water/sludge/sewage treatment, organic compound/hydride/coordination complex catalysts, etc., can solve slow degradation rate, reduced efficiency, insufficient light, etc. problem, to achieve the effect of simple operation, lower cost and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

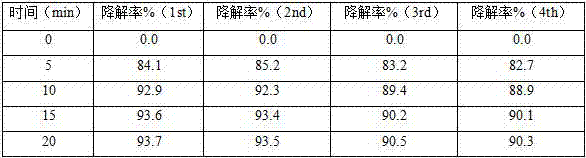

[0027] Embodiment 1: The specific content of the method of this rapid degradation antibiotic is as follows:

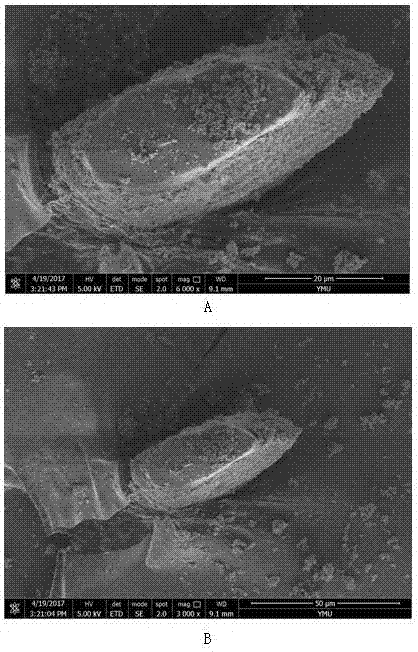

[0028] In this example, MIL-101(Fe) / TiO was prepared under the conditions of 12h / 120°C 2 Catalyst, Research MIL-101(Fe) / TiO 2 For the degradation effect of tetracycline;

[0029] (1) Metal-organic framework composite MIL-101(Fe) / TiO 2 Preparation: Dissolve ferric chloride hexahydrate, terephthalic acid, and titanium dioxide in a molar ratio of 1:1:1 in 40 mL of DMF, and after stirring for 1 hour, transfer the solution to a 100 mL Teflon-lined In the reaction kettle, the reaction kettle was placed in a forced air drying oven, and after reacting at 120° C. for 12 hours, the reaction kettle was taken out, and the reaction kettle was naturally cooled to room temperature. After the reaction kettle was cooled, the product was taken out with a sand core funnel for suction filtration, washed with DMF and ethanol three times, and then vacuum-dried at 60°C for 12 hours; the m...

Embodiment 2

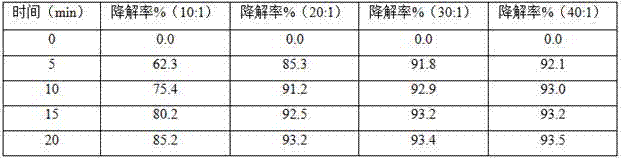

[0038] Example 2: This example is MIL-101(Fe) / TiO prepared under the preparation conditions of 12h / 120°C 2 As a catalyst, the effect of different molar ratios of potassium persulfate and tetracycline (n potassium persulfate / n tetracycline = 10, 20, 30, 40) on the catalytic activation reaction was studied;

[0039] (1) The preparation method of the metal-organic framework composite material is the same as step (1) in Example 1;

[0040](2) Use a photochemical reaction instrument as a simulated visible light source, the light source is 300W natural visible light, add potassium persulfate and tetracycline solution with a molar ratio of 10:1 into the reactor, and keep the solution volume in the reactor at 50mL of 80mg / L tetracycline solution, while adding 50mg MIL-101(Fe) / TiO to the reactor 2 Magnetic stirring is carried out in the optical reaction instrument, the reaction is carried out at room temperature, and sampling and analysis are carried out at fixed points;

[0041] (3)...

Embodiment 3

[0048] Example 3: This example is MIL-101(Fe) / TiO prepared under the conditions of 12h / 120°C 2 As a catalyst, study MIL-101(Fe) / TiO 2 The effect of the dosage (5mg, 25mg, 50mg, 75mg, 100mg) on the catalytic activation reaction

[0049] (1) Metal-organic framework composite MIL-101(Fe) / TiO 2 The preparation method is the same as the step (1) in the implementation case 1;

[0050] (2) Use a photochemical reaction instrument as a simulated visible light source, the light source is 300W natural visible light, add potassium persulfate and tetracycline solution with a molar ratio of 20:1 into the reactor, and keep the solution volume in the reactor at 50mL of 80mg / L tetracycline Solution, add 5mg MIL-101(Fe) / TiO in the reactor at the same time Carry out magnetic stirring in the optical reactor, react under normal temperature conditions, fixed-point sampling analysis;

[0051] (3) Add 25mg MIL-101(Fe) / TiO to the reactor 2 , other conditions are the same as step (2);

[0052] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com