Method and device for removing impurities from phosphogypsum through electromagnetic reinforcement

An electromagnetic strengthening and phosphogypsum technology, which is applied in the field of electromagnetic strengthening phosphogypsum impurity removal, can solve the problems of low separation efficiency, inability to effectively remove heavy metals and radioactive elements, and low resource recycling efficiency, and achieves high processing efficiency and short processing time. , non-selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: The object of treatment in this example is phosphogypsum produced during the wet production of phosphoric acid in a phosphoric acid plant, wherein the content of phosphorus impurities is 1.5%, the content of fluorine impurities is 1.2%, the content of organic impurities is 0.35%, and the oxidation of metals and heavy metals The content of substances and radioactive metal impurities is 1.3%.

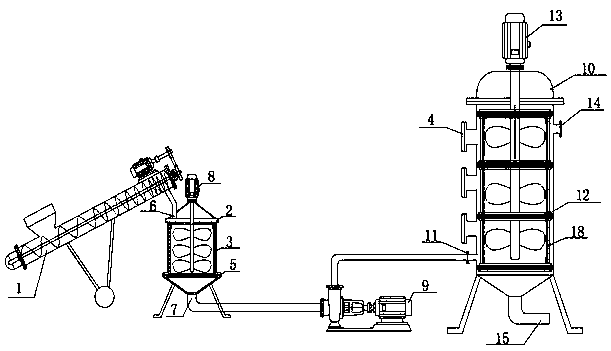

[0039] 1. Acid leaching treatment: Add phosphogypsum and tributyl phosphate into the screw feeder, mix them and add them to the acid leaching tank, put the stainless steel electrode into the electrode card slot, and add the concentration of 28% sulfuric acid, the mass volume ratio of phosphogypsum to organic extractant is 1:5, the mass ratio of phosphogypsum to concentrated sulfuric acid is 1:3, turn on the heating device at the bottom of the acid leaching tank, let the system temperature reach 70°C; Calcium sulfate dihydrate is dissociated into calcium ions and sulfate ...

Embodiment 2

[0045] Embodiment 2: The processing object of this embodiment is the phosphogypsum inventory of a phosphogypsum stacking and processing center, wherein the content of phosphorus impurities is 1.1%, the content of fluorine impurities is 0.9%, the content of organic impurities is 0.22%, metal and heavy metal oxides and radioactivity The content of metal impurities is 0.9%.

[0046] Acid leaching treatment: Add phosphogypsum and carbon tetrachloride to the screw feeder, mix and stir them and add them to the acid leaching tank, put the stainless steel electrode into the electrode card slot, and add the concentration of 30 to the acid leaching tank % of sulfuric acid, the mass volume ratio of phosphogypsum to organic extractant is 1:6, the mass ratio of phosphogypsum to concentrated sulfuric acid is 1:4, turn on the heating device at the bottom of the acid leaching tank, let the system temperature reach 80°C, Calcium sulfate water dissociates into calcium ions and sulfate ions in h...

Embodiment 3

[0050] Example 3: The object of treatment in this example is desulfurized gypsum produced by flue gas desulfurization in a chemical plant, in which the content of phosphorus impurities is 1.5%, the content of fluorine impurities is 0.3%, the content of organic impurities is 0.18%, metal and heavy metal oxides and radioactivity The content of metal impurities is 1.6%.

[0051]Acid leaching treatment: Add phosphogypsum and dioctyl phosphate to the screw feeder, mix and stir them and add them to the acid leaching tank, put the stainless steel electrode into the electrode card slot, and add a concentration of 35 to the acid leaching tank % sulfuric acid, the mass volume ratio of phosphogypsum to organic extractant is 1:7, and the mass ratio of phosphogypsum to concentrated sulfuric acid is 1:5. Turn on the heating device at the bottom of the acid leaching tank and let the system temperature reach 85°C. The heterogeneous calcium sulfate dihydrate is dissociated into calcium ions an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com