Composite flocculant for treating printing and dyeing wastewater

A composite flocculant, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of single function of adsorption or flocculation materials, poor removal efficiency, etc., and achieve good adsorption and flocculation effect, strong capture and sedimentation effect, and the effect of improving the response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

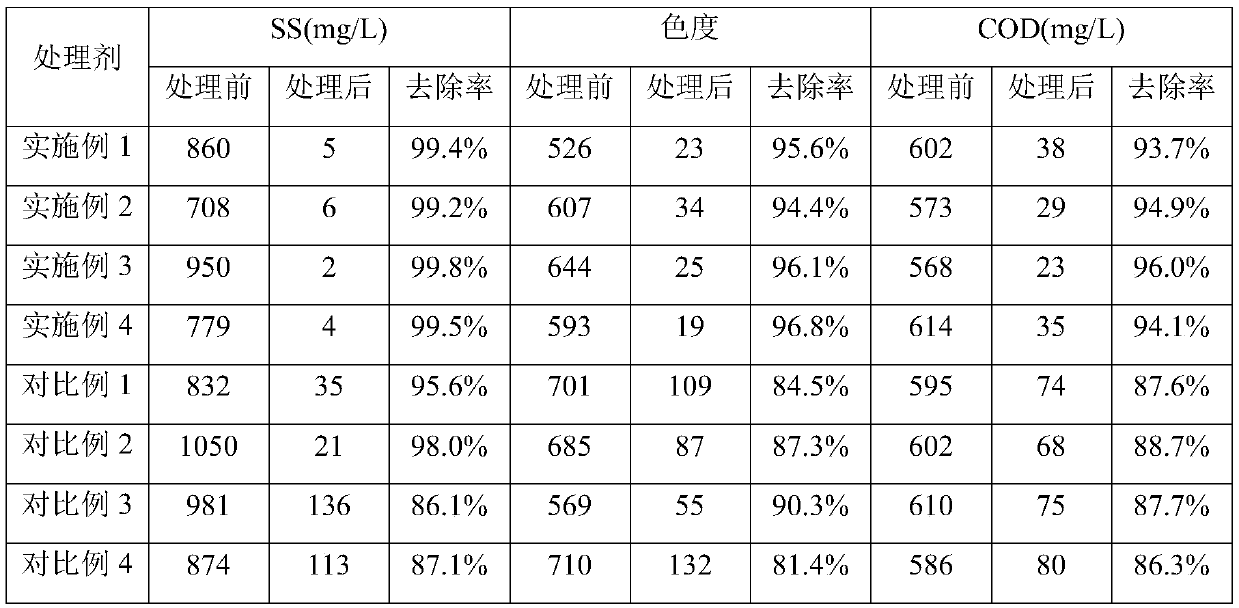

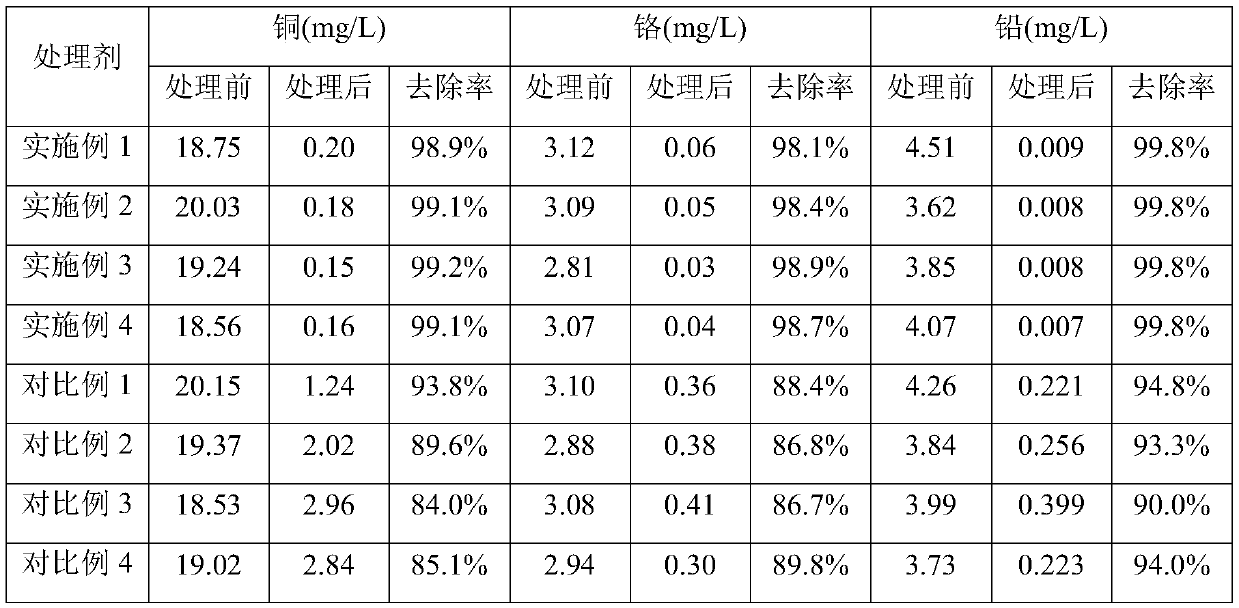

Examples

Embodiment 1

[0034] A composite flocculant for printing and dyeing wastewater treatment, prepared from the following raw materials in parts by weight: 15 parts of activated carbon fiber, 4 parts of acrylamide, 0.003 parts of initiator, 2 parts of sodium carboxymethyl cellulose, and 5 parts of polyvinyl alcohol , 3 parts of crosslinking agent, 3 parts of polyethyleneimine-cellulose composite material, 10 parts of starch xanthate, 25 parts of modified bentonite.

[0035] Further, the activated carbon fiber is obtained from biomass material through hydrothermal carbonization and sulfuric acid activation; its preparation method is as follows:

[0036] (1) removing impurities, washing and drying the biomass material for subsequent use;

[0037](2) adding the dried biomass material into the hydrothermal reaction kettle, adding deionized water, immersing the biomass material, programmatically heating up to 220°C, and cooling to normal temperature after reacting for 24 hours;

[0038] (3) washing...

Embodiment 2

[0051] A composite flocculant for printing and dyeing wastewater treatment is prepared from the following raw materials in parts by weight: 17 parts of activated carbon fibers, 6 parts of acrylamide, 0.004 parts of initiator, 5 parts of sodium carboxymethyl cellulose, and 9 parts of polyvinyl alcohol , 4 parts of cross-linking agent, 4 parts of polyethyleneimine-cellulose composite material, 12 parts of starch xanthate, and 30 parts of modified bentonite.

[0052] Further, the activated carbon fiber is obtained from biomass material through hydrothermal carbonization and sulfuric acid activation; its preparation method is as follows:

[0053] (1) The biomass material is used for subsequent use after removing impurities, washing and drying;

[0054] (2) adding the dried biomass material into the hydrothermal reaction kettle, adding deionized water, immersing the biomass material, programmatically heating up to 220°C, and cooling to normal temperature after reacting for 24 hours...

Embodiment 3

[0068] A composite flocculant for printing and dyeing wastewater treatment is prepared from the following raw materials in parts by weight: 23 parts of activated carbon fibers, 9 parts of acrylamide, 0.005 parts of initiator, 7 parts of sodium carboxymethyl cellulose, and 13 parts of polyvinyl alcohol , 5 parts of crosslinking agent, 4.5 parts of polyethyleneimine-cellulose composite material, 14 parts of starch xanthate, and 32 parts of modified bentonite.

[0069] Further, the activated carbon fiber is obtained from biomass material through hydrothermal carbonization and sulfuric acid activation; its preparation method is as follows:

[0070] (1) The biomass material is used for subsequent use after removing impurities, washing and drying;

[0071] (2) adding the dried biomass material into the hydrothermal reaction kettle, adding deionized water, immersing the biomass material, programmatically heating up to 220°C, and cooling to normal temperature after reacting for 24 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com