Device and method for efficiently removing fine particulate matters by temperature and humidity regulation and control

A technology for fine particulate matter and particulate matter, which is applied in the field of devices for efficient removal of fine particulate matter by temperature and humidity control, can solve problems such as insignificant agglomeration effect, avoid ash accumulation and scaling, strengthen coagulation and removal, and promote coagulation and removal. the effect of elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

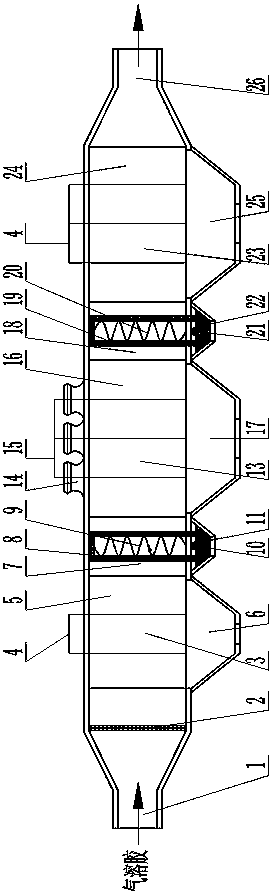

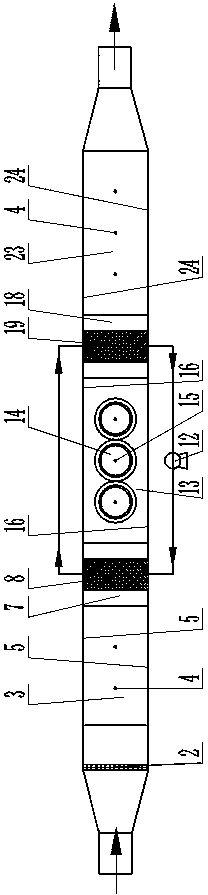

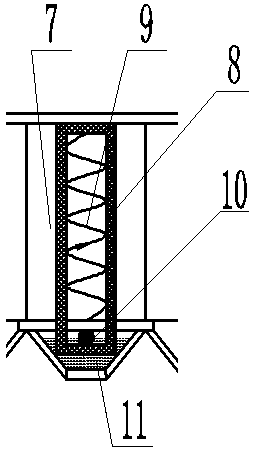

[0039] see Figure 1 to Figure 4 , in this embodiment, a device for efficiently removing fine particles with temperature and humidity control, including an aerosol inlet 1, an air distribution plate 2, a pre-dust collection area 3, a first-level control dust collection area 7, a circulation pump 12, and an acoustic-electric coupling Condensation area 13, secondary control dust collection area 18, direct current dust collection area 23 and aerosol outlet 26; aerosol inlet 1, air distribution plate 2, pre-dust collection area 3, primary control dust collection area 7, acoustic-electric coupling condensation Combining area 13, secondary control dust collection area 18, direct current dust collection area 23 and aerosol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com