Patents

Literature

90 results about "Starch xanthate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional sewage treatment agent and preparation method thereof

ActiveCN103708631AOvercome deficienciesReduce flocculation costScale removal and water softeningWater/sewage treatment by ion-exchangeCross-linkSodium Bentonite

The invention relates to the technical field of water treatment agents and particularly relates to a multifunctional sewage treatment agent. The multifunctional sewage treatment agent comprises the following raw materials in parts by weight: 10-20 parts of sepiolite powder, 30-40 parts of bentonite, 30-40 parts of starch xanthate, 0.1-0.5 part of sodium hydroxide caustic soda, 1-5 parts of polyaspartic acid, 0.1-0.5 part of amino trimethylene phosphonic acid, 25-50 parts of cross-linked rectorite, 20-50 parts of aluminum polychlorid, 5-30 parts of chitosan and 10-30 parts of deionized water. The multifunctional sewage treatment agent provided by the invention is high in purity, free of impurity and dustless, the aqueous solution is clear, transparent, non-toxic and free of effect on operation workers, and the treated water is free of problems such as secondary pollution.

Owner:WENZHOU HONGJIAN CONSTR ENG

Papermaking wastewater treating agent and preparation method thereof

ActiveCN103641245ASustainable processingIncrease concentrationWater/sewage treatment by ion-exchangeWaste water treatment from plant processingStarch xanthatePolyacrylamide

The invention relates to the technical field of wastewater treatment, and in particular relates to a papermaking wastewater treating agent and a preparation method thereof. The papermaking wastewater treating agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 10-20 parts of magnesium sulfate, 0.5-1.5 parts of polyacrylamide, 15-25 parts of ferric nitrate, 1-5 parts of nickel nitrate, 35-50 parts of polyaluminum chloride, 15-30 parts of starch xanthate, 2-5 parts of tetrasodium 2-phosphonobutane-1, 2, 4-tricarboxylate, 0.5-1 part of zinc sulfate, 1-3 parts of benzotriazole, 16-30 parts of modified kieselguhr, 5-20 parts of cross-linked rectorite and 5-8 parts of a chitosan-graphene composite material. The papermaking wastewater treating agent disclosed by the invention is wide in using range, simple in treatment process, small in drug consumption, good in treatment effect, stable in performance and good in effluent quality and is capable of effectively reducing the cost of water treatment, so that the papermaking wastewater treating agent has a very good economic benefit and a wide social benefit.

Owner:SHANTOU LONGHU DISTRICT YUEAN PAPER

Heavy metal sewage treatment agent

InactiveCN104118921ARemove reachEasy to remove by filtrationWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationCelluloseCarbamate

The invention relates to a heavy metal sewage treatment agent which is prepared from dodecyl diethylene triamine, dimethyl diallyl ammonium chloride, acrylamide, dibenzoyl peroxide, powdered activated carbon, ethylene diamine tetraacetic acid, tert-butylamine, carbamate, dithiocar-bamate, thiocarbamic acid ester, starch, cellulose, water soluble starch xanthate ester, sodium silicate, potassium peroxodisulfate, sodium hydrosulfite, strong base and water. The heavy metal sewage treatment agent disclosed by the invention is formed by being modified with a high-molecular compound; the mixture contains a plurality of active groups which can be complexed, chelated, absorbed and exchanged with heavy metal, so that heavy metal ions in the aqueous solution can be removed; the heavy metal sewage treatment agent has good removal effect on heavy metal ions, the removal rate is above 97%, and furthermore, the heavy metal sewage treatment agent has stronger Ca2+ and Mg2+ resistant capability; the removal rate of cadmium-containing sewage is 99.8%, which meets the national emission standard; and the removal rate of chromium-containing sewage is above 99.6%.

Owner:江西省恩皓环保有限公司

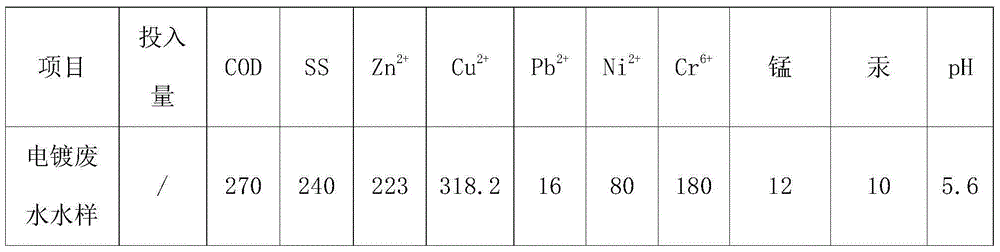

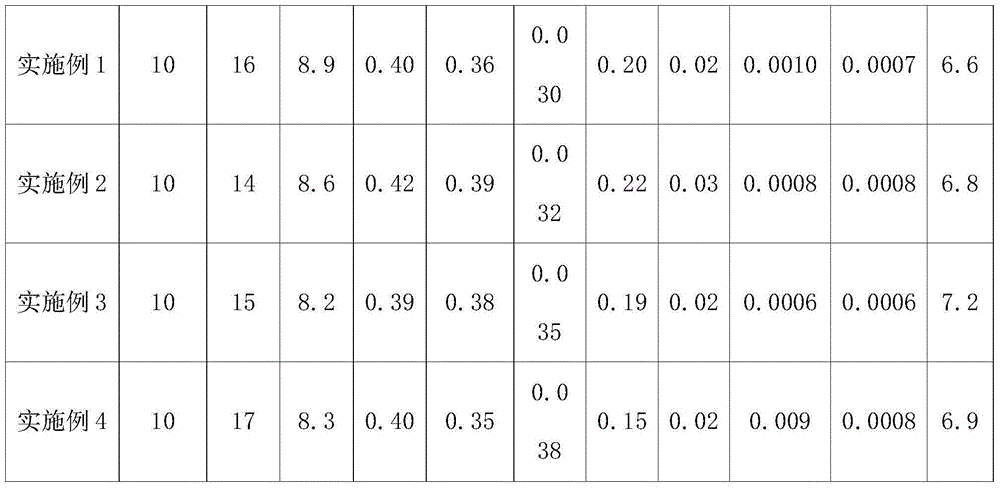

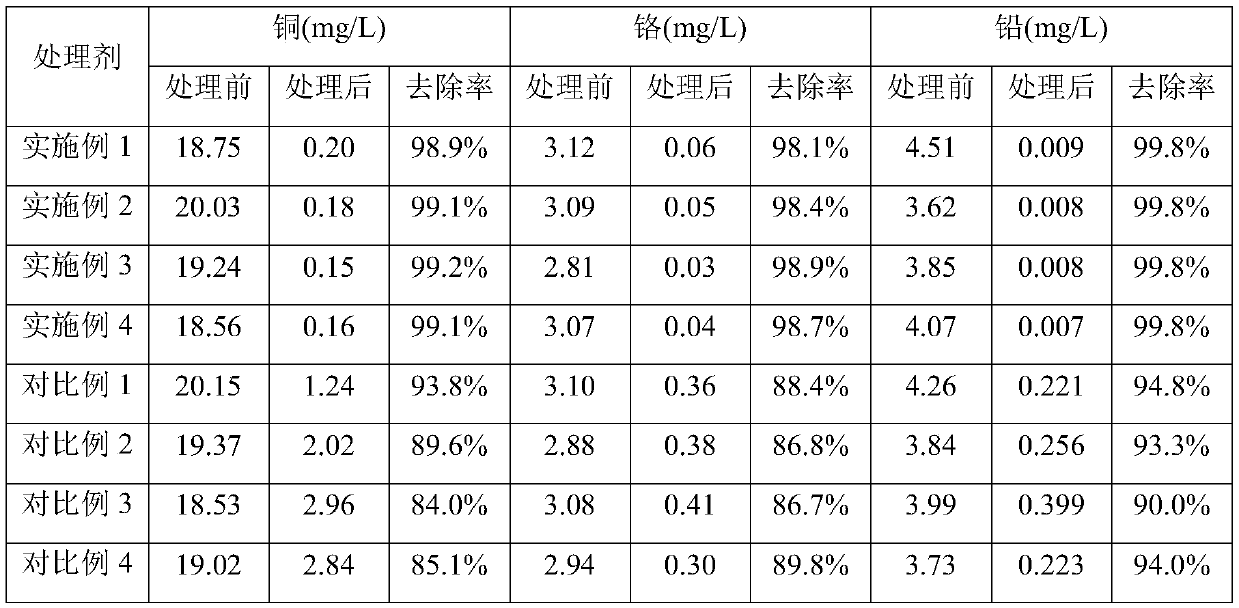

Electroplating wastewater treatment agent

InactiveCN105000651AReasonable ratioEfficient removalWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationCross-linkTreatment effect

The invention discloses an electroplating wastewater treatment agent, consisting of a reducing agent, a composite flocculant, a heavy metal ion collector DTCR, starch xanthate, cross-linked rectorite, quaternary ammonium salt lignin, sodium silicate, an alkaline substance and an adsorption filler. According to the treatment agent, the materials realize a synergistic effect, multiple heavy metal ions can be effectively removed, heavy metal ions with multiple ions coexisting also can be effectively removed, the treatment effect on electroplating wastewater is excellent, the performance is stable, the sedimentation effect is good, and the sedimentation speed is high; besides, the electroplating wastewater treatment agent is reasonable in ratio, non-poisonous and free of environment pollution.

Owner:宁波保税区维迪克环保科技有限公司

Treating agent for electroplating waste water

InactiveCN103739053ALow costSimple processing methodWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationStarch xanthatePolypropylene

The invention belongs to the technical field of sewage treating agents and particularly relates to a treating agent for electroplating waste water. The treating agent for electroplating waste water comprises the following raw materials by weight: 20-30 parts of reducing agent, 5-8 parts of amino trimethylene phosphonic acid, 10-20 parts of sodium polyacrylate, 10-15 parts of heavy metal ion collector, 10-20 parts of starch xanthate, 2-5 parts of GNS (Graphene Nanosheet) / MnO2 composite, 20-30 parts of crosslinking rectorite, 6-8 parts of 1, 3, 5-triazine-2, 4, 6 trithiol trisodium salt, 10-20 parts of quaternary ammonium salt lignin flocculant and 30-40 parts of coal ash. The treating agent for electroplating waste water, which is compounded by the raw materials, performs a synergistic function and can capture various metal ions in water. The treatment method is simple. As long as the chemical agent is thrown in the electroplating waste water, heavy metal ions can be removed. No equipment or technologies are increased, so that the treatment cost of the electroplating waste water is greatly lowered.

Owner:JILIN LEAD CHEM TECH CO LTD

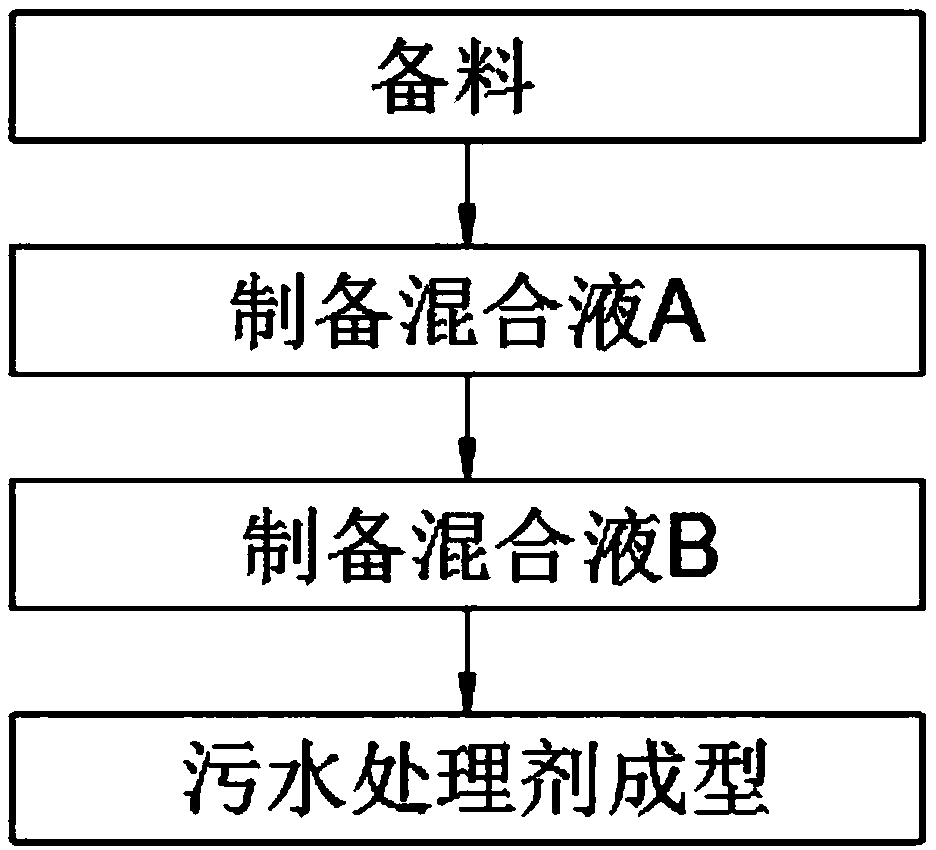

Sewage treating agent for heavy metal pollution

InactiveCN108439525AEfficient additionEasy to addWater/sewage treatment by irradiationWater treatment compoundsCelluloseStarch xanthate

The invention discloses a sewage treating agent for heavy metal pollution. The sewage treating agent is prepared from raw materials in parts by weight as follows: polyethyleneimine, carbon disulfide,sodium hydroxide, starch xanthate, bacillus mucilaginosus, concha haliotidis powder, modified zeolite powder, modified bentonite, sodium alginate, humic acid, ferric trichloride, nanometer titania, cellulose, ferrous sulfate, a photocatalyst, an efficient nickel remover, a chitosan modified polymeric flocculant, a coagulant aid, sephadex and deionized water. A preparation method of the sewage treating agent comprises steps as follows: material preparation, preparation of a mixed liquor A, preparation of a mixed liquor B and forming of the sewage treating agent. Through addition of polyethyleneimine, carbon disulfide and the coagulant aid, the sewage treating agent has a good flocculation effect on various heavy metal ions; through addition of starch xanthic acid, bacillus mucilaginosus, the concha haliotidis powder, the modified zeolite powder and the modified bentonite, the sewage treating agent has a good adsorbing effect, and the heavy metal ions in sewage are effectively removed bydouble cooperation of adsorption and flocculation.

Owner:湖南善循环保科技有限公司

Method for preparing cationic cross-linked starch xanthate

InactiveCN102702367AApplicable removalFast binding reactionWater contaminantsWater/sewage treatment by flocculation/precipitationCross-linkFiltration

The invention discloses a method for preparing cationic cross-linked starch xanthate. The method comprises the following steps of: dissolving NaOH and 2,3-epoxypropyltrimethyl ammonium chloride in cold water, and stirring and mixing with starch; reacting for 9 minutes at the temperature of 60 DEG C in a fast microwave reactor; washing products by using an aqueous solution of ethanol, and finally, drying to obtain etherified starch; adding an alkaline solution prepared by water, sodium hydroxide and sodium chloride into etherified starch to be mixed to form slurry; dissolving epoxy chloropropane in the alkaline solution, dripping the mixture into the slurry, and reacting for 2 hours at the temperature of 50 DEG C; regulating the pH value of the solution to be at 7 by using hydrochloric acid; washing by using absolute ethyl alcohol after suction filtration, and drying to obtain the cross-linked etherified starch; dissolving the etherified starch into the water, adding a solution of sodium hydroxide and adding carbon disulfide, stirring to react for 2 hours at the temperature of 50 DEG C, adding a solution of magnesium sulfate, and continuously reacting for 10 minutes; and performing suction filtration, washing by using distilled water, acetone and diethyl ether in sequence, and drying to obtain the cationic cross-linked starch xanthate. When the cationic cross-linked starch xanthate is used for treating heavy metal wastewater, a cationic polymer is not required to be added.

Owner:SHAANXI UNIV OF TECH

Sewage treatment agent for paper mills

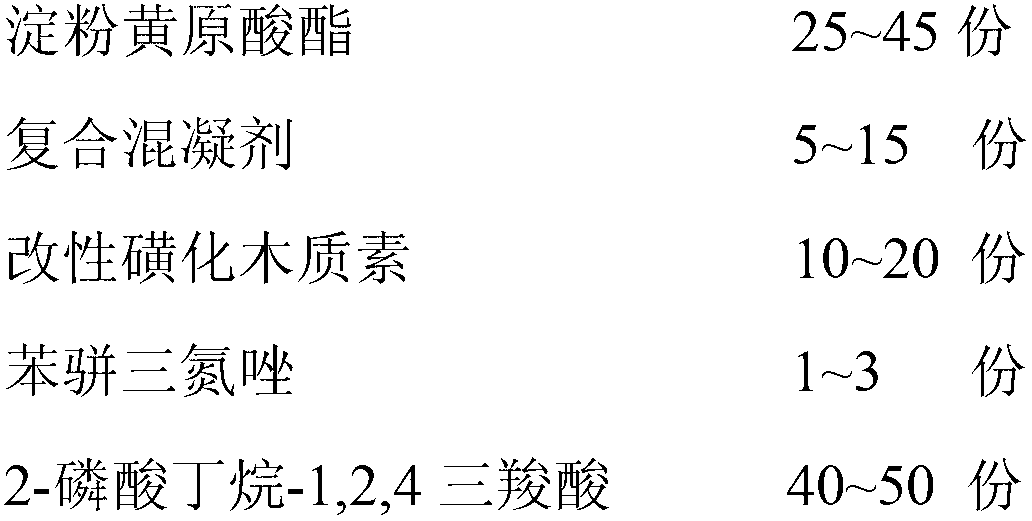

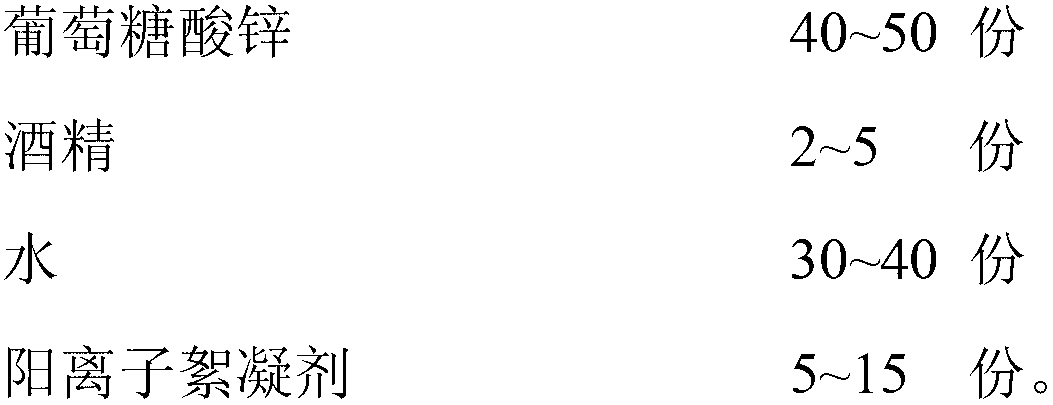

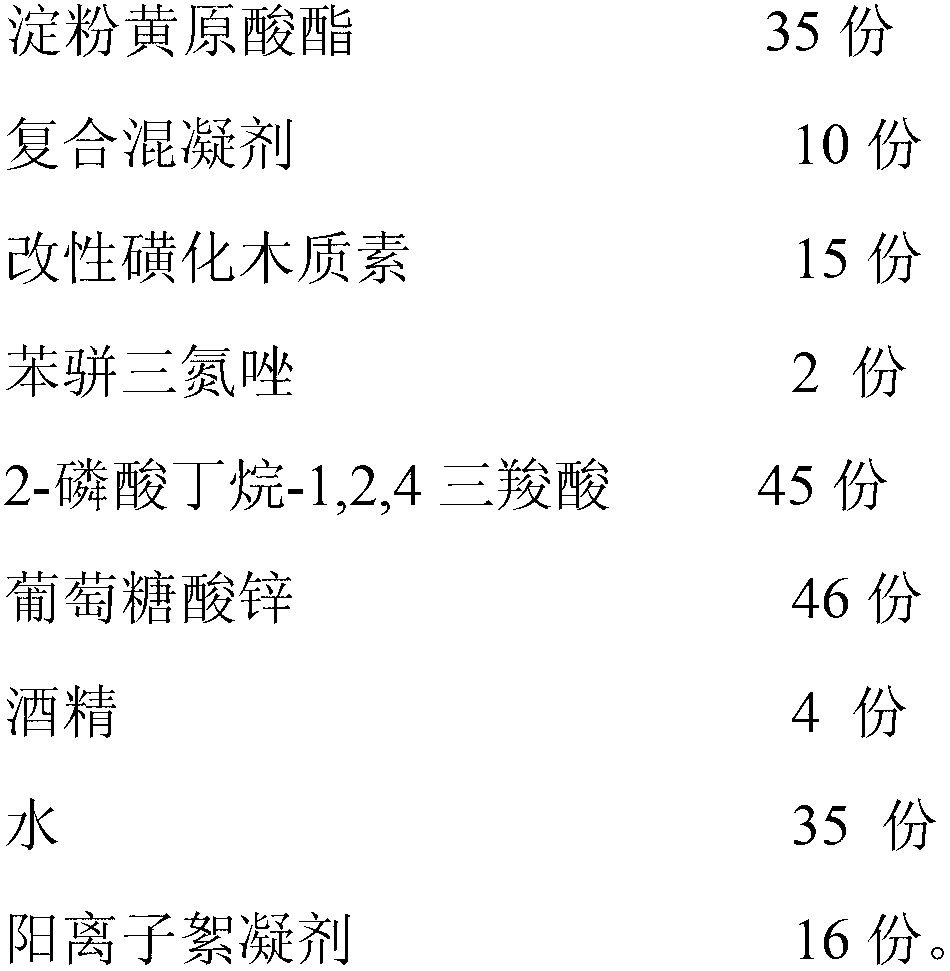

InactiveCN102701472ALow costGrowth inhibitionScale removal and water softeningTricarboxylic acidCarboxylic acid

The invention discloses a sewage treatment agent for paper mills. The sewage treatment agent for paper mills consists of the following components in parts by weight: 25-45 parts of starch xanthate, 5-15 parts of composite coagulant, 10-20 parts of modified ligninsulfonate, 1-3 parts of benzotriazole, 40-50 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 40-50 parts of zinc gluconate, 2-5 parts of alcohol, 30-40 parts of water and 5-15 parts of cationic flocculant. After being added in a circulating water system, the sewage treatment agent for paper mills has the effects of effectively inhibiting corrosion, scale and algae growth, favorable protection function is brought to a cooling water system, and the whole process is free of waste gas / water / residue discharge, so that the black liquor pollution problem of pulping paper mills is solved. The sewage treatment agent for paper mills is used for treating sewage and treating wastes with processes of wastes against one another, the treatment process is simple, the dosage is less, the effect is good, the water treatment cost is effectively reduced, and good economic benefit and wide social benefit are achieved.

Owner:天津市大港巨龙造纸厂

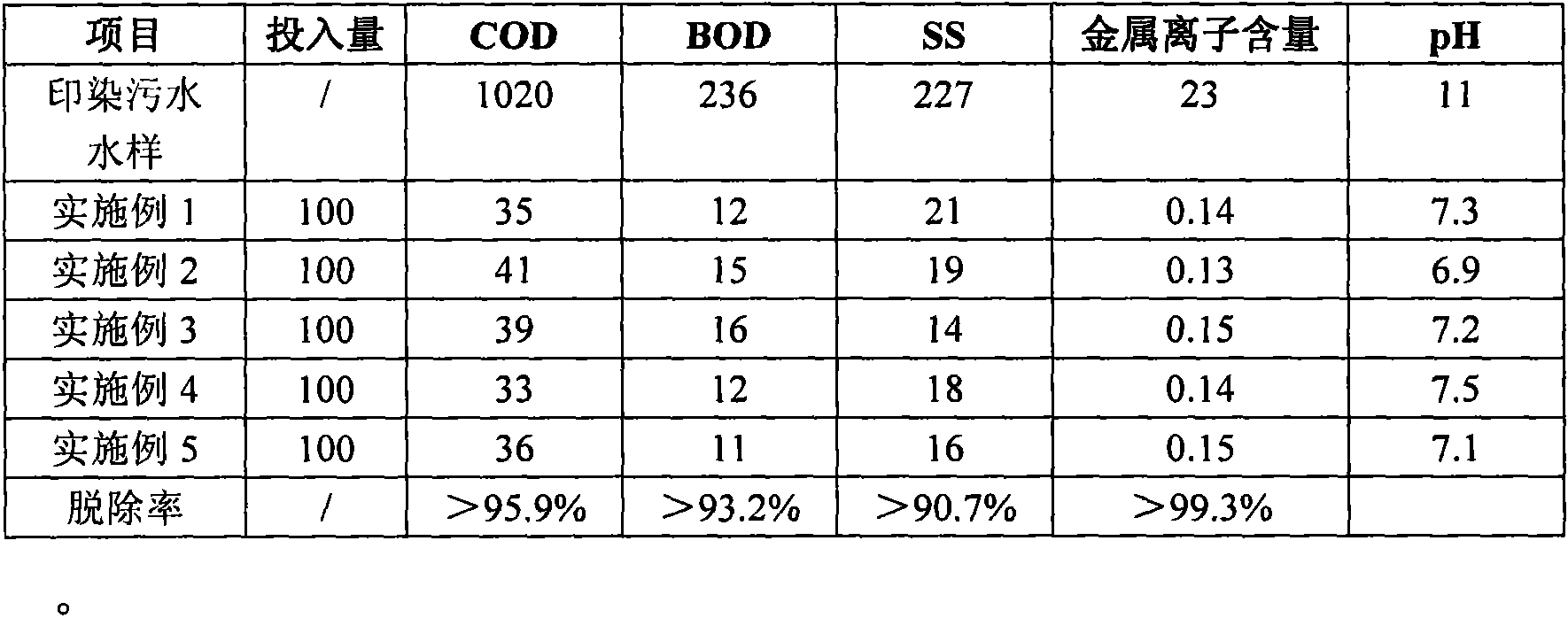

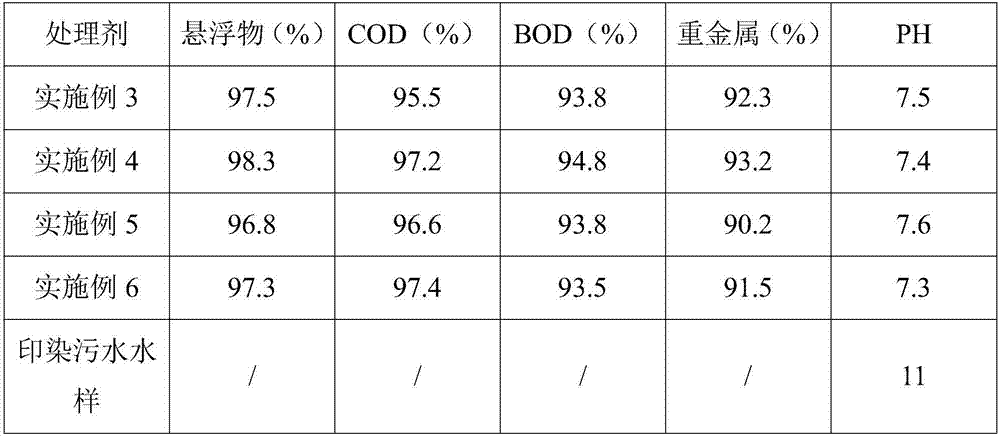

Composite flocculant for treating printing and dyeing wastewater

ActiveCN109734145AGood nucleation effectRealize separation and removalWater contaminantsWaste water treatment from textile industryFiberPolyvinyl alcohol

The invention discloses a composite flocculant for treating printing and dyeing wastewater. The composite flocculant for treating the printing and dyeing wastewater is prepared from the following rawmaterials in parts by weight: 15-25 parts of activated carbon fibers, 4-11 parts of acrylamide, 2-9 parts of sodium carboxymethyl cellulose, 5-17 parts of polyvinyl alcohol, 3-6 parts of a crosslinking agent, 0.003-0.006 part of an initiator, 3-5 parts of a polyethyleneimine-cellulose composite material, 10-15 parts of starch xanthate and 25-36 parts of modified bentonite. The composite flocculantprovided by the invention does not contain components which are complicated, have radiation and easily cause secondary pollution, all the used raw materials are natural, environment-friendly, low inprice and easy to obtain, the preparation method is simple, the feeding amount is small, the composite flocculant has multiple effects of flocculation sedimentation, adsorption decolorization, deodorization and the like, the sedimentation rate is high, the removal rates of organic matters, dye molecules and heavy metals are high, the structure and properties are stable, and the application range is wide.

Owner:XINXIANG UNIV

Method for treating polyether wastewater

ActiveCN103449661AContinue to playPlay evenlyMultistage water/sewage treatmentNature of treatment waterChemical oxygen demandSludge

The invention relates to a method for treating polyether wastewater, and the method is mainly used for solving the problem that the polyether wastewater with high COD (Chemical Oxygen Demand) and low BOD(Chemical Oxygen Demand) / COD ratio can not achieve the discharge standard in the prior art. According to the invention, polyether-containing wastewater with BOD / COD less than or equal to 0.1 and COD more than or equal to 1500 milligrams / liter are treated through a regulating pond, a biochemical pond, an active sludge pond and a secondary sedimentation pond and then discharged, so that the COD contained in the discharged wastewater is less than or equal to 250 milligrams / liter, the SS (Suspended Substance) content is less than or equal to 250 milligrams / liter, the NH3-N content is less than or equal to 7 milligrams / liter, and the TP (Total Phosphorus) content is less than or equal to 0.5 milligrams / liter; a flocculating agent is added to the secondary sedimentation pond, and the flocculating agent is selected from at least one of an aluminum salt inorganic flocculating agent, a ferric salt inorganic flocculating agent, starch phosphate, starch xanthate, chitin, a microbe flocculating agent, polyacrylamide, sodium polyacrylate, chitosan, polyaluminium chloride, polyvinylamine or polyethylene sulphonate. The method disclosed by the invention can be used for better solving the problem and can be used for the industrial production of polyether wastewater treatment.

Owner:JIANGSU CHANGHUA POLYURETHANE SCI & TECH

Papermaking wastewater treatment agent

InactiveCN107337247ASustainable processingReduce CODWater contaminantsWaste water treatment from plant processingAluminium sulfateIron powder

The invention provides a papermaking wastewater treatment agent comprising the following components in parts by weight: 40-60 parts of polyaluminum sulfate, 1-3 parts of polyacrylamide, 10-20 parts of starch xanthate, 15-30 parts of modified diatomite, 6-12 parts of chitosan, 2-5 parts of sepiolite powder, 4-8 parts of cellulose acetate and 1-3 parts of dithiocarbamate salt, wherein the modified diatomite is mainly prepared from diatomite, graphene oxide, iron powder and ferrous sulfate. The treatment agent is stable in performance, and can be used for effectively removing pollutants from papermaking wastewater.

Owner:合肥隆延科技有限公司

Heavy metal wastewater treatment agent

InactiveCN109721127AOvercome antagonismOvercoming competitionWater contaminantsWater/sewage treatment by flocculation/precipitationCross-linkCellulose

The invention discloses a heavy metal wastewater treatment agent, which includes olea europaea pomace, olea europaea sawdust, nitrohumic acid resin, dithiocarboxylated aminomethyl polyacrylamide, biochar, pyrrolidine dithiocarbamate chelated cellulose, starch xanthate, sodium dodecyl sulfonate, a cross-linking agent, sulfonated sulphur heterocarbon, 717 anion exchange resin, modified sericin, polyaspartic acid, beta-cyclodextrin, thiocarbazide, an accelerant, poly(diallylammonium chloride-acrylamide)yl sodium dithiocarbamate. Complexing, precipitation, coagulation, adsorption and other ways are adopted for synergistic coupling integrated treatment of heavy metal wastewater, the treatment agent has the characteristics of coarse flocculation, fast precipitation and strong trapping capacity,and can treat Cu<2+>, Cd<2+>, Hg<2+>, Pb<2+>, Mn<2+>, Ni<2+>, Zn<2+>, Cr<3+> and various heavy metals in wastewater, and also can remove part of COD ammonia nitrogen, phosphorus and Cr<6+>.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

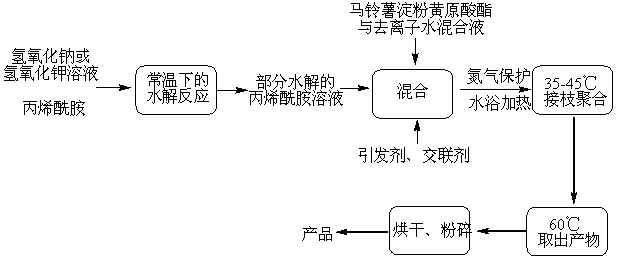

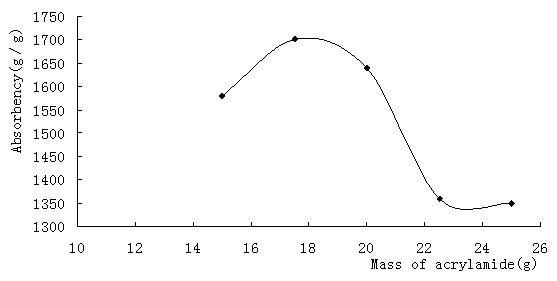

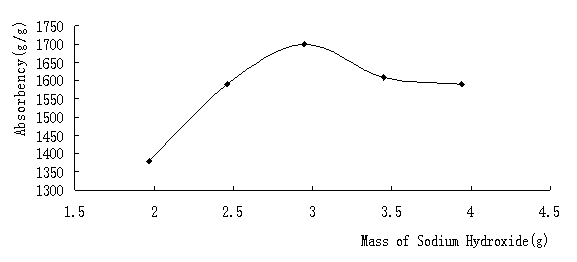

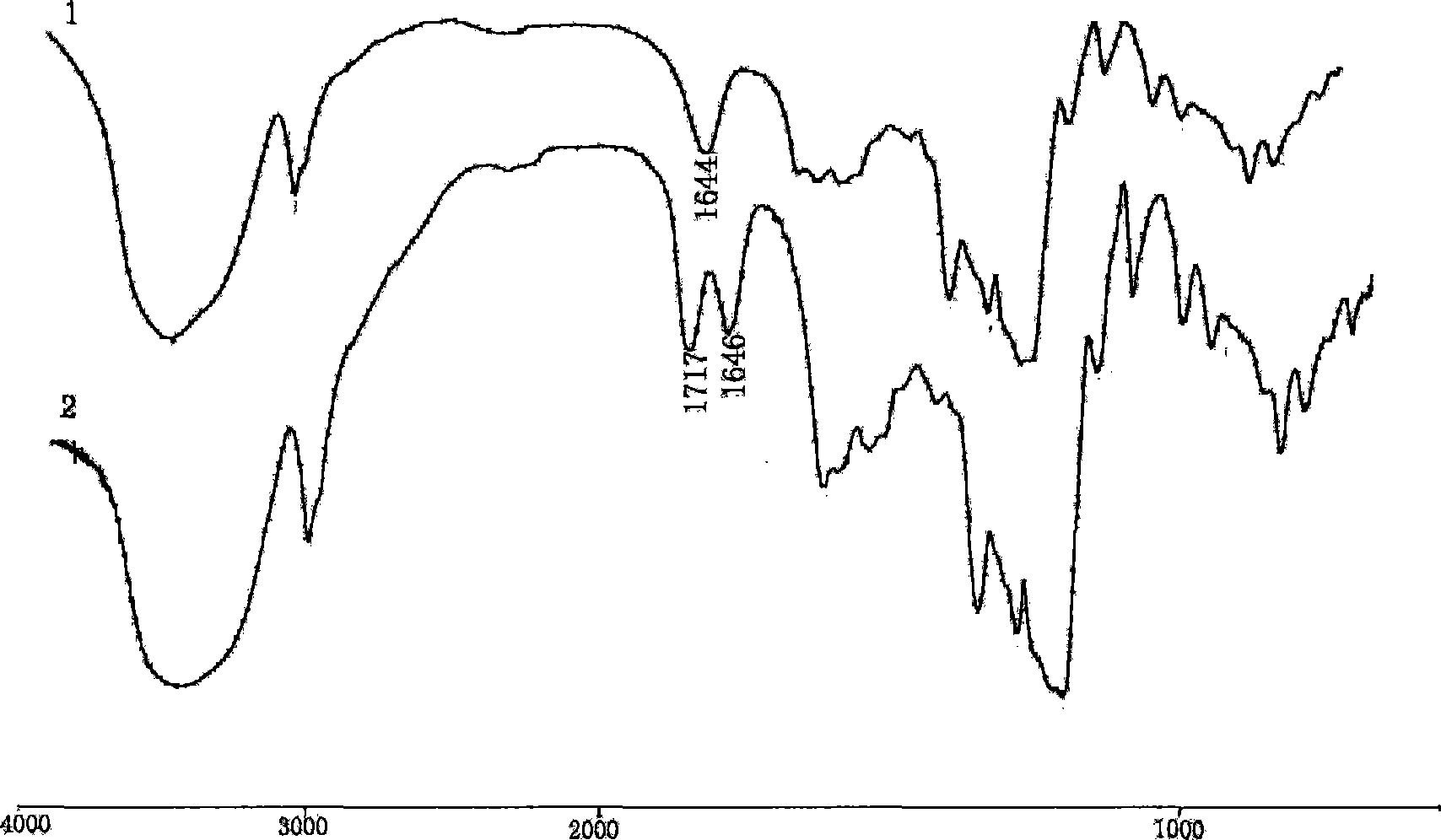

Method for synthesizing high water absorbent polymer by using potato starch xanthate and acrylamide

The invention discloses a method for synthesizing a high water absorbent polymer by using potato starch xanthate and acrylamide. The method is mainly characterized by comprising the following steps of: firstly hydrolyzing the acrylamide by using alkaline, and subsequently heating in water bath under the protection of nitrogen, so the starch xanthate and a part of the hydrolyzed acrylamide are subjected to graft polymerization at 35 to 45 DEG C so as to prepare the high water absorbent polymer. The maximum water absorbing capacity of an optimal product in deionized water of 2500 times can be 2160g / g, and the water absorbing capacity in deionized water of 10000 times can be 5000g / g; and meanwhile the high water absorbent polymer prepared by the method is high in nitrogen content. The methodfor preparing the high water absorbent polymer has the following advantages that the parent potato starch xanthate does not need to be gelatinized, the graft polymerization reaction is low in temperature, and high temperature reaction is not needed, so that the method for synthesizing the high water absorbent polymer provided by the invention is simple in process, easy to operate, low in cost andexcellent in product performance, so that the method is more applicable for scale production and popularization of products.

Owner:INNER MONGOLIA UNIVERSITY

Treating agent for treating electroplating wastewater containing heavy metal ions and preparation method thereof

InactiveCN107311248AEasy to useEfficient removalWater contaminantsWaste water treatment from metallurgical processCross-linkStarch xanthate

The invention discloses a treating agent for treating electroplating wastewater containing heavy metal ions. The treating agent is prepared from the following raw materials in parts by weight: 15 to 20 parts of ethylenediaminetetraacetic acid disodium salt, 7 to 11 parts of starch xanthate, 30 to 35 parts of modified cross-linked rectorite, 18 to 22 parts of sodium pyrosulfite, 46 to 50 parts of coal ash, 3 to 6 parts of hexamethylenebis(nitrilodimethylene)tetrapho acid, 14 to 18 parts of polyacrylamide, 2 to 5 parts of glycerine ethoxylate, 5 to 8 parts of aminopropyltriethoxysilane and 13 to 17 parts of sodium carboxymethyl starch. The invention further discloses a preparation method of the treating agent for treating the electroplating wastewater containing the heavy metal ions. The prepared treating agent disclosed by the invention can effectively removing the heavy metal ions in the electroplating wastewater by a synergistic effect of all ingredients and has convenience in use and a wide market prospect.

Owner:HUNAN VAUBAN ENVIRONMENTAL PROTECTION TECH CO LTD

Disinfection powder for sewage, and preparation method and application method thereof

InactiveCN107094794AReduce CODReduce BODBiocideSpecific water treatment objectivesSodium bicarbonateMonoglyceride

The invention provides a sewage disinfector, and a preparation method and application method thereof. The sewage disinfector comprises, by mass, 40 to 60% of potassium monopersulfate, 0 to 5% of calcium peroxide, 4 to 15% of magnesium sulfate, 6 to 12% of iron chloride, 5 to 15% of sodium bicarbonate, 0 to 7% of nanometer titanium dioxide, 0 to 10% of chitosan, 0 to 12% of starch xanthate, 3 to 8% of fatty acid monoglyceride, 4 to 20% of a weak acid component and 1 to 15% of a stabilizing agent. After dissolving of the sewage disinfector provided by the invention, a plurality of high-activity free radicals are continuously produced and exert combined disinfection effect, so the sewage disinfector has the advantages of a wide disinfection spectrum, good disinfection effect, high efficiency and safety; through combined usage of three flocculating agents consisting of iron chloride, chitosan and starch xanthate, the sewage disinfector can remove metal ions, radioactive substances and organic matters in water and effectively decrease CODs and BODs in a water body; and nanometer titanium dioxide can kill a plurality of bacteria and fungi in water in long duration and is free of toxicity and harm. When the sewage disinfector is applied to treatment of sewage, procedures like grating filtering, fermentation, precipitation and flotation are not necessarily needed, so the sewage disinfector is convenient to use.

Owner:江苏苏沃尚新材料科技有限公司

Multifunctional rubber chemicals and method for producing the same

A multi-functional rubber ingredient and a preparation method thereof relate to the chemical engineering accessory ingredient and the preparation method thereof. Starch derivate is prepared by adding a strong alkaline solution component A with 15 percent of concentration, a halogenating epihydrin component B and a carbon bisulfide component C to the mixed solution of starch and sodium chloride, and then the multi-functional rubber ingredient is obtained by adding a strengthening agent, a coupling agent and a plasticizer. Firstly the starch xanthate is prepared, and then 100 parts of prepared starch xanthate are used as base stock, then the multi-functional rubber ingredient is obtained by adding 20 to 25 parts of strengthening agent, 0.1 to 1 part of coupling agent and 3 to 10 parts of plasticizer. Using the method to prepare the multi-functional strengthening agent has the simple technique and high grafting ratio, so the multi-functional strengthening agent has good effect when being used as a tyre rubber ingredient and processing an accelerating agent.

Owner:DALIAN TIANBAO CHEM IND

Composite material for purifying industrial waste water

InactiveCN104383896AImprove adsorption capacityReduce pollutionOther chemical processesWater contaminantsPolyethylene terephthalate glycolIndustrial waste water

The invention discloses a composite material for purifying industrial waste water. The composite material is prepared from the following raw materials in parts by weight: 6-11 parts of bentonite, 5-10 parts of starch xanthate, 2-6 parts of crosslinking rectorite, 1-5 parts of red lava, 2-8 parts of ferrite, 7-12 parts of polypropylene, 5-9 parts of polyethylene glycol terephthalate, 2-6 parts of cotton stalk powder, 3-8 parts of isooctyl thioglycolate dimethyl tin, 2-6 parts of calcium carbonate, 3-5 parts of trinbutyl phosphate, 8-13 parts of crylic acid macromolecule water-absorbent resin and 1-3 parts of zinc borate. The composite material for purifying industrial waste water has the beneficial effects that the composite material has very good adsorption, can adsorb suspended substances in waste water, and can adsorb heavy metal ions, so that the pollution caused by heavy metal is reduced.

Owner:田琳琳

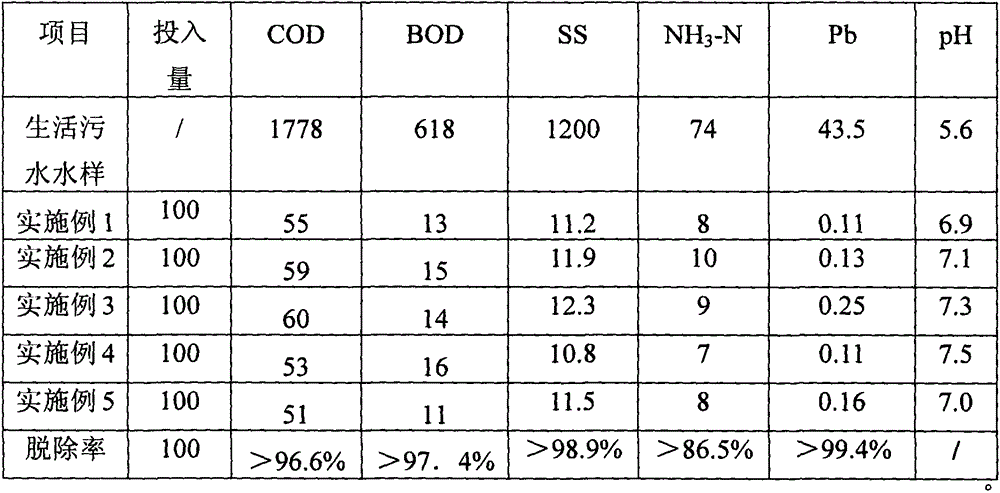

A kind of domestic sewage treatment agent and preparation method thereof

ActiveCN103641247BSustainable processingIncrease concentrationScale removal and water softeningWater/sewage treatment by ion-exchangeHigh concentrationCross-link

The invention relates to the technical field of sewage treatment agents and specifically relates to a domestic sewage treatment agent and a preparation method thereof. The domestic sewage treatment agent comprises the following raw materials in parts by weight: 10-20 parts of ferric trichloride, 5-8 parts of ferrous sulfate, 5-8 parts of magnesium sulfate, 3-5 parts of polyacrylamide, 10-20 parts of caustic soda flakes, 20-35 parts of modified lignin sulfonate, 10-15 parts of starch xanthate, 20-30 parts of modified diatomite, 15-20 parts of cross-linked rectorite and 1-5 parts of chitosan-graphene composite material. The domestic sewage treatment agent provided by the invention is capable of continuously treating high-concentration domestic sewage under the coordination action of the compounded raw materials; in the meantime, the contents of COD (Chemical Oxygen Demand), BOD (Biological Oxygen Demand) and SS (Suspended solids) in the treated domestic sewage are obviously reduced; the treated water can be recycled repeatedly.

Owner:沧州市利达环保工程有限公司

Spinning sewage environmental-protection treating agent

InactiveCN106044894ANothing producedNo corrosionSpecific water treatment objectivesWater/sewage treatmentIsooctyl acrylateHexamethylphosphoramide

The invention relates to a spinning sewage environmental-protection treating agent, which is composed of the following ingredients: amino trimethylene phosphonic acid, pyrrolidine, starch xanthate, NPAM, copper chloride dehydrate, peracetic acid, boric acid, sodium formate, sodium hydrosulfite, sodium hypochlorite, DL-methionine, sodium citrate, white carbon black, caustic alkali, sodium aluminate, flyash, diatomite, activated carbon, hexamethyl phosphoramide, lemon essential oil, propylene glycol, acetic ether, ethylene oxide, triethanolamine, polymethyl hydrogen siloxane, polyethylene glycol octylphenol ether, poly(diallyldimethylammonium chloride), starch phosphate, 2-ethylhexyl acrylate, butyl hydroxyanisole and deionized water. The product has fast reaction speed, and no toxic or harmful gas is generated during the process. A product obtained after the reaction is stable and will no longer be decomposed into toxic substances. The spinning sewage environmental-protection treating agent is efficient and nontoxic, is safe to human before and after the reaction, is noncorrosive to objects, and has high sewage treatment efficiency.

Owner:余志娟

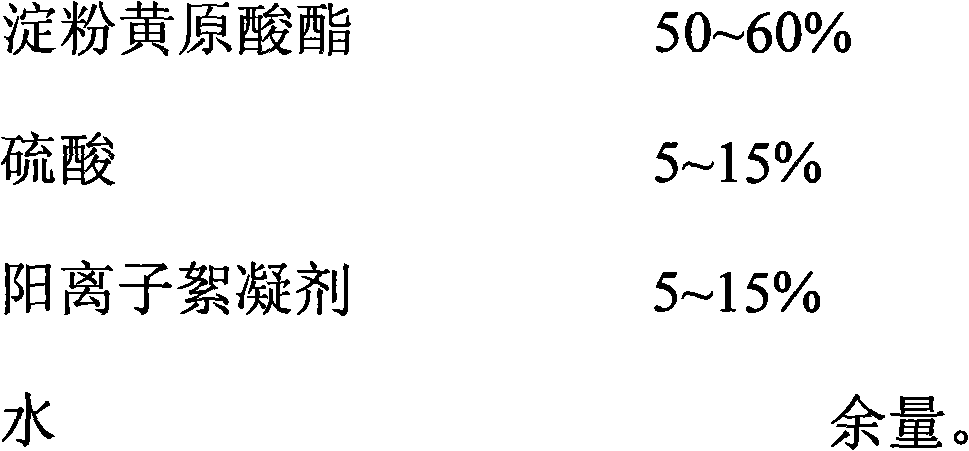

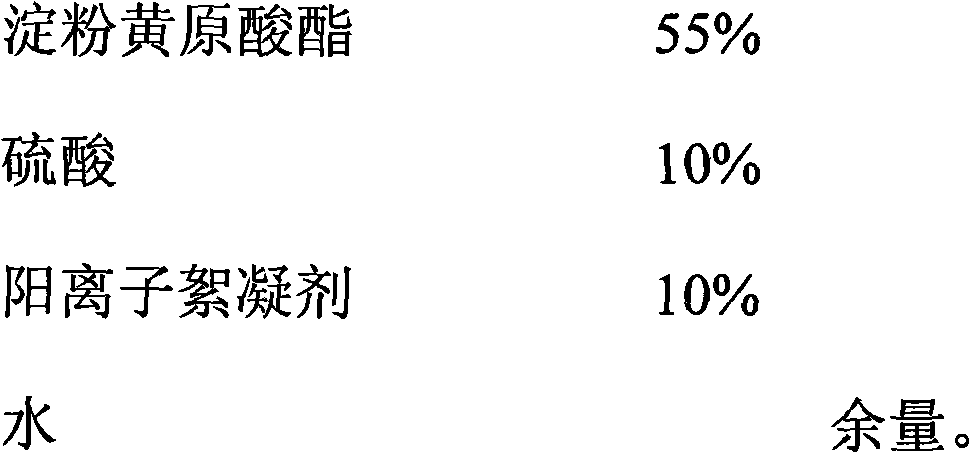

Treatment agent for wastewater from paper mills

InactiveCN102040266AReasonable formulaEasy to useWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationStarch xanthatePaper mill

The invention discloses a treatment agent for wastewater from paper mills. The treatment agent is prepared from starch xanthate, sulfuric acid, a cationic flocculant and water. The treatment agent has the advantages of reasonable formula, good use effect and low production cost.

Owner:吴美云

Treatment agent for domestic wastewater and preparation method thereof

InactiveCN107512744AWide variety of sourcesSimple preparation processWater contaminantsWater/sewage treatment using germicide/oligodynamic-processCross-linkStarch xanthate

The invention discloses a treatment agent for domestic wastewater, wherein the treatment agent is composed of the following raw materials in parts by weight: 12-18 parts of kaolin, 18-25 parts of diatomite, 6-14 parts of barite, 5-8 parts of a talcum powder, 9-18 parts of cross-linked rectorite, 4-8 parts of chitosan, 4-6 parts of starch xanthate, 2-4 parts of acorus calamus, 3-6 parts of bunge corydalis herb, 2-4 parts of cape jasmine, 1-4 parts of sodium hydroxypropyl methyl cellulose, 0.5-2 parts of triethanolamine, 0.5-3 parts of plant starch, and 10-15 parts of mineral waste residues. The invention also discloses a preparation method of the treatment agent. The prepared product is used for treating the domestic wastewater; through compounding of the raw materials, a coordinating role is played, flocculation, sedimentation, adsorption and sterilization effects can be improved, moreover, the cost of treatment can be greatly reduced, and the treatment agent has a wide application prospect and remarkable economic and social benefits.

Owner:黄莉

Boiler waste water treatment agent based on graphene modified polyaspartic acid and preparation method

ActiveCN105251463AEasy to recycleImprove adsorption efficiencyOther chemical processesWater/sewage treatment by sorptionDispersitySalicylic acid

The invention discloses a boiler waste water treatment agent based on graphene modified polyaspartic acid and a preparation method. A composition of the agent is prepared from, by weight, 20-30 parts of polyaspartic acid, 2-3 parts of sodium gluconate, 2-3 parts of citric acid, 40-50 parts of poly-ammonium salt lignin flocculating agents, 20-30 parts of sodium bentonite, 8-10 parts of graphene, 4-6 parts of salicylic acid, 2-4 parts of alkaline trehalose, 20-30 parts of sepiolite powder, 10-14 parts of crosslinked rectorite powder, 3-5 parts of starch xanthate, 2-4 parts of amino tri-methylene phosphonic acid, 1-3 parts of polymerized potassium silicate sulfate, 1-3 parts of dimethyl diallyl ammonium chloride, an appropraite amount of deionized water and an appropriate amount of water. According to the boiler waste water treatment agent and the preparation method, graphene is adopted for modifying polyaspartic acid and improving dispersity of the polyaspartic acid for CaCO<3>, Ca<3>(PO<4>)<2>, dispersed ferric oxide, stable Zn<2+> salt and the like; meanwhile, efficient adsorption is achieved by adding the sodium bentonite, the sepiolite powder and the crosslinked rectorite powder, the boiler waste water treatment agent is low in cost and simple in preparation process, hollow porous particles are obtained, recovery is facilitated, and adsorption efficiency is improved.

Owner:安徽精高水处理有限公司

Coal washing sewage treatment agentia

InactiveCN106006788AEasy to handleWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionSodium bicarbonatePolyethylene glycol

A coal washing sewage treatment agent, consisting of the following substances in parts by mass: 21 parts of menthone, 18 parts of polyaluminum chloride, 2 parts of polysorbate, 20 parts of polyimide, 1 part of polyethylene glycol, polyethylene 8 parts of imine, 5 parts of thiocarbamate, 8 parts of zinc sulfate, 18 parts of expanded graphite, 5 parts of strong alkali, 5 parts of sodium hydroxypropyl methylcellulose, 18 parts of calcium hydroxide, and polyacrylamide 85 parts, 20 parts of aluminum oxide, 5 parts of dodecyl diethylene triamine, 11 parts of tetradecyl alcohol, 8 parts of quartz sand, 5 parts of tert-butylamine, 5 parts of water-soluble starch xanthate, charcoal 10 parts of black, 20 parts of sodium carbonate, 10 parts of sodium bicarbonate, 5 parts of cellulose, 40 parts of octylphenol polyoxyethylene ether, 2 parts of hydrochloric acid, 5 parts of disodium edetate, 40 parts of sodium lauryl sulfate , 2 parts of fatty amine.

Owner:王瑞明

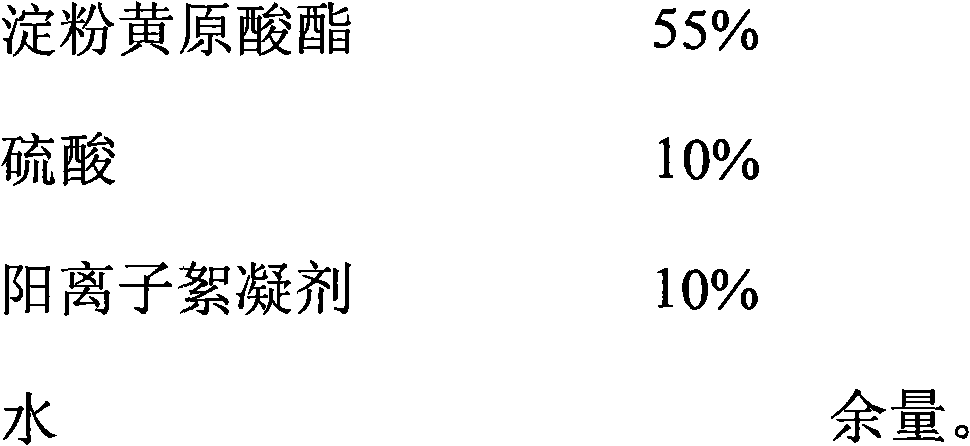

Preparation method of high-performance and low-temperature vulcanized natural rubber

The invention discloses a preparation method of high-performance and low-temperature vulcanized natural rubber, relates to a preparation method of a vulcanized natural rubber. In the formula of natural rubber, starch xanthate is added, and other auxiliaries, namely stearic acid, zinc oxide, a promoter M and sulfur are unchanged. Natural rubber is vulcanized at a lower temperature by virtue of an ordinary rubber processing technology and equipment in the presence of starch xanthate serving as a natural rubber modification auxiliary to prepare the high-performance vulcanized natural rubber.

Owner:HAINAN UNIVERSITY

High-efficiency sewage treatment agent and preparation method thereof

InactiveCN106430370AGood processing effectImprove stabilityWater/sewage treatmentSodium BentoniteTherapeutic effect

The invention discloses a high-efficiency sewage treatment agent and a preparation method thereof. The high-efficiency sewage treatment agent consists of the following raw materials in parts by weight: 25-30 parts of polyacrylamide, 3-6 parts of chitosan, 2-5 parts of aluminum potassium sulfate dodecahydrate, 4-7 parts of activated carbon, 12-15 parts of polyethyleneimine, 2-4 parts of ferrous sulfate, 1-3 parts of sodium citrate, 16-19 parts of leftover bits and pieces of edible mushrooms, 10-13 parts of bentonite and 3-5 parts of starch xanthate. The invention also discloses the preparation method of the high-efficiency sewage treatment agent. The sewage treatment agent prepared through the preparation method disclosed by the invention has good treatment effect to domestic sewage and good stability, a product of the sewage treatment agent can meet the requirements of the market on a domestic sewage treatment product, and the index of the treated domestic sewage can reach the national discharge standard.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Environment-friendly compound fertilizer with soil restoration function and preparation method of environment-friendly compound fertilizer

InactiveCN107382526AAchieve fixHigh in nutrientsBio-organic fraction processingAnimal corpse fertilisersStarch xanthateCadmium Cation

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

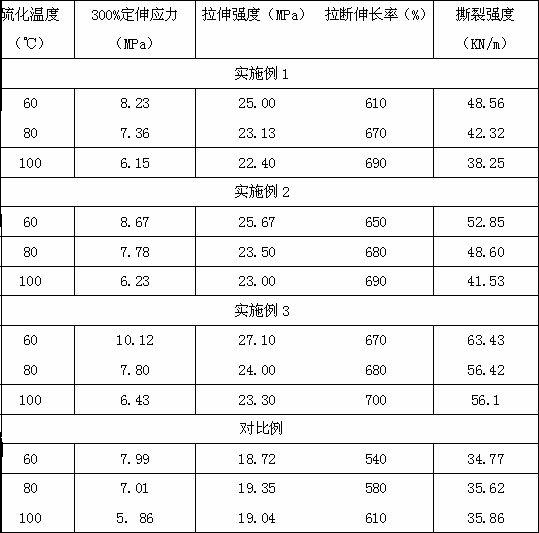

Preparation method of municipal sewage treating agent

The invention provides a preparation method of a municipal sewage treating agent.The method comprises the steps of firstly, picking dry straw, pulverizing the straw, adding a solution of sodium cyanoborohydride, ammonium ceric nitrate and gelatin, mixing the materials to be uniform, raising the temperature, then adding poly(ethyl acrylate), polyacrylonitrile and glutaraldehyde, raising the temperature, lowering the temperature, and conducting filtering, so that solid matter is obtained; then adding etidronic acid and polyhydric alcohol phosphate ester to water, conducting stirring, adding isothiazolinone, sepiolite, starch xanthate, magnesium sulfate heptahydrate, chitosan, N, N-dimethyl methylene diphosphonic acid, lecithin and lignin, and mixing the materials to be uniform, so that a mixture (I) is obtained; finally, adding a sodium hydroxide solution to the mixture (I) to adjust pH to 6.0-7.0, adding organic acid and the obtained solid matter, mixing the materials to be uniform, and then leaving the mixture standing still, so that the municipal sewage treating agent is obtained.By means of the municipal sewage treating agent, the chemical oxygen demand of sewage can be lowered to 63 mg / L, the biochemical oxygen demand can be lowered to 28 mg / L, suspended solids can be decreased to 35 mg / L, and total phosphorus can be decreased to 0.37 mg / L.

Owner:刘平

Electroplating wastewater treating agent

InactiveCN106365225ARaw materials are easy to getLow costWater contaminantsWaste water treatment from metallurgical processStarch xanthateGraphene

The invention discloses an electroplating wastewater treating agent, which is prepared from the following components in parts by weight: 20 to 30 parts of reducing agent, 50 to 60 parts of alkaline matter, 30 to 40 parts of metal ion trapping agent, 10 to 15 parts of chromic nitrate, 10 to 15 parts of n-octyl aldehyde, 5 to 10 parts of graphene, 5 to 10 parts of starch xanthate, 30 to 40 parts of flocculating agent and 3 to 5 parts of coal gangue. The electroplating wastewater treating agent provided by the invention is easily obtained in raw materials, is easy to make, is low in cost, is high in the capacity of treating comprehensive electroplating wastewater, and is further convenient to use; the settling velocity of heavy metal ions can be quickened; the removal rate of the heavy metal ion reaches 99 percent.

Owner:ZHENJIANG HEYUN IND WASTEWATER DISPOSAL CO LTD

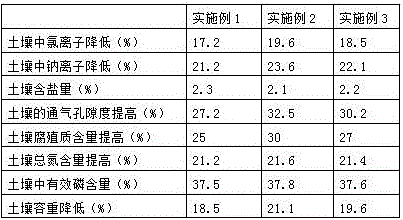

Method for carrying out raw soil greening on chloride-containing sandy soil by using chitin-containing soil conditioner

InactiveCN106008000AReduce chloride ionReduce sodium ion contentSuperphosphatesAgriculture tools and machinesBenzoic acidPhosphate

The invention relates to a method for carrying out raw soil greening on chloride-containing sandy soil by using a chitin-containing soil conditioner. The formula of the soil conditioner comprises, by weight, 25-27 parts of fermented fox manure, 16-18 parts of soybean stalk powder, 8-10 parts of fermented pine bark scales, 5-7 parts of fish bone meal, 2-4 parts of desulphurization wastes, 2-4 parts of antigorite powder, 2-4 parts of vermiculite, 1-3 parts of potassium fulvate, 1-3 parts of potassium dihydrogen phosphate, 2-4 parts of ferrous sulfate, 3-5 parts of calcium hydrogen phosphate, 1-3 parts of amino acid salt, 0.5-0.7 parts of onion extract, 0.5-0.7 parts of benzoic acid, 0.2-0.4 parts of glyphosine, 0.1-0.3 parts of fosamine, 0.1-0.3 parts of chlorflurecol, 3-5 parts of sodium silicoaluminate, 1-3 parts of starch xanthate grafted acrylate, 0.1-0.3 parts of chitin, 0.1-0.3 parts of chelated manganese, 0.1-0.3 parts of chelated copper, 0.1-0.3 parts of Halobacterium salinarium, 0.1-0.3 parts of Halobacillus halophilus, 0.1-0.3 parts of Bacillus coagulans, 0.1-0.3 parts of Bacillus megaterium, 0.1-0.3 parts of Azotobacter vinelandii and 0.1-0.3 parts of microzyme.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Electroplating wastewater treating agent and preparation method thereof

InactiveCN106587190ASimple processing methodSimple methodWater contaminantsWaste water treatment from metallurgical processStarch xanthateReducing agent

The invention discloses an electroplating wastewater treatment agent and a preparation method thereof. The electroplating wastewater treatment agent is prepared from, by mass, 3-5 parts of reducing agent, 6-10 parts of bentonite, 6-8 parts of graphene nanolayer, 3-5 parts of amino trimethylene phosphonic acid, 1-2 parts of heavy metal ion trapping agent, 4-6 parts of poly-ferric sulfate, 6-8 parts of modified sulfonated lignin, 6-10 parts of sodium polyacrylate, 1-3 parts of compound coagulant, 4-6 parts of benzotriazole, 6-8 parts of starch xanthate, 5-7 parts of trithione triazine trisodium salt and 4-6 parts of crosslinked rectorite. The preparation method is simple, heavy metal ions can be removed only by putting the agent, no device nor process is added, and the cost for treating electroplating wastewater is greatly reduced.

Owner:QINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com