Sewage treatment agent for paper mills

A sewage treatment agent, technology for paper mills, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc. problem, to achieve the effect of good protection system, anti-scaling algae growth, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

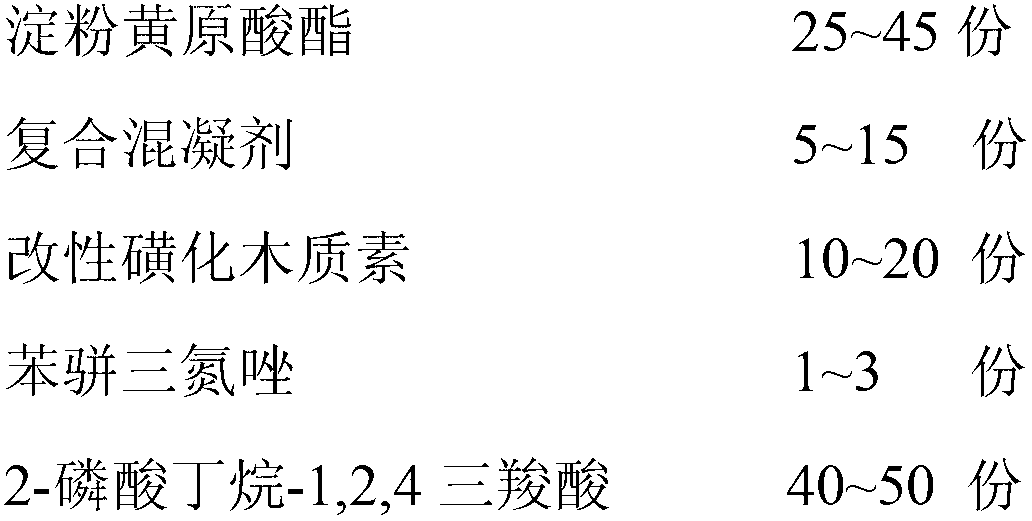

[0018] A paper mill sewage treatment agent is characterized in that it is mixed with the following parts by weight

[0019]

[0020] The preparation method of the composite coagulant is to mix inorganic acid and red clay for leaching reaction, the mass ratio of red clay and inorganic acid is 1:1, wherein the inorganic acid is sulfuric acid, and the mass concentration of sulfuric acid is 30%% , the reaction temperature is 50°C, the reaction time is 70min, and the reaction product is sieved to remove sand and stone.

[0021] The red clay is composed of the following substances in weight percentage: aluminum oxide, 15-40%; ferric oxide, 10-25% silicon dioxide; 25-65%.

[0022] The preparation method of the modified sulfonated lignin is: adding a small amount of polyferric mass ratio to 2000:1 in the papermaking black liquor, adding acid to adjust the pH value to 3, controlling the temperature to 55°C, flocculating and stratifying the black liquor, After filtering, the filter ...

Embodiment 2

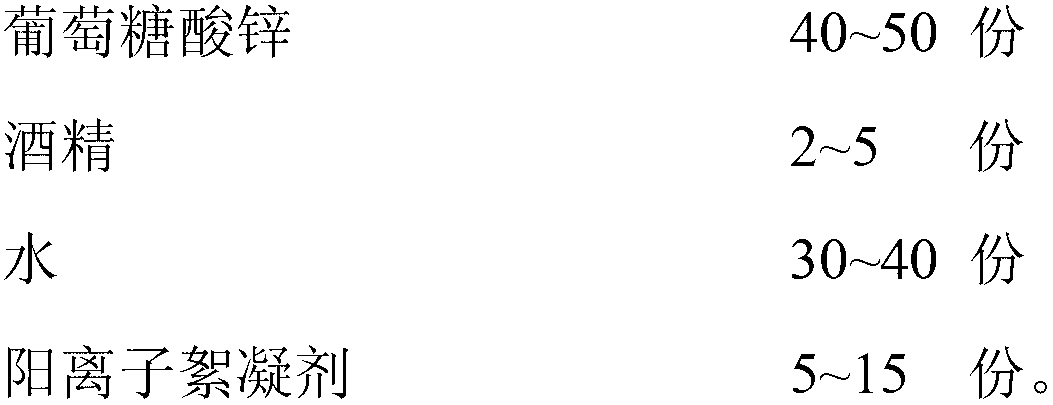

[0024] A paper mill sewage treatment agent is characterized in that it is composed of the following components by weight:

[0025]

[0026] The preparation method of described composite coagulant is to carry out leaching reaction by mixing inorganic acid and red clay, the mass ratio of red clay and inorganic acid is 2: 1, wherein inorganic acid is sulfuric acid, and the mass concentration of sulfuric acid is 45%, Reaction temperature is 55 ℃, and reaction time is 80min, and reaction product is sieved to remove sand and stone.

[0027] The red clay is composed of the following substances in weight percentage: aluminum oxide, 15-40%; ferric oxide, 10-25%; silicon dioxide, 25-65%.

[0028] The preparation method of the modified sulfonated lignin is: adding a small amount of polyferric mass ratio to 2000: 1.5 in the papermaking black liquor, adding acid to adjust the pH value to 4, controlling the temperature to 55° C. After filtering, the filter cake is dried at a constant te...

Embodiment 3

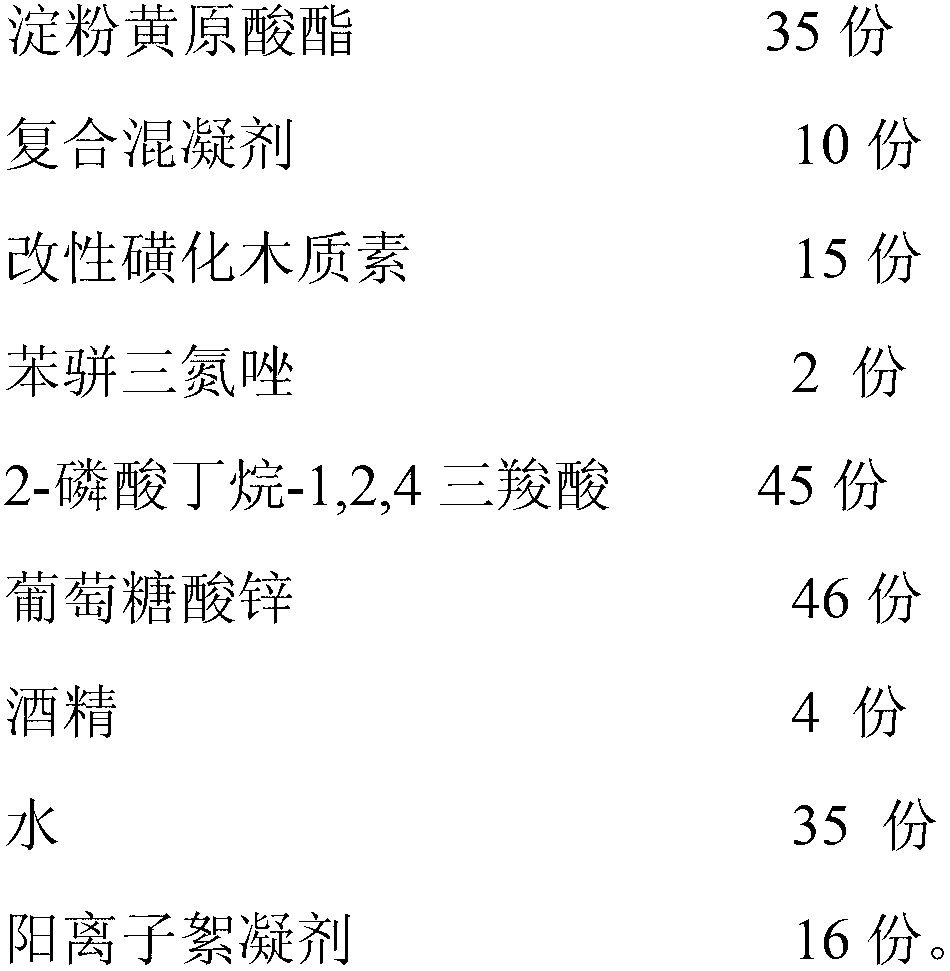

[0030] A paper mill sewage treatment agent is characterized in that it is composed of the following components by weight:

[0031]

[0032] The preparation method of described composite coagulant is to carry out leaching reaction by mixing inorganic acid and red clay, the mass ratio of red clay and inorganic acid is 3: 1, wherein inorganic acid is sulfuric acid, and the mass concentration of sulfuric acid is 55%, Reaction temperature is 60 DEG C, and reaction time is 90min, and reaction product is sieved to remove sand and stone.

[0033] The red clay is composed of the following substances in weight percentage: aluminum oxide, 15-40%; ferric oxide, 10-25%; silicon dioxide, 25-65%.

[0034] The preparation method of the modified sulfonated lignin is: adding a small amount of polyferric mass ratio to 2000:2 in the papermaking black liquor, adding acid to adjust the pH value to 4, controlling the temperature to 55° C. After filtering, the filter cake is dried at a constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com