Sewage treating agent for heavy metal pollution

A sewage treatment agent and heavy metal technology, applied in water/sludge/sewage treatment, water/sewage treatment, adsorbed water/sewage treatment, etc. Flocculation effect, improved convenience, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

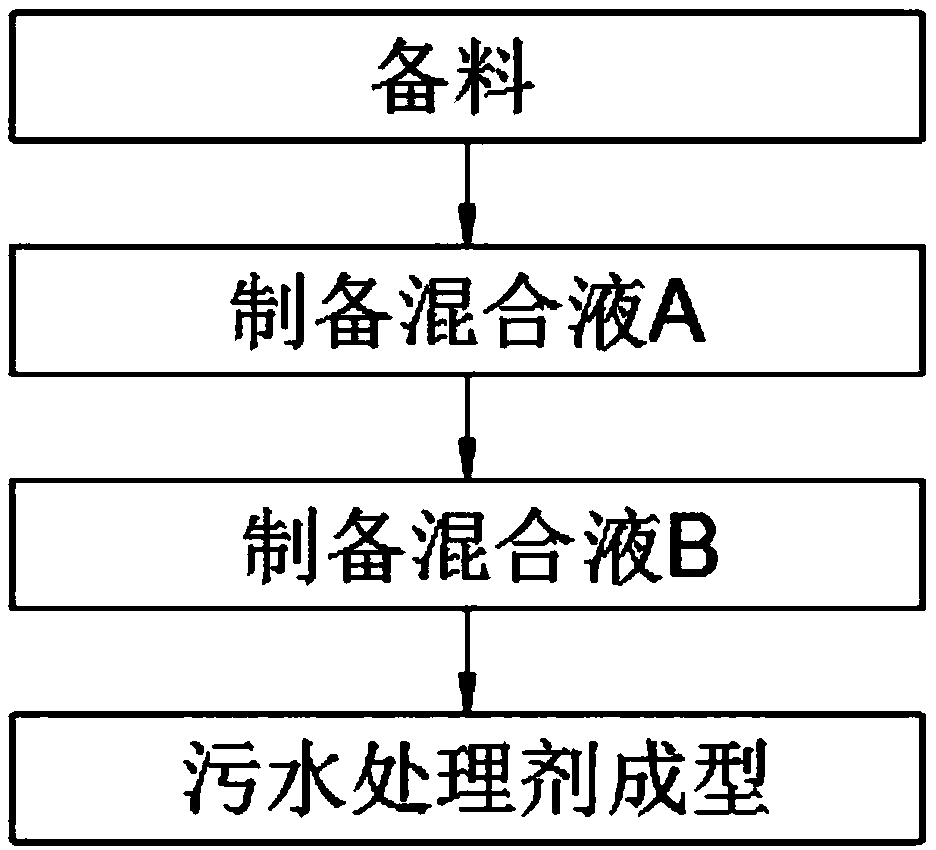

[0019] Example 1: See figure 1 , the invention provides a sewage treatment agent for heavy metal pollution, comprising the following raw materials in parts by weight: 10 parts of polyethyleneimine, 3 parts of carbon disulfide, 5 parts of sodium hydroxide, 3 parts of amyloxanthic acid, Bacillus colioids 4 parts, 5 parts of cassia powder, 8 parts of modified zeolite powder, 2 parts of modified bentonite, 2 parts of sodium alginate, 3 parts of humic acid, 4 parts of ferric chloride, 2 parts of nano-titanium dioxide, 1 part of cellulose 3 parts of ferrous sulfate, 2 parts of photocatalyst, 1 part of high-efficiency nickel removal agent, 0.3 part of chitosan modified polymer flocculant, 0.5 part of coagulation aid, 0.5 part of dextran gel and 60 parts of deionized water share.

[0020] According to the above technical scheme, the preparation method of sodium alginate is to wash the fresh kelp statically, dry it, cut it into sections, put it into the conversion tank, add 10% formal...

Embodiment 2

[0030] Example 2: See figure 1 , the invention provides a sewage treatment agent for heavy metal pollution, comprising the following raw materials in parts by weight: 15 parts of polyethyleneimine, 5 parts of carbon disulfide, 8 parts of sodium hydroxide, 6 parts of amyloxanthic acid, Bacillus colioids 5 parts, 6 parts of cassia powder, 10 parts of modified zeolite powder, 3 parts of modified bentonite, 4 parts of sodium alginate, 6 parts of humic acid, 5 parts of ferric chloride, 4 parts of nano-titanium dioxide, 2 parts of cellulose 4 parts, 4 parts of ferrous sulfate, 4 parts of photocatalyst, 2 parts of high-efficiency nickel removal agent, 0.6 part of chitosan modified polymer flocculant, 0.7 part of coagulation aid, 0.6 part of dextran gel and 70 parts of deionized water share.

[0031] According to the above technical scheme, the preparation method of sodium alginate is to wash the fresh kelp statically, dry it, cut it into sections, put it into the conversion tank, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com