Preparation method of high-performance and low-temperature vulcanized natural rubber

A technology of natural rubber and low-temperature vulcanization, applied in the field of high-performance, low-temperature vulcanized natural rubber, can solve the problems of cross-linking bond breakage, decrease in physical and mechanical properties of vulcanizate, vulcanization reversion, etc., and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. Mix 200g of corn or tapioca starch with 2000ml of water, stir to form a starch emulsion, add 100ml of sodium hydroxide solution with a mass concentration of 15%, stir for 15min, then add 20ml of carbon disulfide, stir at a constant temperature of 30°C for 1h, and dry with hot air dry, to prepare starch xanthate;

[0022] b. Add the starch xanthate prepared in "a" to natural rubber by 5 parts by weight, knead on a double-roller mill, and add various additives, in order: 6.0 parts of zinc oxide, hard 0.5 part of fatty acid, 0.5 part of accelerator M, and 3.5 parts of sulfur to obtain the rubber compound;

[0023] c. Vulcanize the mixed rubber prepared in "b" at 60°C, 80°C and 100°C respectively according to the normal curing time to obtain vulcanized natural rubber. The physical and mechanical properties were tested according to national standards, and the obtained properties are shown in Table 2.

Embodiment 2

[0025] Except that starch xanthate is 15 parts, other is identical with embodiment 1.

Embodiment 3

[0027] Except that starch xanthate is 25 parts, other is identical with embodiment 1.

[0028] Table 1 is the main formula of natural rubber of embodiment 1, example 2 and example 3.

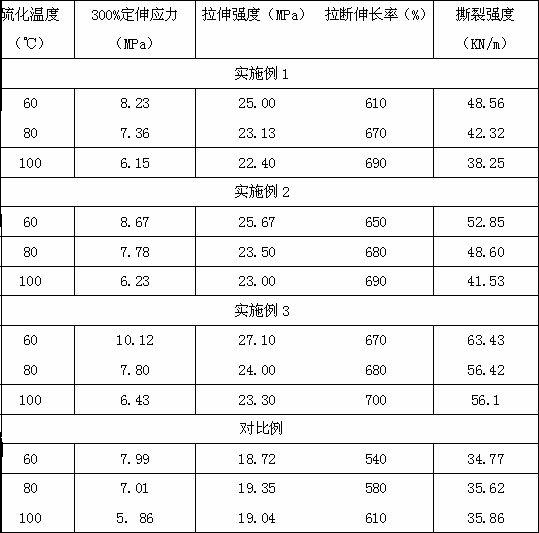

[0029] Table 2 is the physical and mechanical properties of the vulcanized natural rubber of Example 1, Example 2 and Example 3.

[0030]

[0031] Table 1 implementation scheme and comparative scheme formula (parts)

[0032] raw material Example 1 Example 2 Example 3 comparative example natural rubber 100.00 100.00 100.00 100.00 Zinc oxide 6.00 6.00 6.00 6.00 stearic acid 0.50 0.50 0.50 0.50 Accelerator M 0.50 0.50 0.50 0.50 sulfur 3.50 3.50 3.50 3.50 starch xanthate 5.00 15.00 25.00 —

[0033] Table 2 Physical and mechanical properties of vulcanized natural rubber

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com