Electroplating wastewater treatment agent

A technology for electroplating wastewater and treatment agent, applied in the field of water treatment, can solve the problems of high operating cost, large energy consumption, large amount of raw materials, etc., and achieve the effects of good precipitation effect, no environmental pollution, and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

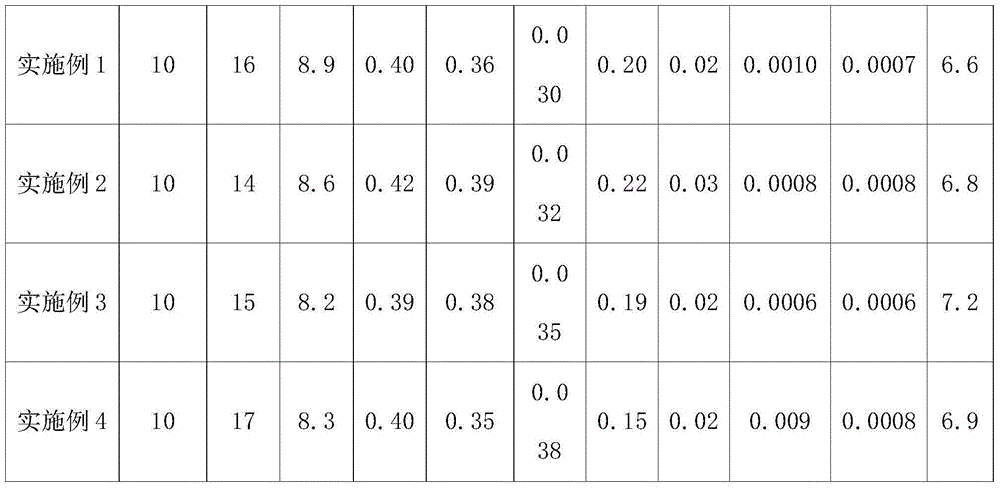

Embodiment 1

[0015] An electroplating wastewater treatment agent is composed of the following raw materials by weight: 30 parts of a reducing agent, 30 parts of a composite flocculant, 16 parts of a heavy metal ion trapping agent DTCR, 22 parts of starch xanthate, 22 parts of cross-linked rectorite, 24 parts of quaternary ammonium salt lignin, 16 parts of sodium silicate, 35 parts of alkaline substances, and 30 parts of diatomaceous earth.

[0016] Wherein, the reducing agent is composed of sodium sulfide and ferrous sulfate in a mass ratio of 2:1.

[0017] The composite flocculant is composed of polyacrylamide, sodium polyacrylate and aluminum chloride in a mass ratio of 1:1:3.

[0018] The alkaline substance is composed of sodium hydroxide and calcium hydroxide in a mass ratio of 1:2.

Embodiment 2

[0020] An electroplating wastewater treatment agent is composed of the following raw materials by weight: 33 parts of reducing agent, 35 parts of composite flocculant, 14 parts of heavy metal ion trapping agent DTCR, 20 parts of starch xanthate, 23 parts of cross-linked rectorite, 22 parts of quaternary ammonium salt lignin, 18 parts of sodium silicate, 30 parts of alkaline substances, and 35 parts of kaolin.

[0021] Wherein, the reducing agent is composed of sodium sulfide and ferrous sulfate in a mass ratio of 3:1.

[0022] The composite flocculant is composed of polyacrylamide, sodium polyacrylate and aluminum chloride in a mass ratio of 1:1:4.

[0023] The alkaline substance is composed of sodium hydroxide and calcium hydroxide in a mass ratio of 1:3.

Embodiment 3

[0025] An electroplating wastewater treatment agent is composed of the following raw materials by weight: 36 parts of reducing agent, 40 parts of composite flocculant, 12 parts of heavy metal ion trapping agent DTCR, 18 parts of starch xanthate, 24 parts of cross-linked rectorite, 18 parts of quaternary ammonium salt lignin, 20 parts of sodium silicate, 25 parts of alkaline substances, and 30 parts of bentonite.

[0026] Wherein, the reducing agent is composed of sodium sulfide and ferrous sulfate in a mass ratio of 4:1.

[0027] The composite flocculant is composed of polyacrylamide, sodium polyacrylate and aluminum chloride in a mass ratio of 1:1:5.

[0028] The alkaline substance is composed of sodium hydroxide and calcium hydroxide in a mass ratio of 1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com