Patents

Literature

77results about How to "Reduce sodium ion content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

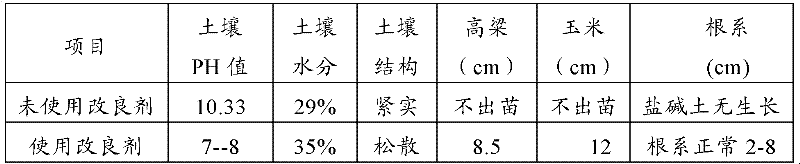

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

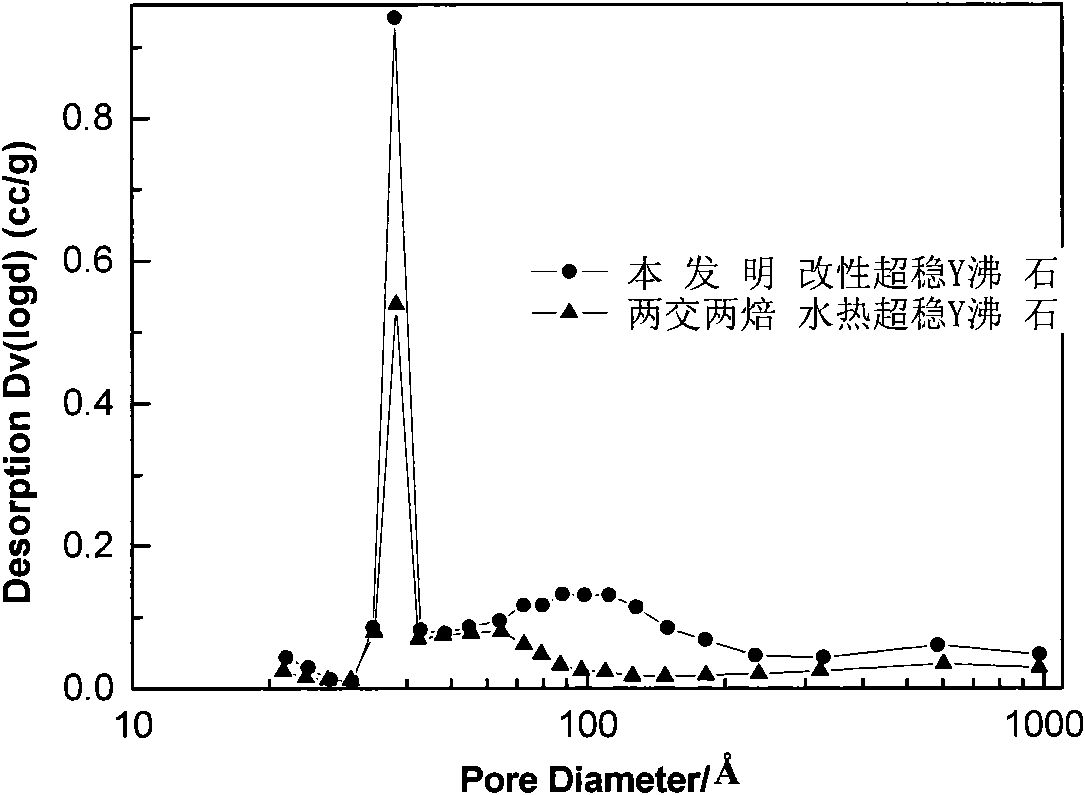

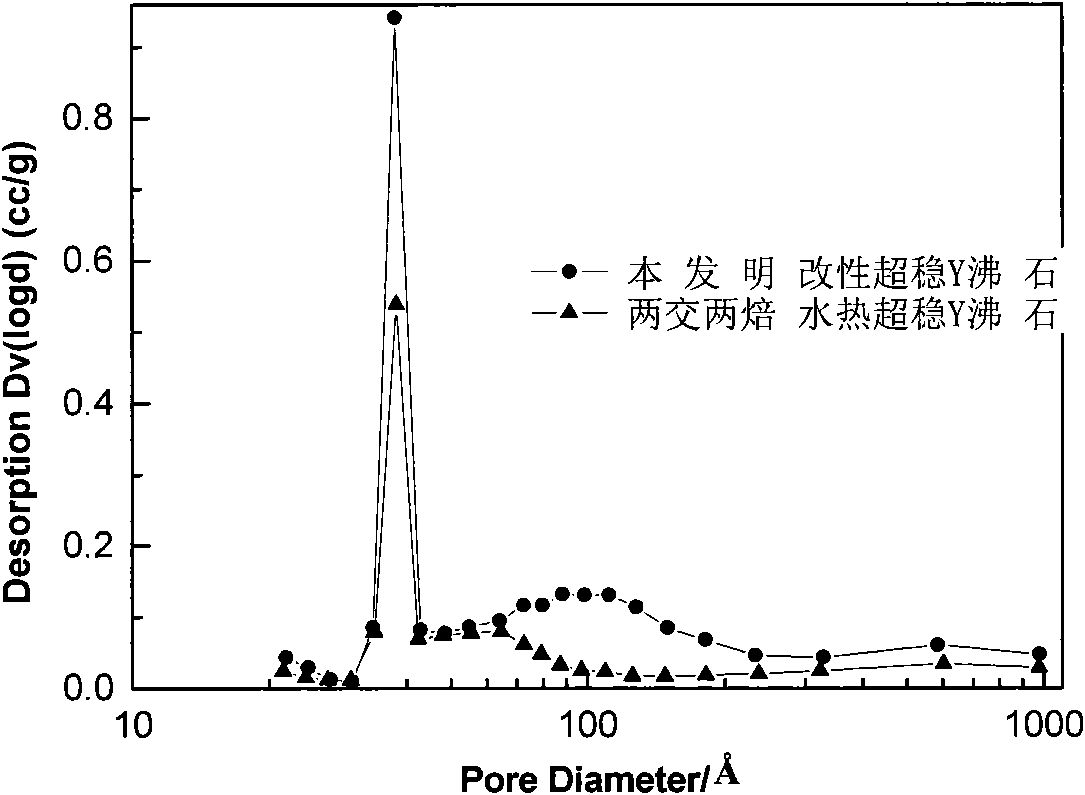

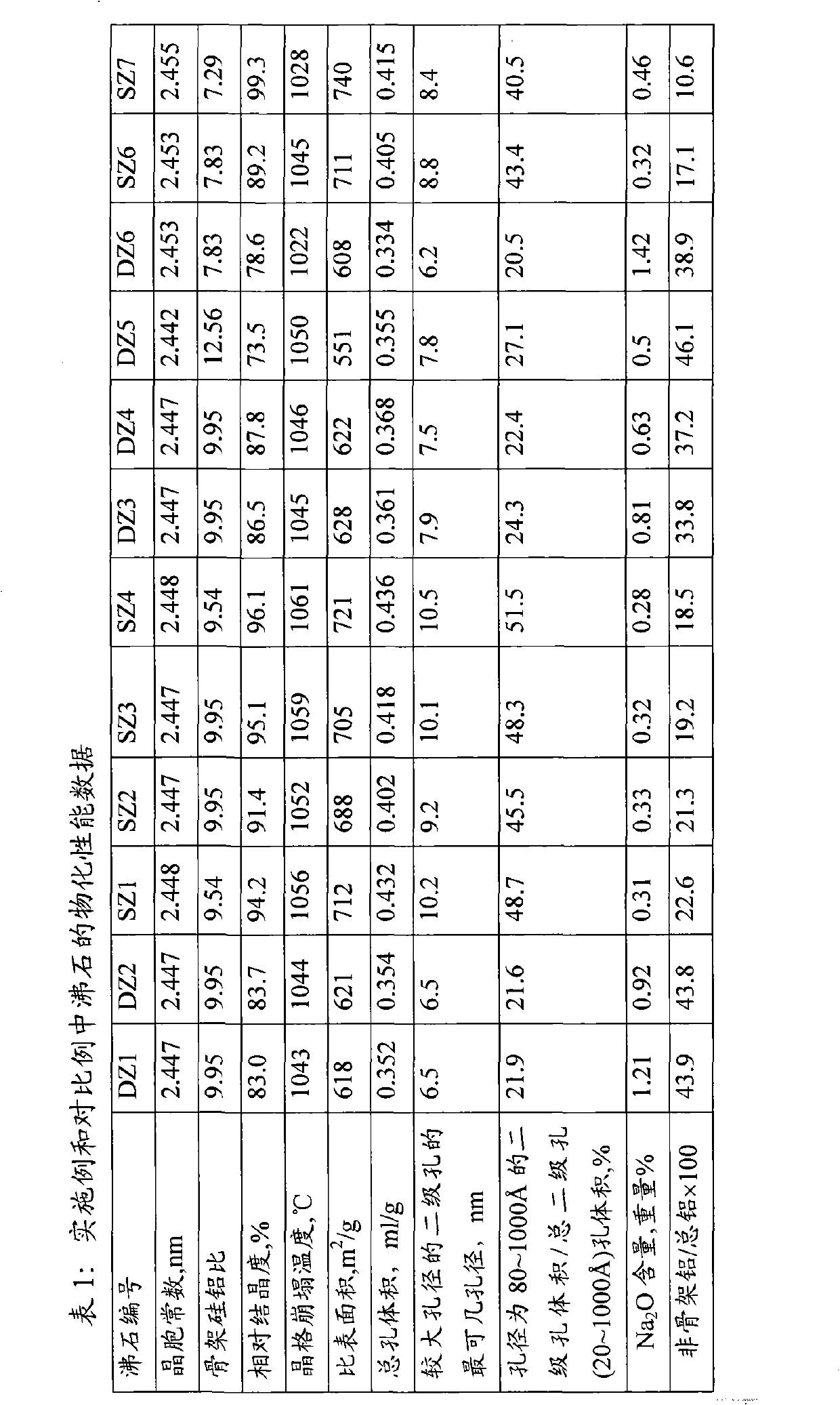

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289AHigh crystallinityIncrease the areaCatalytic crackingMolecular sieve catalystsOrganic acidGasoline

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

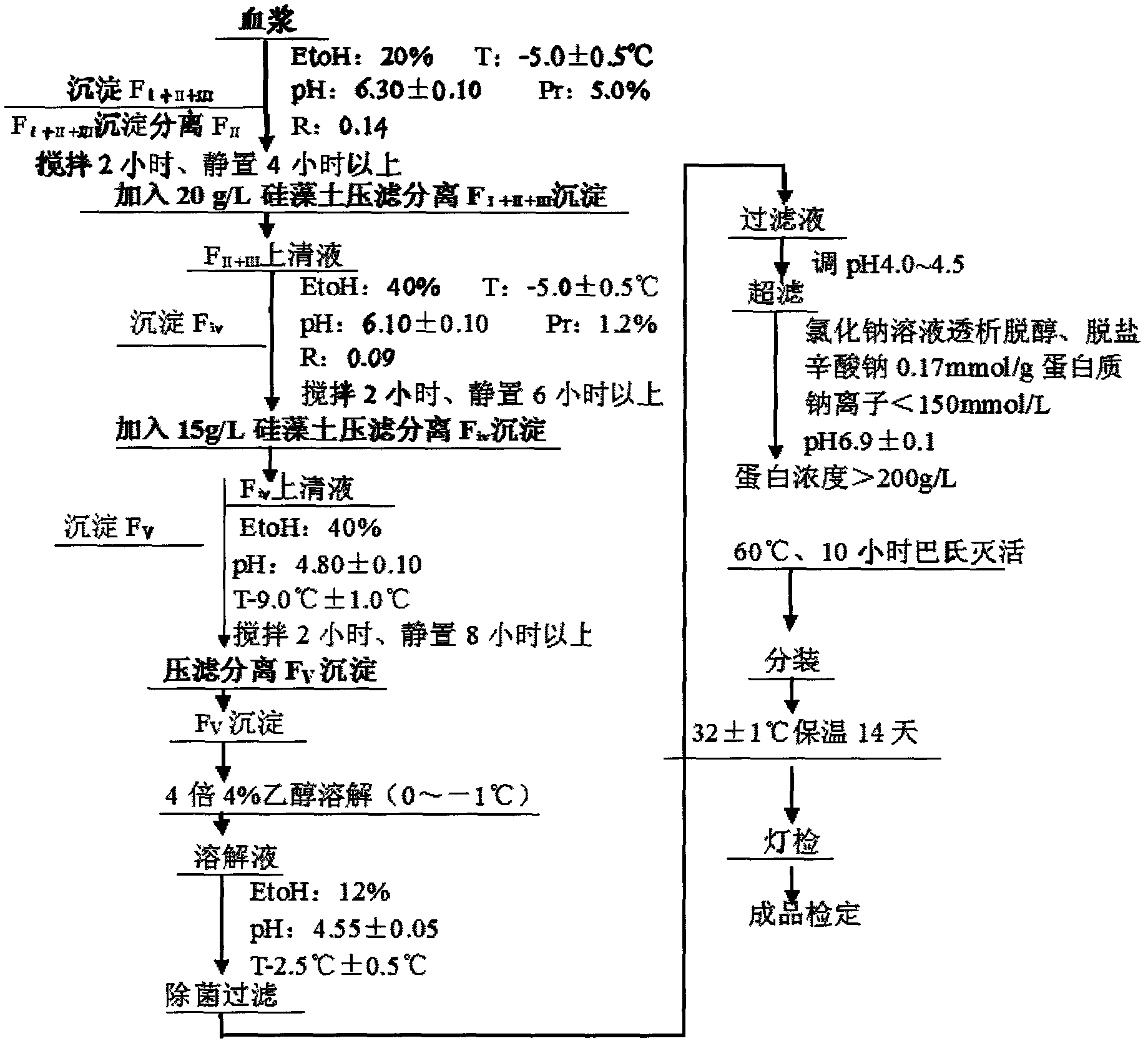

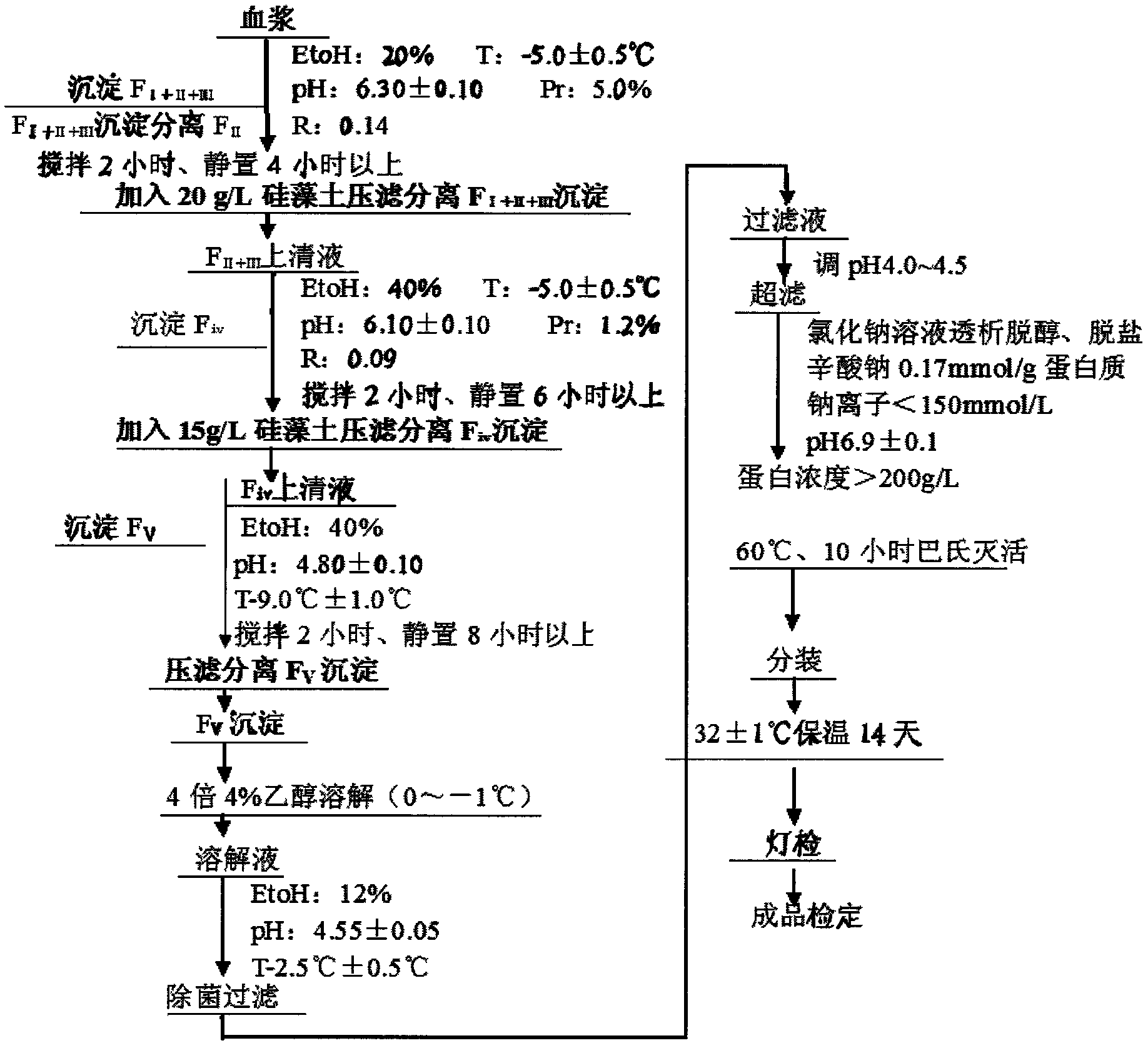

Preparation method of human serum albumin

InactiveCN102532304AStructure has no effectQuality improvementSerum albuminPeptide preparation methodsAluminum IonProtein molecules

The invention relates to a method for separating and extracting protein in a biological product technology, in particular to a preparation method of human serum albumin. The preparation method comprises the following steps of: separating components I, II and III, separating a component IV, separating a component V, and refining and purifying; and performing ultrafiltration, pasteurization and sterilized filling, examining a finished product, and packaging the qualified product by pasting a label, boxing and the like. According to the preparation method disclosed by the invention, a relatively-moderate pressure-filtration separation method is adopted, so that the molecular structure of the protein is not influenced, and the human serum albumin with high quality is ensured to be prepared; moreover, the product yield is greatly increased, the human serum albumin which is low in aluminum ion content or even does not contain aluminum ions can be provided for clinical application, and the quality of the human serum albumin is improved.

Owner:WUHAN ZHONGYUAN RUIDE BIOLOGICAL PROD CO LTD

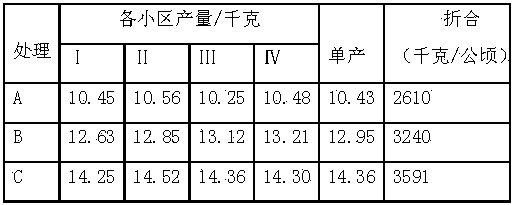

Special cotton fertilizer for regulating and controlling coastal saline-alkali land soil and preparation method thereof

ActiveCN103641666ASimple structureImprove fertilityFertilizer mixturesMagnesium phosphateAlkali soil

The invention discloses special cotton fertilizer for regulating and controlling coastal saline-alkali land soil and belongs to the technical field of special fertilizers for crops. The special cotton fertilizer is prepared from the following raw materials in parts by weight: 300-450 parts of urea, 1-100 parts of diammonium phosphate, 50-120 parts of potassium dihydrogen phosphate, 100-200 parts of potassium sulfate, 50-150 parts of calcium humate, 1-50 parts of calcium-magnesium phosphate, 1-50 parts of magnesium sulfate, 1-10 parts of zinc sulfate and 1-10 parts of high-strength water retention agent. Compared with the prior art, the special cotton fertilizer has the advantages that due to the addition of water-soluble calcium humate, the special cotton fertilizer can be used for inhibiting salt and holding moisture; due to the addition of a proper volume of water retention agent, the special cotton fertilizer can be used for regulating and controlling water retention, increasing the fertilizer effect and increasing fertilizer utilization ratio; due to the addition of essential secondary / trace elements, the resilience resistance is enhanced, and the product yield and quality are improved.

Owner:STANLEY AGRI GRP CO LTD

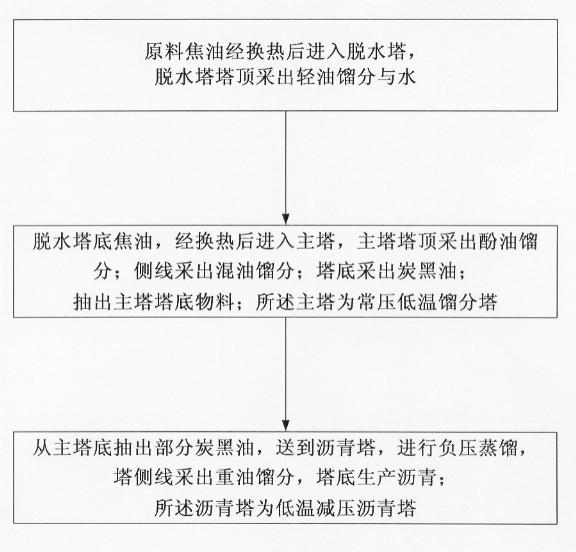

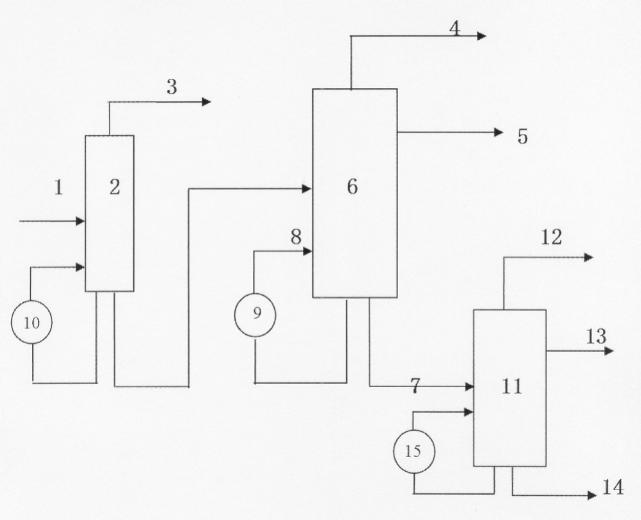

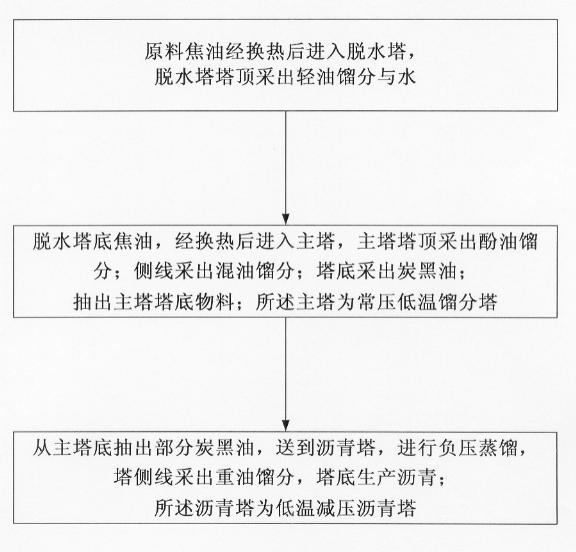

Coal tar alkali-free normal/reduced-pressure distillation process and device

ActiveCN102161901AReduce sodium ion contentAvoid corrosionTar working-up by water removalTar working-up by distillationAlkali freeDistillation

The invention relates to a coal tar alkali-free normal / reduced-pressure distillation process and a coal tar alkali-free normal / reduced-pressure distillation device. In the process, raw material coal tar is subjected to heat exchange and delivered into a dehydrating tower, and light oil distillate and water are collected from the top of the dehydrating tower; the coal tar at the bottom of the dehydrating tower is subjected to heat exchange and delivered to a main tower, and a carbolic oil distillate is collected from the top of the main tower; a mixed oil distillate is collected from a lateralline; carbon black oil or soft asphalt is collected from the bottom of the tower; bottom material of the main tower is pumped out; part of soft asphalt is pumped out from the bottom of the main towerand delivered to an asphalt tower for distillation under a negative pressure, a heavy oil distillate is collected from a lateral line of the tower, and asphalt is produced at the bottom of the tower;and the main tower is a normal-pressure low-temperature distillate tower, the asphalt tower is a low-temperature reduced-pressure asphalt tower, and all distillates are not added with alkali in the whole flow. In the device, the bottom of the dehydrating tower is connected with the middle of the main tower through a pipe, and the bottom of the main tower is connected with the middle of the asphalt tower through a pipe. The internal circulation at bottom of the main tower is realized through a heating furnace, and internal circulation at the bottom of the asphalt tower is realized through a heating furnace. The process and the device have the advantages that: all distillates are not added with alkali; distillates are cut according to market demands and temperature gradient; direct super-heated steam is not used; new process waste water is avoided; the energy consumption is low; the product quality is high; and the like.

Owner:BAOSTEEL ENG & TECH GRP

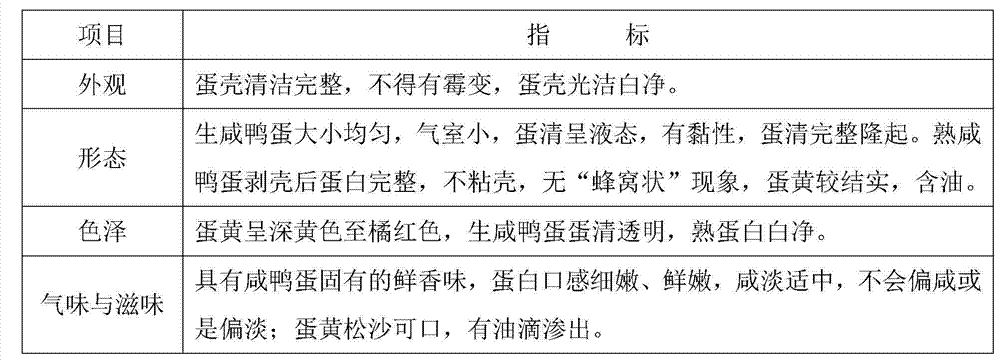

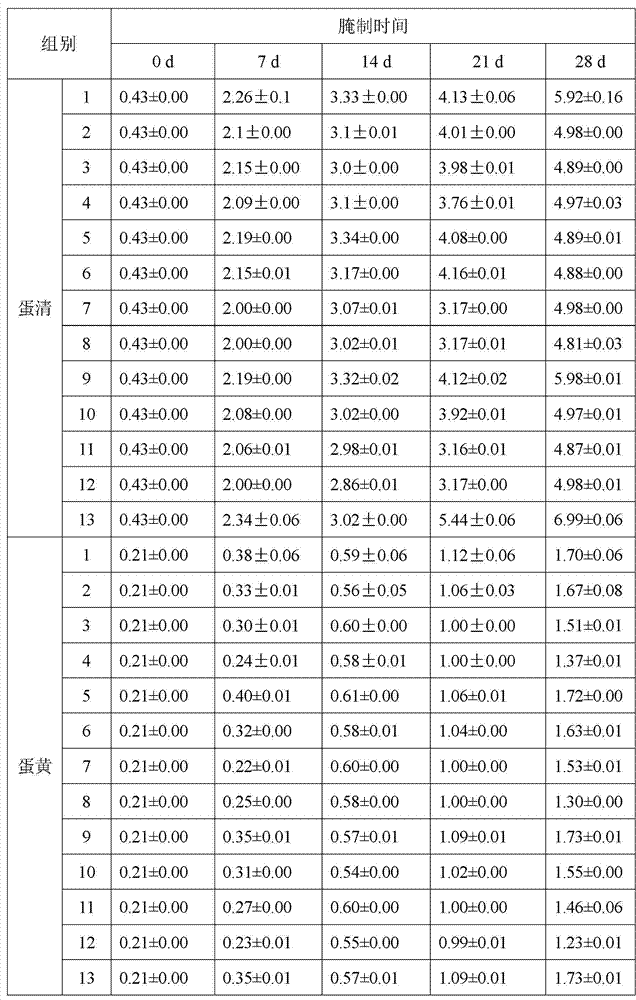

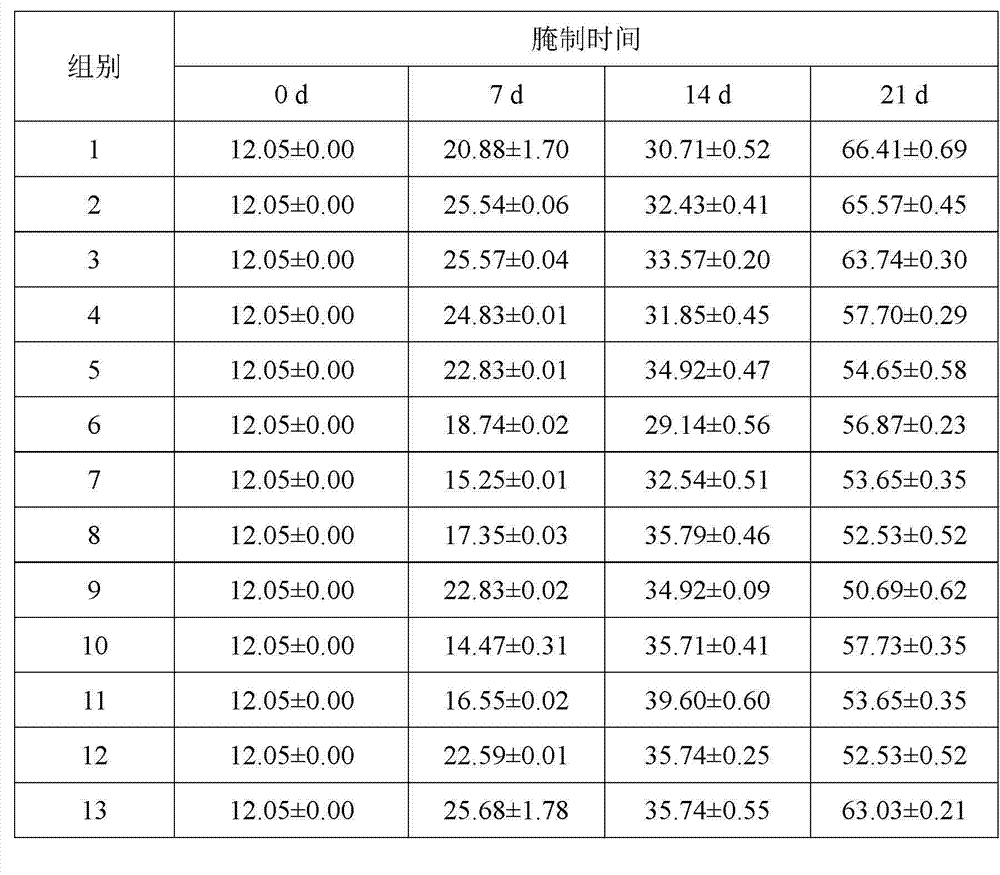

Method for mechanically and rapidly pickling low sodium salted eggs through pulsed pressure

The present invention discloses a method for mechanically and rapidly pickling low sodium salted eggs through pulsed pressure. According to the method, duck eggs are immersed in a low sodium mixing salt pickling liquid, and are subjected to mechanical pickling for 5-10 days by using pulsed pressure, wherein a high pressure value of the pulsed pressure is 90-105 kPa, a high pressure maintaining time is 12-15 minutes, a low pressure value is an atmospheric pressure, and a low pressure maintaining time is 20-30 minutes. According to the present invention, sodium ion content in the salted egg pickled by the method of the present invention is lowered by about 30% compared with sodium ion content in the salted egg pickled by the conventional method, an egg yolk oil yield rate is high, a pickling time is short, and finished products can be obtained in 5-10 days, wherein the time is shortened by 50-70% compared with the time of the traditional pickling process.

Owner:HUAZHONG AGRI UNIV

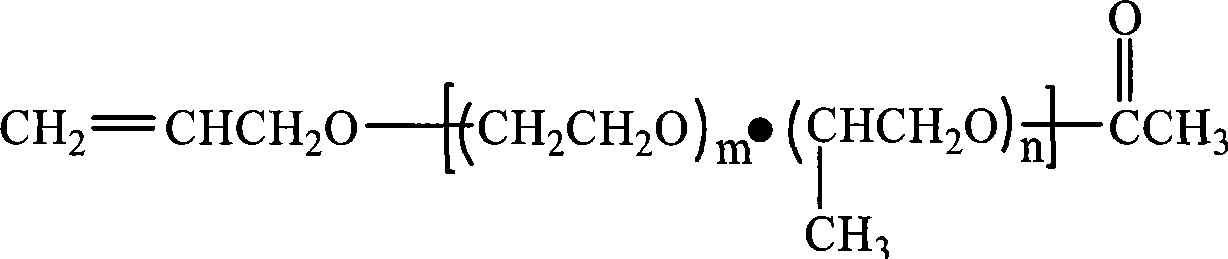

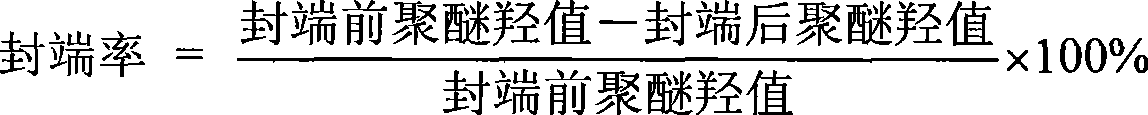

Preparation of acetyl end capping allyl alcohol polyether

The invention relates to a preparation method of acetyl terminated allyl alcohol polyether, which belongs to the field of synthesis technology of terminated polyether. Allyl alcohol polyether and acetic anhydride are taken as raw materials and are deacidified with most of acid in a nitrogen bubbling deacidifying way under the vacuumized condition, water is added in to enable the rest acetic anhydride to be hydrolyzed to acetic acid, acetic acid and trace quantity acetic anhydride are deacidified by creation of vacuum and a falling film evaporator under the vacuumized condition, and last the acetyl terminated allyl alcohol polyether is obtained during the refining adsorption process of the polyether. The invention adopts the mol ratio of 1:1.2 to 3.0 of the allyl alcohol polyether and the acetic anhydride , the temperature of 120-130 DEG C in the nitrogen bubbling deacidifying process under the vacuumized condition, the vacuum negative pressure of -0.080 to -0.090 MPa and the time of 2.0-3.0 hours. The invention has reasonable technology, simple operation and better use performance.

Owner:ZHEJIANG HUANGMA TECH

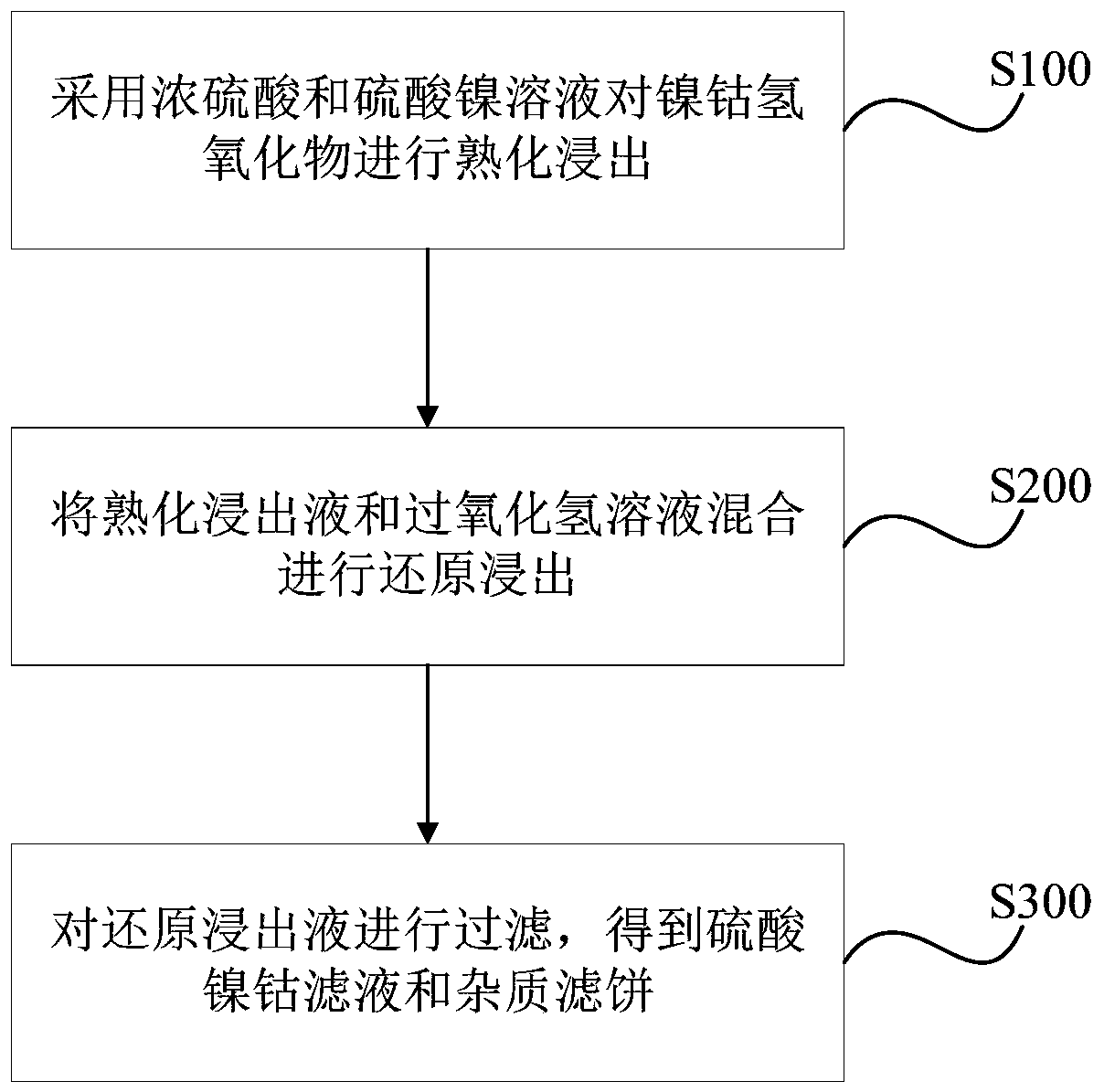

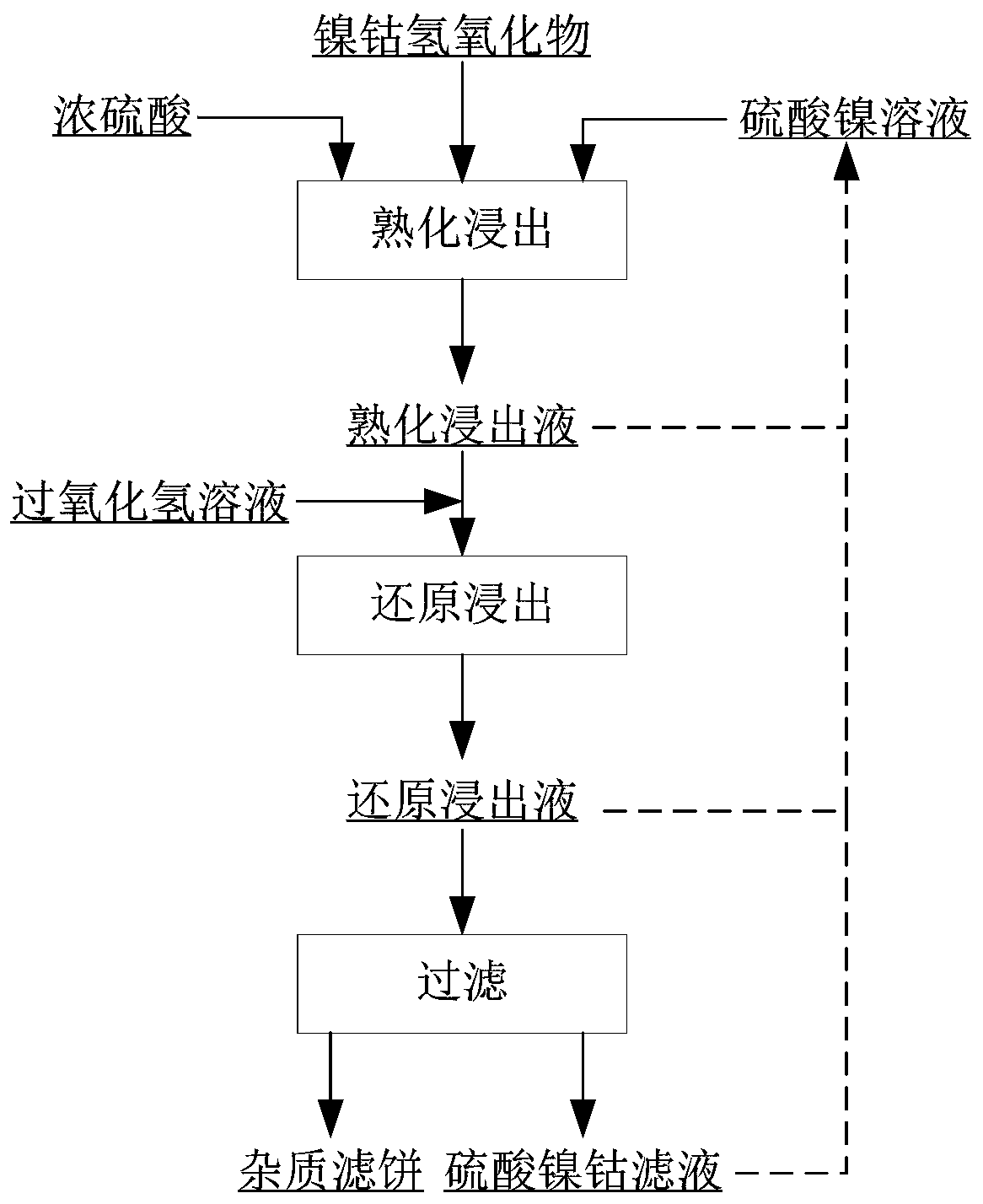

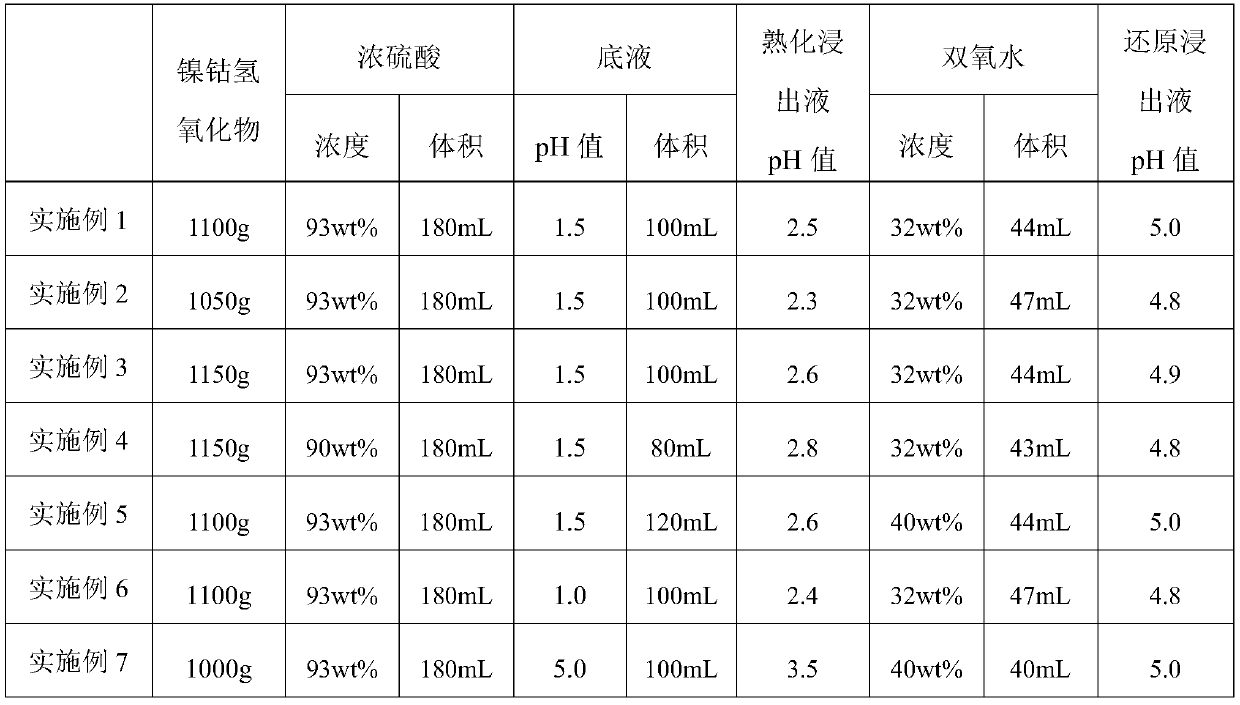

Method for treating nickel-cobalt hydroxide

The invention discloses a method for treating nickel-cobalt hydroxide. The method comprises the following steps that (1) curing leaching is carried out on the nickel-cobalt hydroxide by adopting concentrated sulfuric acid and a nickel sulfate solution so as to obtain a cured leaching solution; (2) the cured leaching solution is mixed with a hydrogen peroxide solution for carrying out reduction leaching so as to obtain a reduction leaching solution; and (3) the reduction leaching solution is filtered so as to obtain nickel-cobalt sulfate filtrate and an impurity filter cake, wherein the nickel-cobalt hydroxide is obtained by recovering nickel-cobalt from laterite-nickel ore, and the pH value of the reduction leaching solution is 3 - 5. According to the method for treating the nickel-cobalthydroxide, the consumption of auxiliary materials can be effectively reduce, the production cost is reduced, the recovery rate of nickel is remarkably improved, and a remarkable effect of removing silicon and removing flocculant is achieved; and the silicon content in the finally obtained nickel-cobalt sulfate filtrate is not higher than 40 mg / L, the sodium ion content is not higher than 1.0 g / L,the COD value is not higher than 100 mg / L, and the requirements of producing ternary precursor products can be effectively met.

Owner:中冶瑞木新能源科技有限公司

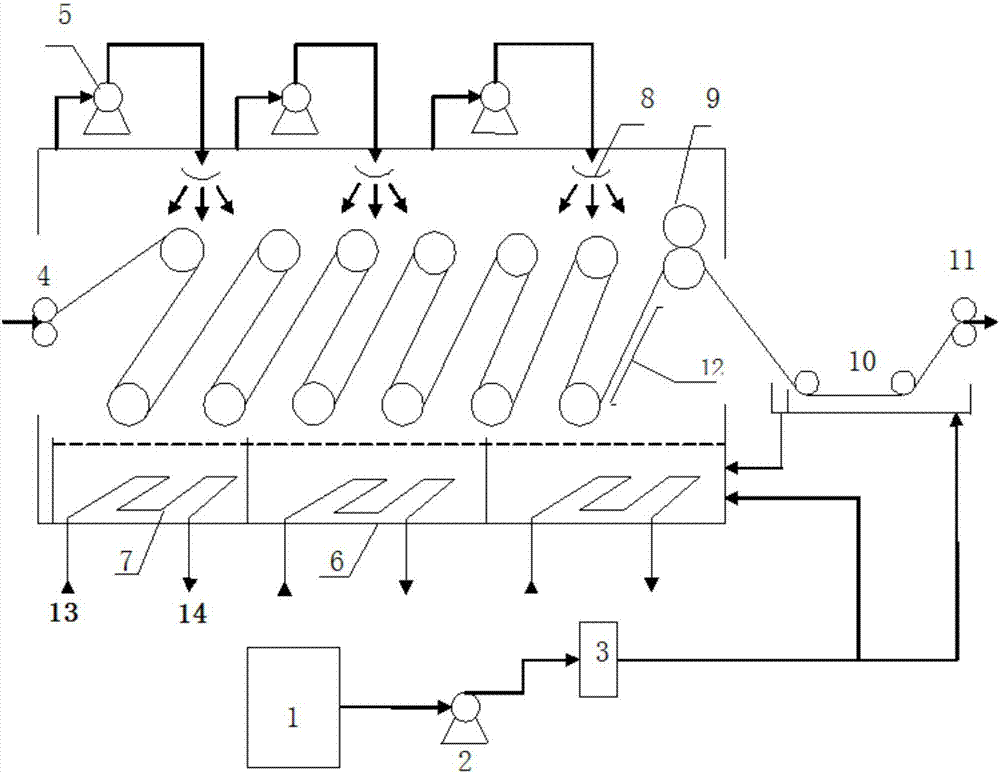

Device and method for carbon fiber precursor washing

PendingCN107268215AIncrease the effective strokeReduce sodium ionsSucessive textile treatmentsTextile treatment machine arrangementsFiberCarbon fibers

The invention discloses a device and method for carbon fiber precursor washing. The device comprises a rinsing machine silk guide roller group, a circulating water channel, a spraying water pump, a spraying nozzle and a rinsing water tank. The rinsing machine silk guide roller group is arranged above the circulating water channel, silk guide rollers are staggered up and down, an outlet is provided with an extrusion roll group, tows having undergone acid dipping enter the rinsing water tank through the rinsing machine silk guide roller group and the extrusion roll group, and the spraying nozzle is arranged above the rinsing machine silk guide roller group and connected with the spraying water pump. The method comprises a step 1) of conveying the desalted water to the rinsing water tank after the desalted water is heated; a step 2) of causing the desalted water in the rinsing water tank to enter the circulating water channel of a rinsing machine through overflow; a step 3) of causing the tows to undergo acid dipping and then enter the rinsing machine, spraying the sprayed water out of the spraying nozzle to form atomized water to wash the tows; a step 4) of washing the tows and then causing the tows to enter the rinsing water tank to be rinsed, and causing the advancing direction of the tows to be opposite to the flowing direction of the desalted water in the rinsing water tank. According to the device and method for carbon fiber precursor washing, sodium ions in the tows can be reduced, and quality of carbon fiber precursors is improved.

Owner:兰州蓝星纤维有限公司

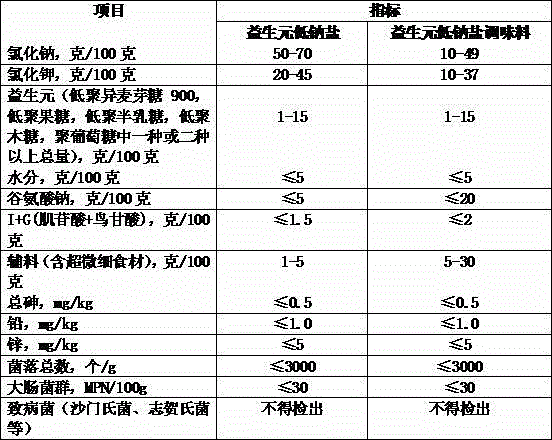

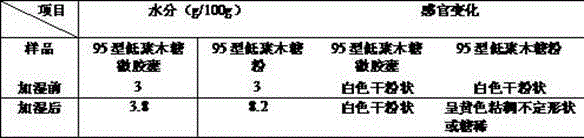

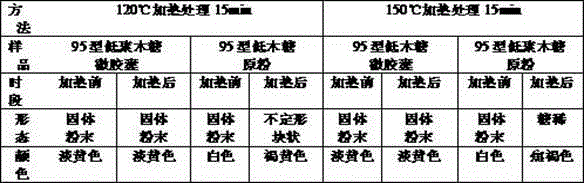

Probiotic low-sodium salt and preparing method thereof

ActiveCN104783123APromote growth and reproductionPrevent sub-health diseasesSugar food ingredientsFood ingredient functionsBiotechnologyHigh sodium

Owner:SICHUAN YISHENGYUAN TECH CO LTD

Method for preparing micron-grade stannic oxide powder

ActiveCN103626222APrevent agglomerationSmall particle sizeTin oxidesElectrically conductiveSodium stannate

The invention discloses a method for preparing micron-grade stannic oxide powder which is applicable to conductive glass, semiconductor materials, high-class ceramic colored glaze materials or electric operation. The method comprises the following steps: dropping an ammonium bicarbonate solution, an ammonium carbonate solution or a mixture solution of ammonium bicarbonate and ammonium carbonate into a reagent-grade sodium stannate solution, controlling the pH value of a reaction liquid to be within the range of 9.0-10.0 so as to prepare tin hydroxide hydrate with high-dispersity, subsequently pulping the tin hydroxide hydrate by using pure water, further conditioning the pH value of the tin hydroxide hydrate pulp so as to obtain metastannic acid, and finally putting metastannic acid solid into a high-temperature furnace to be calcined and dehydrated so as to obtain the high-purity micron-grade stannic oxide powder. According to the method disclosed by the invention, micron-grade powder can be prepared without crushing, the production process is environment-friendly, the production equipment is simple, industrialization is easy to achieve, the micron-grade stannic oxide powder product prepared by using the method disclosed by the invention is small in particle size, high in purity, single in component and capable of meeting the requirements of conductive glass, semiconductor materials, high-class ceramic colored glaze materials or electric operation.

Owner:GUANGDONG GUANGHUA SCI TECH

Sorbitan caprylate emulsifier

InactiveCN106749118ALight smellHigh transparencyOrganic chemistryTransportation and packagingIon contentSynthesis methods

The invention aims to provide a synthesis method of sorbitan caprylate emulsifier. The synthesis method is characterized by comprising the following steps: taking commercially available D-sorbitol and caprylic acid as raw materials, performing etherification and esterification, then vacuumizing, adding water, vacuumizing according to the vapor distillation principle, deacidifying in vacuum through a falling film evaporator to remove the caprylic acid, and finally adsorbing through granular magnesium silicate to prepare the sorbitan caprylate emulsifier. According to the invention, the material addition and proportioning in the reaction process are reasonably adjusted, the reaction temperature and time in deacidification and other working procedures are optimally selected, and the process is reasonable and simple to operate. The sorbitan caprylate emulsifier prepared by the invention is faint in smell, light in color, high in transparency, low in acid value, low in fatty acid residue, low in sodium ion content, less prone to acidification and favorable in stability; and meanwhile, the sorbitan caprylate emulsifier has the advantages of solubilization, emulsification assistance, tackification, corrosion resistance synergy, safe and mild performance and favorable compatibility, thereby being applicable to the fields of daily chemical cosmetics and the like.

Owner:ZHANGJIAGANG GREAT CHEM

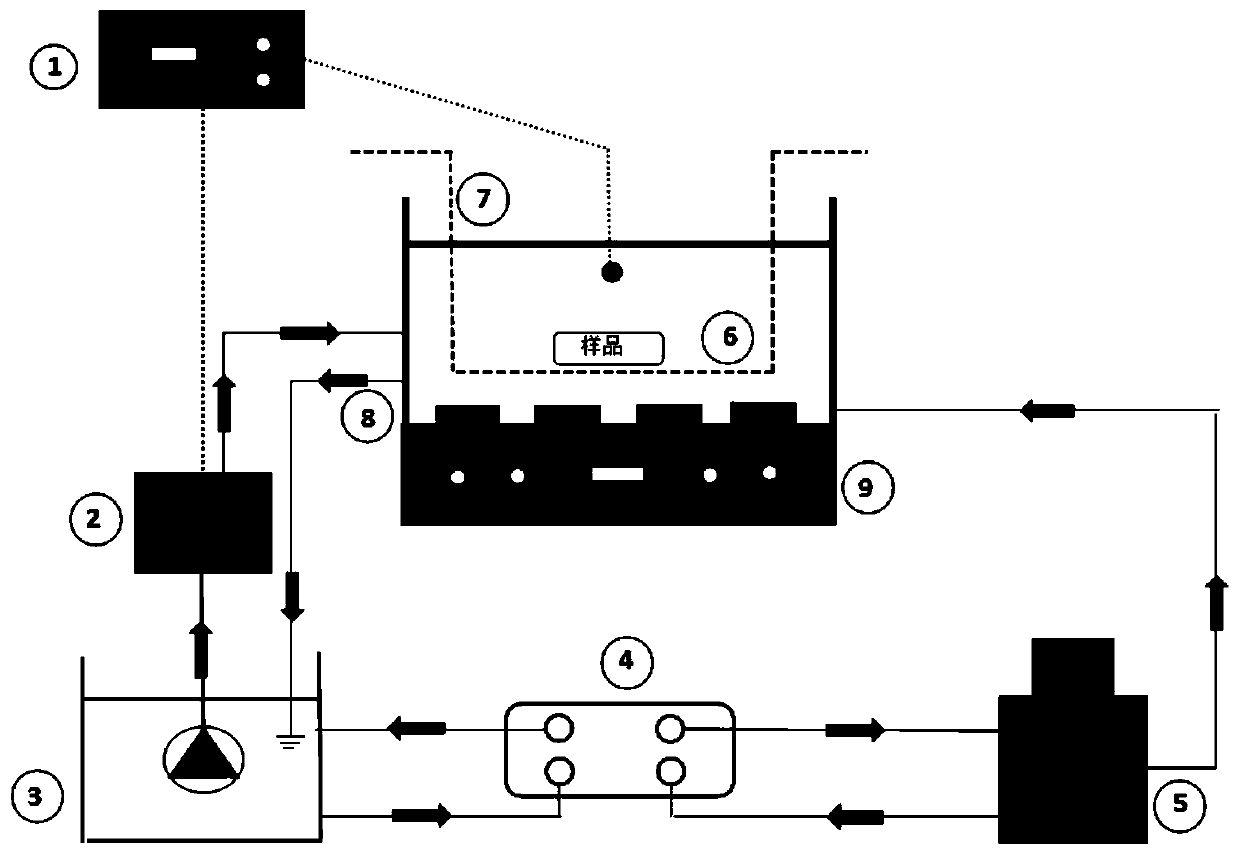

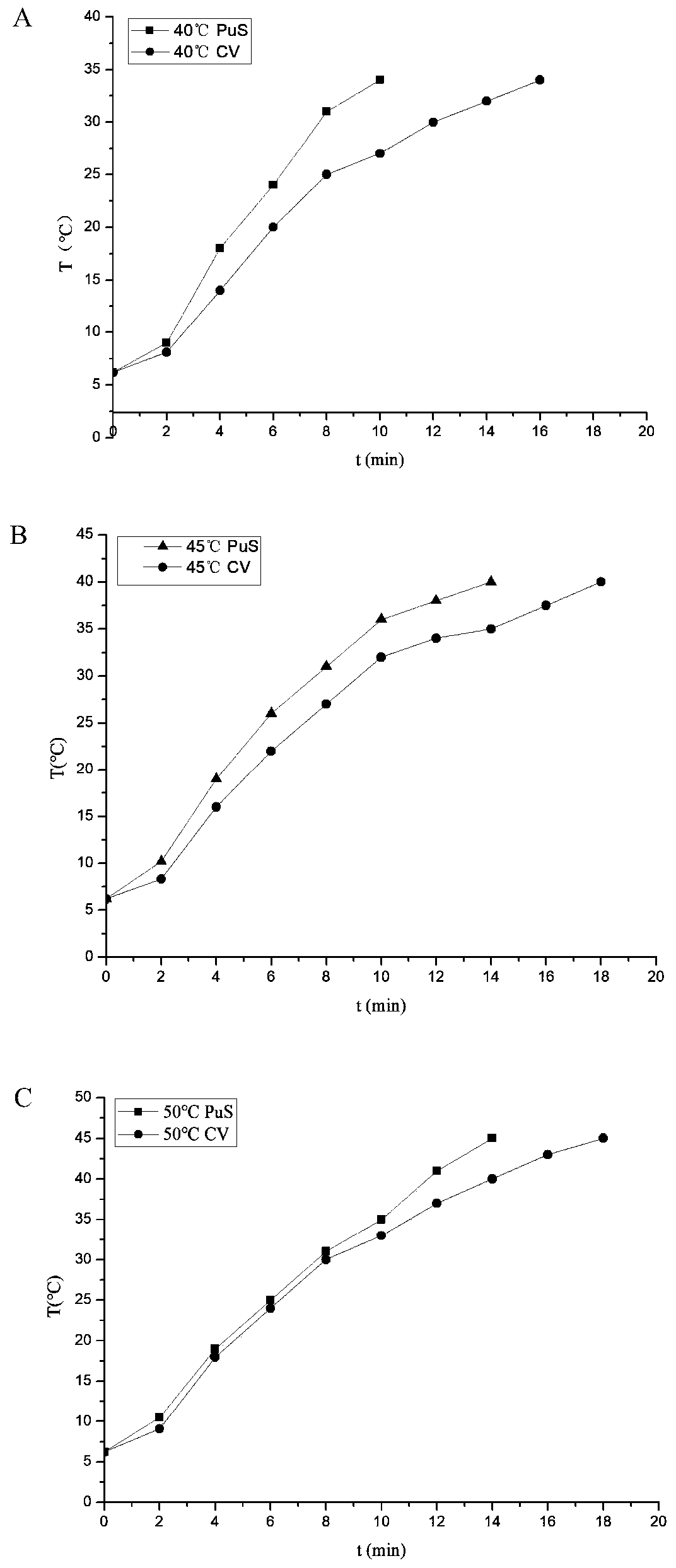

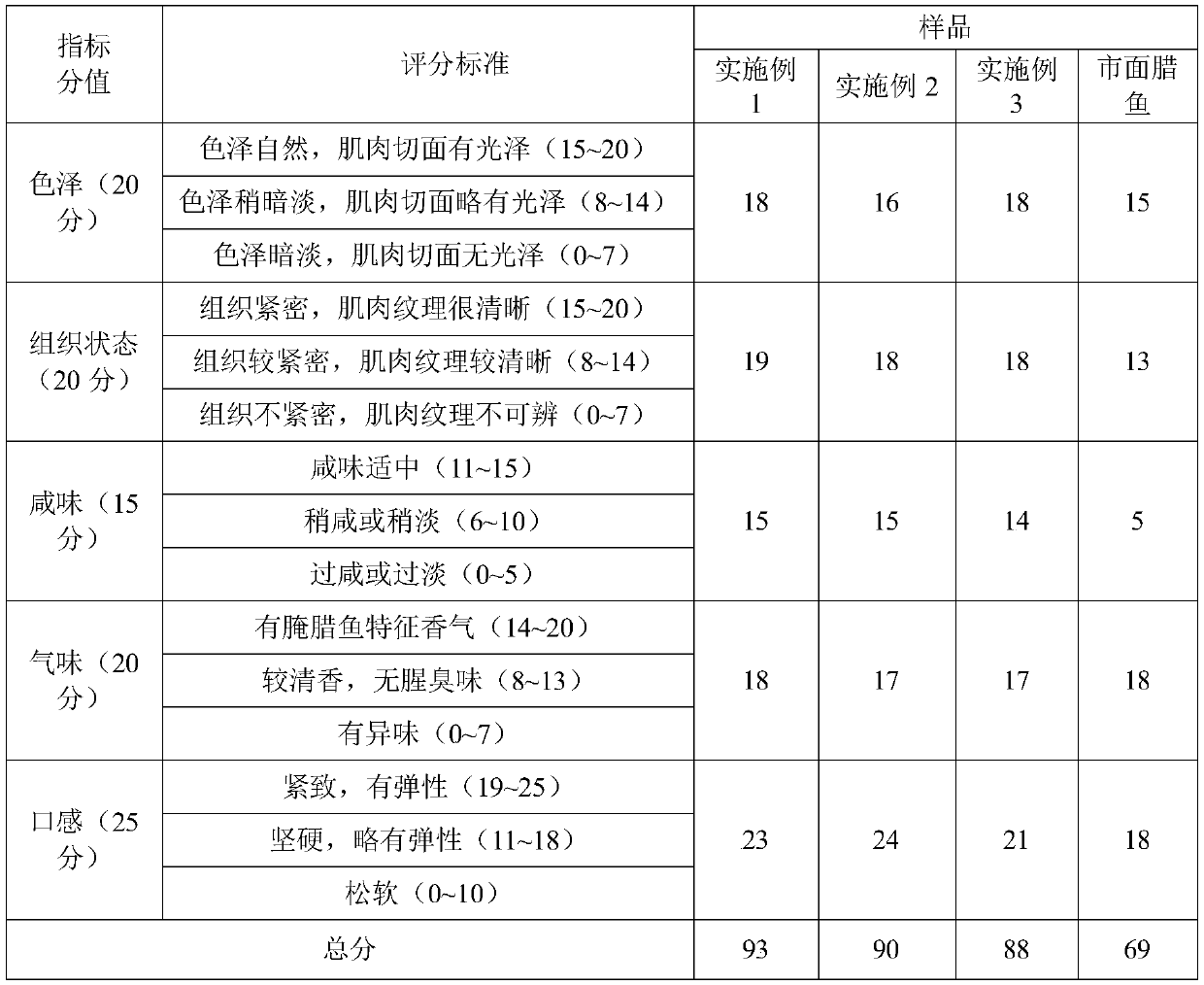

Method for preparing cured fish by ultrasonic-assisted low-temperature heating

PendingCN110771819AIncrease elasticityMaintain colorFood processingMeat/fish preservation using chemicalsMoisture distributionEngineering

The invention relates to a method for preparing cured fish by ultrasonic-assisted low-temperature heating. The method comprises the following steps: after pretreatment, pickling and drying, soaking vacuum packaged cured fish in an ultrasonic tank for ultrasonic treatment, starting a circulating thermostat heating circulating system after a sample is added into the ultrasonic tank, turning off a heater and turning on an ultrasonic device for ultrasonic treatment when the water temperature rises to 40 to 50 DEG C, controlling ultrasonic power and frequency to be 500 to 700W and 18 to 20 kHz respectively, and finishing the treatment after the ultrasonic time of 10 to 20 min to obtain finished cured fish. According to the method disclosed by the invention, the pickling time can be shortened, the muscle elasticity of the cured fish can be improved, the problem of uneven water distribution after a fish body is dried can be solved, and the special color and flavor of the cured fish can be maintained.

Owner:ZHEJIANG UNIV OF TECH

High-temperature resistant silica aerogel heat preservation felt preparation method

The invention belongs to the technical field of thermal insulation materials, and particularly discloses a high-temperature resistant silica aerogel heat preservation felt preparation method, which includes taking industrial sodium silicate as a raw material; adopting fiber coupling; then frequently washing with warm water to remove impurities; continuously circulating and replacing solvent ethanol; and finally drying at normal pressure to prepare the silica aerogel heat preservation felt. The silica aerogel heat preservation felt has the advantages of high purity and high temperature resistance, the sodium ion content of the heat preservation felt is less than 0.05 wt%, and the thermal conductivity at 500 DEG C is less than 0.025 W / (m*k). In addition, the high-temperature resistant silicaaerogel heat preservation felt preparation method has the advantages of cheap and easily-available raw materials, stable operation and easier industrialization.

Owner:冷水江三A新材料科技有限公司

Method for removing sodium ion from recovered nickle sulfate solution of waste nickle-hydrogen and nickle-cadmium

ActiveCN1778687AReduce sodium ion contentImprove crystal qualitySulfate preparationNickel sulfatesRare-earth elementIon content

A method for removing sodium ion from waste nickel hydrogen and nickel cadmium recovered nickelous sulfate solution is carried out by leaching out for positive materials of waste nickel hydrogen and nickel cadmium cell from sulfuric acid, heating reactive mixture at 60í½95íÒC, adding into additive containing rare earth element, generating rare earth double salt sulfate deposition in sulfate salt system, deposition reacting for sodion, filtering and removing filter residue to obtain nickelous sulfate solution with low sodium ion content. It costs low and is simple, safety and efficient.

Owner:广东芳源新材料集团股份有限公司

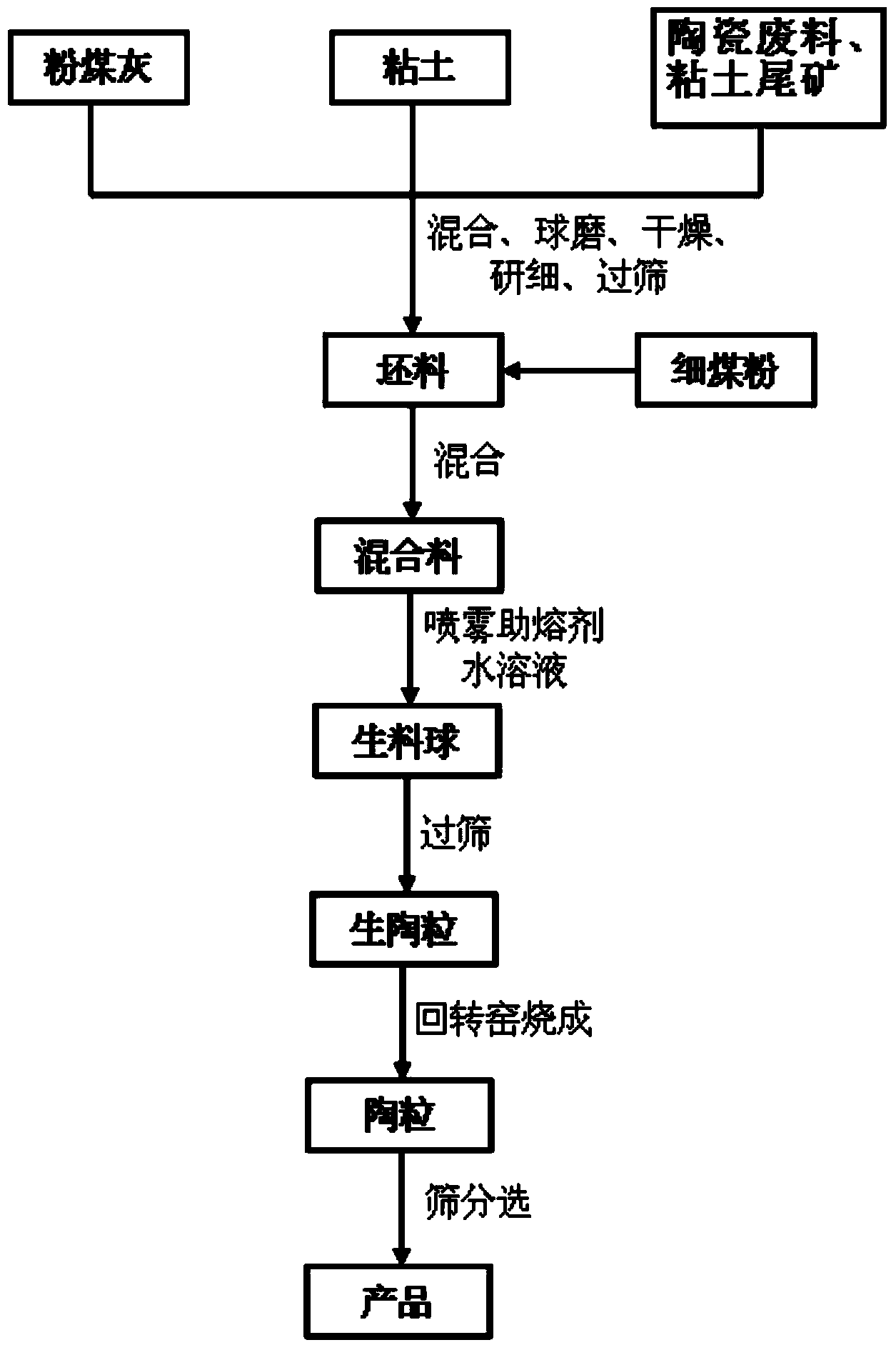

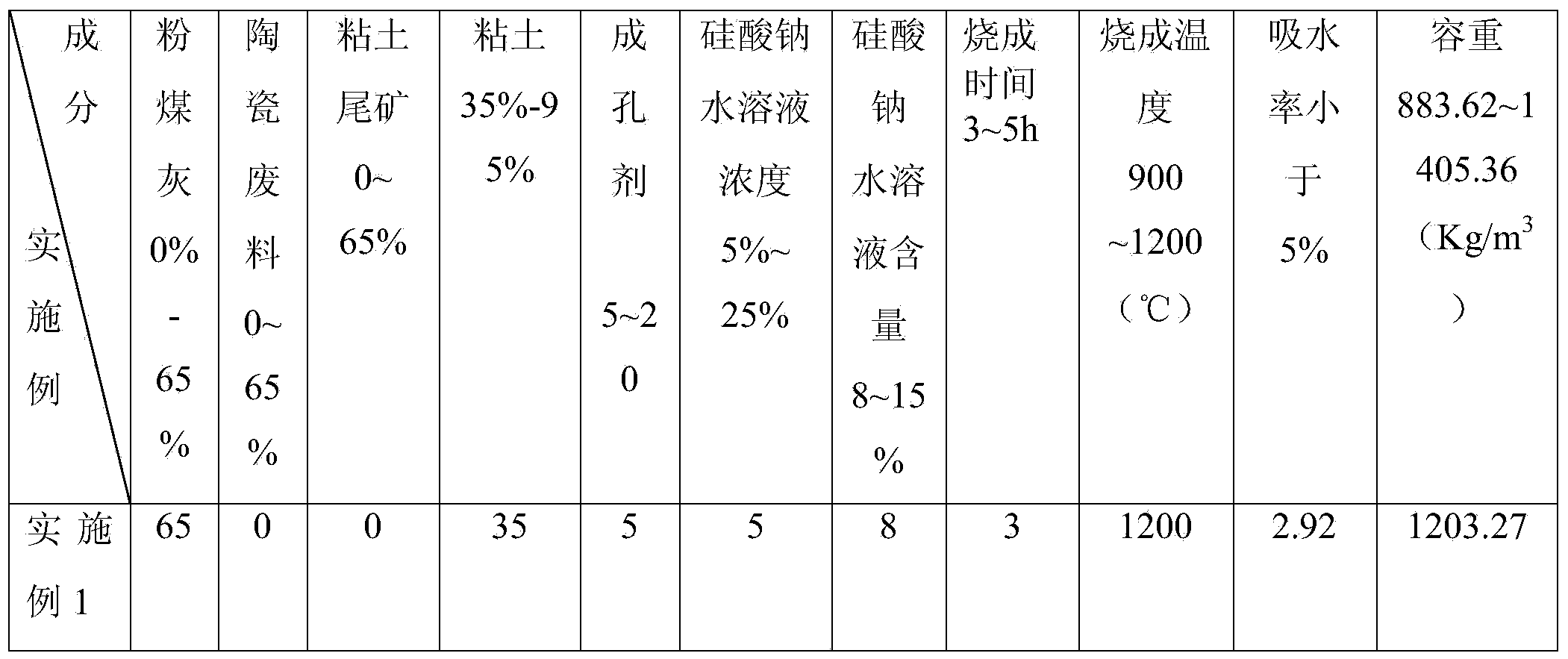

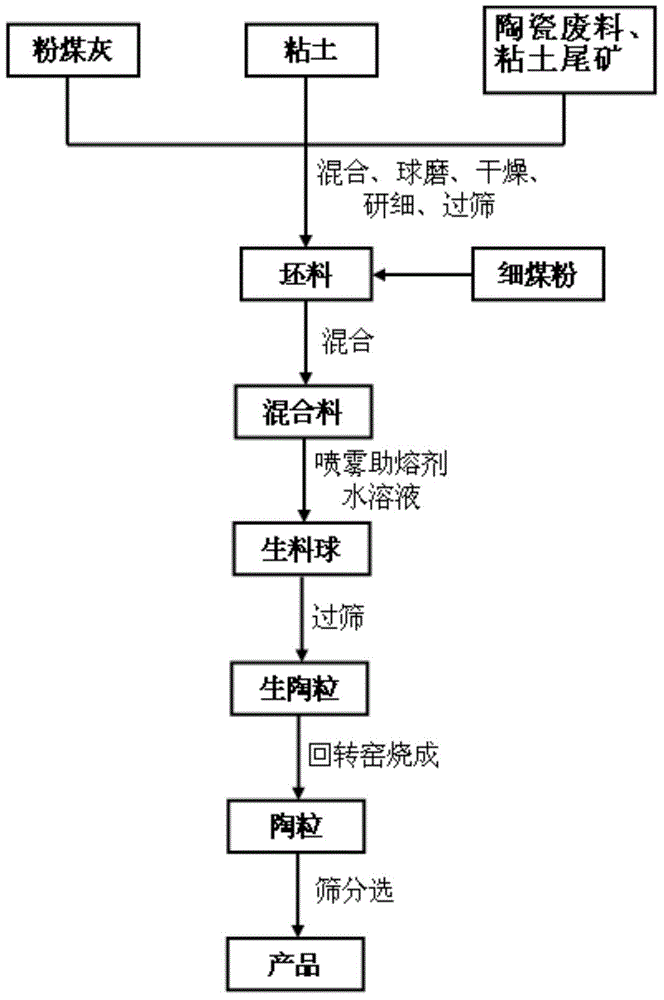

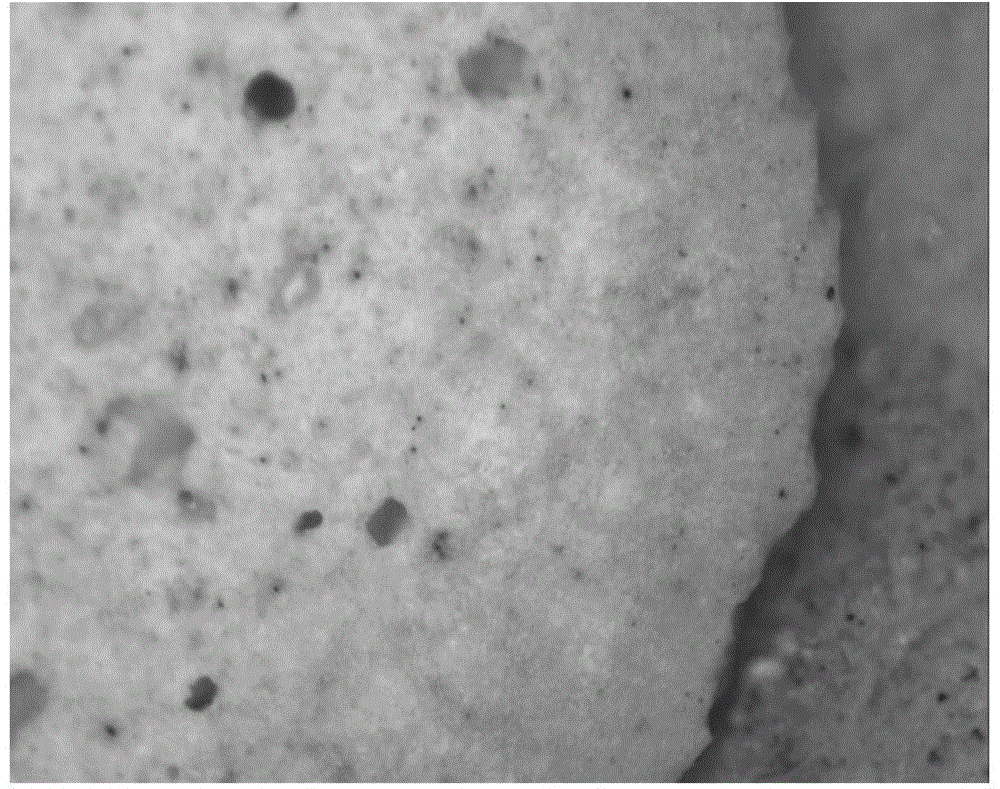

Sodium silicate surface co-sintered light ceramsite and preparation method thereof

ActiveCN104291786ALow costSimple processCeramic materials productionCeramicwareSurface layerHigh volume manufacturing

The invention relates to sodium silicate surface co-sintered light ceramsite and a preparation method thereof. The light ceramsite and the preparation method have the beneficial effects that by spraying a 5-25% sodium silicate solution step by step, during drying, sodium ions dissolved in water diffuse toward the surfaces along with the moisture and gather on the shells of surfaces of raw meal nodules, the sodium ions on the surface layers react with other matters in the sintering process to form fusible matters, thus playing a role of co-sintering agents, and the content of the sodium ions in the co-sintering agents below the surface layers of the raw meal nodules is very low; the ceramsite sintered at a surface layer sintering temperature has relatively low water absorption but the unsintered density of core regions below the surface layers is lower, so that the light ceramsite with low water absorption and low overall density is finally obtained; the problems that the ceramsite not only requires low water absorption and high strength but also requires light volume weight are solved; the preparation method of the sodium silicate surface co-sintered light ceramsite is simple in process and safe to operate, can be used for volume production and is low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

Method for removing sodium ion from recovered nickle sulfate solution of waste nickle-hydrogen and nickle-cadmium

ActiveCN100389520CReduce sodium ion contentImprove crystal qualitySulfate preparationWaste accumulators reclaimingRare-earth elementIon content

Owner:广东芳源新材料集团股份有限公司

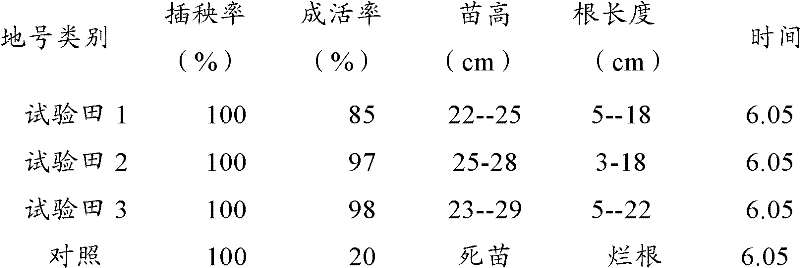

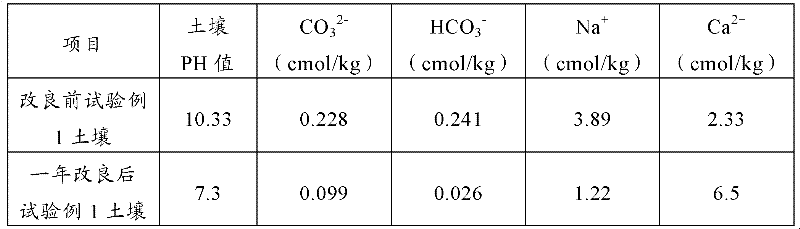

Improving agent for reducing pH value and sodium ion content of saline-alkali land and preparation method of improving agent

InactiveCN107903907AReduce sodium ion contentImprove survival rateAgriculture tools and machinesOther chemical processesIon contentAlkali soil

The invention discloses an improving agent for reducing the pH value and the sodium ion content of saline-alkali land and a preparation method of the improving agent. The improving agent comprises thefollowing components in parts by mass: 90-100 parts of desulfurized gypsum, 90-100 parts of fly ash, 90-100 parts of furfural residues, and 40-50 parts of an improving auxiliary agent. According to the improving agent provided by the invention, the desulfurized gypsum, the fly ash and the furfural residues can significantly reduce the pH value of the saline-alkali soil, promote the elution of Na<+>, reduce the content of HCO3<->, and improve the content of SO4<2->, Ca<+> and Mg<+>, so that the improving effects of the saline-alkaline soil are significant; and an organic fertilizer capable ofproviding nutrients for the growth of crops is selected as the improving auxiliary agent, and therefore the soil conditions are improved while the growth of the crops is promoted.

Owner:WEIFANG YOURONG IND

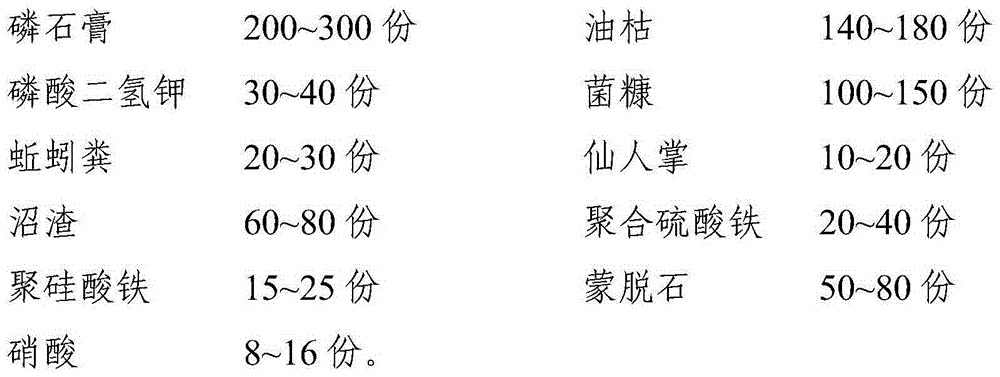

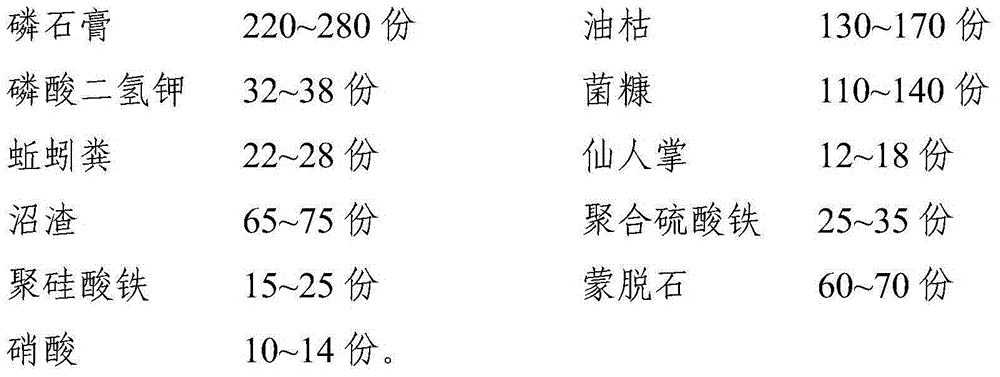

Coastal saline area conditioner and preparation method and application method thereof

InactiveCN105154089AIncrease cation exchange capacityImprove adsorption capacityAgriculture tools and machinesOther chemical processesAlkali soilMonopotassium phosphate

The invention discloses a coastal saline area conditioner and a preparation method and an application method thereof. The coastal saline area conditioner is prepared from phosphorus, oil cake, monopotassium phosphate, mushroom residue, wormcast, cactus, biogas residue, polymeric ferric sulfate, montmorillonite and nitric acid. The coastal saline area conditioner prepared from the montmorillonite, the polymeric ferric sulfate, polymeric ferric silicate-sulfate and ardealite can neutralize charge on the surface of sodium colloid and destabilize the sodium colloid to promote calcium ions in the ardealite to substitute sodions in colloidal complex, salinity content and pH value in the saline area are lowered greatly, few sodions not taken away with water are absorbed by the montmorillonite, and salinity content in aqueous solution in soil is further lowered accordingly.

Owner:GUIZHOU KAILIN GRP CO LTD +1

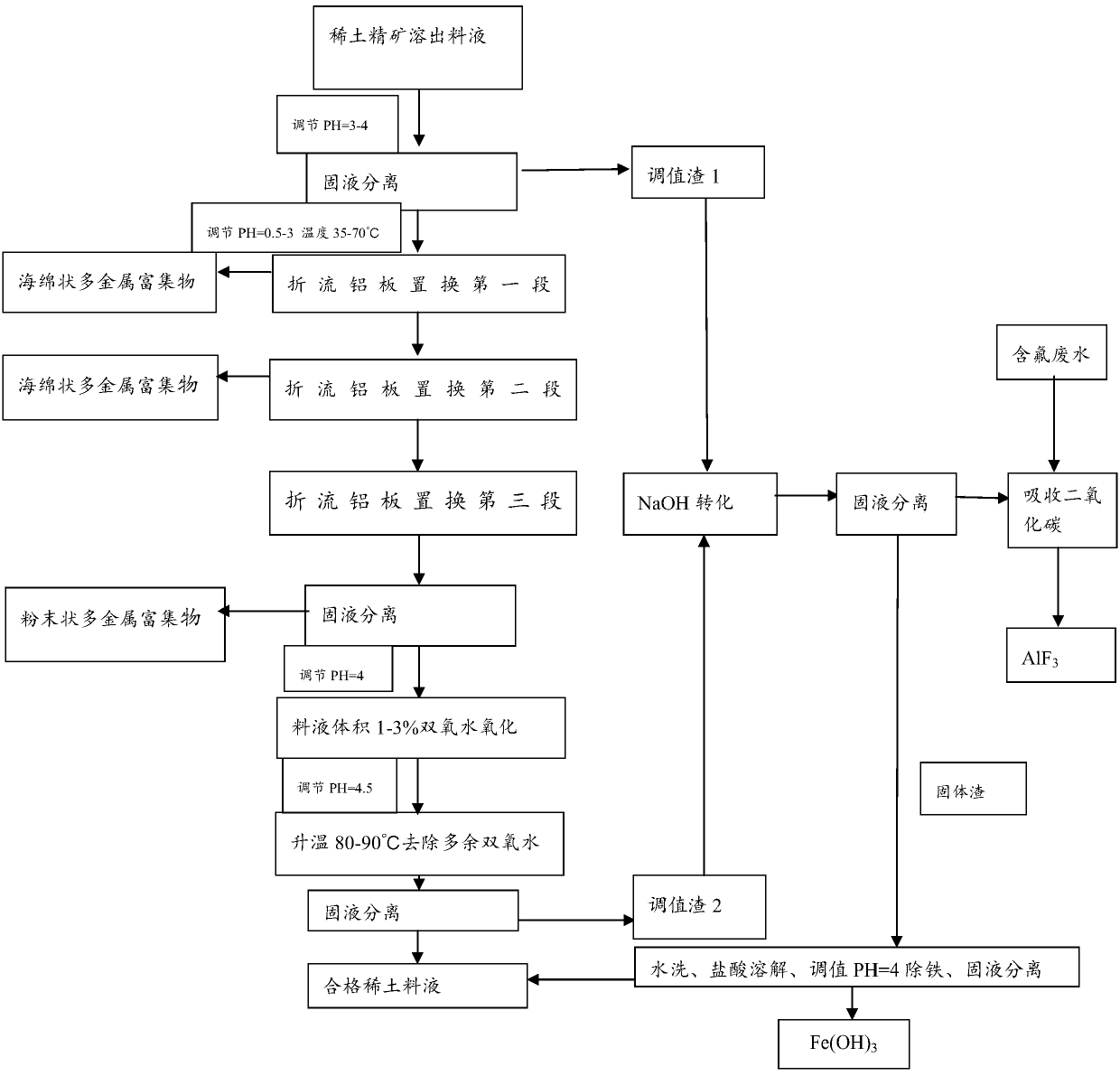

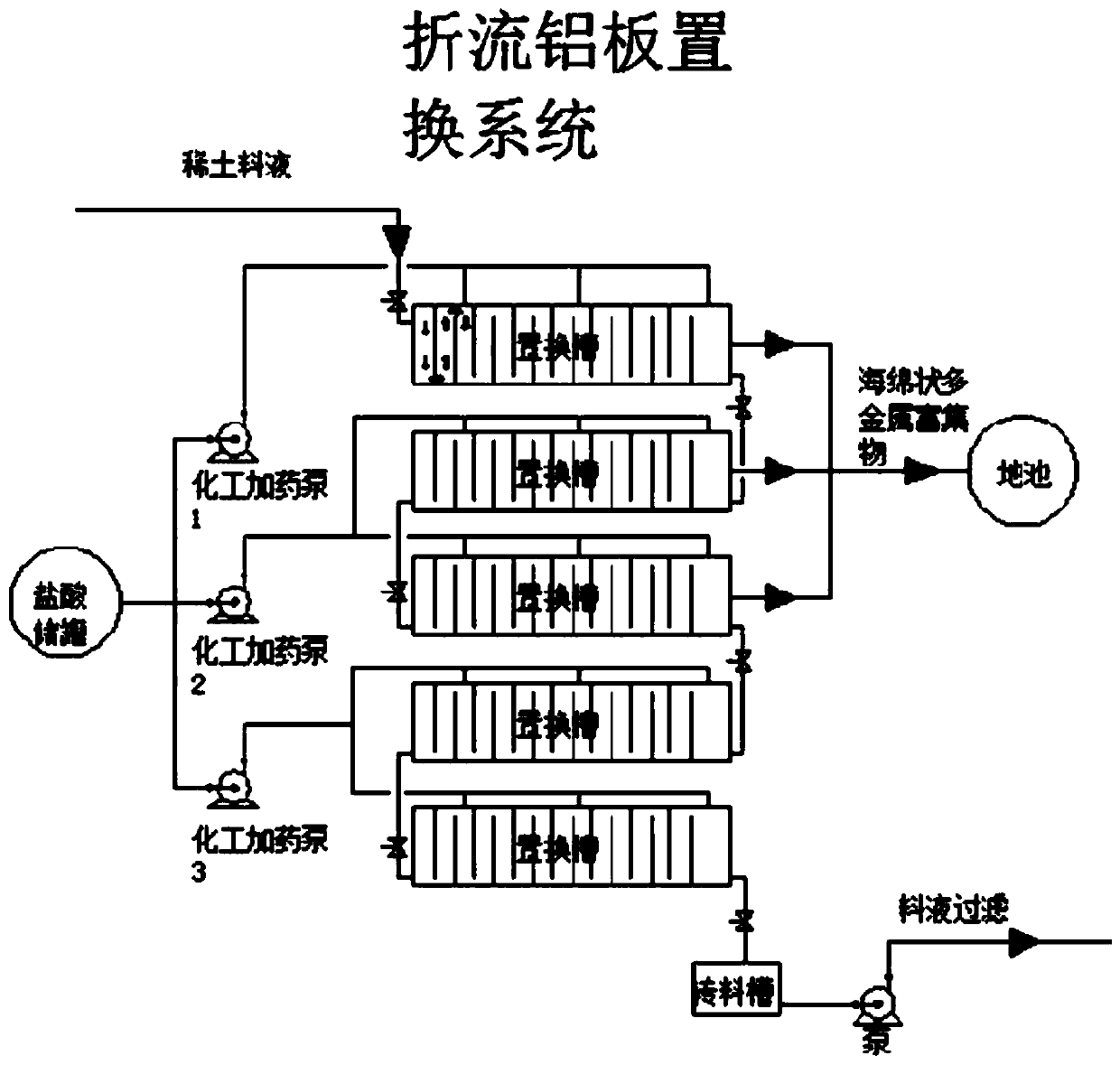

A rare earth material liquid impurity removal process

InactiveCN108411110BAchieve recyclingGreen and efficient impurity removalProcess efficiency improvementRare earthHydrometallurgy

The invention discloses an impurity removing process for rear earth feed liquid and belongs to the technical field of wet metallurgy. The impurity removing process for the rear earth feed liquid includes the following steps that (1) the rear earth feed liquid is preprocessed; (2) the rear earth feed liquid is subjected to three times of replacement in an independently controlled mode; (3) solid-liquid separation and collection of spongy multi-metal enriched products are carried out; (4) low-valence metal ions are subjected to oxidation treatment; and (5) an aluminum element and an iron elementin solid matter produced in the previous steps are solidified. The impurity removing process for the rear earth feed liquid has the beneficial effects that environment-friendly and high-efficiency impurity removing of the rear earth feed liquid is achieved, processing cost is low, higher safety is achieved, and the rear earth loss is less than 0.2% during displacement impurity removing of the rear earth feed liquid; and the lead content in the feed liquid is reduced to 0.005 g / L from 1-2 g / L, the iron content in the feed liquid is reduced to 0.004 g / L from 0.5-2 g / L, the copper content in thefeed liquid is less than 1 PPM after processing, silver, mercury and other trace metal elements capable of being replaced with metal aluminum in the feed liquid can be enriched, the content of sodiumions in the feed liquid is reduced, and the processing difficulty of waste water is reduced.

Owner:四川英创环保科技有限公司

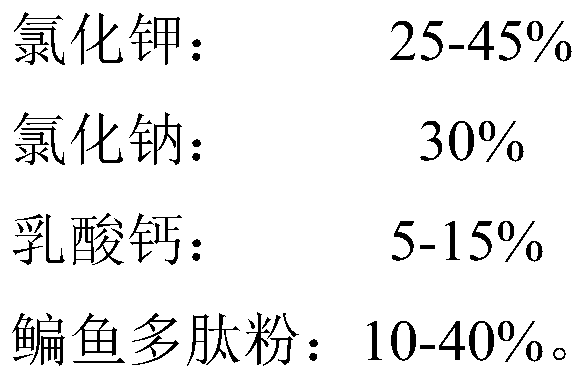

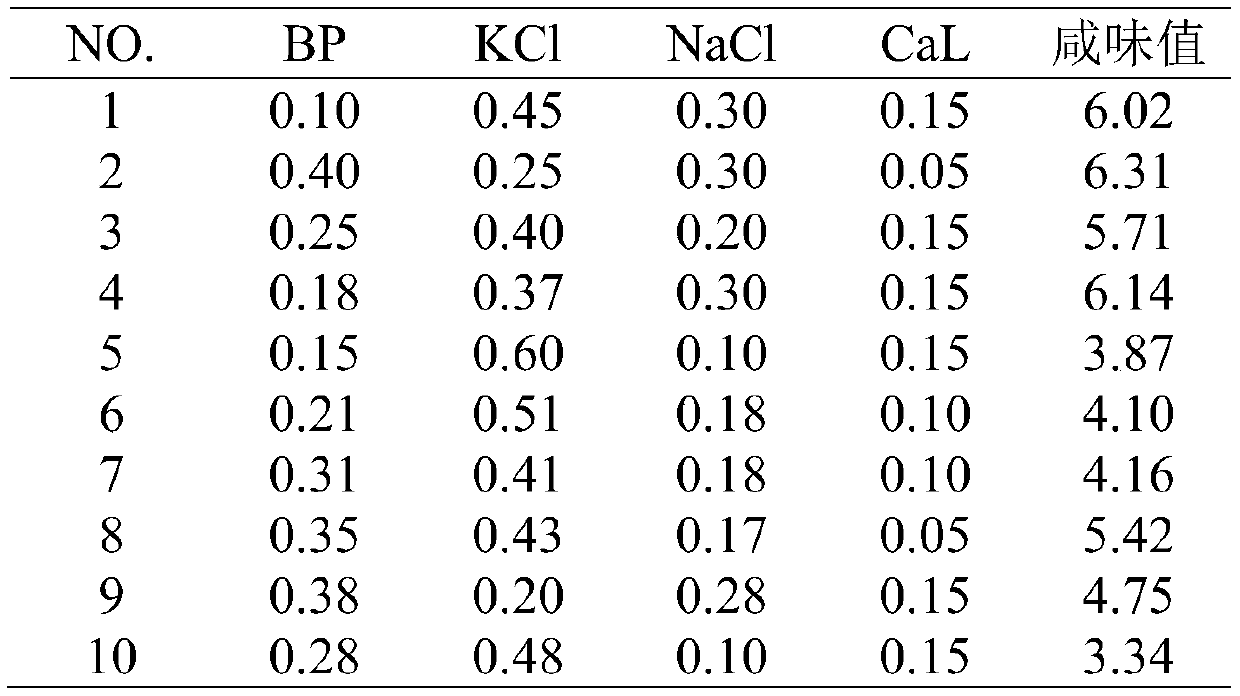

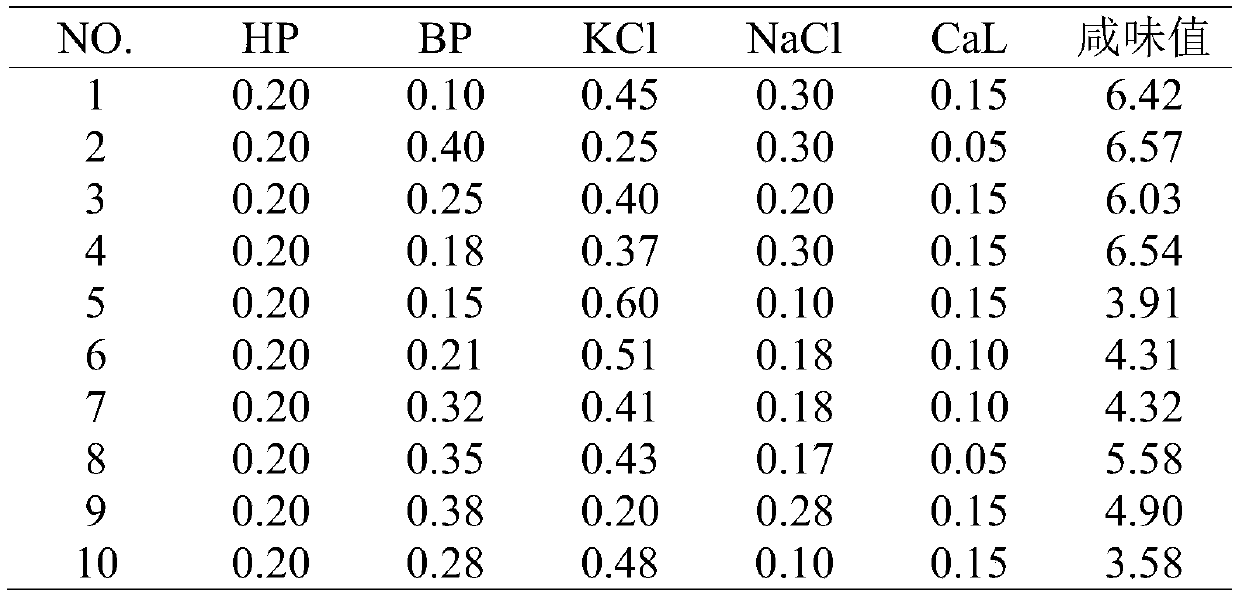

Salty-flavor-enhancing peptide and preparation method and application thereof

ActiveCN110205353ARich in nutritional valueEnhance saltinessFood ingredient as taste affecting agentFermentationFlavorChemistry

The invention discloses a salty-flavor-enhancing peptide and a preparation method and an application thereof. The preparation method of the salty-flavor-enhancing peptide includes the following steps:after pretreatment of large yellow croaker, adding protease, carrying out enzymatic hydrolysis for several hours, carrying out freezing centrifugation, and ultrafiltering the supernatant to obtain anenzymatic hydrolysate; after pretreatment of bream, adding water and protease, carrying out hydrolysis, carrying out freezing centrifugation, and freeze-drying, to obtain bream polypeptide powder; and mixing the bream polypeptide powder with other non-sodium salts, to obtain a solute, adding the solute into the large yellow croaker enzymatic hydrolysate, treating by a pulsed electric field, and freeze-drying to obtain the salty-flavor-enhancing peptide. The content of table salt is reduced under the same salinity, and the sodium ion content is reduced by 40%-50%. Therefore, the salty-flavor-enhancing peptide prepared by the method is a salty-flavor-enhancing agent having rich nutritional value, maintaining the original flavor balance of food and then effectively enhancing the salty flavor.

Owner:SOUTH CHINA UNIV OF TECH +1

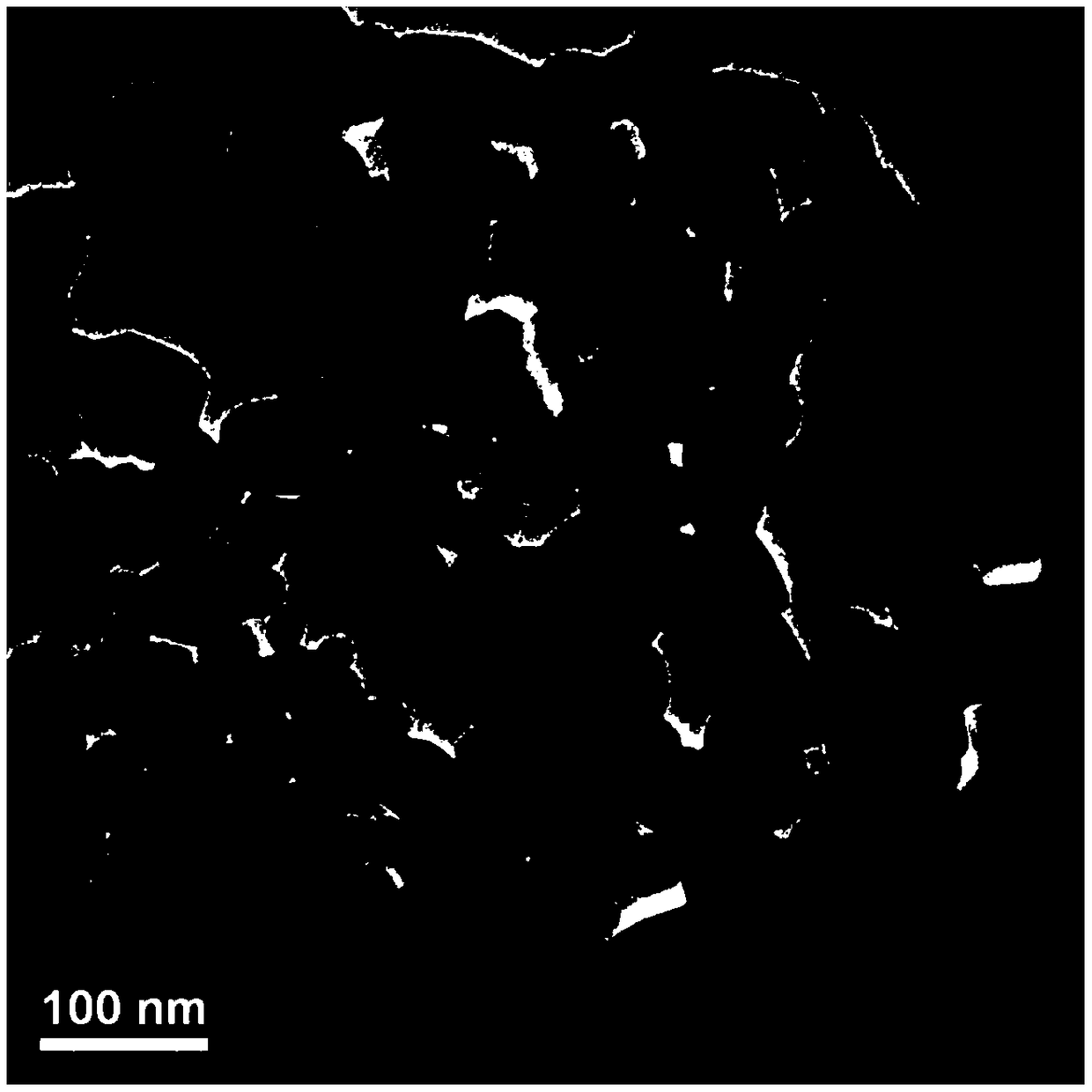

Method for removing sodium ions from nanometer rare earth oxide prepared through sodium salt depositing process

InactiveCN108892165AGood effectReduce sodium ion contentRare earth metal oxides/hydroxidesMaterial nanotechnologyIonNanometre

The invention belongs to the technical field of rare earth compound preparation and specifically relates to a method for removing sodium ions from a nanometer rare earth oxide prepared with a sodium salt serving as a precipitating agent. The method comprises the following steps: adopting dilute nitric acid for adjusting pH of purified water, and then repeatedly washing the prepared nanometer rareearth oxide with water, wherein the content of sodium ions in the oxide washed with water is less than 100ppm, oxide grains are of spherical shape, primary grain size is 30-70 nanometer and the distribution is uniform. The method provided by the invention has the characteristics of simple processing conditions, low production cost and easiness in realizing industrial production. The whole preparation process meets the environmental protection requirement.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

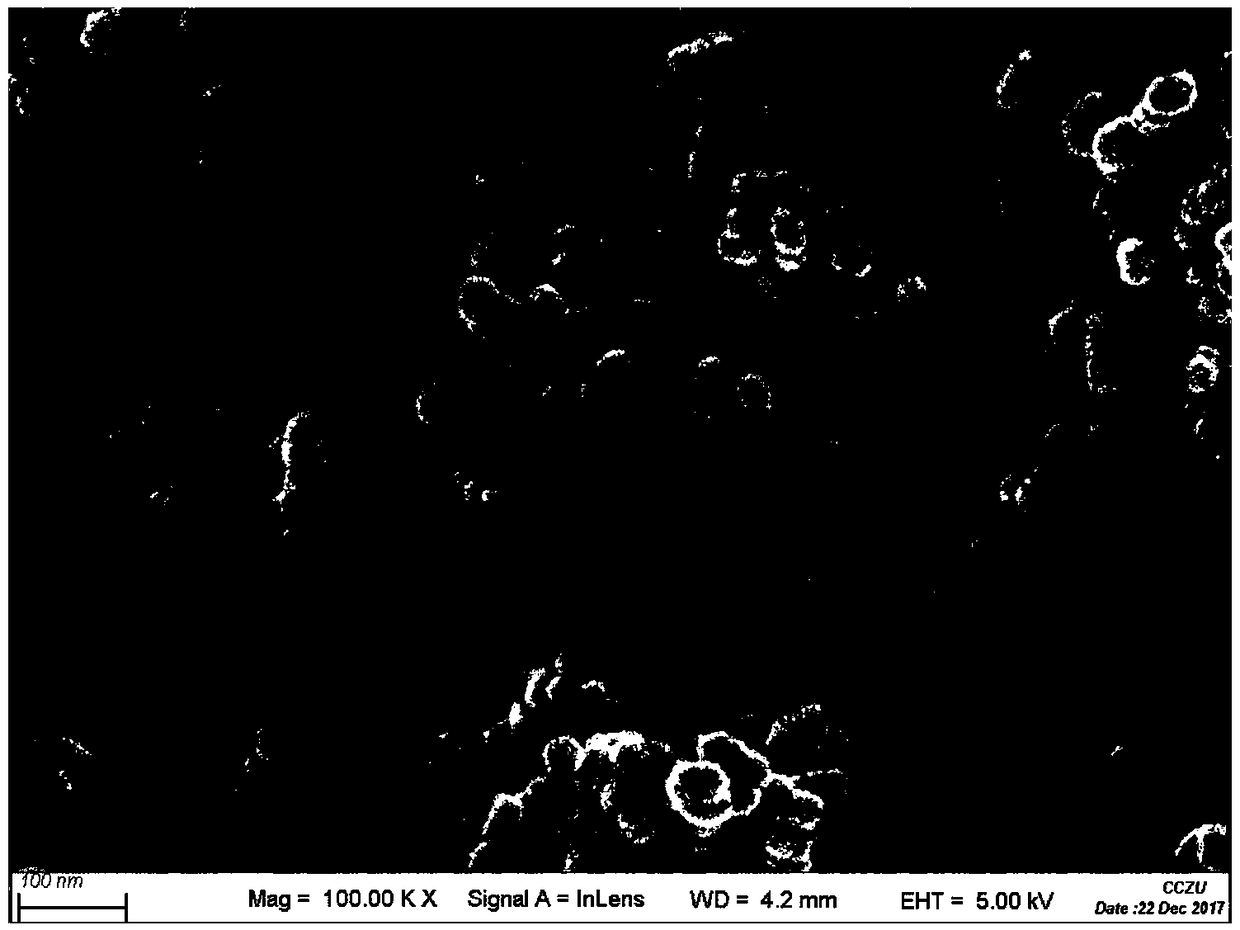

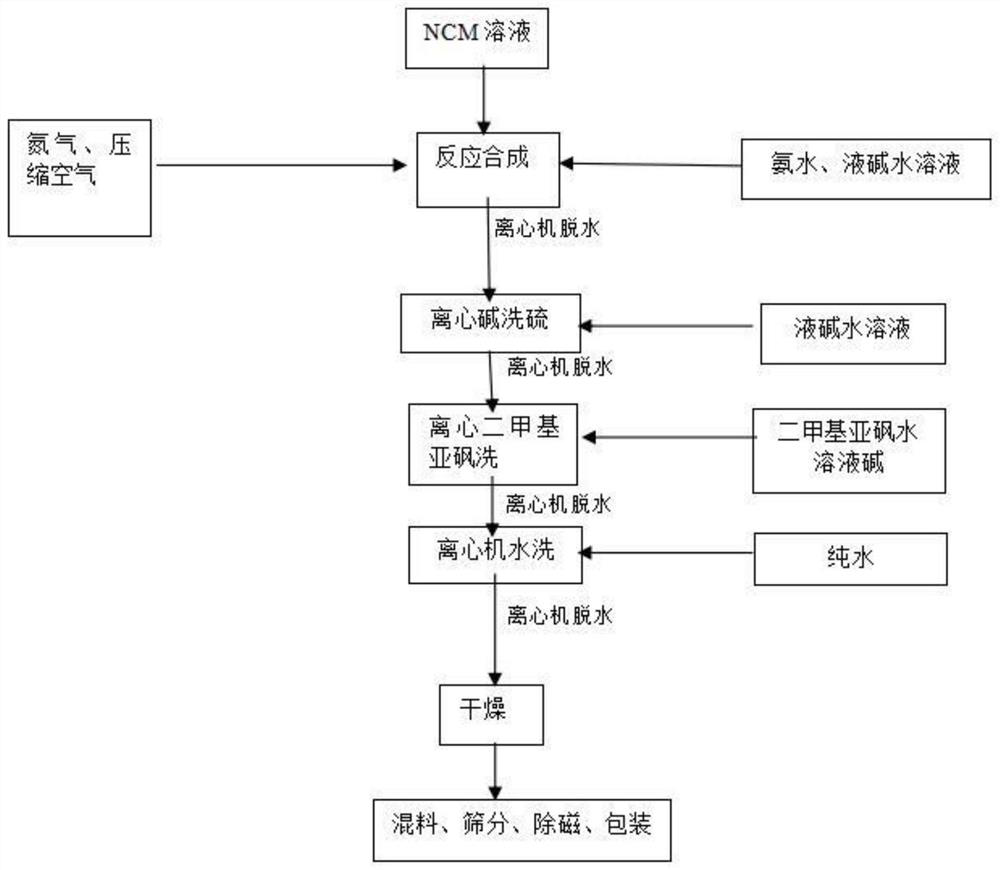

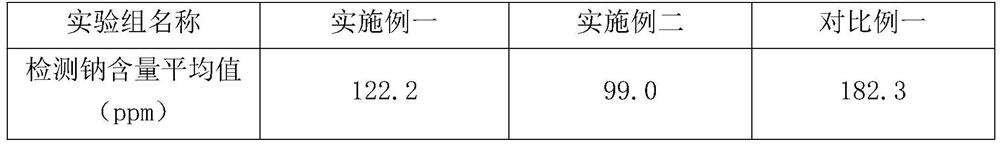

Method for washing nickel-cobalt-manganese ternary precursor to remove impurity sodium

PendingCN114388776AReduce sodium ion contentFinal product manufactureCell electrodesSulfate radicalsManganese

The invention discloses a method for washing a nickel-cobalt-manganese ternary precursor to remove impurity sodium, which comprises the following steps: S1, carrying out solid-liquid separation on a solid-liquid mixture of a nickel-cobalt-manganese ternary precursor crude product to obtain a solid ternary precursor crude product; s2, washing the solid ternary precursor crude product by using a sodium hydroxide solution to remove sulfate ions on the surface, and then dehydrating to obtain a dehydrated solid-phase substance; s3, washing the dehydrated solid-phase substance by using a dimethyl sulfoxide aqueous solution, and then carrying out solid-liquid separation to obtain a solid material; and S4, washing the solid material with pure water, and dehydrating and drying to obtain a finished product. The method has the advantage that the sodium ion content of the nickel-cobalt-manganese ternary precursor can be remarkably reduced.

Owner:宜宾光原锂电材料有限公司 +1

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289BIncrease the areaHigh crystallinityCatalytic crackingMolecular sieve catalystsOrganic acidNitrogen

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

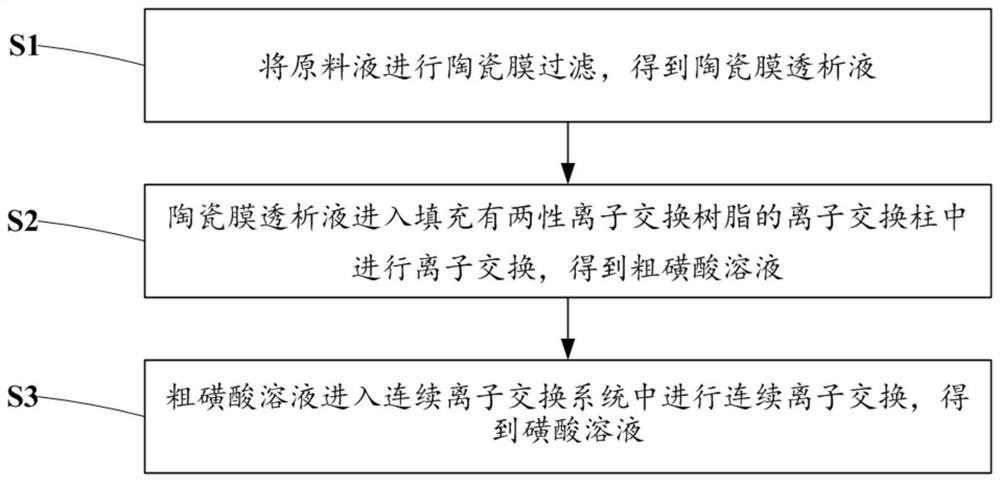

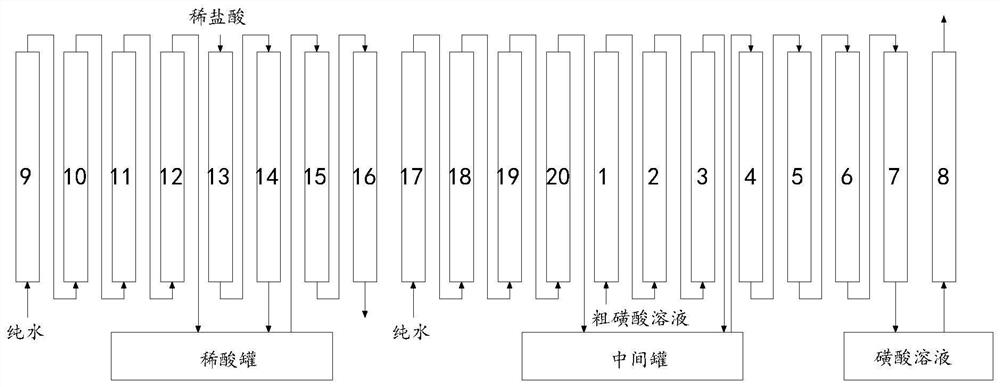

Purification production process of organic sulfonic acid

ActiveCN112174856AReduce pollutionReduce regeneration frequencyOrganic chemistryOrganic compound preparationOrganic sulfonic acidSulfonate

The invention discloses a purification production process of organic sulfonic acid, which comprises the following steps: carrying out ceramic membrane filtration on a raw material solution to obtain aceramic membrane dialysate; the ceramic membrane dialysate enters an ion exchange column filled with amphoteric ion exchange resin for ion exchange, and a crude sulfonic acid solution is obtained; the crude sulfonic acid solution enters a continuous ion exchange system for continuous ion exchange, and a sulfonic acid solution is obtained. According to the method, large-particle substances in theraw material liquid are removed through ceramic membrane filtration, so that the pollution and regeneration frequency of the resin are reduced, and the service life of the resin is prolonged; by adopting the amphoteric ion exchange resin, SO42 and other anions in the organic sulfonic acid can be removed, the content of the organic sulfonic acid is increased, meanwhile, the content of sodium ions is reduced, and the treatment effect of a subsequent continuous ion exchange system is improved; in addition, by means of continuous ion exchange in the mode of combining lower feeding and upper feeding, organic sodium sulfonate can be converted into organic sulfonic acid to the maximum extent, and the content of sodium ions is further reduced.

Owner:湖北吉和昌化工科技有限公司

Cyclohexane oxidation decomposition liquid refinement apparatus

InactiveCN107759453AReduce dosageReduce consumptionCarbonyl compound separation/purificationCyclohexanoneAlcohol

The invention discloses a refining device for cyclohexane oxidative decomposition liquid, which comprises a feed mixer, a saponification tower, a separator, a washing tower, a pretreatment tower, and a reflux tank which are sequentially connected through pipelines; the device also includes a lye mixer , the circulating pump is connected to the separator and the lye mixer respectively through pipelines; the washing water pump is connected to the washing tower and the lye mixer respectively through pipelines. The invention can be applied to the refining and pretreatment process of decomposition liquid in the production of cyclohexanone, reduces by-products, refines and concentrates crude alcohol and ketone, reduces the raw material consumption of the device, and can save energy and protect the environment.

Owner:HUBEI SANNING CHEM

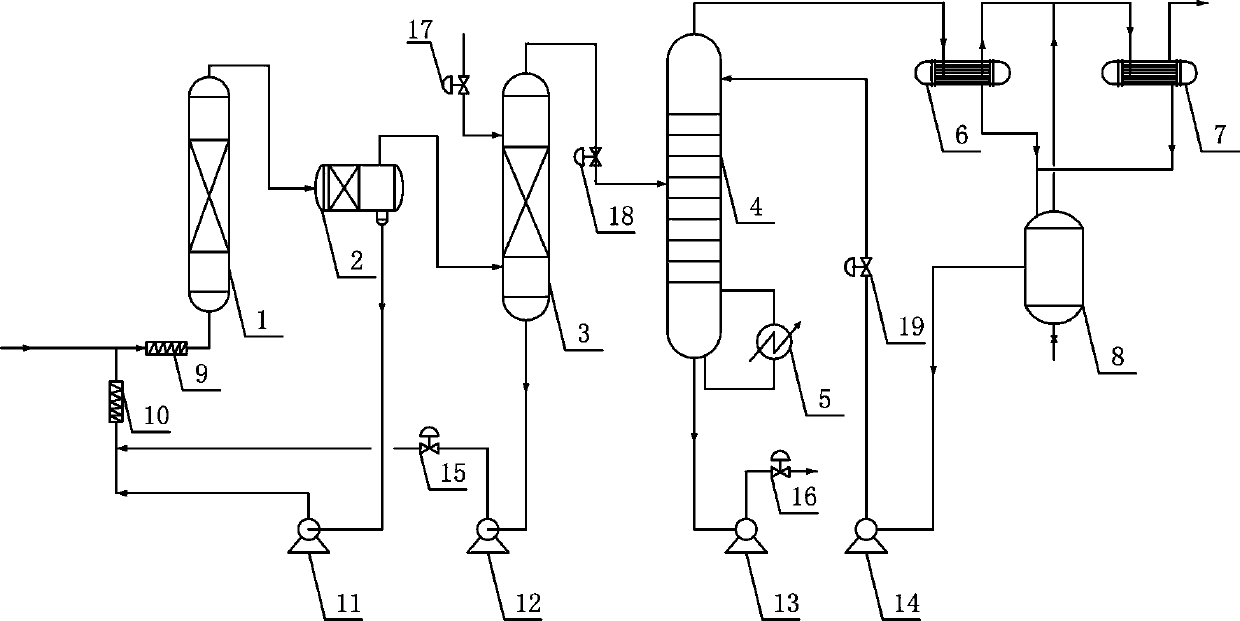

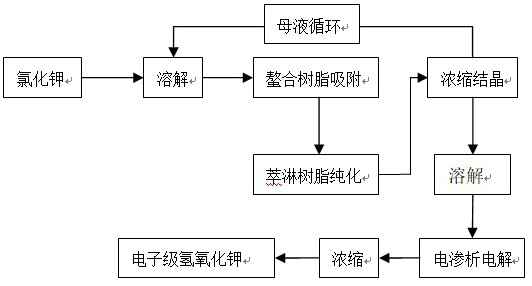

Preparation process of electronic-grade potassium hydroxide

PendingCN113443639AStrong combinationHigh selectivityAlkali metal oxides/hydroxidesAlkali metal halide purificationChloride potassiumChemistry

The invention relates to a preparation process of electronic-grade potassium hydroxide, which comprises the following successive and continuous steps: sequentially passing a potassium chloride aqueous solution through a first chelating resin and a second chelating resin at a constant flow rate for adsorption to obtain a potassium chloride high-purity solution, then conducting concentrating to obtain potassium chloride crystals, adding pure water into the potassium chloride crystals for dissolving, after dissolving, conducting treating by a bipolar membrane electrodialysis system to obtain a low-concentration potassium hydroxide solution, and finally conducting heating and concentrating to obtain the electronic-grade potassium hydroxide. According to the preparation process of the electronic-grade potassium hydroxide, metal cations Fe<2+>, Ca<2+>, Mg<2+>, Ni<2+> and Zn<2+> are less than or equal to 100ppb, Na<+> is less than or equal to 50ppm, the preparation process is simple and easy to operate, and the high-concentration and high-purity electronic-grade potassium hydroxide can be continuously produced on a large scale.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

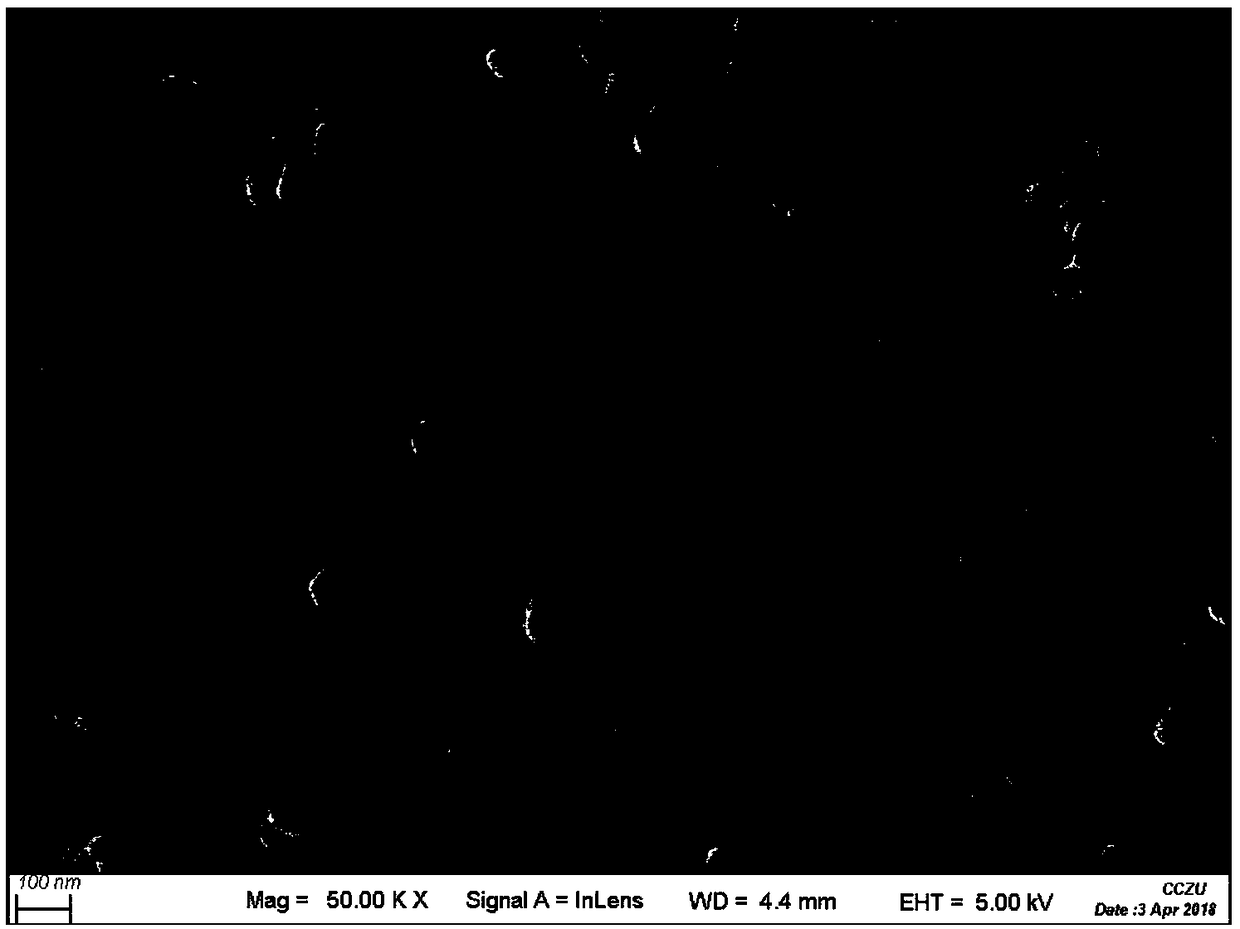

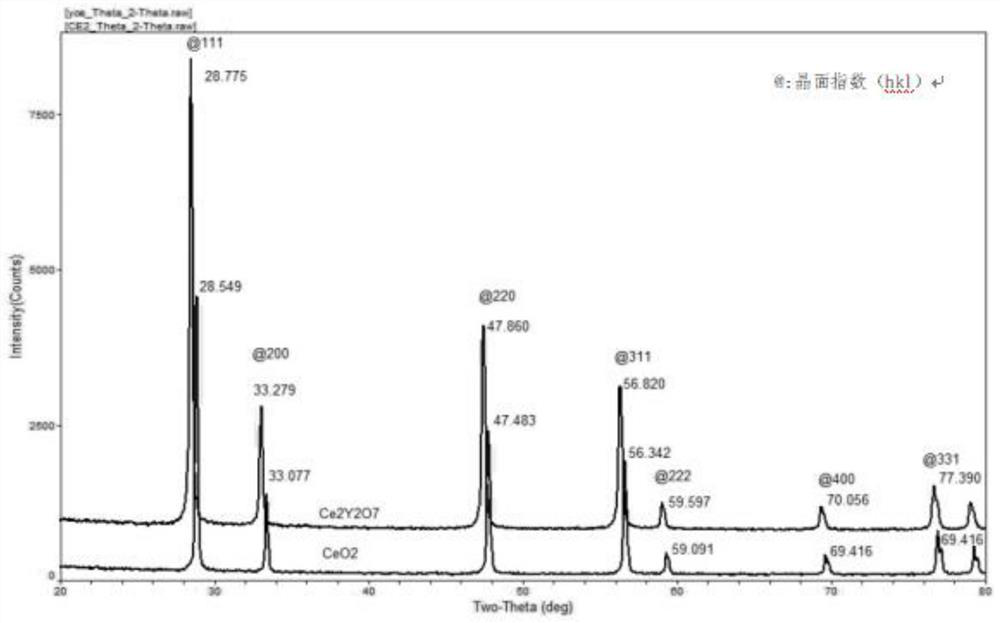

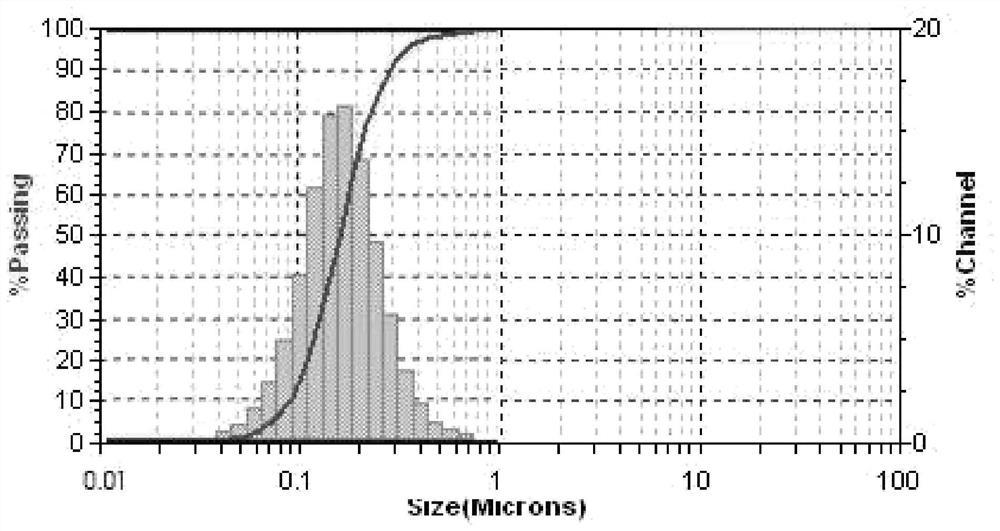

Cerium-yttrium abrasive material for CMP and preparation method thereof

PendingCN112062146AHigh purityReduce sodium ion contentRare earth metal compounds preparation/treatmentYittrium oxides/hydroxidesCeriumSlurry

The invention discloses a cerium-yttrium abrasive material for CMP (chemical mechanical polishing) and a preparation method thereof. The preparation method includes the steps that soluble salt of cerium and soluble salt of yttrium are dissolved respectively and mixed to obtain a yttrium-cerium mixed solution, and yttrium cerium hydroxide is prepared through a homogeneous coprecipitation method; and low-valence cerium in yttrium cerium hydroxide is oxidizedinto high-valence cerium, reactants are filtered, a filter cake is put into a high-pressure reaction kettle, and hydrothermal reaction is carried out to obtain an oxide of cerium and yttrium serving as the cerium-yttrium abrasive material. The cerium-yttrium polishing slurry prepared through the method is high in purity, good in dispersity, uniform in particle and high in grinding efficiency, and the content of metal sodium ions is smaller than 0.5 ppm.

Owner:BAOTOU TIANJIAO SEIMI POLISHING POWDER CO LTD

Mushroom and duck soup with low sodium salt content and industrial preparation method thereof

ActiveCN105614803ARealize online monitoringEasy extractionFood ingredient as taste affecting agentFood ultrasonic treatmentHealthy dietPotassium

The invention discloses mushroom and duck soup with low sodium salt content and an industrial preparation method thereof. According to the method, the mushroom and duck soup is obtained by treating soup-stock, a Jingzhou local shelduck and mushrooms respectively, and then carrying out compounding and mixing treatment on the soup-stock, a duck meat loaf, the mushrooms, NaCl, KCl, pepper and I+G (Disodiuminosine 5'-monophosphate and Disodiumguanosine 5'-monophosphate), and carrying out packaging and high-temperature and high-pressure sterilization on an obtained mixture. The content of sodium in every working procedure is detected by using a sodium ion meter; the on-line monitoring on a sodium ion is realized; the sodium salt content is enabled to meet a requirement set for a product; the problem that the content of the sodium ion in a raw material at different production origins and in different batches is different is solved; the range of the content of the sodium ion from the raw material and an auxiliary material to a final finished product process is enabled to be precise and controllable. A prepared duck soup product has distinct characteristics in flavor and taste, is rich in nutrient, low in sodium element content and high in potassium element content, and meets the demands of a modern person on healthy diet.

Owner:WUHAN POLYTECHNIC UNIVERSITY

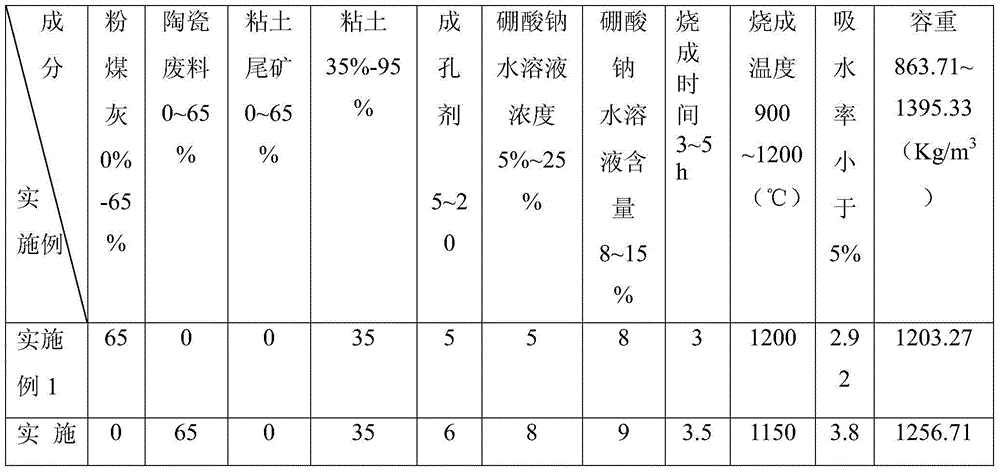

Light ceramsite co-sintered on surface by virtue of sodium borate and preparation method of light ceramsite

The invention relates to light ceramsite co-sintered on the surface by virtue of sodium borate and a preparation method of the light ceramsite. The preparation method of the light ceramsite co-sintered on the surface by virtue of sodium borate comprises the following steps: spraying a 5-25% sodium borate solution in steps, drying and sintering, wherein during drying, sodium ions dissolved in water diffuse toward the surface along with moisture and are enriched on a shell of the surface of each raw nodule; and during sintering, reaction is carried out on the sodium ions in the surface layer and other substances to form fusible substances, an effect of a sintering aid is realized, content of sodium ions in the sintering aid below the surface layer of each raw nodule is low, the ceramsite sintered on the surface layer at a sintering temperature is relatively low in water absorption rate while density of an unsintered core region below the surface layer is relatively low, and finally the light ceramsite with low water absorption rate and low overall density is obtained. The preparation method of the light ceramsite co-sintered on the surface by virtue of sodium borate has the advantages that the problems that the water absorption rate of the ceramsite is low, strength is high and volume weight is low are solved; meanwhile, a technology is simple, operation is safe, mass production can be realized, and cost is low.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com