Preparation process of electronic-grade potassium hydroxide

A potassium hydroxide and preparation technology, applied in the direction of alkali metal oxides/hydroxides, inorganic chemistry, alkali metal compounds, etc., can solve the problems of unfavorable purification, low energy efficiency, slow production efficiency, etc., to improve the adsorption range, Improved adsorption capacity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

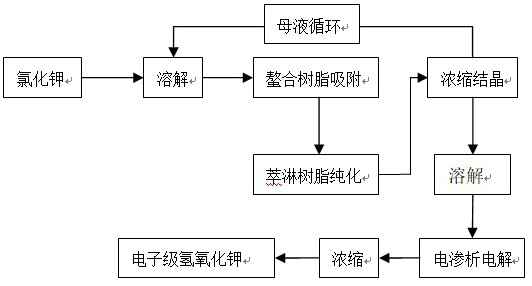

Image

Examples

Embodiment 1

[0029] A preparation process for electronic grade potassium hydroxide, comprising the following steps carried out successively and continuously:

[0030] (1) Dissolve food-grade potassium chloride to form a 300g / L aqueous solution (60°C), and then pass through the adsorption tower filled with aminocarboxylic acid chelating resin, and then the adsorption tower filled with iminodiacetic acid chelating resin (D751) Absorption tower adsorption, adsorption tower flow rate 15m 3 / h, the replacement time is 0.5h, and then purified by P507 extraction resin, the purification time is 0.5h, to obtain a high-purity potassium chloride solution.

[0031] (2) Concentrate and crystallize high-purity potassium chloride solution at 110°C to obtain potassium chloride crystals.

[0032] (3) Dissolve potassium chloride crystals in high-purity water to prepare a 300g / L potassium chloride solution, which is electrolyzed by a bipolar membrane electrodialysis system composed of a bipolar membrane and...

Embodiment 2

[0036] A preparation process for electronic grade potassium hydroxide, comprising the following steps carried out successively and continuously:

[0037] (1) Dissolve food-grade potassium chloride to form a 350g / L aqueous solution (70°C), and then pass through the adsorption tower filled with aminocarboxylic acid chelating resin, and then filled with fluorinated modified iminodiacetic acid chelating The adsorption tower of the resin is adsorbed, and the flow rate of the adsorption tower is 15m 3 / h, the replacement time is 0.5h, and then purified by P507 extraction resin, the purification time is 0.5h, to obtain a high-purity potassium chloride solution.

[0038] (2) Concentrate and crystallize high-purity potassium chloride solution at 110°C to obtain potassium chloride crystals.

[0039] (3) Dissolve potassium chloride crystals in high-purity water to prepare a 300g / L potassium chloride solution, which is electrolyzed by a bipolar membrane electrodialysis system to obtain a...

Embodiment 3

[0043] A preparation process for electronic grade potassium hydroxide, comprising the following steps carried out successively and continuously:

[0044] (1) Dissolve food-grade potassium chloride to form a 350g / L aqueous solution (65°C), and then pass through the adsorption tower filled with aminocarboxylic acid chelating resin, and then filled with fluorinated modified iminodiacetic acid chelating The adsorption tower of the resin is adsorbed, and the flow rate of the adsorption tower is 15m 3 / h, the replacement time is 0.5h, and then purified by P507 extraction resin, the purification time is 0.5h, to obtain a high-purity potassium chloride solution.

[0045] (2) The absorbed potassium chloride solution was concentrated and crystallized at 110°C to obtain potassium chloride crystals.

[0046] (3) Dissolve potassium chloride crystals in high-purity water to prepare a 400g / L potassium chloride solution, which is electrolyzed by a bipolar membrane electrodialysis system to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com