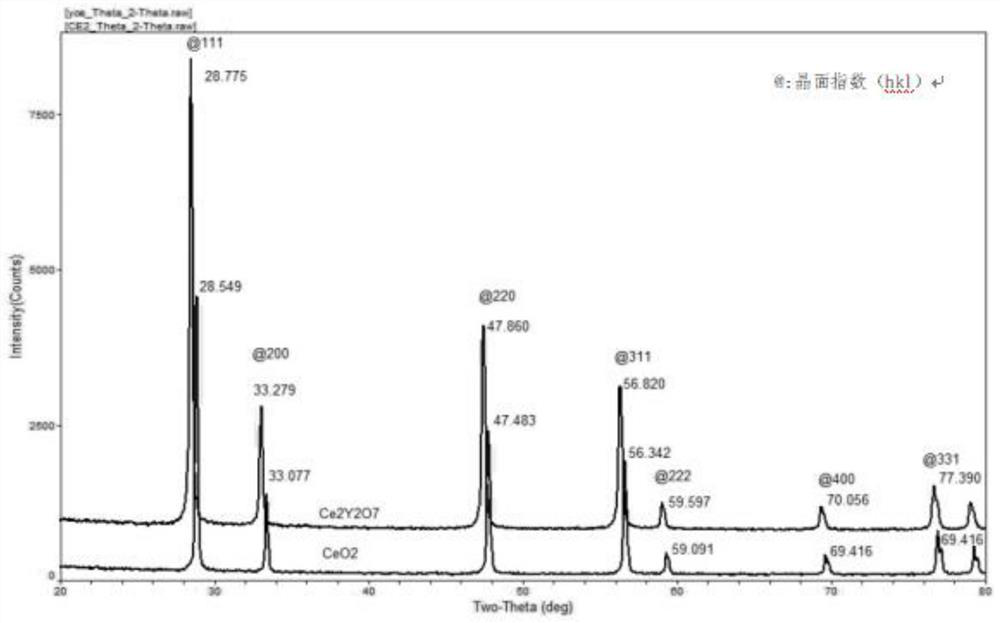

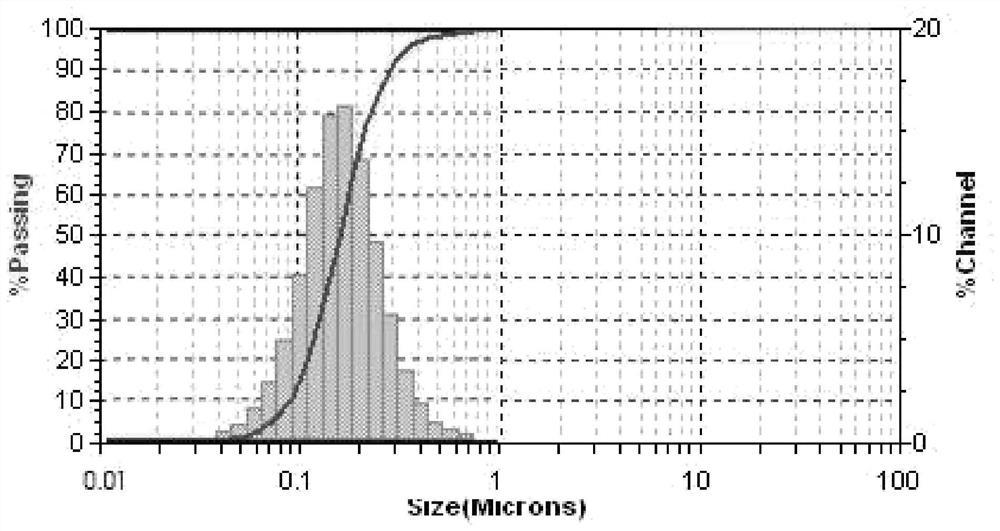

Cerium-yttrium abrasive material for CMP and preparation method thereof

A grinding material, cerium yttrium technology, applied in the field of preparation of cerium oxide grinding material, to achieve the effect of high grinding efficiency, good dispersion and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of cerium yttrium grinding material for CMP, concrete steps are as follows:

[0034] Step 1: dissolving the soluble salts of cerium and yttrium respectively, and mixing them to obtain a mixed solution of cerium and yttrium, and adopting a homogeneous co-precipitation method to obtain cerium and yttrium hydroxide;

[0035] In this preferred embodiment, nitrates of cerium and yttrium are selected for use. Soluble salts are selected from nitrates, chlorides, sulfates, acetates, and citrates. The precipitating agent is selected: urea or ammonia water, or a combination of the two.

[0036] The homogeneous co-precipitation method adopts the following two methods, as follows:

[0037] (1), the cerium nitrate (Y 2 o 3 / TREO (total rare earth oxides) ≥ 99.999%), yttrium nitrate (CeO 2 / TREO (total amount of rare earth oxides) ≥ 99.99%) are dissolved respectively, and the molar ratio of the two solutions is Y 2 o 3 : CeO 2 =0.5~1:5.9~7 set ratio mix...

Embodiment 1

[0056] Configure REO=100g / L solution Y (NO 3 ) 3 , Ce(NO 3 ) 3 solution, (Y 2 o 3 / TREO=99.999%, CeO 2 / TREO=99.98%). Take 4000ml Ce(NO 3 ) 3 solution, adding ammonia water (6%, wt%) to adjust the pH=3 of the solution. Mole ratio is Y 2 o 3 : CeO 2 =1:5.9 ratio will 42mlY(NO 3 ) 3 Added to Ce(NO 3 ) 3 In the solution, the mixed liquid is recorded as liquid α (yttrium cerium mixed nitric acid solution).

[0057] In a constant temperature water bath at 80°C, add 450g of urea into a beaker filled with 5000ml of deionized water, add 8g of polyethylene glycol (PEG-400), and 5g of ammonium polyacrylate, which is the precipitant β.

[0058] Drop the precipitant β into the liquid α at a rate of 50ml / min, and filter the precipitate after the reaction is completed.

[0059] Add 2000ml of deionized water to the precipitate for washing, add 200ml of ammonia water (5mol / L), add 170g of H 2 o 2 Solution (30%, wt%) oxidizes low-valent cerium in cerium hydroxide yttrium to ...

Embodiment 2

[0061] The raw materials used are the same as in Example 1.

[0062] Add 12g of polyethylene glycol (PEG-400) and heat to 50°C. Prepare 2000ml of 10% ammonia solution, and drop the ammonia solution into the raw material solution while stirring at a constant temperature. Cool to 20°C, add 170g H 2 o 2 Solution (30%, wt%) oxidizes low-valent cerium in cerium hydroxide yttrium to high-valent cerium, stirs for 20 minutes, heats to 95° C. and boils for 30 minutes. Filter and wash twice with 2000ml deionized water. Suction filtration, put the filter cake into a high-pressure reactor, pressurize hydrothermal reaction with 150Kg pressure for 6 hours, and obtain the oxides of cerium and yttrium as products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com