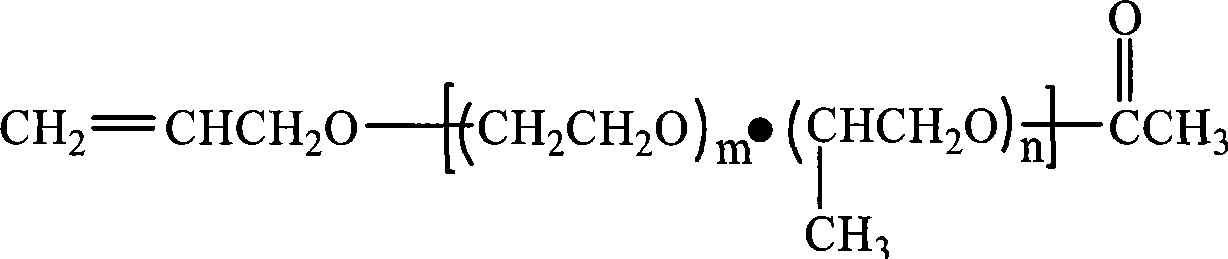

Preparation of acetyl end capping allyl alcohol polyether

A technology of allyl alcohol polyether and terminal allyl alcohol, which is applied in the field of preparation of acetyl-terminated allyl alcohol polyether, and achieves the effects of high end capping rate, simple operation and reasonable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

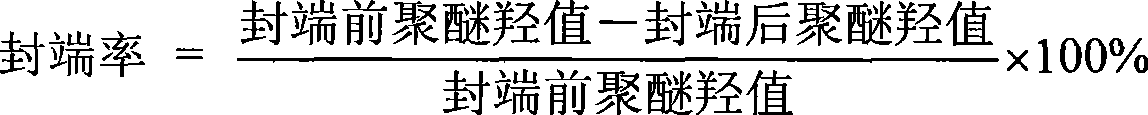

Embodiment 1

[0016] Example 1: Add 1600 parts of allyl alcohol atactic polyether (M=5000) and 82 parts of acetic anhydride into the reactor, connect it to a condensing reflux device, raise the temperature to 130-140° C., and reflux for 2.5 hours. Connect to the distillation device, adjust the amount of nitrogen gas to make the vacuum degree be -0.080~-0.085MPa, and deacidify by bubbling for 2.5 hours. Cool down to 70°C, add 50 parts of water, stir for 40 minutes, vacuumize for 0.8 hours at a temperature of 90°C, and a vacuum degree of -0.070 to -0.090 MPa, then transfer to a falling film evaporator, at a temperature of 100 to 120 Deacidification for 1.5 hours under the condition of ℃ and vacuum degree ≤100Pa, and then purified and adsorbed by polyether to obtain acetyl-capped allyl alcohol random polyether, the capping rate is 96%, the content of acetic acid is 45ppm, and the content of acetic anhydride is 0ppm .

Embodiment 2

[0017] Example 2: Add 1600 parts of allyl alcohol atactic polyether (M=7000) and 68 parts of acetic anhydride to the reactor, connect it to a condensing reflux device, raise the temperature to 130-140° C., and reflux for 2.5 hours. Connect to the distillation device, adjust the amount of nitrogen gas to make the vacuum degree be -0.085~-0.090MPa, and deacidify by bubbling for 3.0 hours. Cool down to 70°C, add 65 parts of water, stir for 40 minutes, vacuumize for 1.0 hour at a temperature of 90°C, and a vacuum degree of -0.070 to -0.090 MPa, then transfer to a falling film evaporator, and at a temperature of 110 to 130 Deacidification for 2.0 hours under the condition of ℃ and vacuum degree ≤100Pa, and then refined and adsorbed by polyether to obtain acetyl-capped allyl alcohol random polyether, the capping rate is 95%, the content of acetic acid is 72ppm, and the content of acetic anhydride is 0ppm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com