Printing method of different patterns of double surfaces of warp knitting plush single-layer blanket

A printing method and plush technology, applied in warp knitting, dyeing, fabric surface trimming, etc., can solve the problems of undying, unclear, and lack of high-grade feeling of the fiber wool, so as to achieve a neat and elastic suede and a woolen texture. Bright glossy, smooth and plump feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, a kind of printing method of warp-knitted plush single-layer blanket with different patterns on both sides, its steps are as follows:

[0038] (1) Raw material selection

[0039] The face yarn is made of polyester low-stretch yarn, and the fineness / composite number is 300D / 144F; the chain yarn and weft insertion yarn used for the weaving base fabric are made of polyester full-drawn yarn, and the fineness / composite number is 150D / 36F;

[0040] (2) Weaving and cutting

[0041] Weaving: using a double-needle bed warp knitting machine with a gauge of 16-42mm to weave the gray cloth, the face thread threading method of the gray cloth is full wear, and the base cloth of the gray cloth adopts the method of four-needle weft insertion and knitting chain; the vertical and horizontal dimensions of the gray cloth are obtained like this The direction extensibility is relatively small in the warp knitted fabric, which is beneficial to the subsequent processing and can al...

Embodiment 2

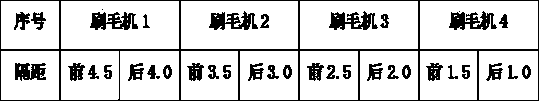

[0062] Embodiment 2, in the printing method of the warp-knitted plush single-layer blanket described in Embodiment 1 with different patterns on both sides, in the step of high-speed brushing before the white gray cloth: the rotating speed of the large cylinder of the 24-roller high-speed brushing machine is 78 rpm / min, the bristle speed is 10m / min, and the cloth tension 1 is 1.086N / m 3 , Tension 2 is 1.087N / m 3 , tension 3 is 1.0882N / m 3 , the cloth tension is 2.048N / m 3 , The rotating speed of the brush roller is 300 rpm.

Embodiment 3

[0063] Embodiment 3, in the printing method of the warp-knitted plush single-layer blanket described in Embodiment 1 with different patterns on both sides, in the step of roughening the reverse side of the gray cloth before the white gray cloth: the speed of the wire raising machine is 8m / min, and Cloth tension is 1.07N / m 3 , the fluffing tension is 1.2N / m 3 , the cloth tension is 1.07N / m 3 , the rotating speed of the cylinder is 80 revs / min, the rotating speed of the clockwise raising roller is 80 revs / min, and the rotating speed of the anti-knit raising roller is 20 revs / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com