Fuel oil catalysis system with catalytic converter and assembling method thereof

A catalytic system and catalytic converter technology, which is applied in the field of fuel catalytic converters, can solve the problems of large influence of ambient temperature and catalytic effect, and achieve the effect of high safety factor and stable oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

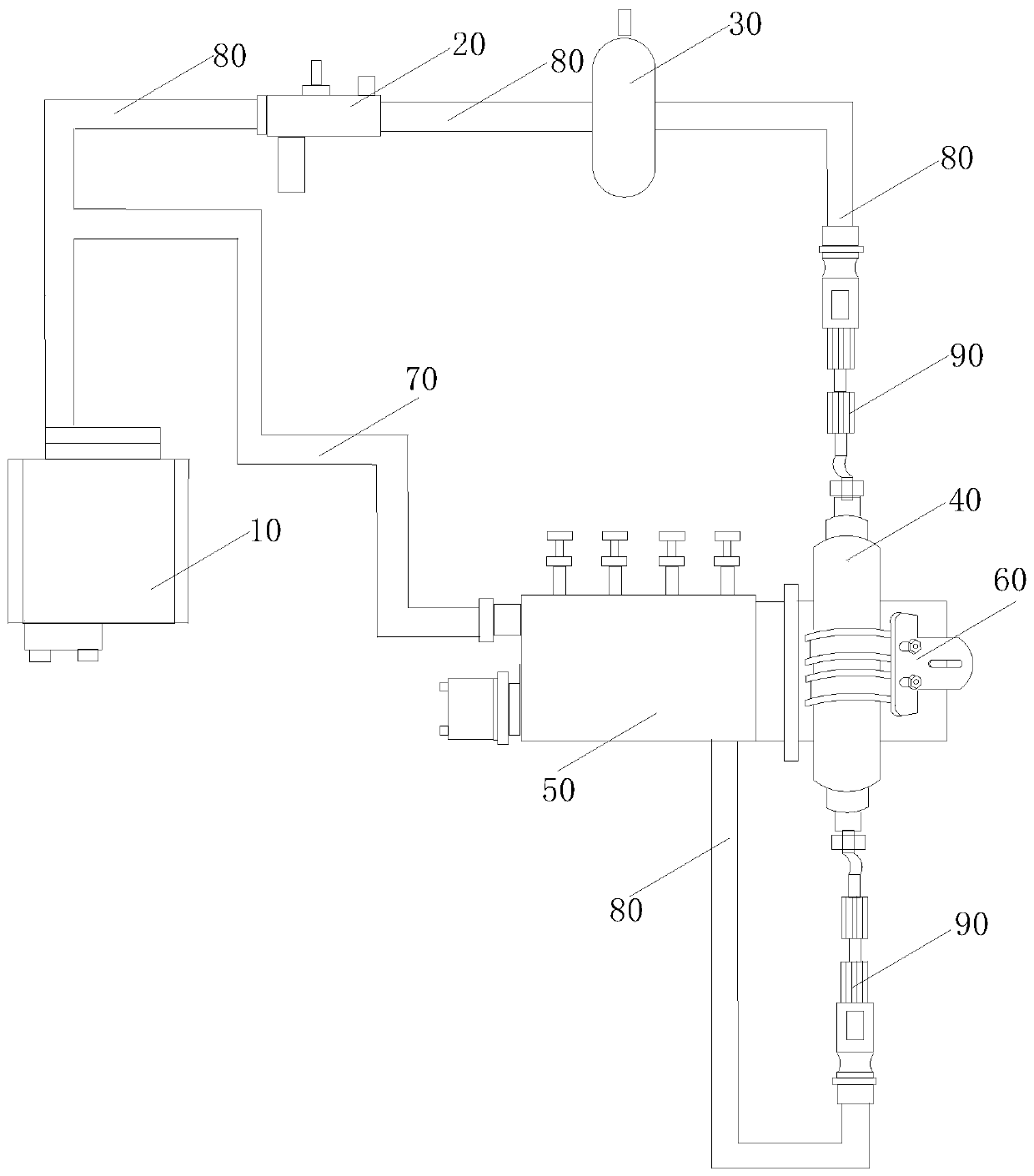

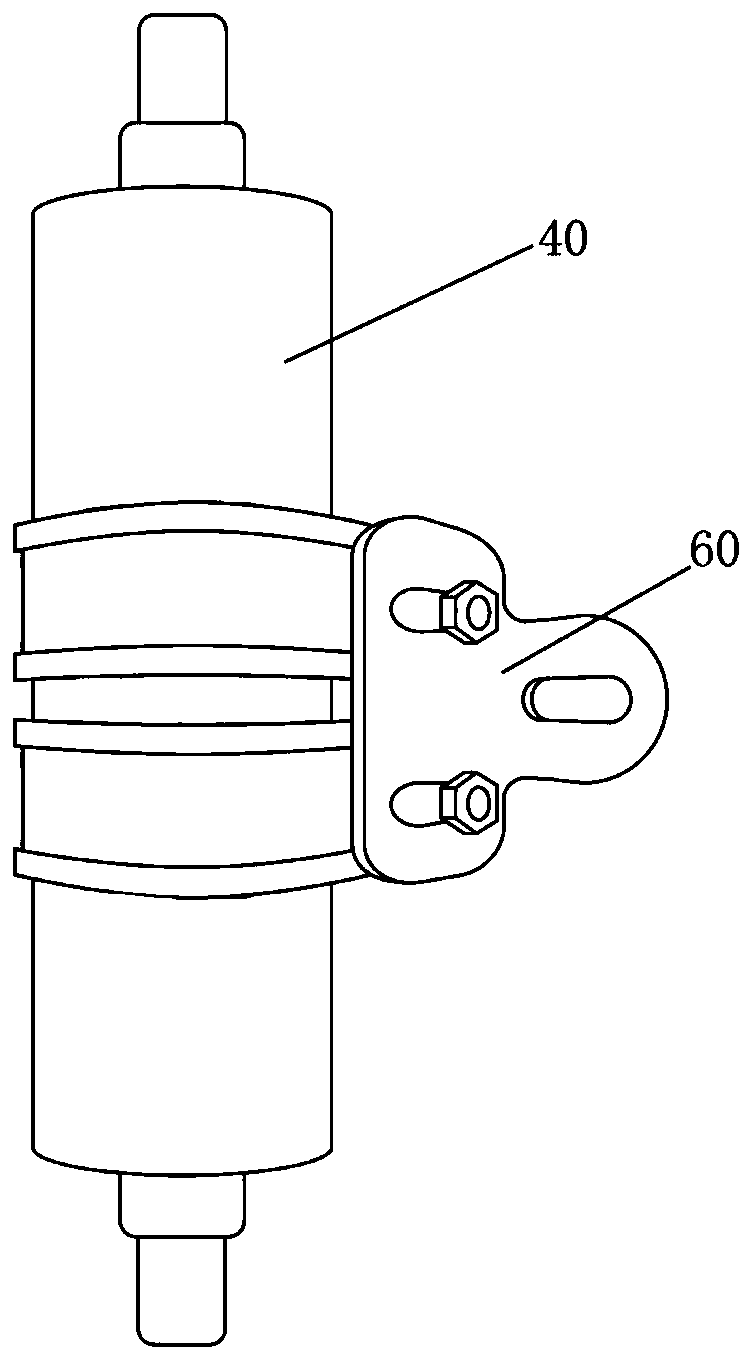

[0022] In this example, refer to figure 1 and figure 2 , a fuel catalytic system with a catalytic converter, including a fuel tank 10 and an engine 50, the fuel tank 10 is connected to the engine 50 through a fuel pipe 80, the oil pipe 80 is equipped with a fuel cut-off port 90, and the fuel cut-off ports 90 are connected There is a fuel catalyst 40, wherein the fuel catalyst 40 is fixedly installed on the engine 50. When the engine 50 starts, the vibration of the engine 50 drives the fuel catalyst 40 to vibrate, so that the oil molecules in the fuel catalyst 40 It is catalyzed into a single oil molecule, which is easy to fully burn; the fuel catalyst 40 is fixedly installed on the engine 50 through a fastening bracket 60. During installation, the fastening bracket 60 is sleeved on the surface of the fuel Screw adjustment is fixed.

[0023] The described fuel catalytic system with catalytic converter also includes a filter 30, the filter 30 is arranged between the fuel tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com