No-peculiar-smell alcohol-soluble modified acrylate resin and preparation method thereof

A technology of acrylate and hydroxyalkyl acrylate, which is applied in the field of polymer chemistry and can solve the problems that the odor of resin products cannot be eliminated, and the odor cannot be eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

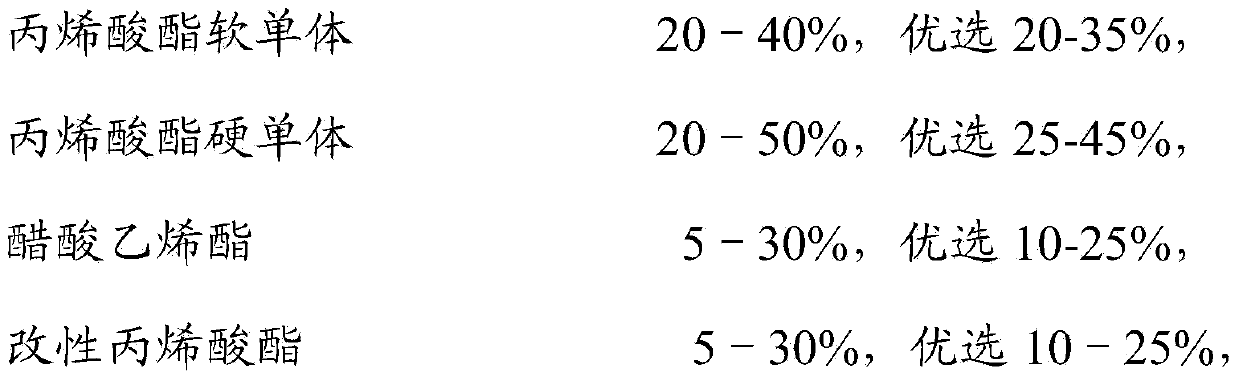

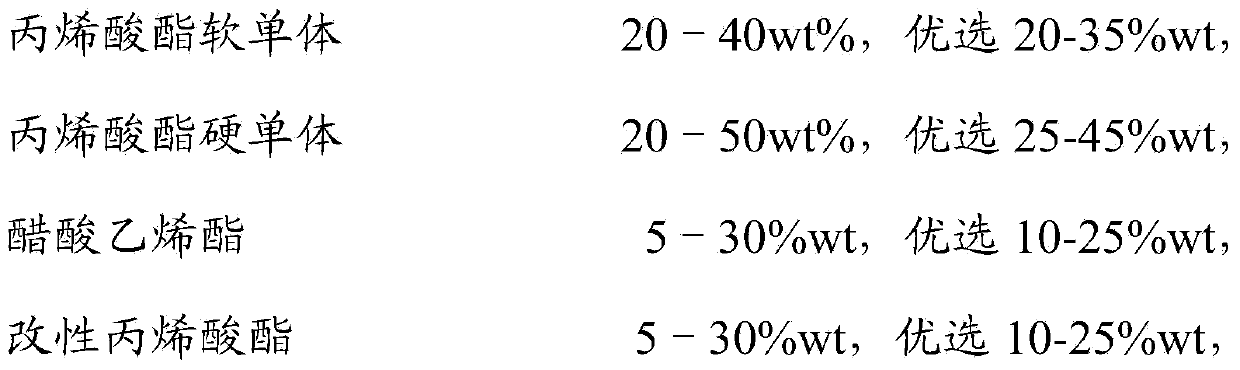

Method used

Image

Examples

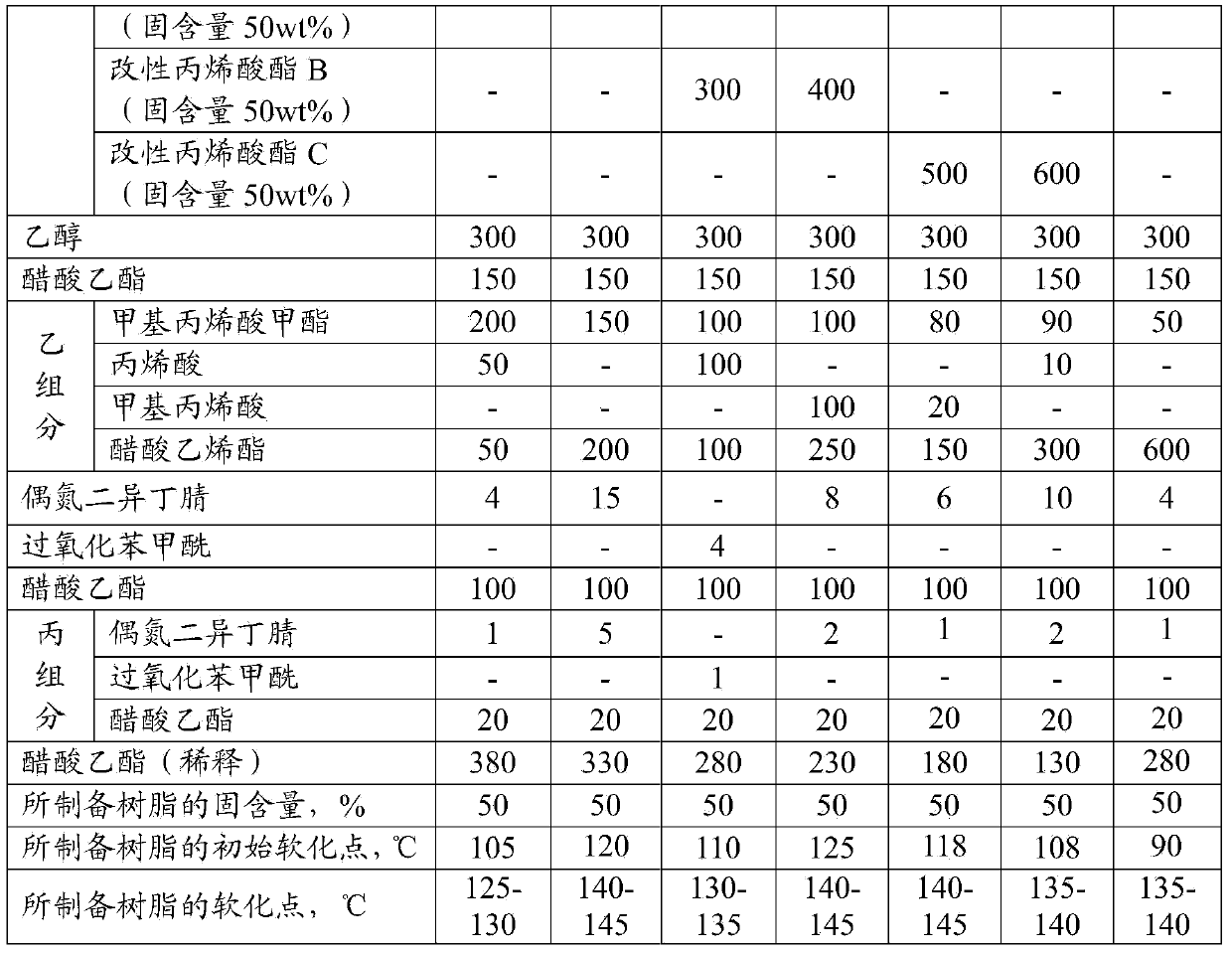

Embodiment 1

[0095] Embodiment 1 Preparation of modified acrylate A

[0096] The first step: Weigh 280 grams (0.4mol hydroxyl) of polyketone resin with a hydroxyl value of 80mgKOH / g, 111.2 grams (1mol NCO) of isophorone diisocyanate (IPDI), 70 grams (0.6mol hydroxyl) of hydroxyethyl acrylate ).

[0097]The second step: add isophorone diisocyanate and 30 grams of ethyl acetate into the reactor equipped with a stirring device, a reflux condenser, a heating control temperature temperature control device and a dropping device, heat up to 40°C and keep it. Adding method: add a solution formed by dissolving hydroxyethyl acrylate, 0.1 g of dibutyltin dilaurate catalyst in 20 g of ethyl acetate into the reactor, and finish adding dropwise within 2 hours; after dropping, control the temperature of the material at 40-50 °C for 3 hours.

[0098] The third step: add 560g (0.4mol hydroxyl) solid content 50wt% polyketone resin solution I (the polyketone resin taken in the first step is dissolved in 28...

Embodiment 2

[0100] Embodiment 2 Preparation of modified acrylate B

[0101] The first step: Weigh 234 grams (0.5mol hydroxyl) of polyketone resin with a hydroxyl value of 120mgKOH / g, 111.2 grams (1mol NCO) of isophorone diisocyanate (IPDI), 65 grams (0.5mol hydroxyl) of hydroxypropyl acrylate ).

[0102] The second step: add isophorone diisocyanate and 30 grams of ethyl acetate into the reactor equipped with a stirring device, a reflux condenser, a heating control temperature and a dropping device, heat up to 70°C and keep it, and drop it Adding method Add the solution formed by dissolving hydroxypropyl acrylate and 0.2 g of dibutyltin dilaurate catalyst in 20 g of ethyl acetate into the reactor, and finish adding dropwise within 1.5 hours; after dropping, control the temperature of the material at 80-90 °C to continue the reaction for 1 hour.

[0103] The third step: add 468g (0.5mol hydroxyl group) polyketone resin solution II with a solid content of 50wt% to the material obtained in ...

Embodiment 3

[0105] Example 3 Preparation of modified acrylate C

[0106] The first step: Weigh 140 grams of polyketone resin (0.6mol hydroxyl group) with a hydroxyl value of 240mgKOH / g, 84.1 grams (1mol NCO) of 1,6-hexamethylene diisocyanate (HDI), and 52 grams of hydroxyethyl methacrylate (0.4 mol hydroxyl).

[0107] The second step: add 1,6-hexamethylene diisocyanate and 30 grams of ethyl acetate into a reactor equipped with a stirring device, a reflux condenser, a heating control temperature and a dropping device, heat up to 60°C and keep it, Add the solution formed by dissolving hydroxyethyl methacrylate and 0.1 gram of dibutyltin dilaurate catalyst in 20 grams of ethyl acetate to the reactor by dropwise addition, and finish the dropwise addition within 1 hour; control the temperature of the material after the dropwise addition The reaction was continued for 2 hours at 70-80°C.

[0108] The third step: add 280 grams (0.6mol hydroxyl group) polyketone resin solution III with a solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com