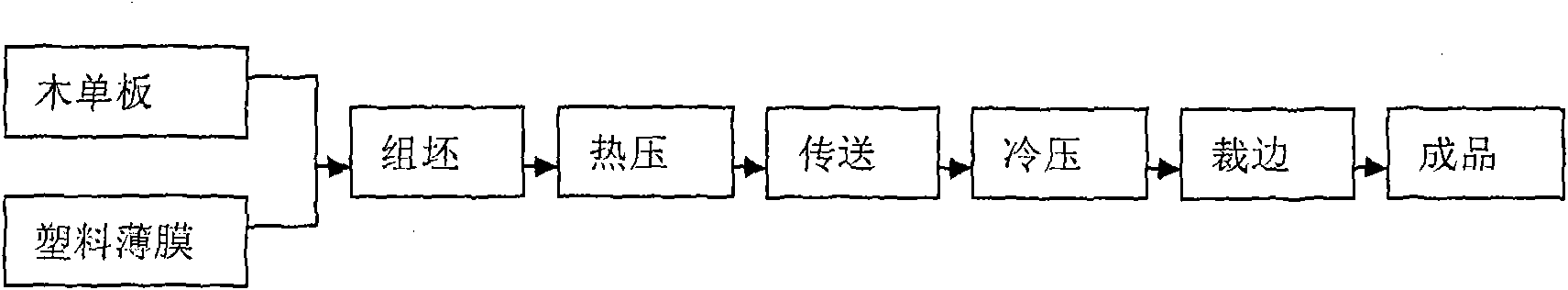

Manufacturing method of thermoplastic resin wood composite board and special equipment

A thermoplastic resin and manufacturing method technology, applied in the field of wood composite panels, can solve the problems of improper use of equipment, difficult to obtain products with gluing properties, etc., and achieve the effects of simple equipment, unique application value, and good waterproof and moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

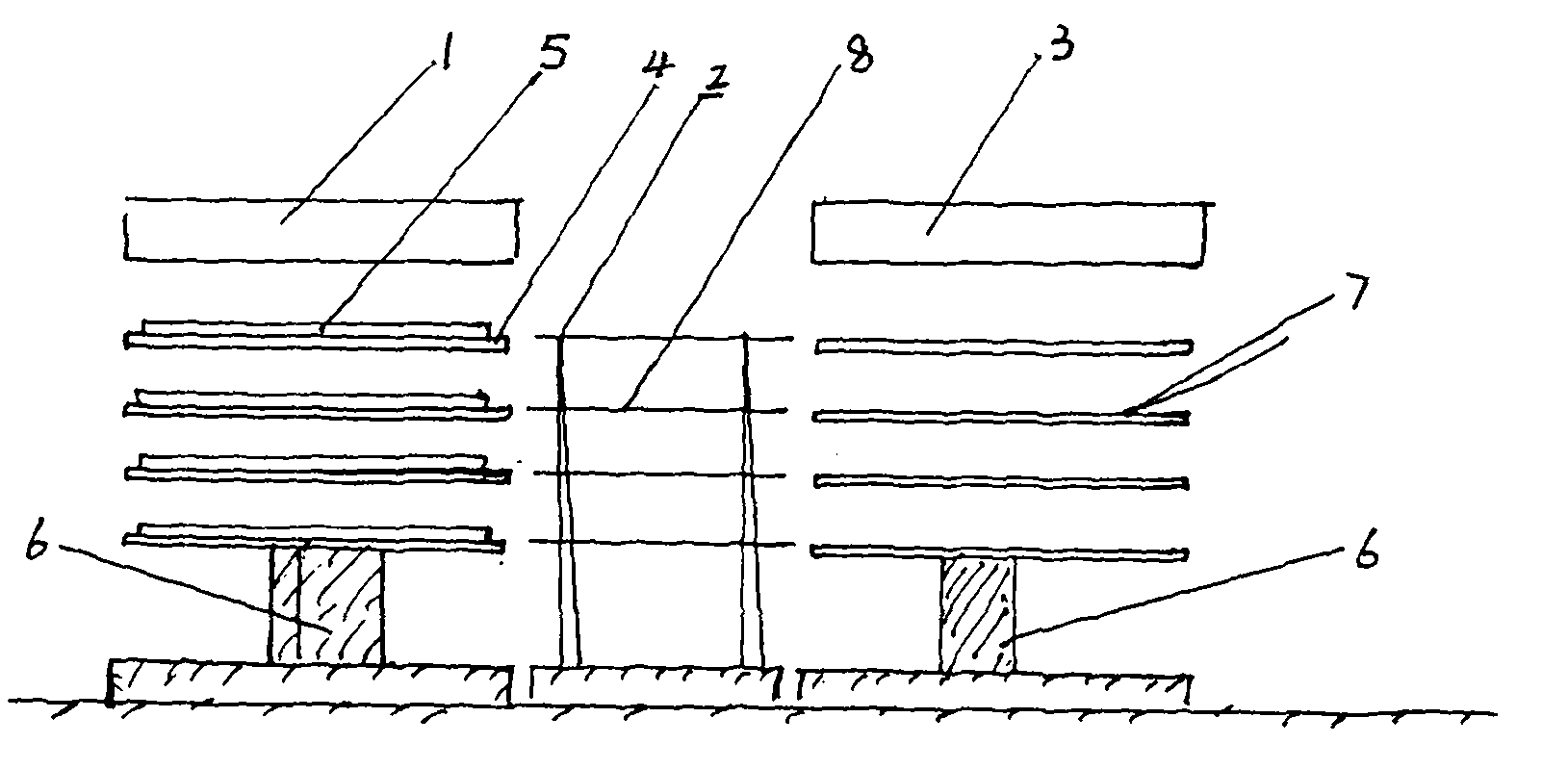

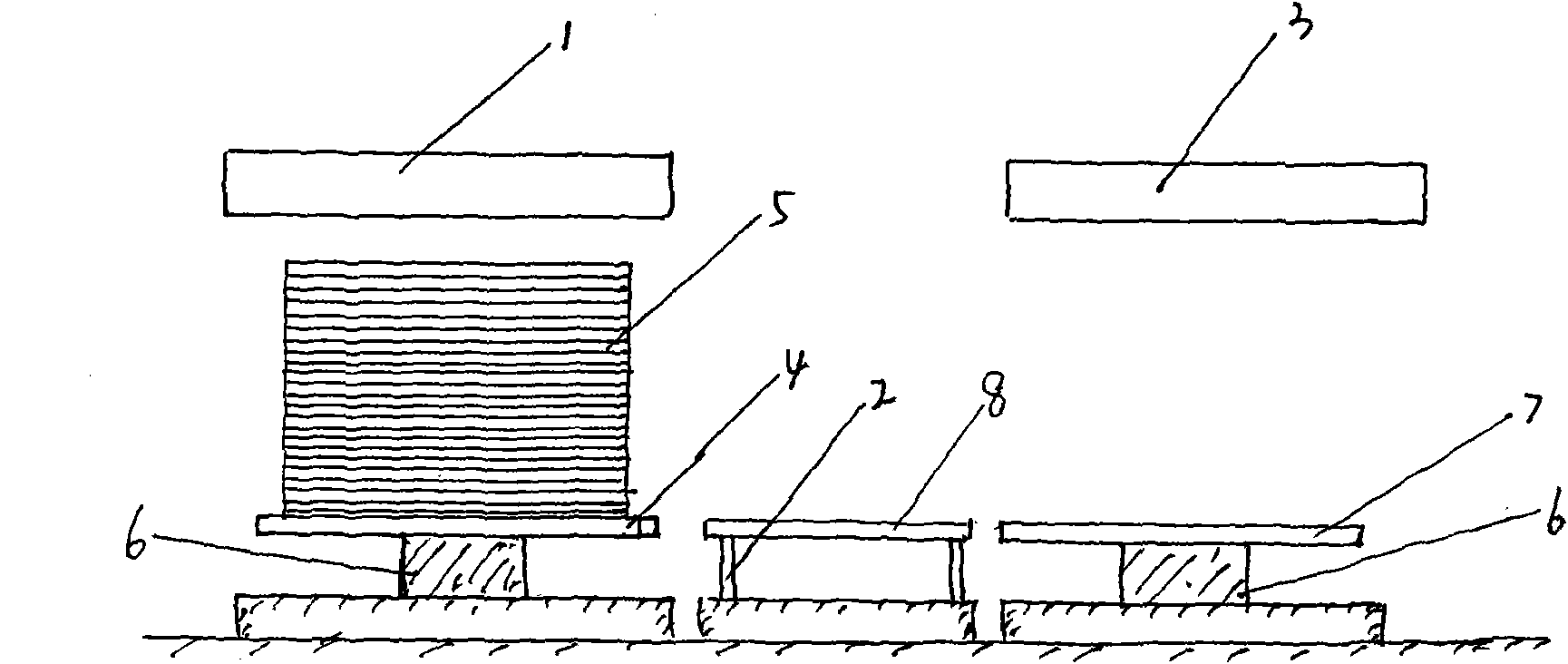

[0029] Embodiment 1: The manufacturing method of thermoplastic resin wood composite board comprises several layers of wooden rotary-cut veneer and plastic film, and plastic film is polyethylene new film, and veneer and plastic film are arranged alternately to form slab, and plastic film can be 1 in every layer Sheets, or several sheets can be stacked together to form a glue layer. The combined slabs are sent to a hot press for hot pressing, and then quickly sent to a cold press for cold pressing. The hot pressing temperature is greater than or equal to that of the wood composite board. Plastic film melting temperature, pressure 1-50kg / cm 2 , the hot pressing time is greater than or equal to the melting time of the plastic film in the wood composite board, and the cold pressing pressure is 1-50kg / cm 2 , The wooden composite slab is released from the hot press to the cold press for less than 2 minutes, and the molten thermoplastic resin is condensed and hardened by cold pressing...

Embodiment 2

[0030] Embodiment 2: other is the same as embodiment 1, but hot pressing temperature is 140-180 ℃.

Embodiment 3

[0031] Embodiment 3: Others are the same as in Embodiment 2, but the time for the wooden composite board to be pushed out from the hot press to the cold press is 1-60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com