Purification production process of organic sulfonic acid

A production process, the technology of organic sulfonic acid, applied in the field of purification production process of organic sulfonic acid, can solve the problem of low content of sulfonic acid, achieve the effect of reducing sodium ion content, reducing pollution and regeneration frequency, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

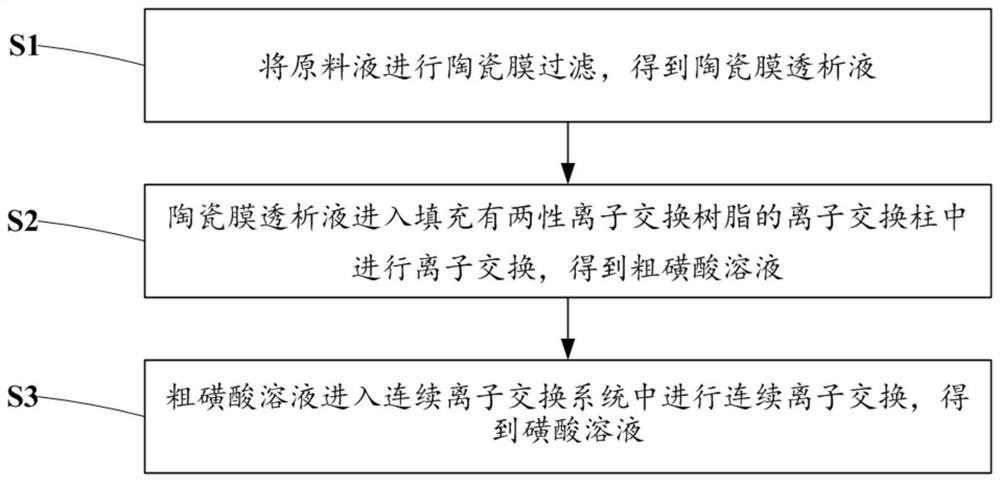

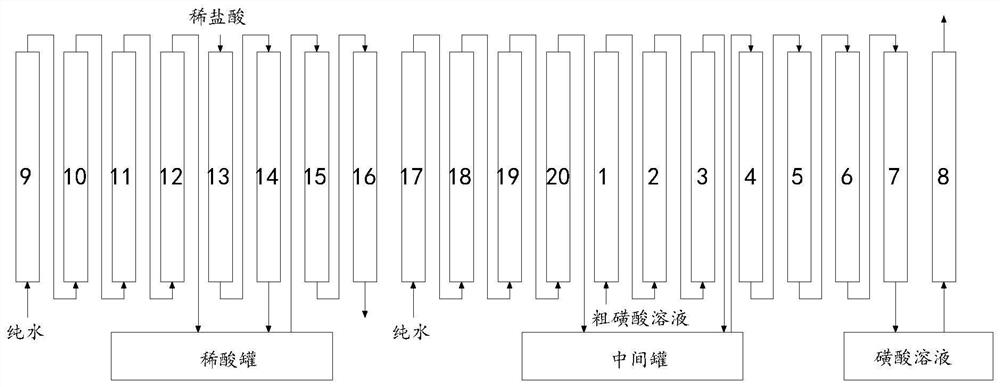

Method used

Image

Examples

Embodiment 1

[0032] The raw material solution is sodium propanesulfonate solution, the concentration of sodium propanesulfonate is 25%, and the concentration of sodium sulfate is 2.7%; the pore diameter of the ceramic membrane is 100nm.

Embodiment 2

[0034] The raw material solution is sodium propanesulfonate solution, the concentration of sodium propanesulfonate is 20%, and the concentration of sodium sulfate is 2.1%; the pore diameter of the ceramic membrane is 200nm.

Embodiment 3

[0036] The raw material solution is sodium propanesulfonate solution, the concentration of sodium propanesulfonate is 30%, and the concentration of sodium sulfate is 3%; the pore diameter of the ceramic membrane is 150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com