Method for mechanically and rapidly pickling low sodium salted eggs through pulsed pressure

A pulsating pressure, salted egg technology, applied in the field of food processing, can solve the problems of low degree of mechanization and long processing cycle, and achieve the effect of saving labor, ensuring quality and taste, and shortening pickling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for pickling low-sodium salted eggs quickly, comprising the following steps:

[0016] 1. Preparation of low-sodium marinade:

[0017] Weigh 2 kg of KCl and 6 kg of NaCl, add them into boiling water to make the mass fraction of KCl and NaCl reach 22-26%, stir to dissolve completely, and cool for later use.

[0018] 2. Duck eggs cleaning and tanking:

[0019] Salted eggs are marinated by soaking in salt water. Wash and dry the fresh duck eggs, put them into a cleaned and disinfected container, pour in the low-sodium pickling solution, fully submerge the duck eggs, cover the surface of the pickling solution with a plastic film and press it down with stones to prevent the duck eggs from floating up. The whole container is put into the pulse pressure pickling device.

[0020] The pulsating pressure pickling device is composed of a pressure generating device, a pressure control system and a pressure vessel. The pressure generating device pressurizes the pressure ...

Embodiment 2

[0026] Embodiment 2 The preferred low-sodium pickling solution

[0027] 1 Test method

[0028] 1.1 Pickling process

[0029] Fresh duck eggs→sensory inspection for damage→cleaning and disinfection→drying→put into pickling barrels→preparation of pickling solution→sampling inspection→finished product packaging

[0030] 1.2 Experimental design

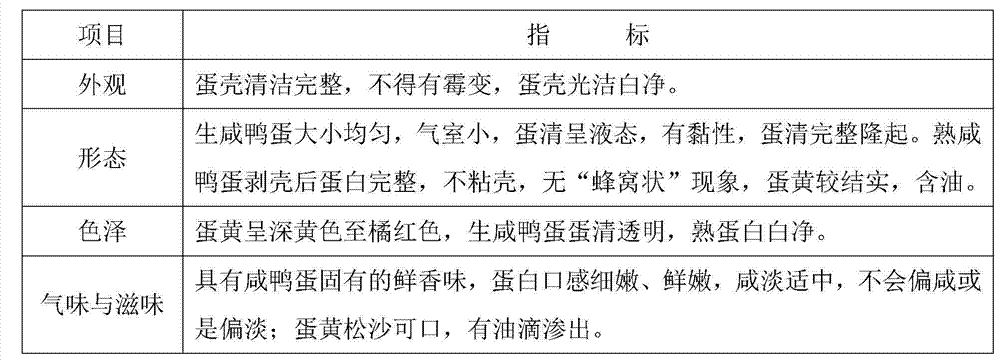

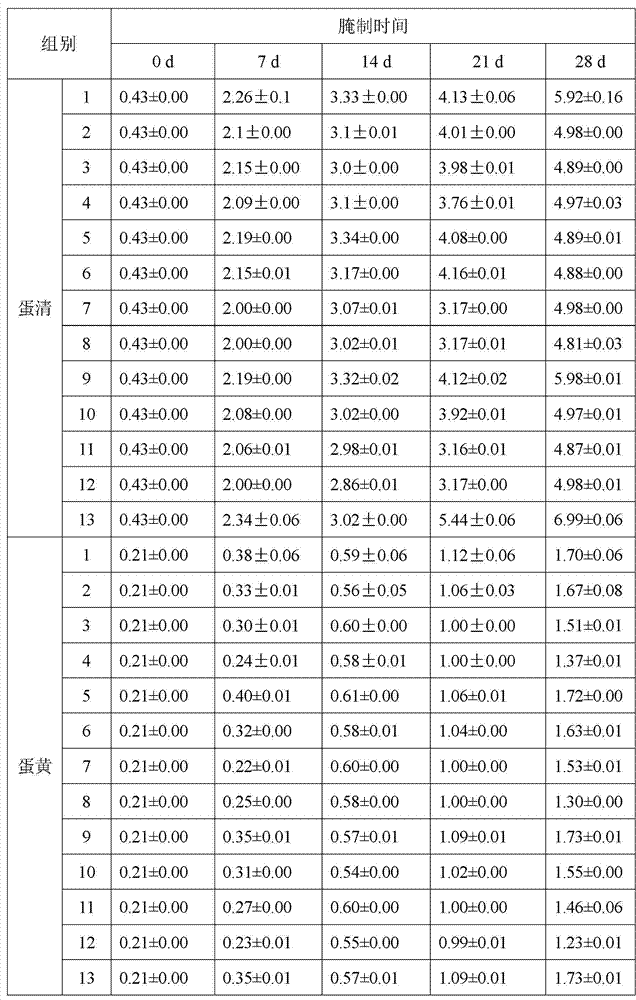

[0031] KCl, sorbitol, and potassium glutamate were used to partially replace NaCl for pickling. The test groups and the mixed pickling formulas of each group are shown in Table 1.

[0032] Table 1 mixed pickling formula table

[0033] group

NaCl

KCl

Potassium glutamate

1

20 %

5 %

0 %

0 %

2

18.5 %

6.5 %

0 %

0 %

3

16.5 %

8.5 %

0 %

0 %

4

12.5 %

12.5 %

0 %

0 %

5

20 %

0 %

5 %

0 %

6

18.5 %

0 %

6.5 %

0 %

7

16.5 %

0 %

8.5 %

0 %

8

12.5 %

...

Embodiment 3

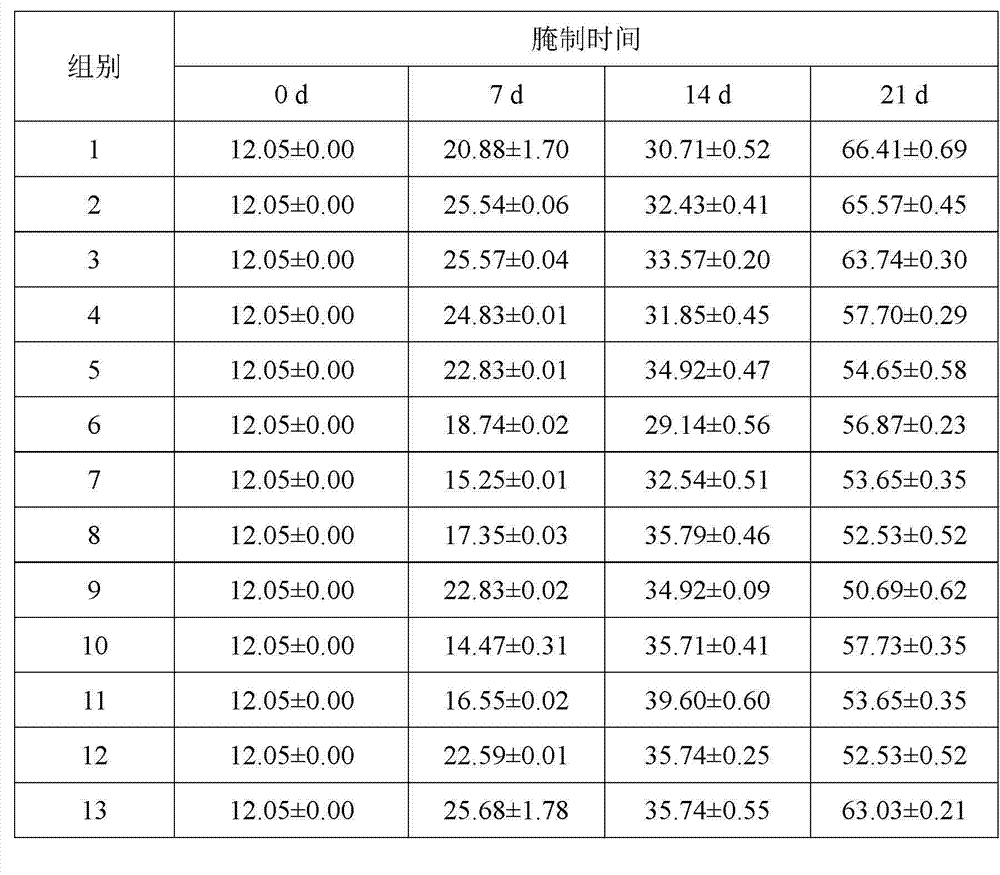

[0058] Example 3 Selection of process parameters for pulsating pressure salted low-sodium salted eggs

[0059] 1 Test method

[0060] 1.1. Preparation of low-sodium marinade:

[0061] Use the mixed salt formula of KCl and NaCl, weigh the two salts according to the mass ratio of KCl and NaCl as 1:3, add them into boiling water, so that the total mass fraction of the mixed salt reaches 25%, stir to dissolve completely, and cool down use;

[0062] 1.2. Duck eggs cleaning and tanking:

[0063] Salted eggs are marinated by soaking in salt water. Fresh duck eggs, raw materials, are washed and dried, put into a cleaned and sterilized container, poured into the pickling solution according to the ratio of duck eggs: pickling solution = 1:2, completely submerge the duck eggs, and cover the surface of the pickling solution with a plastic film And press it with stones to prevent the duck eggs from floating up, and put the container as a whole into the pulsating pressure pickling devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com