Patents

Literature

77results about How to "Fast oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly polypropylene filament yarn oil agent and production method thereof

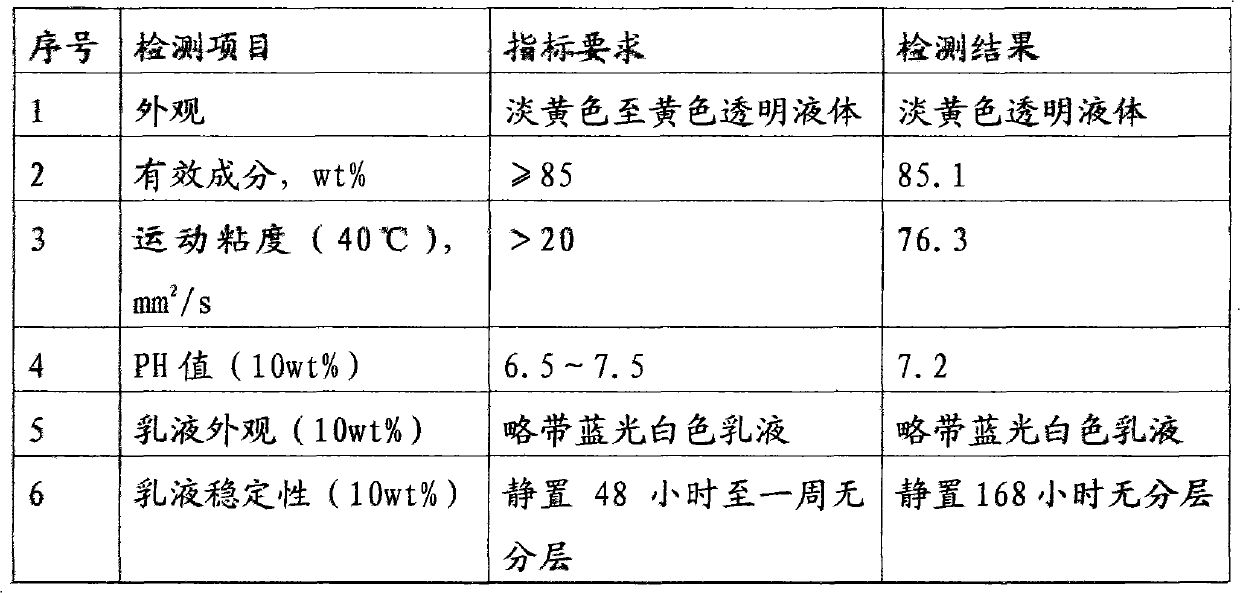

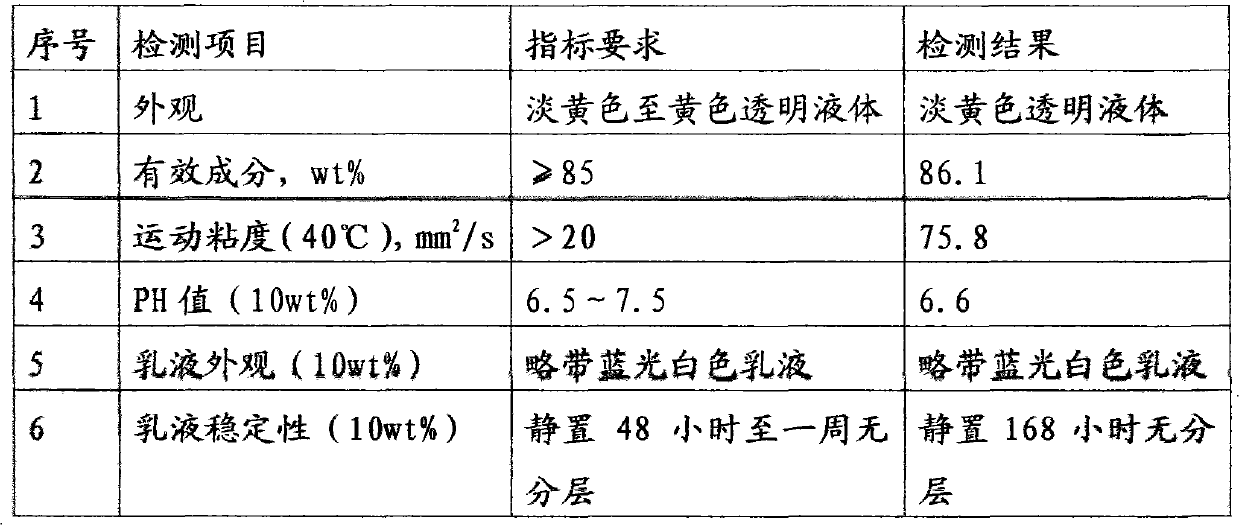

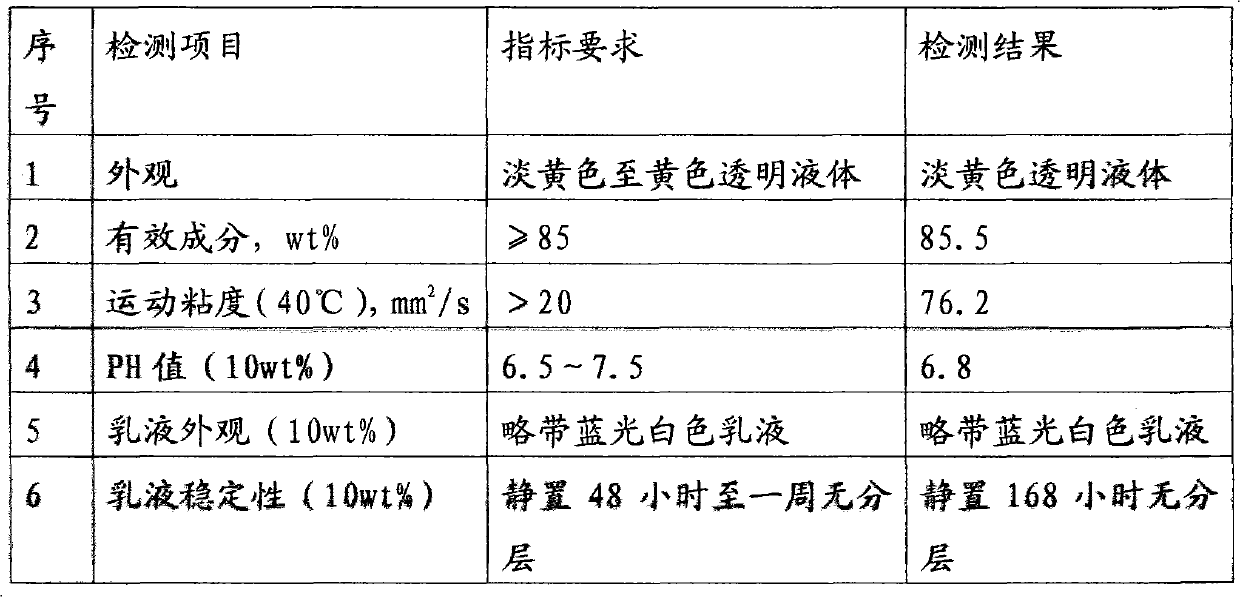

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

Terylene FDY nano spinning finish and its preparing process

The invention relates to polyester FDY nanometer spinning oil solution and a method for preparing the polyester FDY nanometer spinning oil solution, wherein the polyester FDY nanometer spinning oil solution takes the oil solution total weight as benchmark and comprises: smoothing agent 46-48%, emulsifier 28-32%, anstatic agent 9-10%, balance adjuster 5-7% and inorganic nanometer additive 5-7%. Each component of the oil solution is rationally mixed and mutually coordinated, and the oil solution has good comprehensive property. The method for preparing the polyester FDY nanometer spinning oil solution comprises: preparing inorganic nanometer additive, adding the smoothing agent, the emulsifier and the anstatic agent into a reactor, heating and stirring until the mixture becomes even, cooling the mixture which is evenly stirred, filtering, and obtaining the oil solution products. The method for preparing is simple and easy to operate.

Owner:吴江市良燕纺织助剂厂

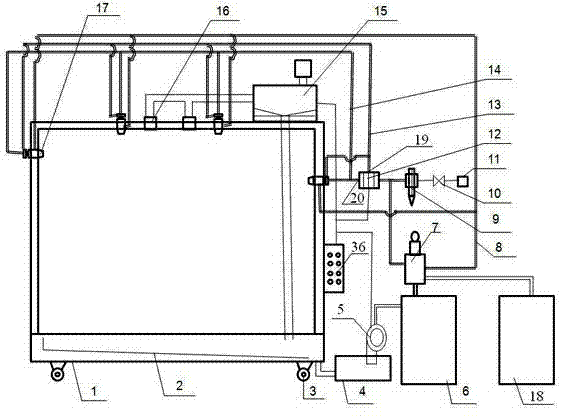

Automatic oil spraying device and method

ActiveCN103657941ARealize automatic separationPrevent rustLiquid surface applicatorsLiquid spraying apparatusControl systemElectromagnetic valve

The invention discloses an automatic oil spraying device which comprises a closed oil spraying room, a fog spraying system, an oil recycling system and a control system. The fog spraying system comprises a main air source, a pressurizing mechanism, an oil drum, an electromagnetic valve and fog spraying valves, wherein the main air source is connected with the pressurizing mechanism, and the oil drum, the pressurizing mechanism and the fog spraying valves are sequentially connected through oil pipes. The electromagnetic valve comprises an air inlet, a first air outlet and a second air outlet, wherein the air inlet is connected with the main air source through a pipe, the first air outlet is connected with the fog spraying valves through a driving air source pipe, and the second air outlet is connected with the fog spraying valves through an atomization air source pipe. The driving air source pipe and the atomization air source pipe are provided with a first pressure adjustment mechanism and a second pressure adjustment mechanism respectively. The electromagnetic valve and the oil recycling system are respectively connected with the control system, and the oil recycling system is connected with the closed oil spraying room. The invention further discloses an automatic oil spraying method achieved through the automatic oil spraying device. By means of the automatic oil spraying device and the automatic oil spraying method, rapid and safe rust prevention processing on a large number of plates can be achieved, operation risks to persons are reduced, and waste oil can be recycled.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

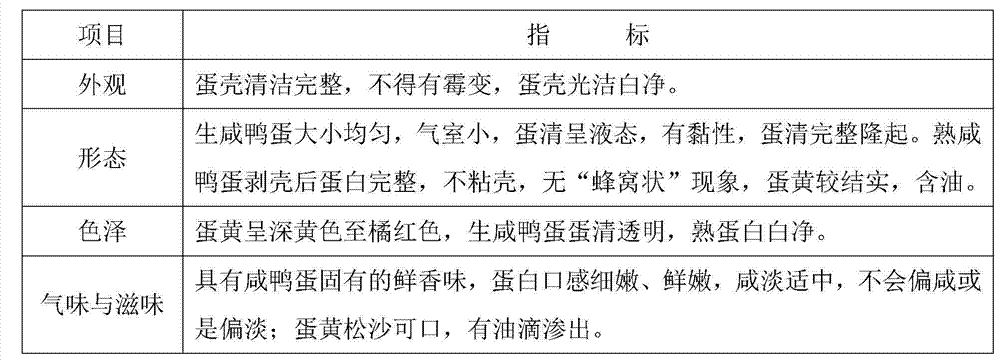

Mint coconut fragrant low-salt duck egg and preparation method thereof

The present invention discloses a mint coconut fragrant low-salt duck egg prepared from the following parts by weight of raw materials: 70-80 parts of fresh duck eggs, 10-12 parts of mint leaves, 6-8 parts of strawberries, 8-10 parts of green olives, 4-5 parts of broadleaf holly leaf, 2-3 parts of radix isatidis, 4-5 parts of achene of great burdock, 1-2 parts of calyx seu fructus physalis, 3-4 parts of gotu kola, 2-3 parts of Indian Kalimeris herb, 4-5 parts of loquat flower, 20-30 parts of high-degree Chinese liquor, 40-50 parts of coconut milk, and proper amount of yellow sand, white vinegar and table salt; the duck eggs are soaked with the white vinegar for formation of small holes on eggshell to facilitate the exchange of substances such as salt and the like, then duck eggs are first pickled with a pickle liquid and then pickled with a pickle wine with same salt content with that of the pickle liquid, the osmotic pressure of egg white and the osmotic pressure outside the shell are consistent, so that salt permeates into egg yolk for dehydration of the egg yolk, salt content of the egg white may not rise, the first phase is quickly completed by vacuum pickling, by addition of the Chinese liquor, the coagulation of protein is accelerated, the egg yolk releases oil quickly, the egg white of cooked salted duck eggs tastes appropriate, the egg yolk is loose, oily and smooth, and the mint coconut fragrant low-salt duck egg is overflowed in liquor aroma, rich in coconut flavor, and rich in mint flavor.

Owner:柳培健

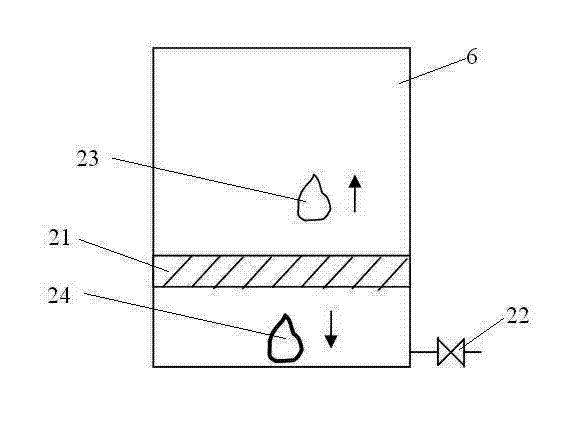

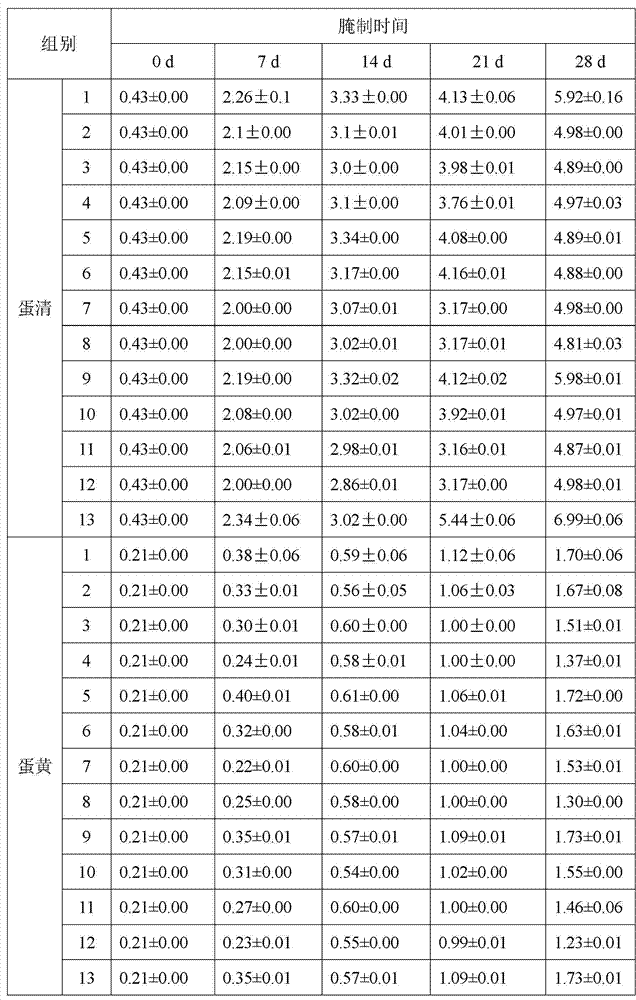

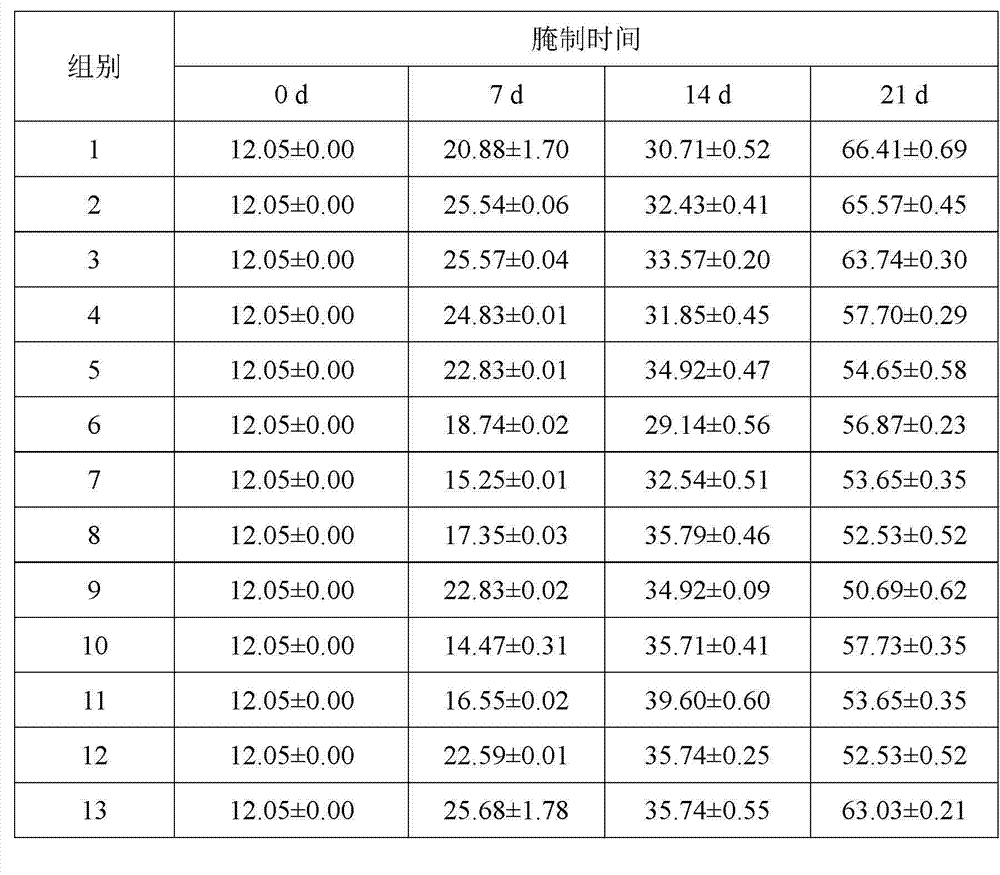

Method for mechanically and rapidly pickling low sodium salted eggs through pulsed pressure

The present invention discloses a method for mechanically and rapidly pickling low sodium salted eggs through pulsed pressure. According to the method, duck eggs are immersed in a low sodium mixing salt pickling liquid, and are subjected to mechanical pickling for 5-10 days by using pulsed pressure, wherein a high pressure value of the pulsed pressure is 90-105 kPa, a high pressure maintaining time is 12-15 minutes, a low pressure value is an atmospheric pressure, and a low pressure maintaining time is 20-30 minutes. According to the present invention, sodium ion content in the salted egg pickled by the method of the present invention is lowered by about 30% compared with sodium ion content in the salted egg pickled by the conventional method, an egg yolk oil yield rate is high, a pickling time is short, and finished products can be obtained in 5-10 days, wherein the time is shortened by 50-70% compared with the time of the traditional pickling process.

Owner:HUAZHONG AGRI UNIV

Fragrant peanut oil and preparation method thereof

ActiveCN103509643AKeep the scentFast oilAnimal feeding stuffFatty-oils/fats productionUltravioletUltraviolet irradiation

The invention belongs to the technical field of food processing and particularly discloses a preparation method of fragrant peanut oil. The preparation method comprises the steps of material selection, purification, sorting, a procedure 1, a procedure 2, oil producing, waste residue utilization and the like. The method adopts a unique perfume generation and reserving technology, the perfume of the peanut oil is reserved to the greatest extent, the oil yield of peanut kernels is increased by ultraviolet irradiation, and wastes are utilized, so that the wastes are turned into wealth. The invention further discloses the fragrant peanut oil.

Owner:SHANDONG YUHUANG GRAIN & OIL FOOD

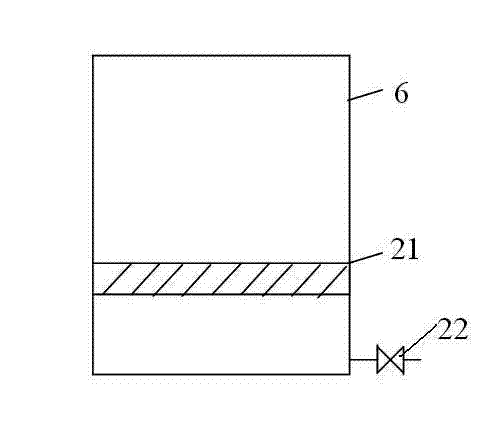

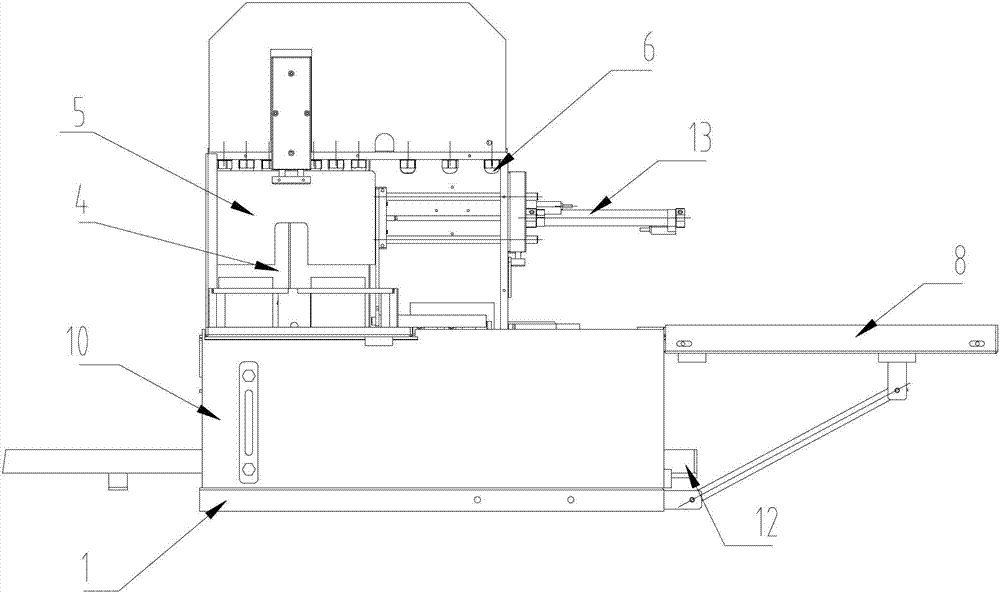

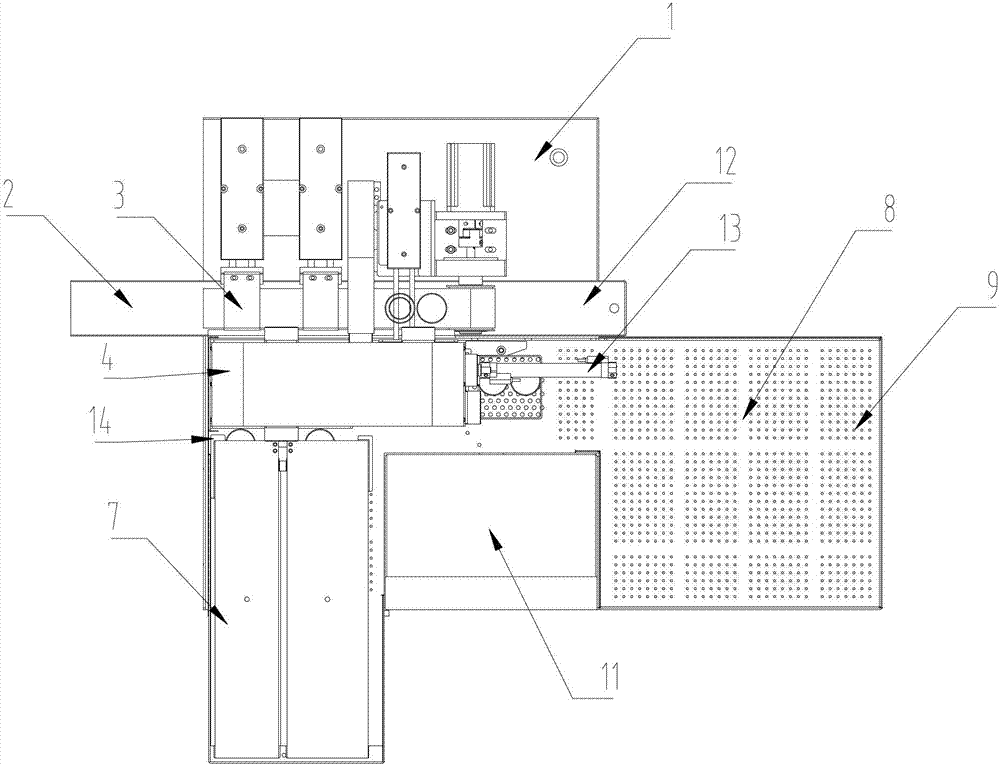

Automatic oiling device

InactiveCN103203300AExquisite structureEasy to manufactureLiquid surface applicatorsCoatingsFuel tankEngineering

The invention relates to an automatic oiling device. The automatic oiling device comprises a machine body, wherein a workpiece conveyor belt is arranged on the left side of the machine body, a plurality of straight material pushing devices and a plurality of oiling chambers are respectively arranged on the two sides of the workpiece conveyor belt, oil retaining plates are arranged at the feed ends and the discharge ends of the oiling chambers, a plurality of atomization spray heads with different angles are arranged in the oiling chambers, corresponding material storage areas are arranged at the discharge ends of the oiling chambers, an oil collecting tray is arranged on the right side of the oiling chamber on the rightmost side of the plurality of oiling chambers, the atomization spray heads and oil dripping holes are connected with a filter oil box, and an air pressurization device is connected between the atomization spray heads and the filter oil box. The automatic oiling device disclosed by the invention has the beneficial effects that the device can work alone and can also be integrated with detection equipment into a whole for operation; and the automatic oiling device has the advantages of modular structural design, exquisite structure, convenience in manufacturing and simplicity and convenience in maintenance, and can realize multi-station and multi-workpiece fast and efficient uniform surface oiling of workpieces and enable the efficiency to achieve 5 seconds / piece.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

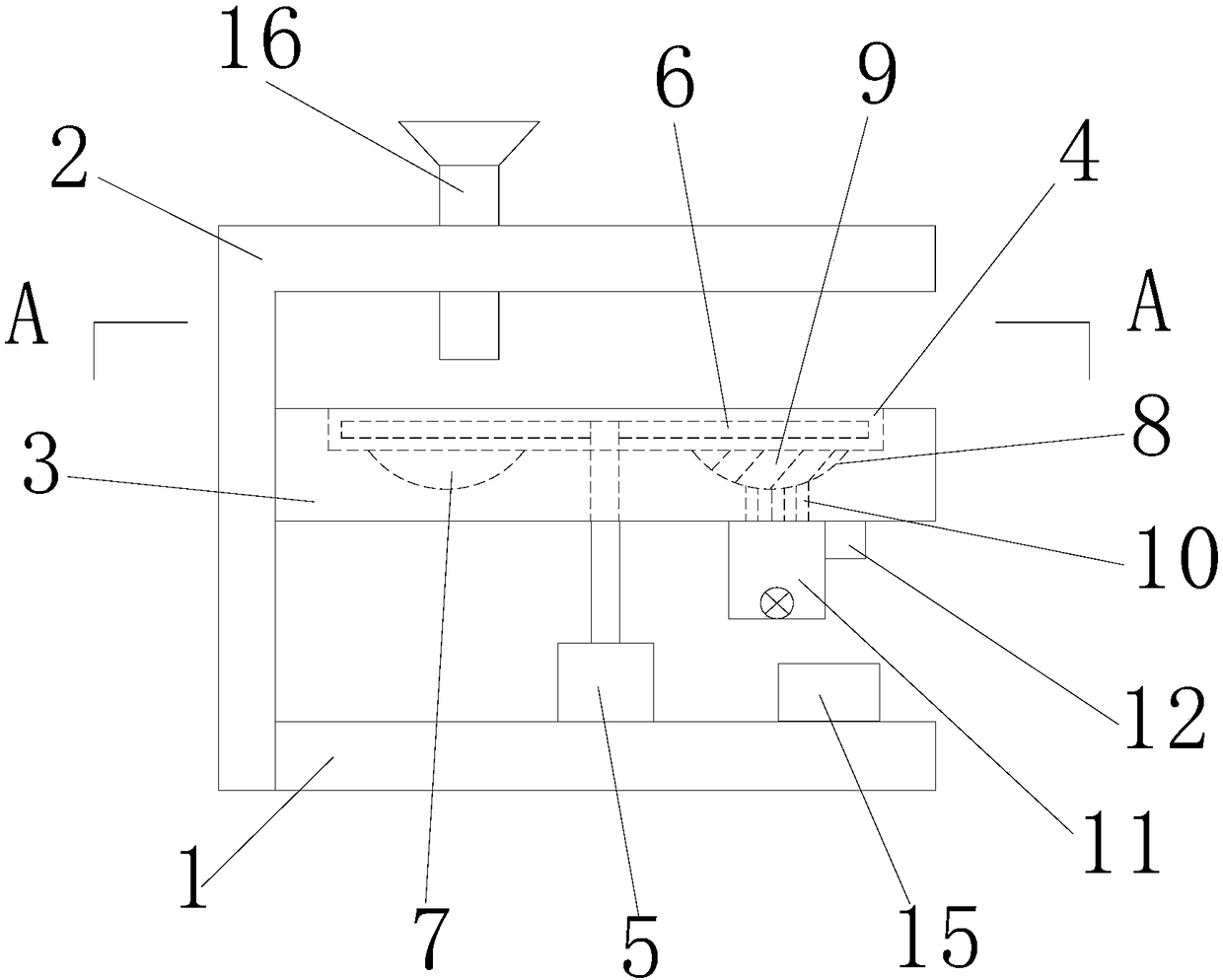

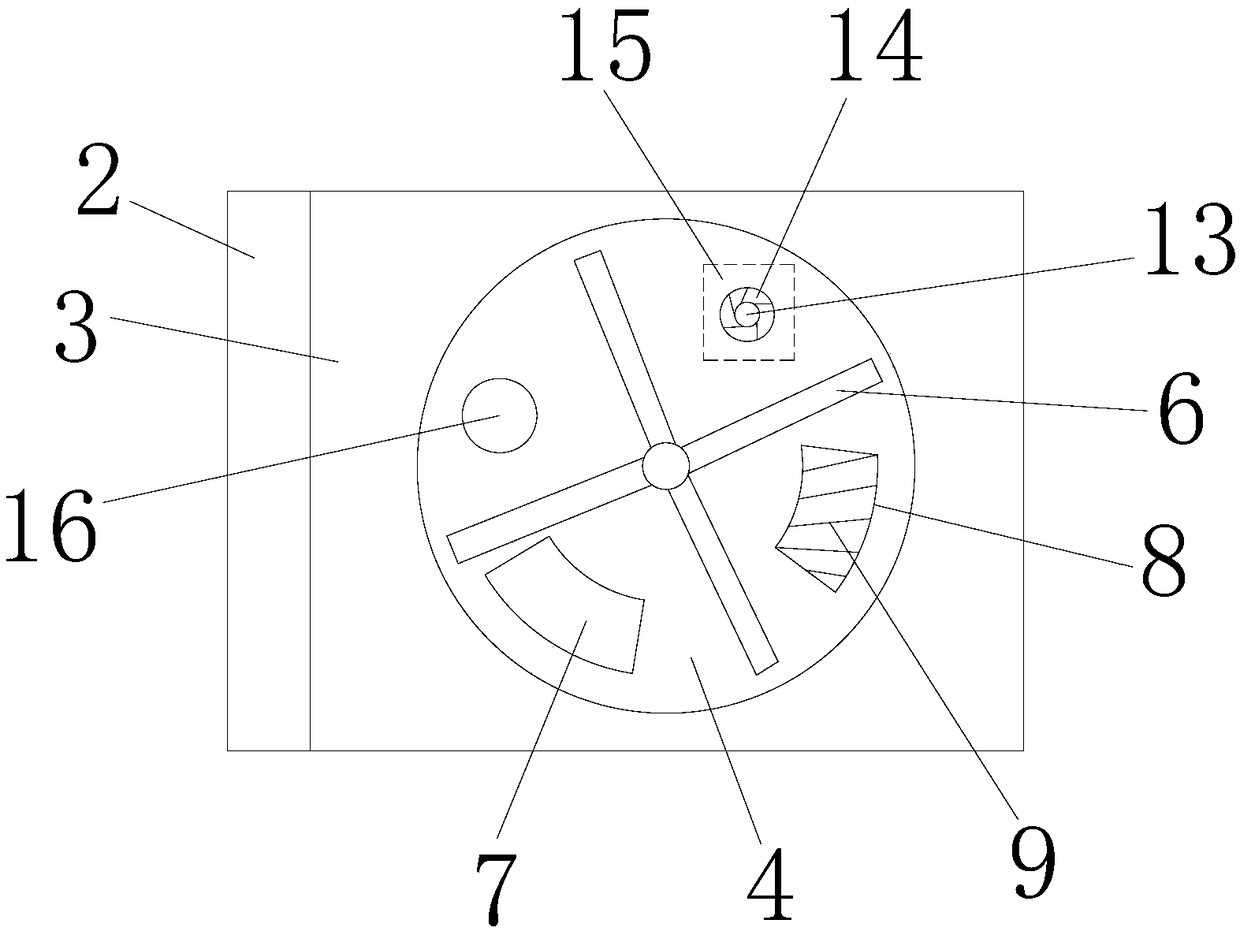

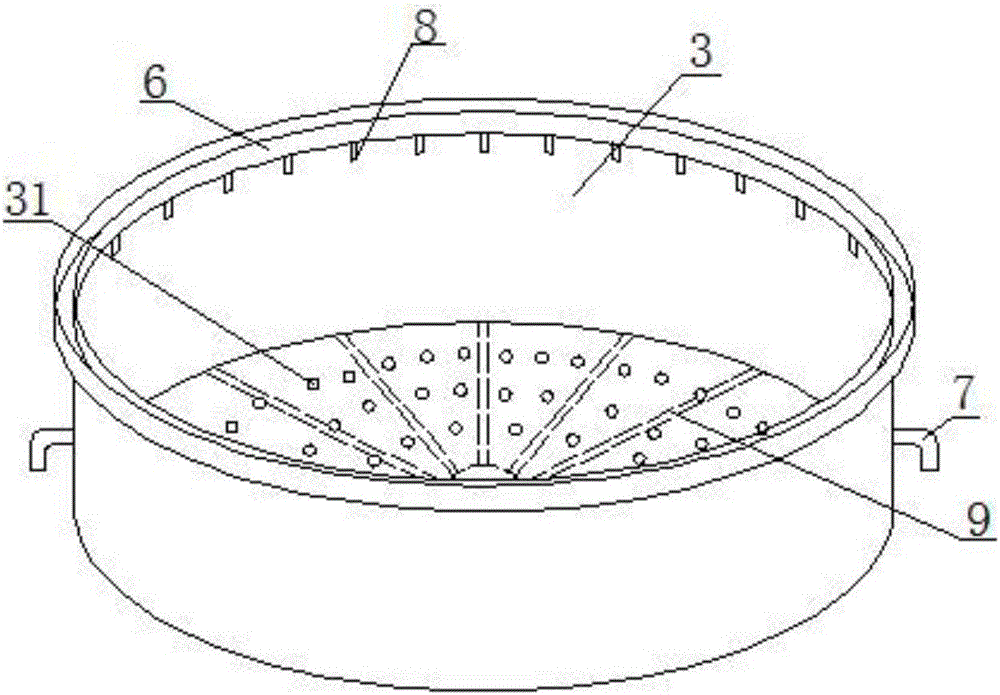

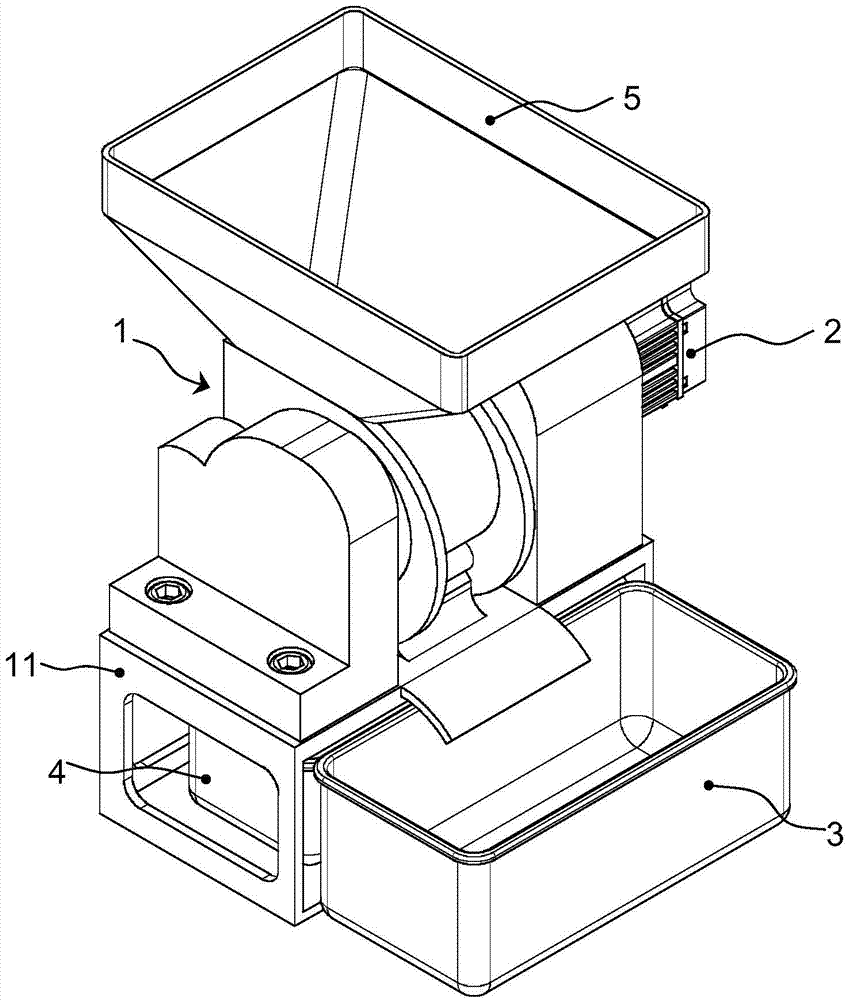

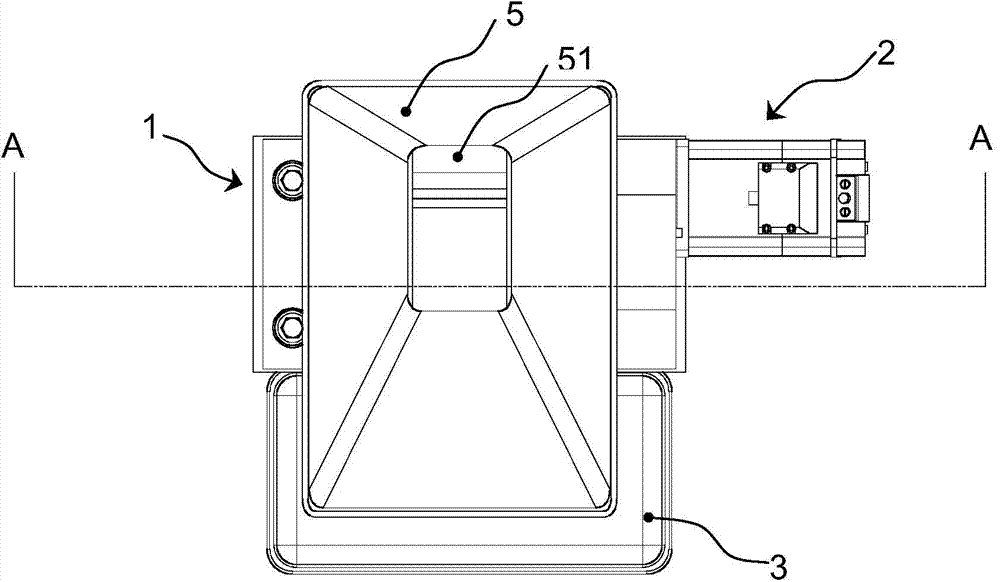

Quick oiling equipment for bearing

InactiveCN108126863AFast oilOiling is efficient and fastLiquid surface applicatorsCoatingsFuel tankEngineering

The invention discloses quick oiling equipment for a bearing. The quick oiling equipment comprises a base, a rack, a mounting plate, a sink tank, a motor, poke rods, an oil storage tank, an oil suction tank, a sponge mat, an oil outlet, an oil storage box, an aspirator pump, a discharge port, a sponge layer, a material receiving box and a discharging hopper, wherein the rack is fixedly arranged atone end of the base; the horizontally arranged mounting plate is fixedly arranged on the lateral part of the rack; the round sink tank is formed in the upper part of the mounting plate; a motor, theoutput shaft of which is vertically arranged upward, is fixedly arranged right below the sink tank on the upper portion of the base; the output shaft of the motor penetrates through the center of circle of the sink tank and extends to the upper side of the sink tank; and the plurality of uniformly distributed poke rods are fixedly arranged on the lateral part of the upper end of the output shaft of the motor radially. Compared with the prior art, the quick oiling equipment disclosed by the invention can oil the bearing efficiently and quickly, so that the oiling efficiency and effect of the bearing are enhanced, the processing environment is prevented from being polluted by residual lubricating oil effectively, and the labor intensity of workers is reduced.

Owner:XINCHANG SANYUAN BEARING CO LTD

Method for quickly pickling salted duck eggs with spicy lentinus edodes compound flavor

The invention discloses a method for quickly pickling salted duck eggs with a spicy lentinus edodes compound flavor. The method provided by invention comprises the following steps: firstly treating duck eggs with acetic acid solution to remove an outer film on the surface of duck egg shell to reduce the immersion resistance to the salt so that the duck eggs are easier to pickle; adopting partial potassium chloride to replace sodium chloride to prepare pickling solution, so as to reduce the penetration of sodium ions and keep the taste of the salted duck eggs intact; and drying wasted lentinus edodes pedicels, grinding the wasted lentinus edodes pedicels into powder, preparing the lentinus edodes powder and spices like chilies and star anise to into spicy lentinus edodes compound pickling materials, mixing the spicy lentinus edodes compound pickling materials with diatomaceous earth and white spirit to prepare a pickling substrate, and wrapping the first-time pickled duck eggs in the pickling substrate and pickling the duck eggs in an airtight space. Due to the addition of the white spirit, alcohol can destroy biological membrane structures, open membrane pore passages and increase the permeability of the duck egg shell to improve the penetration rate of salt, the chilies and the lentinus edodes so that the duck eggs can have diversified tastes and aromas; and the precipitation and accumulation of the protein of egg yolks occur so that dispersed extremely tiny oil drops gather together to promote the generation of egg yolk oil.

Owner:HEFEI FULAIDUO FOOD

Spicy low-salt duck eggs and making method thereof

The invention discloses spicy low-salt duck eggs. The spicy low-salt duck eggs are prepared from, by weight, 60-70 parts of fresh duck eggs, 8-10 parts of red pepper, 6-8 parts of green red pepper, 4-5 parts of vanilla powder, 5-6 parts of pepper leaves, 2-3 parts of common cnidium fruit, 1-2 parts of hairyvein agrimonia herb and buds, 4-5 parts of pericarpium granati, 1-2 parts of herba polygoni avicularis, 2-3 parts of sessile stemona roots, 3-4 parts of elm seeds, 20-30 parts of hot pepper oil, 30-40 parts of high-degree baijiu, an appropriate amount of yellow sand, an appropriate amount of white vinegar and an appropriate amount of salt. The duck eggs are soaked the white vinegar, and small holes are formed in egg shells, so that exchange of substances of salt and the like is facilitate; the duck eggs are pickled through pickling liquid and pickling wine of which the salt content is the same as that of the pickling liquid, due to the fact that the osmotic pressure of egg white is in accordance with that outside the shells , the salt penetrates into egg yolks to make the egg yolks dewatered, and the effects of achieving looseness and oil formation are achieved; the salt content of the egg white does not rise any more, decompressing pickling is adopted to enable the first stage to be completed rapidly, baijiu is added, protein coagulation is accelerated, oil is rapidly generated in the egg yolks, and the cooked salted duck eggs are appropriate in mouthfeel, the egg yolks are loose and rich in oil, wine fragrance is rich, and the spicy low-salt duck eggs are spicy and delicious.

Owner:柳培健

Preserving agent for salted yolk and processing method of salted yolk

The invention discloses a preserving agent for salted yolk and a processing method of the salted yolk. The preserving agent of the salted yolk consists of the following raw materials in parts by weight of 55-65 parts of salt, 80-85 parts of sodium alginate, 130-135 parts of sodium dihydrogen phosphate, 10-15 parts of Baijiu, and 1-2 parts of potassium sorbate. The processing method of the salted yolk is characterized by comprising the following steps of enabling the yolk to be immersed in the preserving agent, and performing preserving at 20-30 DEG for 48-72h; and placing the preserved yolk inthe place of 30-40 DEG C for 1-1.5h, taking out the baked yolk, uniformly applying the edible oil onto the taken yolk, placing the applied yolk in the pace of 45-55 DEG C for baking for 0.25-0.5h, and performing sterilizing, so that the salted yolk is obtained. According to the preserving agent disclosed by the invention, the probability that the surface of the salted yolk is cracked can be effectively reduced, the condition that salted yolk is stuck to form blocks can be avoided, and the yolk is beautiful and bright in color.

Owner:HUBEI SHENDAN HEALTHY FOOD

Raspberry seed oil product and extraction method

InactiveCN101411363AGuaranteed oil yieldFast oilFood preparationEdible oils/fats production/working-upNutritive valuesUltrasonic assisted

The invention relates to a plant seed oil product and a method for extracting the same, in particular to a red raspberry seed oil product and a method for extracting the same. The red raspberry seed oil is the plant fat product extracting from seeds of red raspberry fruits, thereby having extremely high nutritive value and better health care function, solving the problem of utilizing the seed separated when the product such as fruit juice and fruit jam is prepared by the red raspberry, changing waste into valuable and having great significance for the development of the red raspberry industry and the comprehensive utilization of byproducts. The extraction and preparation method for the red raspberry seed oil is as follows: seeds separated by pulping the red raspberry fruit is dried, crushed by a crusher and soaked in a solvent with a certain ratio for extraction, by the cooling or ultrasonic auxiliary extraction, the working efficiency and the oil yield are improved, and the seed soaked in the solvent is filtered to separate the solvent and then packaged to obtain the red raspberry seed oil product.

Owner:LIAONING TODAY AGRI

Salted duck egg having orange peel film and function of regulating qi and preparation method of salted duck egg

InactiveCN106165842AIncrease nutritionShorten the pickling processEggs preservation by coatingFood thermal treatmentEggshellPolyvinyl alcohol

The invention discloses a salted duck egg having an orange peel film and a function of regulating qi. The salted duck egg comprises the following raw materials, by weight part, 500-510 of duck eggs, 17-20 of orange peel, 30-34 of hawthorn fruits, 3-4 of dendrobium officinale, 27-30 of bean curd residues, and a proper amount of sodium carbonate, malic acid, polyvinyl alcohol, glycerin, salt and water. A preserving liquid for soaking duck eggs contains multiple kinds of raw materials, such as orange peel and hawthorn fruits and is abundant in nutrients. A lot of nutrient elements are adsorbed in the duck eggs, and the nutrition of the whole salted duck egg is improved. The salted duck egg has an orange peel flavor when consumed and has the function of regulating qi and middle. After the process is improved, the permeability of an egg shell is improved, thereby shortening the process of preserving the duck egg. A film is formed on the egg shell, so that the salted duck egg can be kept fresh.

Owner:HEFEI FULAIDUO FOOD

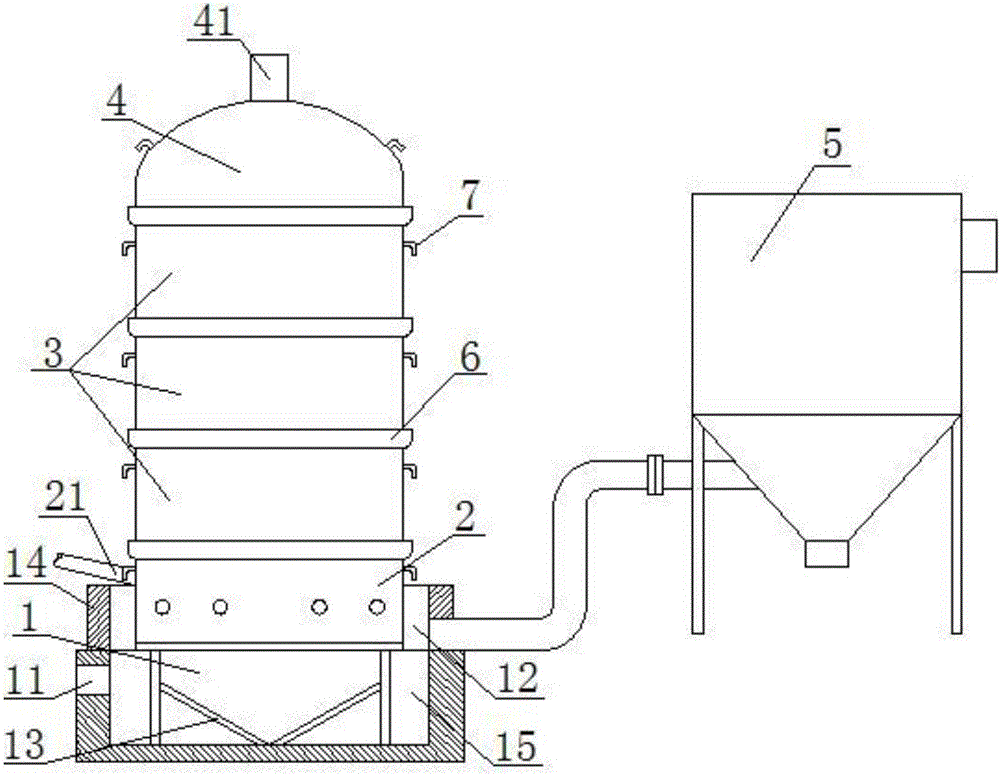

Efficient distillation equipment suitable for mass production of cinnamomum petrophilum oil

InactiveCN106167741AIncreased load-bearing capacityHigh strengthEssential-oils/perfumesDistillationHearth

The invention relates to the field of distillation equipment, in particular to efficient distillation equipment suitable for mass production of cinnamomum petrophilum oil. The distillation equipment for cinnamomum petrophilum can greatly increase one-time processing amount and increase distillation efficiency. The efficient distillation equipment comprises a hearth, a distillation pot is disposed on the hearth, a fuel inlet and an annular flue are arranged on the side face of the hearth, the annular flue is connected to a soot treatment device through a soot pipe,, a backflow pipe is arranged on the side all of the distillation pot, a multi-layer steaming drawer is disposed on the distillation pot, a steaming cover is arranged on the top layer of the steaming drawer, an air gathering port is arranged at the top of the steaming cover, a plurality of air holes are evenly distributed at the bottom of the steaming drawer, and lifting lugs are arranged on the peripheral surface of the distillation pot, the steaming drawer and the steaming cover. The efficient distillation equipment is suitable for mass production of cinnamomum petrophilum oil.

Owner:PENGXI MINXIN CINNAMOMUM SUBAVENIUM MIQ CO LTD

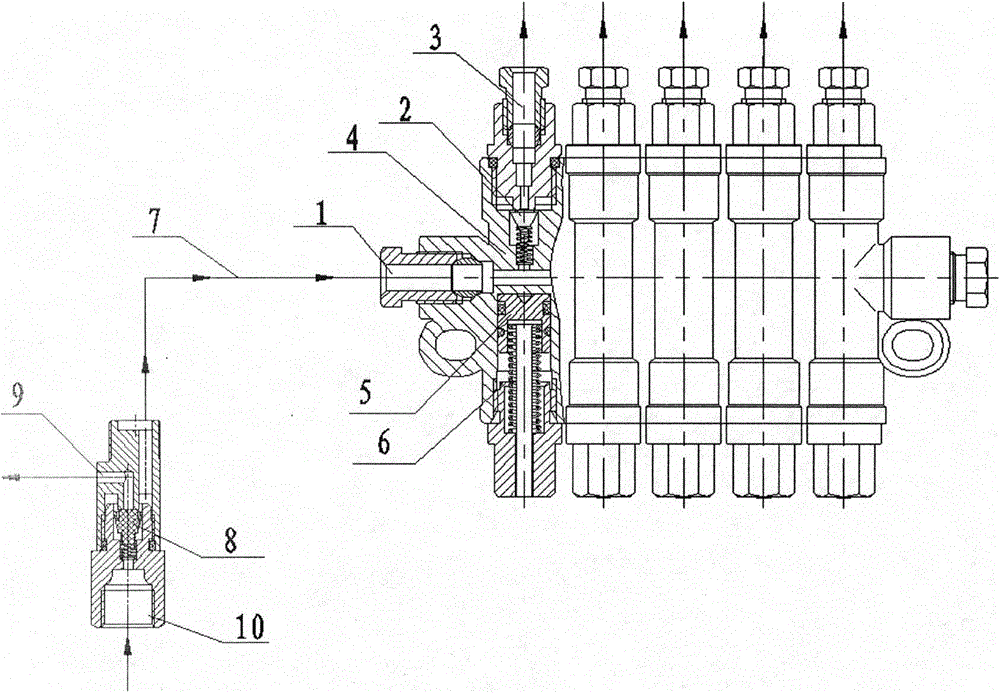

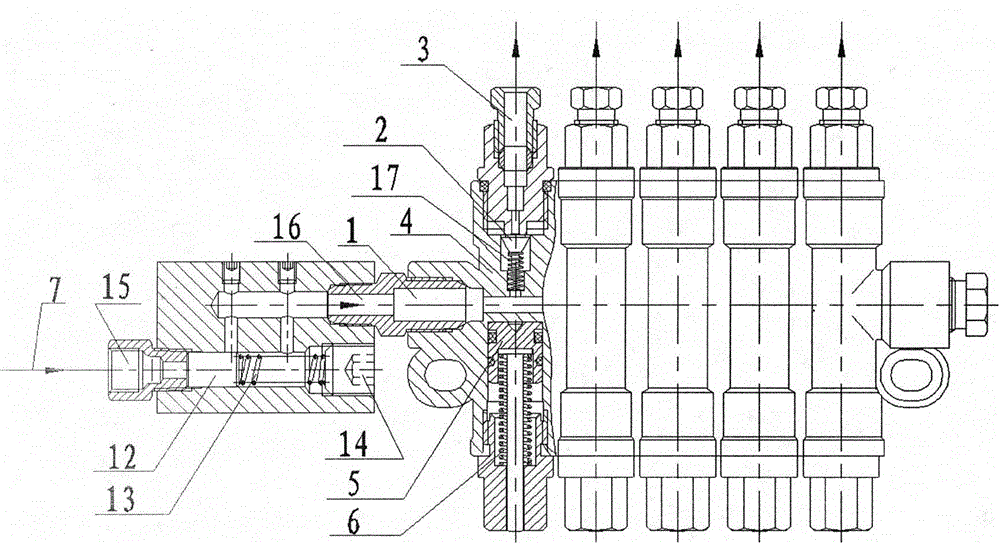

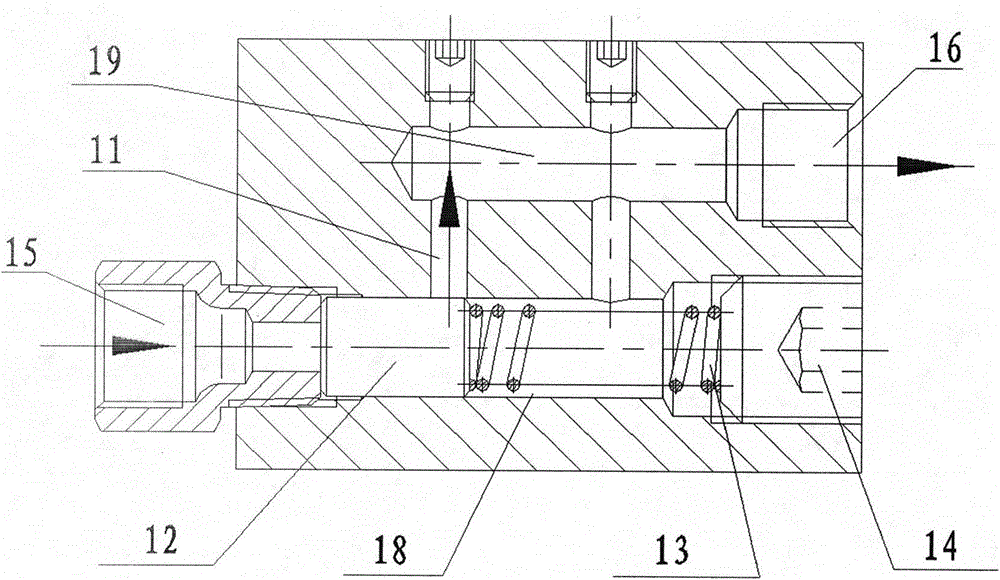

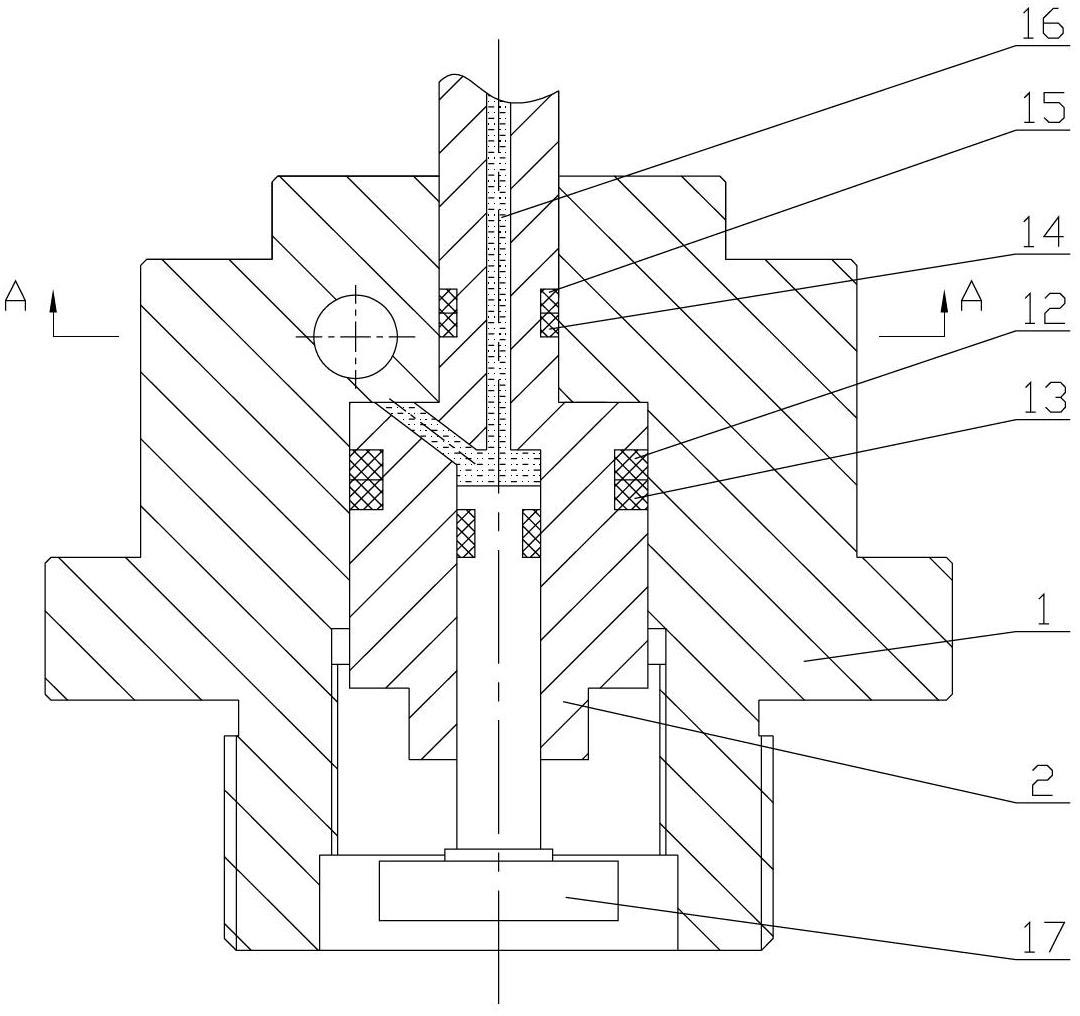

Volumetric distributor with depressurizing function

The invention relates to a volumetric distributor with a depressurizing function. The volumetric distributor comprises a distributor body, an oil grease delivery pipeline, a first oil inlet and a second oil outlet. The volumetric distributor further comprises a plunger type depressurizing mechanism, the plunger type depressurizing mechanism comprises an oil inlet cavity and an oil outlet cavity, the oil inlet cavity is sequentially provided with a second oil inlet, a depressurizing plunger, a plunger spring and a plug, and the depressurizing plunger is in slide fit with the oil inlet cavity; one end of the oil outlet cavity is provided with a second oil outlet, and the other end of the oil outlet cavity is sealed. A communicating pipeline is arranged between the oil inlet cavity and the oil outlet cavity; the second oil outlet is communicated with the first oil inlet, and the second oil inlet is communicated with the oil grease delivery pipeline. The pressure of the first oil inlet can be quickly decreased to zero, and the volumetric distributor is suitable for the long oil grease delivery pipeline and used for treating high-viscosity oil grease. Meanwhile, the volumetric distributor has the advantages of fast oil discharge and the like.

Owner:浙江胜祥机械有限公司

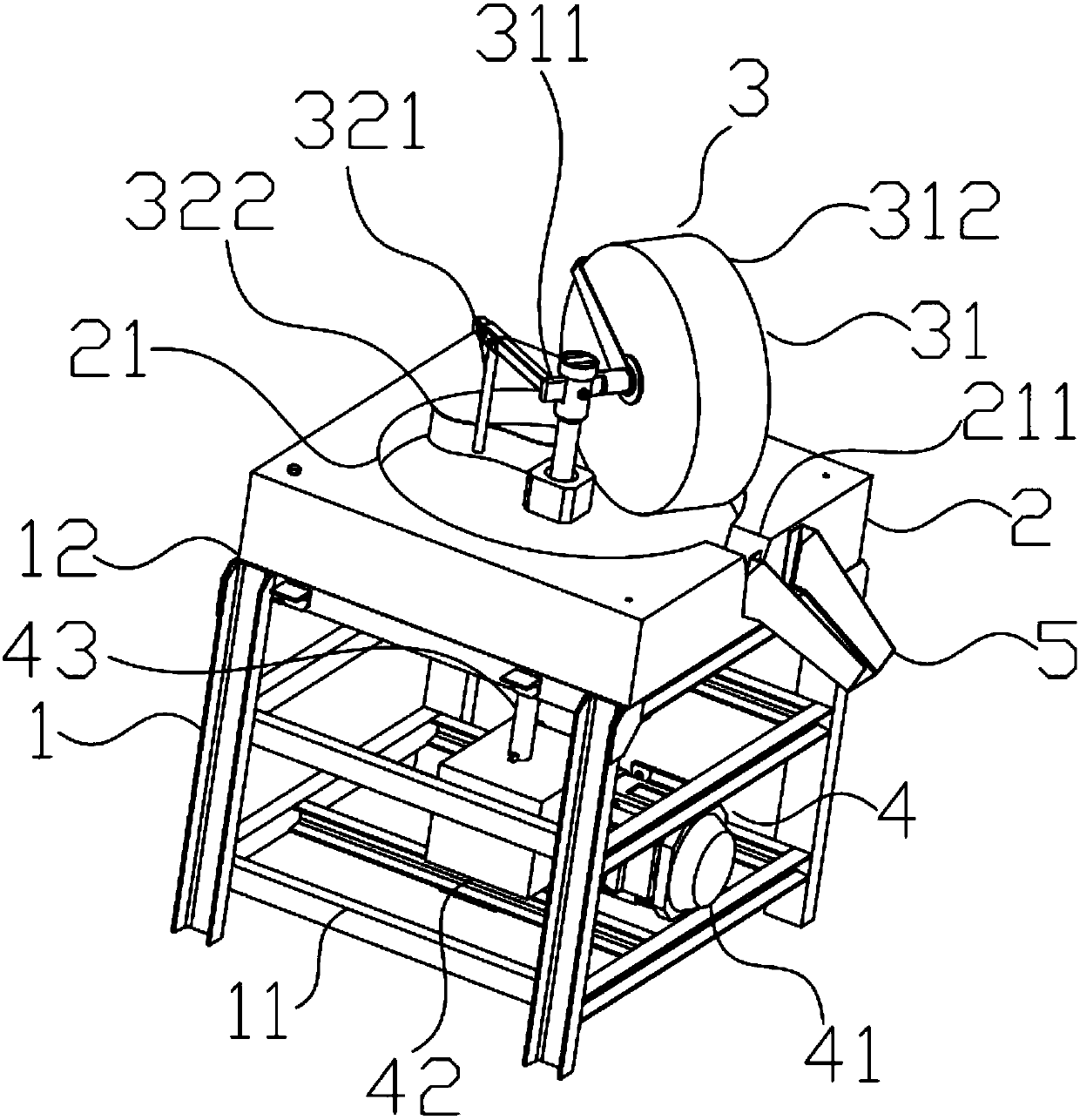

Squeezing equipment

InactiveCN107650414ASimple structureImprove oil yieldFatty-oils/fats productionPressesBiochemical engineering

The invention discloses squeezing equipment. The squeezing equipment comprises a machine frame, a squeezing table, a squeezing device, a driving device and an oil outlet guide groove; the machine frame is provided with a first working platform and a second working platform; the second working platform is located above the first working platform; the squeezing table is arranged on the second working platform and is provided with a squeezing groove; the squeezing groove is provided with an opening; the squeezing device is located in the squeezing groove; the driving device is arranged on the first working platform; the output end of the driving device penetrates through the squeezing table to be connected to the squeezing device; and the oil outlet guide groove is formed in the squeezing table and corresponds to the opening. The squeezing equipment has the advantages that the structure is simple, the oil extraction speed is high in the nut squeezing process, the oil yield is high, the use of enterprise personnel can be reduced, the production cost of an enterprise can be lowered, and the production efficiency of the enterprise can be improved.

Owner:HUIZHOU JIBORUI TECH CO LTD

Production method of two-time preserved salted duck eggs having health-care efficacy

InactiveCN107484978AImprove permeabilityMarinating process shortenedFood scienceEggshellHigh pressure

The invention discloses a production method of two-time preserved salted duck eggs having health-care efficacy. A two-time preserving method is adopted, first-time liquid impregnating is performed, and high pressure acts on the surfaces of eggshells, so that the permeability of the eggshells is improved; and besides, a certain temperature range is controlled, so that the diffusion rate of effective components into eggs is increased, and the maturing cycle of the salted eggs can be shortened; second-time clay coating packing is performed, so that effective components are completely packed; and under the action of Baijiu, second-time preserving is performed, so that mellow and rich mouth feel of the salted duck eggs is guaranteed. The raw materials adopted by an entire technology are broad in sources, and low in cost, and the technology is convenient to operate, and is suitable for mass production.

Owner:HEFEI FULAIDUO FOOD

Salted duck eggs capable of clearing lung and eliminating heat and coated with membranes and preparation method of salted duck egg

InactiveCN106070539AIncrease nutritionUnique tasteEggs preservation by coatingFood ingredient functionsEggshellPolyvinyl alcohol

The invention discloses salted duck eggs capable of clearing the lung and eliminating heat and coated with membranes. The salted duck eggs are prepared from raw materials in parts by weight as follows: 500-510 parts of duck eggs, 20-24 parts of fermented glutinous rice juice, 12-15 parts of chili powder, 3-4 parts of bamboo leaves, 30-35 parts of walnuts and an appropriate amount of sodium carbonate, malic acid, polyvinyl alcohol, glycerin, salt and water. A soaking and salting liquid for the salted duck eggs contains multiple kinds of raw materials such as the fermented glutinous rice juice, the walnuts and the like, the salted duck eggs are nutrient-rich, a variety of nutrient elements are adsorbed in the duck eggs, the overall nutrition of the salted duck eggs is improved, and the salted duck eggs taste unique and have the functions of clearing the lung and eliminating heat; after technological improvement, the permeability of egg shells is improved, the salting process of the duck eggs can be shortened, and the membranes are formed outside the egg shells, so that the salted duck eggs can keep fresh better.

Owner:HEFEI FULAIDUO FOOD

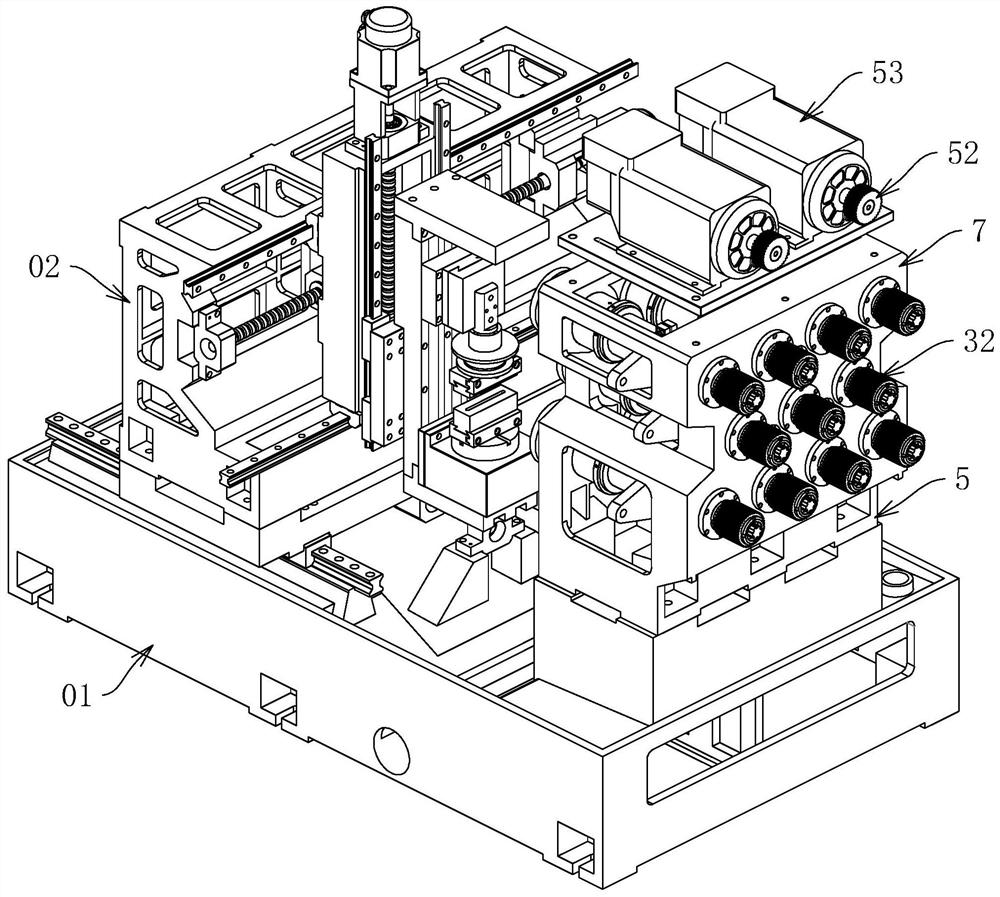

Numerically-controlled machine tool

InactiveCN111957990AImplement stealth settingsEasy to controlLarge fixed membersPositioning apparatusNumerical controlMachine

The invention discloses a numerically-controlled machine tool and relates to the field of the numerically-controlled machine tool. The numerically-controlled machine tool comprises a machine base, wherein a feed system and a spindle box are arranged at two ends of the machine base respectively, multiple spindles used for allowing cutting tools to be fixed are horizontally and independently rotationally connected to the spindle box, and the spindles are horizontally connected to the spindle box in a sliding manner. The numerically-controlled machine tool has advantages and effects as follows: by means of the spindle box assembled with a plurality of independently working spindles, independent selection and work of different cutting tools are realized, so that non-stop selection of the cutting tools and non-stop machining of workpieces are realized, and processing efficiency of the workpieces is increased.

Owner:台州松普数控科技有限公司

Plumula nelumbini pressure lowering and defatting film-coating salted duck egg and preparation method thereof

InactiveCN106174128AIncrease nutritionShorten the pickling processEggs preservation by coatingNatural extract food ingredientsPOMEGRANATE SEED OILEggshell

The invention discloses a plumula nelumbini pressure lowering and defatting film-coating salted duck egg. The plumula nelumbini pressure lowering and defatting film-coating salted duck egg is prepared from the following raw materials in parts by weight: 500 to 510 parts of duck eggs, 28 to 32 parts of plumula nelumbini, 21 to 24 parts of fishbone, 5 to 7 parts of broken masson pine pollen, 8 to 10 parts of pomegranate seed oil and a proper amount of sodium carbonate, malic acid, polyvinyl alcohol, glycerol, edible salts and water. A soaking and salting solution of the salted duck egg contains a plurality of raw materials, including the plumula nelumbini, the broken masson pine pollen and the like, so the salted duck egg is abundant in nutrition; nutrient elements adsorbed in the duck egg are more, so that the integral nutrition of the salted duck egg is improved; after the salted duck egg is eaten, the efficacy of life cultivation and health preservation is achieved, the pressure can be lowered and fat can be removed; after a process is improved, the transparent performance of an egg shell is improved, and the salting process is shortened; a coating film is formed outside the egg shell, so that the freshness of the salted duck egg can be better retained.

Owner:HEFEI FULAIDUO FOOD

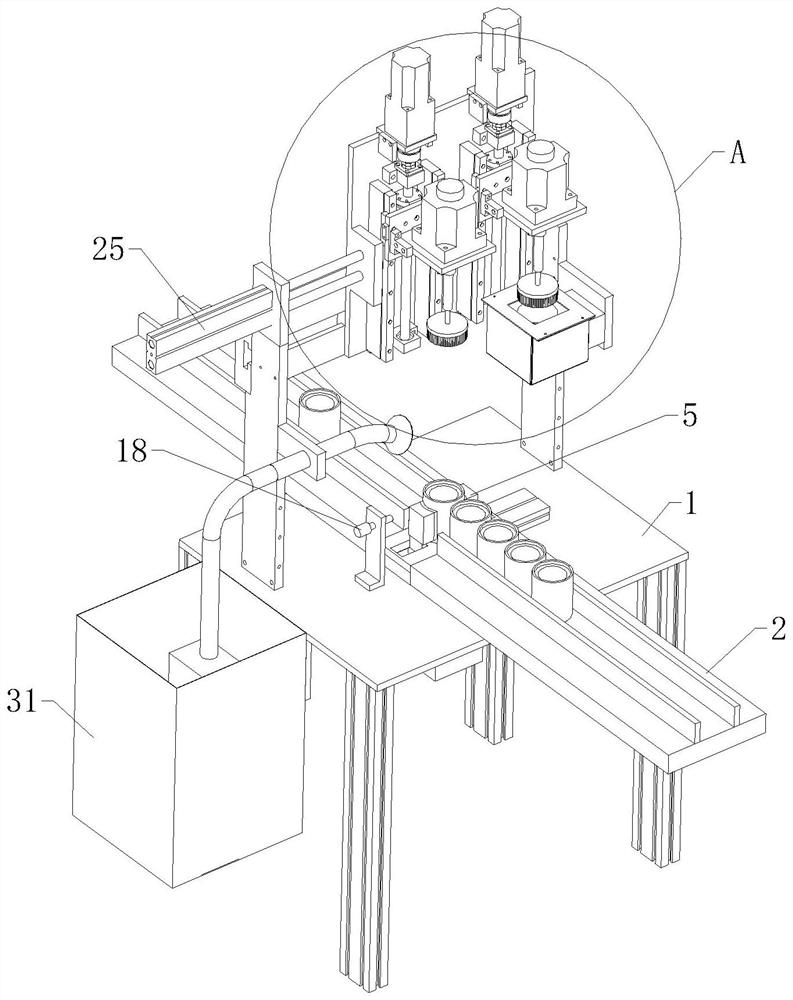

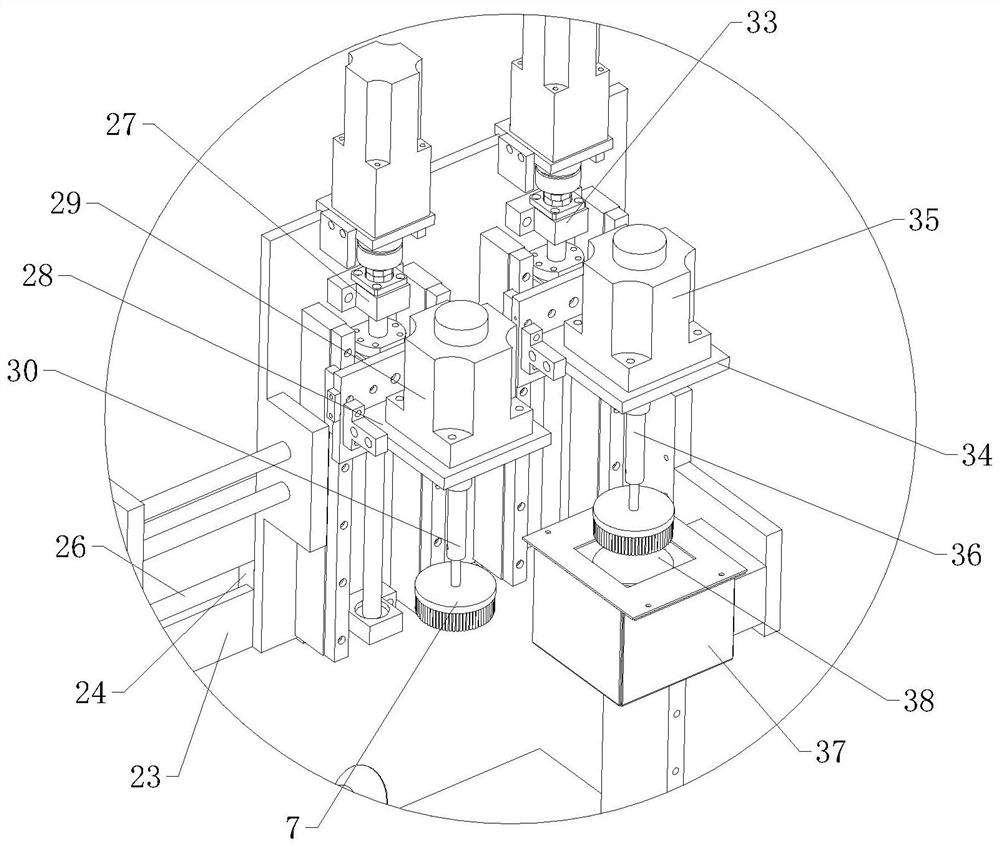

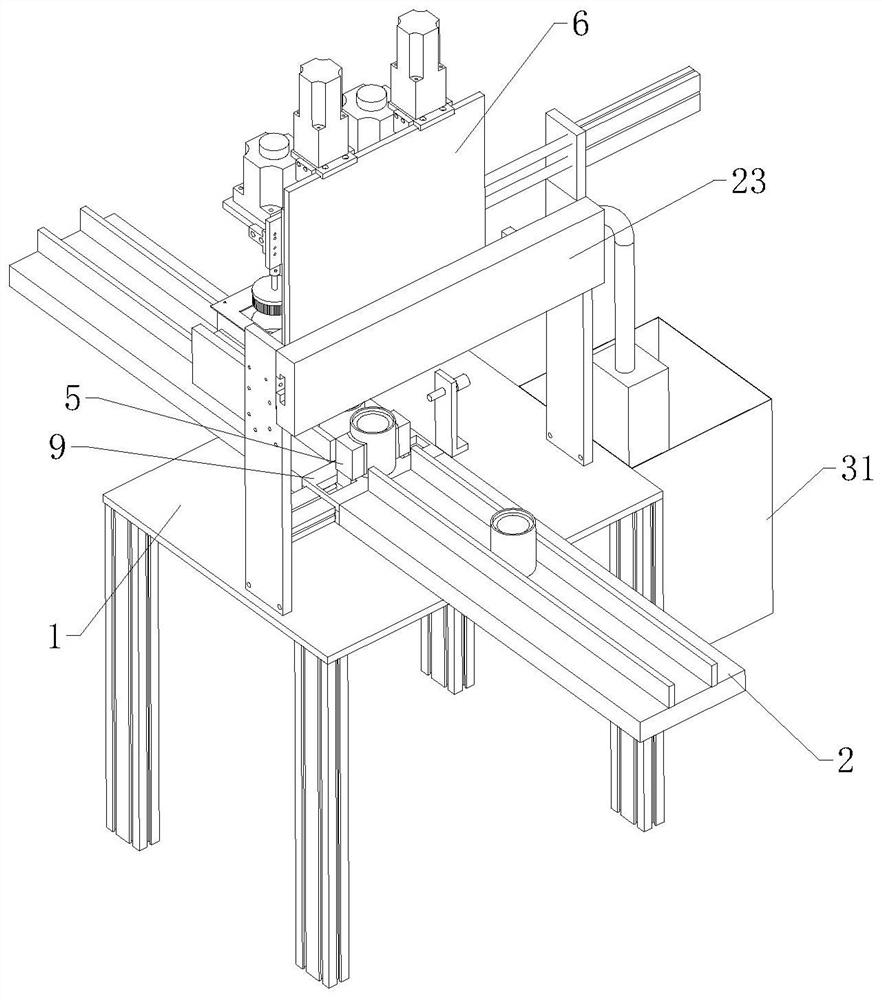

Oiling equipment for mechanical sealing seat production

PendingCN113210188AFast oilImprove oil qualityLiquid surface applicatorsCleaning using toolsEngineeringBrush

The invention relates to the technical field of mechanical sealing seat processing, in particular to oiling equipment for mechanical sealing seat production. The oiling equipment comprises a workbench, a pair of sealing seat feeding conveyors, a positioning mechanism arranged on the workbench, and a deashing and oiling mechanism arranged on the workbench, wherein the positioning mechanism comprises a pair of sealing seat clamps, the sealing seat clamps are symmetric and can be arranged at two sides of the sealing seat feeding conveyors toward each other or away from each other, and each sealing seat clamp is provided with an arc-shaped abutting groove capable of abutting against the outside of a sealing seat; the deashing and oiling mechanism comprises a transverse moving plate, a deashing brush and an oiling brush; the deashing brush is arranged at one end of the transverse moving plate in a lifting manner; and the oiling brush is arranged at the other end of the transverse moving plate in a lifting manner, and the oiling brush and the deashing brush are symmetrically arranged. Through exchange operation of the deashing brush and the oiling brush, deashing and oiling can be automatically and efficiently carried out on the sealing seat, so that the oiling quality is guaranteed, and the labor cost is reduced.

Owner:浙江中吉机械密封件有限公司

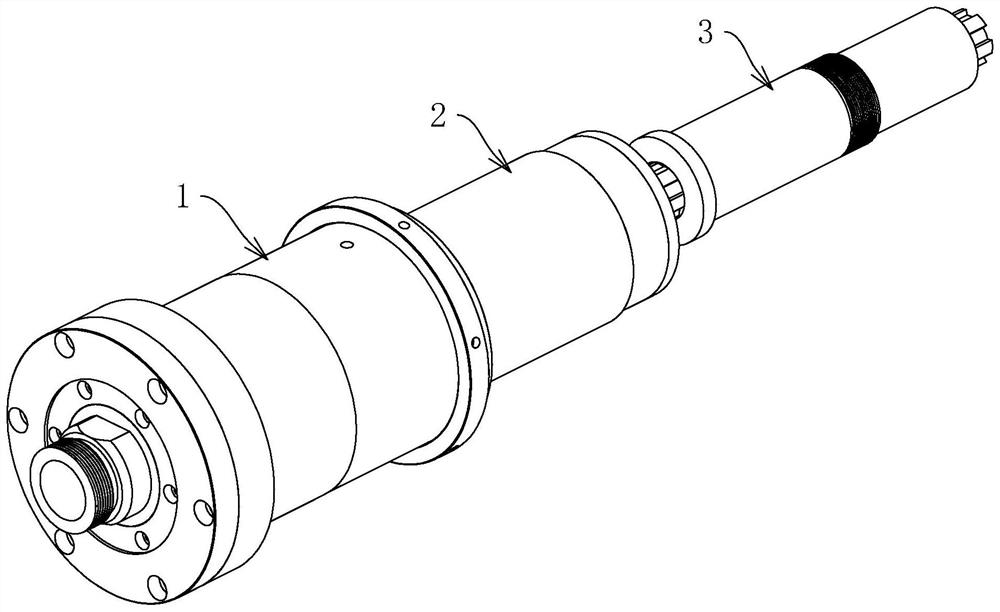

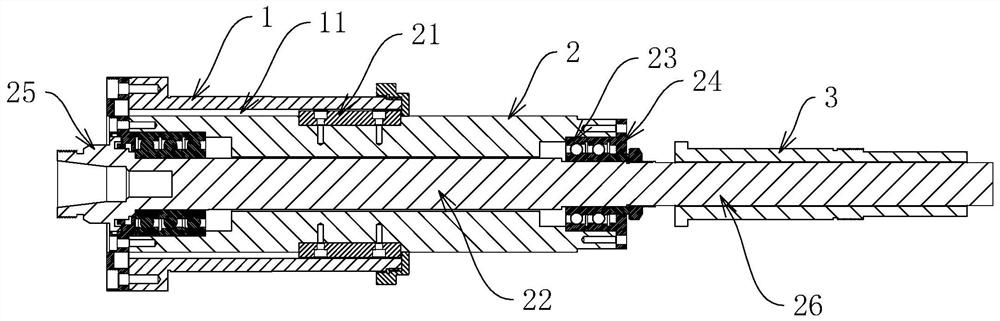

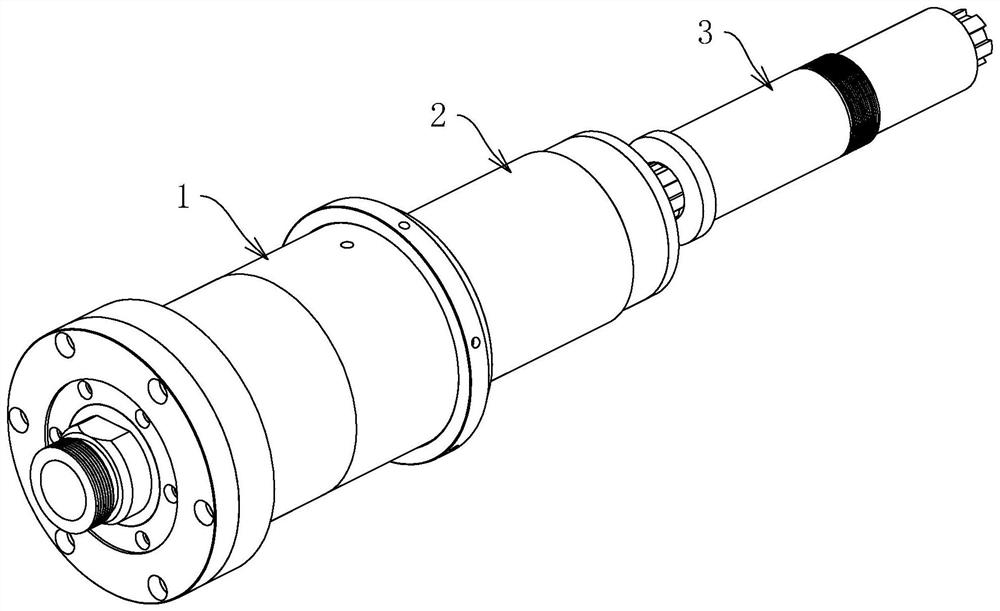

Main shaft of numerical control machine tool and main shaft box thereof

InactiveCN111957992AImprove ease of useRealize free feed controlLarge fixed membersNumerical controlDrive shaft

The invention discloses a main shaft of a numerical control machine tool, and relates to the field of numerical control machine tools. The main shaft comprises a shaft sleeve, wherein a mounting shaftis horizontally and slidably connected in the shaft sleeve; a mandrel is horizontally and rotatably connected in the mounting shaft; end covers are arranged between the mandrel and the two ends of the mounting shaft; a tool apron used for fixing a tool is arranged at the end, positioned outside the mounting shaft, of the mandrel; a sliding shaft is arranged at the other end, positioned outside the mounting shaft, of the mandrel in an extending mode; a driving shaft is arranged on the outer wall of the sliding shaft; the sliding shaft is horizontally and slidably connected to the driving shaft; a spline is arranged on the outer wall of the sliding shaft; and a key groove allowing the spline to slide is formed in the inner wall of the driving shaft. The main shaft has the following advantages and effects that the mandrel and the sliding shaft which slide and rotate independently are arranged, the whole main shaft does not need to be driven to move synchronously for feeding, free feedingcontrol during rotation of the tool apron and the tool can be realized, and the use convenience of the main shaft is improved.

Owner:台州松普数控科技有限公司

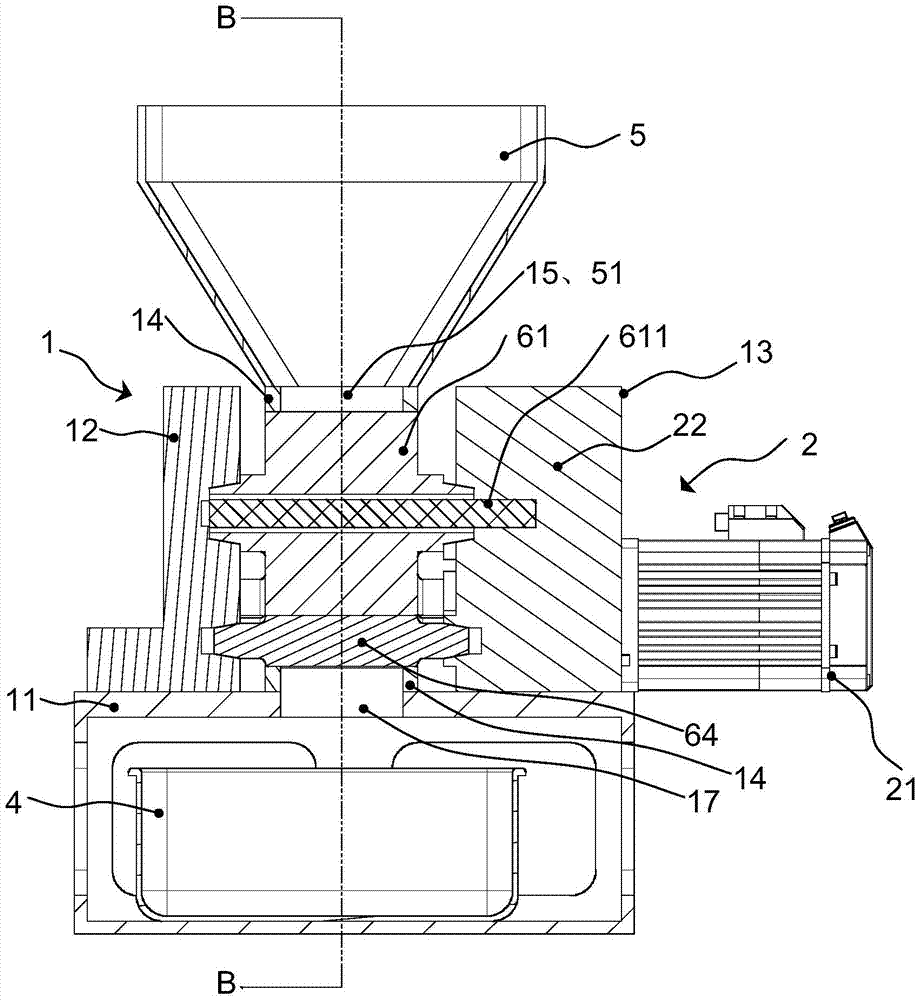

Oil press

The invention relates to an oil press, which comprises a machine frame, a power device and a temperature control device, wherein the interior of the machine frame of the oil press is provided with a main roll and a plurality of auxiliary rolls, the auxiliary rolls are matched with the main roll, and are sequentially and tightly attached to the periphery of the main roll, a certain distance is formed between the first auxiliary roll and the peripheral surface of the main roll to facilitate the feeding of oil, the gaps between the auxiliary rolls and the peripheral surface of the main roll are gradually reduced until the auxiliary rolls are tightly attached to the peripheral surface of the main roll, the main roll and the auxiliary rolls form a pressing space, the temperature control device is used for adjusting the temperature of the oil in the pressing space, the power device is used for driving the main roll and / or the auxiliary rolls, the oil firstly enters the first auxiliary roll, then is pressed in the pressing space, and is finally treated by the final auxiliary roll, the slag is discharged out, and the pressed oil liquid leaks out via the gaps between the auxiliary rolls. The oil press has the advantages that the oil is pressed and pressurized by the roll pair type of multiple rolls, and the compression type is direct; compared with the existing spiral oil press, the friction loss of power is greatly reduced, namely that the loss of component parts is reduced, and the consumption of energy sources is reduced.

Owner:深圳市不多科技有限公司

Cool and refreshing mint flavored film coated salted duck eggs and preparation method thereof

InactiveCN106174130AAvoid damageActs as a sterilizerEggs preservation by coatingFood ingredient as taste affecting agentEggshellPumpkin seed

The present invention discloses cool and refreshing mint flavored film coated salted duck eggs. The salted duck eggs are prepared from the following raw materials in parts by weight: 500-510 parts of duck eggs, 20-24 parts of duck blood, 35-40 parts of pumpkin seeds, 4-6 parts of fresh mints, 23-26 parts of pearl powder, and an appropriate amount of sodium carbonate, malic acids, polyvinyl alcohol, glycerin, edible salt and water. Pickling liquid for soaking the duck eggs has various raw materials, including the duck blood, fresh mints, etc., so that the salted duck eggs are rich in nutrition, the nutrients absorbed within the duck eggs are much, and the method improves the whole nutrition of the salted duck eggs. After consumption, the salted duck eggs have a cool and refreshing mint flavor and also have a certain health-care efficacy. After the improvement of the technology, the permeability of eggshells is increased, the pickling process of the duck eggs can be shortened, and a coating film is formed outside the eggshells, so that the preparation method can better preserve the salted duck eggs.

Owner:HEFEI FULAIDUO FOOD

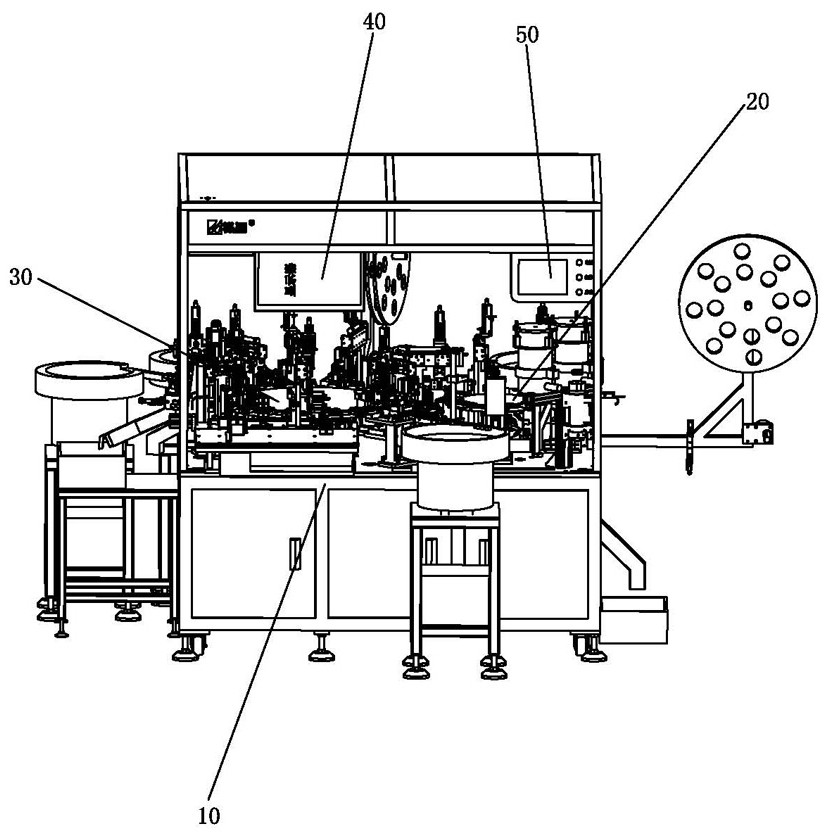

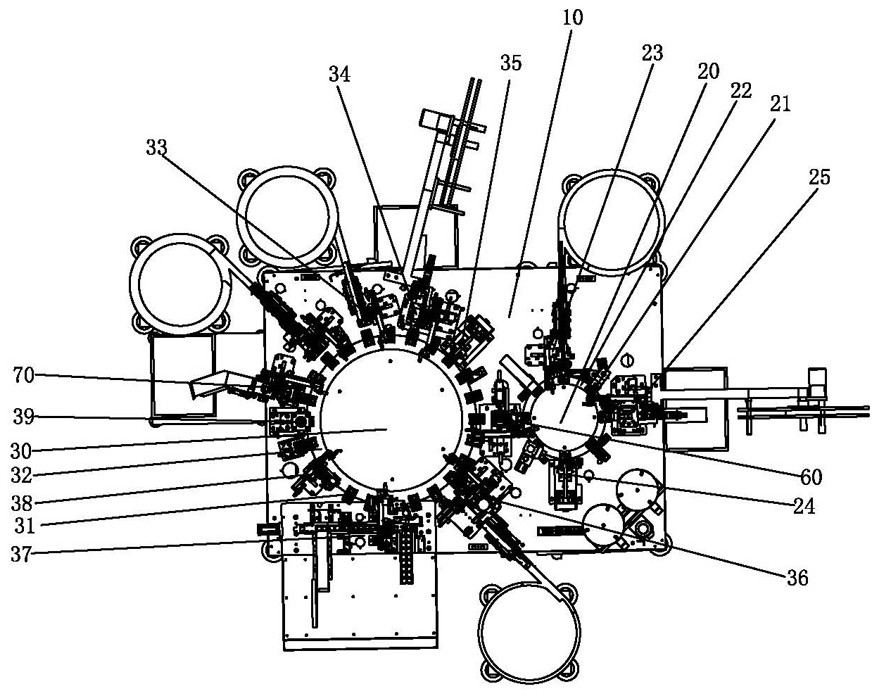

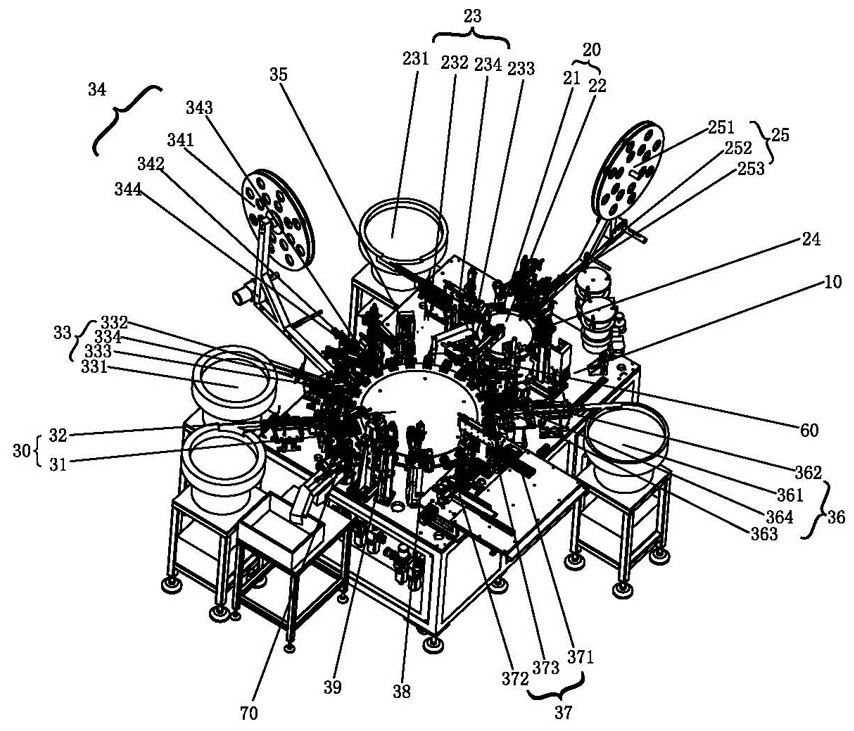

Automatic assembling equipment for logic encoder for household appliance

PendingCN112355635AReduce reworkIncrease productivityAssembly machinesMetal working apparatusComputer hardwareSystems engineering

The invention discloses automatic assembling equipment for a logic encoder for a household appliance. The automatic assembling equipment comprises a base, a first assembling table and a second assembling table, wherein the first assembling table and the second assembling table are arranged on the base; the upper end of the base is provided with a display screen and a control system used for controlling the first assembling table and the second assembling table; and the first assembling table is arranged on one side of the second assembling table, and a transfer clamping mechanism used for transferring products on the first assembly table is arranged between the first assembly table and the second assembly table. According to the automatic assembling equipment, one detection device is additionally arranged on each assembly part, parts neglected to be assembled can be found in time, and the situation of later reworking is reduced; and full-automatic assembling is adopted, each part can be quickly assembled, oiled and bent, two stations operate synchronously, therefore, the production efficiency can be further improved, the cost of an enterprise is reduced, and the labor intensity ofworkers is relieved.

Owner:广东钺河智能科技有限公司

Low-salt passiflora-edulis duck eggs and making method thereof

The invention discloses a passion fruit low-salt duck egg, which is made of the following raw materials in parts by weight: 60-70 fresh duck eggs, 10-14 passion fruit, 6-8 corn grains, and 2-3 pecan kernels , hijiki 4-5, walnut flower 2-3, kudzu root 1-2, cassia seed 4-5, turmeric 2-3, apocynum leaf 4-5, orchid seed 3-4, seaweed powder 2-3, high alcohol , an appropriate amount of white vinegar and salt; the present invention soaks duck eggs with white vinegar so that the eggshell produces tiny holes to facilitate the exchange of substances such as salt. Consistent osmotic pressure allows the salt to permeate into the egg yolk to dehydrate it to loosen the sand and produce oil, and the salt content of the egg white will no longer rise. The first stage is quickly completed by using reduced-pressure marinating, adding white wine to accelerate protein coagulation, so that the egg yolk quickly produces oil , the cooked salted duck egg protein tastes right, the egg yolk is loose and sandy, the wine is full of fragrance, the fragrance is strong, and the taste is delicious.

Owner:柳培健

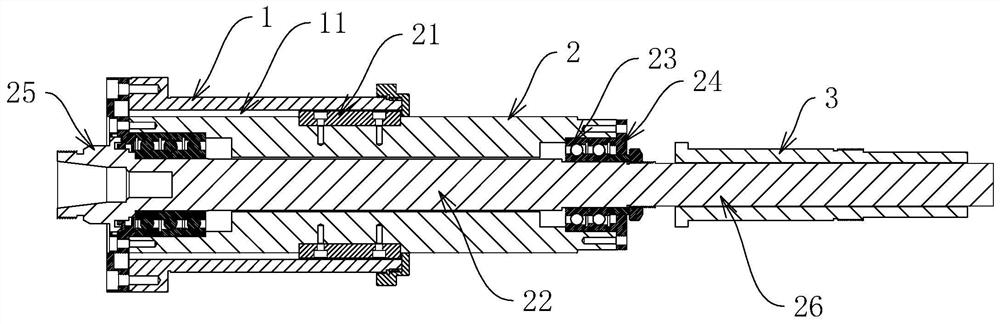

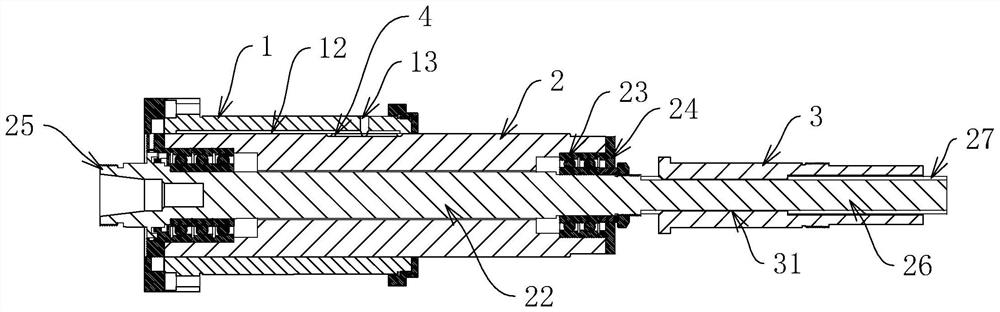

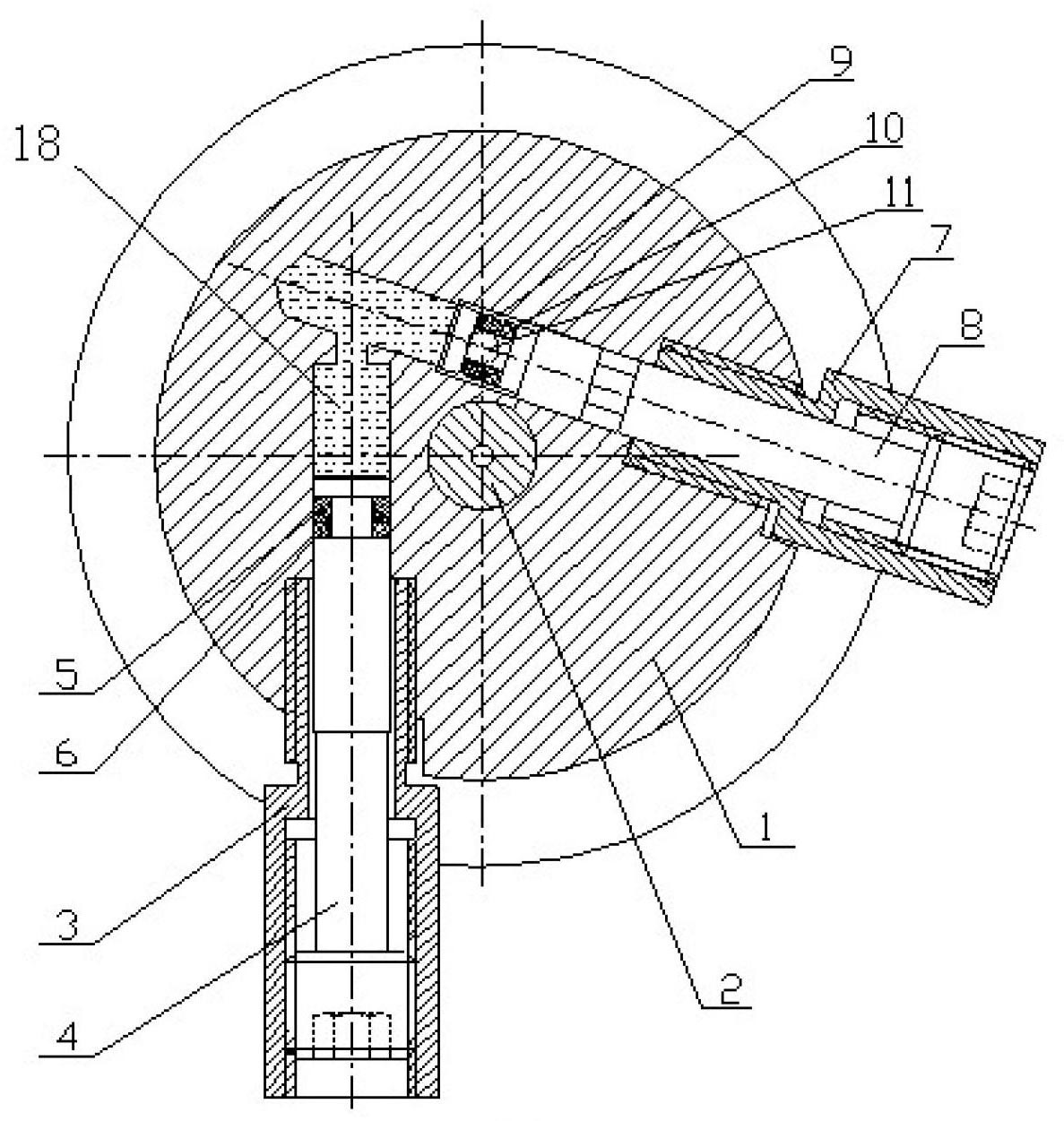

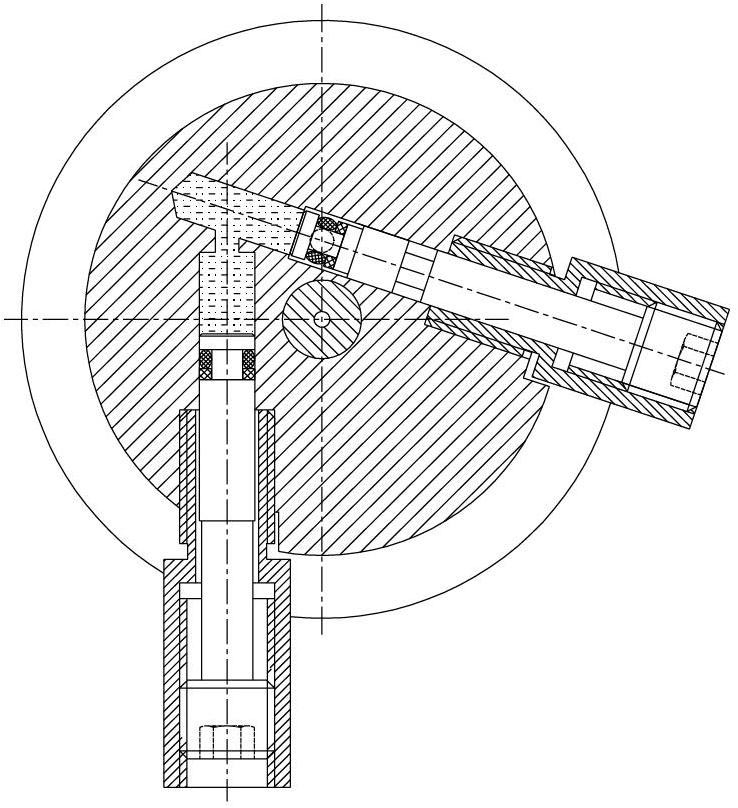

Fast oiling mechanism for hydraulic locking mechanical arm

ActiveCN102661301AQuick oilingRapid quantitationFluid-pressure actuator componentsPistonPetroleum engineering

The invention discloses a fast oiling mechanism for a hydraulic locking mechanical arm. The fast oiling mechanism comprises a hydraulic source part, wherein the hydraulic source part comprises a hydraulic source shell, a hydraulic source piston and a first articulated shaft which is in clearance fit with the hydraulic source shell, wherein hydraulic oil pipelines which are communicated with each other are formed on the first articulated shaft and the hydraulic source shell; sides of the hydraulic source shell are connected with an oil injection module and a separation module; the inner ends of the oil injection module and the separation module are provided with oil injection cavities which are communicated with each other; a connecting hole is formed in the hydraulic source shell; the oil injection cavities are connected with the hydraulic oil pipelines through the connecting hole; and the separation module controls the opening and closing of the connecting hole. The oil injection module is matched with the separation module, so that the mechanical arm hydraulic system can be rapidly oiled and quantified so as to be finely adjusted.

Owner:BEIJING BAIHUI WEIKANG SCI & TECH CO LTD

Lemon stomach-tonifying low-salt duck eggs and making method thereof

The invention discloses a low-salt duck egg with lemon, which is made of the following raw materials in parts by weight: 70-80 fresh duck eggs, 14-18 lemons, 8-10 edible cactus, 10-12 lemongrass, and 7-12 pomegranates. 8. Bay leaf 3-4, corn silk 4-5, mango core 2-3, nard pine 1-2, emblica 4-5, Peilan 2-3, high-grade liquor, white vinegar and salt; the present invention uses duck eggs Soaking in white vinegar makes the eggshell produce tiny holes to facilitate the exchange of salt and other substances. First use the pickling solution and then pickle the duck eggs with the same salt content to pickle the duck eggs. Because the osmotic pressure of the egg white and the shell is consistent, the salt penetrates into the egg yolk to make it Dehydration reaches loose sand and oil, and the salt content of egg white does not rise anymore. The first stage is quickly completed by using reduced-pressure marinating, and white wine is added to accelerate protein solidification, so that egg yolk quickly produces oil. Oily, lemon fragrance, has the effects of invigorating the stomach and eliminating food, regulating qi and refreshing the spleen.

Owner:柳培健

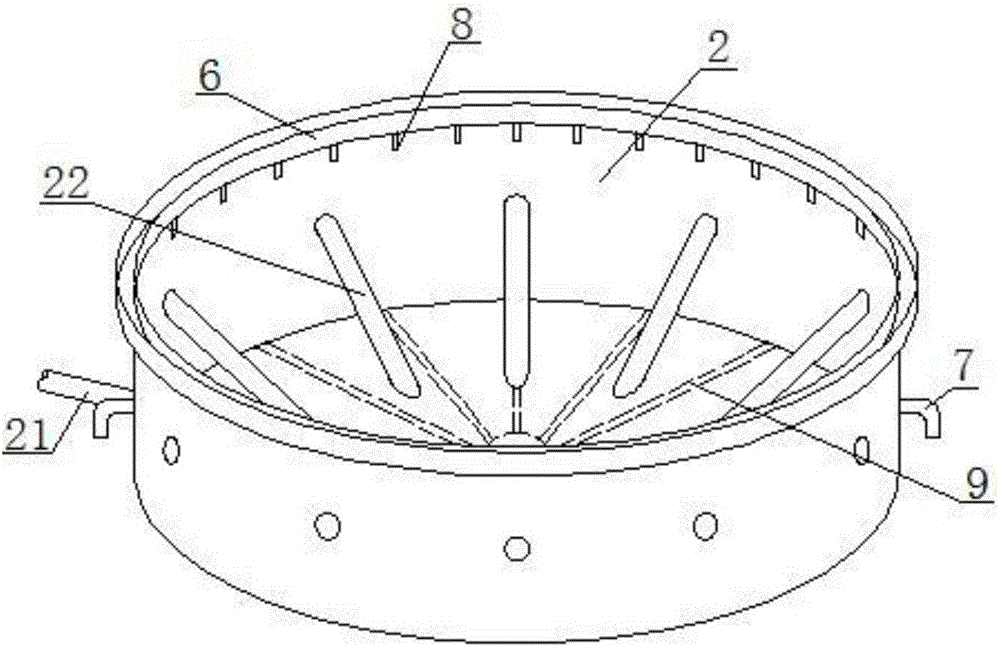

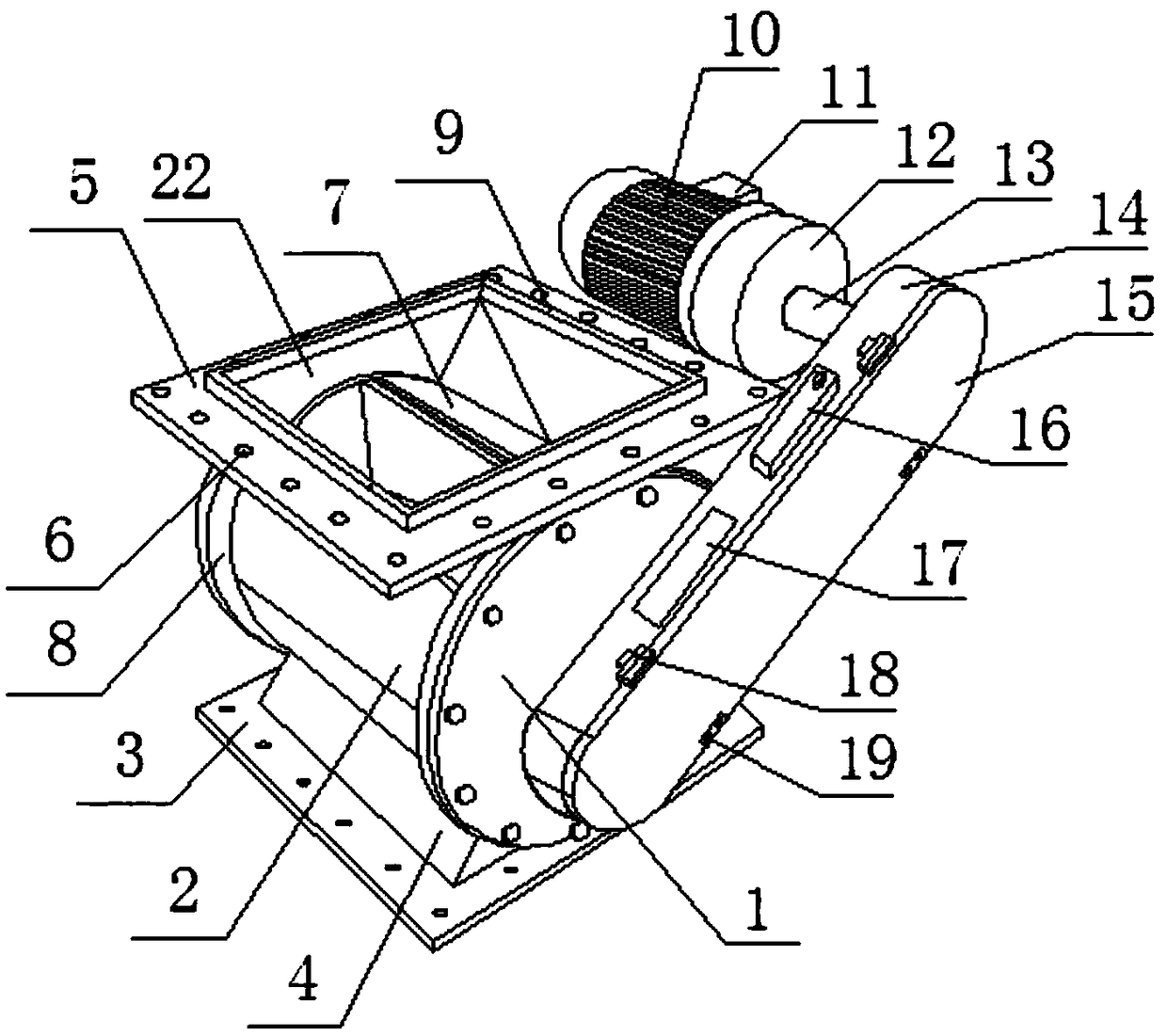

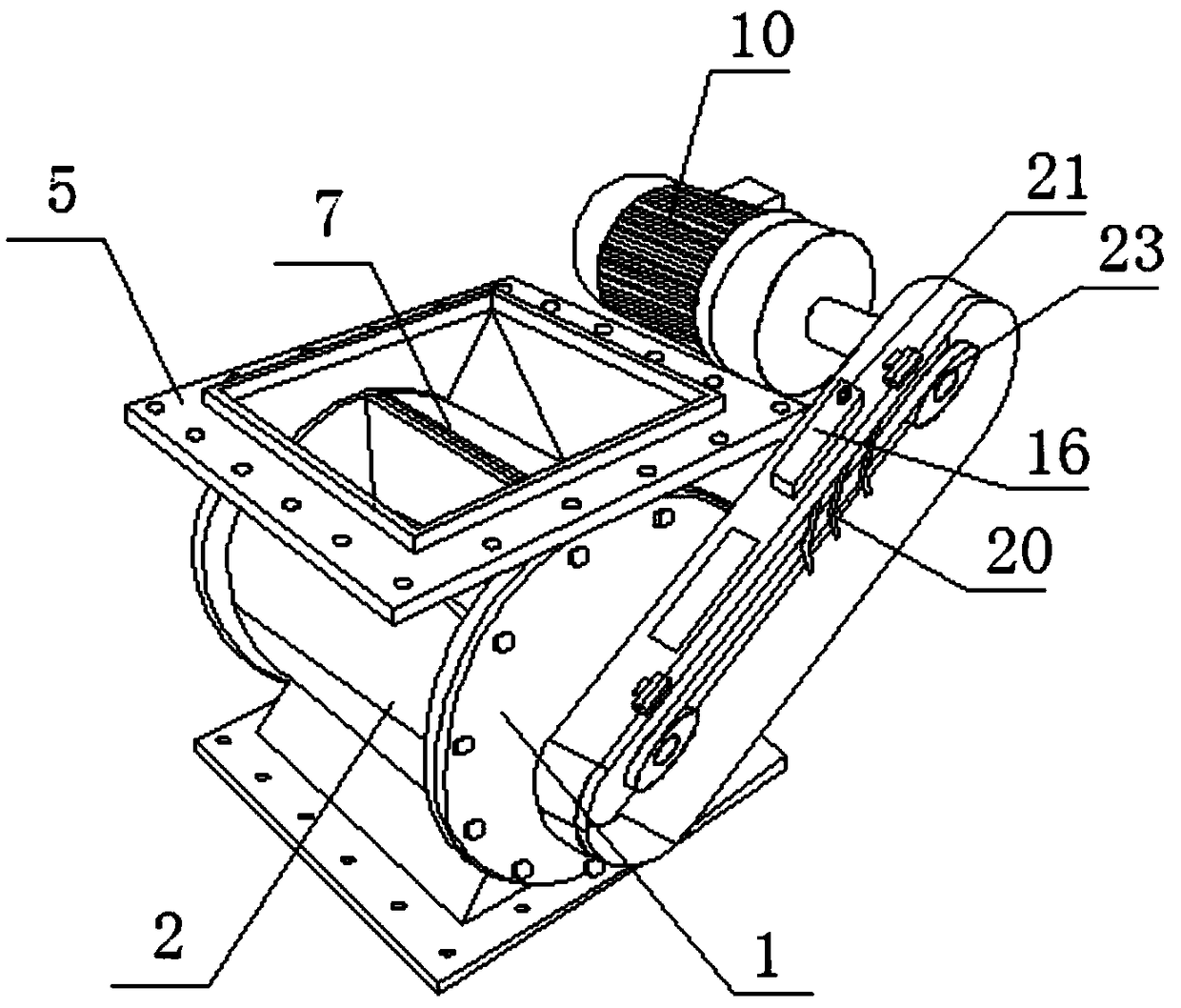

Chain transmission type rotary valve convenient to maintain

The invention discloses a chain transmission type rotary valve convenient to maintain. The chain transmission type rotary valve convenient to maintain comprises a rotary valve body, a box body, a bottom plate, a discharging hopper, a connecting flange, a flange connecting bolt hole, a material shifting impeller, an impeller bearing, a sealing gasket, a motor, a junction box, a gear box, a rotatingshaft, a chain box, a chain box cover, a lubricating oil box, a transparent acrylic plate, a buckle, a hinge, an oil dipping sliver, an oil inlet, a feeding hopper and a chain, wherein the bottom plate is arranged at the bottom end of the rotary valve body, the discharging hopper is arranged at the top end of the bottom plate, the box body is arranged at the top end of the discharging hopper, andthe material shifting impeller is arranged in the box body. The rotary valve can quickly open the chain box, can replace a chain without disassembling the chain box, can quickly brush oil on the chain, prevent the chain from rusting and affecting the service life, can see the service condition of the chain, improve the maintenance efficiency, ensure the normal use of the rotary valve and prolongthe service life of the rotary valve.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Garlic liver-protecting coating salted duck egg and making method thereof

InactiveCN106174129AIncrease nutritionShorten the pickling processFood coatingFood ingredient functionsEggshellPolyvinyl alcohol

The invention discloses a garlic liver-protecting coating salted duck egg. The egg is made from, by weight, 500-510 parts of duck eggs, 20-24 parts of donkey-hide gelatin, 30-34 parts of garlic powder, 3-4 parts of dandelion, 20-23 parts of olive juice and a proper amount of sodium carbonate, malic acid, polyvinyl alcohol, glycerinum, table salt and water. The raw materials of salted duck egg soaking and pickling liquid are diverse and include donkey-hide gelatin, garlic powder and the like, nutrients are rich, lots of nutrients are adsorbed in duck eggs, the overall nutritional value of the salted duck egg is improved, and the salted duck egg has fatigue resisting and liver protecting functions after being eaten; after the process is improved, the permeability of egg shells is improved, and the duck egg pickling process is shortened; a coating is formed outside the egg shell, and the freshness of the salted duck egg can be better preserved.

Owner:HEFEI FULAIDUO FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com