Quick oiling equipment for bearing

A bearing and oiling technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of labor intensive, unsatisfactory oiling effect, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

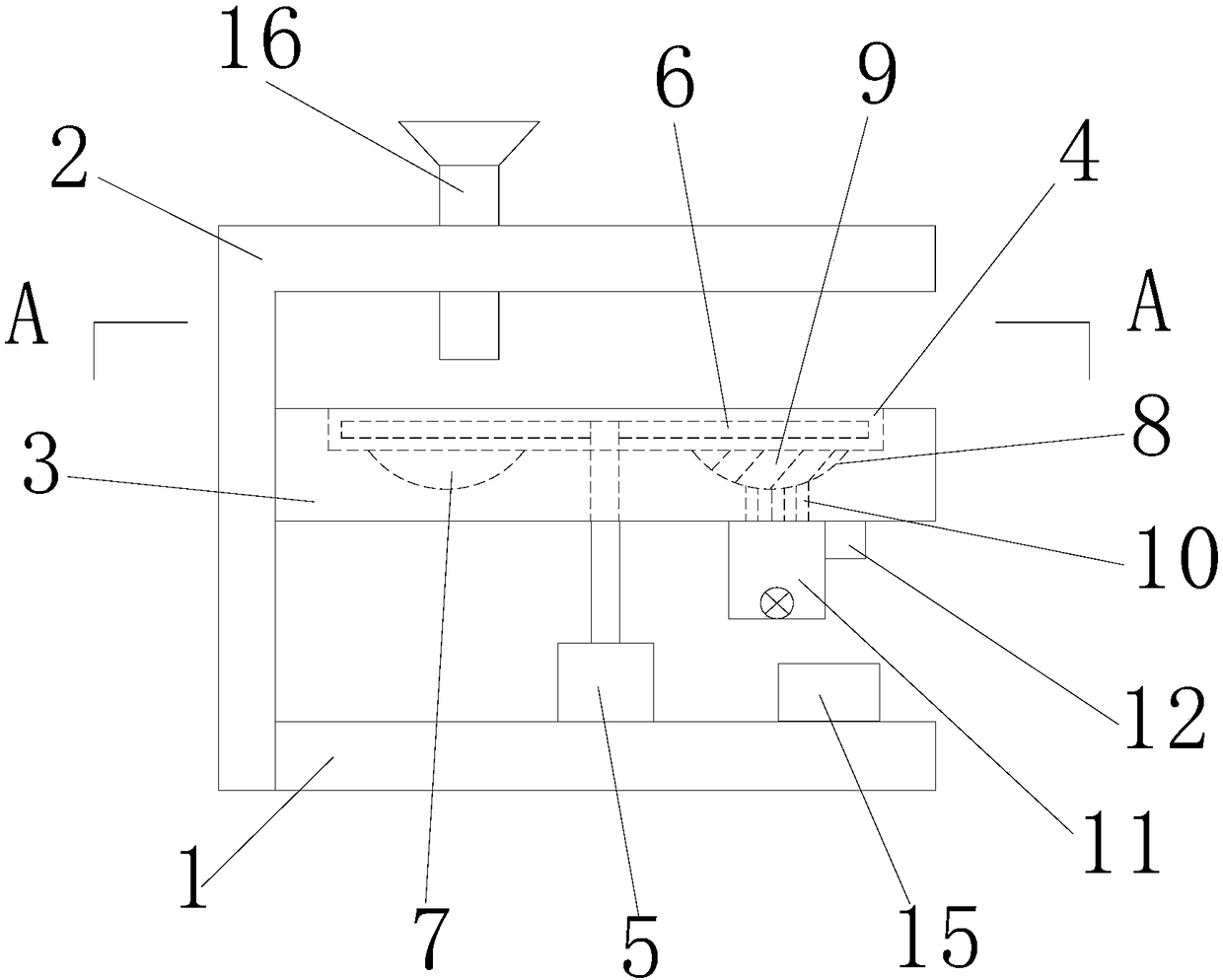

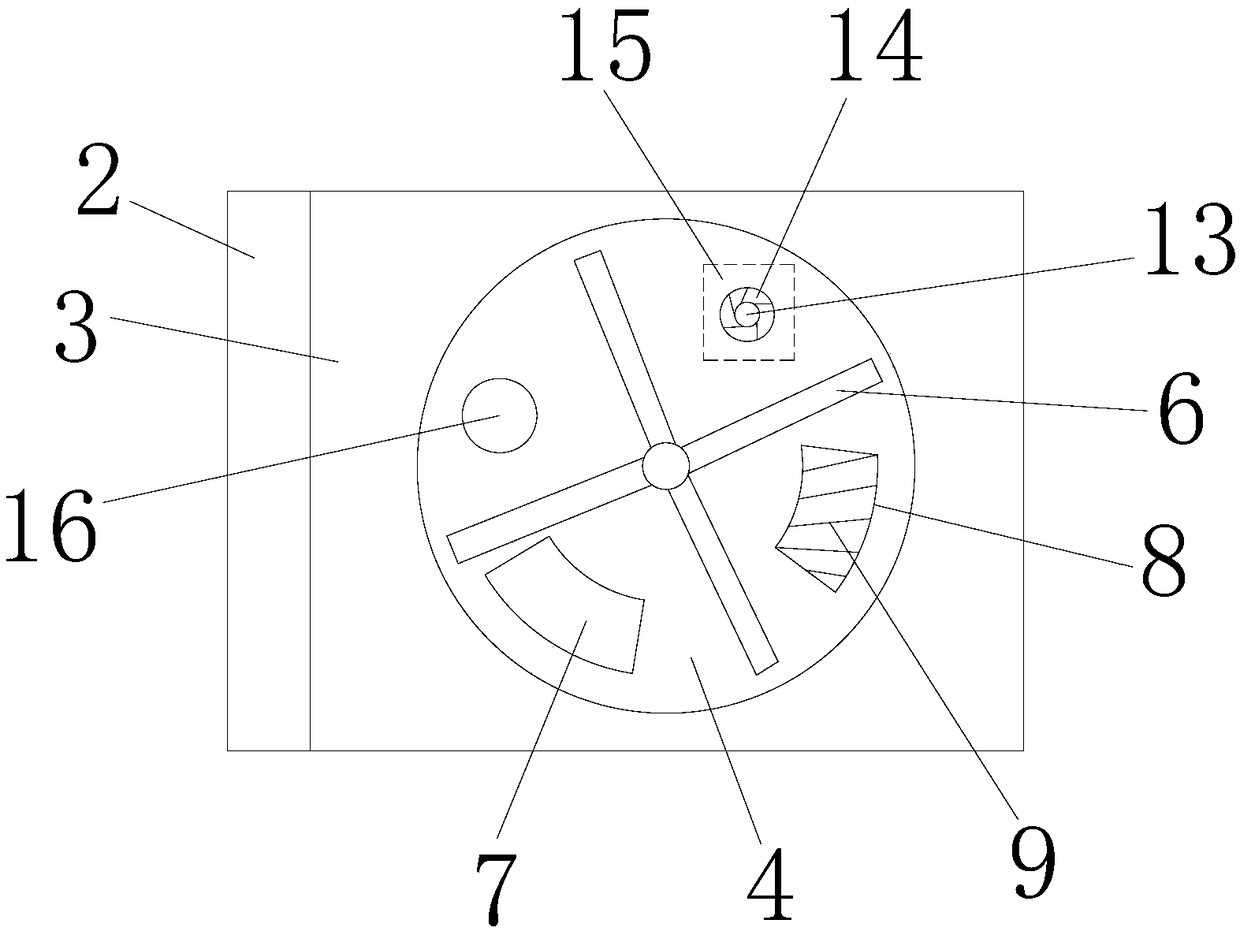

[0017] refer to figure 1 , 2 , a quick oiling device for bearings of the present invention, comprising a base 1, a frame 2, a mounting plate 3, a sinker 4, a motor 5, a toggle lever 6, an oil storage tank 7, an oil suction tank 8, a sponge pad 9, and an oil discharge hole 10. Oil storage tank 11, suction pump 12, discharge port 13, sponge layer 14, material receiving box 15 and lower hopper 16, one end of the base 1 is fixed with a frame 2, and the side of the frame 2 A horizontally arranged mounting plate 3 is fixed, and a circular sinking groove 4 is provided on the upper part of the mounting plate 3. The upper part of the base 1 is located directly below the sinking groove 4 and is fixed with a motor whose output shaft is vertically upwardly arranged. 5. The output shaft of the motor 5 passes through the center of the sinker 4 and extends above the sinker 4, and the side of the upper end of the output shaft of the motor 5 is fixed with a plurality of evenly distributed tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com