Patents

Literature

43results about How to "Moderate time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

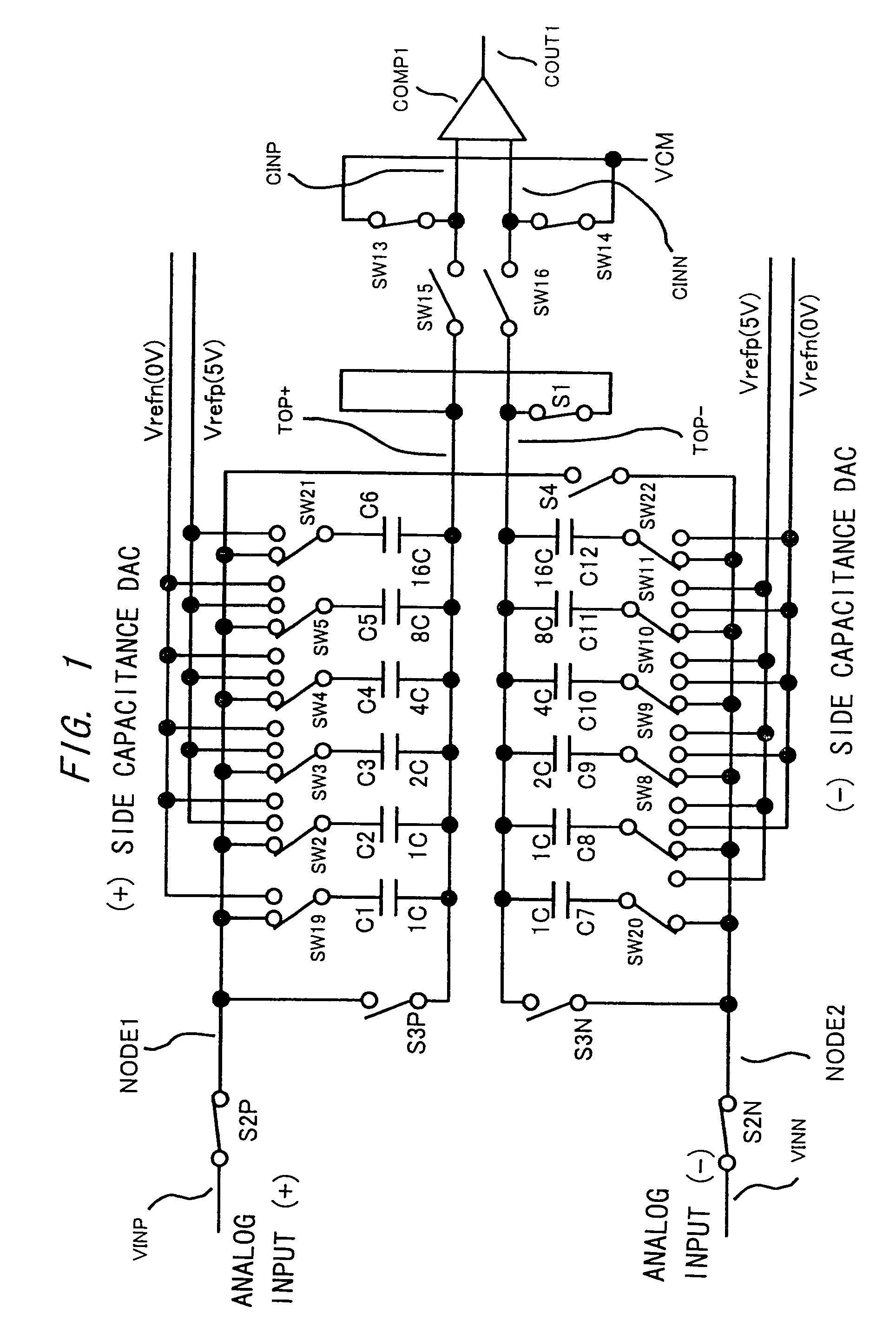

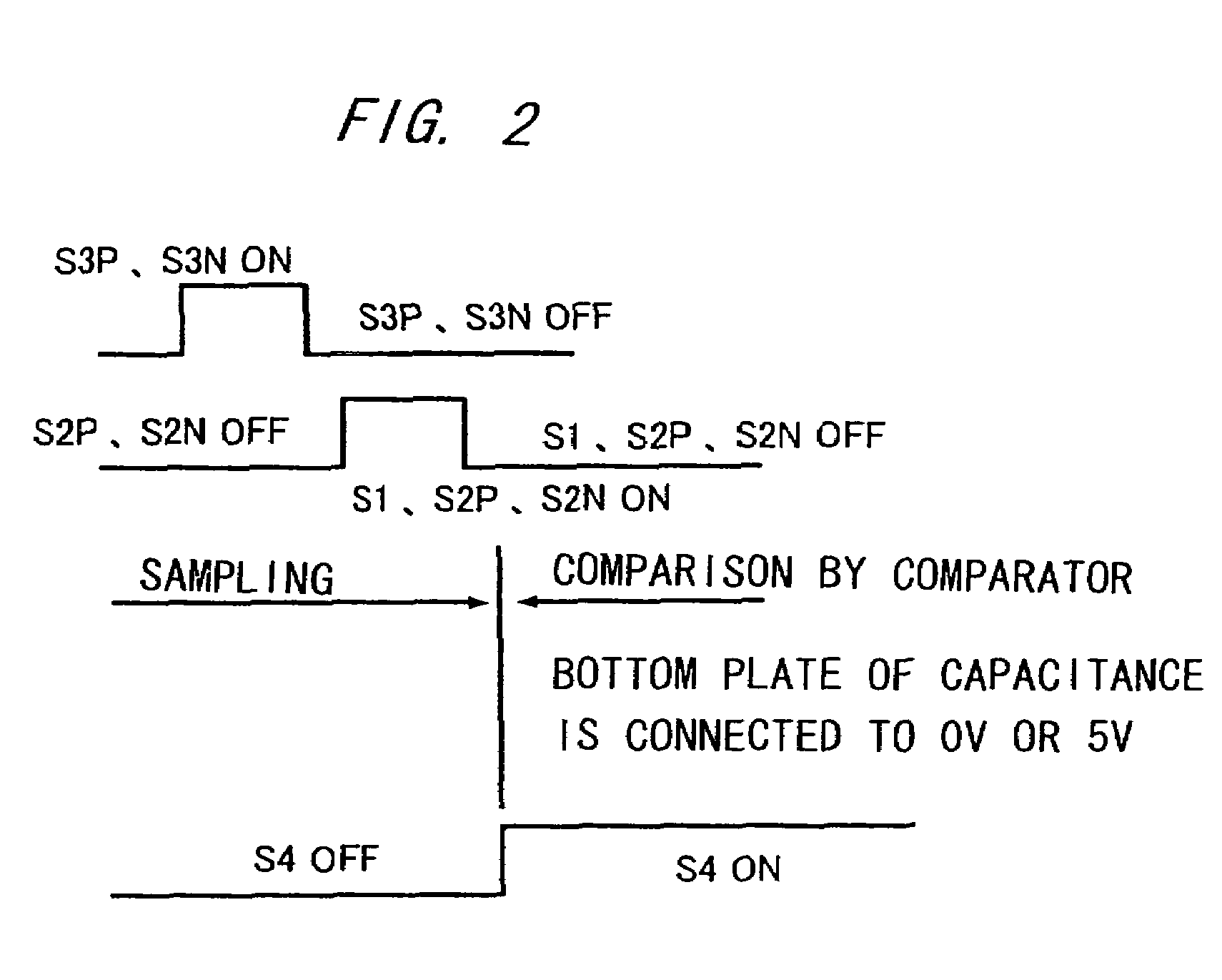

Analog-to-digital converter

InactiveUS20070115159A1Avoid volatilityOperating with small areaElectric signal transmission systemsAnalogue-digital convertersA d converterEngineering

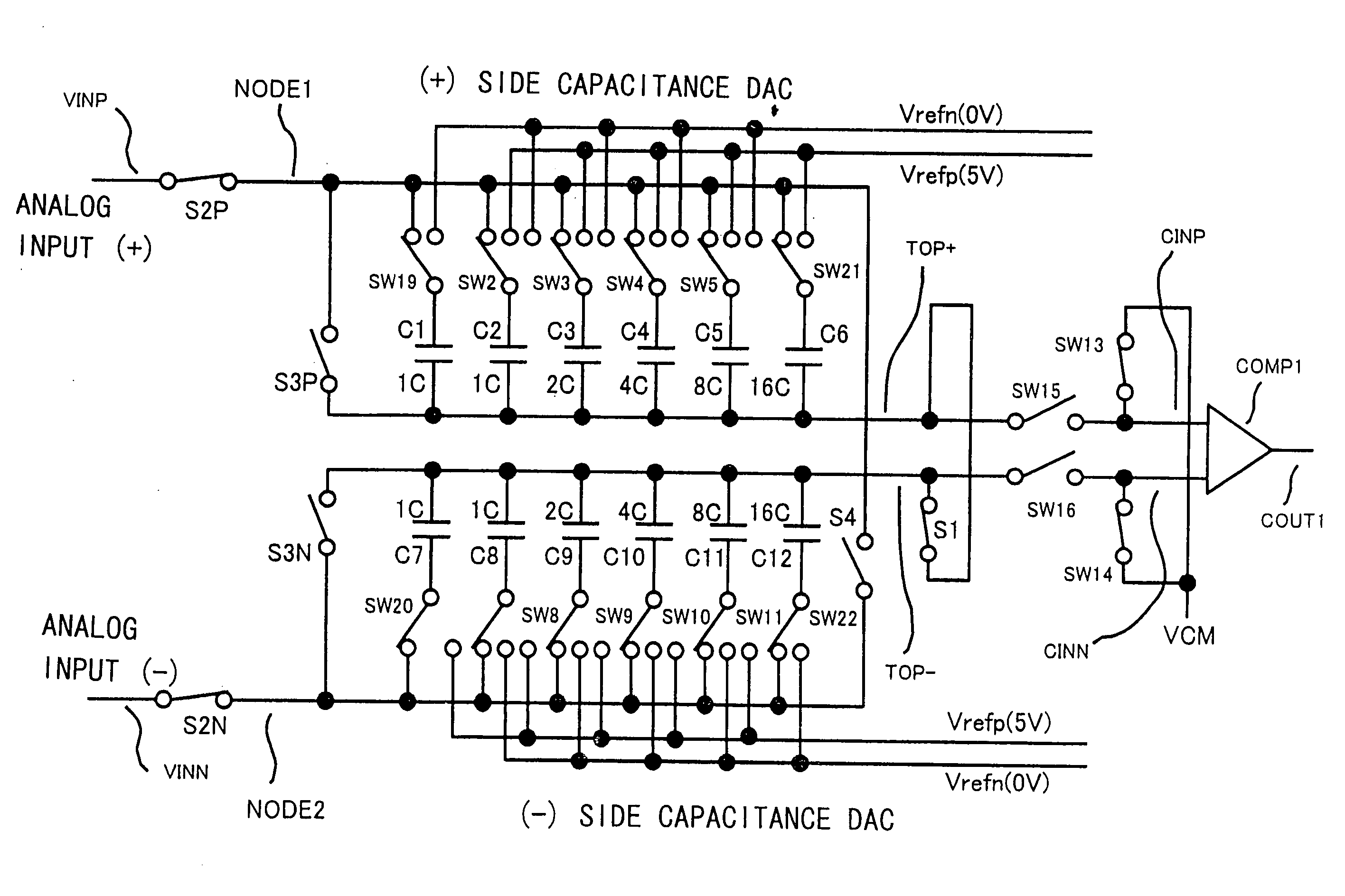

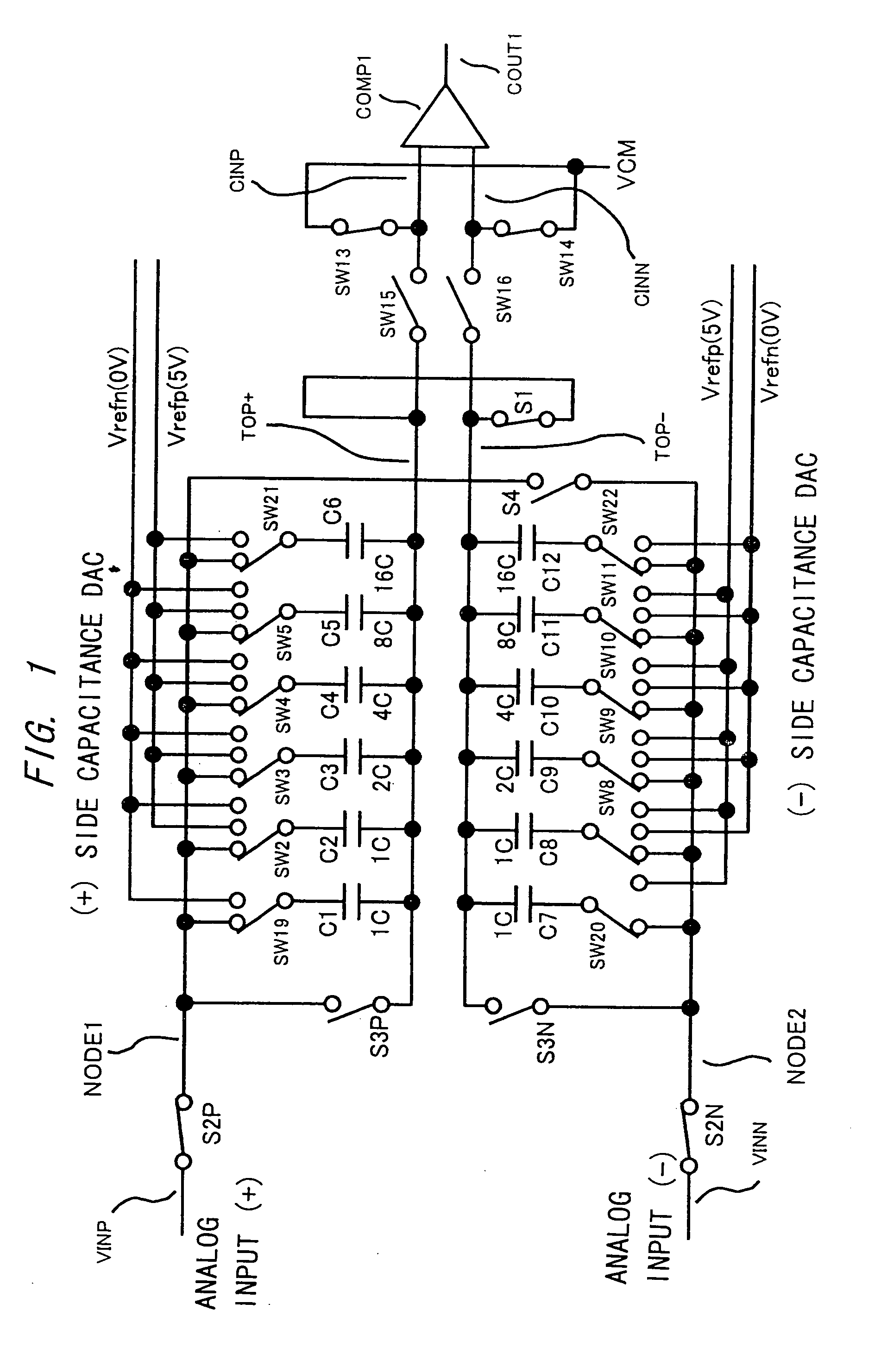

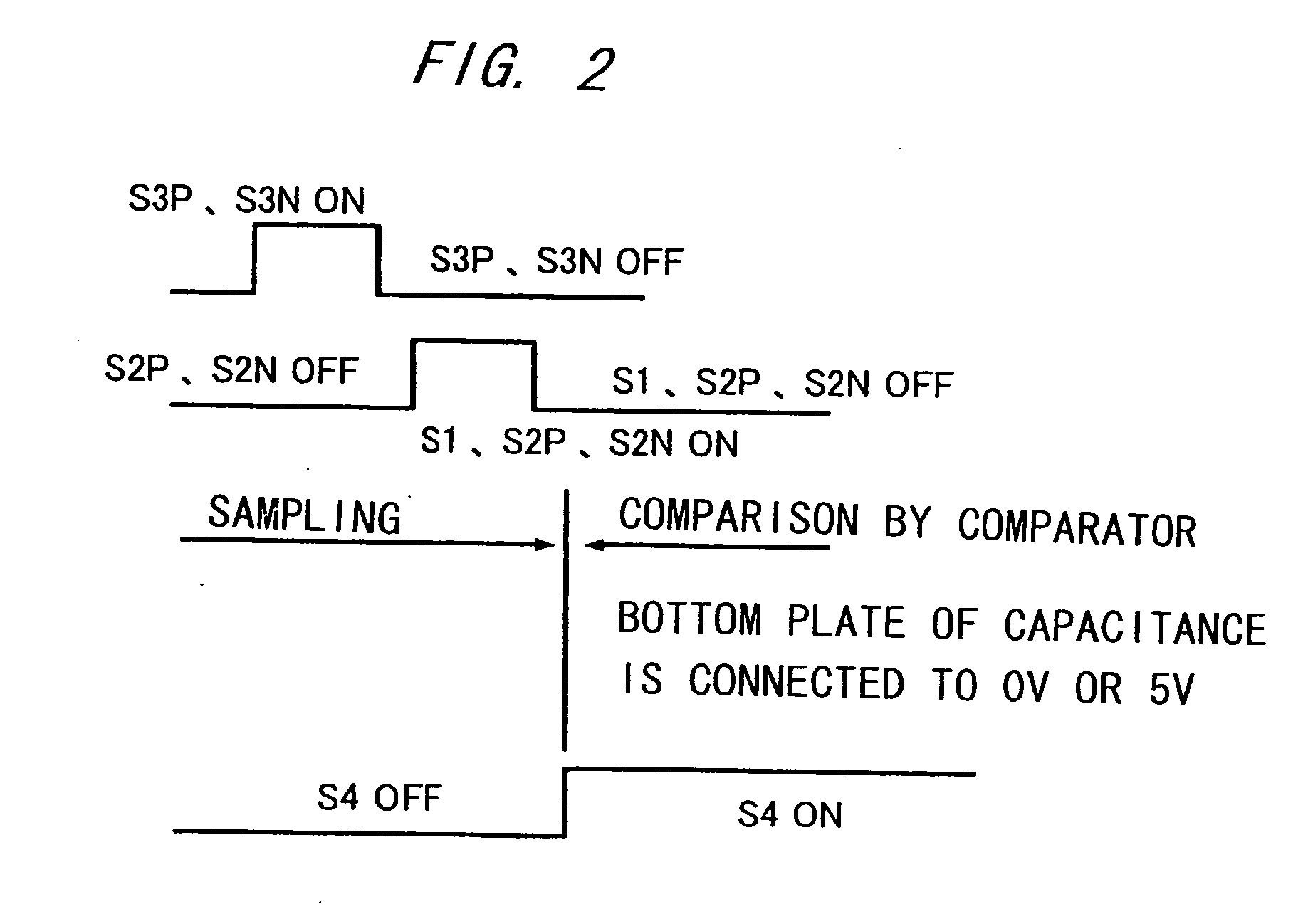

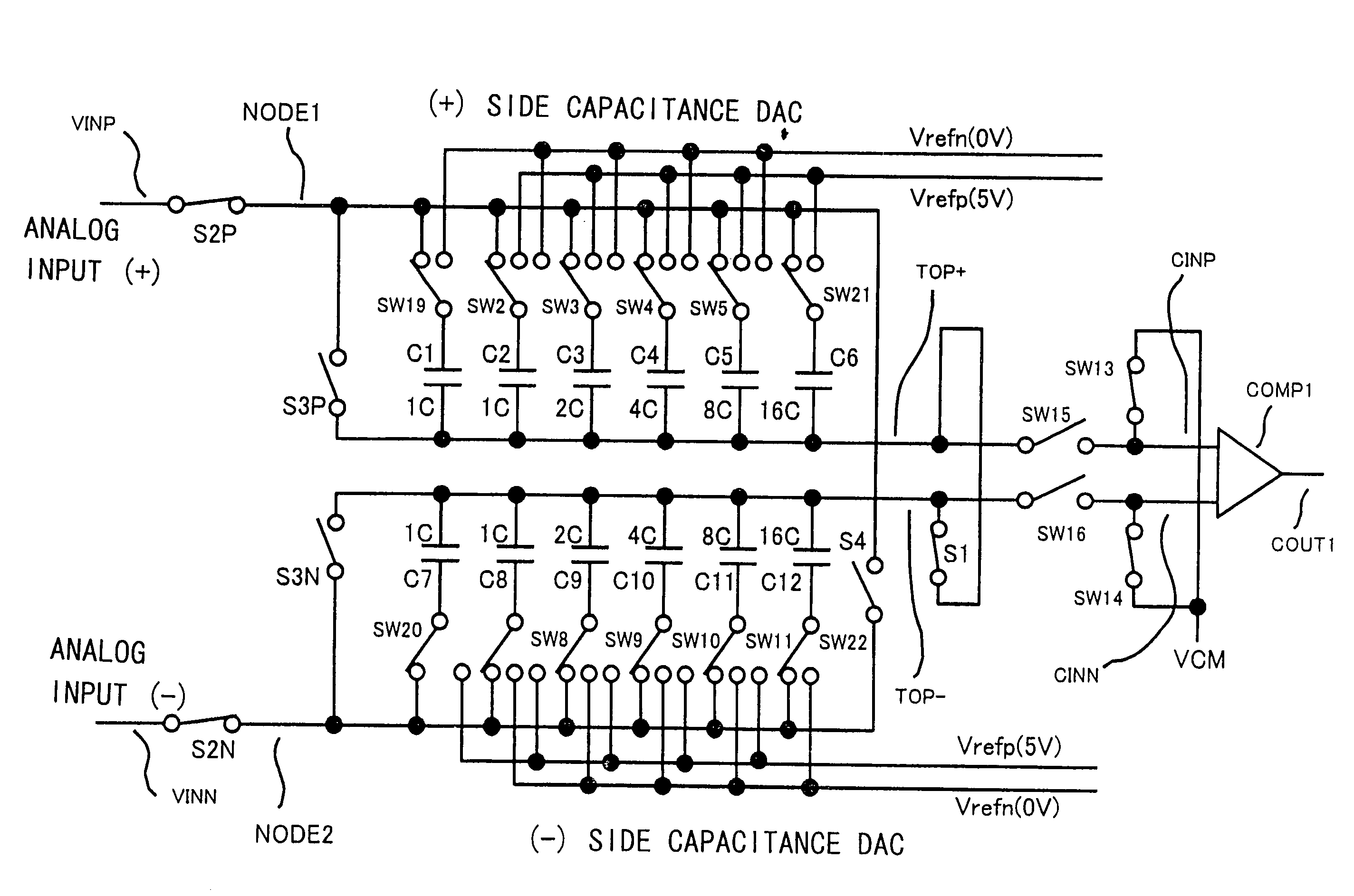

Included are a first DAC taking in and retaining sample data of a first analog signal and generating a comparison signal serving as an object of comparison with the first analog signal, a second DAC taking in and retaining sample data of a second analog signal and generating a comparison signal as an object of comparison with the second analog signal, a first switch connecting the first digital-to-analog converter to an output side of a second digital converter in a openable / closable manner, a comparator comparing, when the first switch is opened, a differential value between the first analog signal and the second analog signal with a differential value between an output signal of the first DAC and an output signal of the second DAC, and an electric potential control circuit controlling fluctuations in electric potentials of a first analog terminal and a second analog terminal.

Owner:CYPRESS SEMICON CORP

Analog-to-digital converter

InactiveUS7233273B2Low costReduce power consumptionElectric signal transmission systemsAnalogue-digital convertersDigital down converterControl circuit

Included are a first unit including a DAC which generates a comparison signal serving as an object of comparison with the first analog signal, taking in and retaining the first analog signal, a second unit including a DAC which generates a comparison signal serving as an object of comparison with the first analog signal, taking in and retaining the second analog signal, a first switch connecting the first unit to an output side of the second unit, a comparator comparing a differential value between the first analog signal and the second analog signal with a differential value between the comparison signal of the first DAC and an output signal of the second DAC, and an electric potential control circuit controlling fluctuations in electric potentials of the first analog terminal and the second analog terminal.

Owner:CYPRESS SEMICON CORP

Tea coffee solid beverage and preparation method thereof

InactiveCN103202362AStrong fragranceGood rehydrationPre-extraction tea treatmentRoasted coffee treatmentCoffeaNutrition

The invention relates to a solid beverage, and in particular relates to a tea coffee solid beverage and a preparation method thereof. The tea coffee solid beverage comprises the following materials according to mass ratio: 80-120 parts of Vietnam medium coffee beans, 60-80 parts of Yunnan small coffee beans, 140-160 parts of Dianhong Kungfu tea, 55-65 parts of vegetable fat powder and 46-50 parts of white sugar. The preparation method comprises the following steps of: A. mixing; B. baking; C. crushing; D. extracting; E. concentrating; F. homogenizing; G. sterilizing; H. cooling and drying; and I. packaging. The mixing ratio of the Vietnam medium coffee beans to the Yunnan small coffee beans is proper, the tea coffee solid beverage is high in content of caffeine, fragrant, pure and mild in flavor and high in content of effective nutritional ingredients after the working procedures of baking, crushing, extracting and concentrating. The extraction of distilled water of coffee mixed powder and red tea powder is proper in temperature and moderate in time. The finished product can be good in reconstitution property without residues, and the color, the fragrance, the taste and the nutritional ingredients of coffee and red tea can be well maintained.

Owner:普洱漫崖咖啡实业有限公司

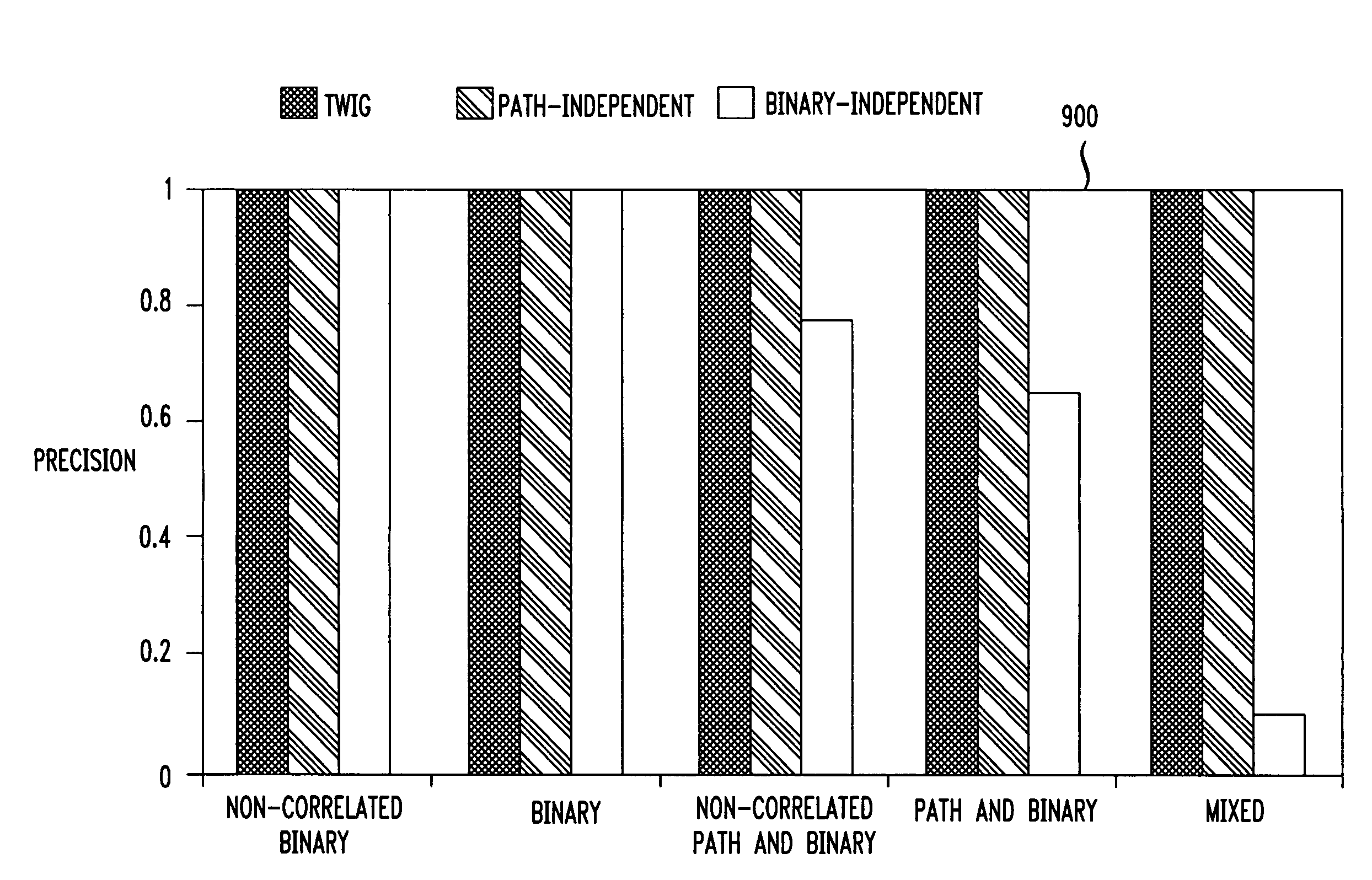

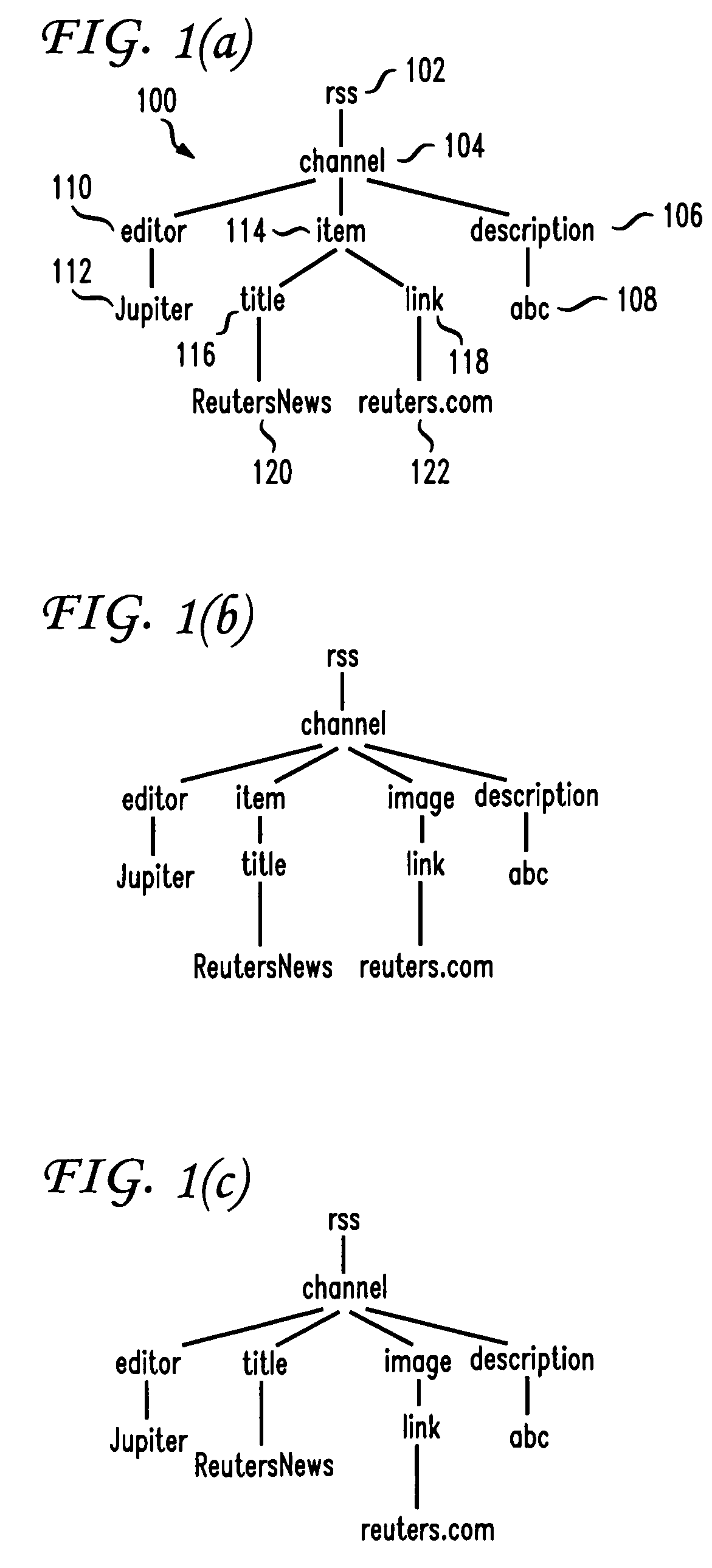

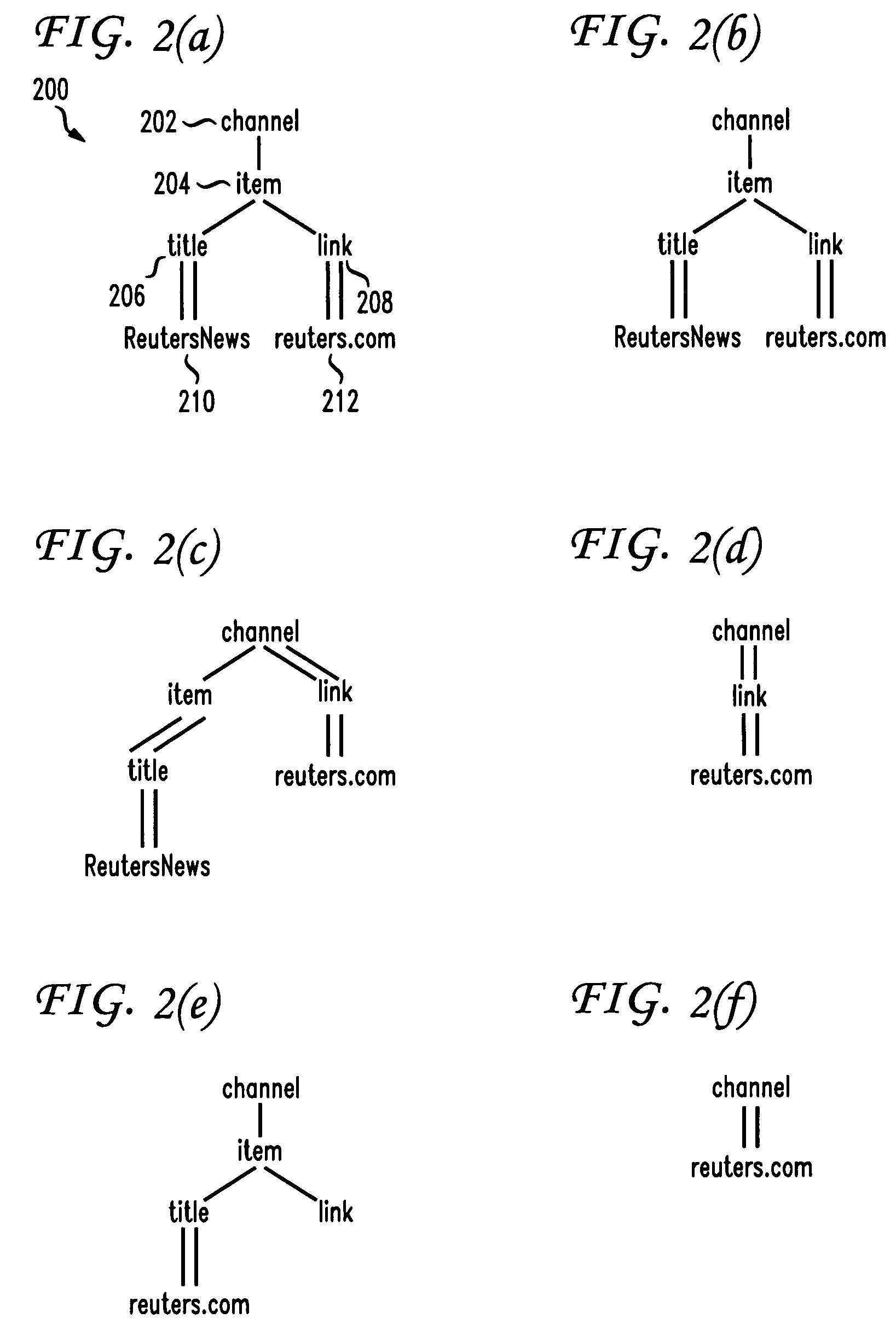

System and method for providing structure and content scoring for XML

InactiveUS8005817B1Quick fixEffective evaluationDigital data information retrievalDigital data processing detailsDatabase queryRelative significance

A system, method and computer readable medium are disclosed. The method embodiment relates to a method of computing score of candidate answers to a database query. The method comprises receiving a database query, assigning a first score to a match to the query, the first score being associated with a relative importance of an individual keyword in a collection of documents based on all structural and content predicates in the query, assigning a second score to the match, the second score being associated with a relative importance of a keyword in an individual document and using the assigned first score and second score to compute an answer score for the query.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

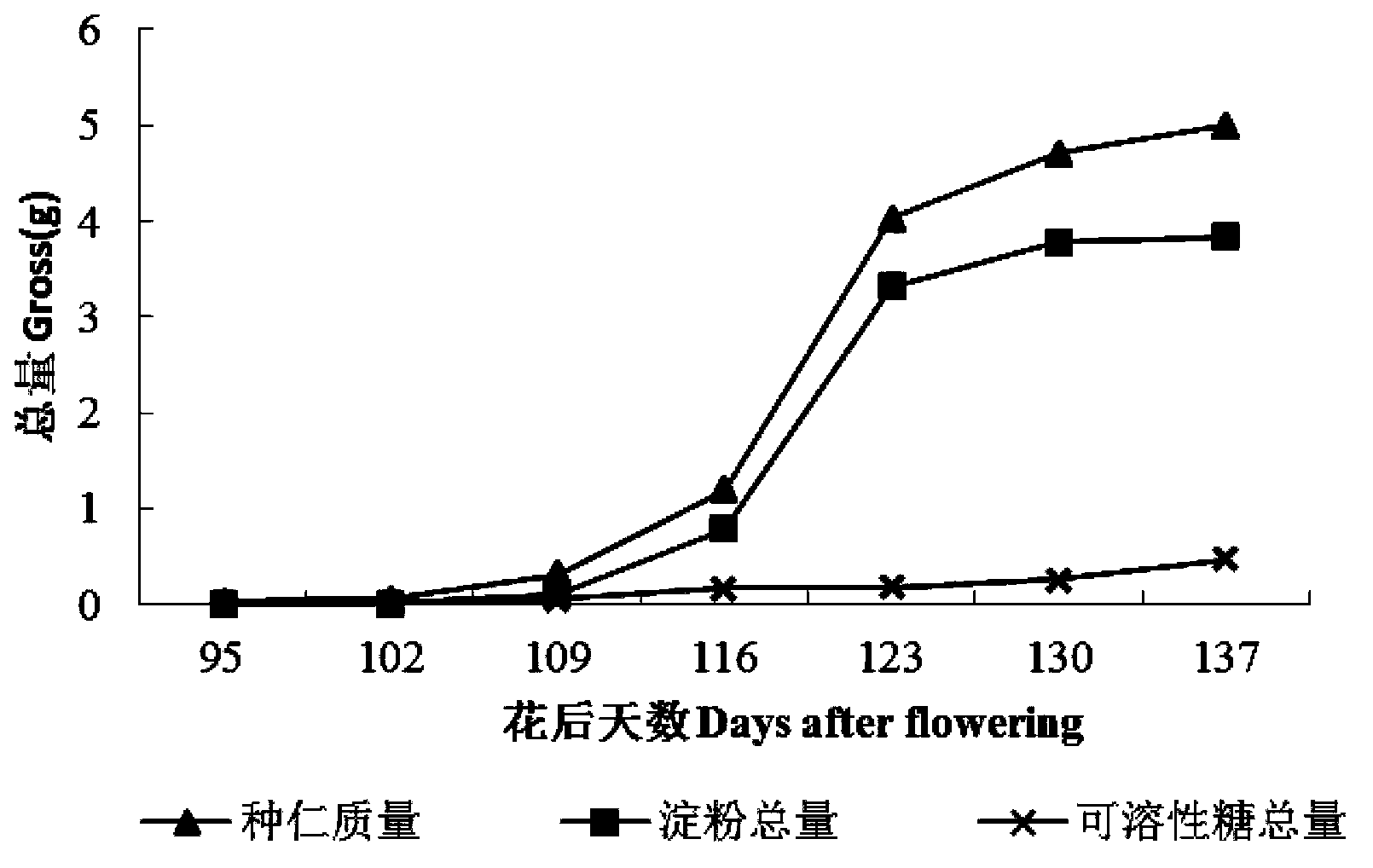

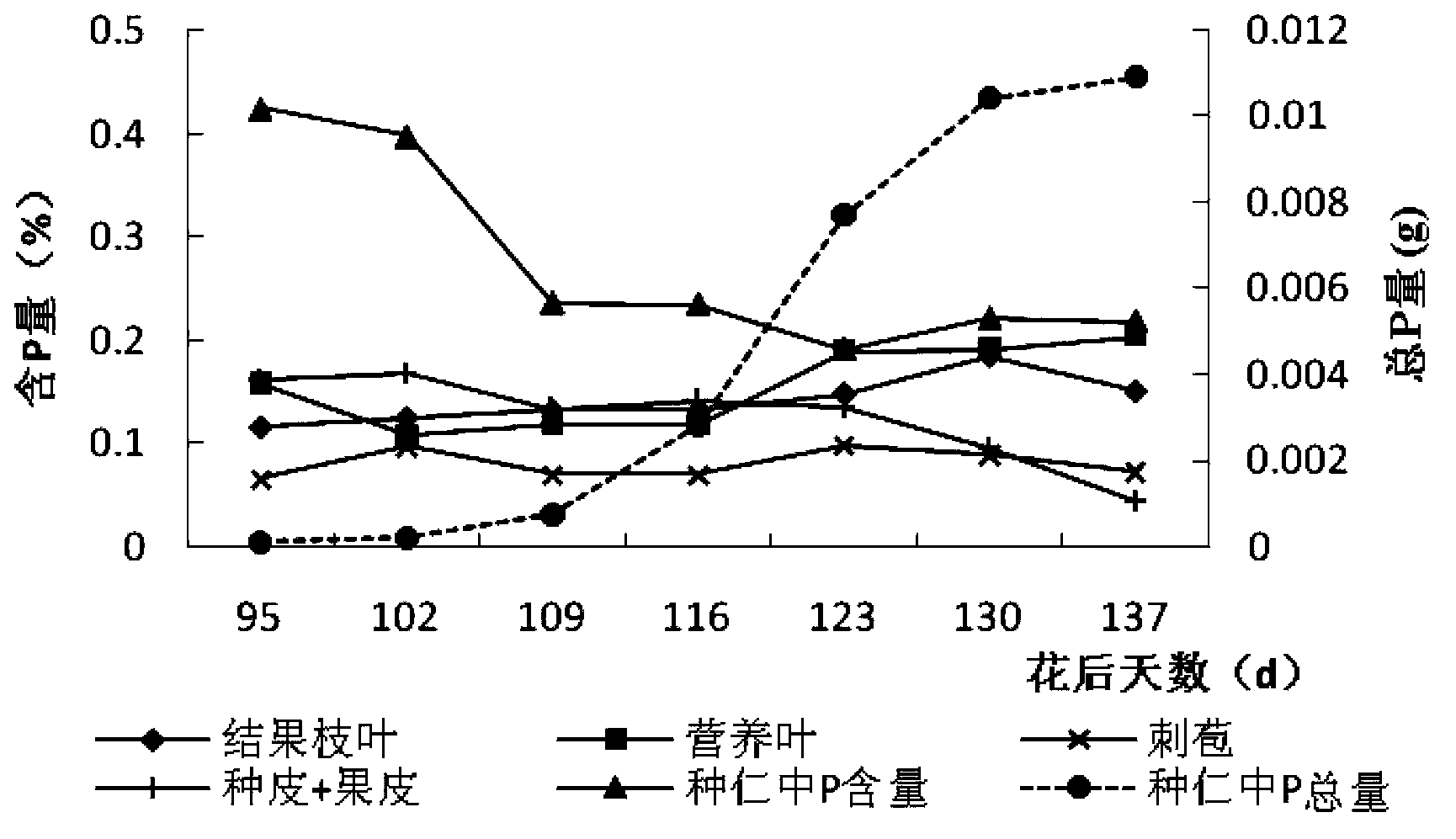

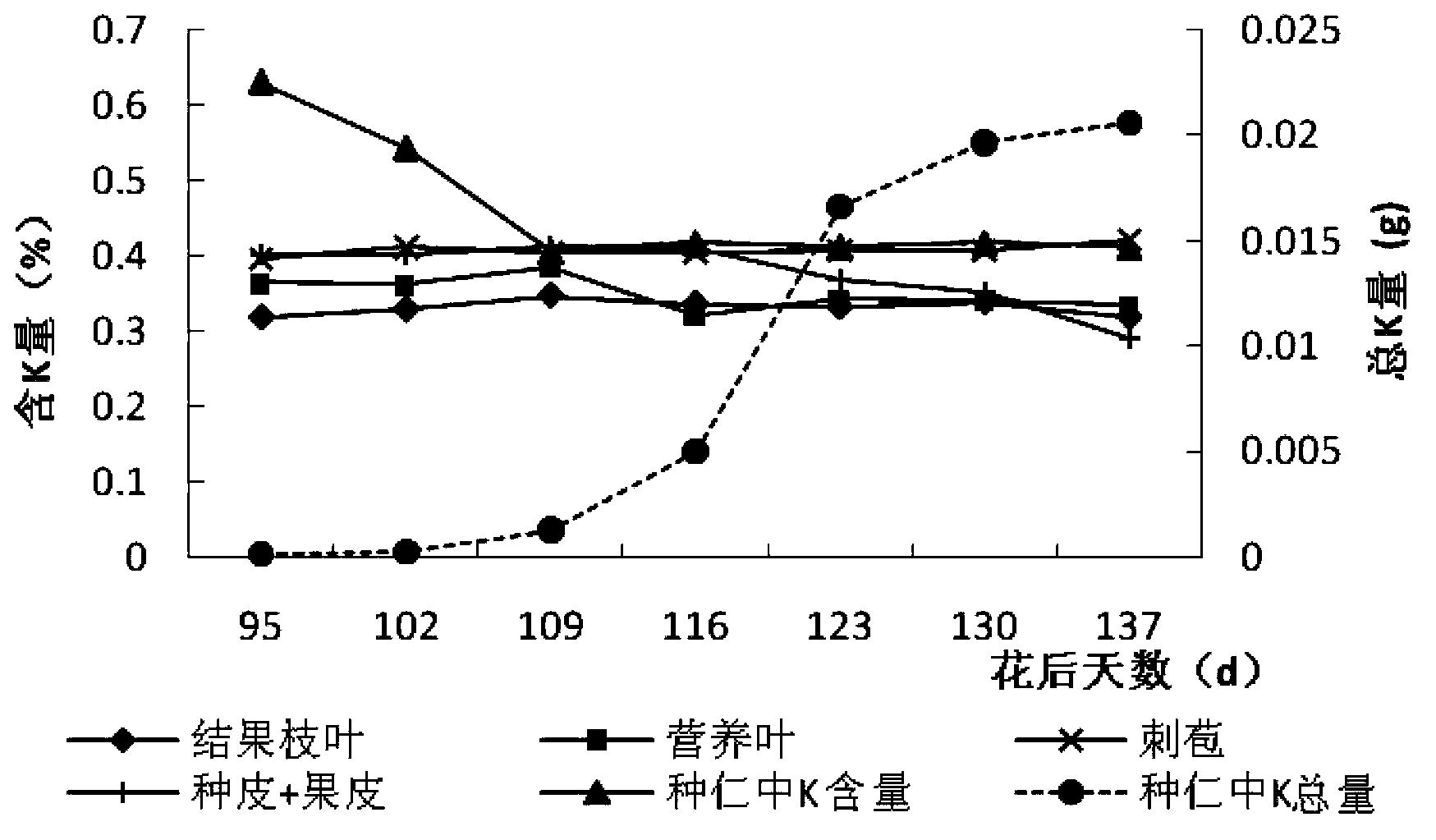

Castanea henryi high-yielding regulator and application thereof

ActiveCN103360159AMake up for the disadvantages of short blooming period and low efficiency of pollination and fertilizationMake up for the disadvantages of low pollination and fertilization efficiencyFertilising methodsFertilizer mixturesPhosphateMonopotassium phosphate

The invention provides a Castanea henryi high-yielding regulator and application thereof. The Castanea henryi high-yielding regulator is composed of a Castanea henryi high-yielding regulator 1 and a Castanea henryi high-yielding regulator 2, wherein the Castanea henryi high-yielding regulator 1 contains the following components in parts by weight: 10-150 parts of potassium dihydrogen phosphate, 20-150 parts of calcium chloride, 50-100 parts of boric acid, 50-100 parts of sucrose, 0.5-3 parts of 2,4-dichlorphenoxyacetic acid, 20-70 parts of gibberellin and 1-4 parts of indolebutyric acid; and the Castanea henryi high-yielding regulator 2 contains the following components in parts by weight: 100-300 parts of urea, 10-70 parts of ammonium phosphate, 20-50 parts of potassium sulfate, 30-70 parts of magnesium chloride, 50-100 parts of calcium chloride, 50-100 parts of manganese chloride, 10-30 parts of zinc sulfate and 50-200 parts of ferrous sulfate. The Castanea henryi high-yielding regulator provided by the invention can obviously enhance the yield of the Castanea henryi, and ensure the high and stable yield of the Castanea henryi.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

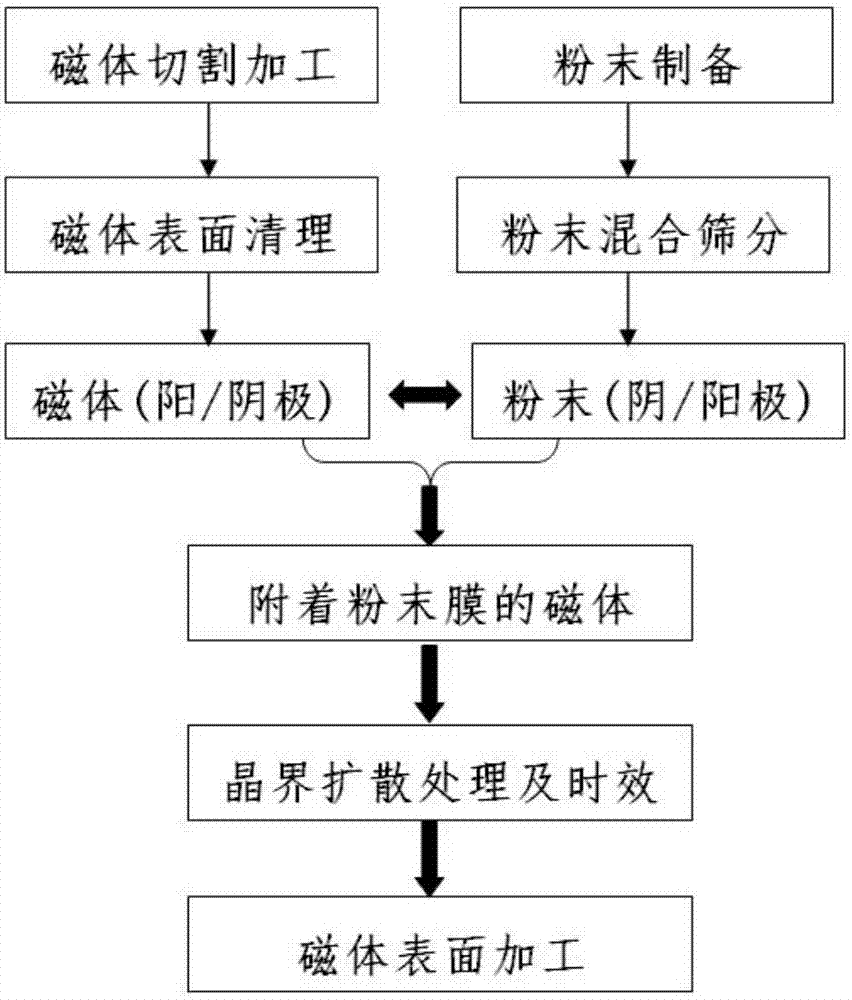

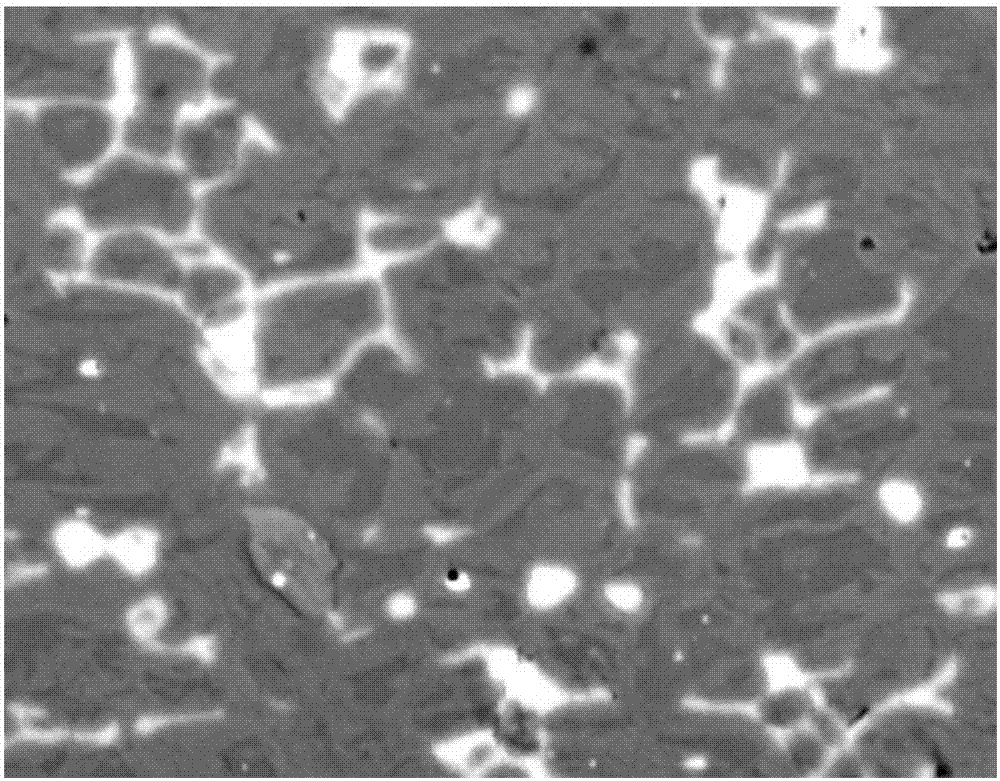

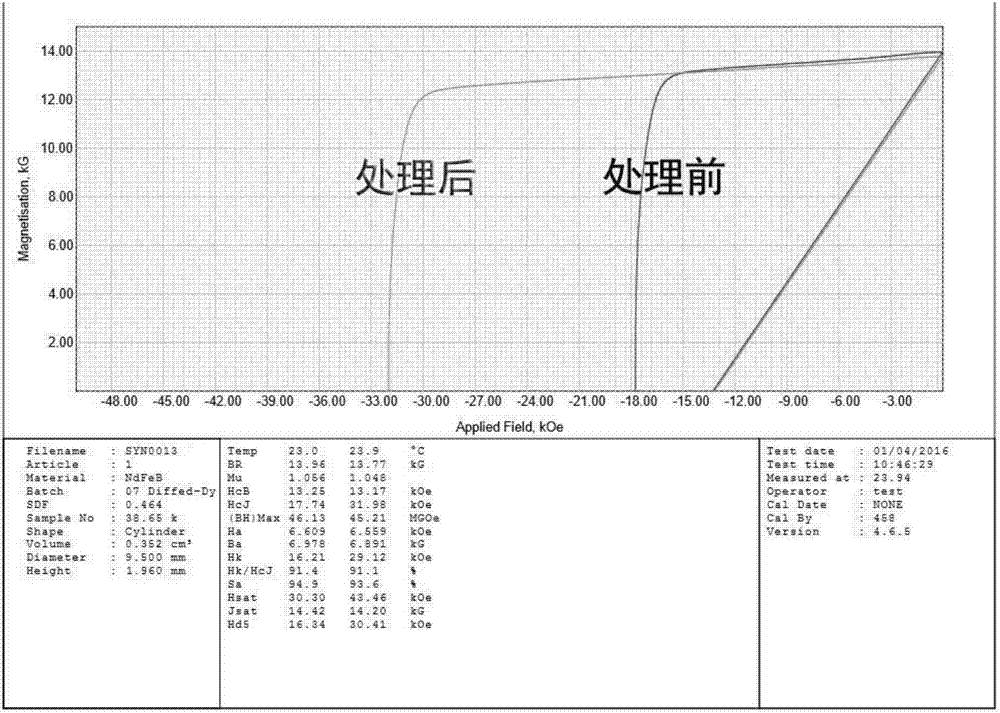

Preparation method for rare earth permanent magnet material

PendingCN107146670AReduce usageImprove performanceSolid state diffusion coatingInductances/transformers/magnets manufactureRare-earth elementSurface cleaning

The invention relates to a preparation method for a rare earth permanent magnet material. The preparation method comprises the steps of weighing powder of three kinds of raw materials of H, M and Q according to atomic percentage contents in a general formula of H<100-x-y>M<x>Q<y>, and performing mixing and screening processing in nitrogen or other oxygen-less environment to obtain composite powder; next, performing mechanical processing on a sintered NdFeB magnet to obtain specific shapes and dimensions, and performing surface cleaning and drying to obtain a to-be-processed NdFeB magnet; next, enabling the composite powder to be attached to the surface of the to-be-processed NdFeB magnet through static in an oxygen-less environment; and performing vacuum heat treatment and tempering treatment in sequence to obtain the rare earth permanent magnet material. By adoption of the method, high efficiency, high binding force between heavy rare earth element attachment and the base magnet, and convenience in residual powder recycling are realized; and the coercivity of the prepared NdFeB magnet can be improved by 4,000-14,000Oe, the residual magnetism is only reduced by 1-2%, and the heavy rare earth usage amount can be saved by 30% compared with that of the equivalent-performance magnet.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Fruit-coffee solid drink and preparation method thereof

The invention relates to a solid drink, and in particular relates to a fruit-coffee solid drink and a preparation method thereof. The fruit-coffee solid drink comprises the following raw materials in parts by mass: 144-160 parts of Vietnam medium-granule coffee beans, 100-116 parts of Yunnan small-granule coffee beans, 165-189 parts of fresh longan or 55-63 parts of dried longan, 40-50 parts of non-dairy creamer, 26-34 parts of white sugar and 35-45 parts of glucose. The preparation method comprises the following steps of: A, mixing; B, baking; C, grinding; D, extracting; E, concentrating; F, preparing a longan extract; G, homogenizing; H, sterilizing; I, freeze drying; and J, packaging. The fruit-coffee solid drink contains more caffeine, is rich, pure and mild in fragrance, and contains more effective nutritional ingredients. Distilled water for extracting coffee mixed powder is proper in temperature and moderate in time. Enzyme extraction adopted by the method can be used for maintaining the flavor and the nutritional ingredients of the longan. The finished product is good in rehydration property and free from residue, and can well maintain the color, the flavor, the taste and the nutritional ingredients of the coffee and the longan.

Owner:普洱漫崖咖啡实业有限公司

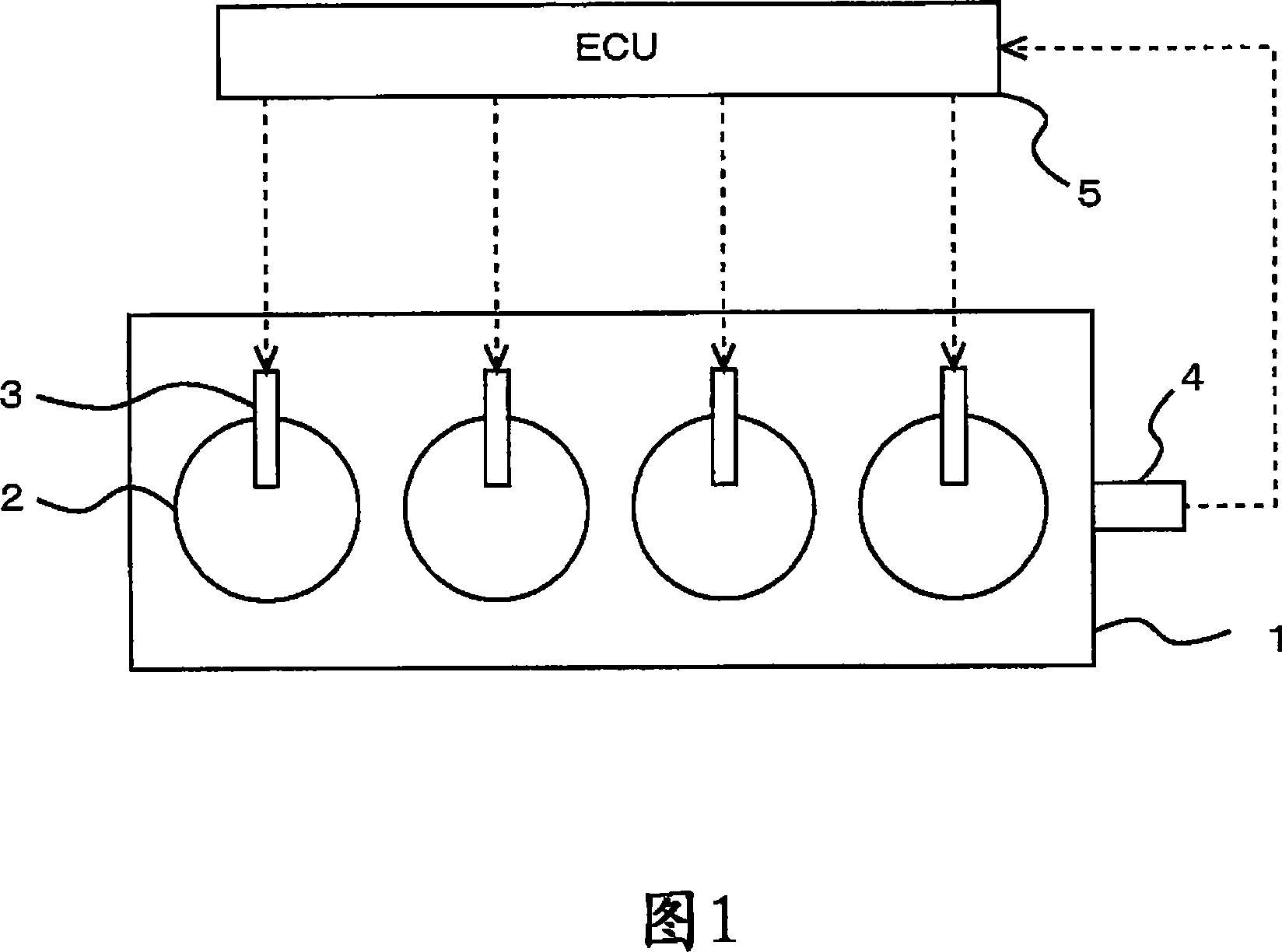

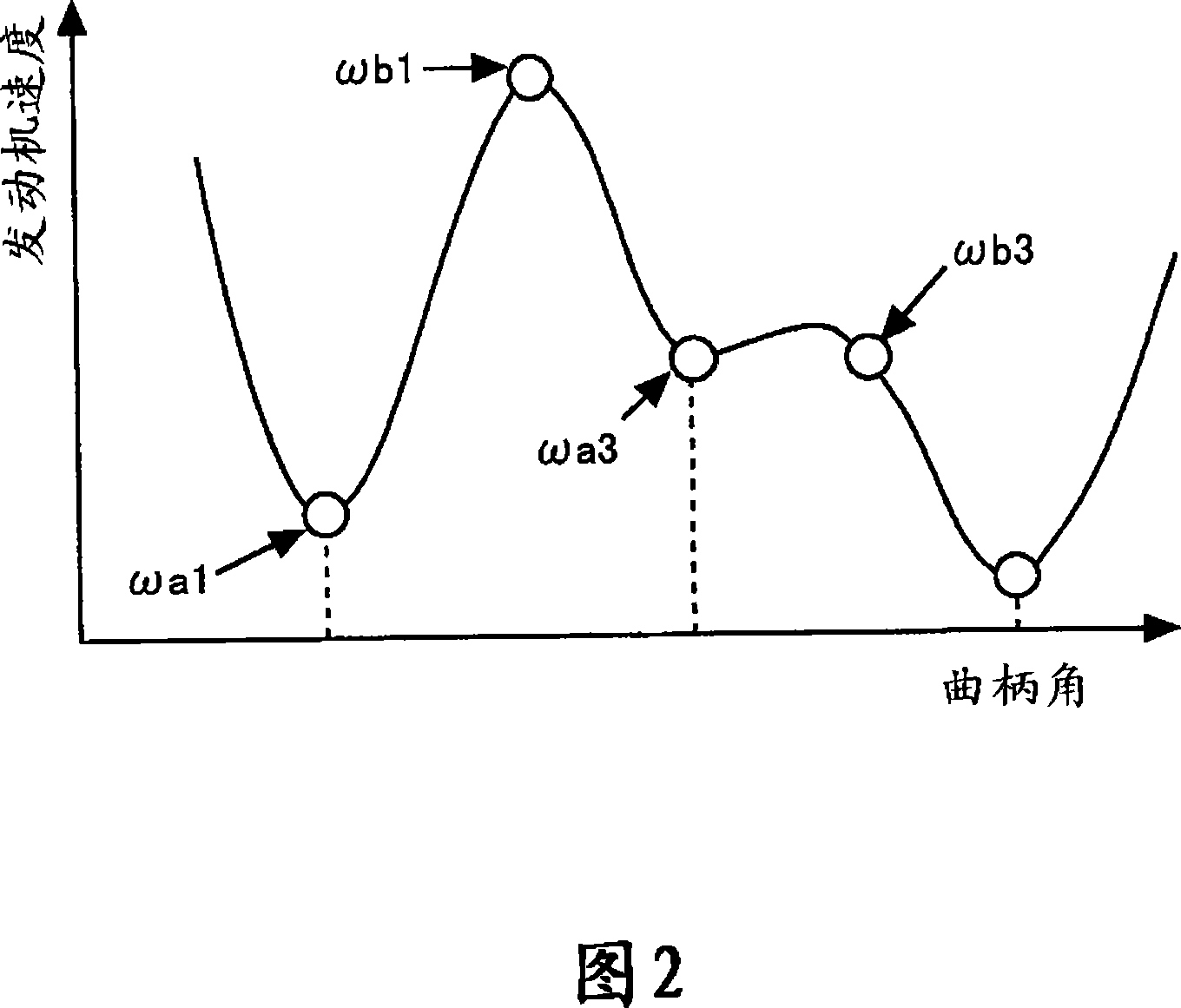

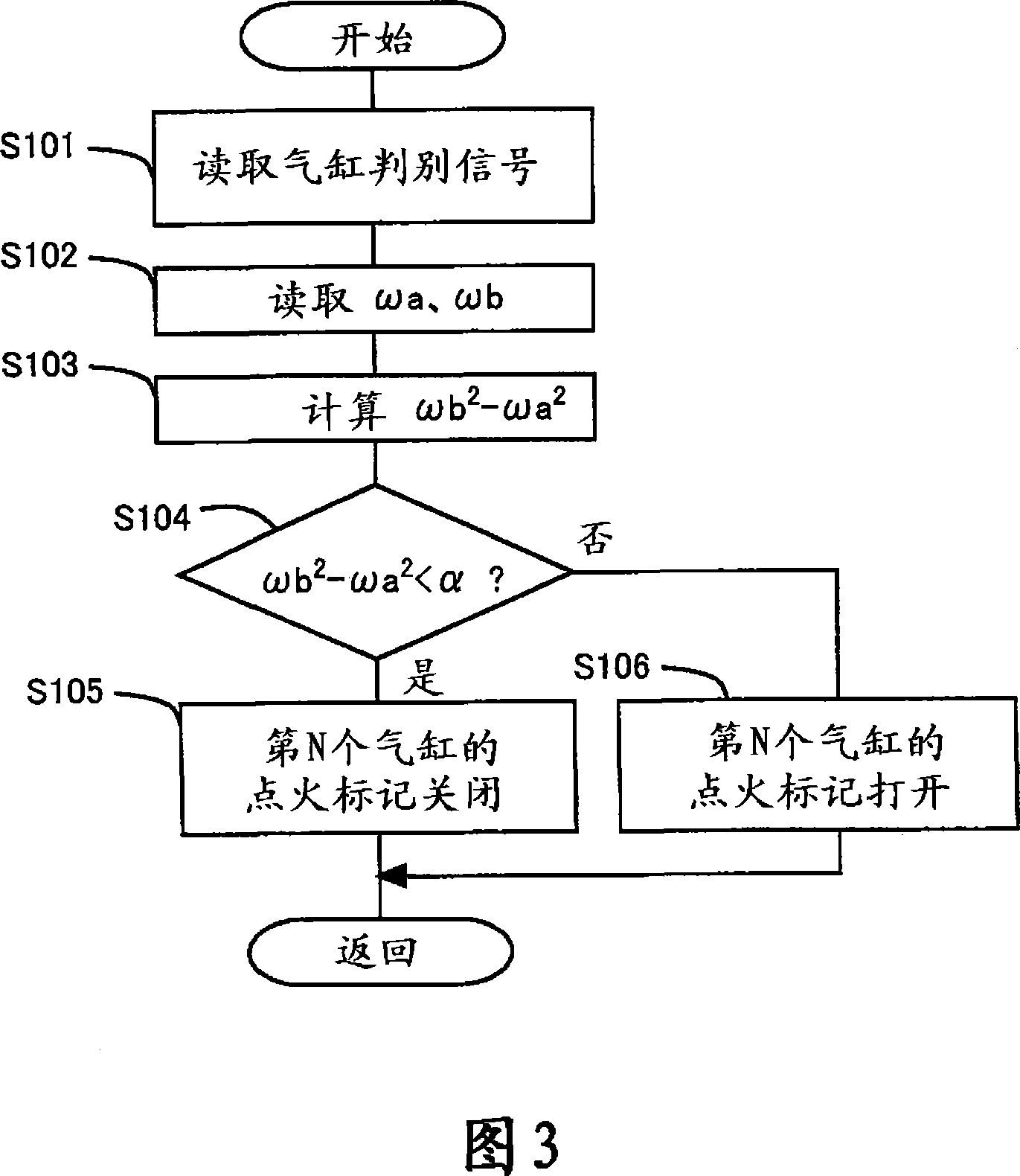

Fuel injection control device for internal combustion engine

InactiveCN101076661AHigh torqueShorten the timeElectrical controlInternal combustion piston enginesCombustionExternal combustion engine

A fuel injection control device for an internal combustion engine, in which a misfire in engine starting is suppressed to make time from the initiation of engine starting to the completion of the starting more appropriate. The fuel injection control device is a device for a compression-ignition-type internal combustion engine having plural cylinders, and the device has a fuel injection valve provided for each cylinder and injecting fuel into inside each cylinder; a combustion condition detection means for estimating or detecting combustion conditions of each cylinder; and a fuel injection timing setting means for changing fuel injection timing of a cylinder that the combustion condition detection means has estimated or detected it misfiring to first fuel injection timing. That is, fuel injection timing is changed on a cylinder-by-cylinder basis.

Owner:TOYOTA JIDOSHA KK

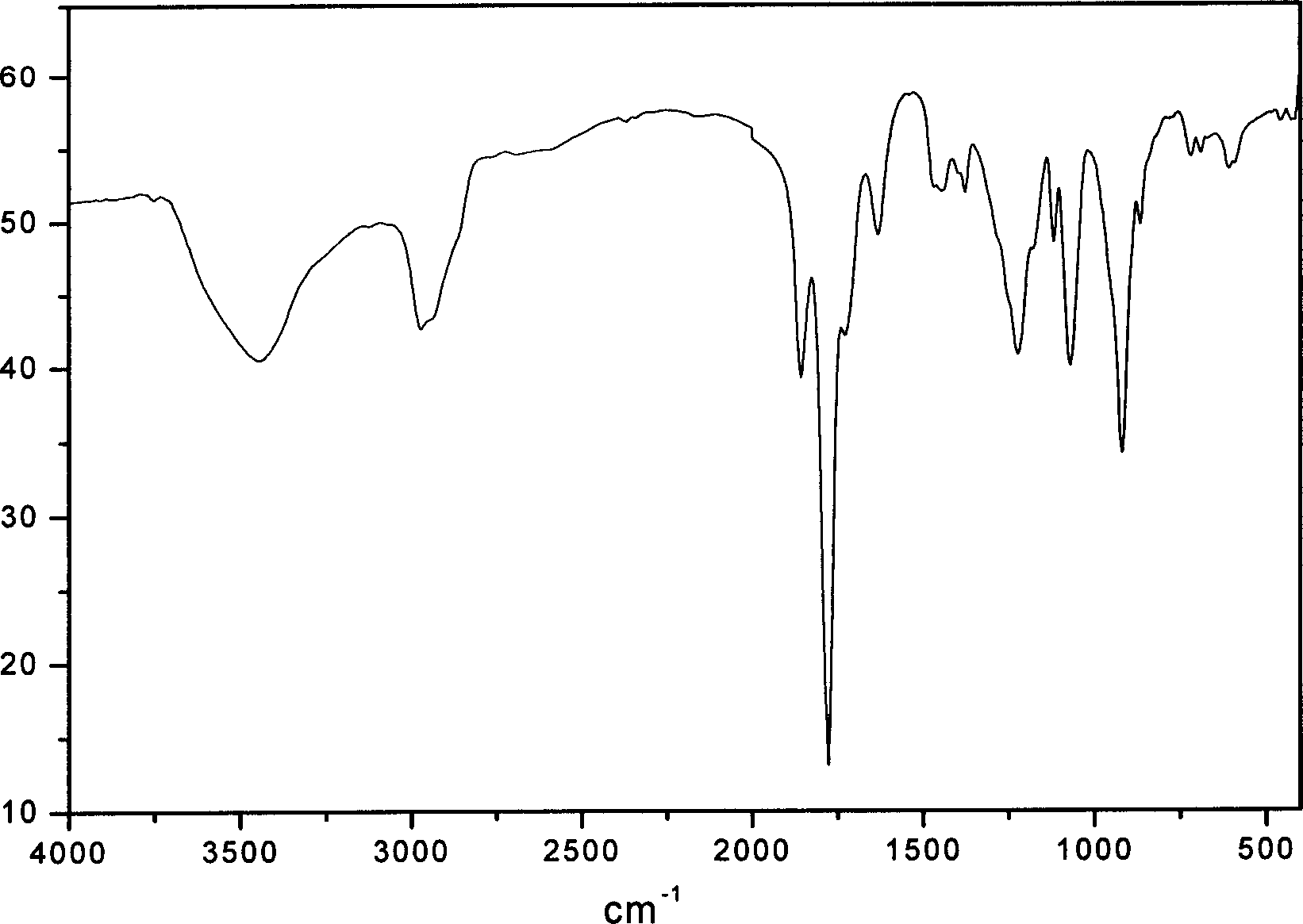

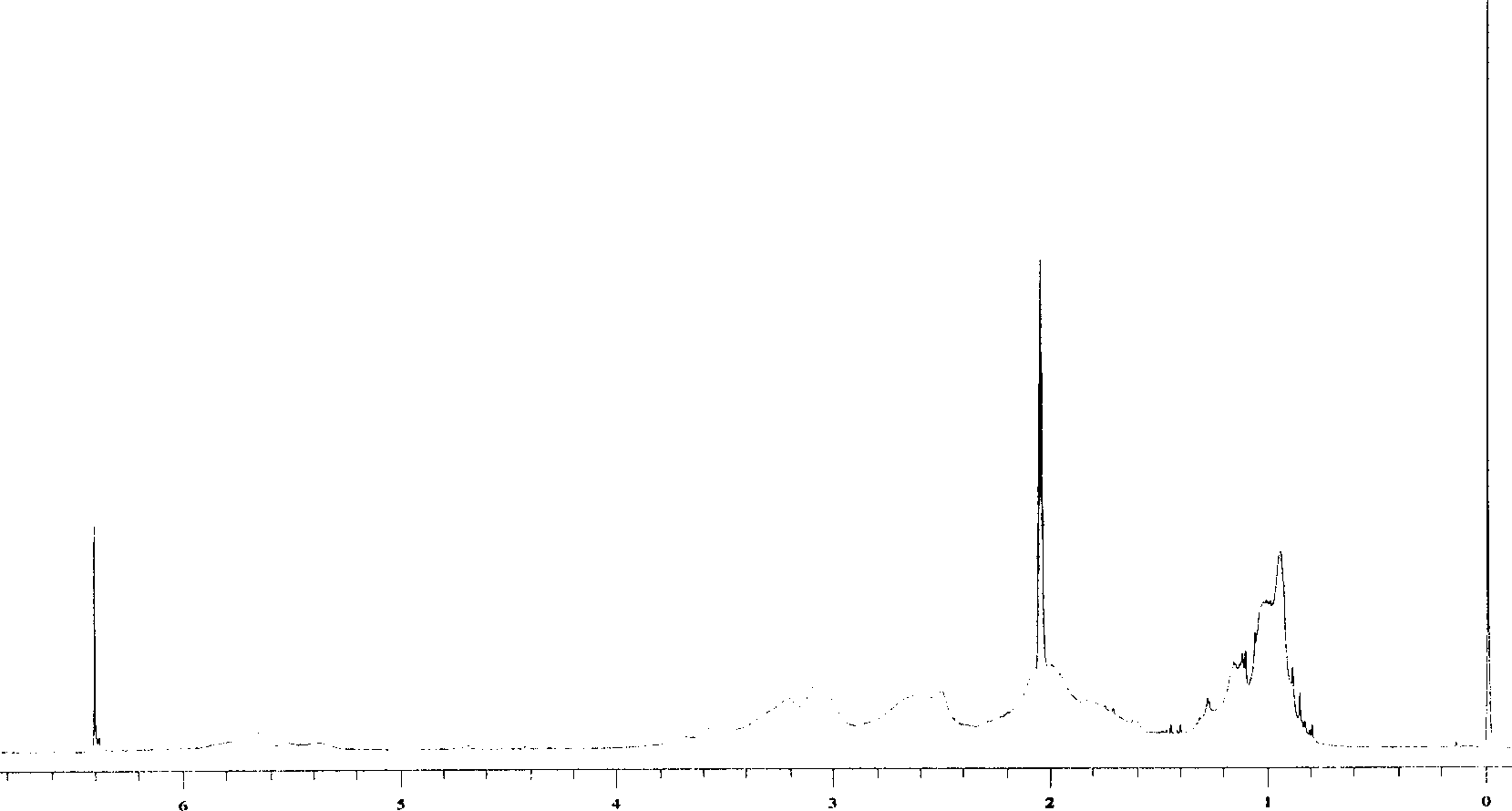

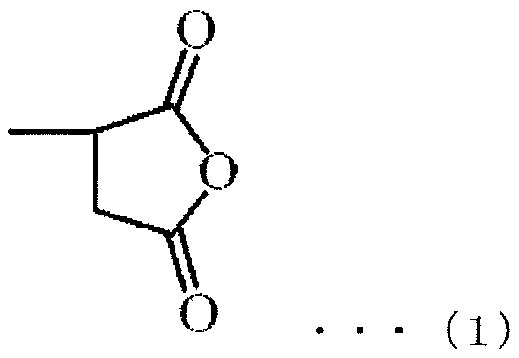

Process for synthesizing beta-pinene/maleic anhydride copolymer

The present invention discloses process of synthesizing beta-pinene / maleic anhydride copolymer. Inside a solvent system, beta-pinene and maleic anhydride in the weight ratio of 0.5-5 to 1 are mixed and heated while adding free radical initiator to reaction for 6-18 to obtain beta-pinene / maleic anhydride copolymer. The synthesized beta-pinene / maleic anhydride copolymer has relatively great molecular weight, and the process has mild condition, moderate reaction temperature and time, convenient post treatment of the product and no need of one third component.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Solid coffee granule beverage and preparation method thereof

InactiveCN109043073AIncrease health functionKeep the tasteCoffee extractionAdditive ingredientToxic material

The invention discloses a solid coffee granule beverage and a preparation method thereof. The solid coffee granule beverage comprises the following ingredients by in parts by mass: 110 parts of coffeebeans, 25 parts of white sugar, 7 parts of fructus lycii, 5 parts of red dates, 5 parts of roselle, 5 parts of radix bupleuri, and 7 parts of semen cassiae. By adding fructus lycii, red dates, roselle, radix bupleuri and semen cassiae, the solid coffee granule beverage has functions of clearing away heat and toxic materials, improving eyesight and lowering blood pressure, and increasing health care function of coffee, so that the coffee retains the original taste and has increased pharmacological effects; the beverage has health maintenance function; temperature and time of extracting coffeefiltrate provided by the invention is suitable, which can not only retain the fragrance of the coffee but also avoid destroying effective nutrient components of the coffee; particles of the beverage are fine, and can be quickly dissolved in water, without the need for residue filtering, troublesome is also avoided.

Owner:安徽咖力士咖啡食品有限公司

Preserving agent for salted yolk and processing method of salted yolk

The invention discloses a preserving agent for salted yolk and a processing method of the salted yolk. The preserving agent of the salted yolk consists of the following raw materials in parts by weight of 55-65 parts of salt, 80-85 parts of sodium alginate, 130-135 parts of sodium dihydrogen phosphate, 10-15 parts of Baijiu, and 1-2 parts of potassium sorbate. The processing method of the salted yolk is characterized by comprising the following steps of enabling the yolk to be immersed in the preserving agent, and performing preserving at 20-30 DEG for 48-72h; and placing the preserved yolk inthe place of 30-40 DEG C for 1-1.5h, taking out the baked yolk, uniformly applying the edible oil onto the taken yolk, placing the applied yolk in the pace of 45-55 DEG C for baking for 0.25-0.5h, and performing sterilizing, so that the salted yolk is obtained. According to the preserving agent disclosed by the invention, the probability that the surface of the salted yolk is cracked can be effectively reduced, the condition that salted yolk is stuck to form blocks can be avoided, and the yolk is beautiful and bright in color.

Owner:HUBEI SHENDAN HEALTHY FOOD

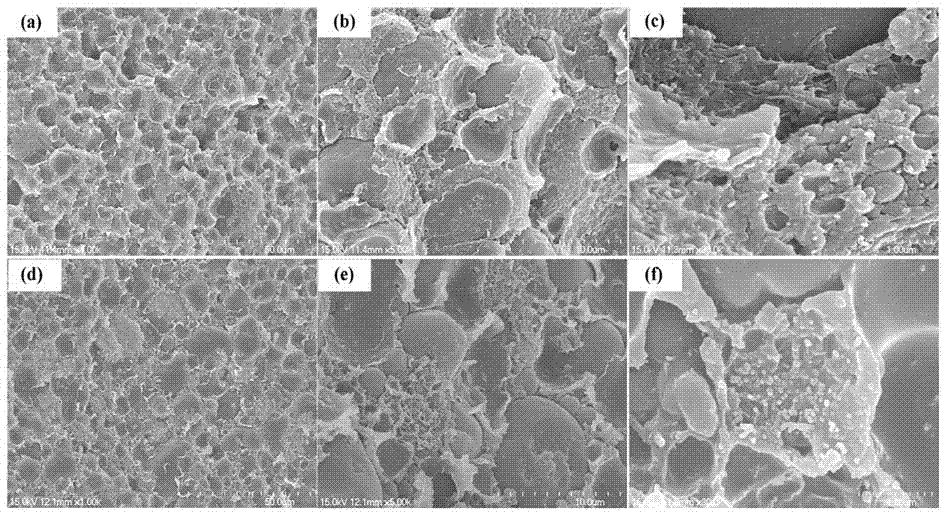

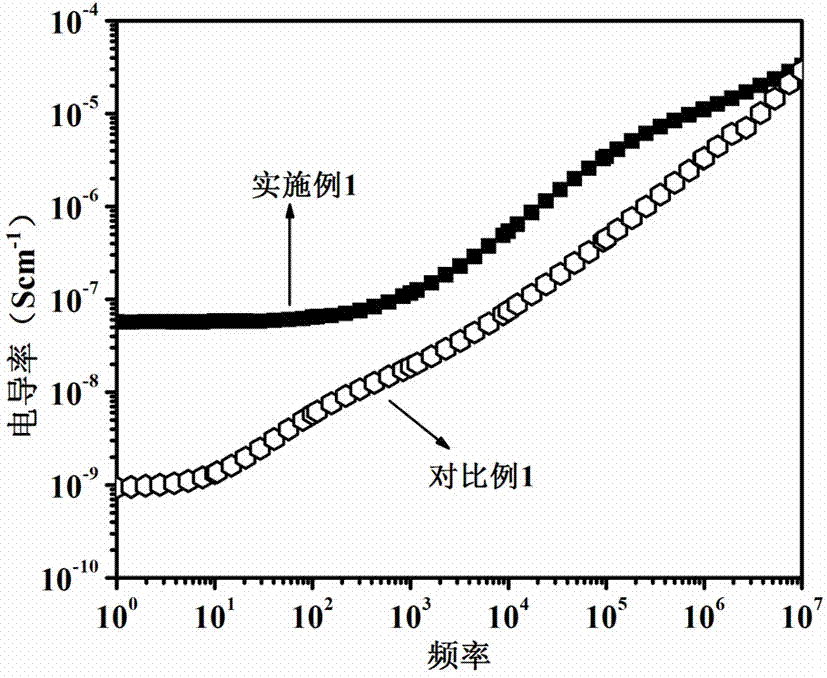

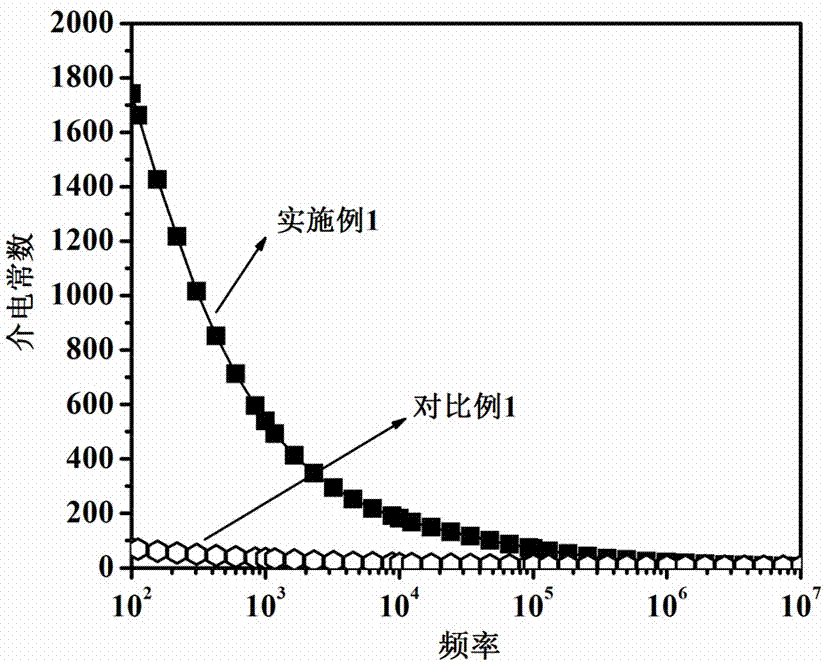

Carbon nanotube/polyetherimide/thermosetting resin dielectric composite material and preparation method thereof

ActiveCN104513485AGood physical propertiesSuitable for direct contactPlastic/resin/waxes insulatorsPolyetherimideDielectric loss

The invention discloses a carbon nanotube / polyetherimide / thermosetting resin dielectric composite material and a preparation method thereof. The preparation method comprises the following steps: in parts by weight, uniformly mixing 100 parts of polyetherimide and 1-7 parts of carbon nanotubes in a Haake torque molting cavity to obtain a carbon nanotube / polyetherimide composite; dissolving 20 parts of the carbon nanotube / polyetherimide composite into 100-150 parts of dichloromethane, adding a mixed solution into 100 parts of molten thermocurable thermosetting resin, mixing, preserving heat, stirring until a mixture is in a uniform state, curing, and post-treating to obtain a carbon nanotube / thermosetting resin dielectric composite material, wherein a substrate of the carbon nanotube / thermosetting resin dielectric composite material has a typical reverse phase structure, while the carbon nanotubes are dispersed in a polyetherimide phase. The carbon nanotube / polyetherimide / thermosetting resin dielectric composite material has a relatively low percolation threshold, a high dielectric constant and low dielectric loss. The preparation method is simple in process and suitable for large-scale production.

Owner:SUZHOU UNIV

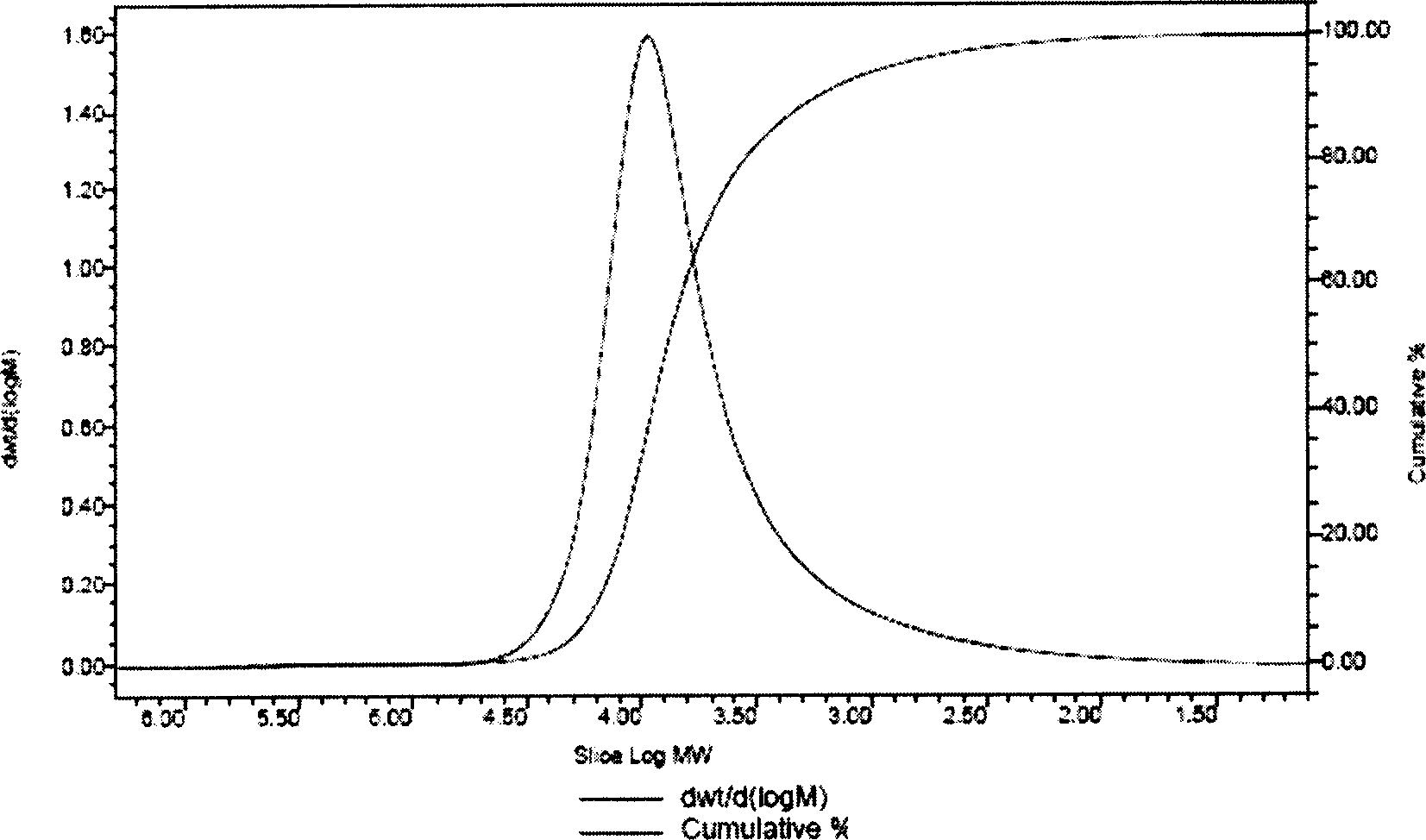

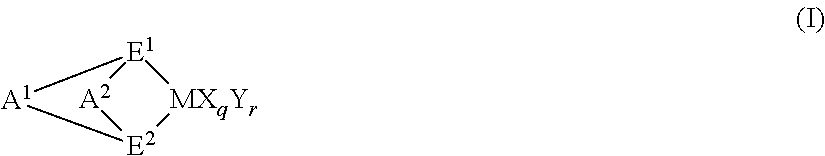

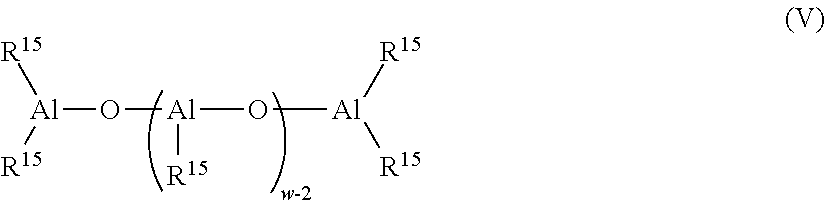

Propylene-based polymer and hot melt adhesive

ActiveUS20150284600A1Excellent balanceModerate open timeSynthetic resin layered productsAdhesivesPolymerPolymer science

A propylene-based polymer which satisfies the following (a1) to (d1): (a1) [mmmm]=60 to 80 mol %; (b1) weight-average molecular weight (Mw)=10,000 to 55,000; (c1) Mw / Mn≦2.5; and (d1) [rmrm]≦2.5 mol %.

Owner:IDEMITSU KOSAN CO LTD

Method for detoxifying culture of anthurium andraeanum

ActiveCN104542276AIncrease in sizeEasy to operatePlant tissue cultureHorticulture methodsSeedlingBiology

The invention relates to the technical field of plant tissue culture, and provides a method for detoxifying culture of anthurium andraeanum to solve the problems that a detoxified tissue culture seedling is high in operation difficulty, low in detoxification efficiency, long in production cycle and the like in production. The method comprises the following steps: explant preparation, induced culture, enrichment culture, variable-temperature heat treatment, differentiation culture, induced culture of a quasi detoxification stock plant, proliferation and differentiation of the quasi detoxification stock plant, growth of a quasi detoxification strain, virus detection, proliferation and differentiation of detoxification materials, and rooting and transplantation of detoxified seedlings. The method for detoxifying culture of the anthurium andraeanum is simple and convenient to operate, high in detoxification material yield and high in speed.

Owner:ZHEJIANG XIAOSHAN COTTON & FLAX RES INST

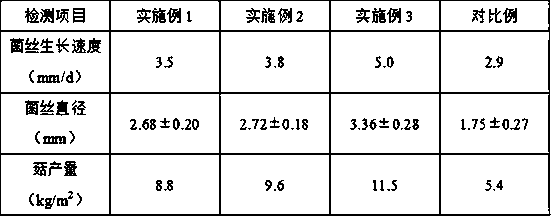

Cultivation method for agaricus bisporus

InactiveCN107896818AShort ageHigh activityCultivating equipmentsMushroom cultivationAgaricusIon exchange

The invention relates to the field of cultivation of mushrooms, and in particular relates to a cultivation method for agaricus bisporus. According to the method provided by the invention, expanded vermiculite is obtained through modification of vermiculite, the expanded vermiculite has very strong water absorbing performance, through the ion exchange ability of the vermiculite, cover soil can be loosened, the formation of a primordium of a sporocarp of the agaricus bisporus is facilitated, the problem that hyphae have reduced activity due to hypoxia caused by poor ventilation is improved, andthe water retaining capacity is enhanced; polyglutamic acid is added, and a mixture of the polyglutamic acid and the modified vermiculite is spread between the hyphae and the cover soil, in the process that the hyphae grow to a cover soil layer, through water dissolution, a film is formed at the surface layer of the hyphae, so that the nutrients and moisture in the cover soil can be in contact with and conveyed to the hyphae, the dissolution, storage, conveying and absorption of the nutrients can be extremely efficiently improved, and the producing rate of the agaricus bisporus can be improved.

Owner:常州莱尚纺织品有限公司

Low-temperature shaped dried egg and processing method thereof

InactiveCN110338365AAdd flavorIncrease elasticityFood ingredient as taste affecting agentLipidic food ingredientsYolkCooking & baking

The invention discloses a low-temperature shaped dried egg and a processing method thereof. The dried egg mainly takes fresh egg white and fresh egg yolk, and the main production steps include seasoning, injection molding, molding and baking. The method is characterized in that the injection molding and molding steps are as follows: adding an edible alkali solution to the seasoned egg liquid, uniformly stirring the materials, and then injecting the material into a mold to perform molding, wherein the molding temperature is 30-50 DEG C, and after 24h-48h, fixing the egg liquid in the mold to obtain the formed dried egg. The dried egg has soft and tender taste, and has full taste, smooth mouthfeel, long-lasting taste, and long aftertaste, and has a slightly preserved egg-like flavor withoutastringent mouthfeel.

Owner:HUBEI SHENDAN HEALTHY FOOD

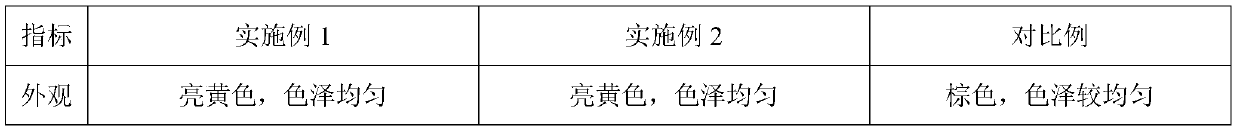

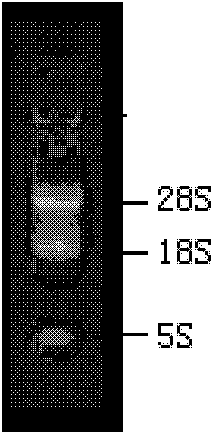

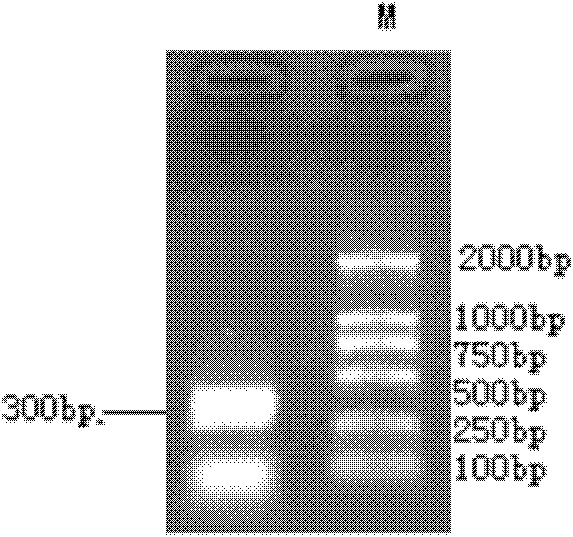

Anti-prothymosin α polyclonal antibody and its preparation method and application

InactiveCN102295701AHigh potencyStrong potencySerum immunoglobulinsPeptide preparation methodsSmall sampleProstate cancer

The anti-thymosin pro-alpha polyclonal antibody and its preparation method and application relate to an anti-thymosin pro-alpha polyclonal antibody. The anti-prothymosin α polyclonal antibody is a polyclonal anti-GST-ProTα antiserum obtained after immunizing New Zealand white rabbits with a fusion protein prepared by using GST-ProTα fusion expression. First prepare the fusion protein GST-ProTα, and then prepare the antibody. It can be used for immunoblotting and ELISA immunoassay of various samples and cells containing ProTα components, and tissue endogenous ProTα. Using the antibody to detect the ProTα level in urine can be used to diagnose urinary system tumors such as bladder cancer, kidney cancer and prostate cancer. The antibody has high titer and strong specificity. Various samples containing ProTα can be detected. Using prothymosin α in urine as a tumor marker for the diagnosis of urinary system cancer. The total process does not exceed 4 hours, and the required amount of samples is small.

Owner:XIAMEN UNIV

Propylene-based polymer and hot melt adhesive

A propylene-based polymer which satisfies the following (a1) to (d1): (a1) [mmmm]=60 to 80 mol %; (b1) weight-average molecular weight (Mw)=10,000 to 55,000; (c1) Mw / Mn≦2.5; and (d1) [rmrm]≦2.5 mol %.

Owner:IDEMITSU KOSAN CO LTD

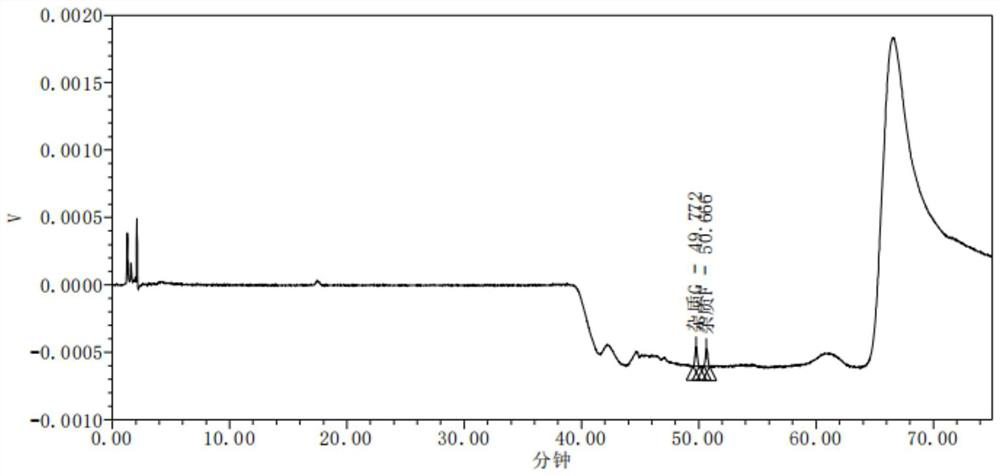

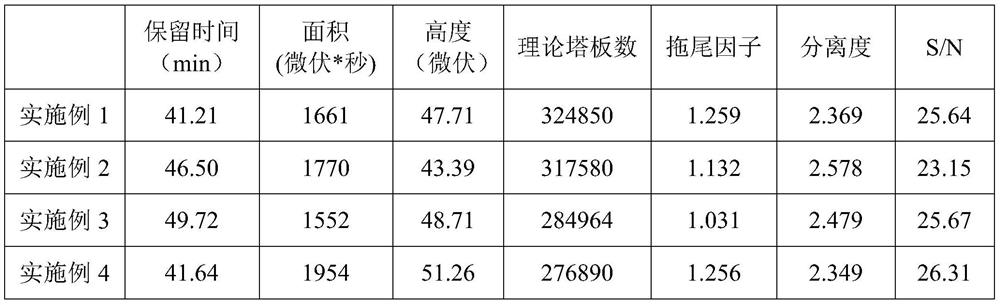

Method for detecting impurity F and impurity G of omeprazole sodium

InactiveCN112816590APrevent leakageEfficient detectionComponent separationOmeprazole SodiumFluid phase

The invention provides a method for detecting an impurity F and an impurity G of omeprazole sodium. The omeprazole sodium impurity F and the omeprazole sodium impurity G are detected by adopting high performance liquid chromatography, optimization is carried out on the basis of raw material medicines, and the proportion of an organic phase is increased so that the omeprazole sodium impurity F and the omeprazole sodium impurity G can be effectively eluted, and the omeprazole sodium impurity F and the omeprazole sodium impurity G can be effectively detected. Main peak retention time, an area and a height are moderate, a theoretical plate number and a separation degree are good, a tailing factor is in the range of 0.9-1.95, the S / N is 10-30, the requirements are met, and a reference basis is provided for the quality control of omeprazole sodium.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

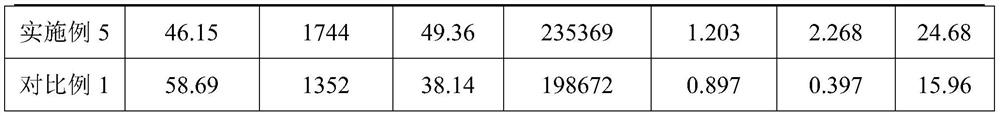

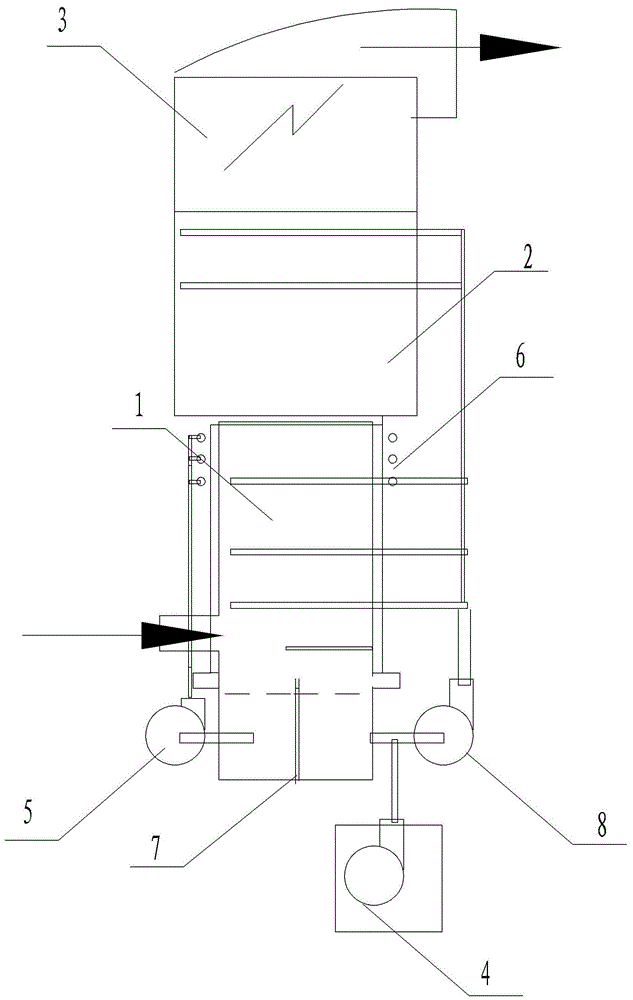

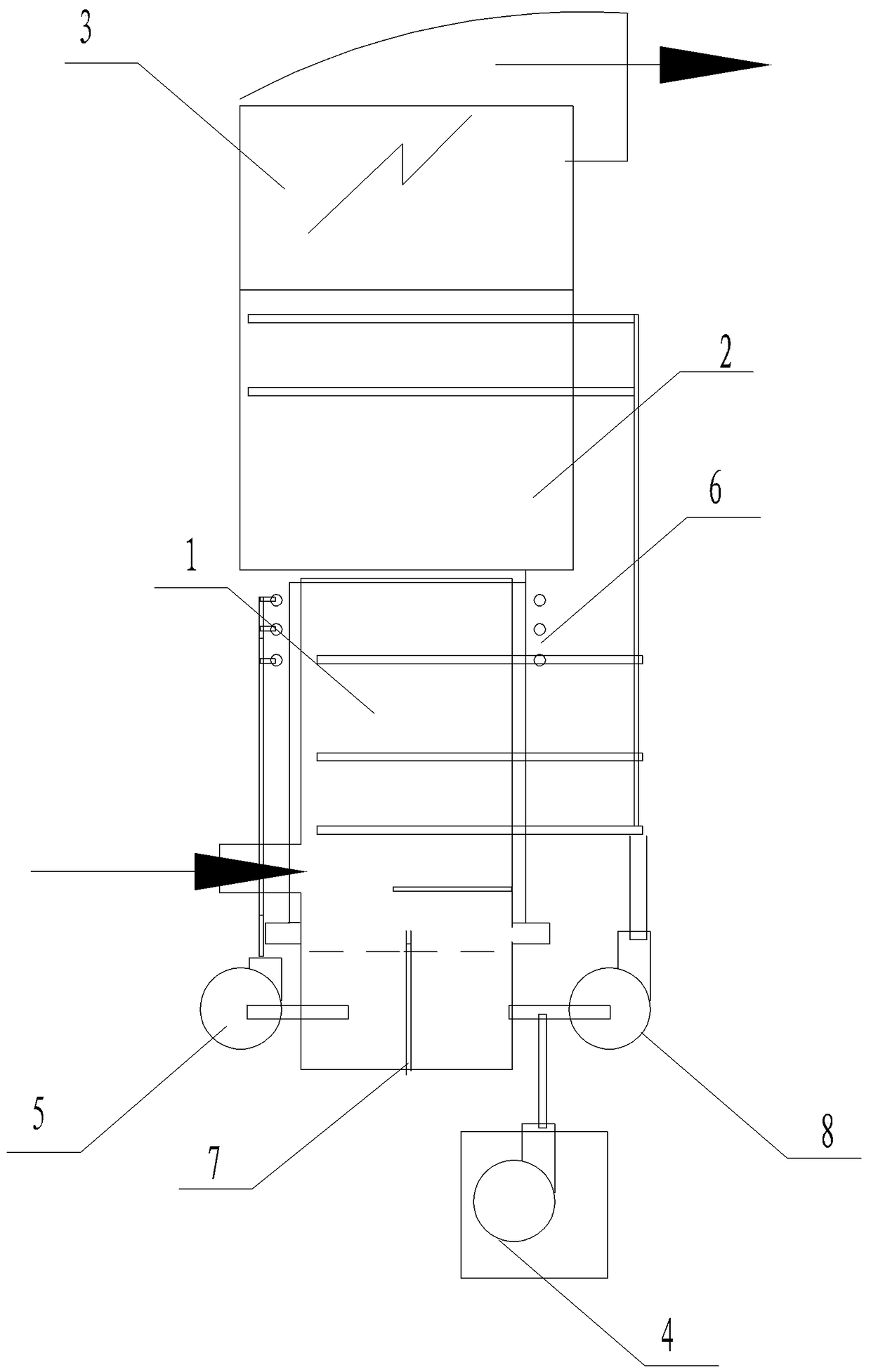

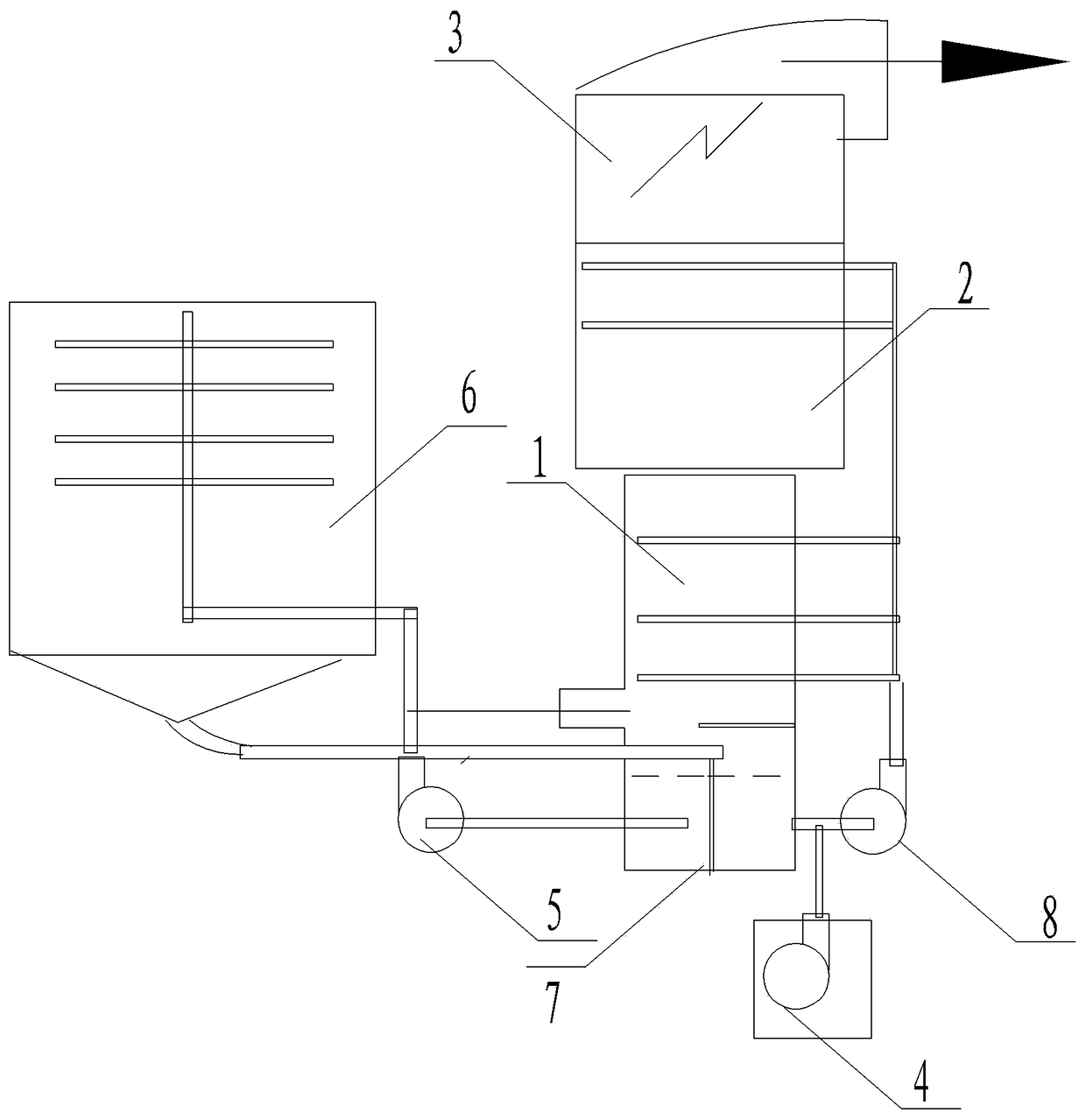

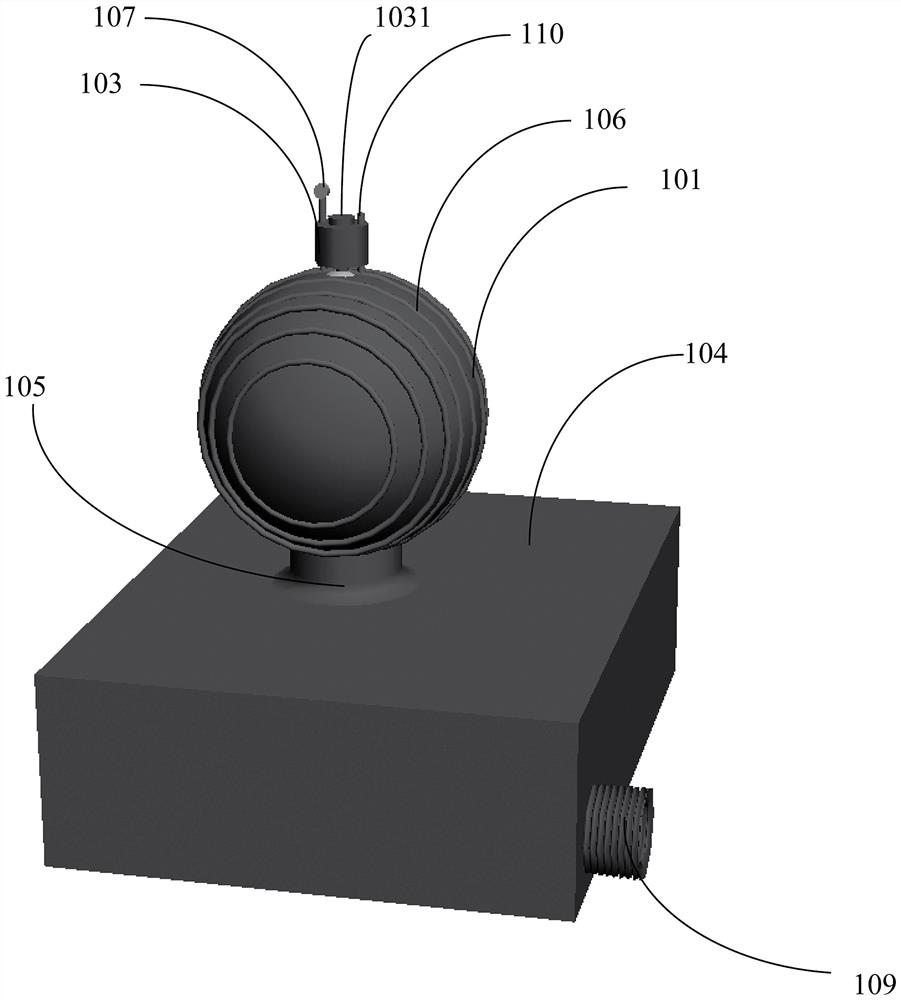

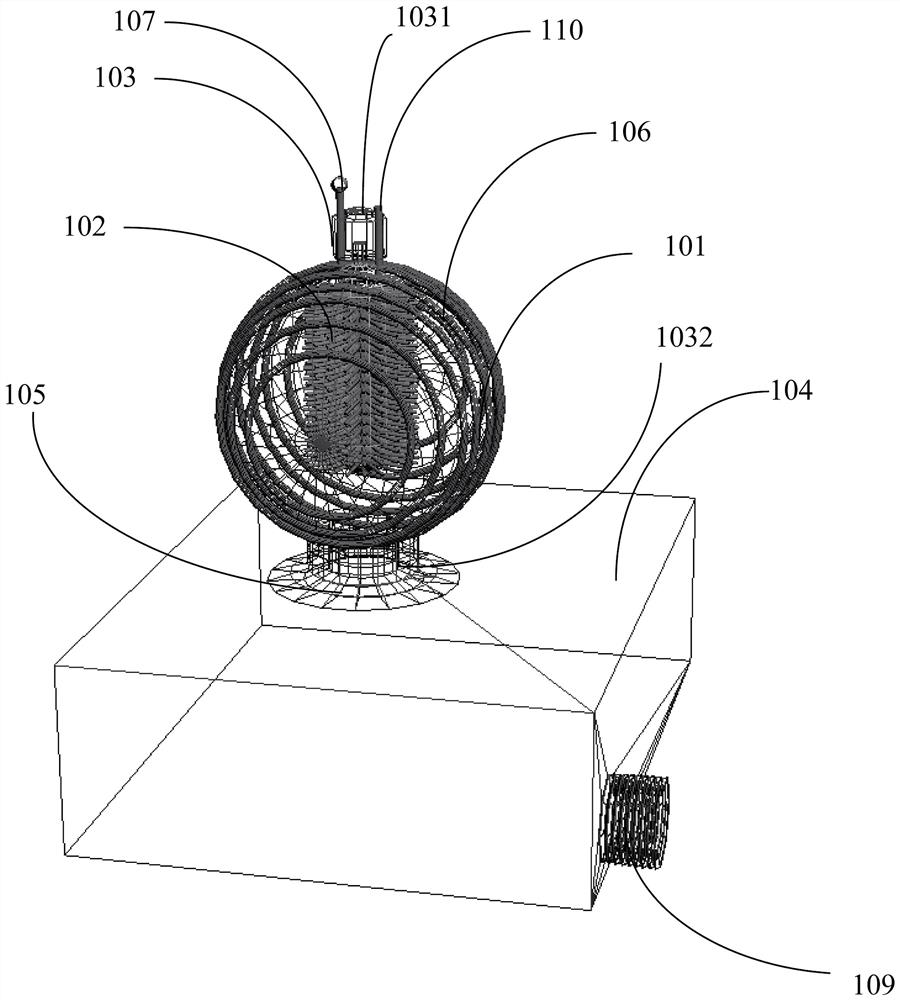

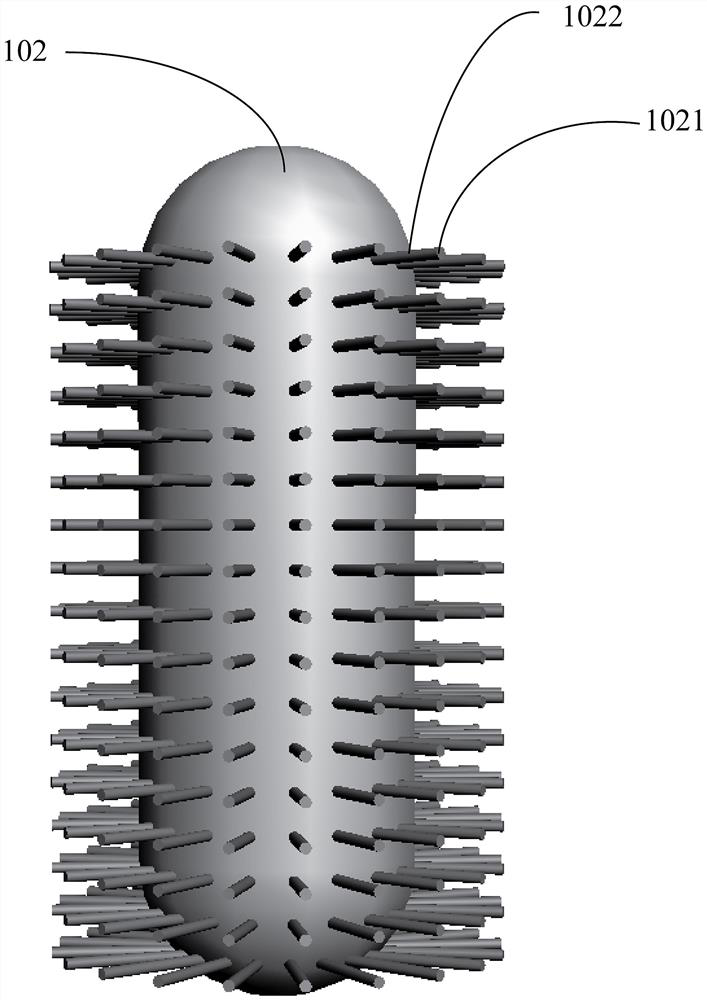

Wet desulfurization equipment for coal fired boiler

InactiveCN105879636AIncrease flow rateModerate timeCombination devicesGas treatmentSpray towerCirculating pump

The invention belongs to the technical field of environmental protection equipment and particularly relates to wet desulfurization equipment for a coal fired boiler. The wet desulfurization equipment for the coal fired boiler has a very good desulfurization effect, comprises a desulfurization tower and is structurally characterized in that a spray tower is arranged at the upper end of the desulfurization tower, an electrostatic tower is arranged at the upper end of the spray tower, a circulating pool is arranged at the lower end of the desulfurization tower and connected with an inlet of a first circulating pump through a pipeline, an outlet of the first circulating pump is connected with an inlet of a spray oxidation pipe at the spray oxidation part through a pipeline, and an output end, for a liquid after spray oxidation, of the spray oxidation part is connected with inside of the circulating pool; a concentration tank is connected with an inlet of a second circulating pump through a pipeline, an outlet of the second circulating pump is connected with an inlet of a spray pipe, one part of an outlet of the spray pipe is arranged at the upper part of the spray tower, and the other part of the outlet of the spray tower is arranged at the upper part of the desulfurization tower; a transverse smoke inlet is formed in the lower part of the desulfurization tower.

Owner:庄建中

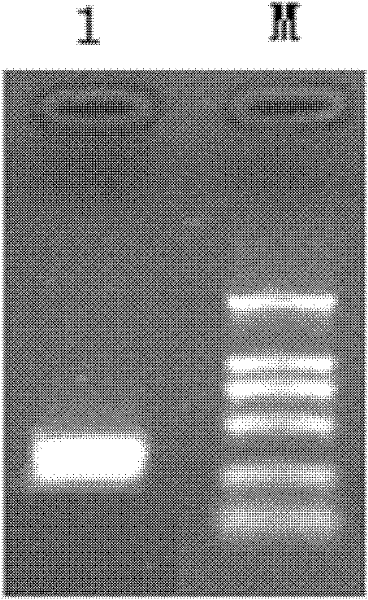

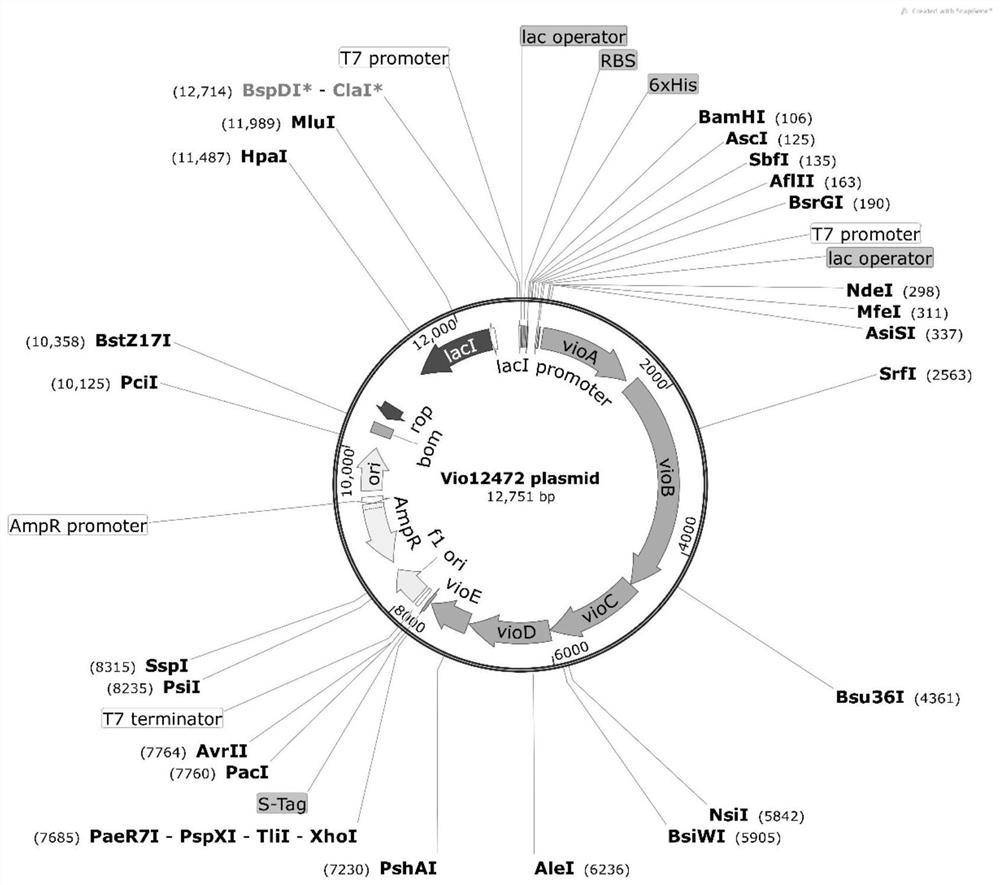

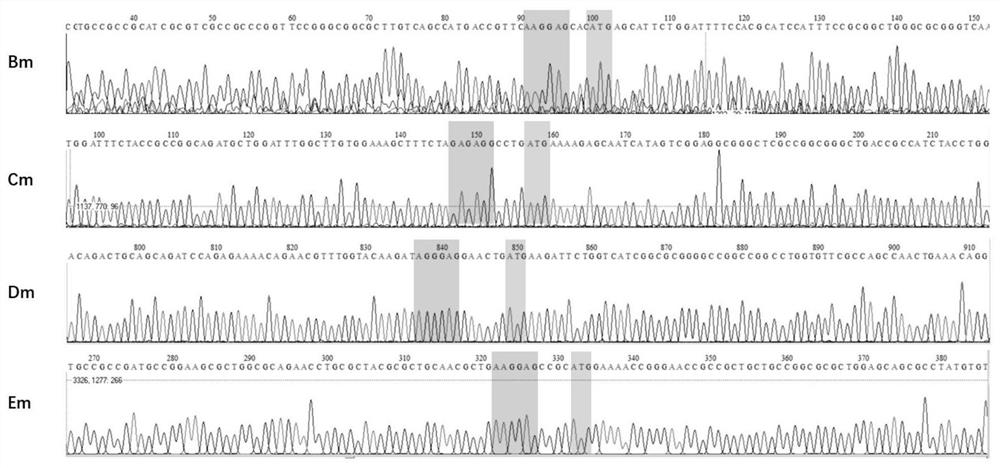

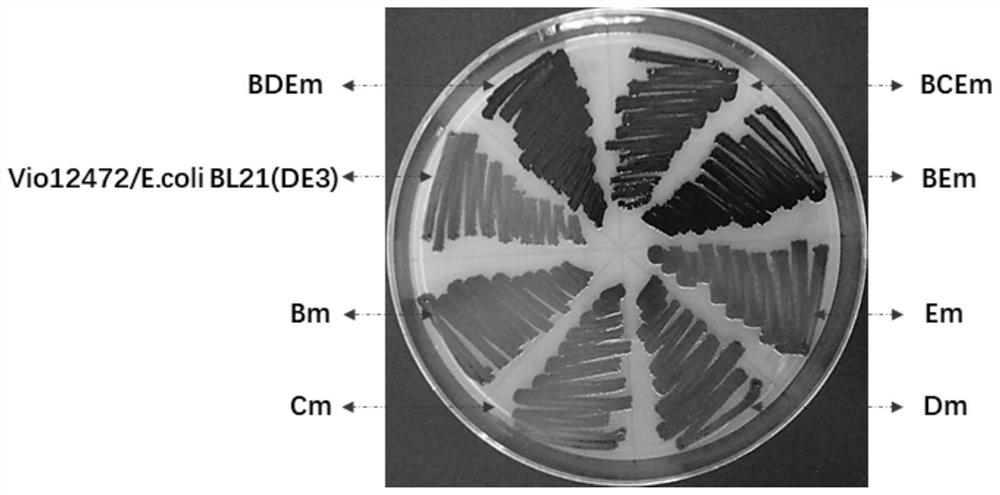

Genetically modified violacein biosynthetic gene cluster, recombinant expression vector, engineering bacterium and application thereof

ActiveCN111748564AIncrease productionEfficient productionOrganic chemistryBacteriaGene clusterMolecular biology

The invention discloses a genetically modified violacein biosynthetic gene cluster, a recombinant expression vector, engineering bacteria and application thereof. The ribosome binding site of the violacein biosynthetic gene cluster is subjected to site-specific mutagenesis and codon deletion mutation transformation, so that effective translation of violacein synthetic protein is promoted, and thetransformed gene cluster with remarkably improved production potential is obtained; by introducing the modified gene cluster or the recombinant vector containing the modified gene cluster into host bacteria, engineering bacteria for high yield of violacein are obtained; furthermore, fermentation conditions of engineering bacteria are optimized, and a method for separating and purifying violacein is provided. The genetic engineering strain constructed by the invention has the advantages that the yield of violacein can be obviously improved; different from conventional low-temperature fermentation of violacein at 20 DEG C or 25 DEG C, the violacein metabolite can be efficiently produced under the temperature condition of 25-37 DEG C, the problem of high cooling cost in the fermentation process is solved, and the invention is suitable for large-scale production.

Owner:XINXIANG MEDICAL UNIV

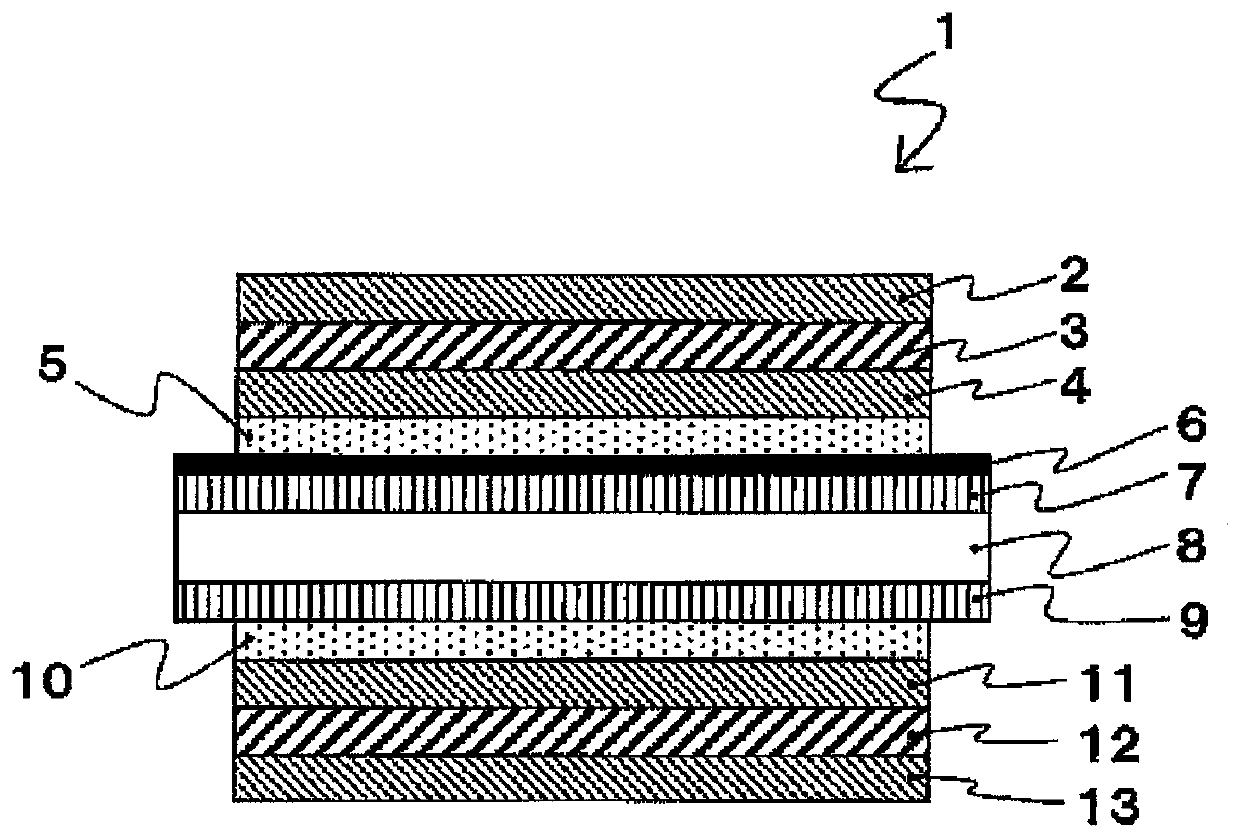

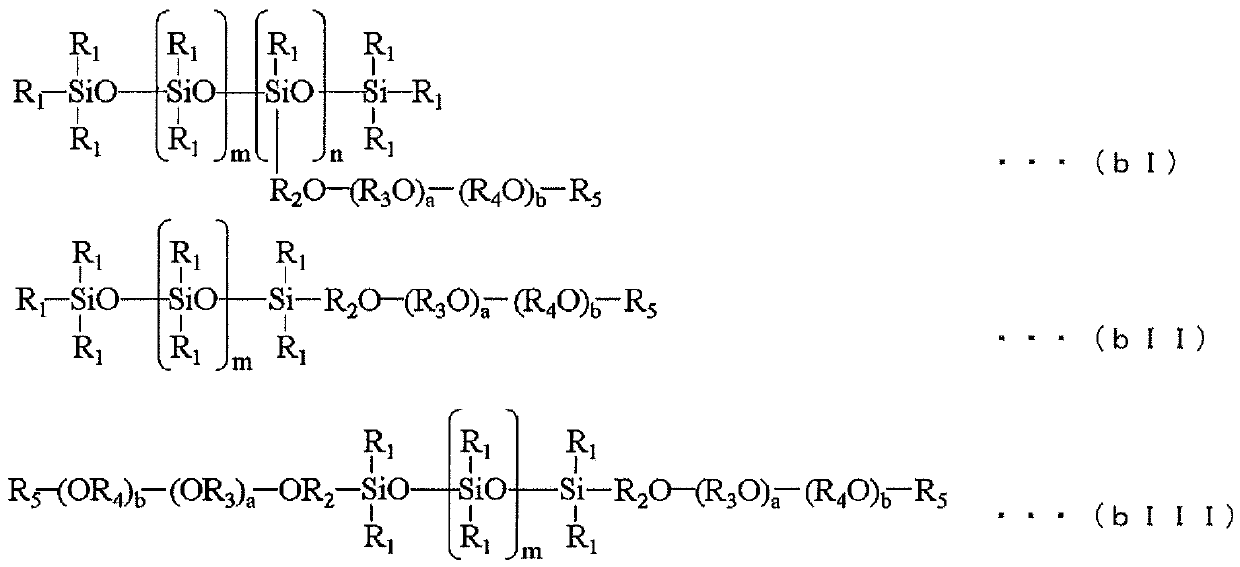

Pressure-sensitive adhesive layer, optical film provided with pressure-sensitive layer, optical laminate, and image display device

ActiveCN110809616AEasy to peelExcellent reoperabilityNon-macromolecular adhesive additivesSynthetic resin layered productsMeth-Indium

A pressure-sensitive adhesive layer formed from a pressure-sensitive adhesive composition containing, as monomer units, at least a (meth)acrylic polymer (A) that contains an alkyl (meth)acrylate, anda silicon compound (B), wherein: the silicon compound (B) is an organopolysiloxane compound; and when a laminate, in which a pressure-sensitive adhesive layer of a polarizing film provided with a pressure-sensitive adhesive layer having the pressure-sensitive adhesive layer and a polarizing film is laminated to an indium-tin composite oxide layer on a transparent conductive substrate having a transparent substrate and the indium-tin composite oxide layer, has been autoclaved for 15 minutes at 50 DEG C and 5 atm, and then the pressure-sensitive adhesive layer has been peeled away, the ratio ofelemental silicon relative to the total of elemental carbon, nitrogen, oxygen, silicon, indium, and tin detected by X-ray photoelectron spectroscopy is 0.5-5 atomic% in the surface of the indium-tin composite oxide layer. This pressure-sensitive adhesive layer has reworkability with respect to a transparent conductive layer and high durability.

Owner:NITTO DENKO CORP

Production technology of roxburgh rose flower and leaf tea

The invention provides a production technology of roxburgh rose flower and leaf tea. The production technology comprises the following steps: spreading and cooling picked roxburgh rose tender leaves and flower petals; carrying out fixation on the leaves and flowers respectively through a tea leaf wok under the conditions that the temperature is 220 DEG C and the time is 4min, and the temperature is 110 DEG C to 150 DEG C and the time is 2min; then uniformly mixing the flowers and the leaves at the ratio of 1 to 1, 1 to 0.7 or 1 to 0.4; putting the mixture into a fixation groove of a carding machine and molding; finally, putting the mixture into a drying machine and drying until the drying is finished, wherein when the drying is finished, stems are easy to break and the moisture content is5 percent to 6 percent; finally, spreading and cooling to room temperature, and packaging and storing. By adopting the production technology provided by the invention, the problems that a large amountof roxburgh rose leaves and roxburgh rose flowers are not effectively utilized and a lot of wastes are caused are solved. The production technology of the roxburgh rose flower and leaf tea belongs tothe technical field of tea leaf improvement.

Owner:GUIZHOU UNIV

Double-extraction production process of tea-flavored blended beverage

InactiveCN109170040ARich and mellow fragranceKeep the scentTea extractionCoffee extractionBlack teaTangerine Peel

The invention discloses a double-extraction production process of a tea-flavored blended beverage. The process comprises a brewing method and a cold extraction method. The brewing method uses the following raw materials: osmanthus flowers, dried tangerine peel, Chinese wolfberries, rock sugar, oolong tea, Liubao tea, dried red dates, dried longan pulp, coffee powder and coffee beans; and the coldextraction uses the following raw materials: black tea and coffee powder. The double-extraction brewing process of the tea-flavored blended beverage endows the beverage with the characteristics of Eastern and Western beverages, combines tea and coffee to make the beverage have the taste and nutrients of the tea, as well as the aroma and functions of the coffee; and the tea-flavored blended beverage meets the needs of domestic and foreign consumers, and is suitable for promotion to the public.

Owner:浙江听客餐饮管理有限公司

A kind of method of anthurium anthurium virus-free cultivation

ActiveCN104542276BIncrease in sizeEasy to operateHorticulture methodsPlant tissue cultureEnrichment cultureSeedling

The invention relates to the technical field of plant tissue culture, and provides a method for detoxifying culture of anthurium andraeanum to solve the problems that a detoxified tissue culture seedling is high in operation difficulty, low in detoxification efficiency, long in production cycle and the like in production. The method comprises the following steps: explant preparation, induced culture, enrichment culture, variable-temperature heat treatment, differentiation culture, induced culture of a quasi detoxification stock plant, proliferation and differentiation of the quasi detoxification stock plant, growth of a quasi detoxification strain, virus detection, proliferation and differentiation of detoxification materials, and rooting and transplantation of detoxified seedlings. The method for detoxifying culture of the anthurium andraeanum is simple and convenient to operate, high in detoxification material yield and high in speed.

Owner:ZHEJIANG XIAOSHAN COTTON & FLAX RES INST

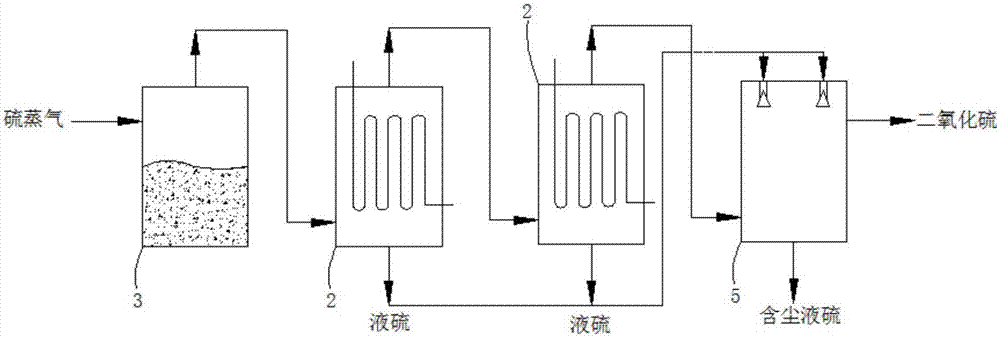

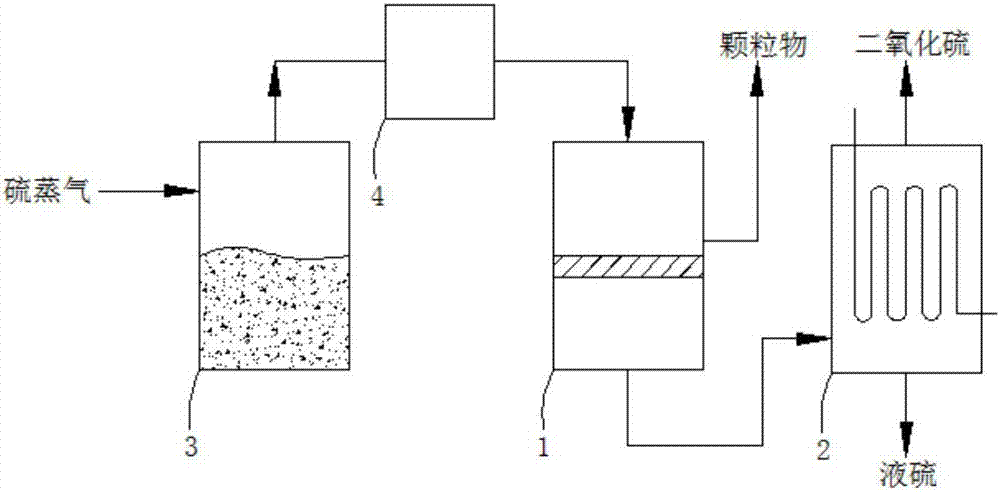

Method for separating particulate matter, sulfur vapor and sulfur dioxide in smoke and application of method

PendingCN107413190ASimple processGood liquidityGas treatmentDispersed particle filtrationChemistryDecomposition

The invention discloses a method for separating particulate matter, sulfur vapor and sulfur dioxide in smoke. The smoke is gas which is produced by a byproduct, calcium sulfate, in decomposition of gypsum with sulfur and comprises particulate matter, sulfur vapor and sulfur dioxide. The method comprises steps as follows: 1) a membrane filter is used for filtering the smoke at the temperature higher than or equal to 300 DEG C at the filtering air speed of 0.5-2.0 m / min; the particulate matter in the smoke is intercepted by a filtering medium of the membrane filter, the smoke penetrates through the filtering medium of the membrane filter, first smoke is obtained, and the dust content of the first smoke is lower than or equal to 10 mg / Nm<3>; 2) the first smoke flows through a condenser at the condensation temperature of 100-200 DEG C, the sulfur vapor is condensed, second smoke is obtained after the first smoke flows through the condenser, and the concentration of the sulfur vapor in the second smoke is lower than or equal to 100 mg / Nm<3>. With the adoption of the method, the particulate matter, sulfur vapor and sulfur dioxide in the smoke are effectively separated, and the recovery rate and the purity are high.

Owner:CHENGDU INTERMENT TECH

Castanea henryi high-yielding regulator and application thereof

ActiveCN103360159BMake up for the disadvantages of low pollination and fertilization efficiencyIncrease productionFertilising methodsFertilizer mixturesSaccharumSucrose

The invention provides a Castanea henryi high-yielding regulator and application thereof. The Castanea henryi high-yielding regulator is composed of a Castanea henryi high-yielding regulator 1 and a Castanea henryi high-yielding regulator 2, wherein the Castanea henryi high-yielding regulator 1 contains the following components in parts by weight: 10-150 parts of potassium dihydrogen phosphate, 20-150 parts of calcium chloride, 50-100 parts of boric acid, 50-100 parts of sucrose, 0.5-3 parts of 2,4-dichlorphenoxyacetic acid, 20-70 parts of gibberellin and 1-4 parts of indolebutyric acid; and the Castanea henryi high-yielding regulator 2 contains the following components in parts by weight: 100-300 parts of urea, 10-70 parts of ammonium phosphate, 20-50 parts of potassium sulfate, 30-70 parts of magnesium chloride, 50-100 parts of calcium chloride, 50-100 parts of manganese chloride, 10-30 parts of zinc sulfate and 50-200 parts of ferrous sulfate. The Castanea henryi high-yielding regulator provided by the invention can obviously enhance the yield of the Castanea henryi, and ensure the high and stable yield of the Castanea henryi.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Special adhesive for hollow composite insulator and preparation method thereof

PendingCN113025250AFast curingImprove impact toughnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesInterference fitAdhesive

The invention relates to the technical field of adhesives, and discloses a special adhesive for a hollow composite insulator and a preparation method of the special adhesive, and the special adhesive comprises the following components in parts by mass: a component A: 90-110 parts of epoxy resin, 1-2 parts of nano aluminum oxide, 0.5-1 part of a silane coupling agent, 8-12 parts of an organic solvent and 120-160 parts of a filler a; The component B comprises the following components in parts by weight: 60-70 parts of a curing agent, 20-30 parts of a toughening agent, 1 part of an accelerant, 60-80 parts of filler b and 0.5-1 part of a flatting agent; The mass ratio of the component A to the component B is 1: 1. The curing time of the current common adhesive is about 2 hours, and the curing time of the adhesive disclosed by the invention is 30-45 minutes; According to the method, the damage test is carried out on a hollow composite insulator sample, and the final damage value is increased by about 13% compared with the prior art. Therefore, the adhesive has the characteristics of good bonding performance, high impact toughness, moderate viscosity, rapid curing and the like, is particularly suitable for an end connection structure in interference fit, and is high in process applicability.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID

Coal-fired boiler wet desulfurization equipment

InactiveCN105879636BIncrease flow rateModerate timeCombination devicesGas treatmentSpray towerPulp and paper industry

The invention belongs to the technical field of environmental protection equipment and particularly relates to wet desulfurization equipment for a coal fired boiler. The wet desulfurization equipment for the coal fired boiler has a very good desulfurization effect, comprises a desulfurization tower and is structurally characterized in that a spray tower is arranged at the upper end of the desulfurization tower, an electrostatic tower is arranged at the upper end of the spray tower, a circulating pool is arranged at the lower end of the desulfurization tower and connected with an inlet of a first circulating pump through a pipeline, an outlet of the first circulating pump is connected with an inlet of a spray oxidation pipe at the spray oxidation part through a pipeline, and an output end, for a liquid after spray oxidation, of the spray oxidation part is connected with inside of the circulating pool; a concentration tank is connected with an inlet of a second circulating pump through a pipeline, an outlet of the second circulating pump is connected with an inlet of a spray pipe, one part of an outlet of the spray pipe is arranged at the upper part of the spray tower, and the other part of the outlet of the spray tower is arranged at the upper part of the desulfurization tower; a transverse smoke inlet is formed in the lower part of the desulfurization tower.

Owner:庄建中

A device and method for high-efficiency batch continuous production of collagen for industrial use

ActiveCN110063405BIncrease contentIncrease productivityEvaporationAnimal proteins working-upThermodynamicsMedicine

The invention relates to a device and method for continuous production of collagen in high-efficiency batches for industrial use, comprising a casing; a drainage device for introducing collagen solution, which is arranged inside the casing; a motor part, including at least one motor; a storage The liquid pool is arranged at the lower part of the housing and is connected with the housing, and the connected part is movable; at least one heating device is attached to the outside of the housing; a temperature display device is used to display the temperature The device is installed outside the shell to measure the internal temperature of the shell; the concentration process of the present invention is fast, and the time to concentrate collagen under normal pressure and temperature is moderate, and it is easy to produce in batches, with high production efficiency, and the final concentrated The content of collagen is high, and for today's extensive and consuming Chinese market, it can be mass-produced and promoted automatically, and the produced collagen is suitable for use in medicine, food or cosmetic preparations.

Owner:江苏美德实医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com